Material increase manufacturing method for titanium alloy shape part by using double-arc hybrid heat source

A compound heat source and additive manufacturing technology, which is applied in the direction of manufacturing tools, arc welding equipment, metal processing equipment, etc., can solve the problems of low efficiency of additive manufacturing, achieve fast heat source operation speed, high metal deposition rate, and avoid overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

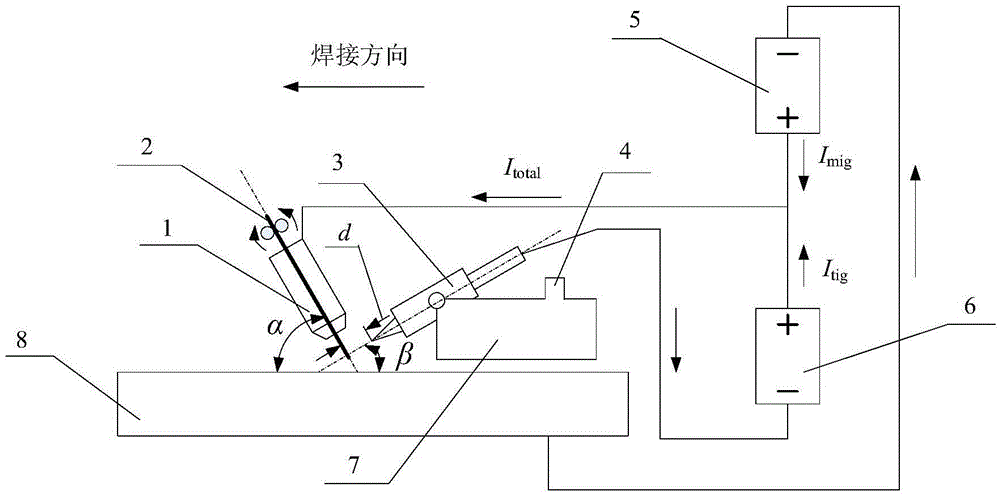

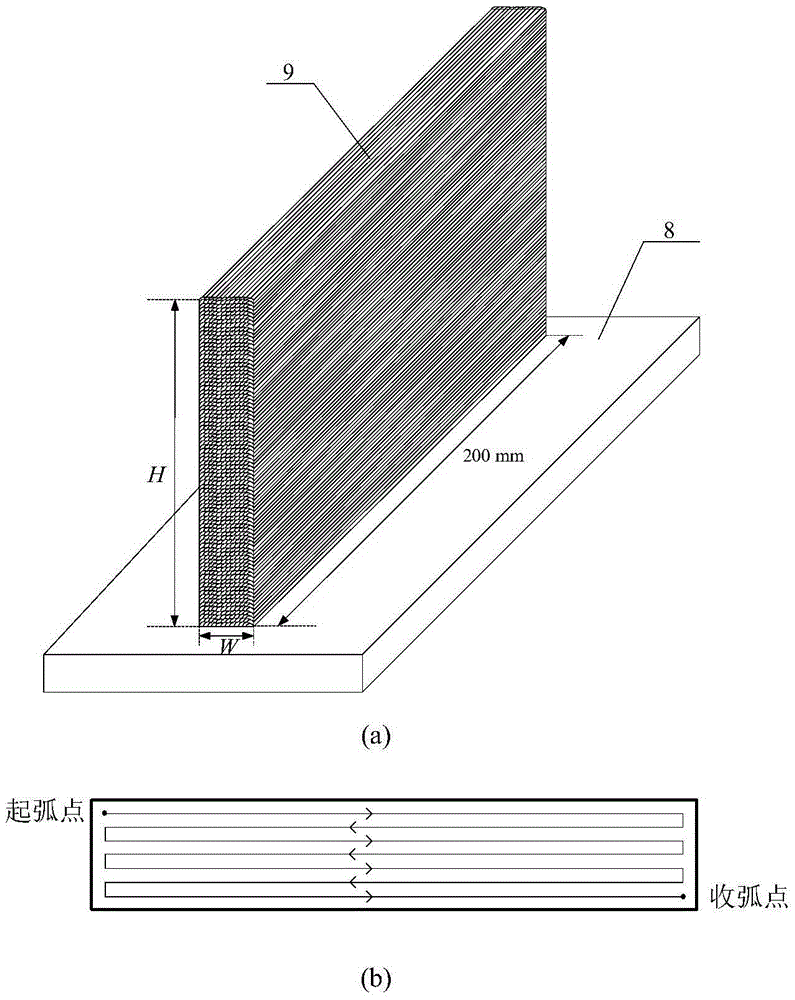

[0045] Such as figure 2 As shown in (a) and (b), the titanium alloy shaped part 9 has a height H of 120 mm and a width W of 20 mm. It is formed by 100 layers of surfacing, each layer of surfacing is 1.2 mm high, and each layer is 13 layers of surfacing welding. Welding process platform: Fronius digital MIG welding machine and Panasonic TIG welding machine form a composite heat source welding device. MIG welding torch 1 is in front and TIG welding torch 3 is in the back; TC4 welding wire 2 with a diameter of 1.2mm is used, and TC4 titanium alloy is selected as the substrate 8. The specific steps are as follows:

[0046] (1) Pre-ventilate at the arc starting position of the substrate for 5s, first start MIG welding, then start TIG welding, wait for 1-2s, and then perform the first layer of first surfacing welding after the arc is stable.

[0047] (2) After the first surfacing welding is completed, turn the composite welding torch 180°, then move it sideways by 1.5mm, reverse t...

Embodiment 2

[0053] Such as figure 2 As shown in (a) and (b), the titanium alloy shaped part 9 has a height H of 100 mm and a width W of 15 mm. It is formed of 100 layers of surfacing, each layer of surfacing is 1.0 mm high, and each layer is 10 layers of surfacing welding. Welding process platform: Fronius digital MIG welding machine and Panasonic TIG welding machine form a composite heat source welding device. MIG welding torch 1 is in front and TIG welding torch 3 is in the back; TC1 welding wire 2 with a diameter of 1.2mm is used, and TC1 titanium alloy is selected as the substrate 8 . The specific steps are as follows:

[0054] (1) Pre-ventilate at the arc starting position of the base plate 8 for 5 seconds, start MIG welding, and then start TIG welding. After 1-2 seconds, the arc is stable and the first layer of first surfacing welding is performed.

[0055] (2) After the first surfacing welding is completed, turn the composite welding torch 180°, then move it sideways by 1.5mm, re...

Embodiment 3

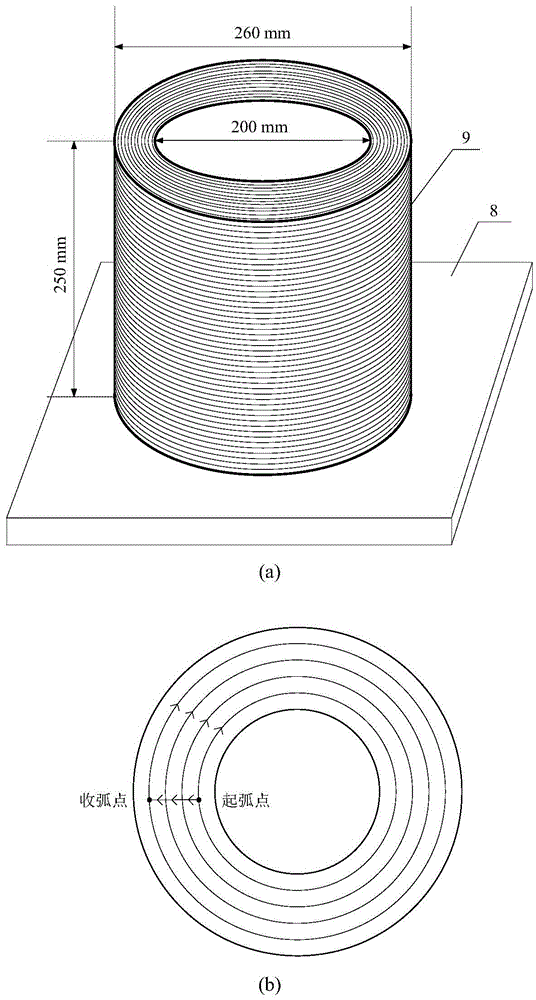

[0061] Such as image 3 As shown in (a) and (b), the titanium alloy shape 9 has a height of 250mm, an inner diameter and an outer diameter of 200mm and 260mm respectively, and is formed by 100 layers of surfacing, each layer of surfacing is 2.5mm high, and each layer has 15 layers Overlay welding. Welding process platform: Fronius digital MIG welding machine and Panasonic TIG welding machine form a composite heat source welding device, MIG welding torch 1 is in front, and TIG welding torch 3 is in the back; TC4 welding wire 2 with a diameter of 1.6mm is used, and TC4 titanium alloy is selected as the substrate 8; welding During the process, the substrate is fixed on the positioner, only the positioner rotates, and the welding torch is fixed and only moves sideways. The specific steps are as follows:

[0062] (1) Pre-ventilate at the arc starting position of base plate 8 for 6 seconds, start MIG welding first, and then start TIG welding. After 1-2 seconds, after the arc is st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height h | aaaaa | aaaaa |

| Width w | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com