Operation method of vulcanized catalyst

A catalyst and sulfurization type technology, which is applied in the field of starting the preparation of sulfurized hydrogenation catalysts, can solve the problems of not mentioning the starting plan of sulfurized catalysts, the hydrogenation activity of the catalyst needs to be improved, and the hydrogenation activity of the catalyst is affected, so as to achieve economical start-up. The effect of time, high performance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] 1. Preparation of catalyst carrier: Prepare the catalyst carrier by conventional methods, and select the carrier type according to the number of acid sites required by the catalyst, such as silica-alumina, silica with additives, alumina with additives, or molecular sieves. The carrier powder is mixed with binder, pore-enlarging agent and extrusion aid, extruded on an extruder, dried and calcined to make a catalyst carrier. The catalyst carrier preparation method is well known to those skilled in the art.

[0029] 2. Configuration of impregnation solution: the sulfide precursors of Group VIB metals Mo and W, inorganic salts of Group VIII metal Ni or Co, and organic additives are prepared into a solution.

[0030] 3. Impregnate the catalyst carrier with the impregnating solution: load the impregnating solution on the catalyst carrier by impregnating method, and dry at 20°C-200°C for 1-10 hours to obtain a vulcanized catalyst.

Embodiment 1

[0033] a) Preparation of sulfurized catalyst A

[0034] Take by weighing pseudo-boehmite (produced by Shandong Alumina Plant, 73% by weight on a dry basis) 900g, 19g of scallop powder, 32g of citric acid, 48ml of nitric acid (30% by weight), silica gel (containing two by weight) Silica 30%) 159ml, deionized water 250ml mix evenly, extrude into 1.2mm clover strips on extruder, after drying, bake at 600 ℃ for 3 hours, obtain the required catalyst carrier 1.

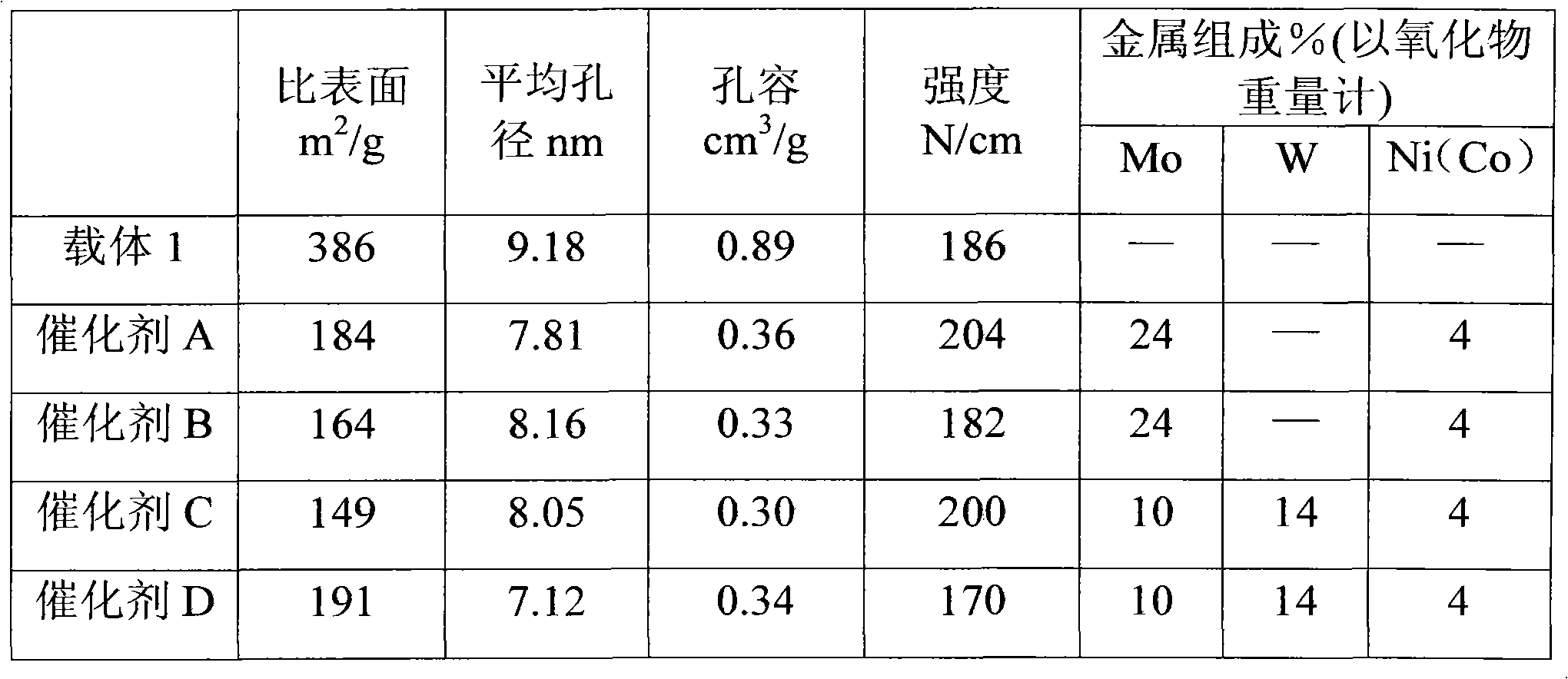

[0035] Dissolve cobalt nitrate and ATMP (aminotrimethylene phosphonic acid) in deionized water to obtain a transparent solution, and mix tetraethylammonium thiomolybdate solution with it to form a solution. The amount of active components in the solution is determined according to the data in Table 1. The mixed solution was spray-soaked into carrier 1, and dried at 120°C for 3 hours to obtain catalyst A. The main physical properties are shown in Table 1.

[0036] b) Catalyst start-up method and evaluation

[0037] After i...

Embodiment 2

[0039] a) Preparation of sulfurized catalyst B

[0040] Dissolve nickel nitrate and nitrilotriacetic acid in deionized water to obtain a transparent solution, and then dissolve ammonium thiomolybdate in the solution to form an impregnation solution. The amount of active components in the impregnation solution is determined according to the data in Table 1. The impregnating solution was sprayed and impregnated with carrier 1, and dried at 120°C for 3 hours to obtain catalyst B. The main physical properties are shown in Table 1.

[0041] b) The catalyst start-up method and evaluation are the same as in Example 1. See Table 2 for the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com