Patents

Literature

195 results about "Hybrid heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hybrid heat system reacts to changing temperatures and automatically adjusts to the most efficient energy saving method available to heat or cool a home. It can be a fuel-saving alternative to traditional heating and cooling systems in that it combines a furnace with a heat pump, rather than an air conditioner.

Hybrid heat exchangers

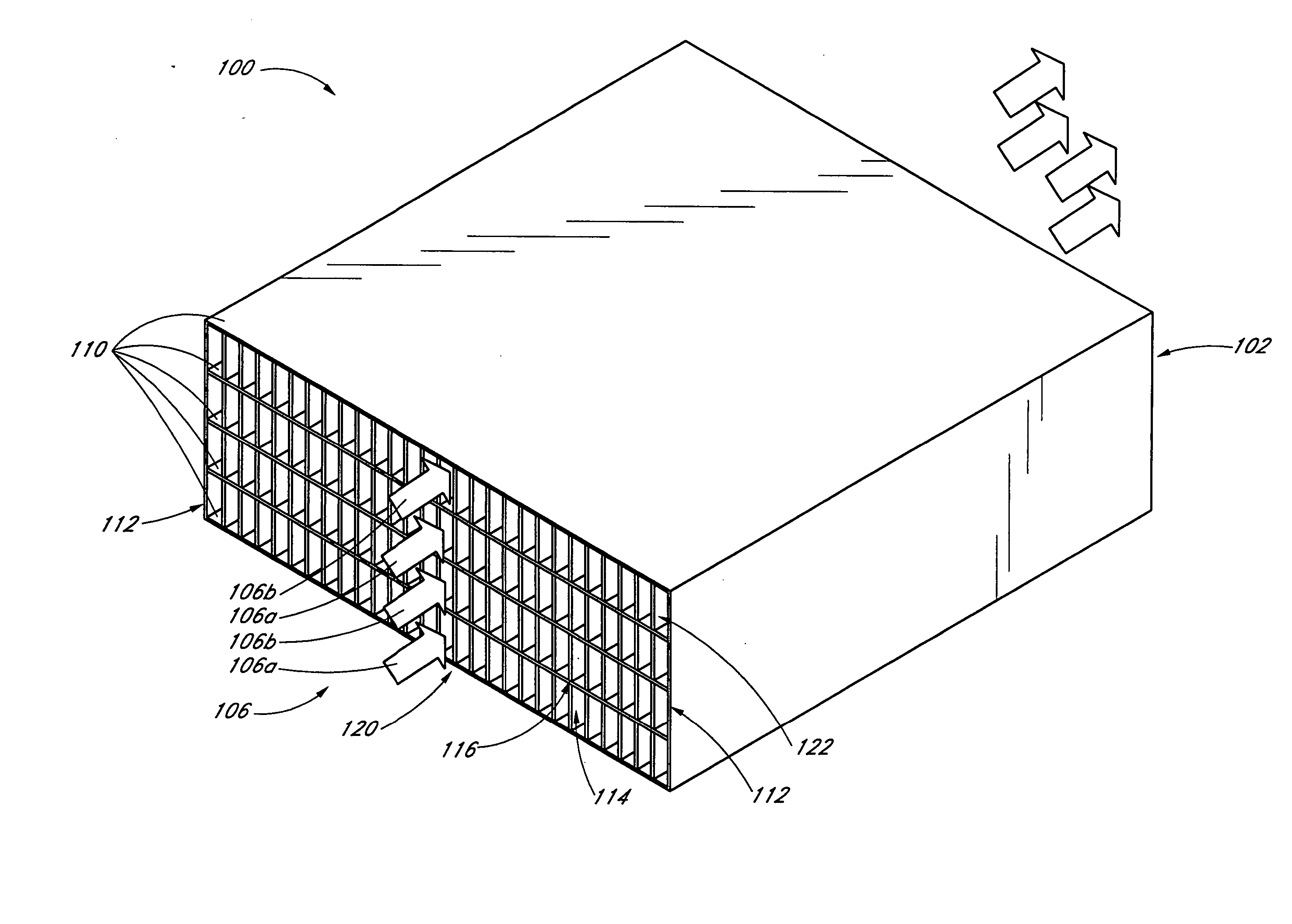

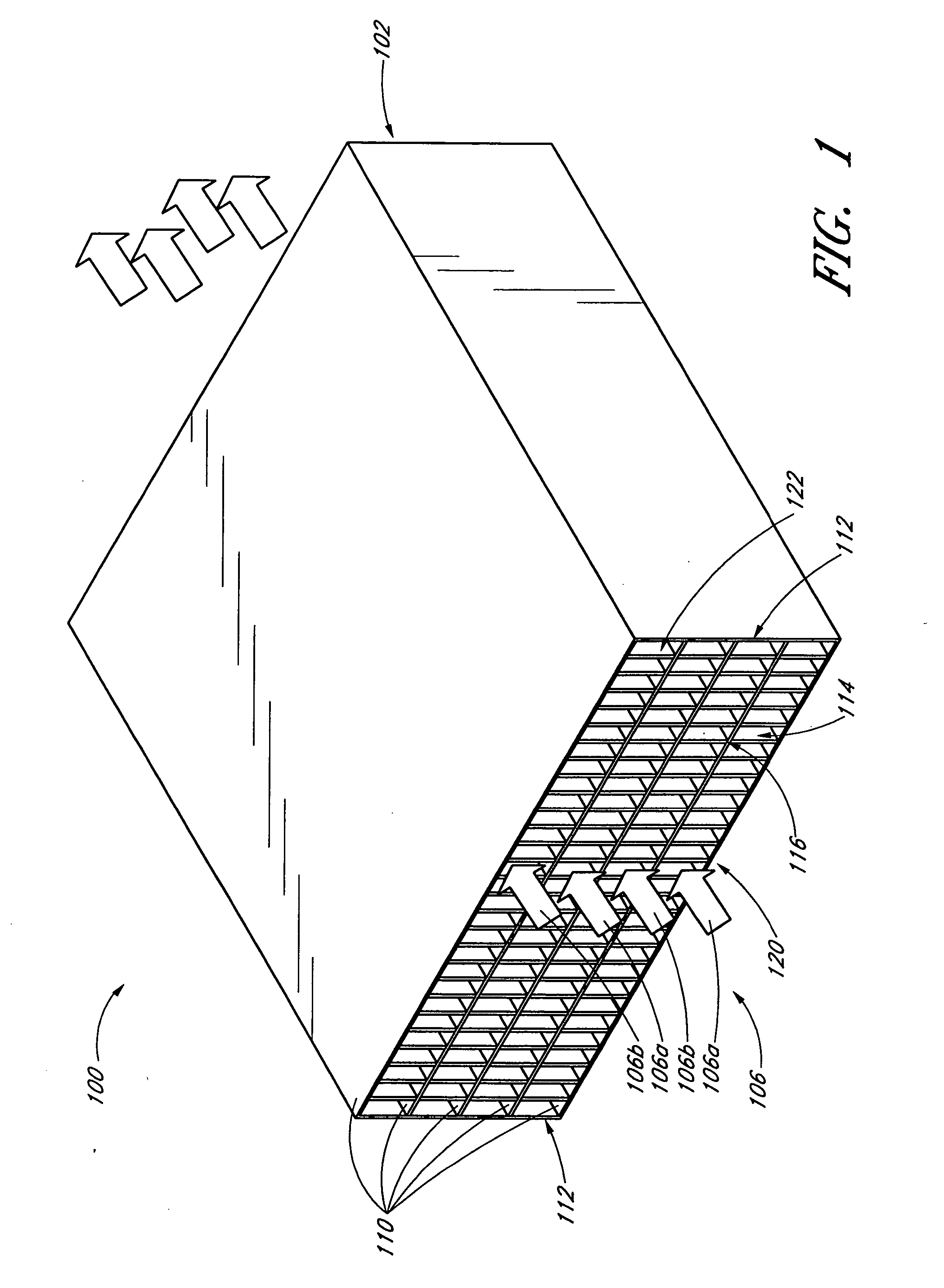

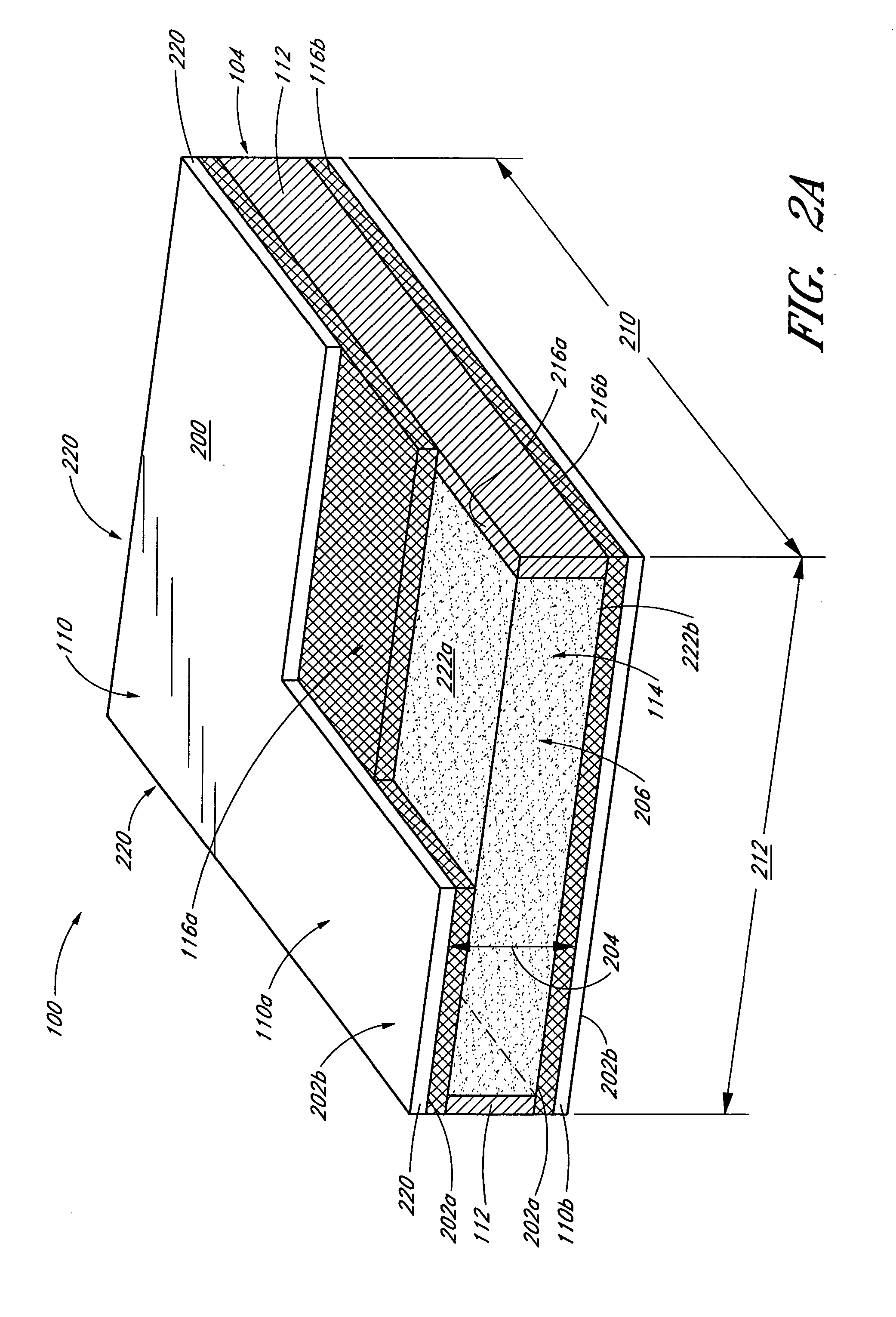

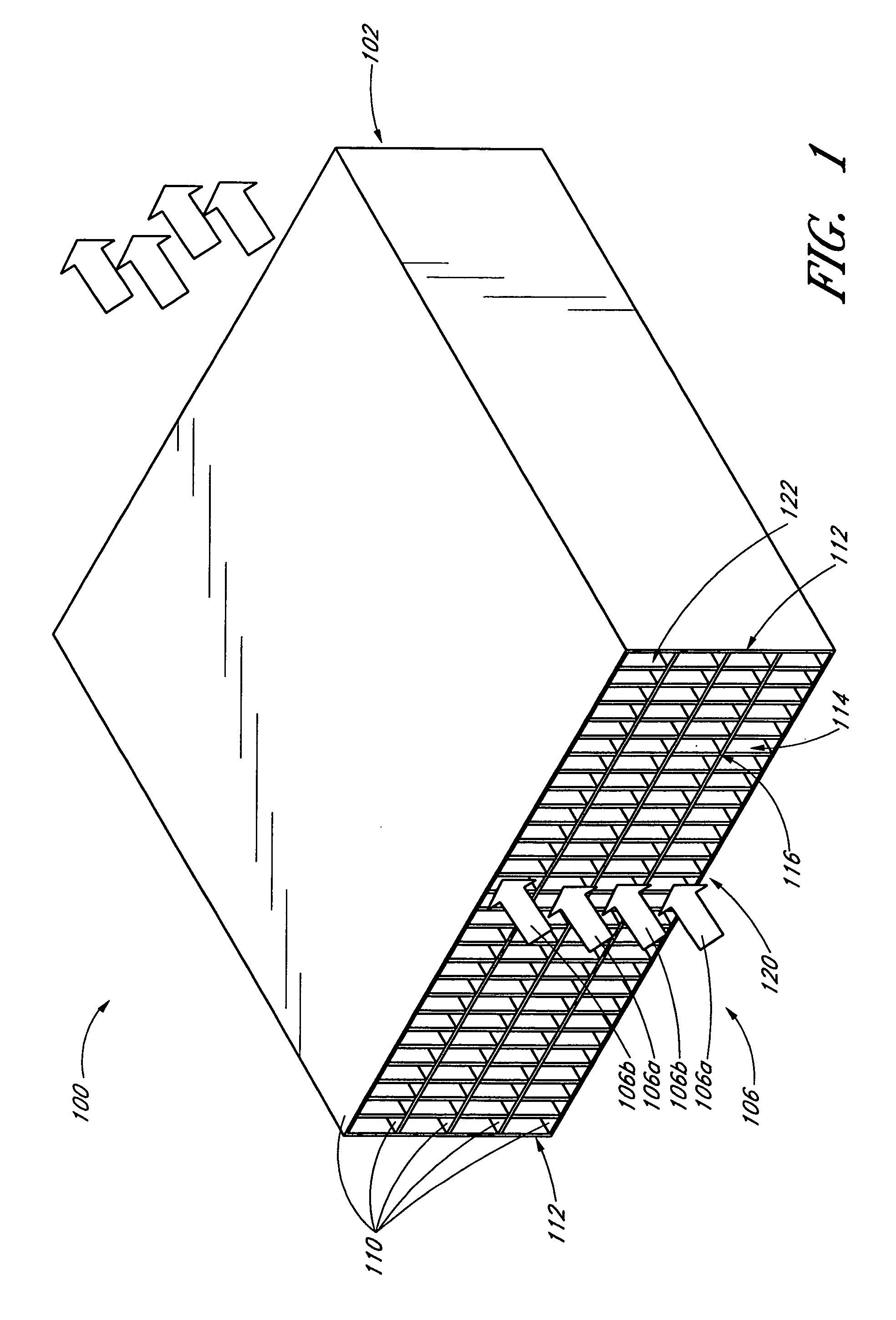

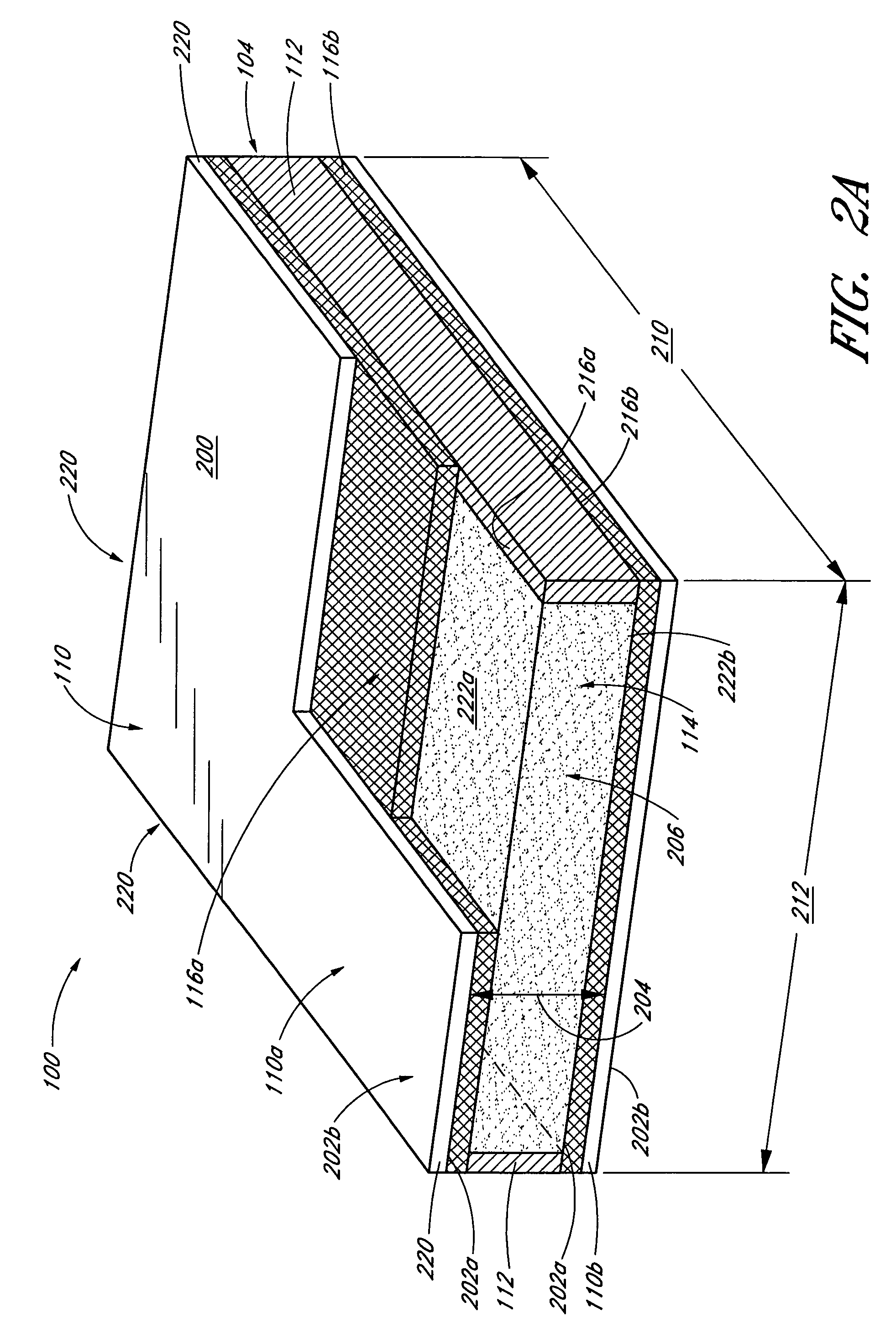

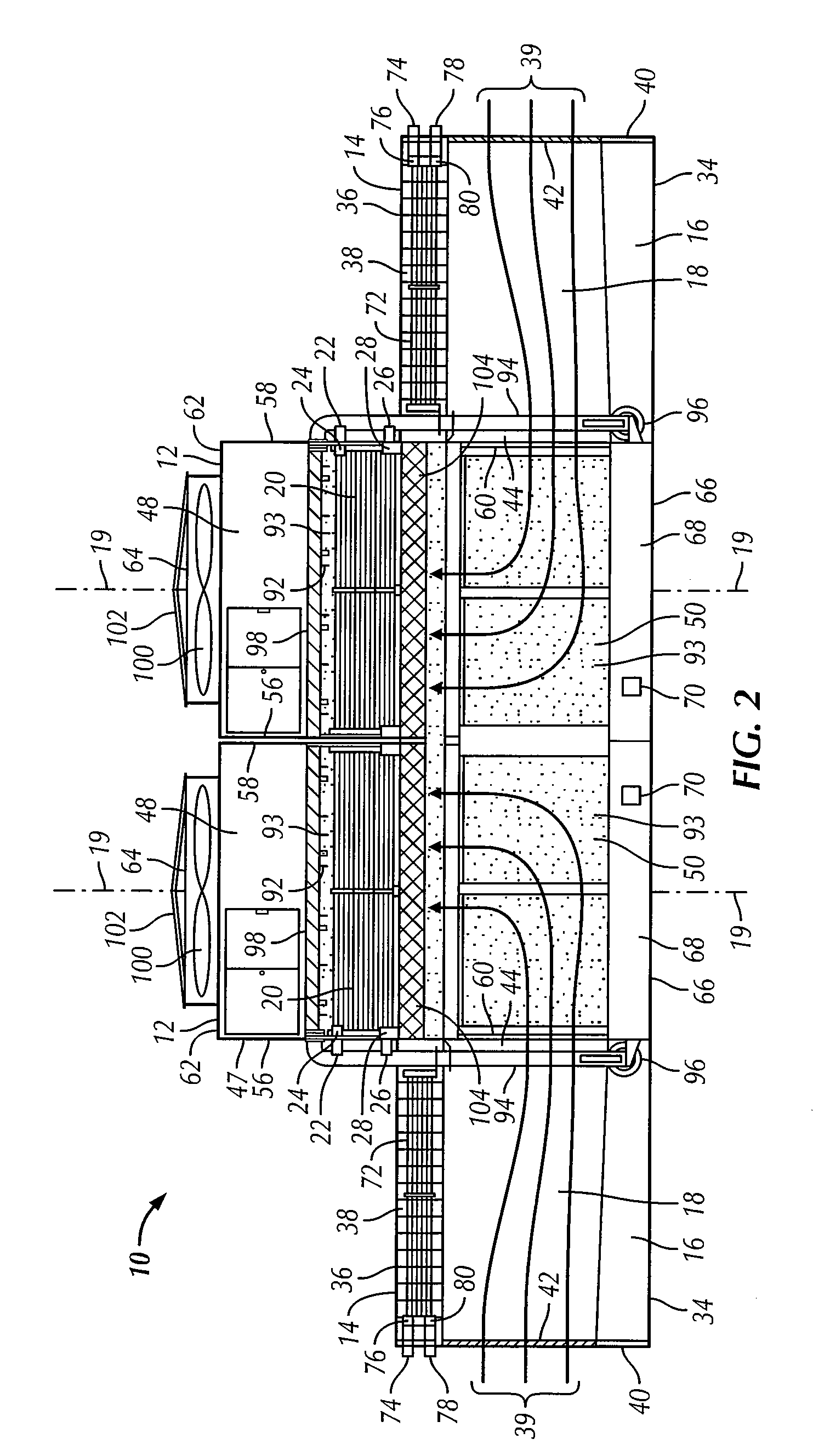

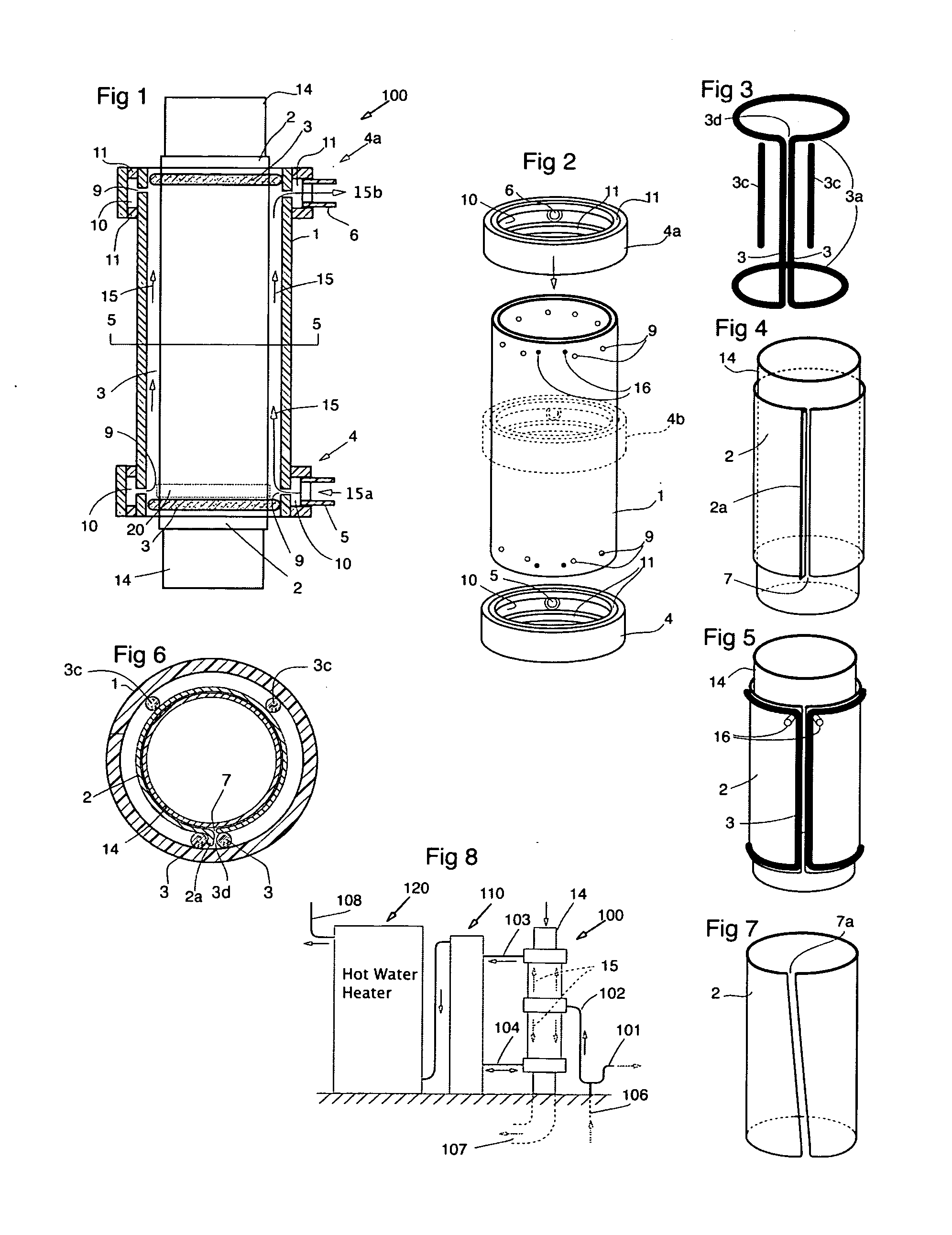

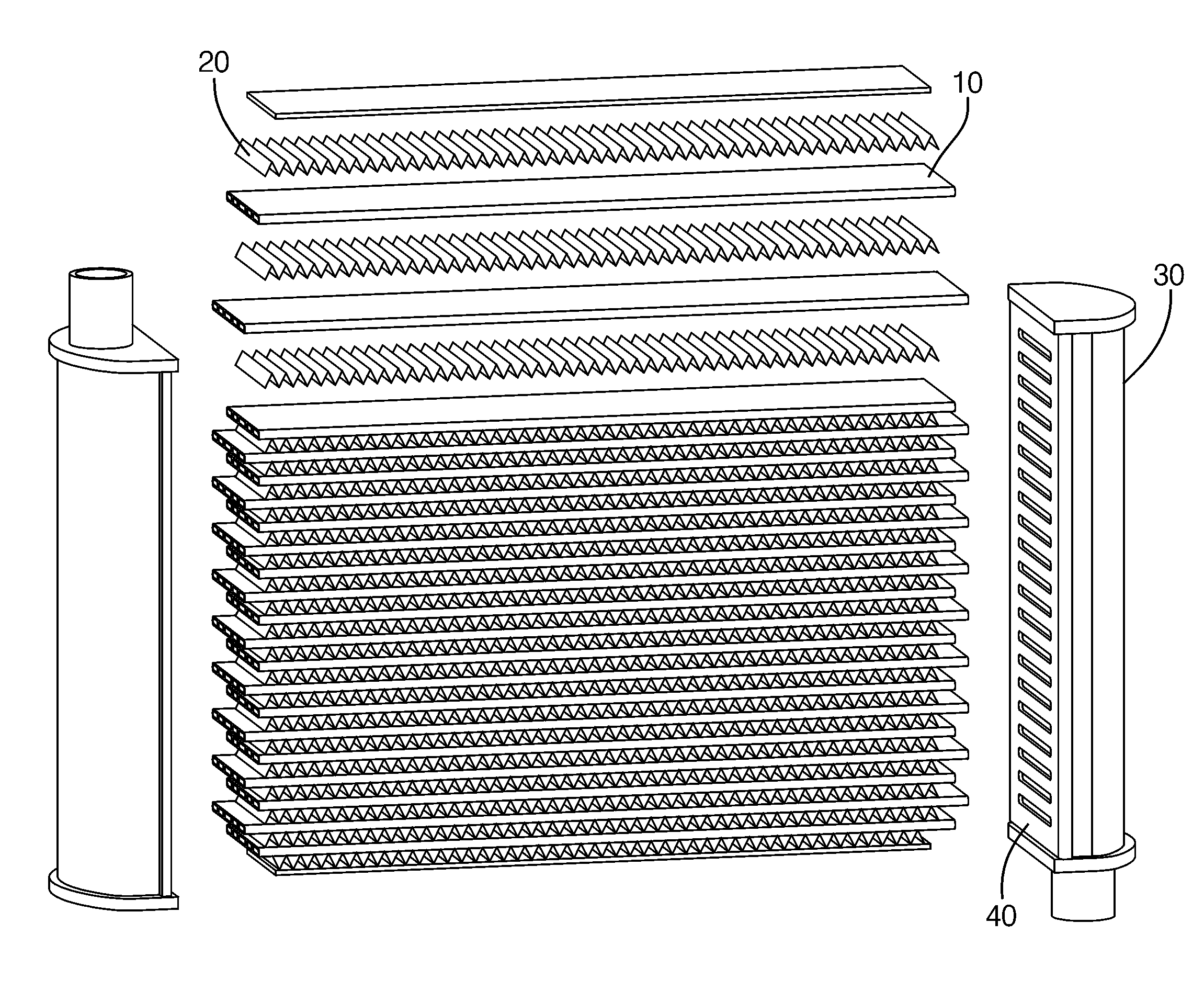

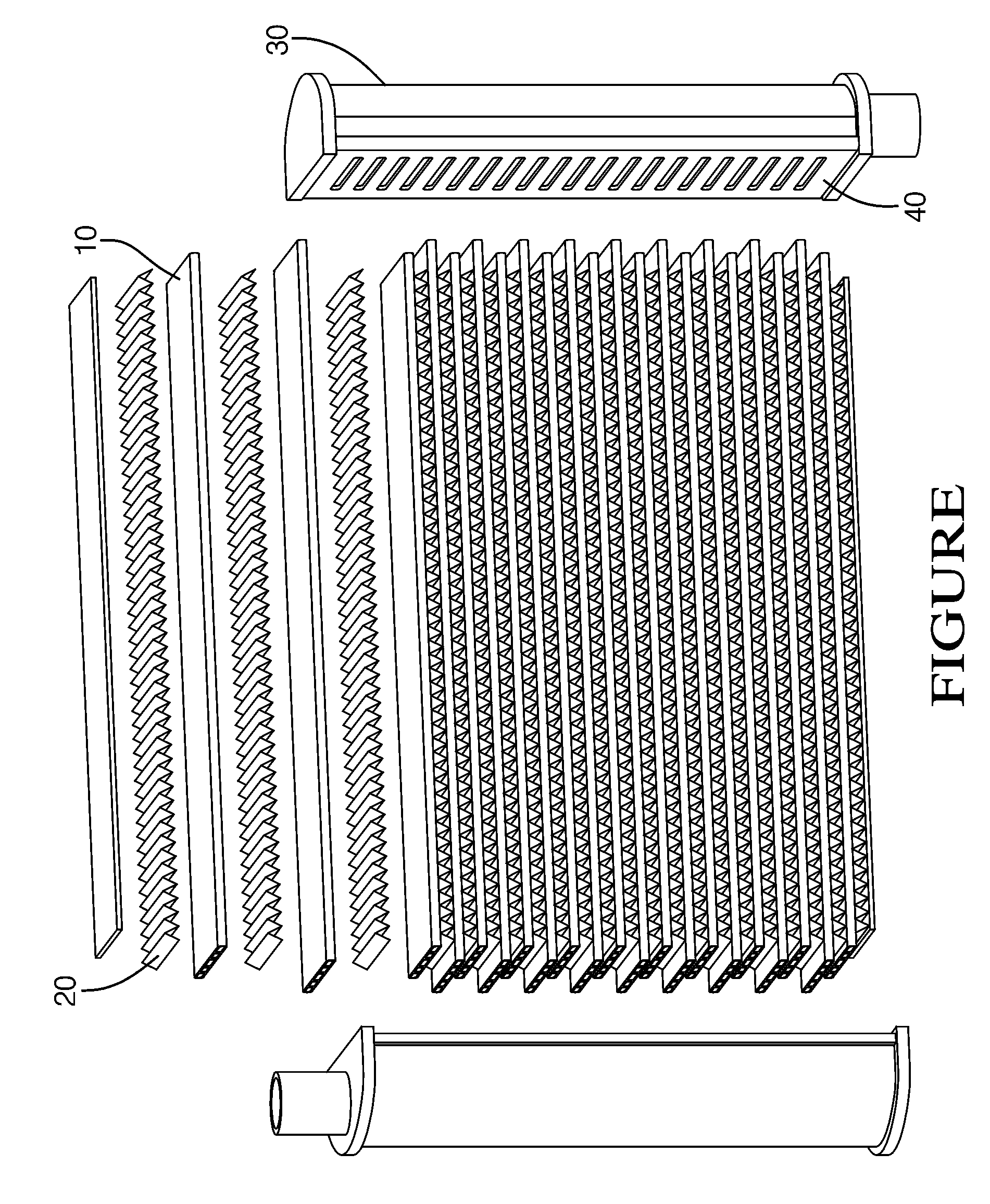

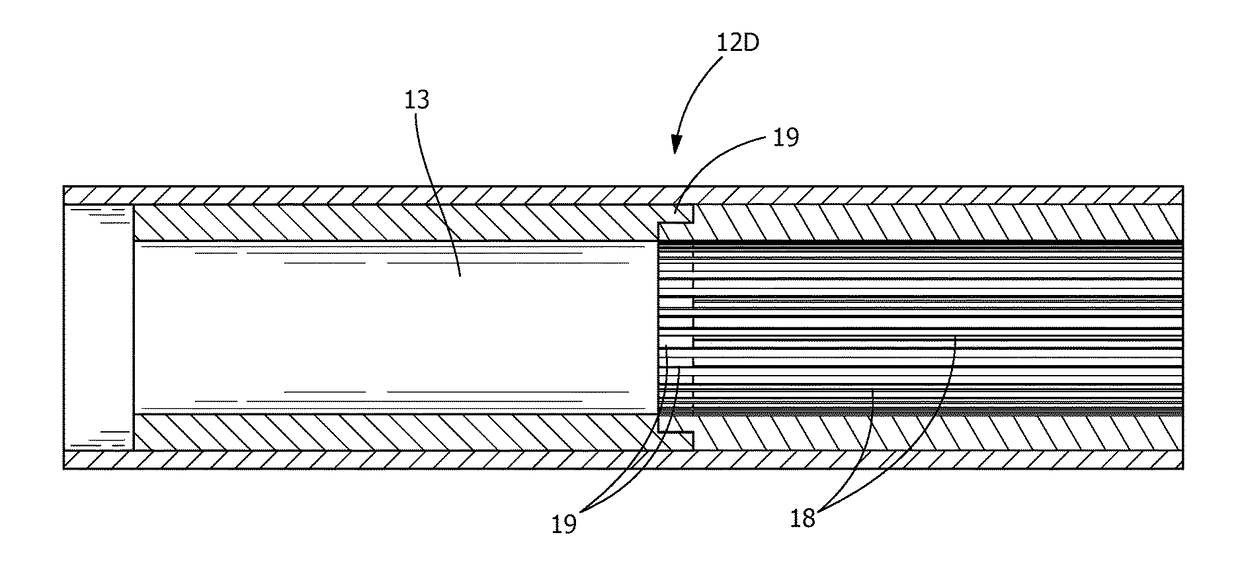

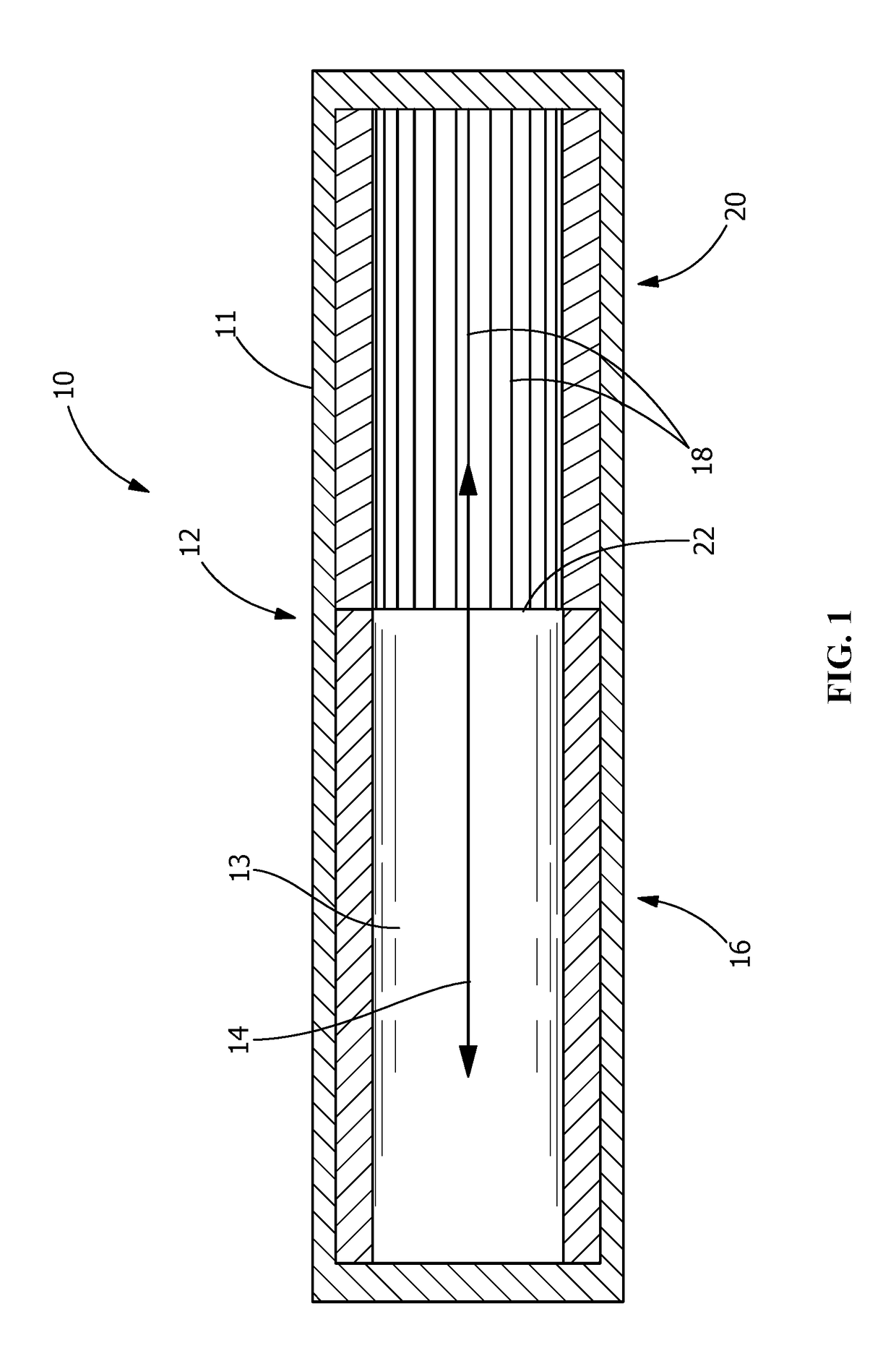

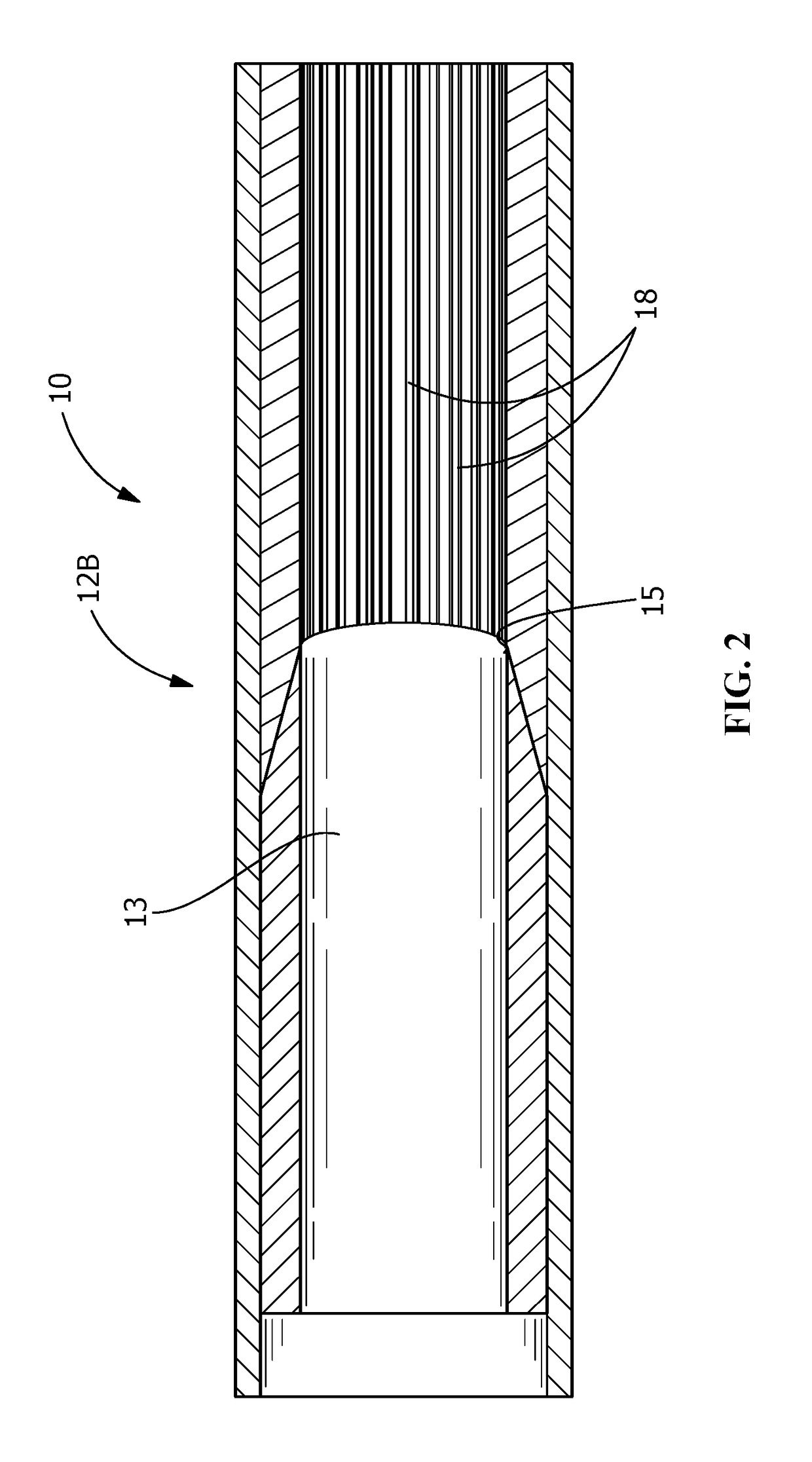

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

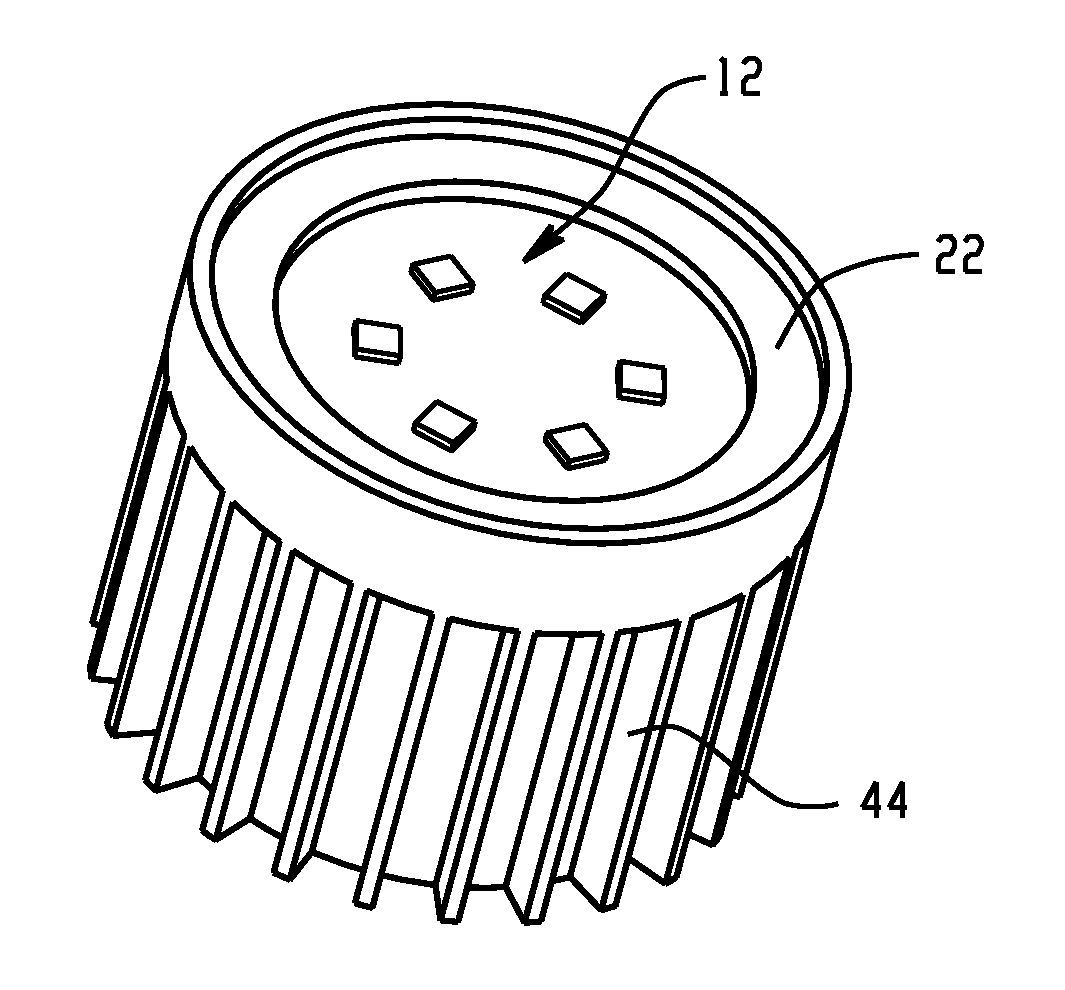

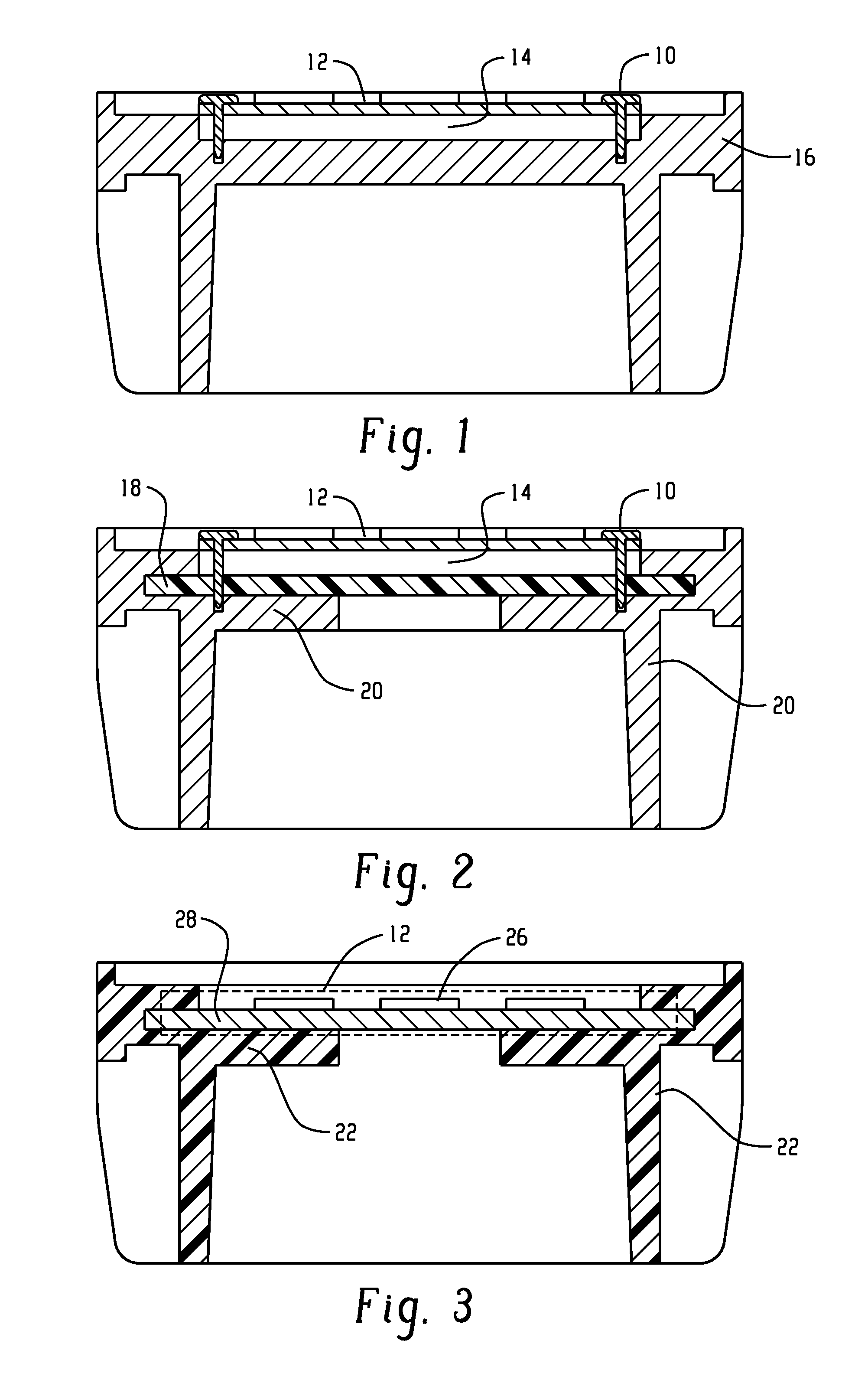

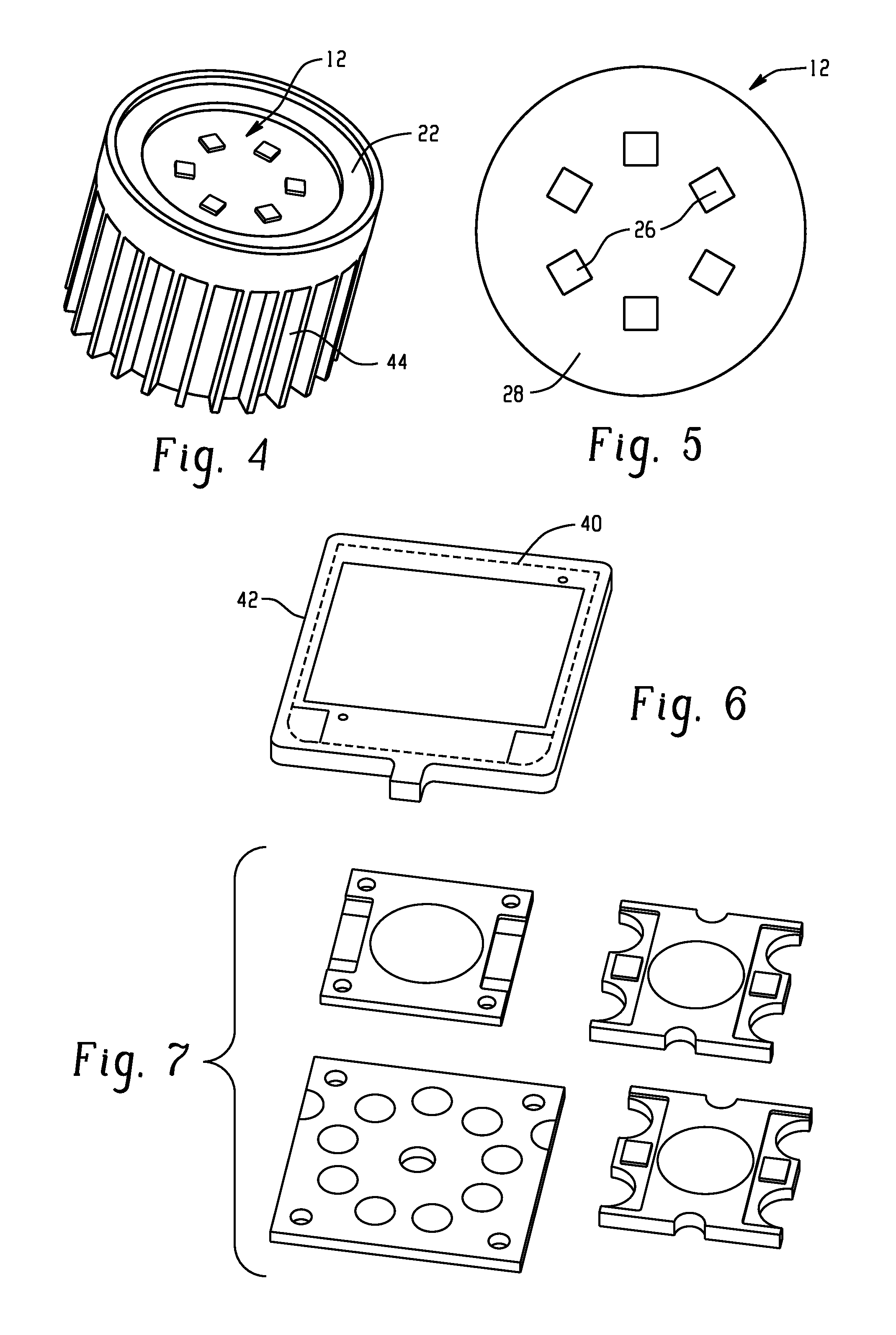

LED plastic heat sink and method for making and using the same

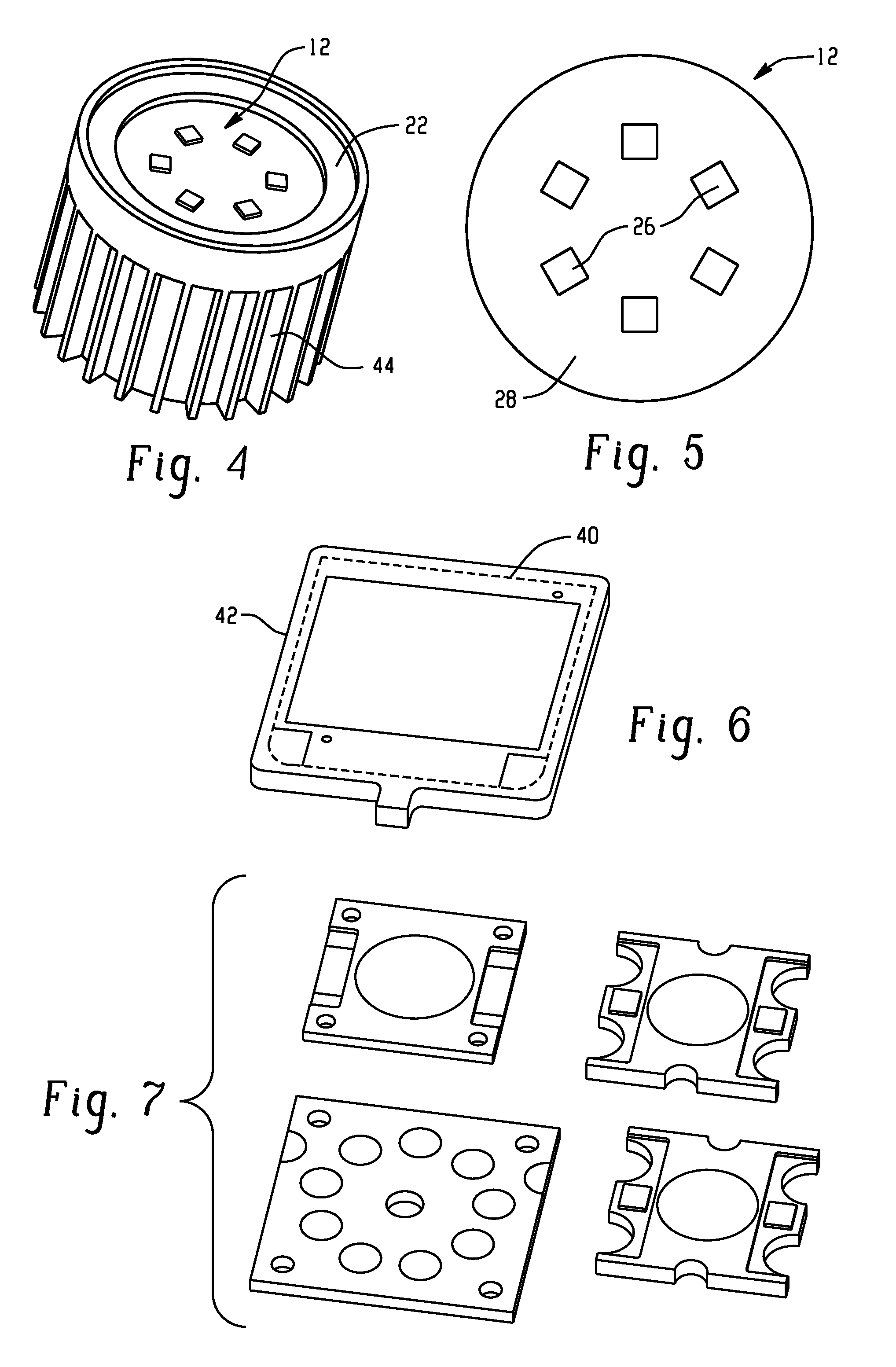

In an embodiment, heat sink system can comprise: an integrally formed plastic heat sink and a printed circuit board package, wherein the plastic heat sink comprises a thermally conductive plastic having a thermal conductivity of at least 1.0 W / mK. In another embodiment, hybrid heat sink system, comprising: an integrally formed plastic heat sink and an insert, wherein the plastic heat sink comprises a thermally conductive plastic, the plastic heat sink and the insert each having a cylindrical shape, and wherein the insert comprises a feature of lancing provisions, corrugations, embossing, holes, or a combination comprising at least one of the foregoing features.

Owner:SHPP GLOBAL TECH BV

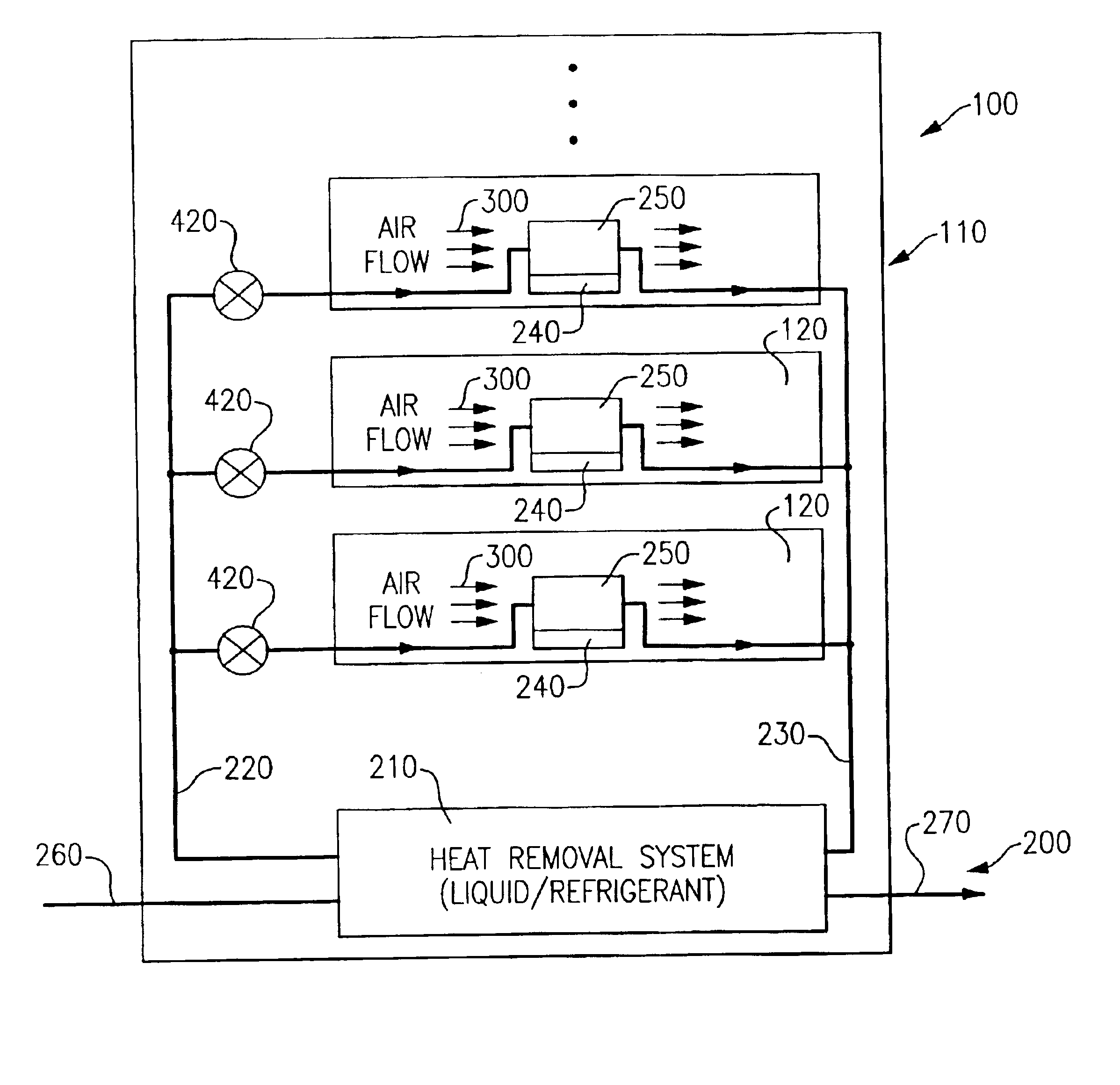

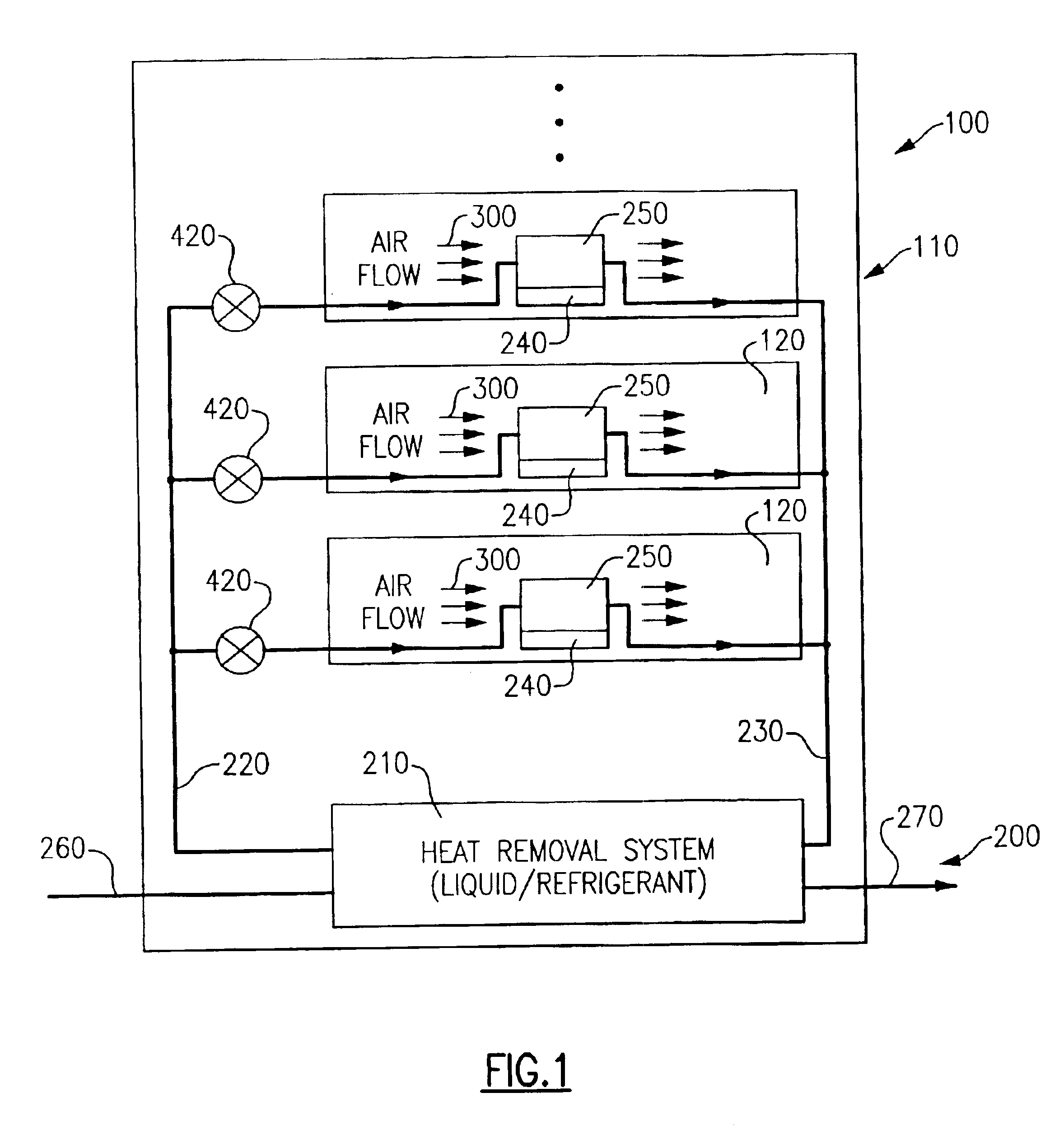

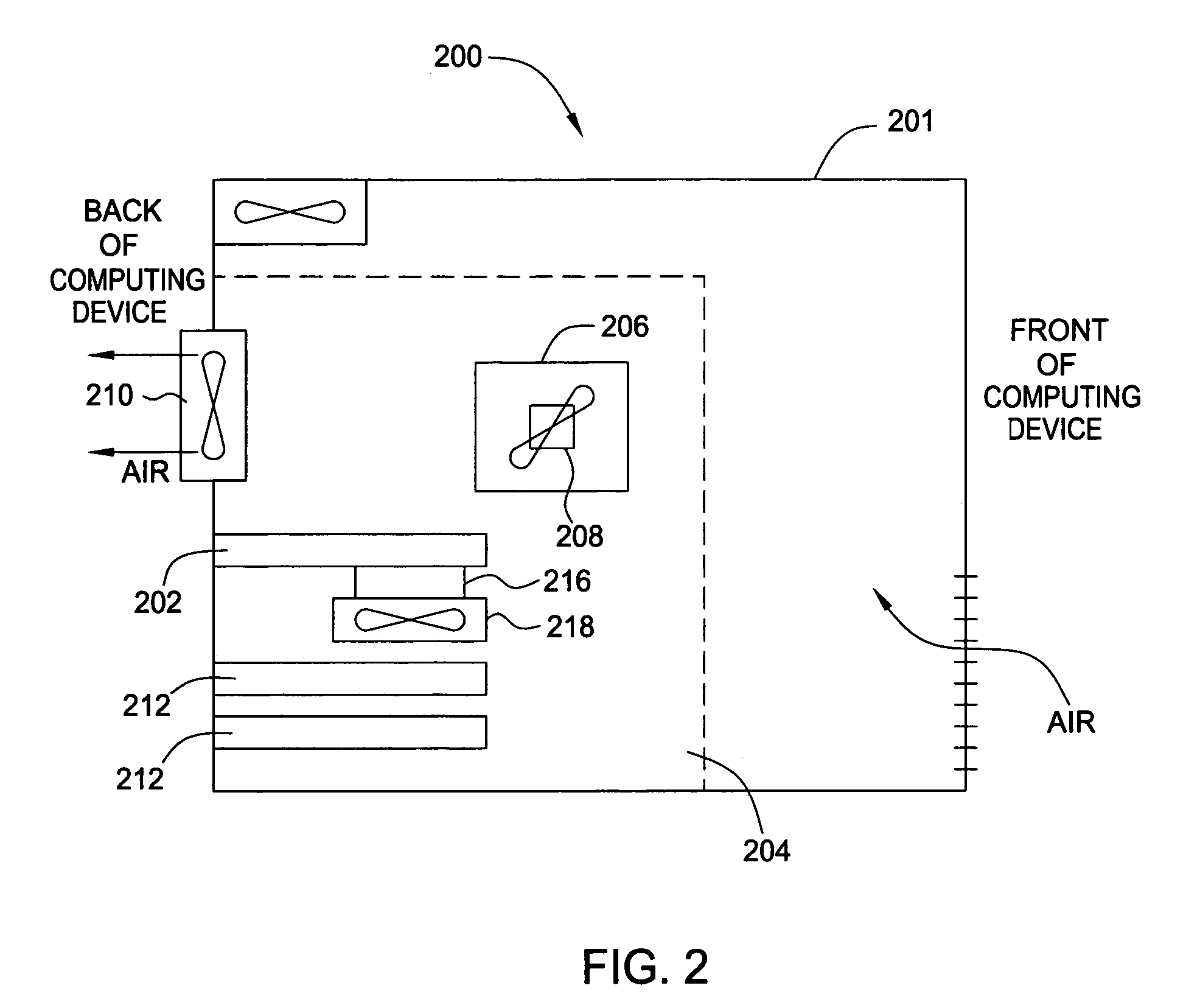

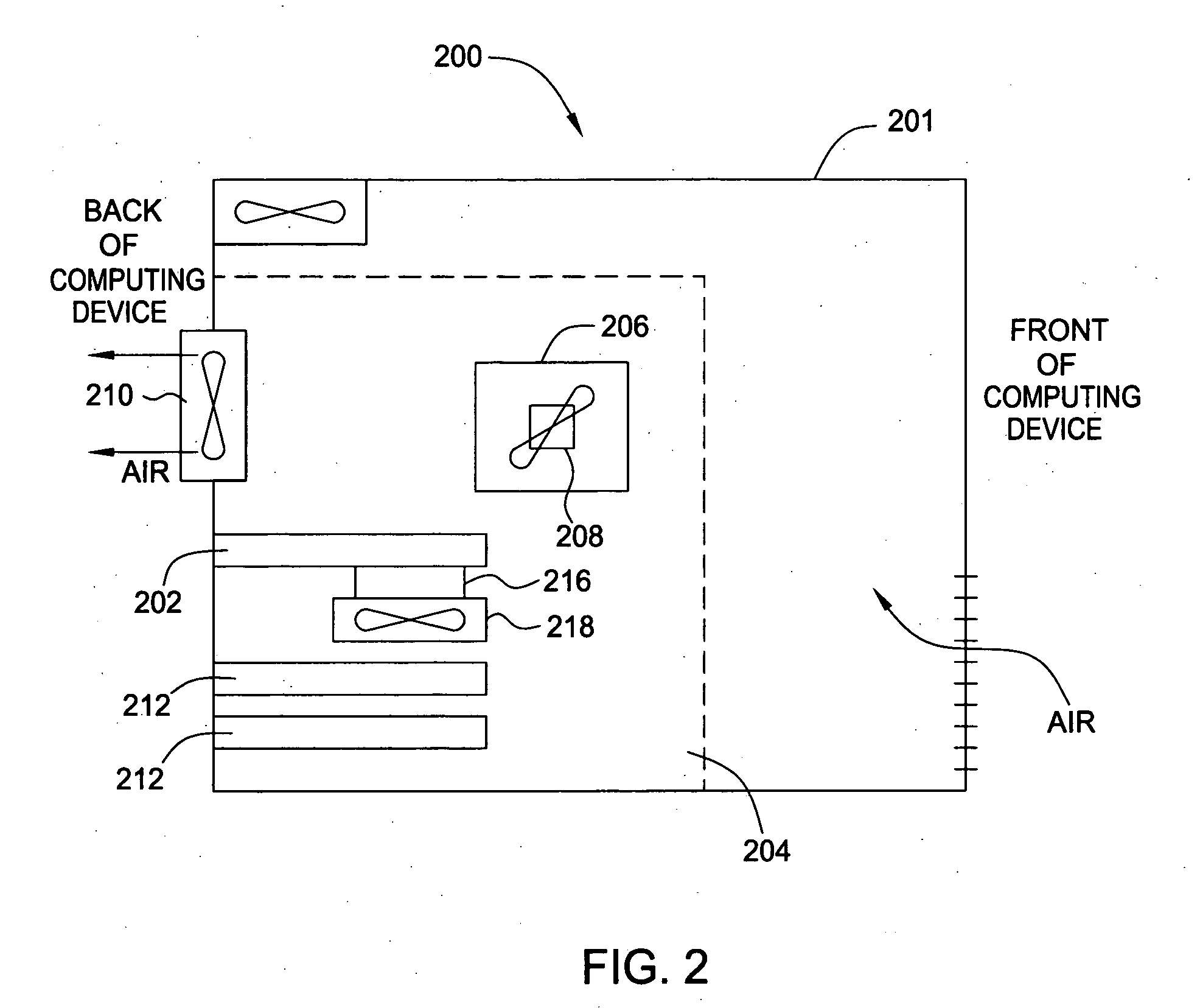

Frame level partial cooling boost for drawer and/or node level processors

InactiveUS6970355B2Small dimensionAvoid the needDomestic cooling apparatusSemiconductor/solid-state device detailsSystems designEngineering

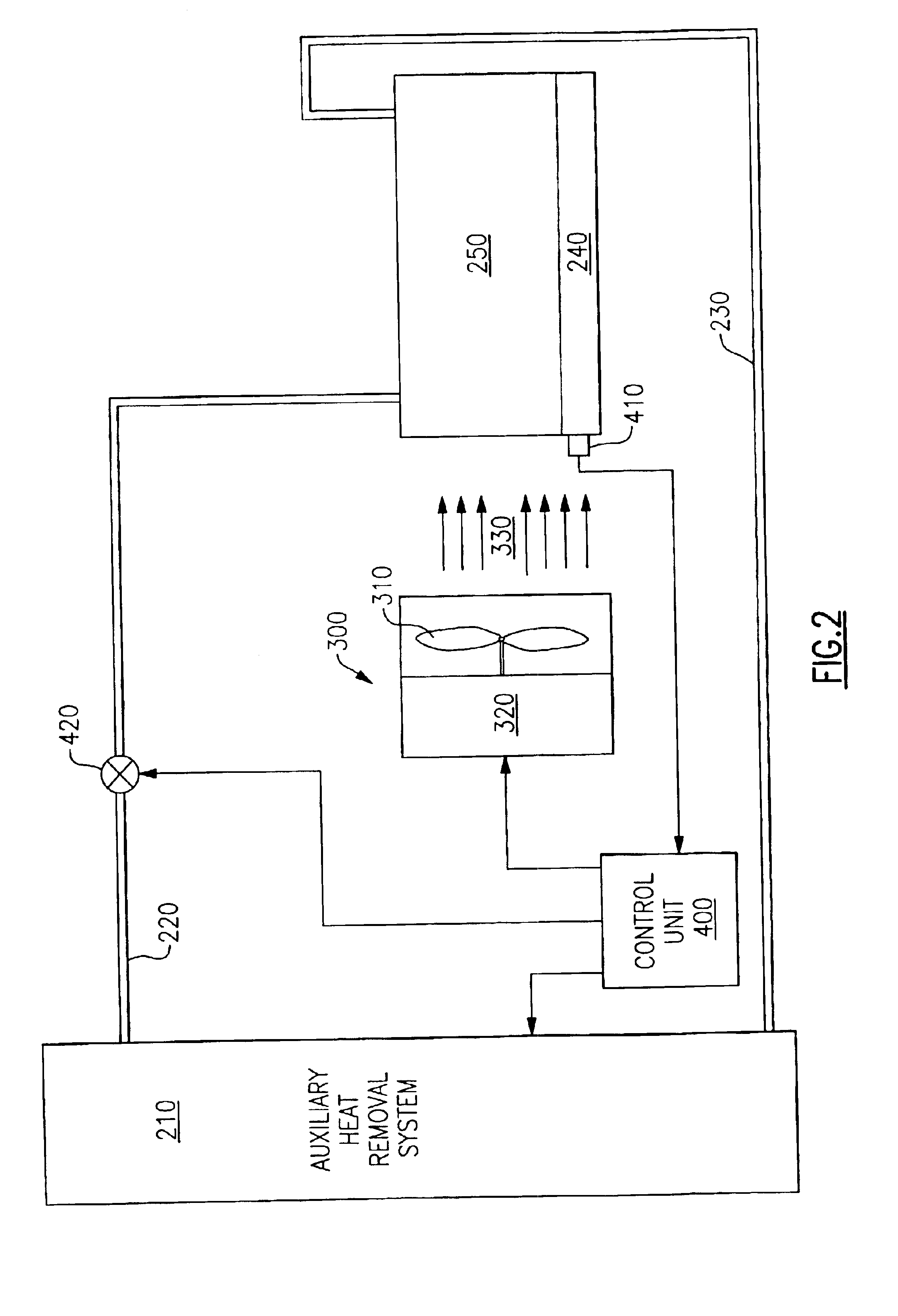

A hybrid cooling system is provided which is particularly useful for cooling electronic circuit components disposed on circuit boards arranged in a plurality of drawers within a cabinet or frame. Air cooling is provided locally with a supplementary, auxiliary, or secondary cooling system being provided at more distant frame level locations. This configuration permits optimal sizing of the respective hybrid cooling system components without negatively impacting the coefficient of performance (COP). Hybrid heat sinks are employed to accommodate the hybrid cooling system design.

Owner:IBM CORP

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

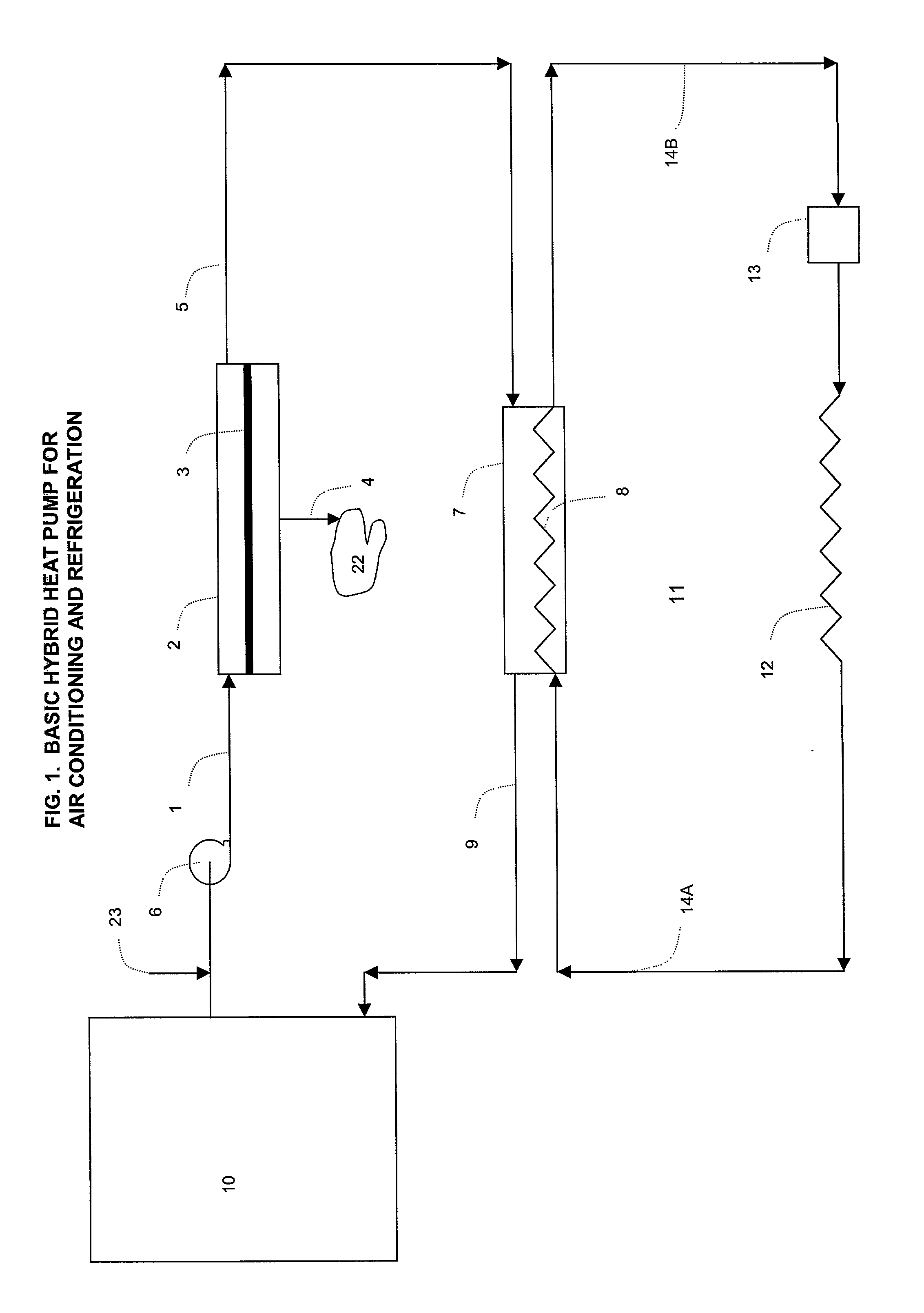

Hybrid heat pump

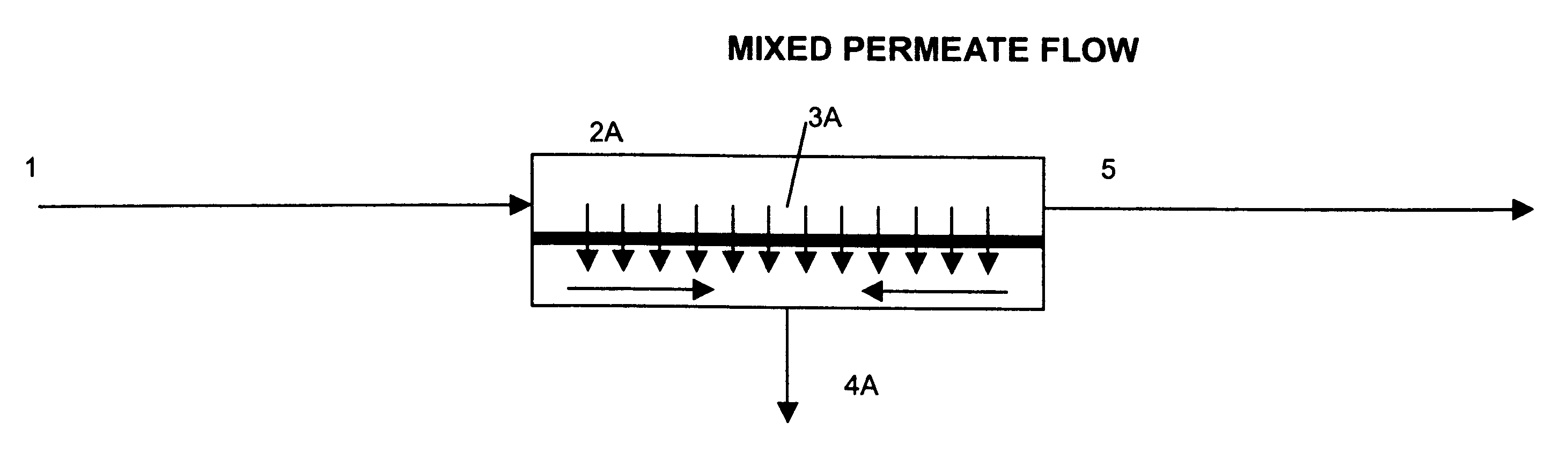

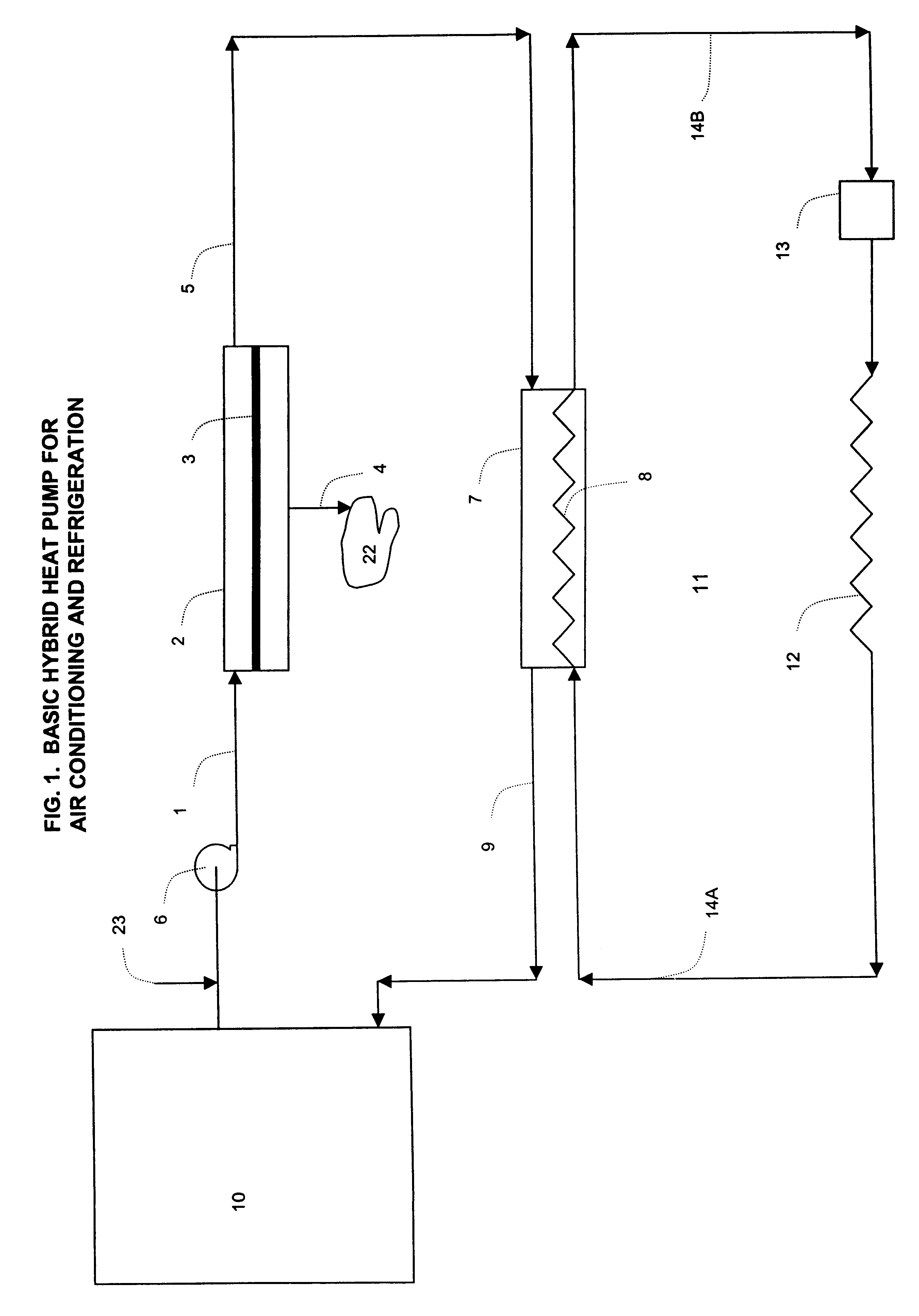

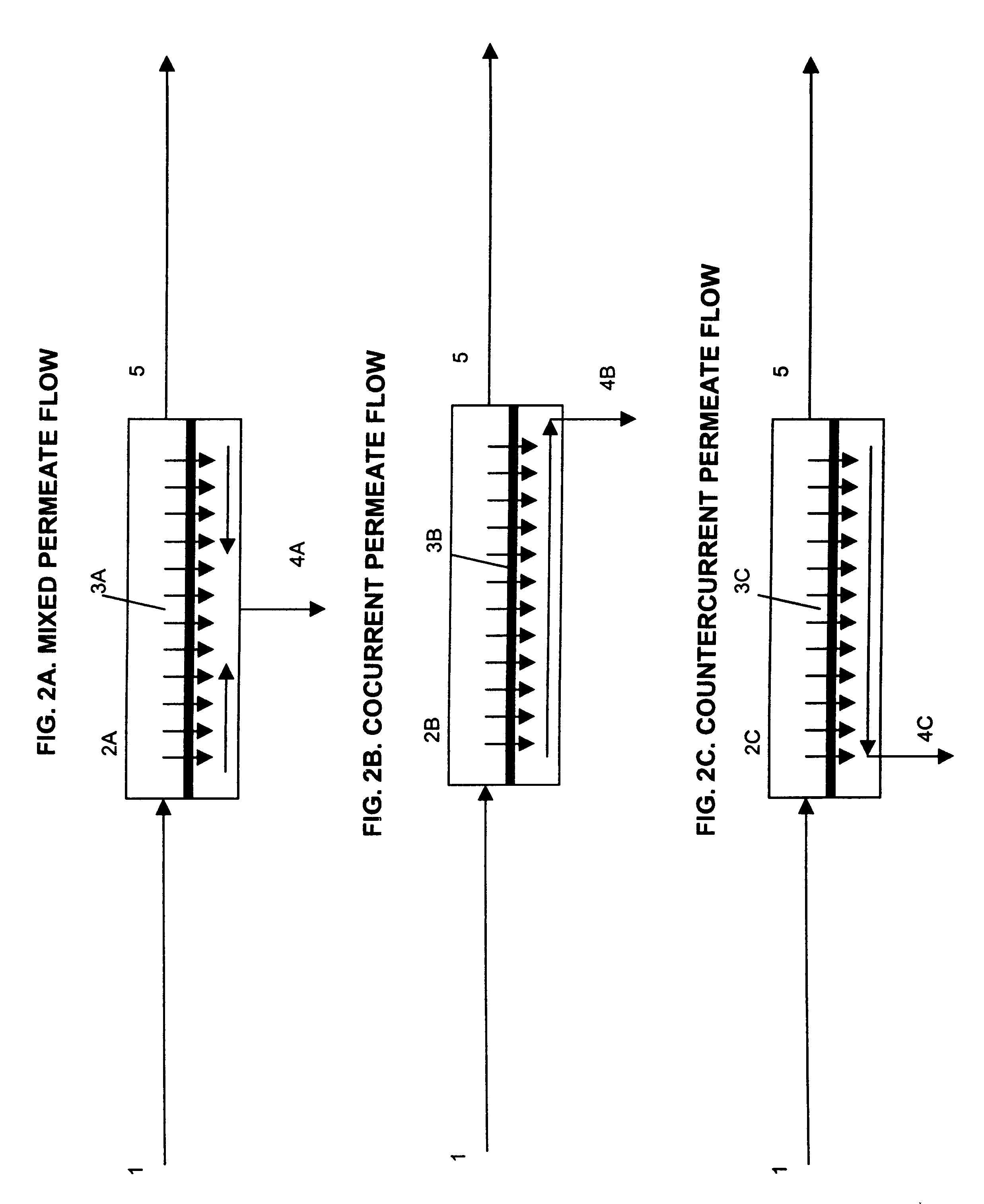

InactiveUS20020078696A1Improve economyImprove efficiencyHeat pumpsDispersed particle separationThermal energyProduct gas

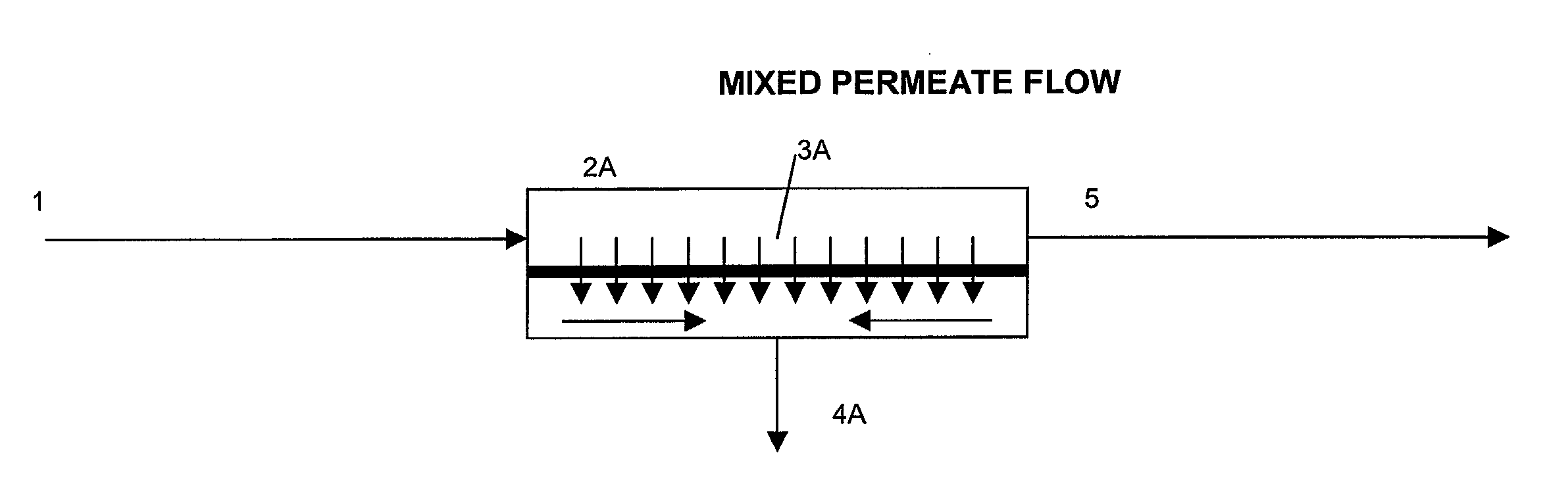

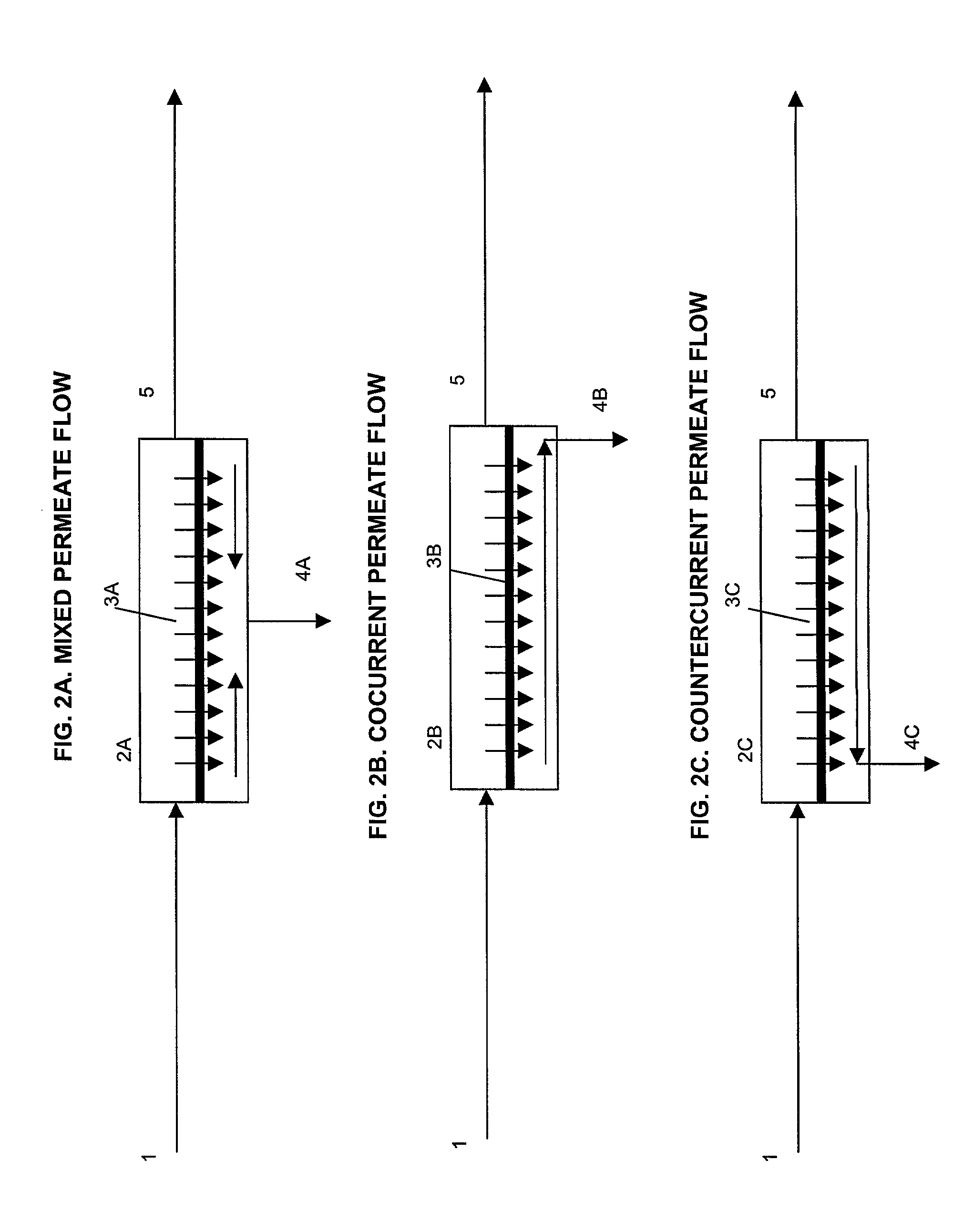

There is provided a hybrid heat pump system. The system includes (i) a membrane permeator having a permselective membrane capable of selectively removing vapor from a vapor-containing gas to yield a dry gas, (ii) a heat pump having (a) an internal side for exchanging thermal energy with a process fluid, (b) an external side for exchanging thermal energy with an external environment, and (c) a thermodynamic mechanism for pumping thermal energy between the internal side and the external side in either direction, (iii) means for conveying the vapor-containing gas into the membrane permeator, and (iv) means for routing the dry gas to either of the internal side or the external side.

Owner:KORIN AMOS

Hybrid heat pump / refrigerator with magnetic cooling stage

InactiveUS20070186560A1Improve efficiencyIncrease powerHeat recovery systemsCompression machines with cascade operationCyclic processWorking fluid

A device for transporting heat from a cold reservoir to a warm reservoir, in which at least two cyclic processes are employed for transporting heat thereby absorbing work, of which at least one is a regenerative cyclic process, and at least one is a magnetocaloric cyclic process, wherein the regenerative cyclic process has a working fluid and a heat storage medium, is characterized in that the heat storage medium of the regenerative cyclic process comprises a magnetocaloric material for the magnetocaloric cyclic process, wherein the magnetocaloric material is in a regenerator area with a cold end and a warm end, the working fluid of the regenerative cyclic process additionally serving as a heat transfer fluid for the magnetocaloric cyclic process. This produces a compact device with low apparative expense, wherein the power density and also the efficiency of the device are increased. The device may advantageously be used for cooling a superconducting magnet configuration.

Owner:BRUKER BIOSPIN

Hybrid heat pump

InactiveUS6539728B2Improve economyImprove efficiencyHeat pumpsDispersed particle separationThermal energyProduct gas

Owner:KORIN AMOS

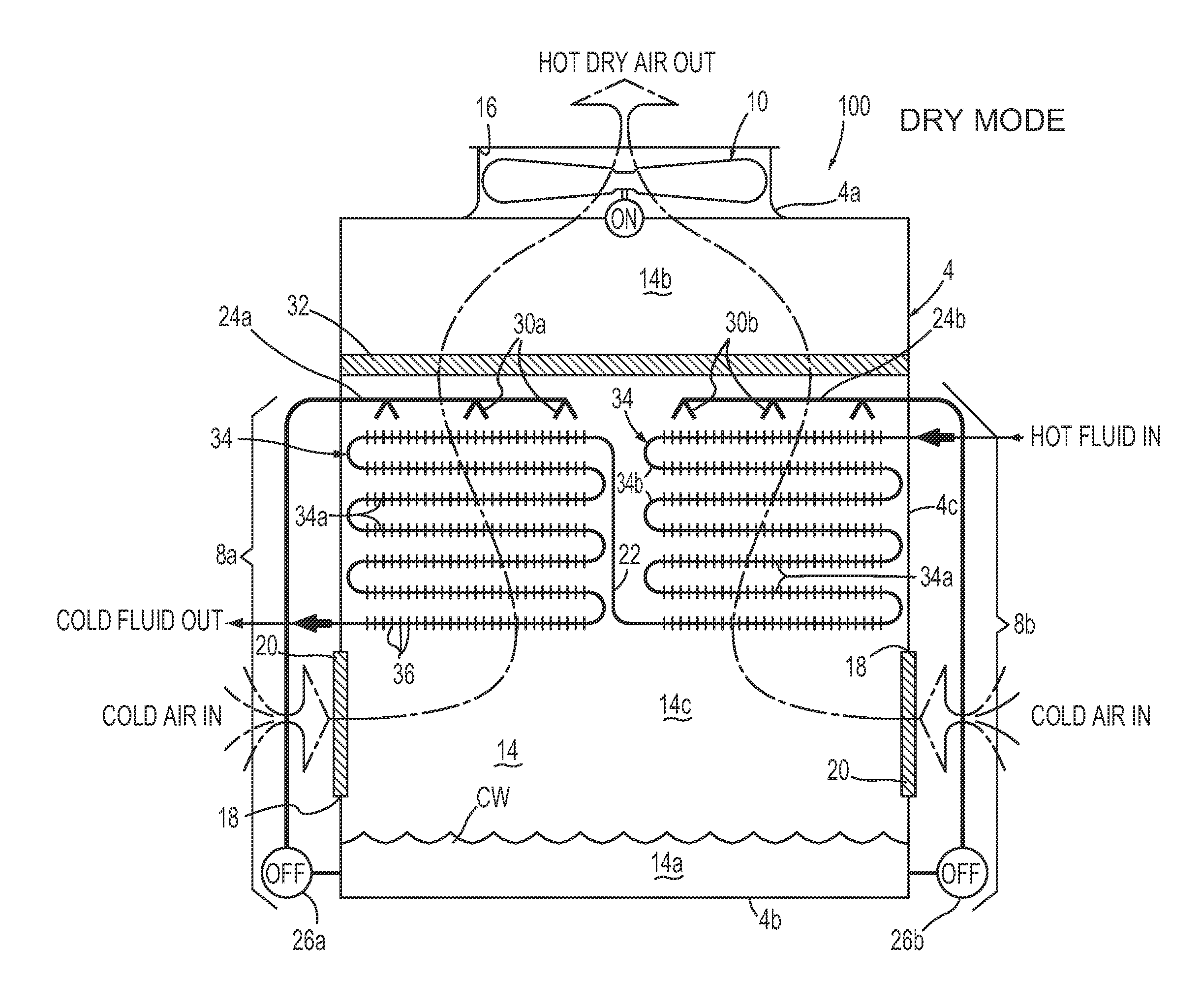

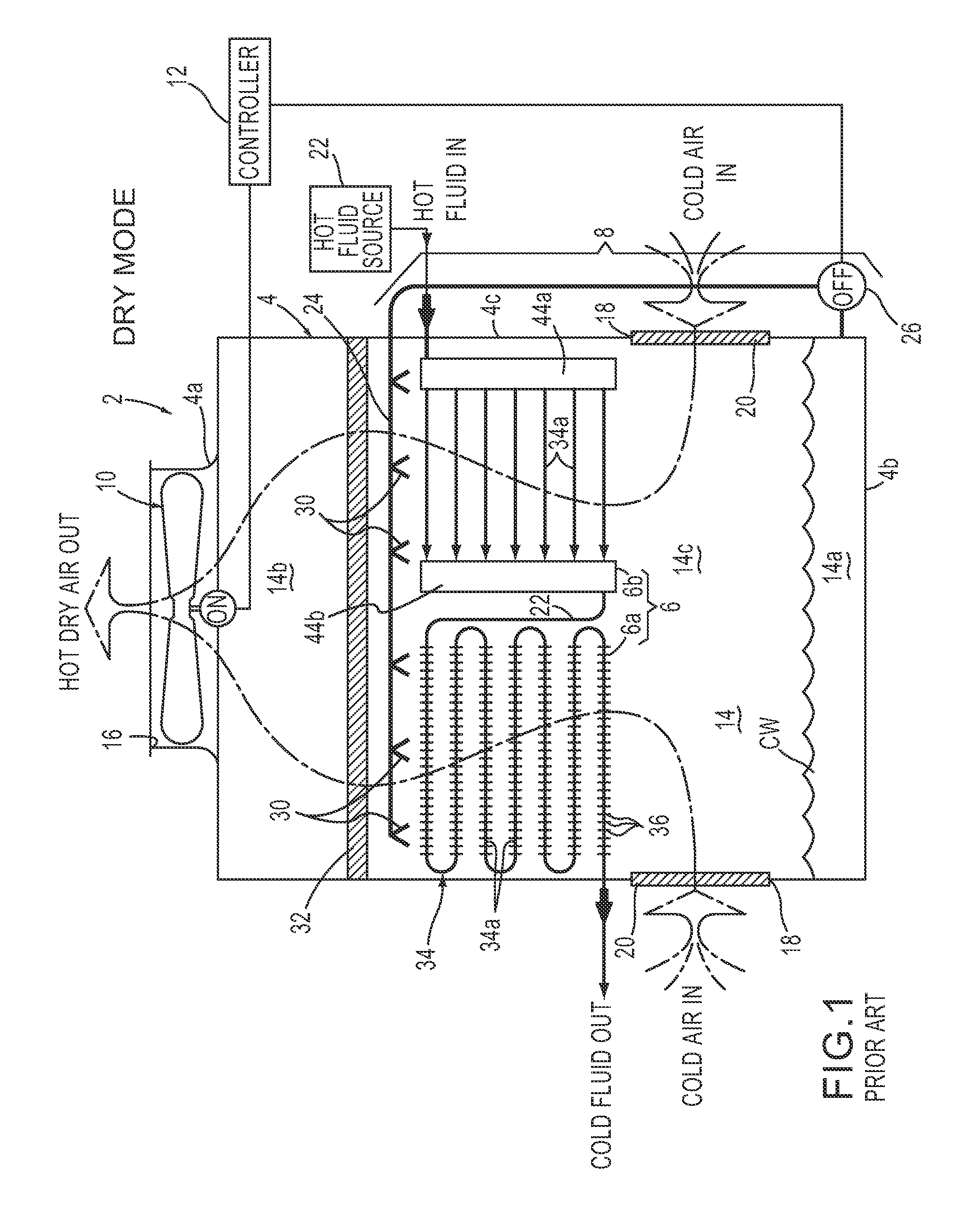

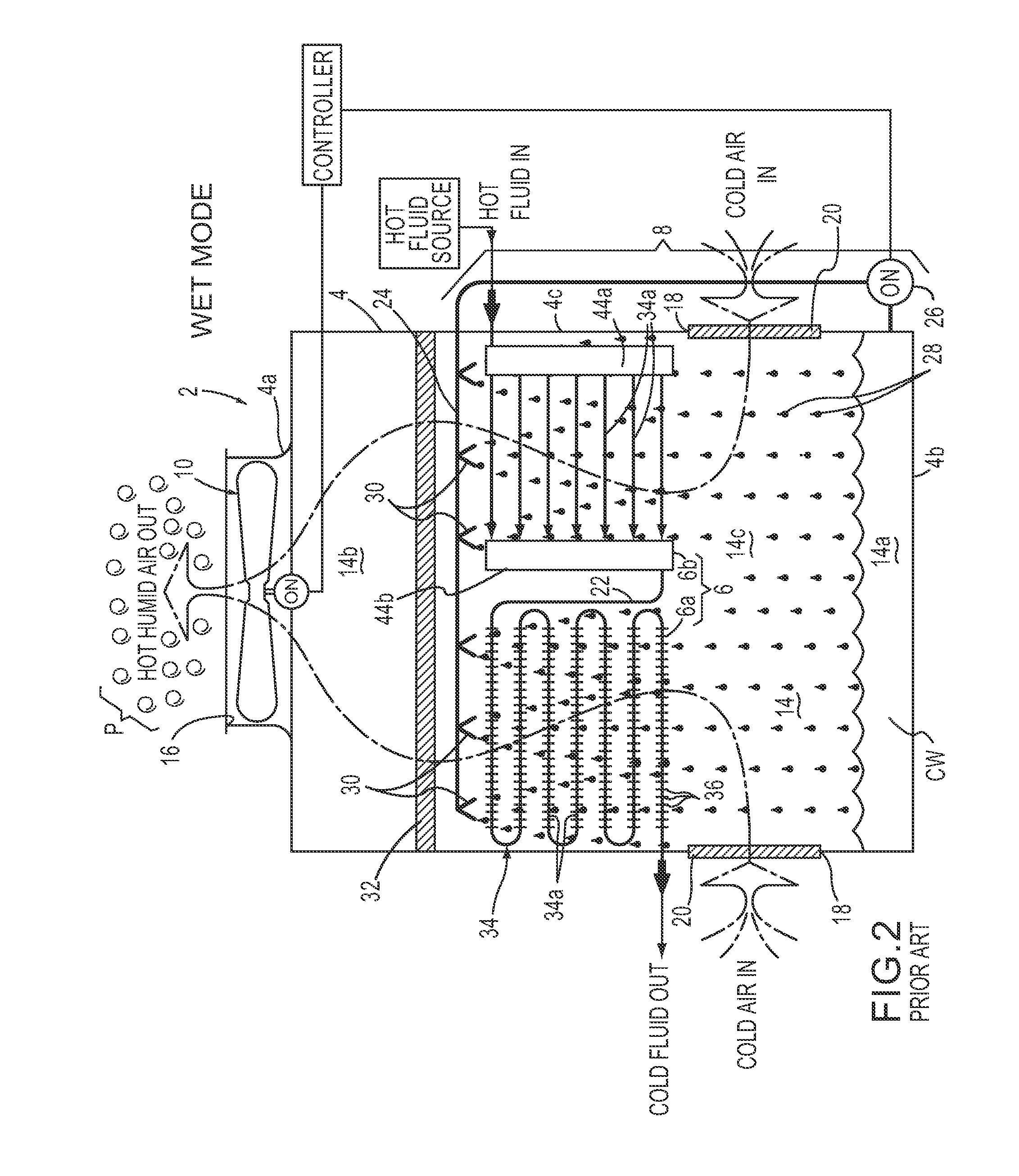

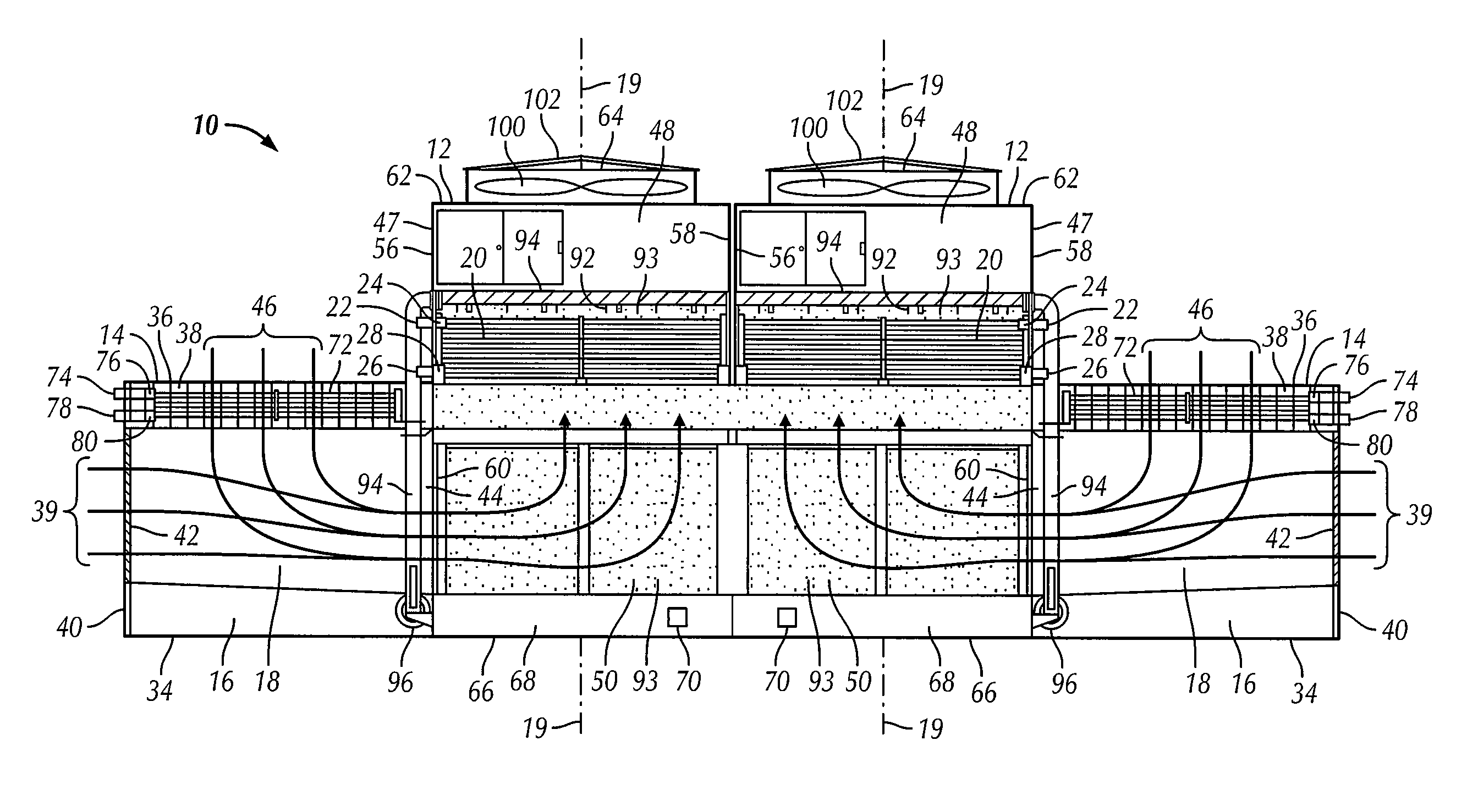

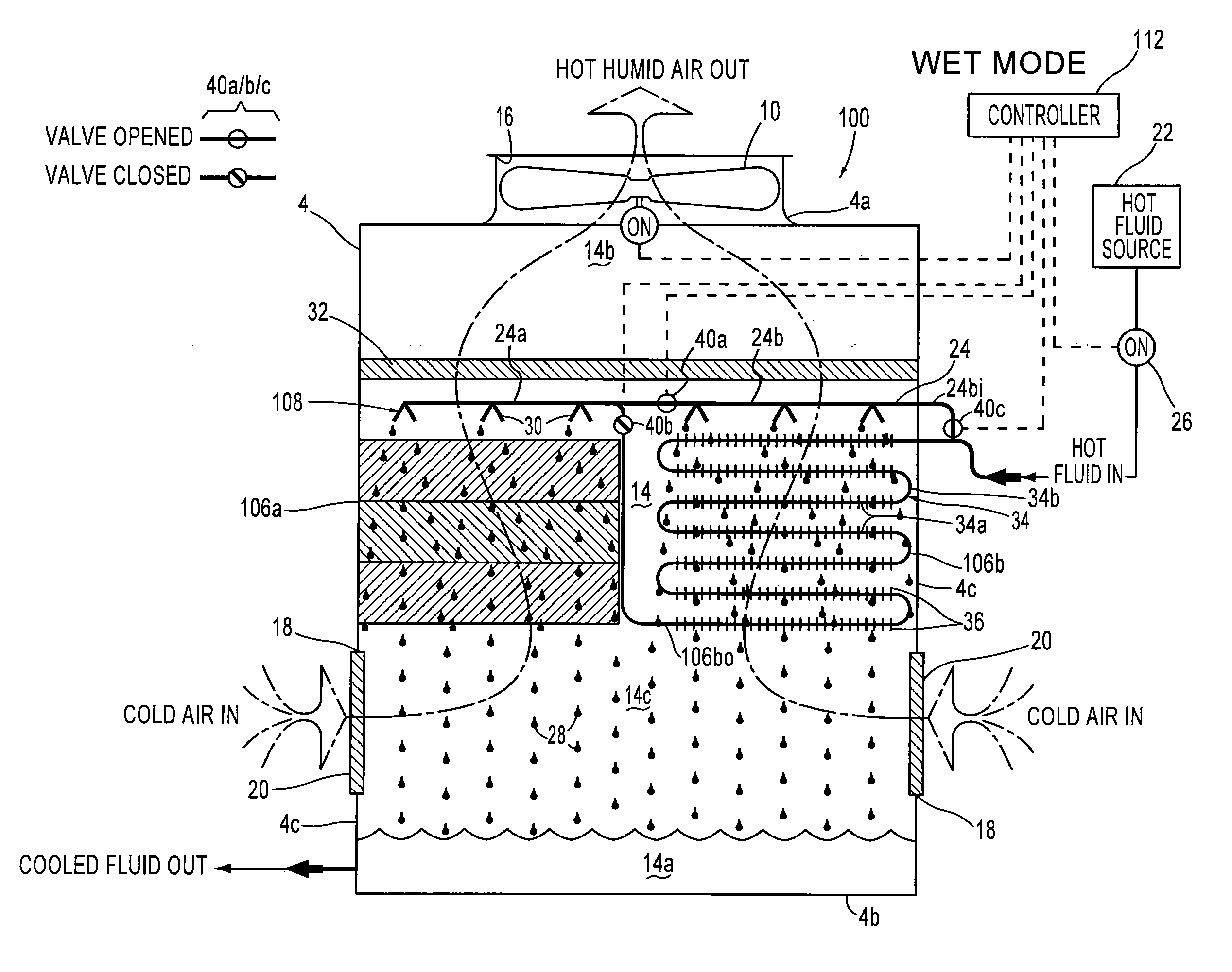

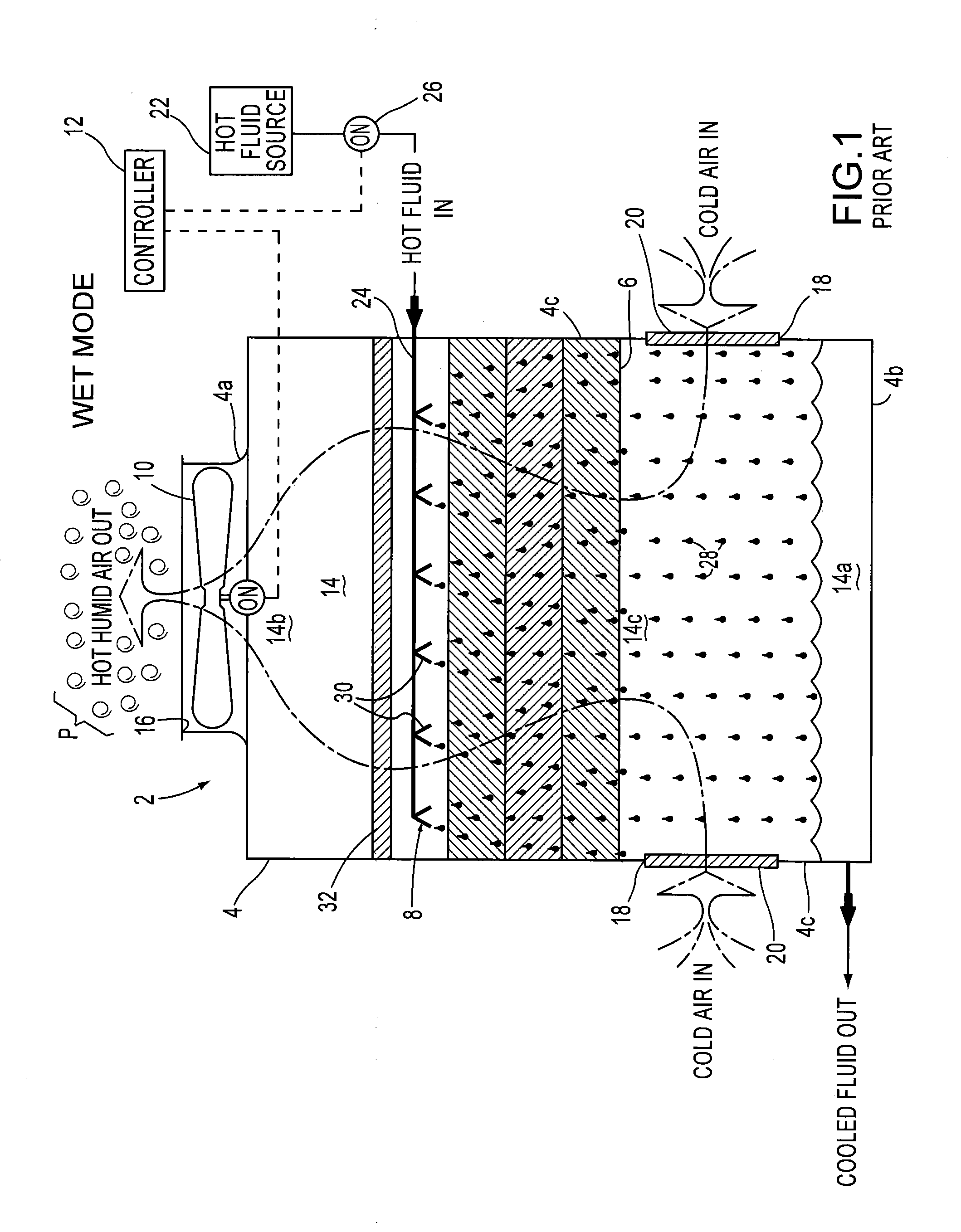

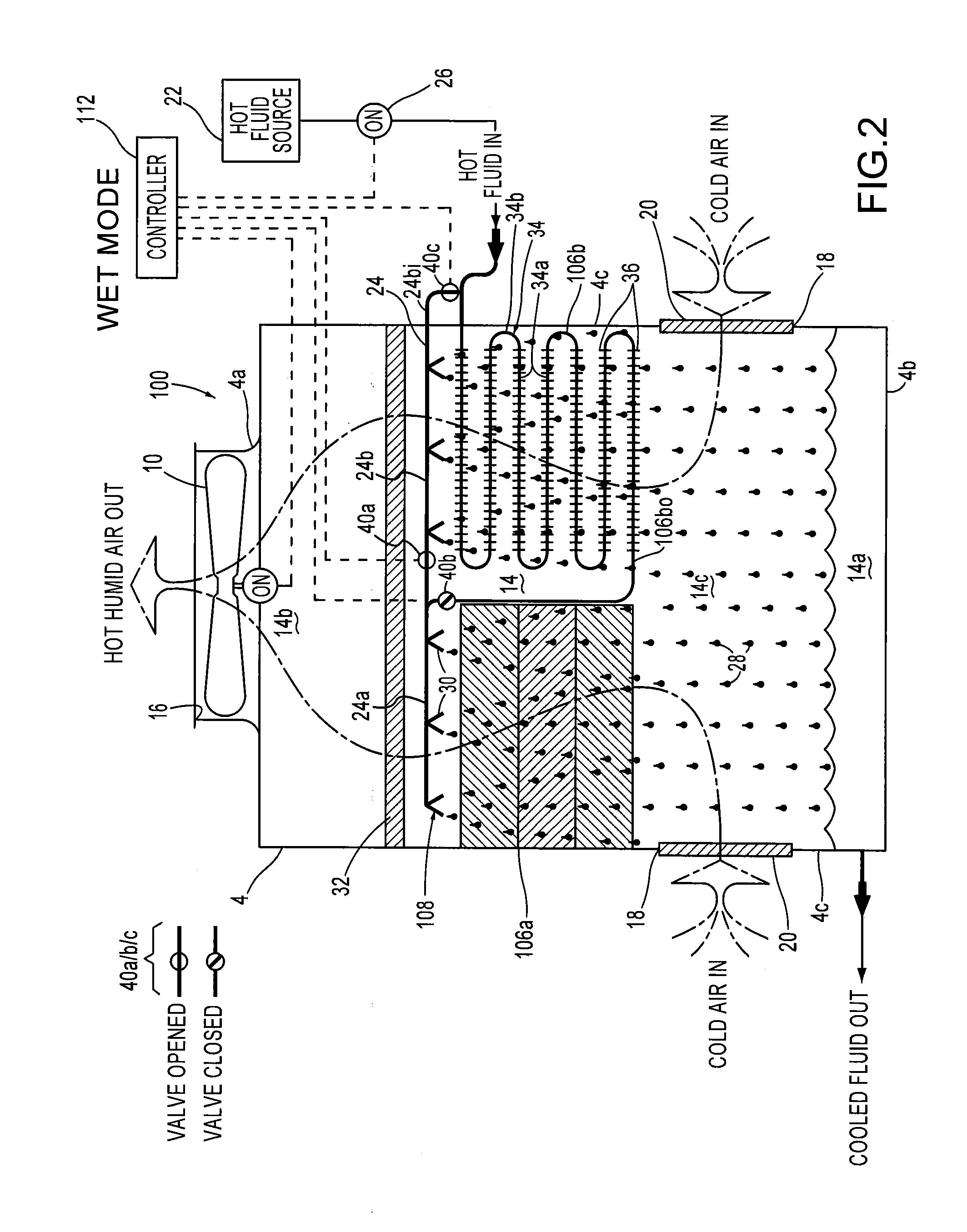

Hybrid heat exchanger apparatus and method of operating the same

InactiveUS20120067546A1Inhibition formationConserve waterFree-cooling systemsStationary conduit assembliesDistribution systemEngineering

A hybrid heat exchanger apparatus having a heat exchanger device with a hot fluid flowing therethrough includes a cooling water distribution system and an air flow mechanism for causing ambient air to flow across the heat exchanger device. The cooling water distribution system distributes evaporative cooling water onto the heat exchanger device to wet only a portion of the heat exchanger device while allowing a remaining portion of the heat exchanger device to be dry. The air flow mechanism causes ambient air to flow across the heat exchanger device to generate hot humid air from the ambient air flowing across the wet portion of the heat exchanger device and hot dry air from the ambient air flowing across the remaining dry portion of the heat exchanger device. Methods are also described.

Owner:EVAPCO

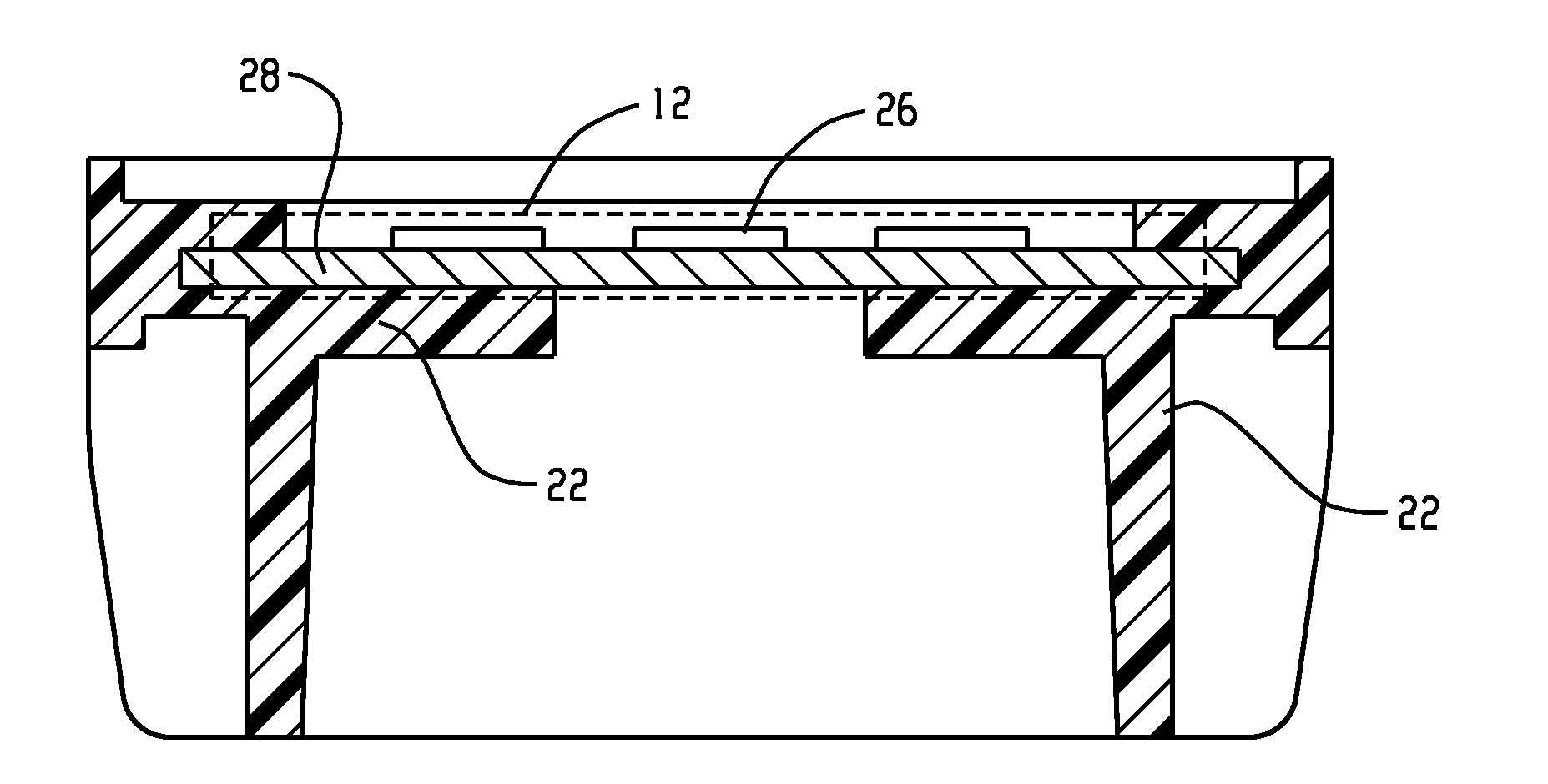

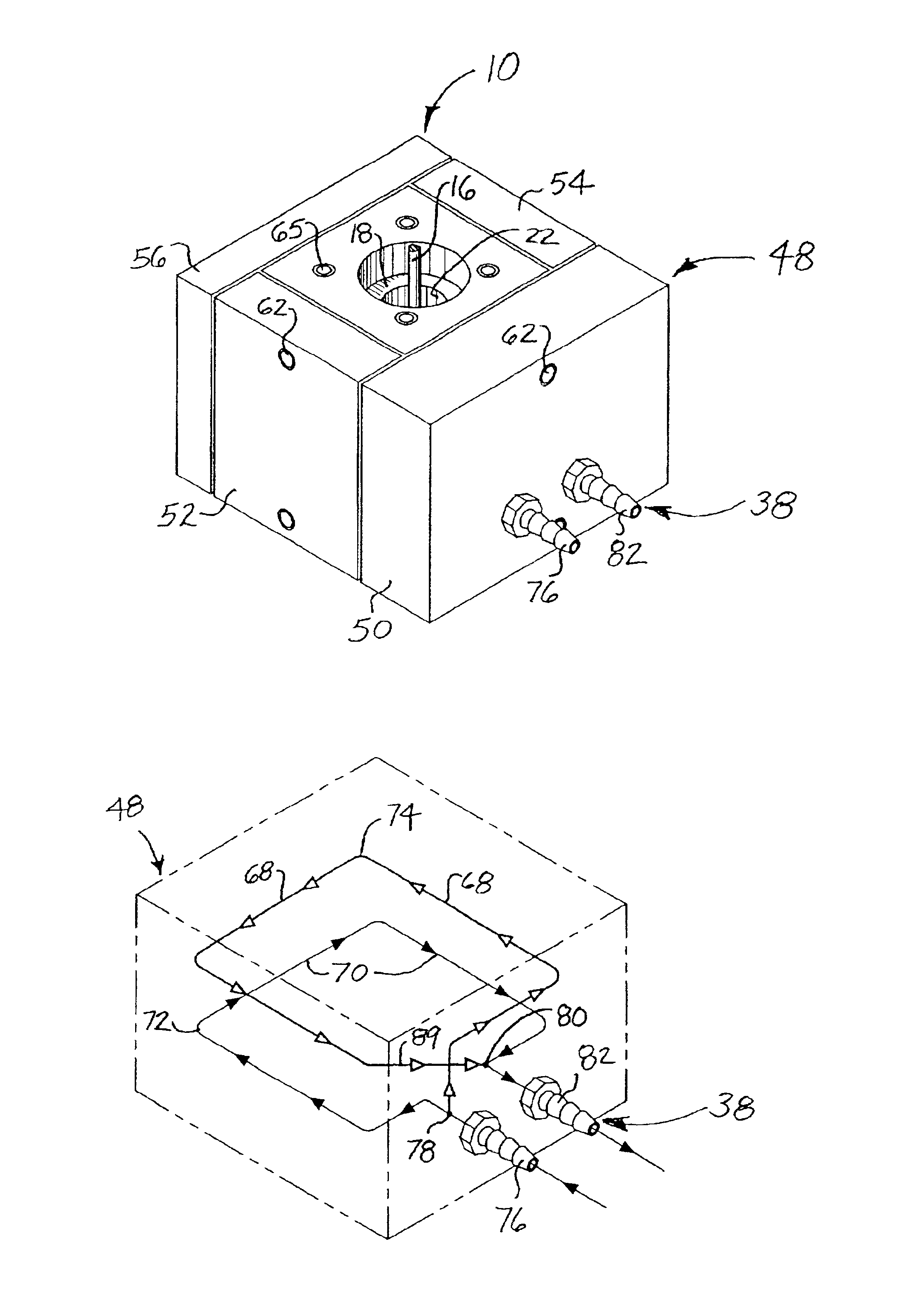

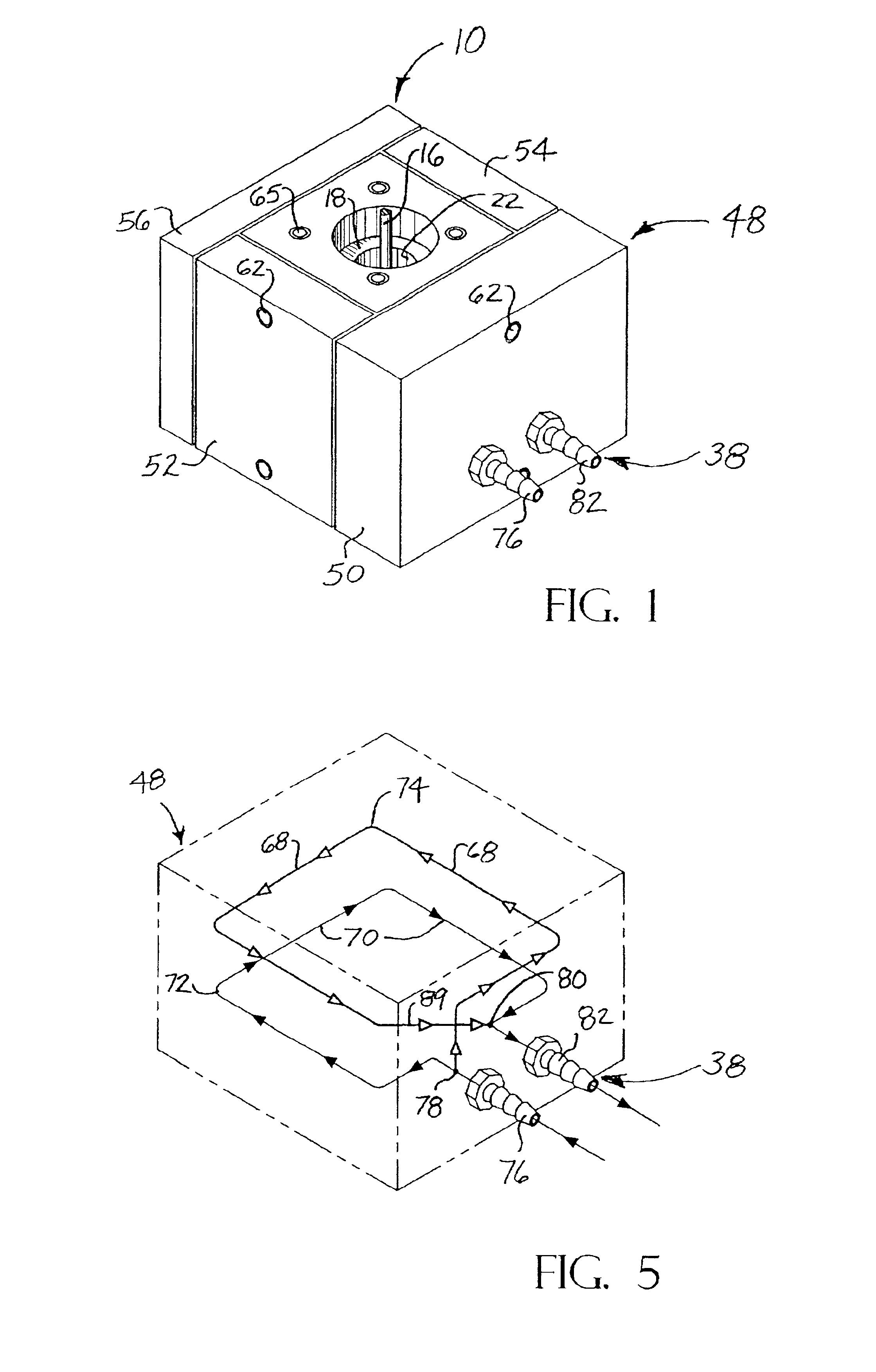

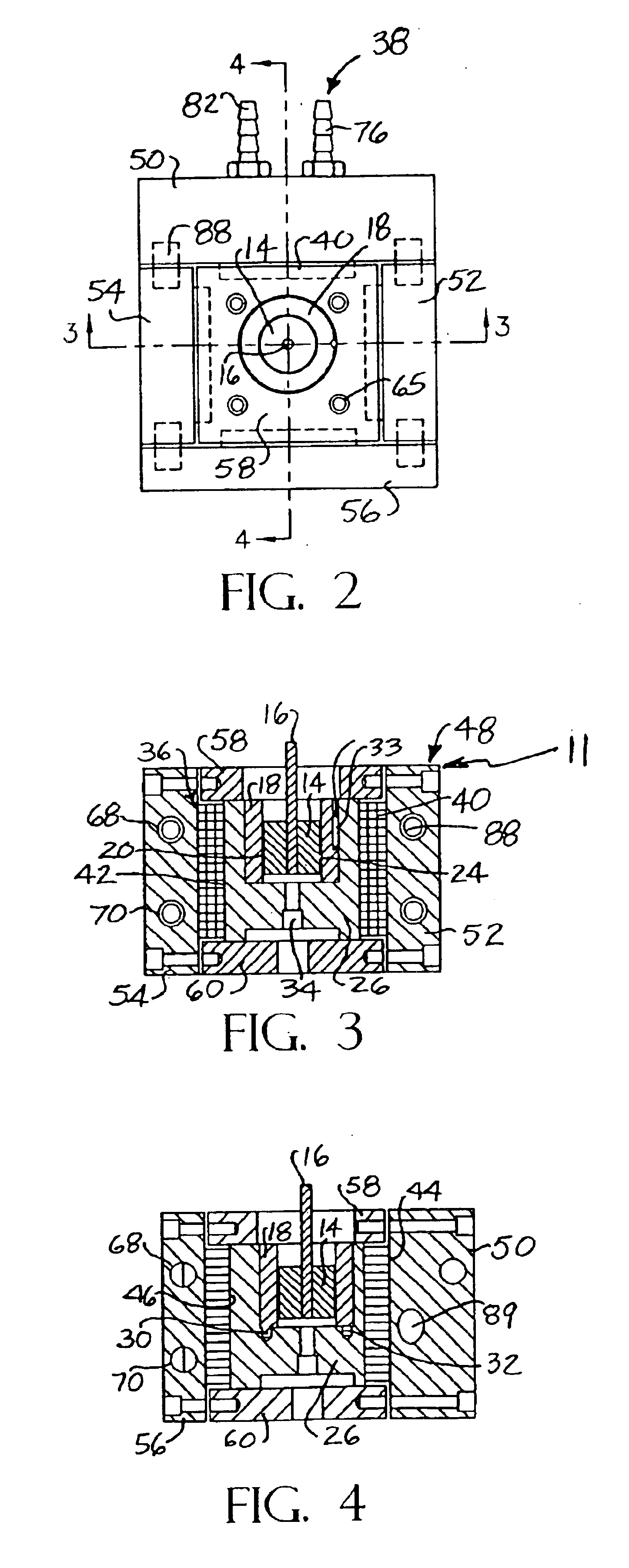

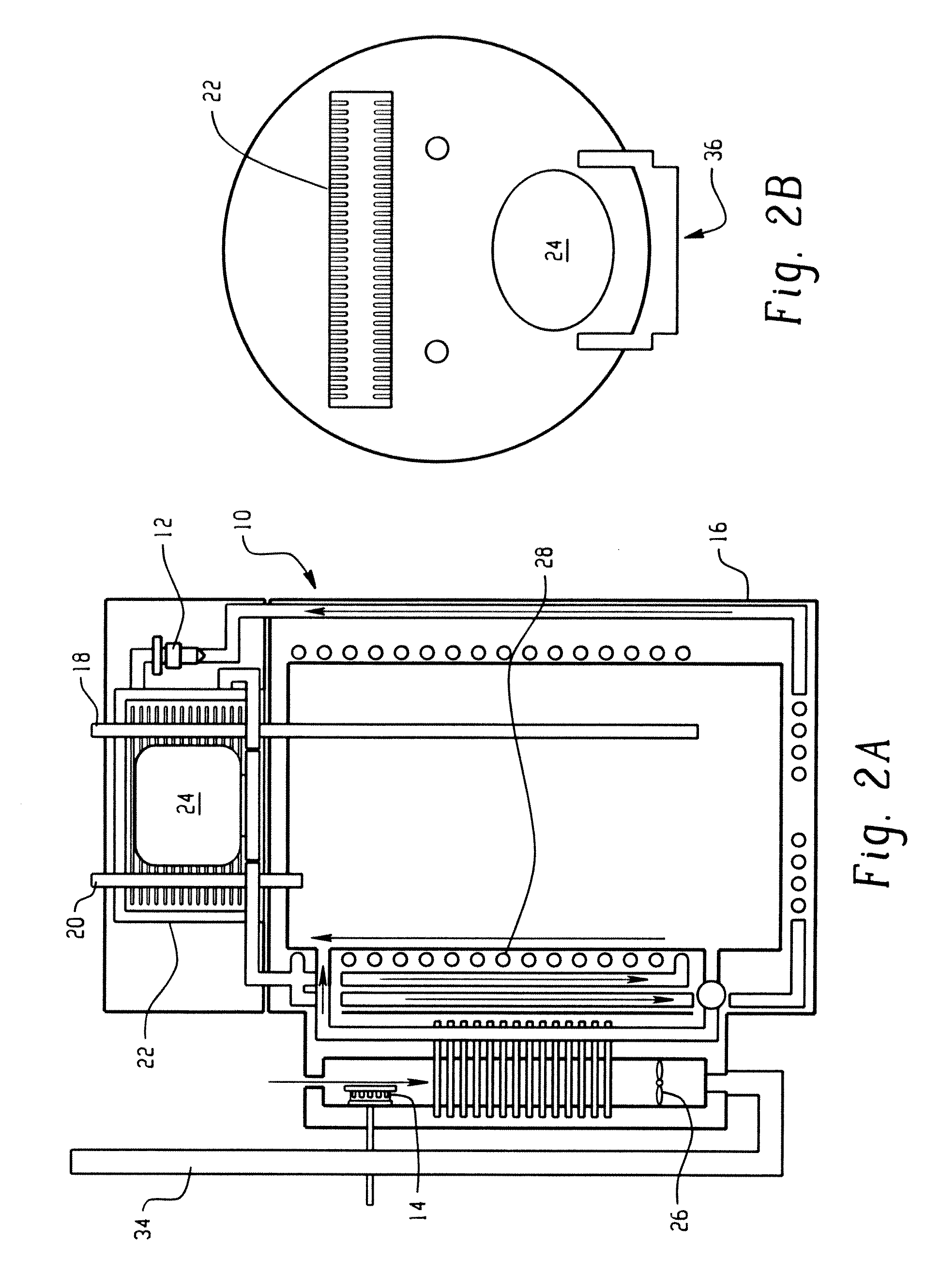

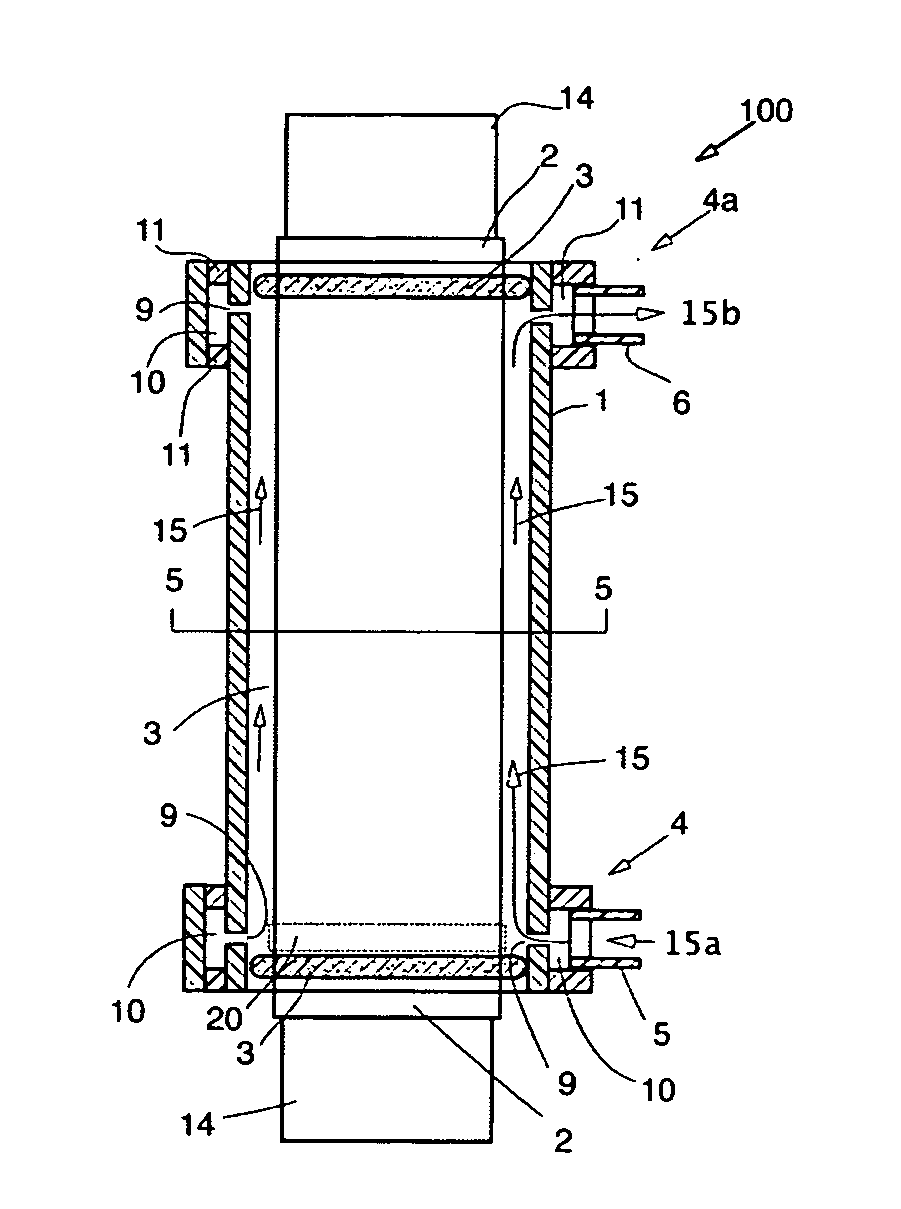

Cold cranking simulator having hybrid heat transfer system

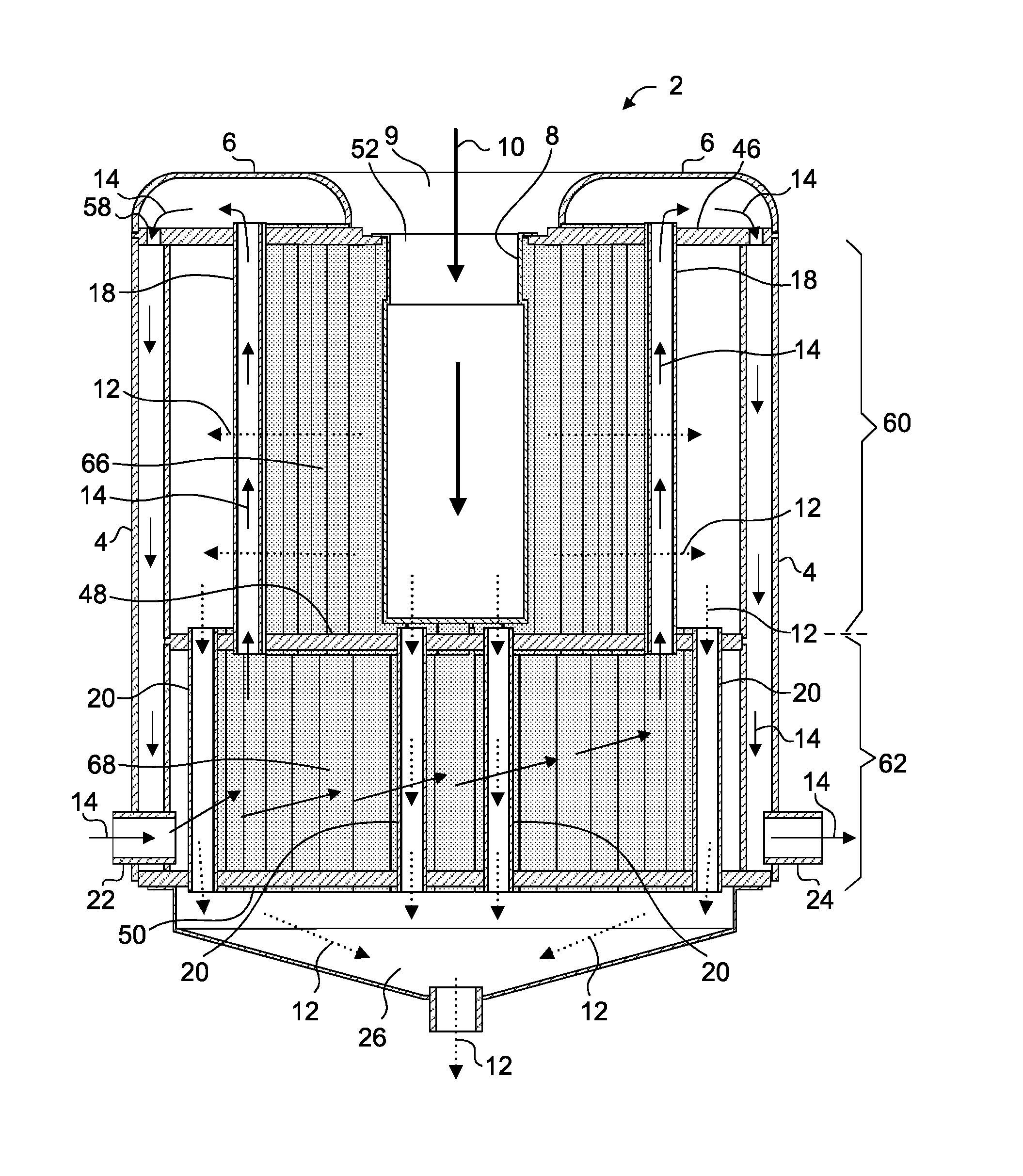

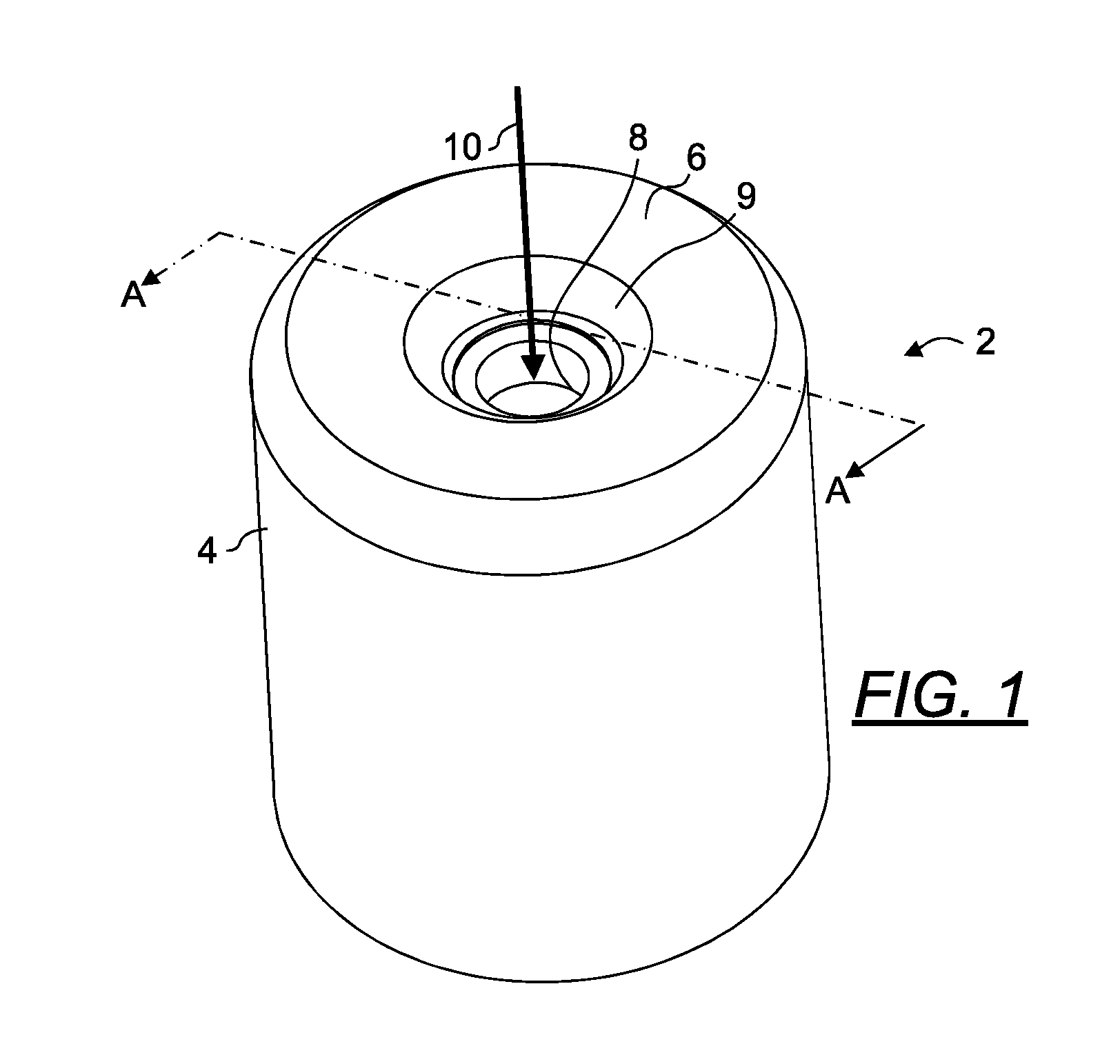

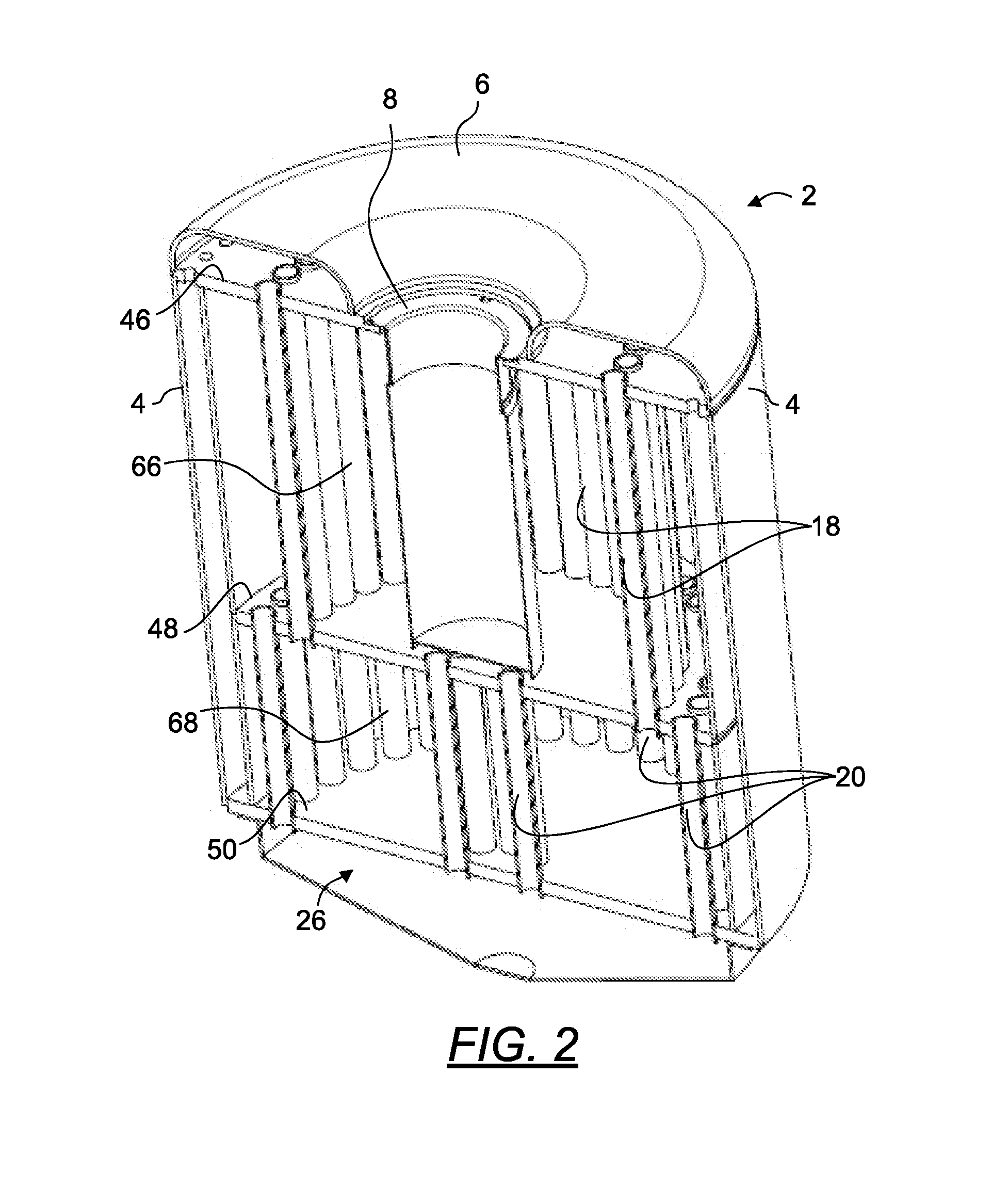

A heat transfer apparatus for use in measuring a rheological property of a test sample includes a receptacle for receiving the test sample and a heat conveying member in heat transfer relation to the receptacle. The heat conveying member has internal passages extending substantially equidistantly from one another through at least a portion of the heat conveying member to provide for counter-flow circulation of a fluid. The heat transfer apparatus may include heat exchanging elements in heat transfer relation to the receptacle responsive to electric current to transfer heat to or from the receptacle.

Owner:CANNON INSTR

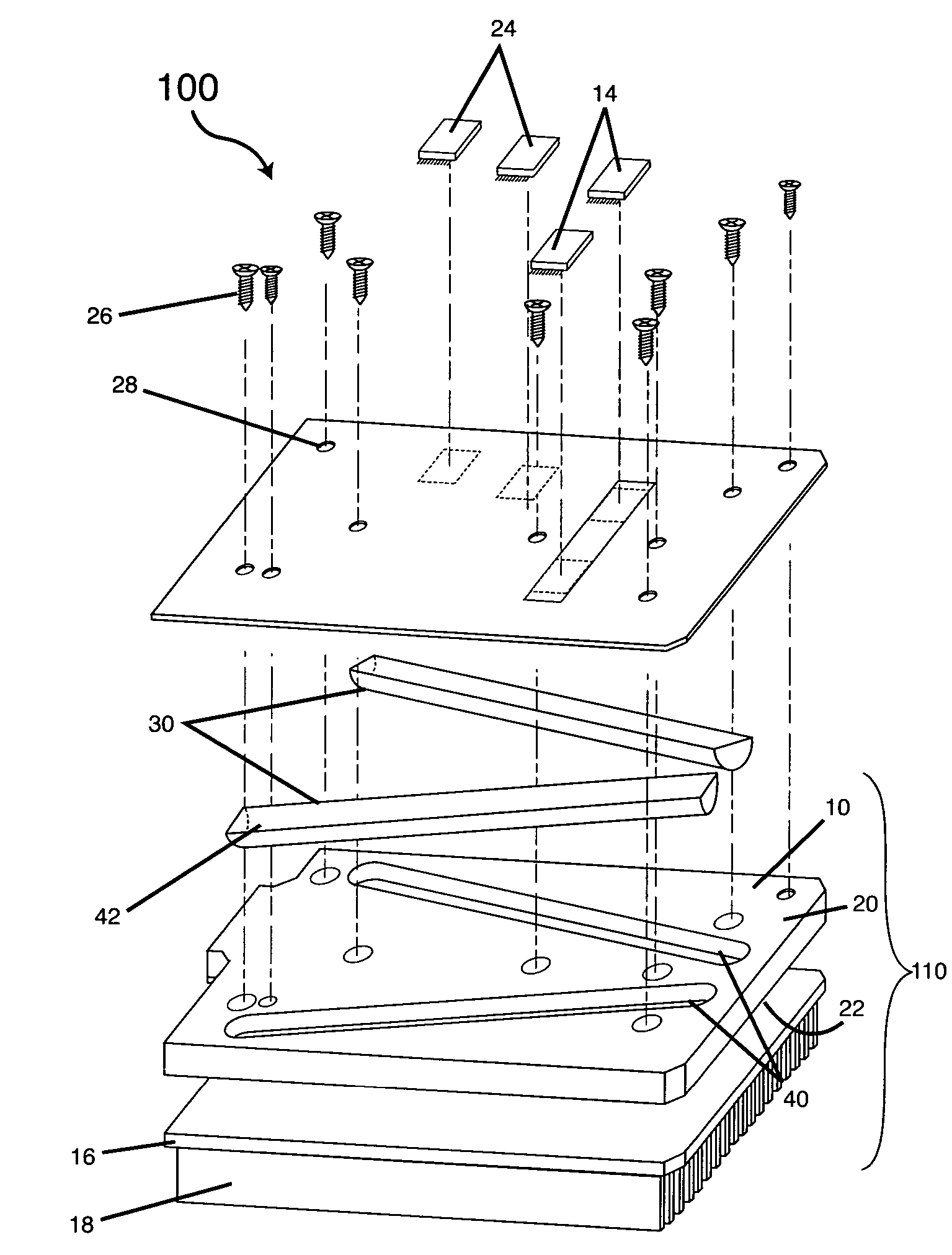

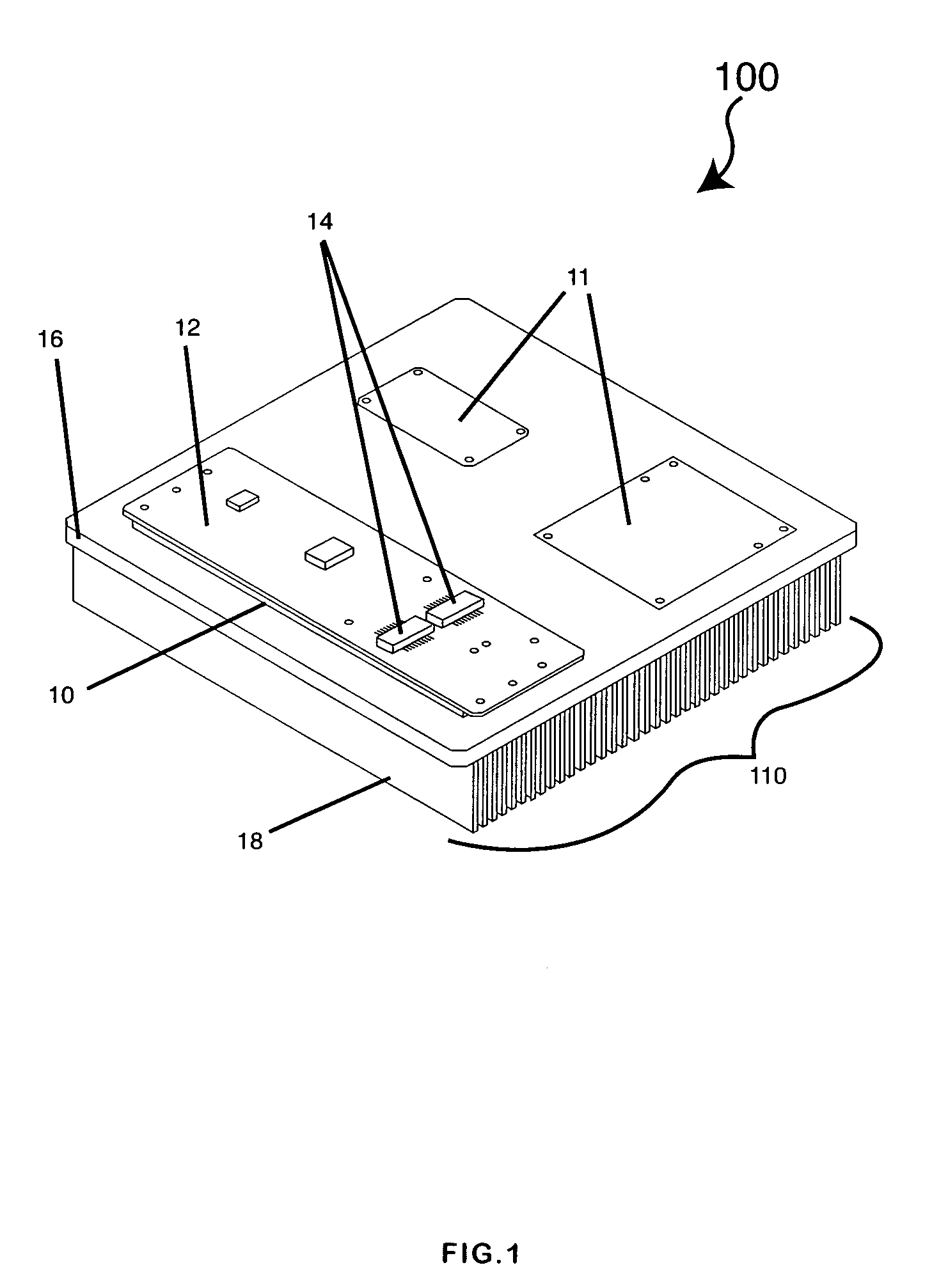

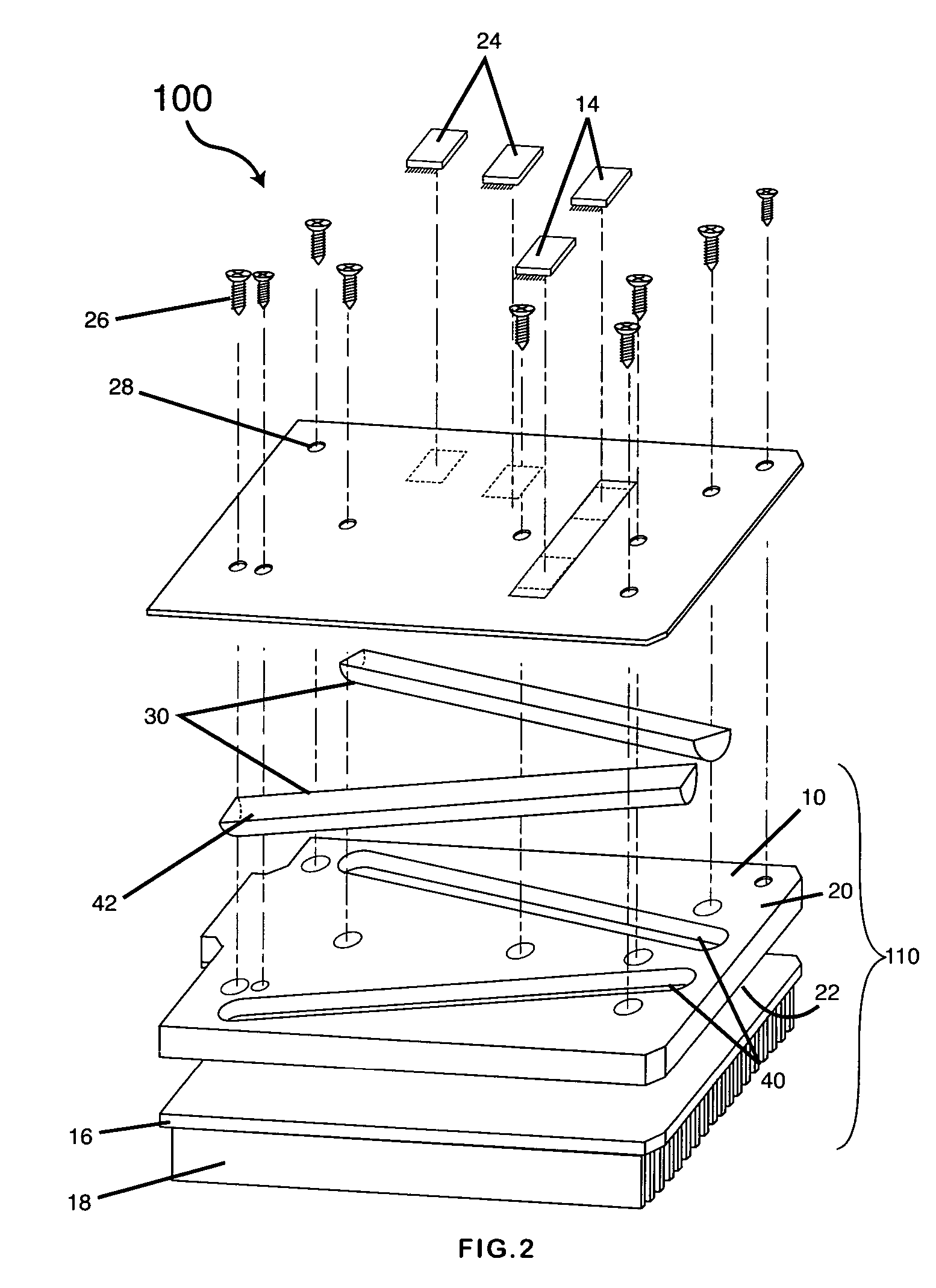

RF power amplifier assembly with heat pipe enhanced pallet

Owner:INTEL CORP

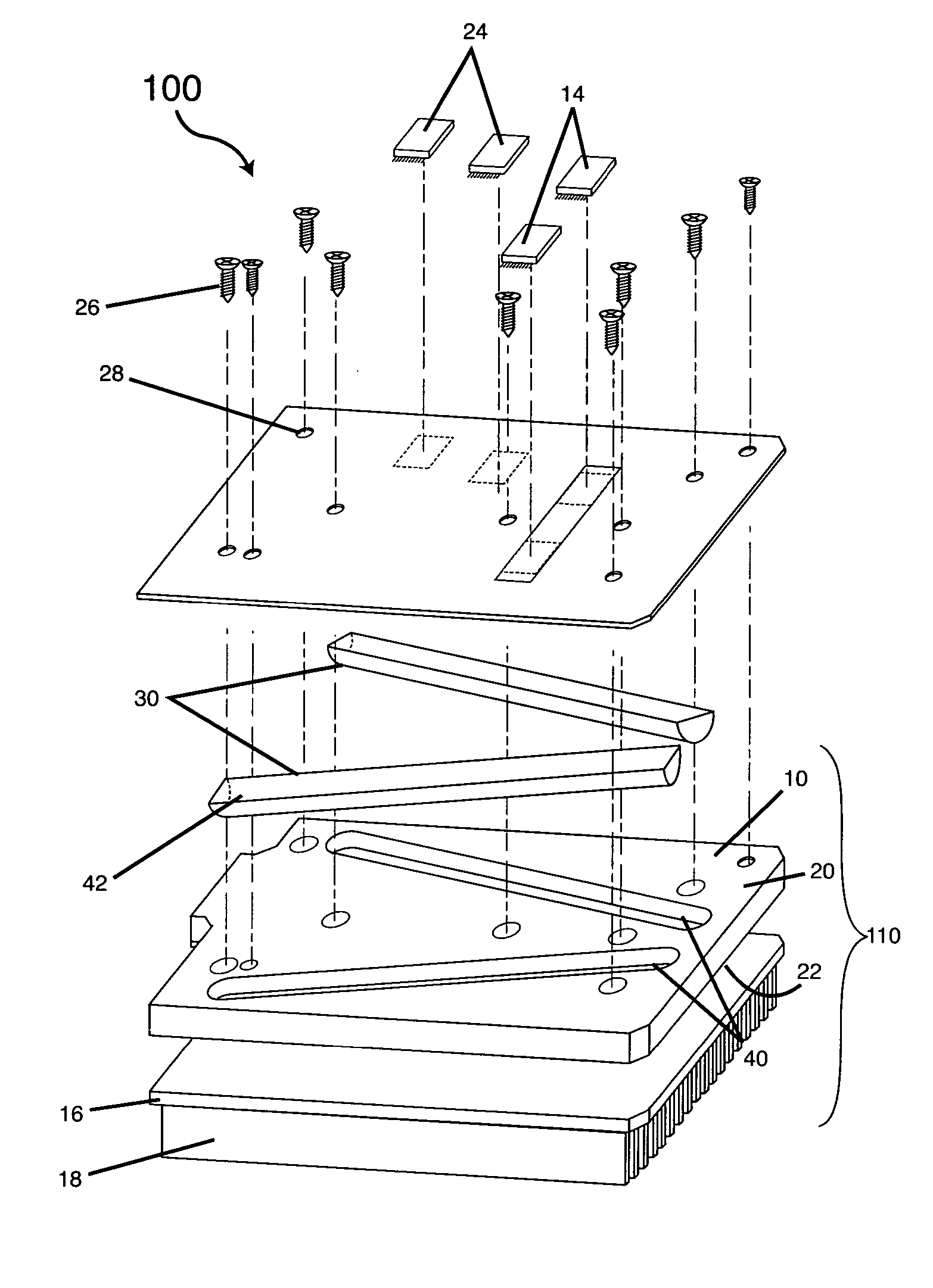

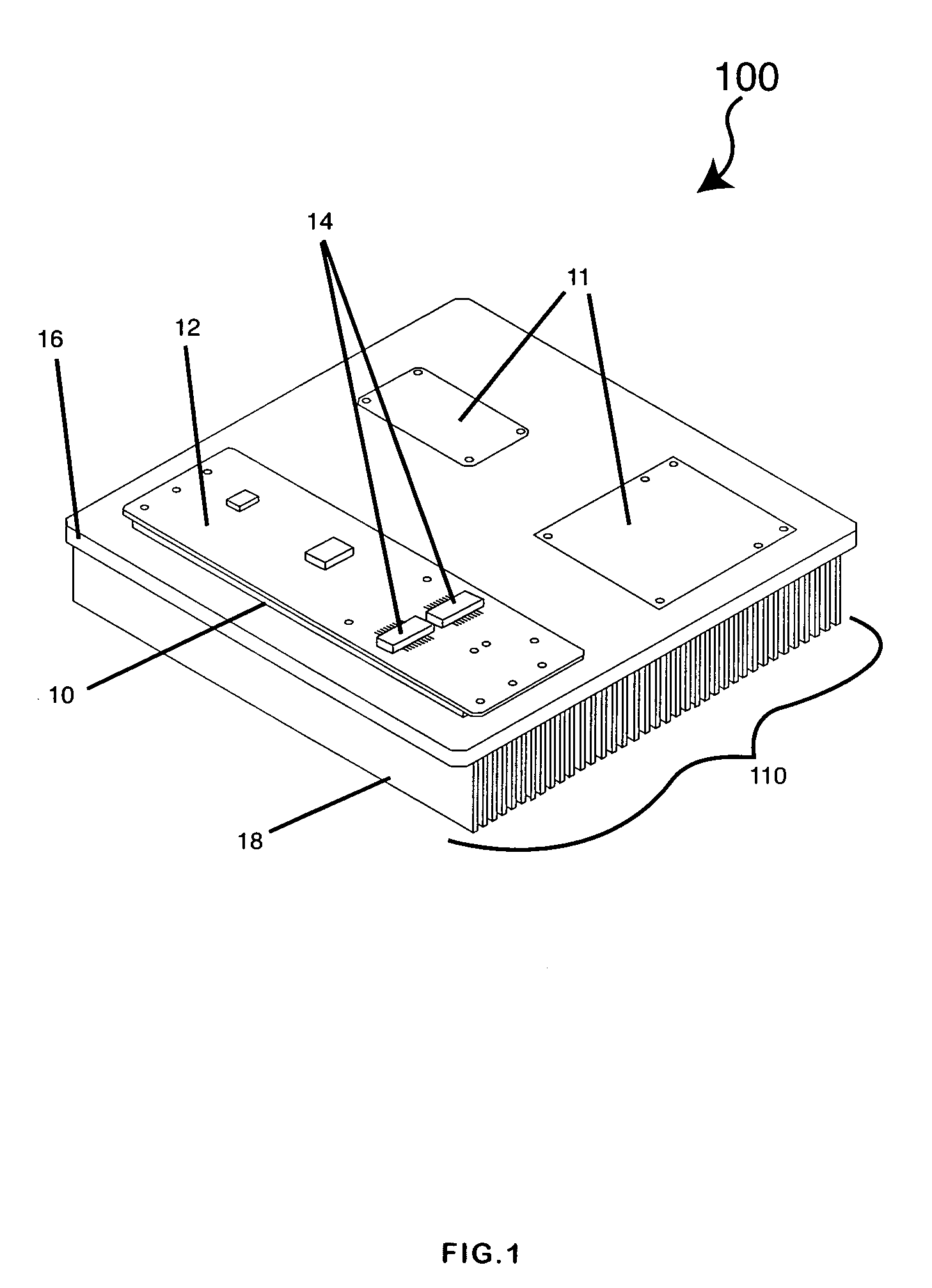

RF power amplifier assembly with heat pipe enhanced pallet

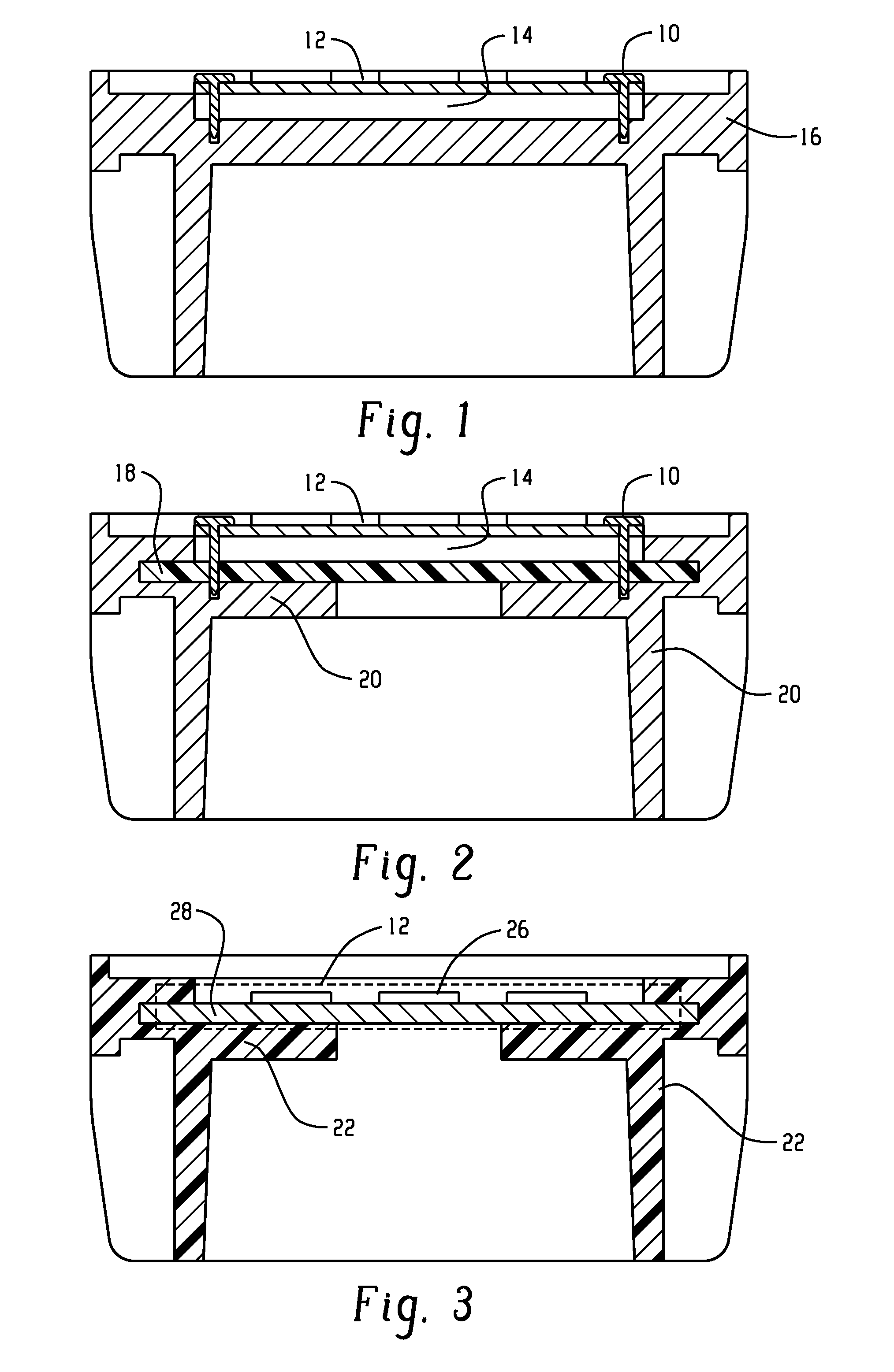

ActiveUS20050201061A1Indirect heat exchangersHeat exchanger fasteningJunction temperatureEngineering

An RF amplifier assembly employing a finned heat sink and a heat pipe enhanced aluminum pallet is disclosed. The hybrid heat pipe enhanced aluminum pallet reduces the spreading thermal conduction resistance associated with the conduction of localized energy from RF amplifier devices when compared to a copper pallet. The localized energy concentration of RF amplifier devices is spread along the length of the heat pipe increasing the overall efficiency of the heat sink coupled to the pallet and accommodating non-uniform heat loading. This reduces the junction temperature of the devices, which leads to higher mean time before failure and higher output levels. The pipes are formed and embedded into the pallet so as to pass under different areas of interest and extend to the under-utilized regions.

Owner:INTEL CORP

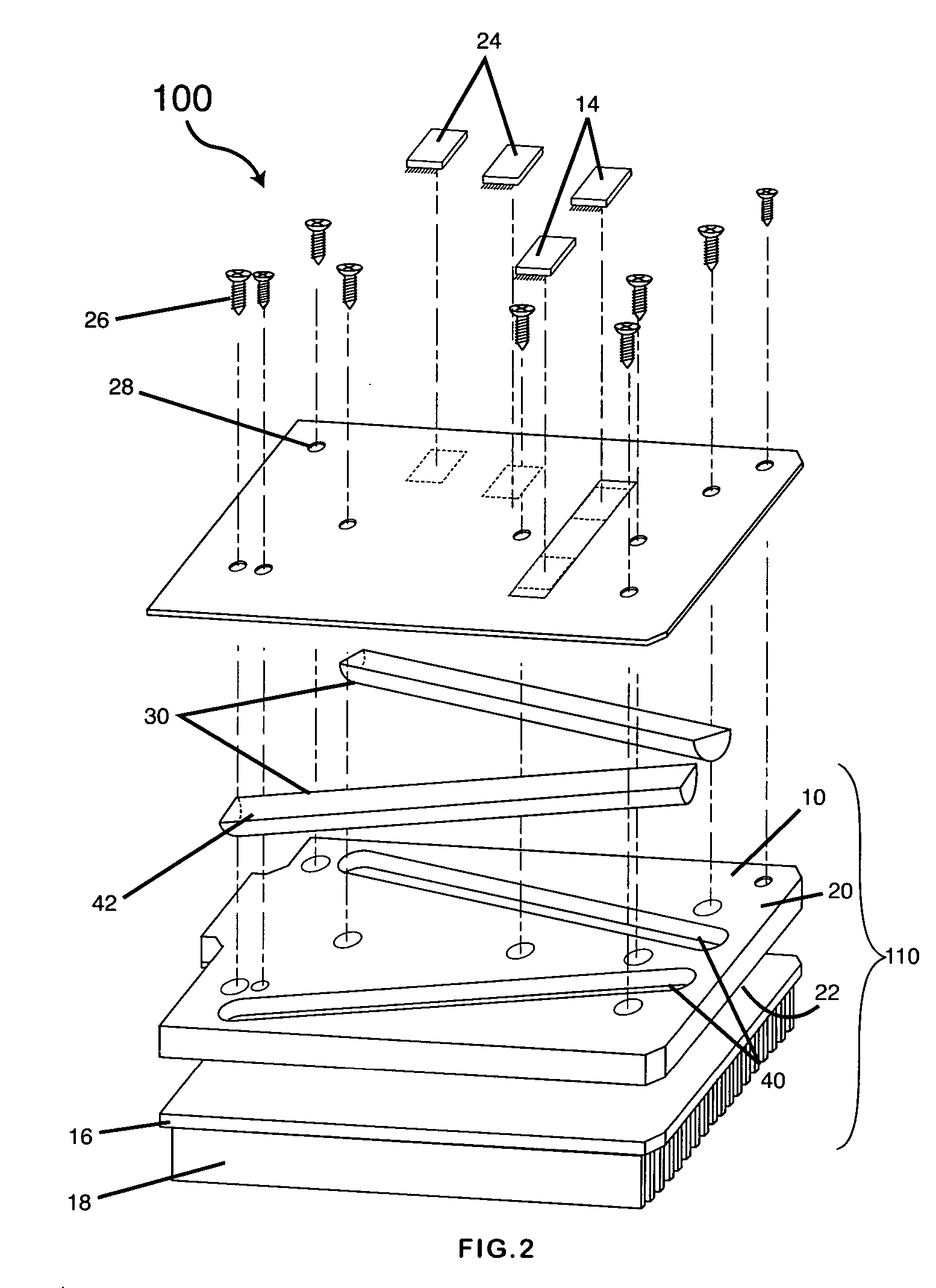

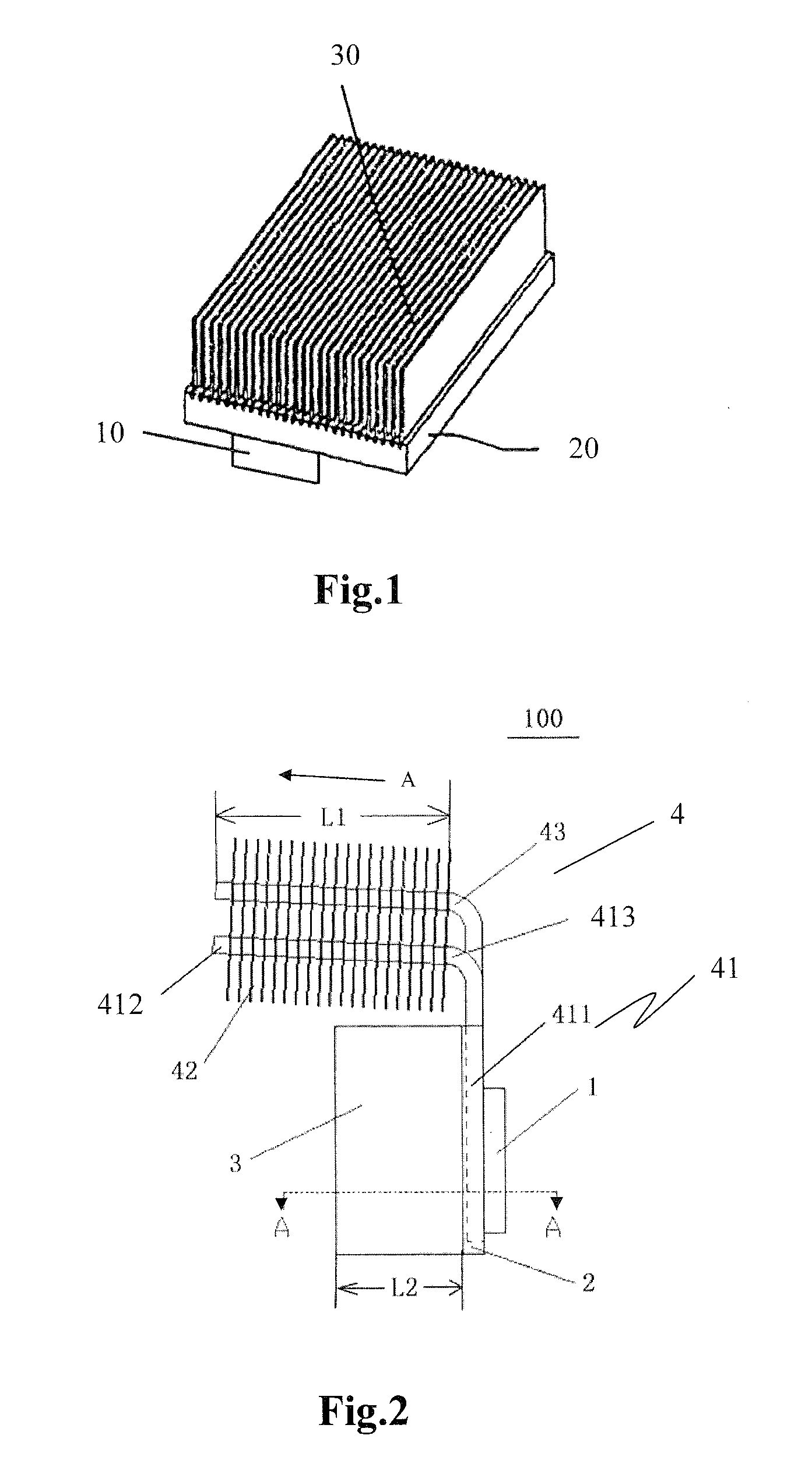

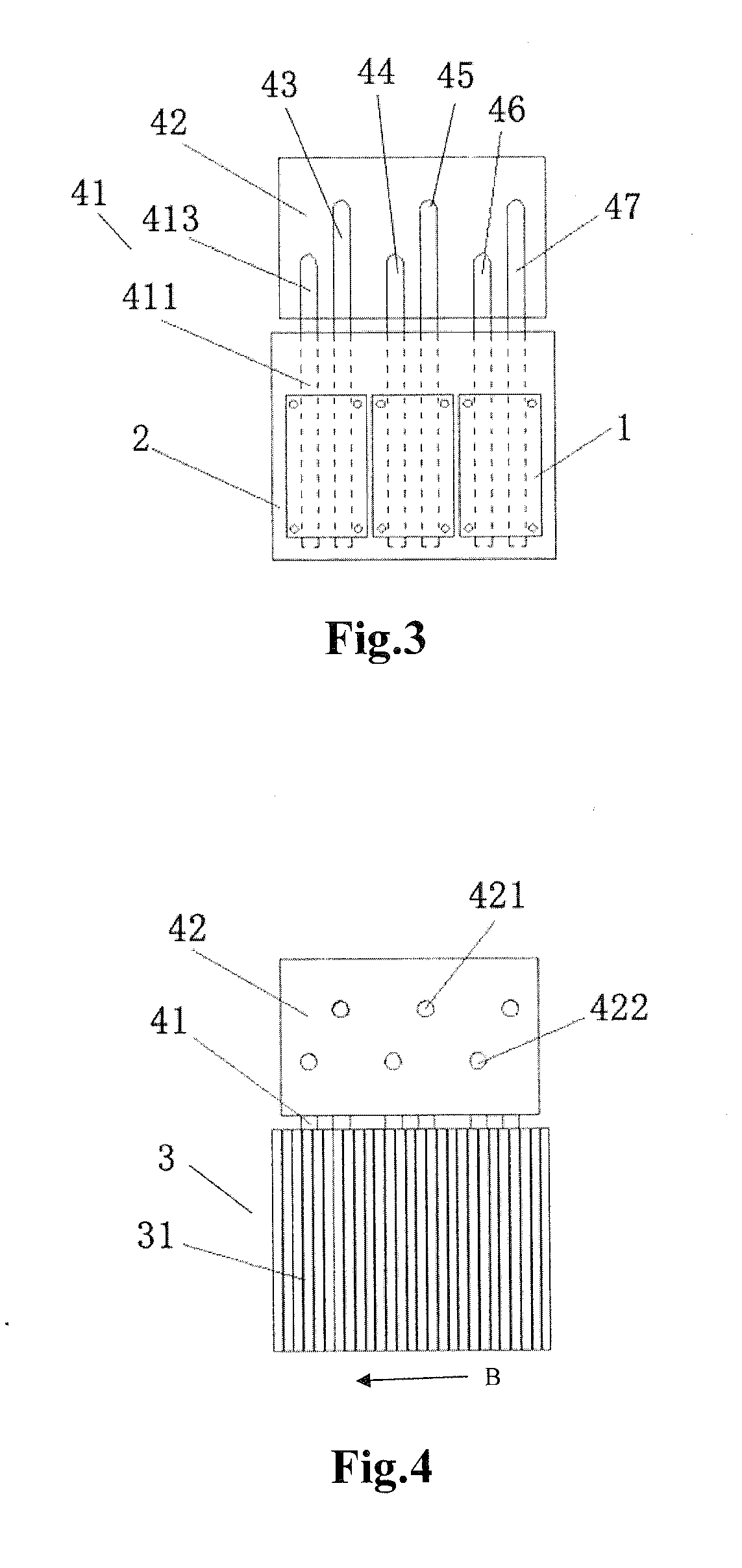

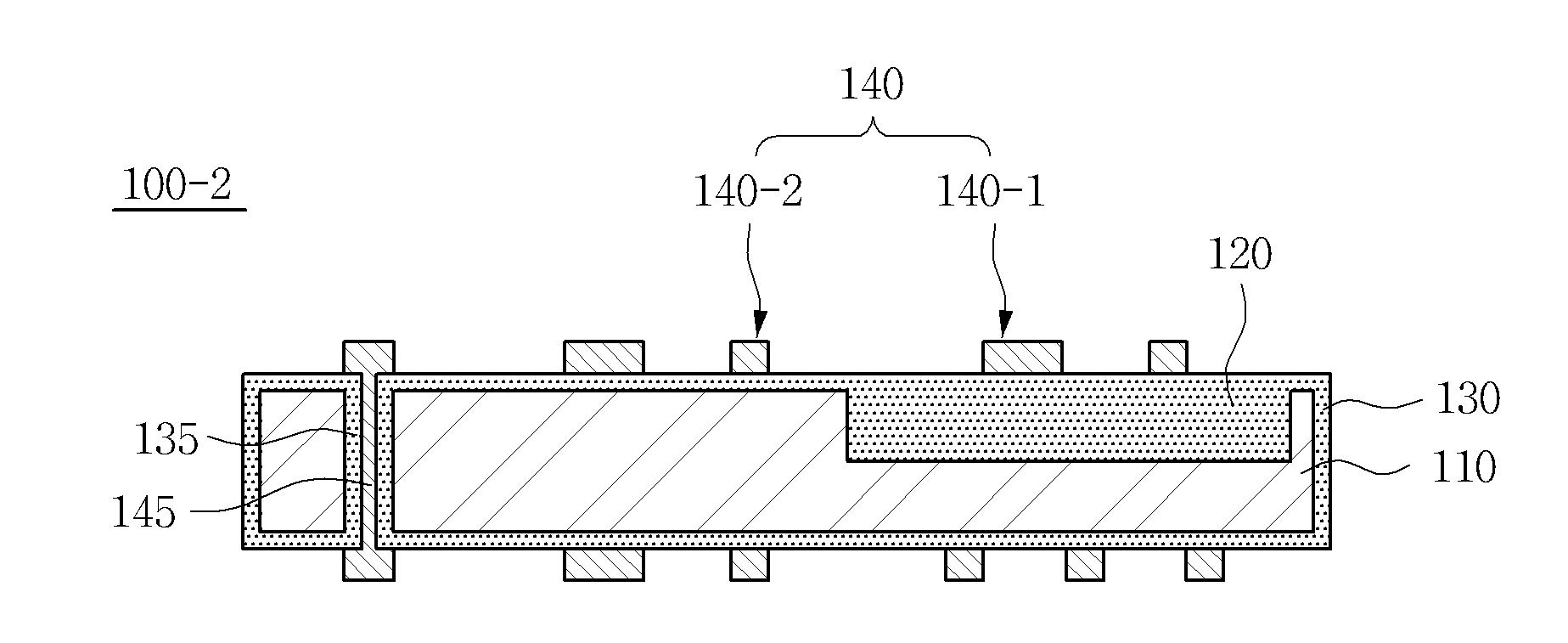

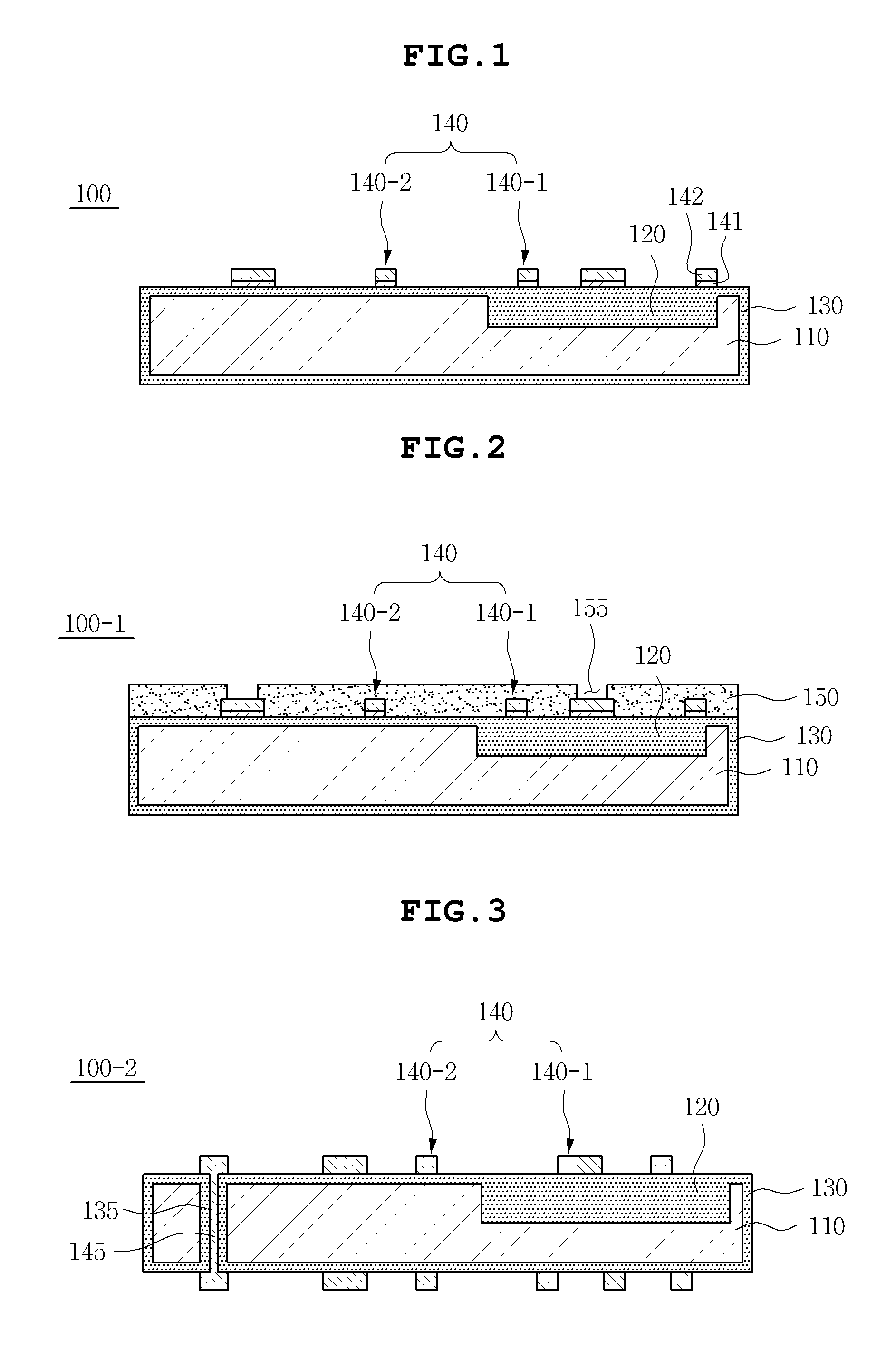

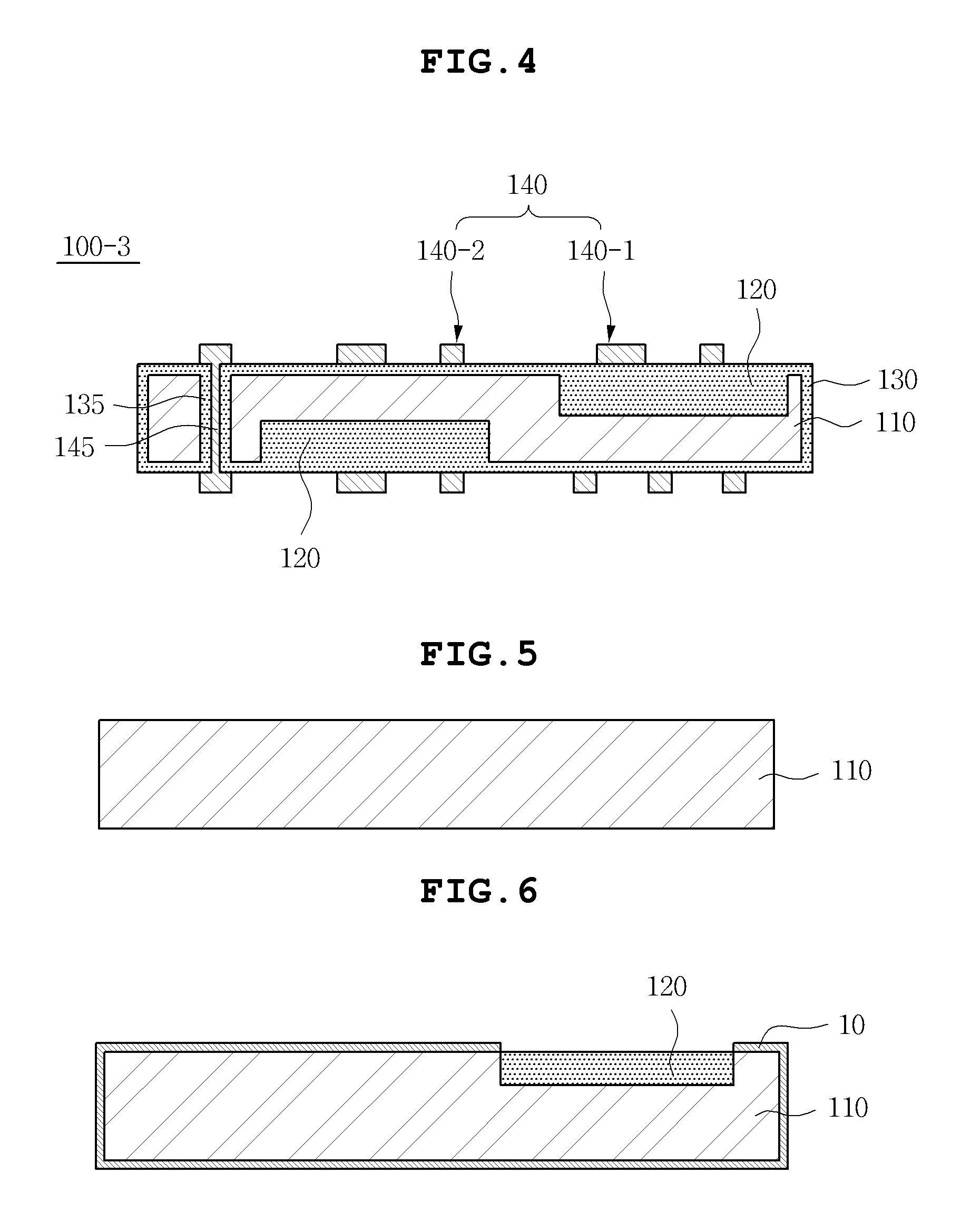

Hybrid heat sink and hybrid heat sink assembly for power module

ActiveUS20130155616A1Increase cooling areaCompact structureSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

Disclosed are a hybrid heat sink and a hybrid heat sink assembly for a power module. The hybrid heat sink comprises a base provided with at least one power module on one side thereof, a first heat dissipation unit being a first heat dissipation fin group which is composed of a plurality of heat dissipation fins intervally arranged and is located on the other side of the base, and a second heat dissipation unit comprising a plurality of heat pipes and a second heat dissipation fin group. Each of the heat pipes comprises an evaporating section provided in the base and close to the power module, a condensing section, and an adiabatic section located between the evaporating section and the condensing section and comprises an extension portion and a folding portion, the second heat dissipation fin group is provided on the condensing sections.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

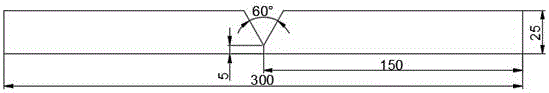

Heat pump water heater in conjunction with gas water heater

InactiveUS20130042635A1Improve energy efficiencyLow costCompression machines with cascade operationWater heatersCombined useEngineering

A method for heating water delivered and stored in a water heater storage tank includes activating at least one of dual fuel heater types in response to various modes of operation. The water heater is preferably a dual fuel or hybrid heat pump gas water heater that includes a heat pump as the first type of heater for heating the water, and a gas burner as the second type of heater that transfer heat to the water. One or more sensors monitor water temperature and communicate with a controller to activate one of, or both of, the first and second types of heaters. If there is an electrical power outage, the hybrid heat pump gas water heater is still able to heat the water.

Owner:GENERAL ELECTRIC CO

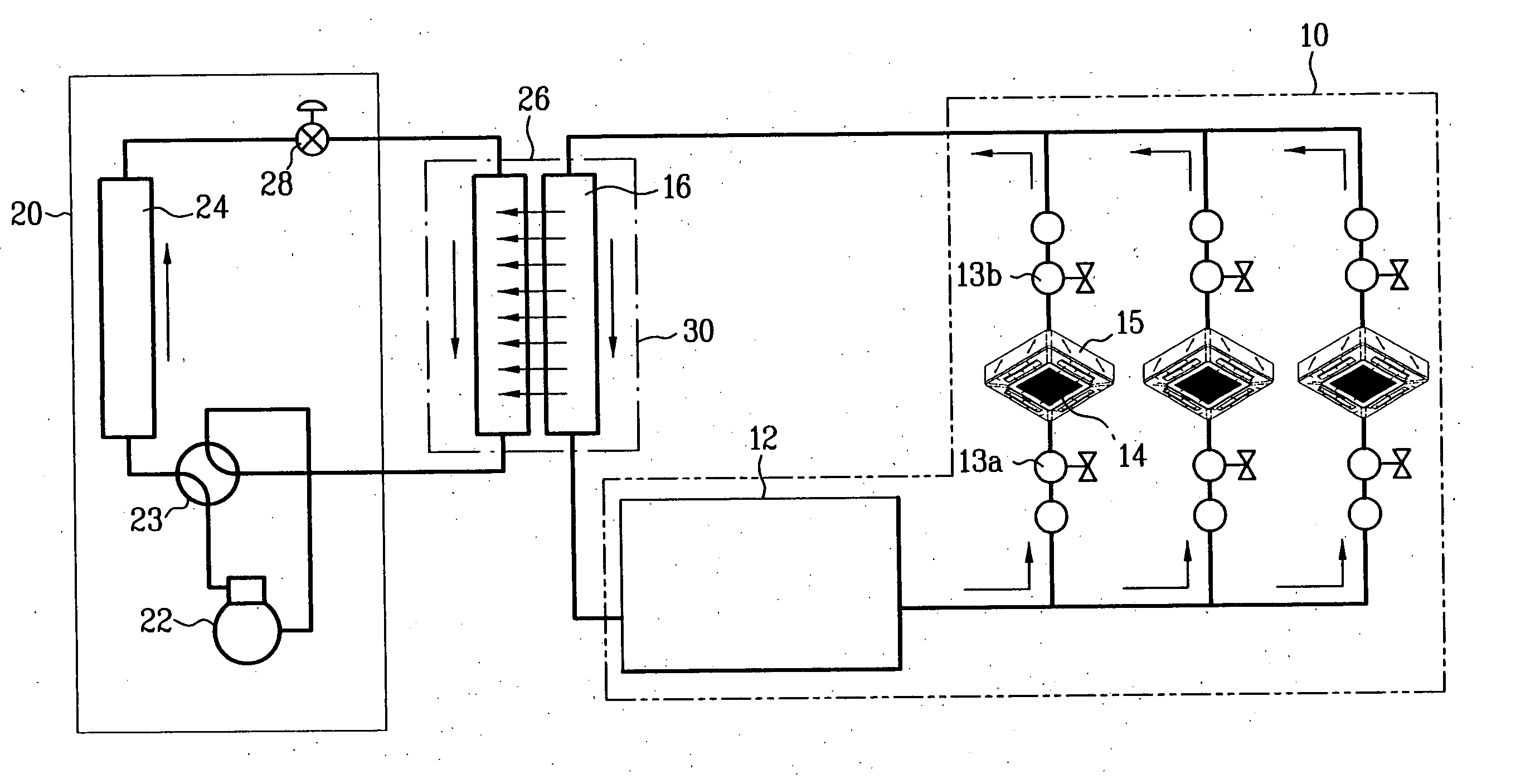

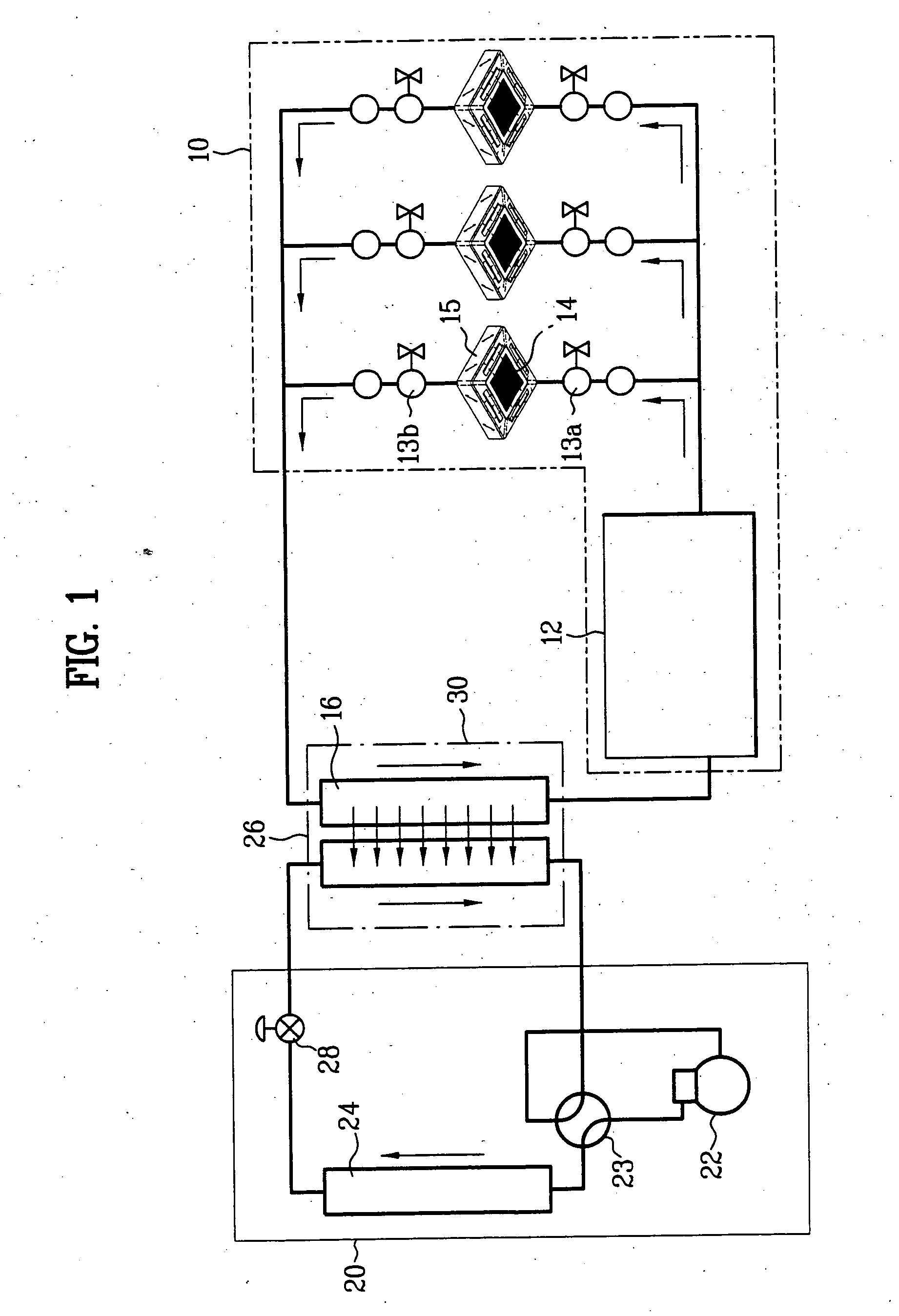

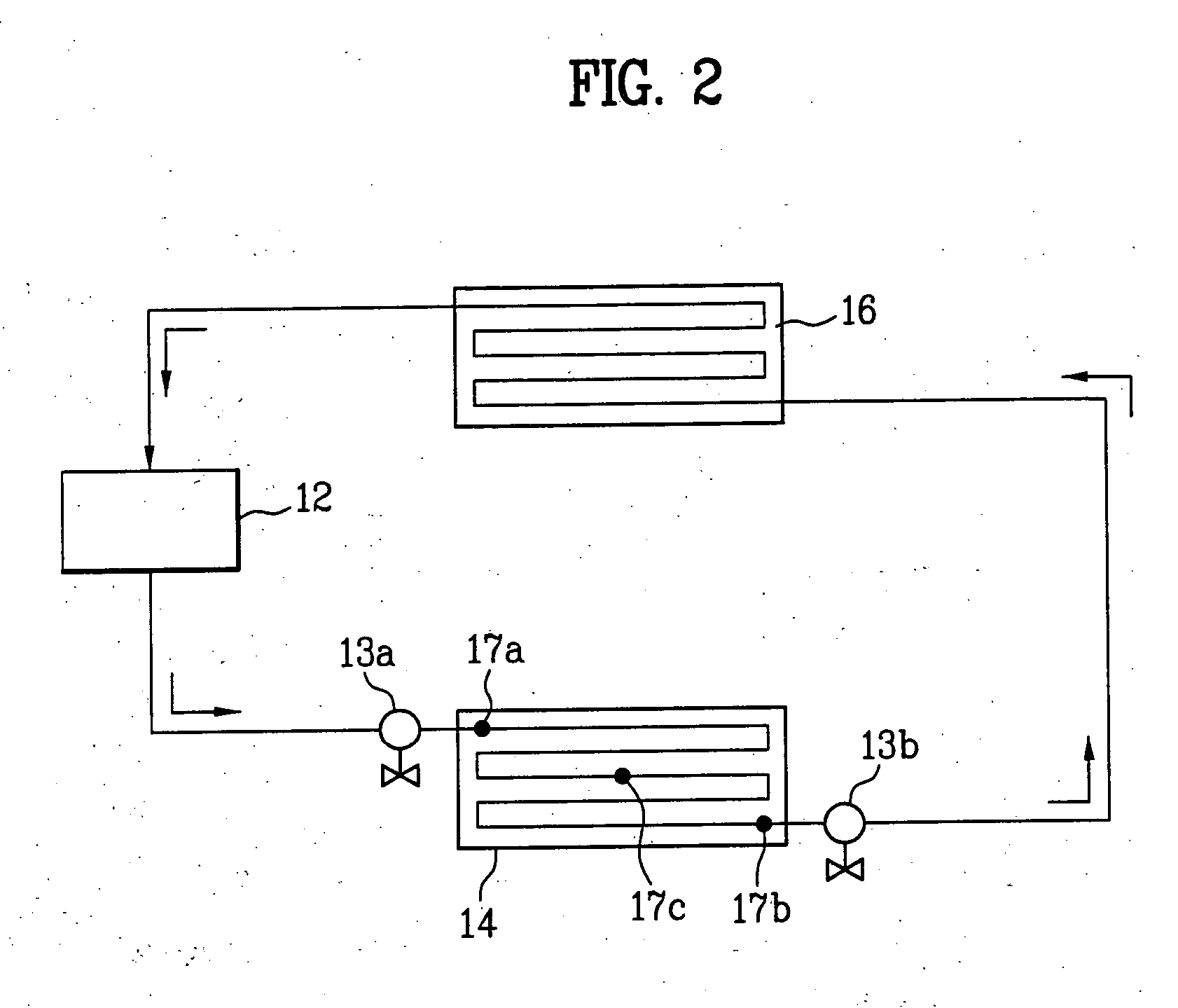

Air conditioning system and method for controlling the same

InactiveUS20060107683A1Easy to controlMechanical apparatusSpace heating and ventilation safety systemsEngineeringRefrigerant

The present invention relates to air conditioning systems, and more particularly, to an air conditioning system which can control a refrigerant flow rate to a heat exchanger exchanging heat with room air to be optimum; and a method for controlling the same. The air conditioning system includes an outdoor heat exchange part including a compressor for compressing refrigerant, an outdoor heat exchanger for making the refrigerant to heat exchange with outdoor air, and an expansion device for expanding the refrigerant, an indoor heat exchange part including a pump for making refrigerant in a flow path independent from the outdoor heat exchange part to flow, at least one indoor heat exchanger for making the refrigerant heat exchange with room air, and a flow rate control device for controlling a flow rate of the refrigerant, and a hybrid heat exchange part for making the outdoor heat exchange part and the indoor heat exchange part, which are independent from each other, to heat exchange with each other. According to this, the air conditioning system can be installed on a multistory building without limitation of a height of the building as far as a capacity of the pump permits. Moreover, even if a refrigerant pipe is long, the air conditioning system is applicable even to a system with a refrigerant pipe line longer than the related art as far as the capacity of the pump permits, and fine control of a room air temperature is possible.

Owner:LG ELECTRONICS INC

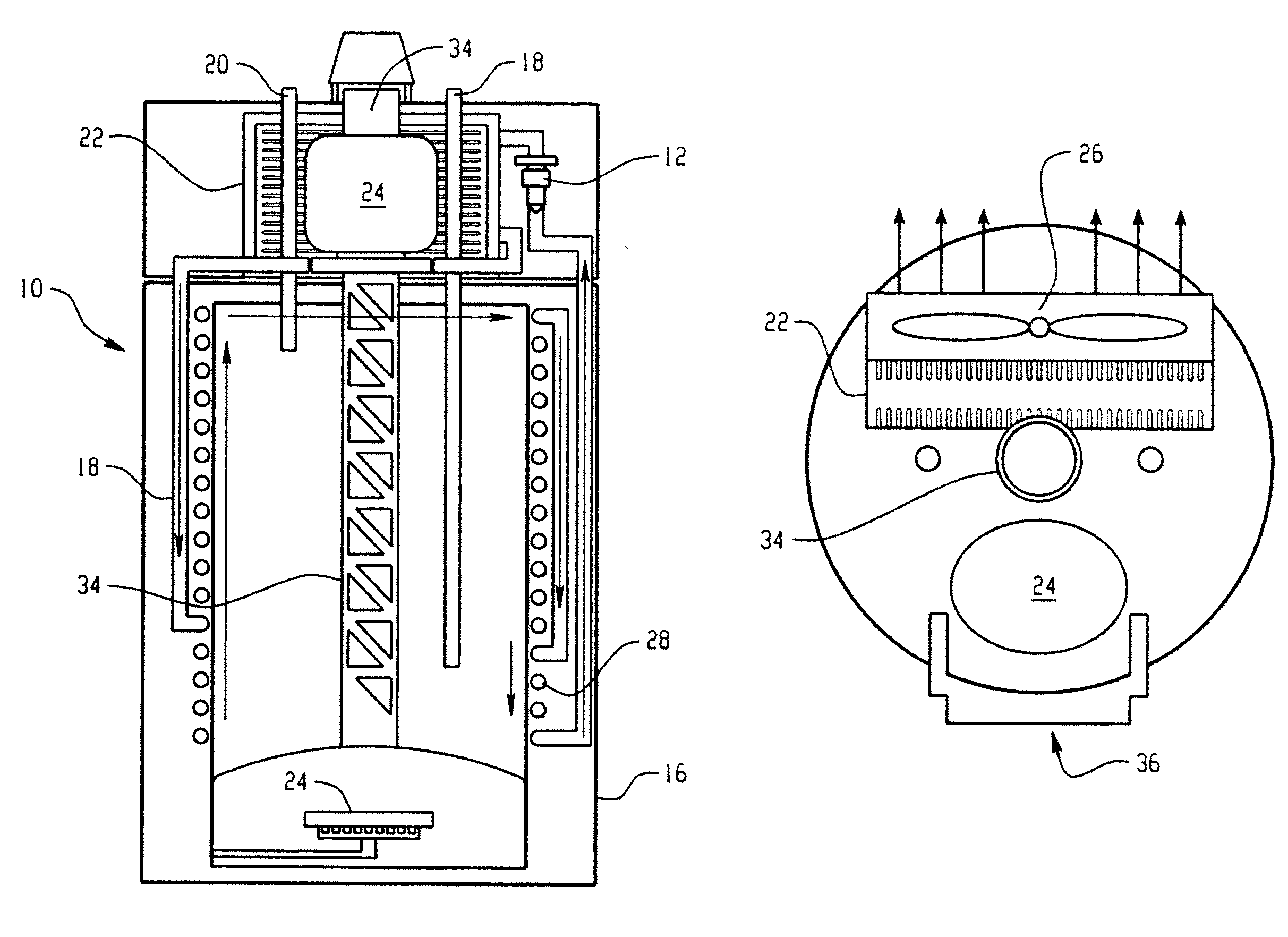

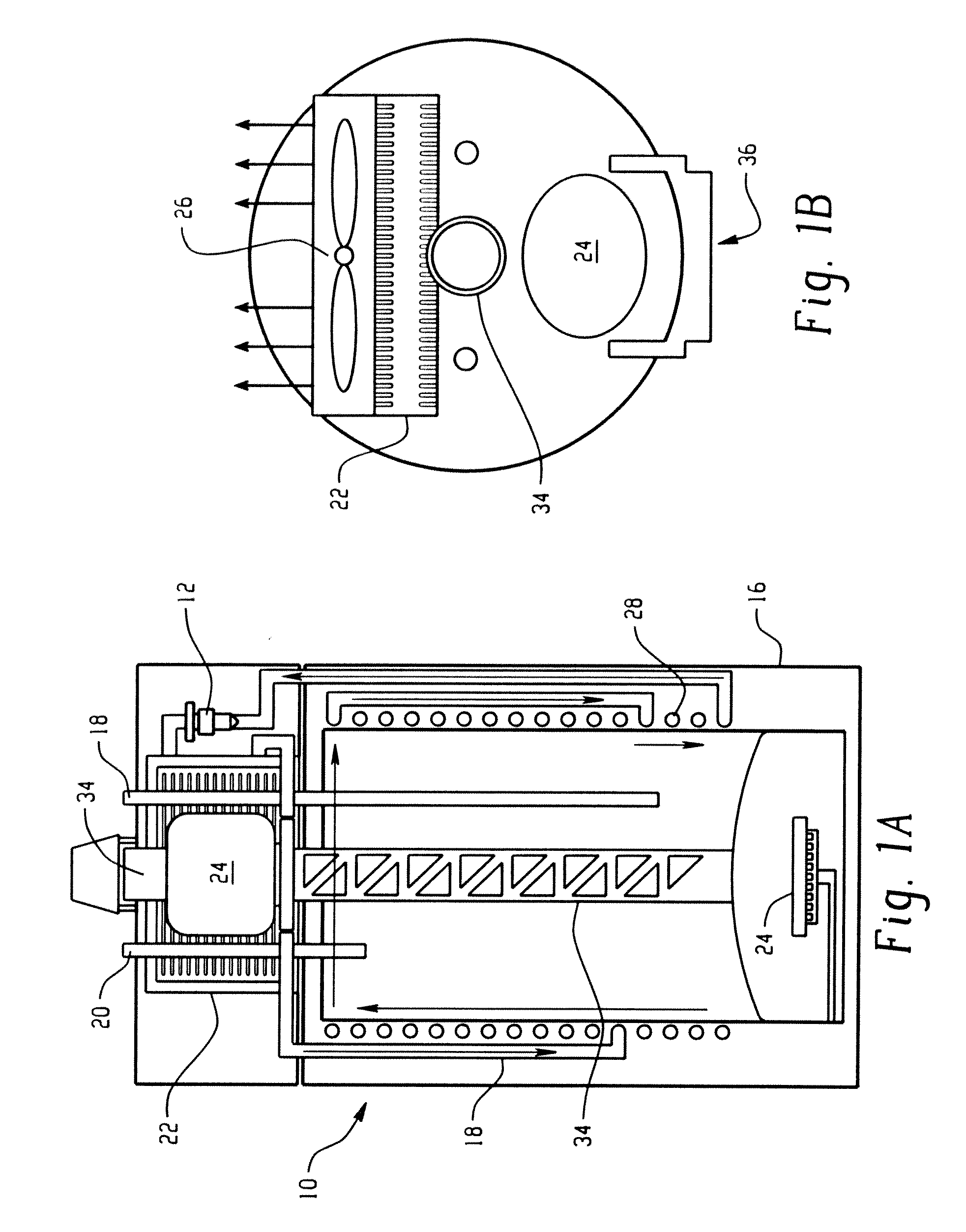

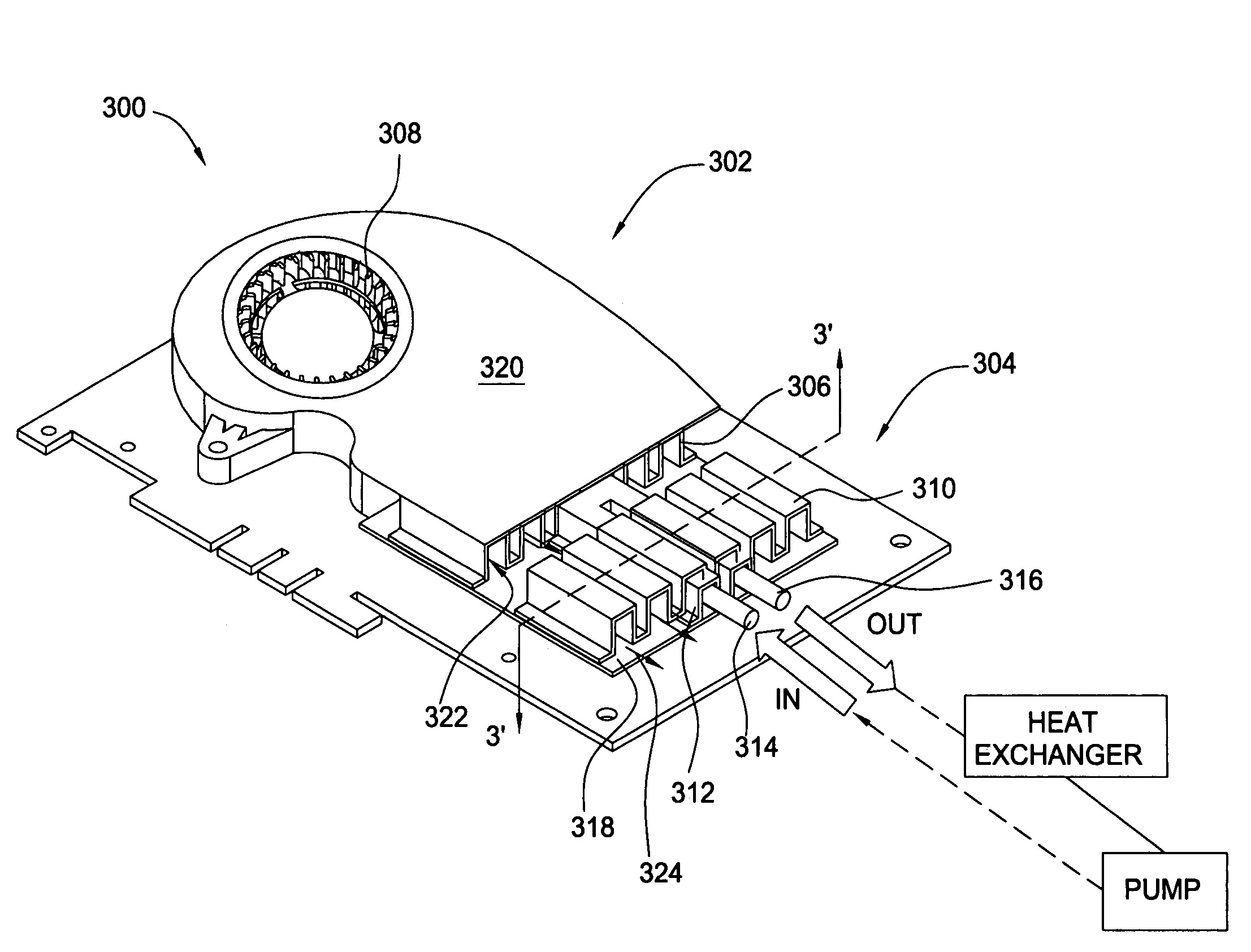

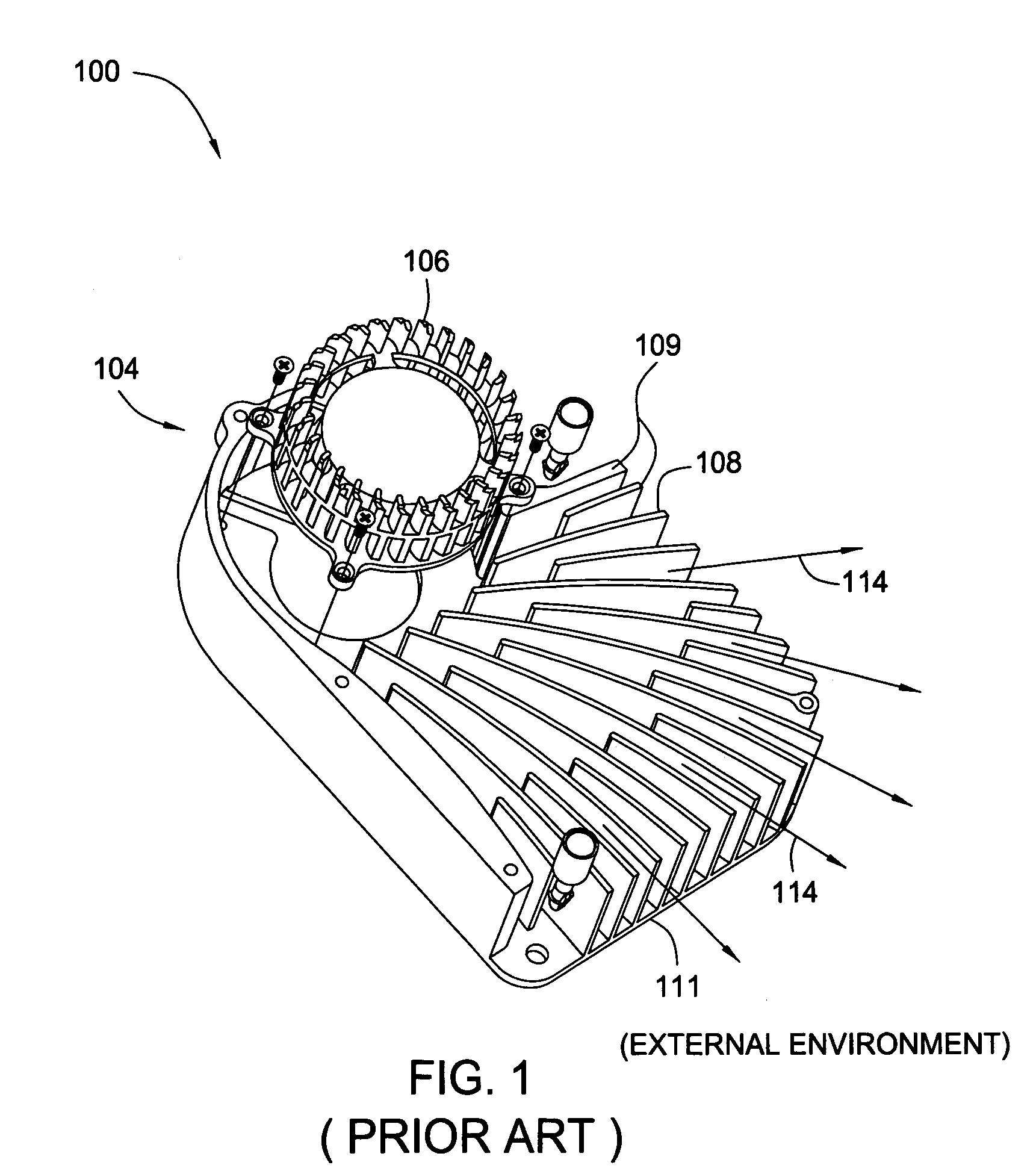

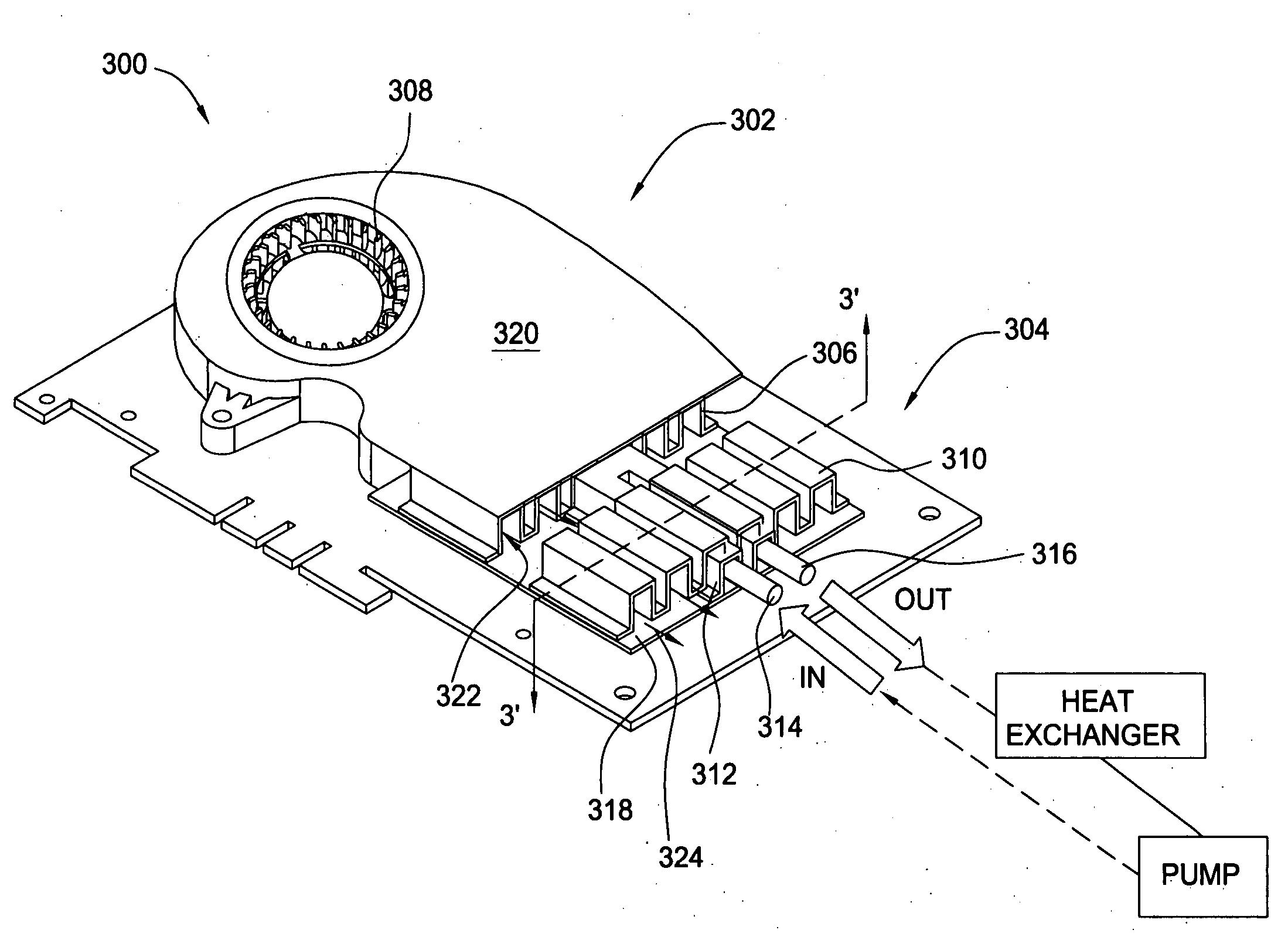

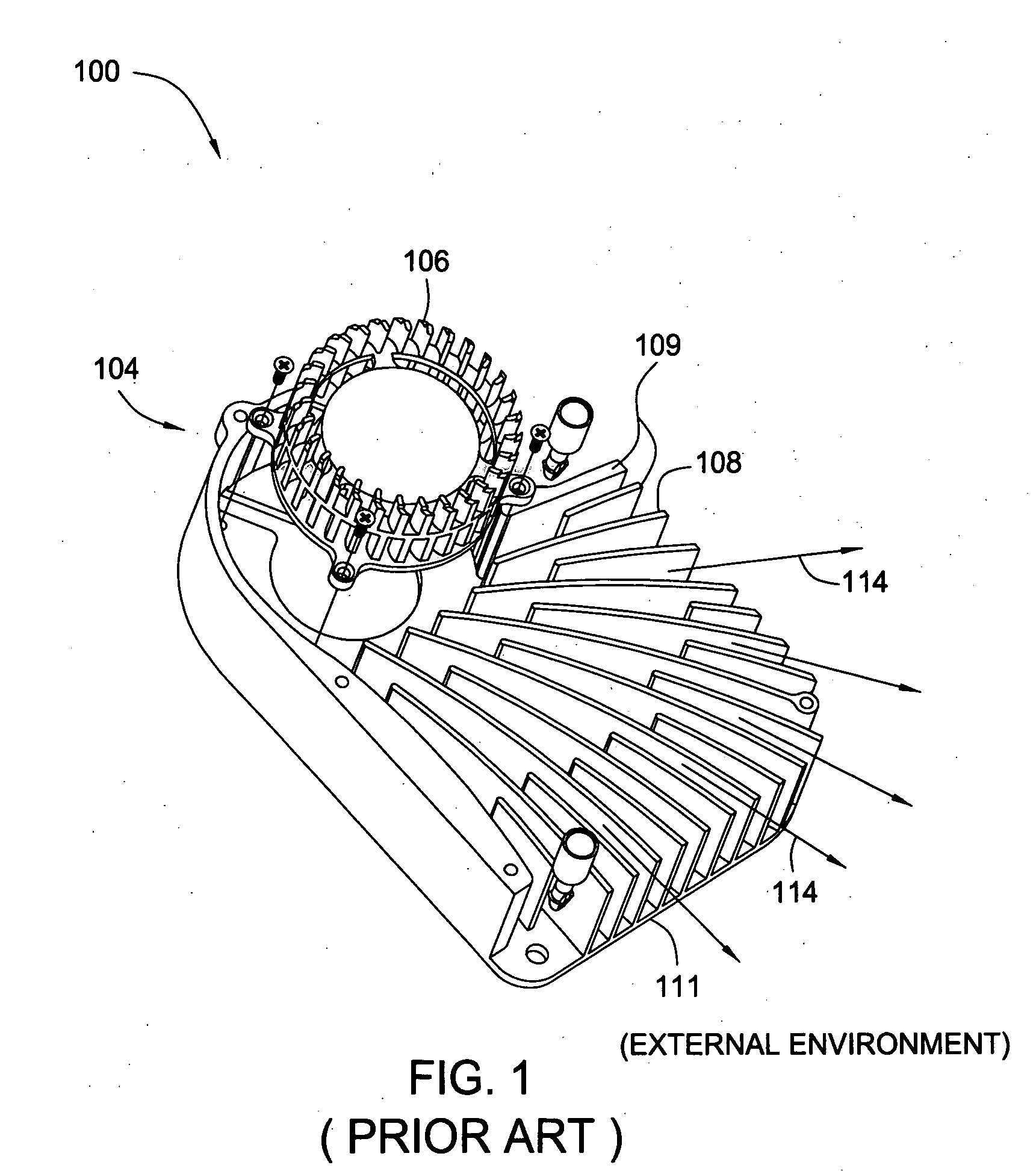

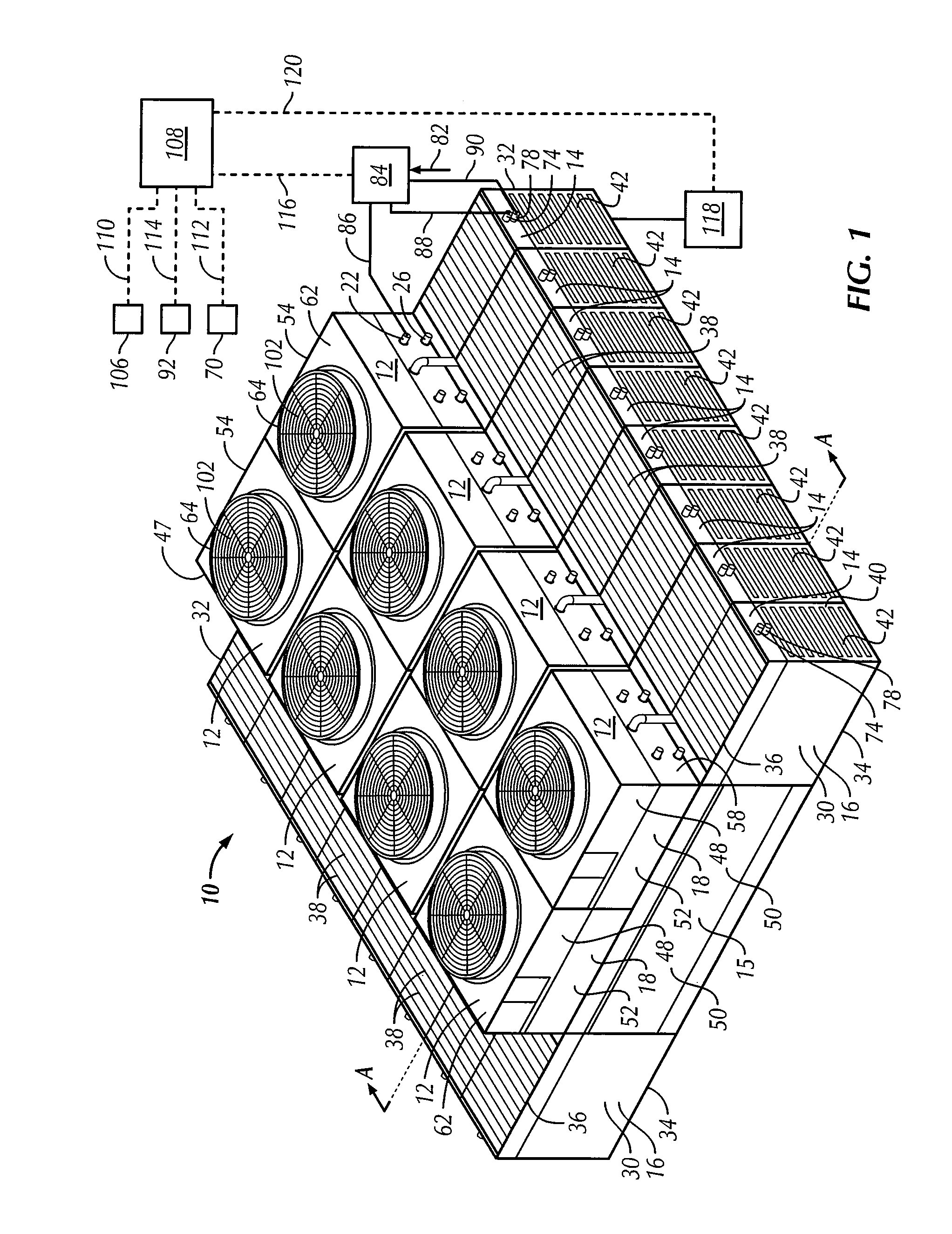

System for efficiently cooling a processor

ActiveUS7359197B2Reduce noiseDigital data processing detailsSemiconductor/solid-state device detailsComputer moduleEngineering

One embodiment of a system for efficiently cooling a processor includes an active hybrid heat transport module adapted to be integrated with a fansink. The hybrid heat transport module comprises both a fluid channel and an air channel adapted for transporting heat. The hybrid heat transport module and the fansink may be used alone or in combination to dissipate heat from the processor.

Owner:NVIDIA CORP

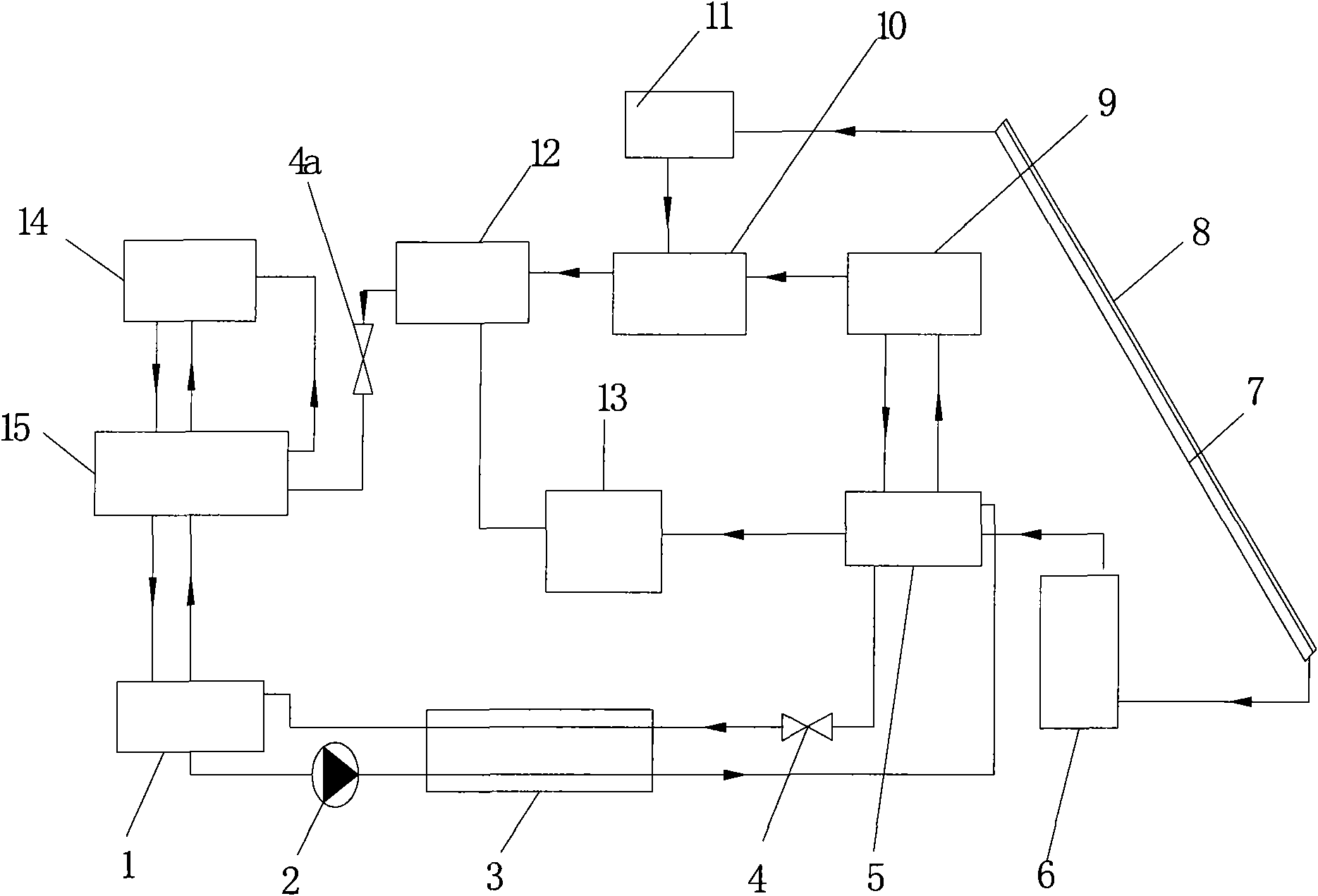

Solar photovoltaic and photothermal cogeneration type hybrid heat pump

InactiveCN101566406AImprove efficiencyTo achieve an organic combinationBatteries circuit arrangementsSolar heat devicesCollection systemCogeneration

The invention discloses a solar photovoltaic and photothermal cogeneration type hybrid heat pump, and aims to provide a novel heat pump which uses solar energy as main energy and is used for family heating in winter, refrigeration in summer and hot water supply. The solar photovoltaic and photothermal cogeneration hybrid heat pump comprises a solar collection system and a hybrid heat pump system; the solar collection system is a photovoltaic and photothermal cogeneration type system and comprises a solar film battery, a solar heat collector, a phase change heat accumulator and an accumulator; and the rear of the film battery is provided with a fluid passage which is connected with the heat collector. The heat collector comprises the heat pump system consisting of an ammonia absorption refrigeration system, an ammonia compression and refrigeration system and an ammonia diffusion and refrigeration system which are connected in series and coupled, share heat exchange equipment and throttling equipment and a refrigerating medium; and the heat pump comprises a liquid accumulator, a solution pump, a generator, a dephlegmator, a condenser, a compressor, a throttle valve, an evaporator and an absorber which are sequentially communicated by pipes. The generator of the heat pump is provided with phase change heat accumulator heat supply; and a secondary compressor of the heat pump is provided with accumulator power supply.

Owner:李智虎

System for efficiently cooling a processor

ActiveUS20050243516A1Excessive heatingReduce noiseDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

One embodiment of a system for efficiently cooling a processor includes an active hybrid heat transport module adapted to be integrated with a fansink. The hybrid heat transport module comprises both a fluid channel and an air channel adapted for transporting heat. The hybrid heat transport module and the fansink may be used alone or in combination to dissipate heat from the processor.

Owner:NVIDIA CORP

Hybrid heat exchangers

InactiveUS7331381B2Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesEngineering

Owner:ALLCOMP

Hybrid heat exchange apparatus

ActiveUS9243847B2Increase temperatureSteam/vapor condensersEfficient regulation technologiesEvaporation heat transferDry heat

Heat is indirectly transferred between a process fluid and ambient air in apparatus that includes an evaporative heat transfer cell operative in a wet mode or a dry mode, a dry heat transfer cell and a fan. The air may bypass the dry heat transfer cell to flow through a first air passage or may flow through a second air passage through the dry heat transfer cell and in either event, then through the evaporative heat transfer cell. The air may partially flow through and partially bypass the dry heat transfer cell, and then through the evaporative heat transfer cell. The evaporative heat transfer cell optionally may include a direct contact evaporative heat exchanger.

Owner:EVAPCO

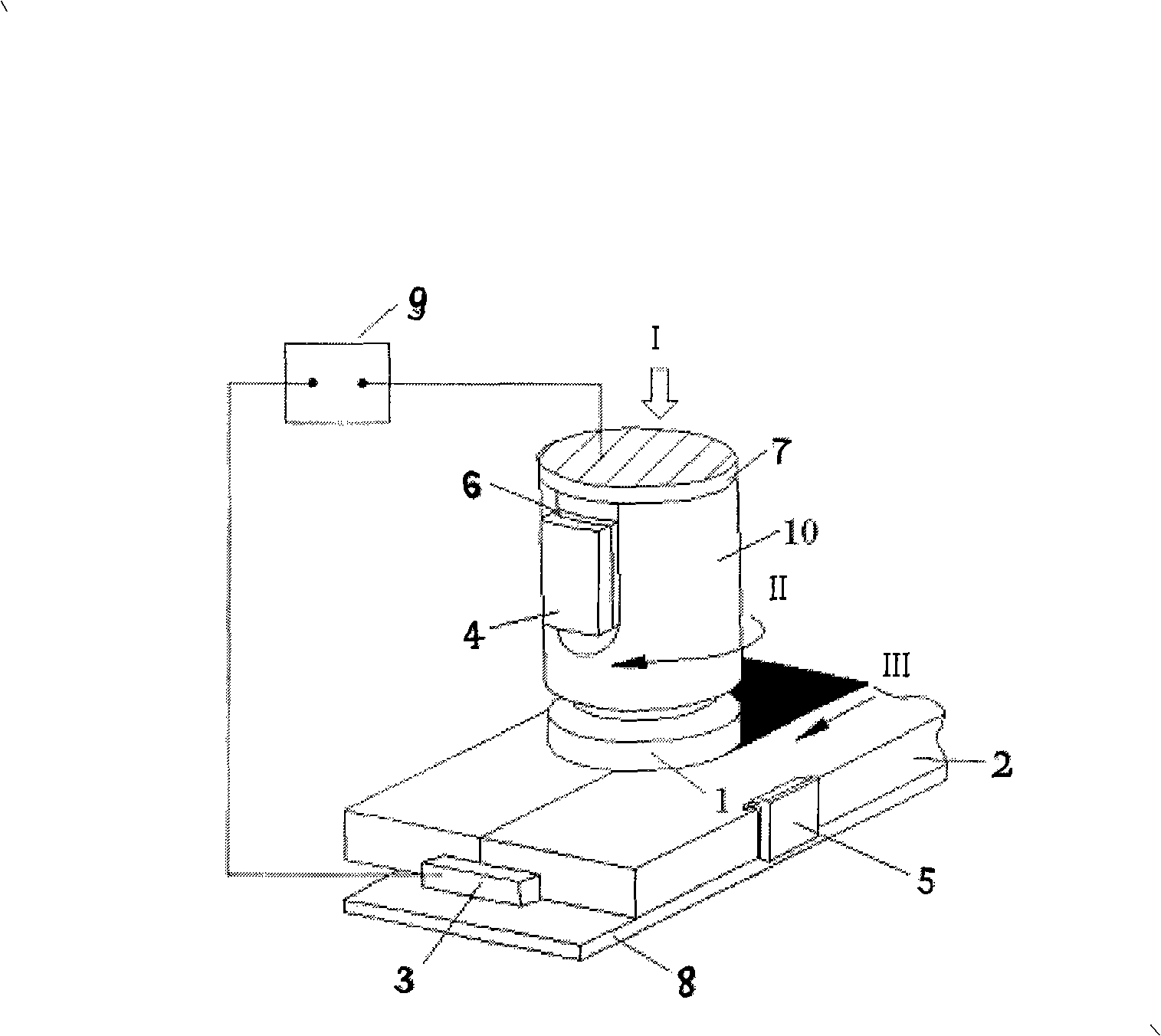

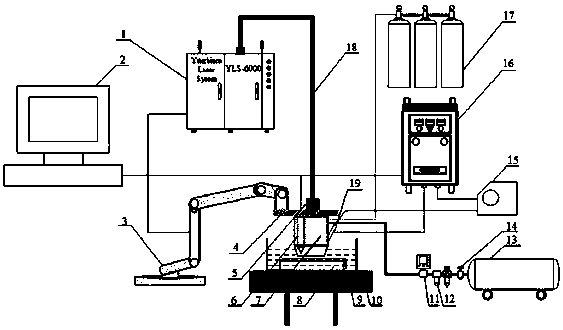

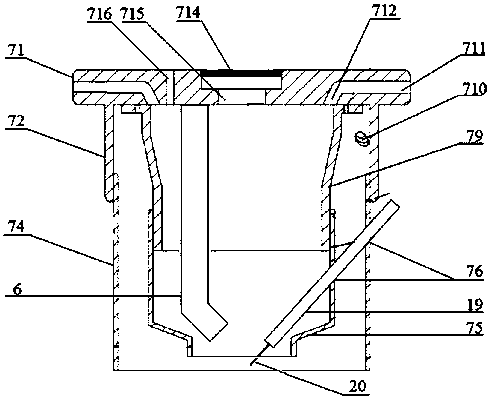

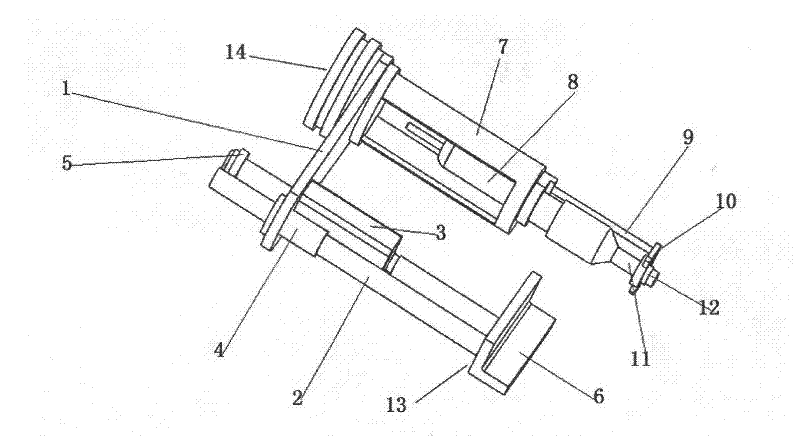

Underwater hybrid heat source additive manufacturing device and application method thereof

ActiveCN107838550AAdditive manufacturing apparatusLaser beam welding apparatusGas cylinderUnderwater

The invention provides an underwater hybrid heat source additive manufacturing device and an application method thereof and relates to the field of underwater additive manufacturing. The underwater hybrid heat source additive manufacturing device comprises a fiber laser, a control system, a welding robot, a laser head, a scanning device, an underwater laser welding torch, a gas flowmeter, an air compressor, a welding machine, a wire feeder, protective gas cylinders, an optical fiber and a welding gun. The fiber laser is connected with the laser head through the optical fiber. The laser head isconnected with the welding robot through a transfer board. The underwater laser welding torch comprises an upper end cover, an inner drainage barrel and an outer drainage barrel. The upper end coveris provided with a welding port. A glass board is arranged on the welding port. The inner drainage barrel is sleeved with the outer drainage barrel. The upper end of the inner drainage barrel is connected with the upper end cover in a sealed mode. The upper end cover is provided with inner drainage cavity air inlet holes. The outer drainage barrel is provided with outer drainage cavity air inlet holes. The inner drainage barrel and the outer drainage barrel are provided with wire feeding holes. The inner drainage cavity air inlet holes are connected with an air compressor. The outer drainage cavity air inlet holes are connected with the welding protective gas cylinders. The underwater hybrid heat source additive manufacturing device has the advantages of being simple in structure, convenient to use, high in material increasing rate, high in stability and material increasing quality and the like.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Hybrid vertical drainpipe heat exchanger

InactiveUS20130306290A1Area maximizationAffect performanceHeat recovery systemsRecuperative heat exchangersWater useEngineering

A low-cost hybrid heat exchanger uses sheet copper and rigid plastic tubing. Copper is used only where actual heat transfer takes place, adjacent the drainpipe wall. All other components are plastic to lower cost. It pre-heats fresh cold water using waste heat from the drain such as from a shower drain. The heat exchanger comprises an inner copper conduit or drainpipe, a rolled sheet copper cylinder, an outer plastic tube and manifolds, and O-ring. On assembly, inserting the drainpipe results in the O-ring being compressed between the copper cylinder and the plastic tube. The result is a sealed water chamber wherein heat transfer takes place. The ends of the plastic tube have radially spaced water distribution holes into the chamber and inlet and outlet manifolds, each with water connections to the building's cold water supply. A method of recovering heat from non-shower hot water uses using a separate reservoir is also disclosed.

Owner:MACKELVIE WINSTON

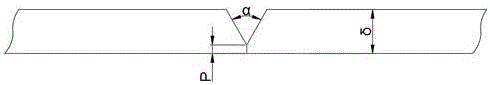

Welding method of Q890 high-strength steel

InactiveCN105880834AGood mechanical propertiesStrong crack resistanceWelding/soldering/cutting articlesLaser beam welding apparatusAngle alphaHeat treated

The invention discloses a Q890 high-strength steel welding method, which belongs to the technical field of high-strength steel welding. It is characterized by processing the test plate: beveling, the form of the bevel is shown in the figure, the thickness of the test plate is δ≤50mm, the bevel angle is α=40~60°, and the blunt edge p=4~10mm. Clean the surfaces on both sides of the groove. Select welding material: the welding material is 90KG grade welding wire. Preheat the base metal Q890 steel to be welded, and the preheating temperature is 60~100°C. Apply laser-arc compound heat source to control the welding interlayer temperature, and the interlayer temperature is controlled at 150~250℃. Temper heat treatment after welding.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

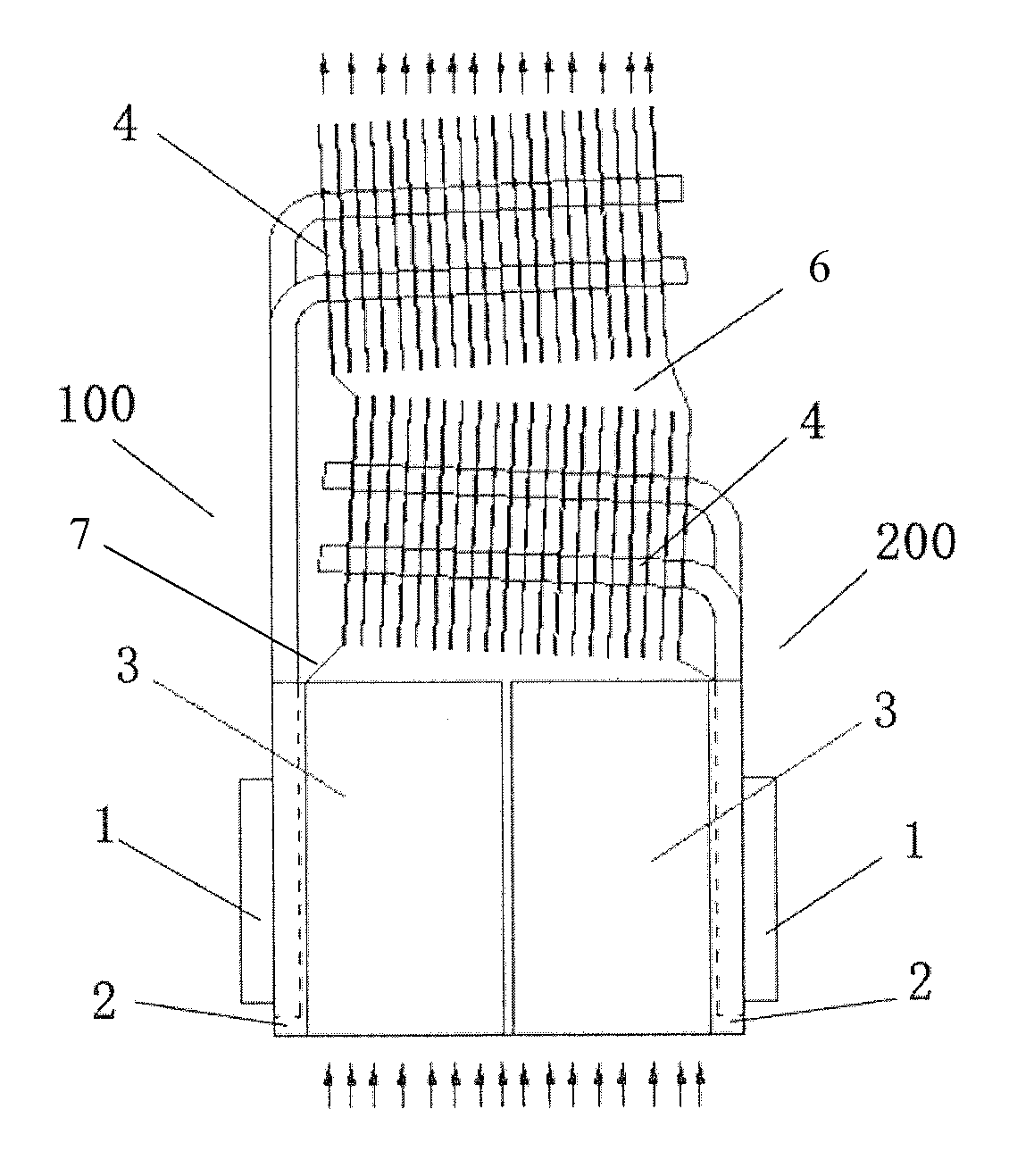

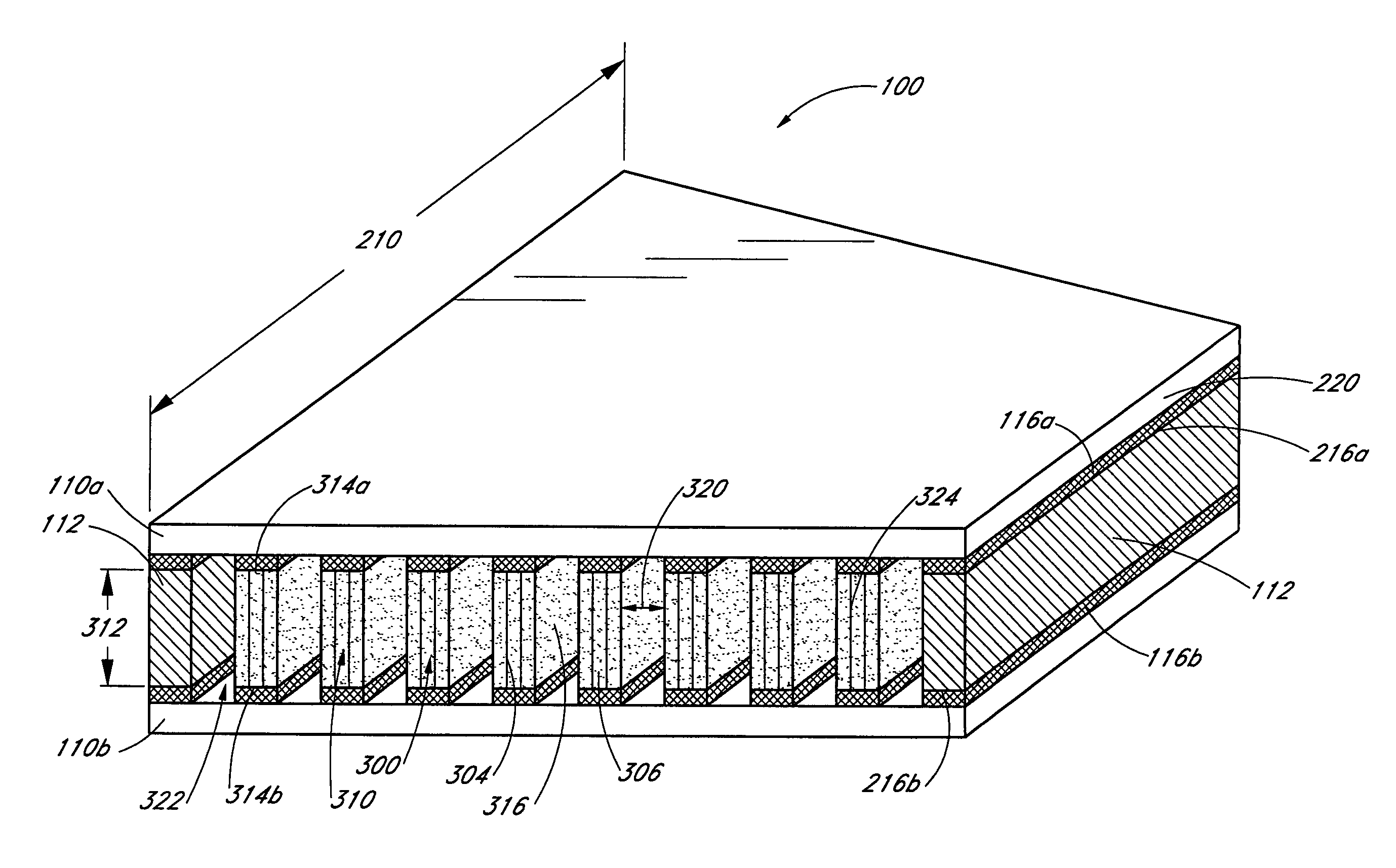

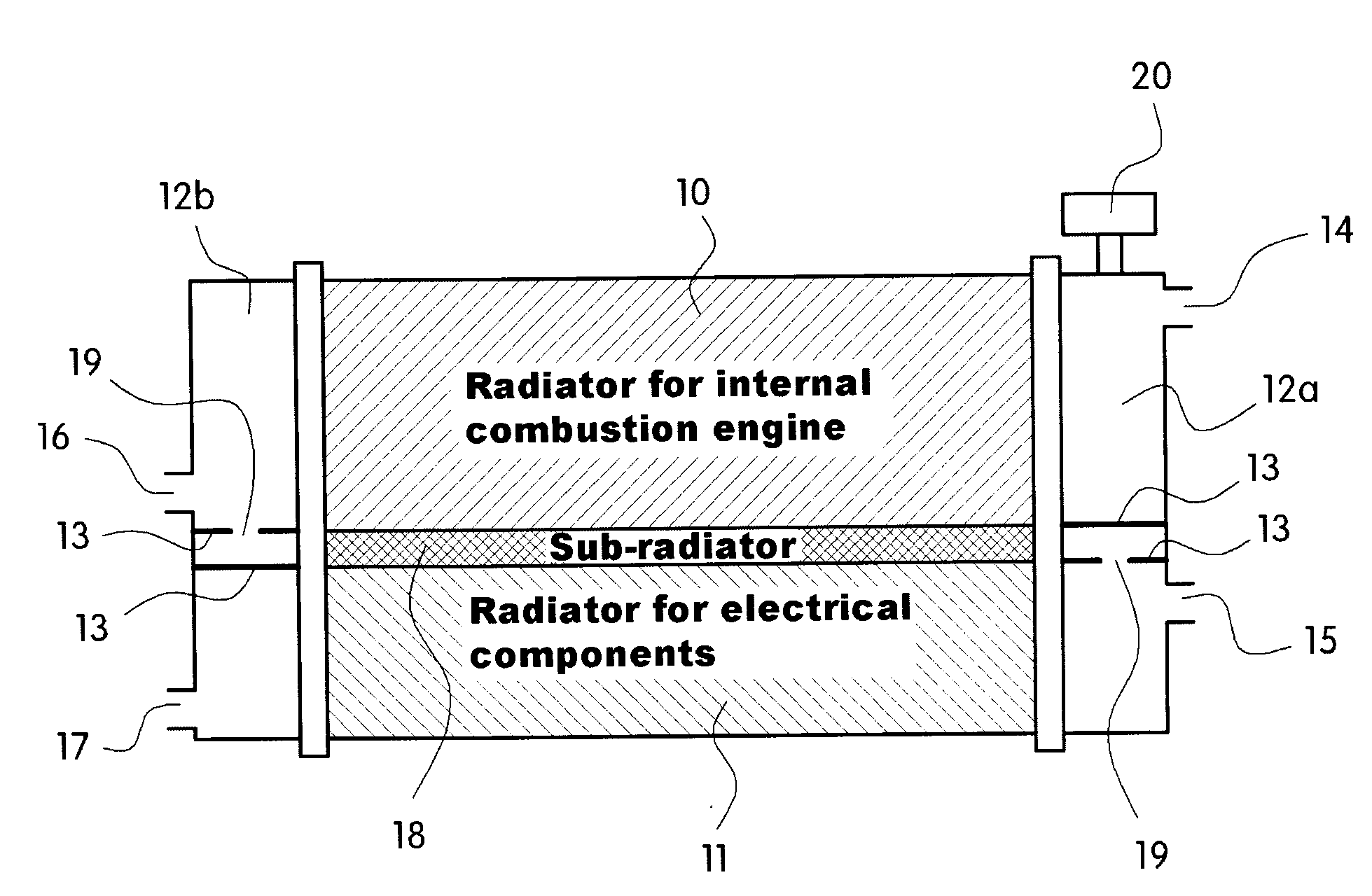

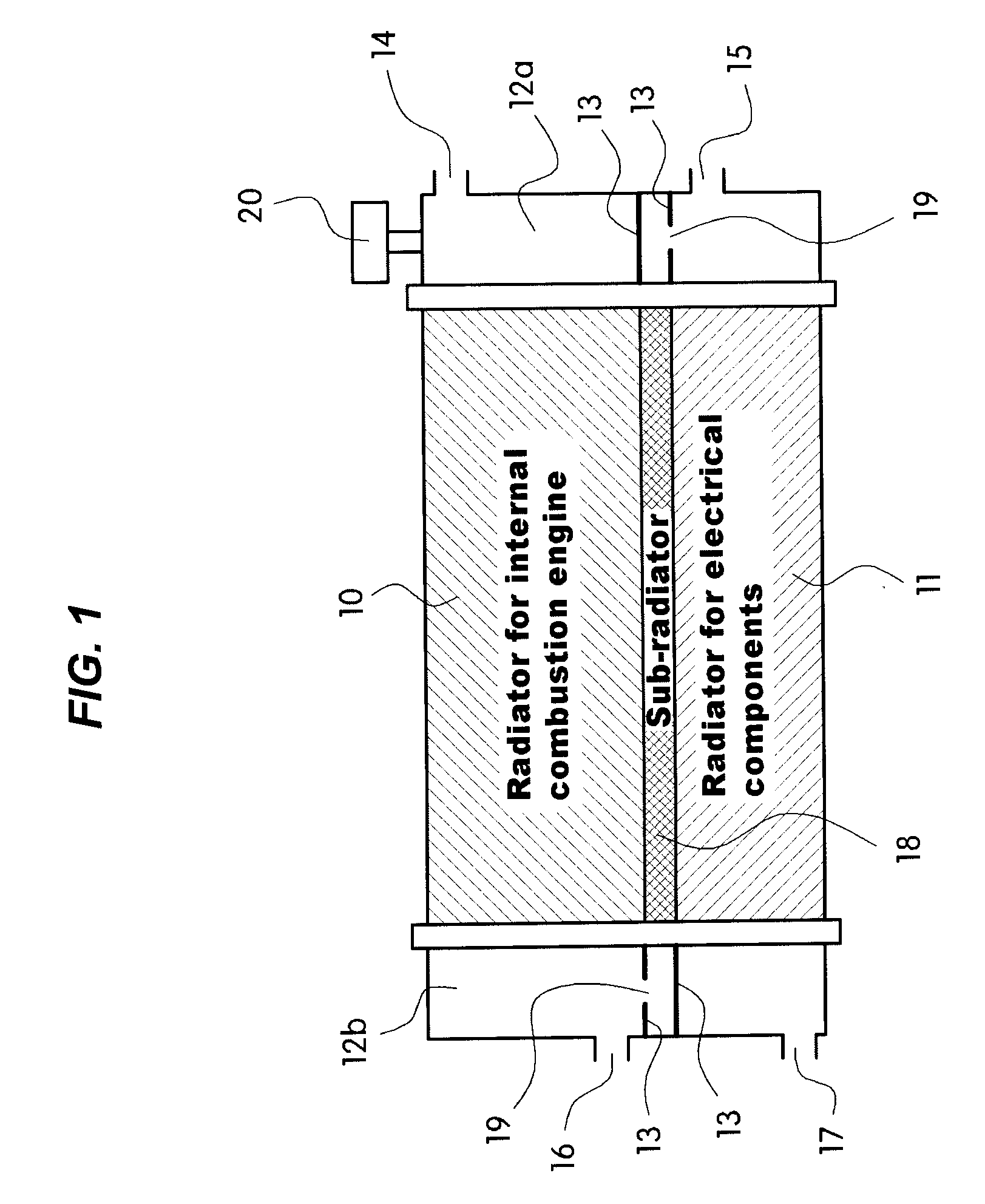

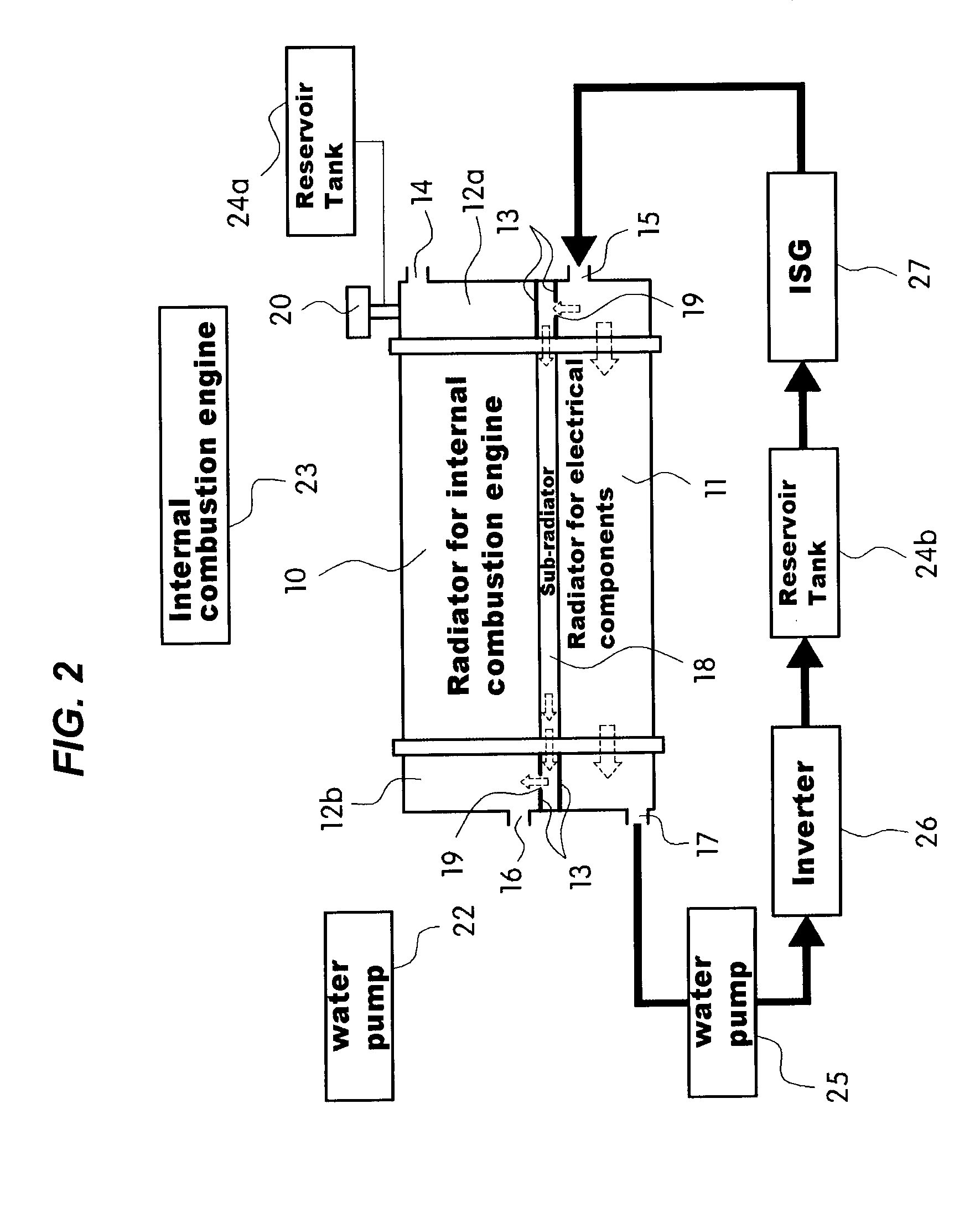

Integrated hybrid heat exchanger with multi-sectional structure

ActiveUS20100126692A1Improve thermal resistance to thermal conductionImprove cooling efficiencyLiquid coolingAir-treating devicesDeuteron radiationHeat spreader

An integrated hybrid heat exchanger with a multi-sectional structure, may include a first radiator and a second radiator, and / or at least a coolant bypass member disposed between the first and second radiators, the coolant bypass member connecting one end portion of the first radiator and the other end portion of the second radiator so as to fluid-communicate between the first radiator and the second radiator.

Owner:HANON SYST +1

Method of Making a Hybrid Metal-Plastic Heat Exchanger

InactiveUS20100043230A1Simple designReduce material costsMetal-working apparatusStationary conduit assembliesThermoplasticPlate heat exchanger

A method of manufacturing a metal-plastic hybrid heat exchanger including the steps of providing a plurality of metallic fins, providing a plastic tank with a melting point above a predetermined temperature and having a header plate that includes a plurality slots, and providing a plurality of plastic tubes with a melting point above the predetermined temperature. The plastic tubes are inserted into the corresponding slots of the plastic tank to form an assembly. The metal fins are inserted between the plastic tubes of the assembly. A thermoplastic adhesive is applied onto the mating surfaces of the metal fins and the plastic tubes, and onto mating surfaces of the slots and the plastic tubes of the assembly. The metal plastic heat exchanger assembly is then heated with infrared radiation to the predetermined temperature to cure the thermoplastic adhesive, thereby bonding the metal fins and the slotted headers to the tubes.

Owner:DELPHI TECH INC

LED plastic heat sink and method for making and using the same

In an embodiment, heat sink system can comprise: an integrally formed plastic heat sink and a printed circuit board package, wherein the plastic heat sink comprises a thermally conductive plastic having a thermal conductivity of at least 1.0 W / mK. In another embodiment, hybrid heat sink system, comprising: an integrally formed plastic heat sink and an insert, wherein the plastic heat sink comprises a thermally conductive plastic, the plastic heat sink and the insert each having a cylindrical shape, and wherein the insert comprises a feature of lancing provisions, corrugations, embossing, holes, or a combination comprising at least one of the foregoing features.

Owner:SHPP GLOBAL TECH BV

Hybrid heat-radiating substrate and method of manufacturing the same

InactiveUS20110303440A1Low thermal conductivityPrinted circuit aspectsConductive pattern formationOptoelectronicsMetal

Disclosed herein are a hybrid heat-radiating substrate including a metal core layer; an oxide insulating core layer that is formed in a thickness direction of the metal core layer to have a shape where the oxide insulating core layer is integrally formed with the metal core layer, an oxide insulating layer that is formed on one surface or both surfaces of the metal core layer, and a circuit layer that is configured to include first circuit patterns formed on the oxide insulating core layer and second circuit patterns formed on the oxide insulating layer, and a method of manufacturing the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

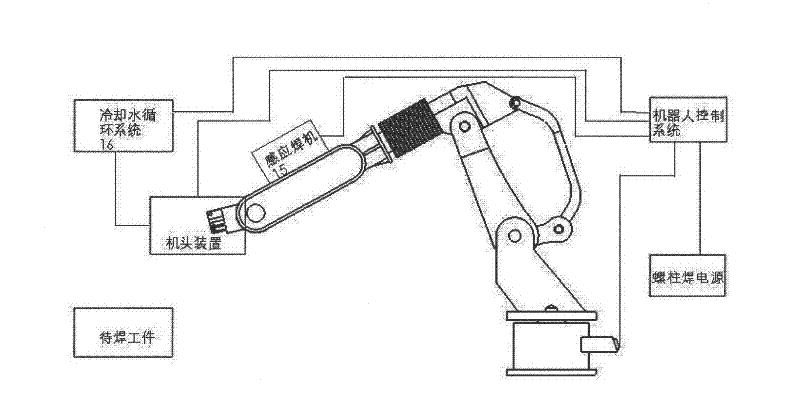

Hybrid heat source stud welding method using welding robot and hybrid heat source stud welding system with welding robot

InactiveCN102489845AAchieve weldingEfficient integrationArc welding apparatusStud weldingEngineering

The invention discloses a hybrid heat source stud welding method using a welding robot and a hybrid heat source stud welding system with the welding robot. The welding robot moves to a workpiece at the position of a stud to be welded, and a cylinder moves to place an induction heating ring on the workpiece at the position of the stud to be welded; an induction welder and a cooling water circulating system are started to perform induction heating for the workpiece at the position of the stud to be welded; the cylinder moves to lift the induction heating ring off the workpiece after induction heating; the welding robot moves to move a stud welding gun onto the workpiece at the position of the heated stud to be welded; the stud welding gun is started to weld the workpiece, and the welding robot moves to remove a head device and move the induction heating ring onto the welded stud; and post-weld heat treatment can be performed for the stud. The welding method and the welding system are used for automatically welding the stud with a hybrid heat source based on robot technology, and can be used for effectively integrating the automatic stud welding gun with the robot.

Owner:NANJING UNIV OF SCI & TECH

Hybrid heat pipe

A heat pipe with a capillary structure that consists of heat conductive capillary grooves in the condenser region that meet with a porous wick in the evaporator section. The embodiments include several structures of the interface at the junction of the porous wick and the capillary grooves. One such interface is a simple butt joint. Others have interlocking shapes on the wick and the grooves such as parts of the wick that fit into or around the grooves.

Owner:ADVANCED COOLING TECH

Hybrid heat exchanger apparatus and method of operating the same

ActiveUS20120061055A1Inhibition formationConserve waterIndirect heat exchangersHeat exchange apparatusDistribution systemEngineering

A hybrid heat exchanger apparatus includes a direct heat exchanger device and an indirect heat exchanger device and a method of operating the same encompasses conveying a hot fluid to be cooled from a hot fluid source through the indirect heat exchanger device to a cooling fluid distribution system. The hot fluid to be cooled is distributed from the cooling fluid distribution system onto the direct heat exchanger device. In a hybrid wet / dry mode, ambient air flows across both the indirect heat exchanger device and the direct heat exchanger device to generate hot humid air from the ambient air flowing across the direct heat exchanger device and hot dry air from the ambient air flowing across the indirect heat exchanger device.

Owner:EVAPCO

Combined gas-water tube hybrid heat exchanger

ActiveUS20140326197A1Simpler and less-costly construction techniqueHeat exchanger casingsStationary tubular conduit assembliesCombustorEngineering

A heat exchanger having a cylindrical body comprising an upper section, a lower section, a side water jacket surrounding the upper and lower sections, a top water jacket disposed atop the upper section and a gas exhaust disposed below the lower section. A water cavity is disposed substantially in the lower section while a gas cavity having a burner is disposed substantially centrally within the gas cavity. A plurality of water tubes disposed in a ring formation, connect the water cavity through the gas cavity to the top water jacket and a plurality of gas tubes also disposed in ring formations, connect the gas cavity through the water cavity to the gas exhaust. At least one of the gas tubes ring has a diameter that is greater than that of the water tubes ring.

Owner:INTELLIHOT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com