Underwater hybrid heat source additive manufacturing device and application method thereof

A technology of additive manufacturing and composite heat source, applied in the direction of manufacturing tools, additive processing, welding equipment, etc., can solve the problems of limited emergency repair capacity, lack of key technologies and equipment for underwater operations of ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

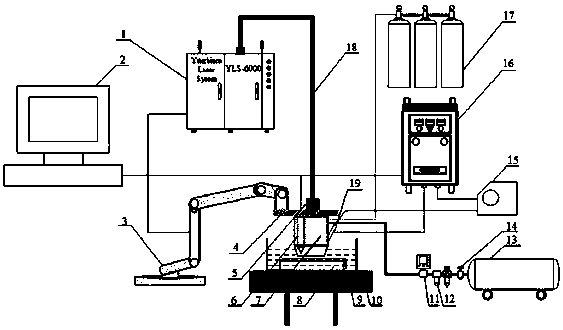

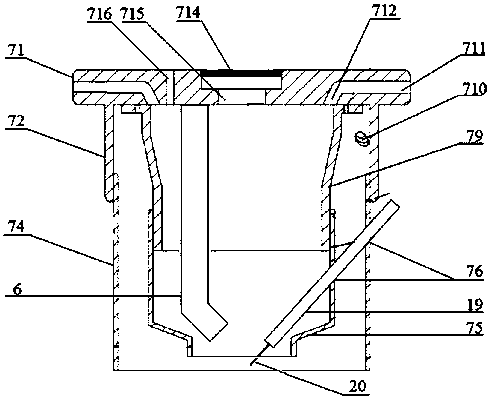

[0029]An underwater composite heat source additive manufacturing device, including fiber laser 1, control system 2, welding robot 3, adapter plate 4, laser head 5, scanning device 6, underwater laser welding torch 7, gas flow meter 11, oil and water Separator 12, air compressor 13, stop valve 14, MIG welding machine 16, wire feeder 15, shielding gas cylinder 17, optical fiber 18 and MIG welding torch 19; fiber laser 1 is connected with laser head 5 through optical fiber 18, and the laser head 5 is connected to the welding robot 3 through the adapter plate 4, and the laser beam generated by the fiber laser enters the laser head through the optical fiber; the underwater laser welding torch is arranged directly below the laser head 5, and the laser head and the underwater laser welding torch Located on the same straight line in the vertical directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com