Hybrid heat source stud welding method using welding robot and hybrid heat source stud welding system with welding robot

A composite heat source and welding method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of slag inclusion, cold cracks, unfused joints, etc., to improve efficiency, improve welding quality, and realize automatic operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

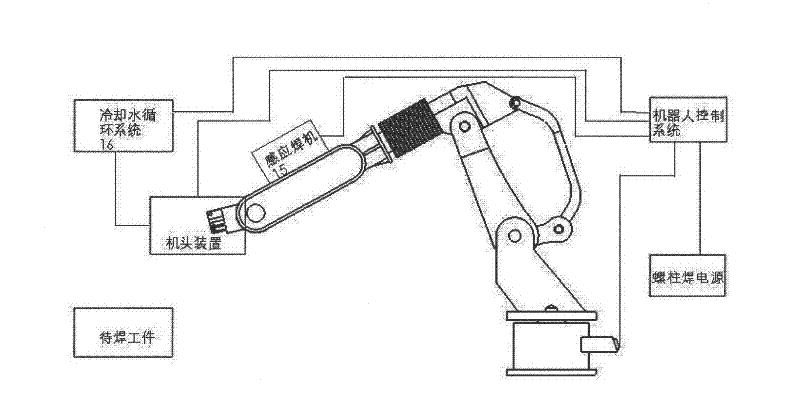

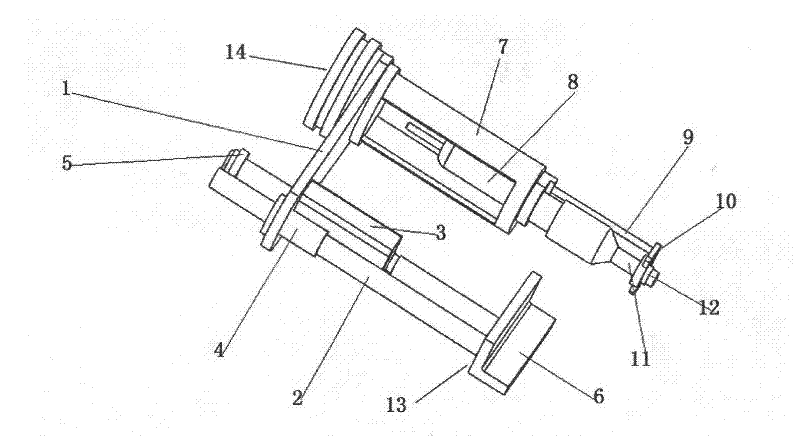

[0045] Example 1. combine figure 1 and figure 2 , Take the automatic stud welding of a stud with a diameter of 19mm and a length of 52mm on a steel plate with a thickness of 60mm as an example. After welding, post-weld heat treatment is required. A steel stud with a diameter of 19mm and a length of 52mm and the ceramic ring matching the stud are pre-installed on the stud welding torch and the ceramic ring fixing device. Then the robot control system sends a series of control signals to complete the entire automatic welding process. The specific steps are as follows: (1) the robot moves to the workpiece at the stud to be welded, and the cylinder 3 moves to place the induction heating ring 13 on the stud to be welded. above the workpiece; (2) the induction welding machine 15 and the cooling water circulation system 16 are turned on to inductively heat the workpiece at the stud to be welded to about 600°C; (3) after the induction heating is completed, the cylinder 3 moves to i...

Embodiment 2

[0046] Example 2. combine figure 1 , Take the automatic stud welding of a stud with a diameter of 19mm and a length of 52mm on a steel plate with a thickness of 60mm as an example. After welding, post-weld heat treatment is required. A steel stud with a diameter of 19mm and a length of 52mm and the ceramic ring matching the stud are pre-installed on the stud welding torch and the ceramic ring fixing device. Then the robot control system sends a series of control signals to complete the entire automatic welding process. The specific steps are as follows: (1) the robot moves to the workpiece at the stud to be welded, and the cylinder 3 moves to place the induction heating ring 13 on the stud to be welded. above the workpiece; (2) the induction welding machine 15 and the cooling water circulation system 16 are turned on to inductively heat the workpiece at the stud to be welded to about 600°C; (3) after the induction heating is completed, the cylinder 3 moves to inductively heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com