Patents

Literature

964 results about "Turning frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

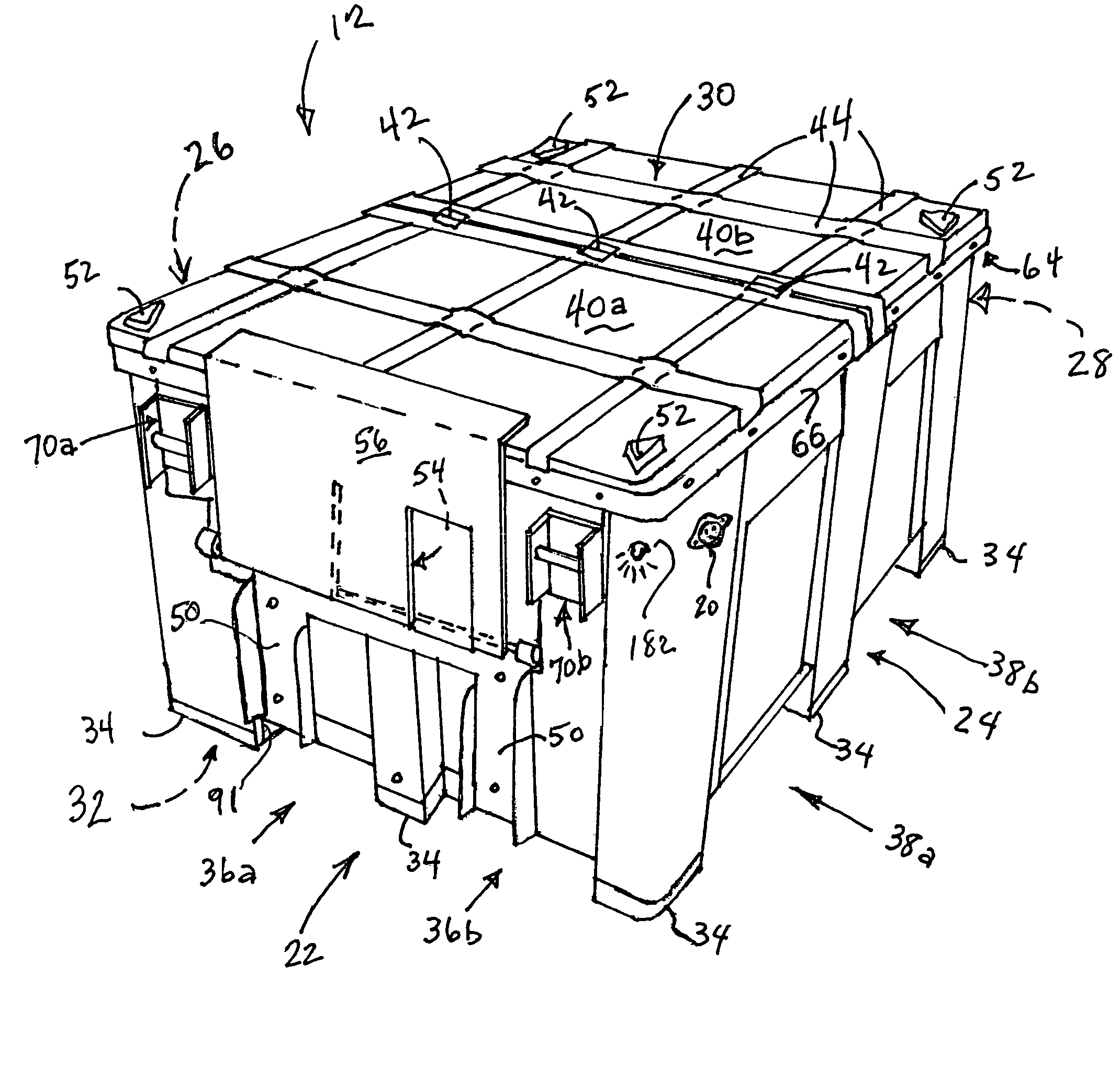

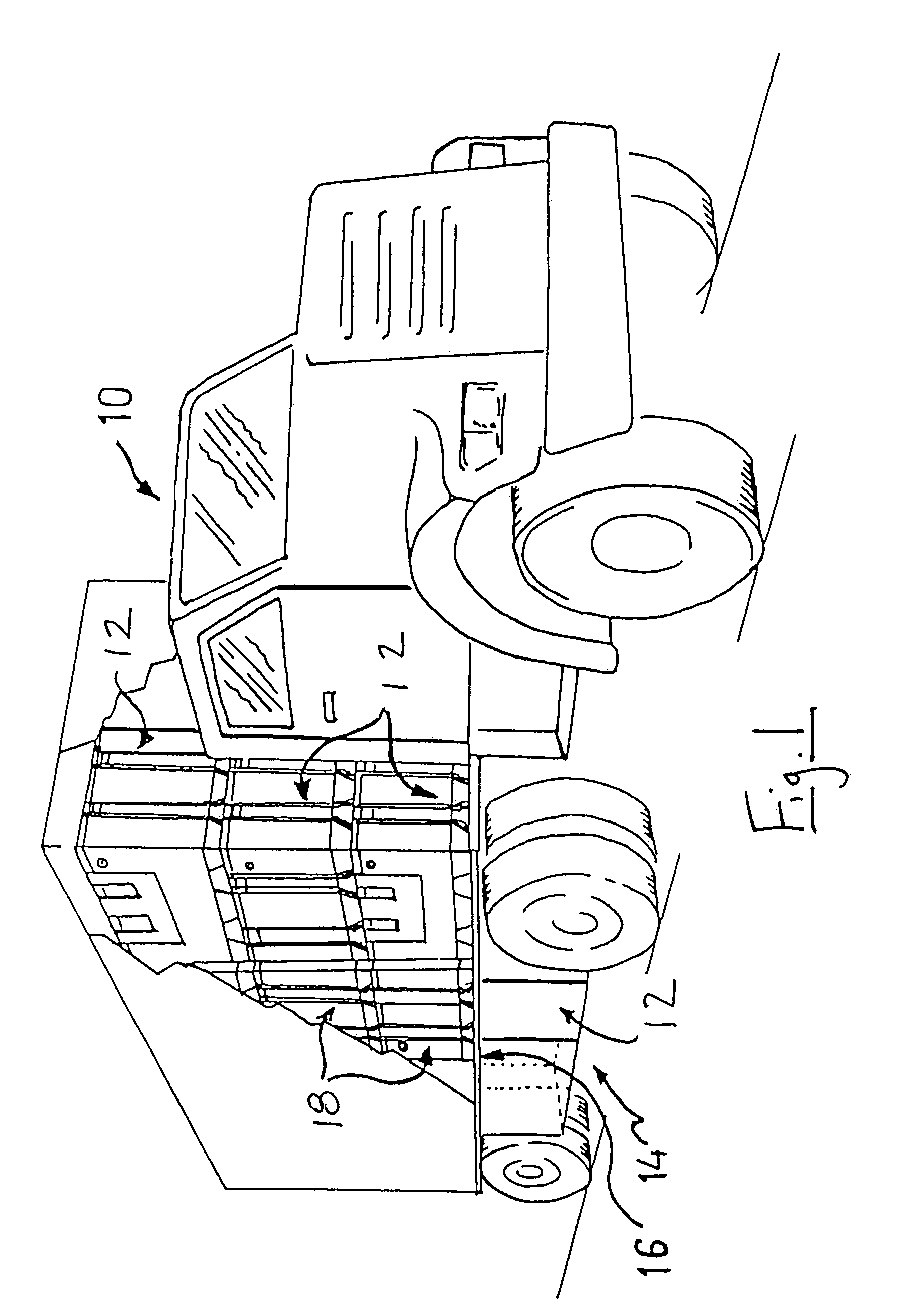

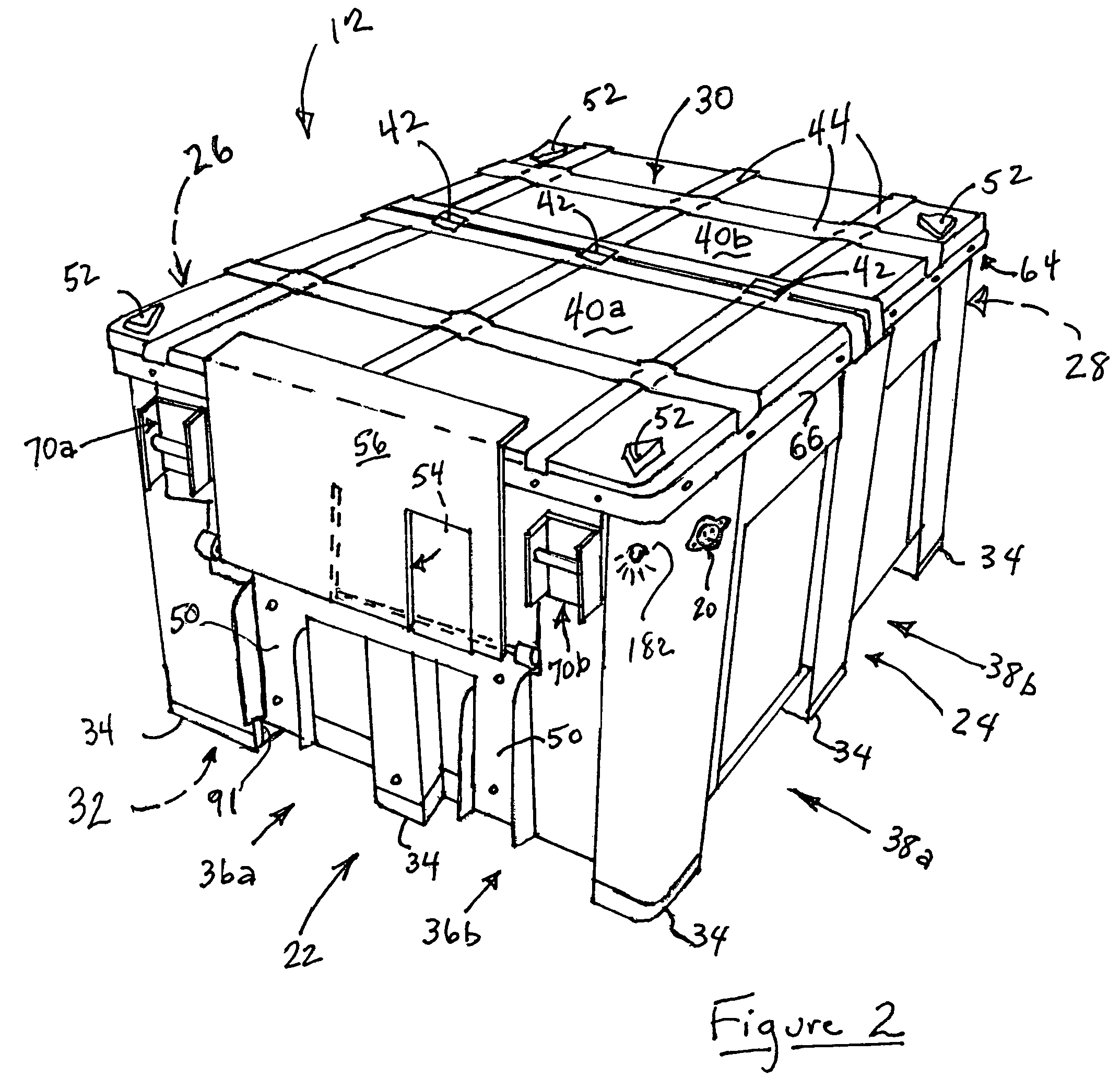

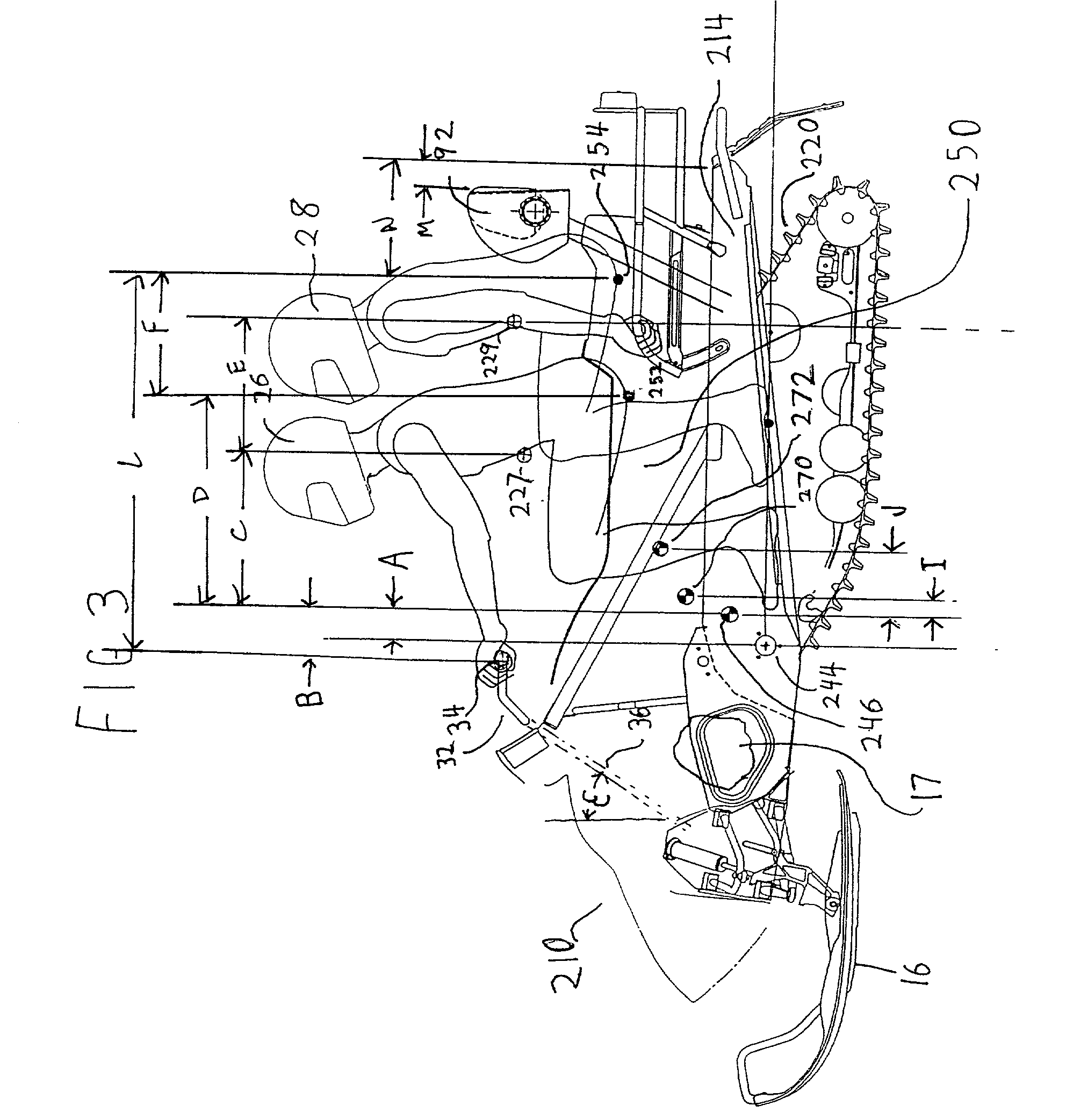

Smart pallet-box cargo container

Smart cargo container system comprising auditable, secure, sealable, stackable, trackable and pollable, universal, “pallet boxes” used: 1) auto-latchingly secured to the under-carriage transverse I-beams of over-the-road semi-trailers by means of a guiding latching system; and 2) stackable, up to three or more high, in the trailers or warehouses. Sophisticated battery-powered electronic locks, sensors and alarms are provided, as well as an RF communications and GPS locator module that radios to a base station the time, location and status of the inventive smart cargo container, and any anomalous events as they occur, including unauthorized attempts to open or break into the container, or potential damage events. In addition, both the locks and comm modules are programmable, and provide extensive, and selectably pollable and downloadable event, access and transport history and audit trails. The comm system permits remote tracking and real time status check via the Internet, LAN or WAN wireless networks.

Owner:VERDASEE SOLUTIONS

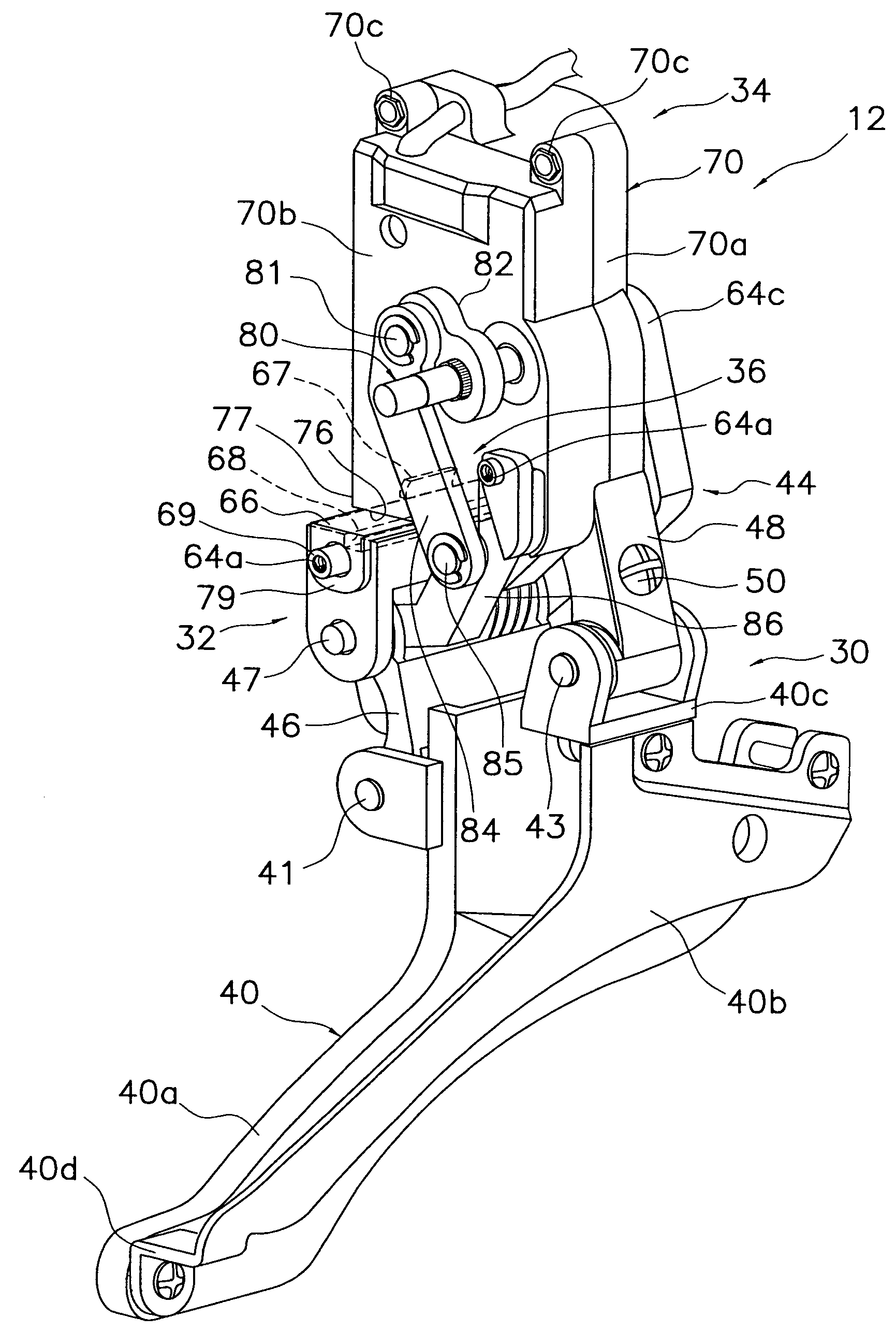

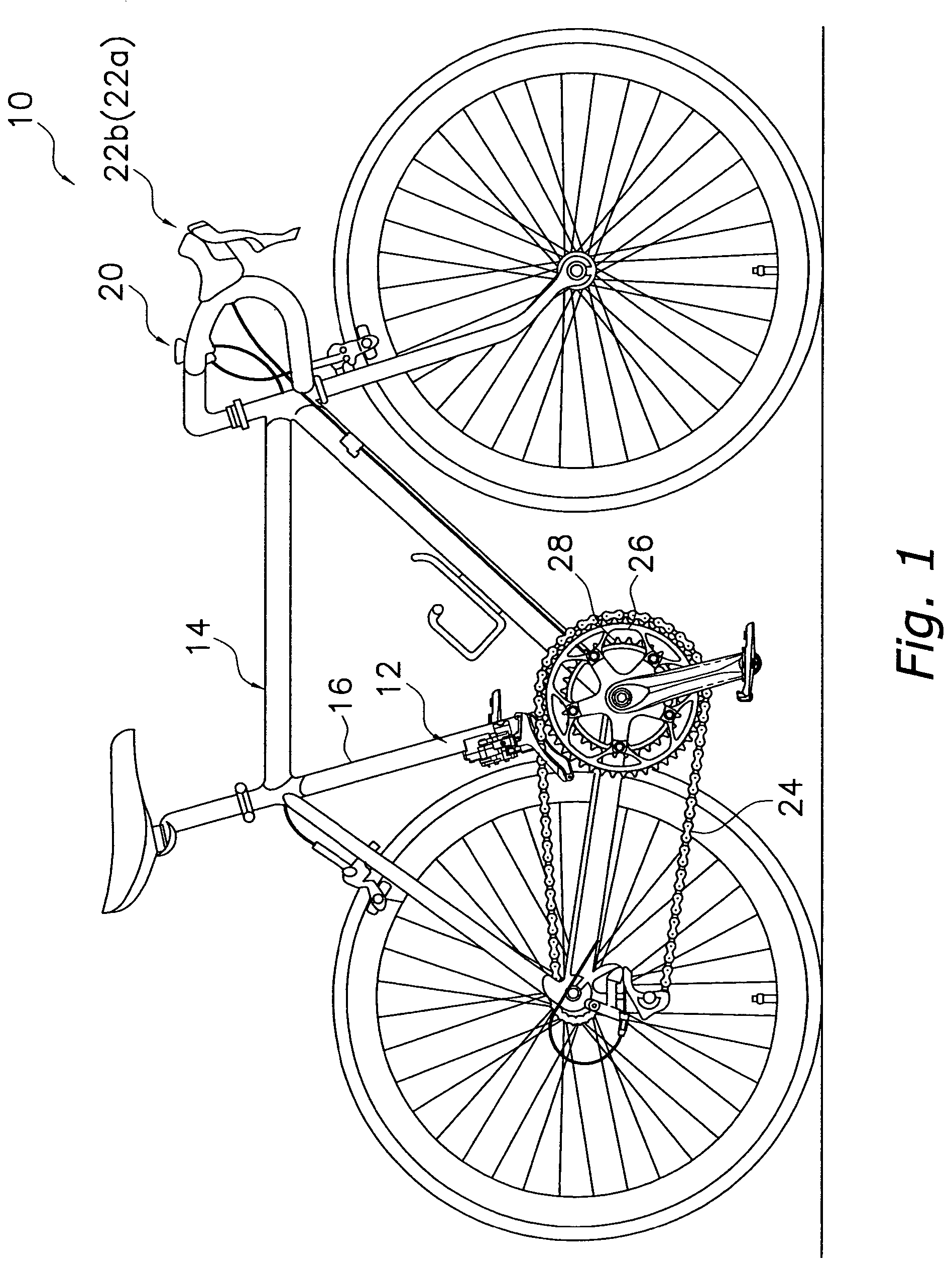

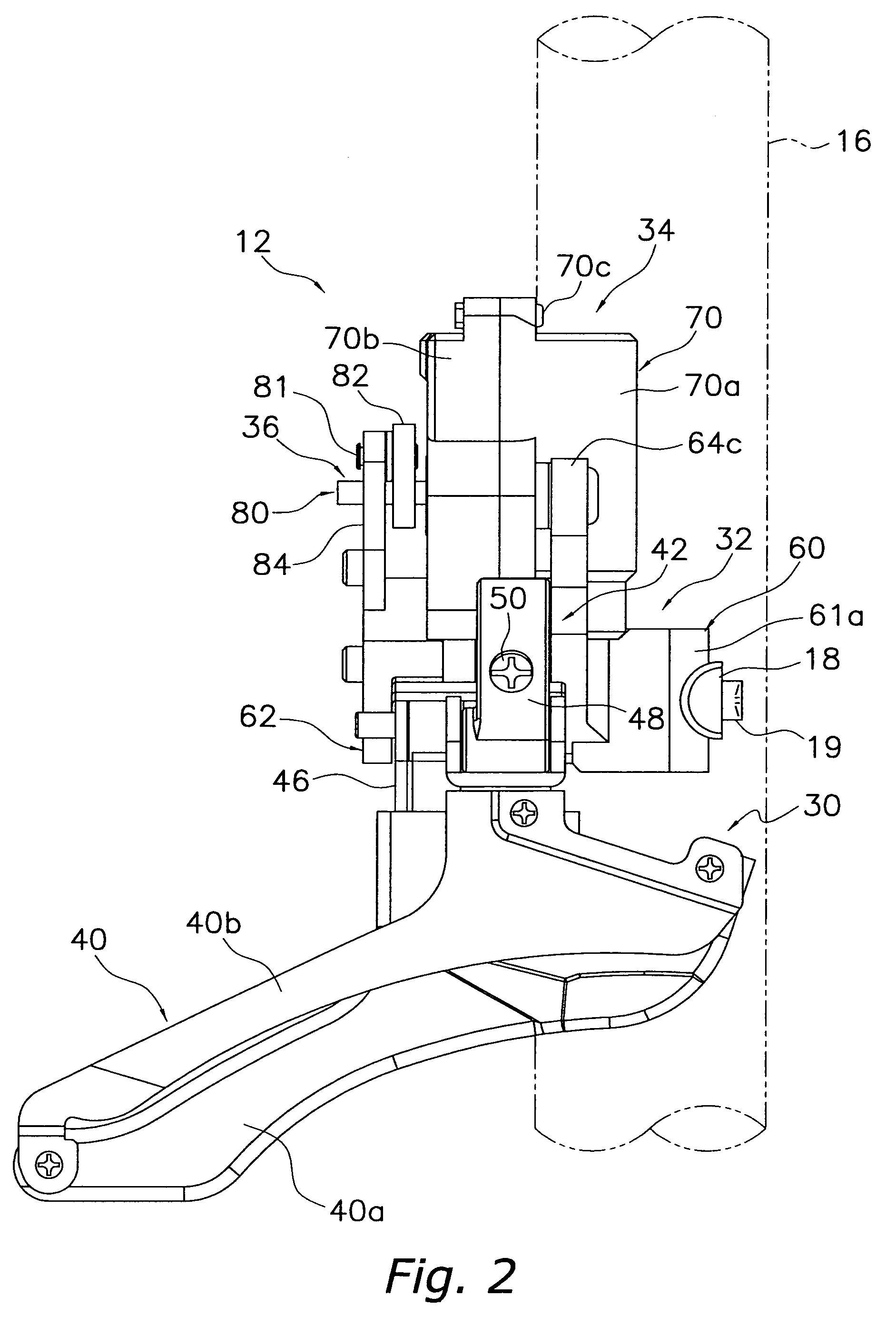

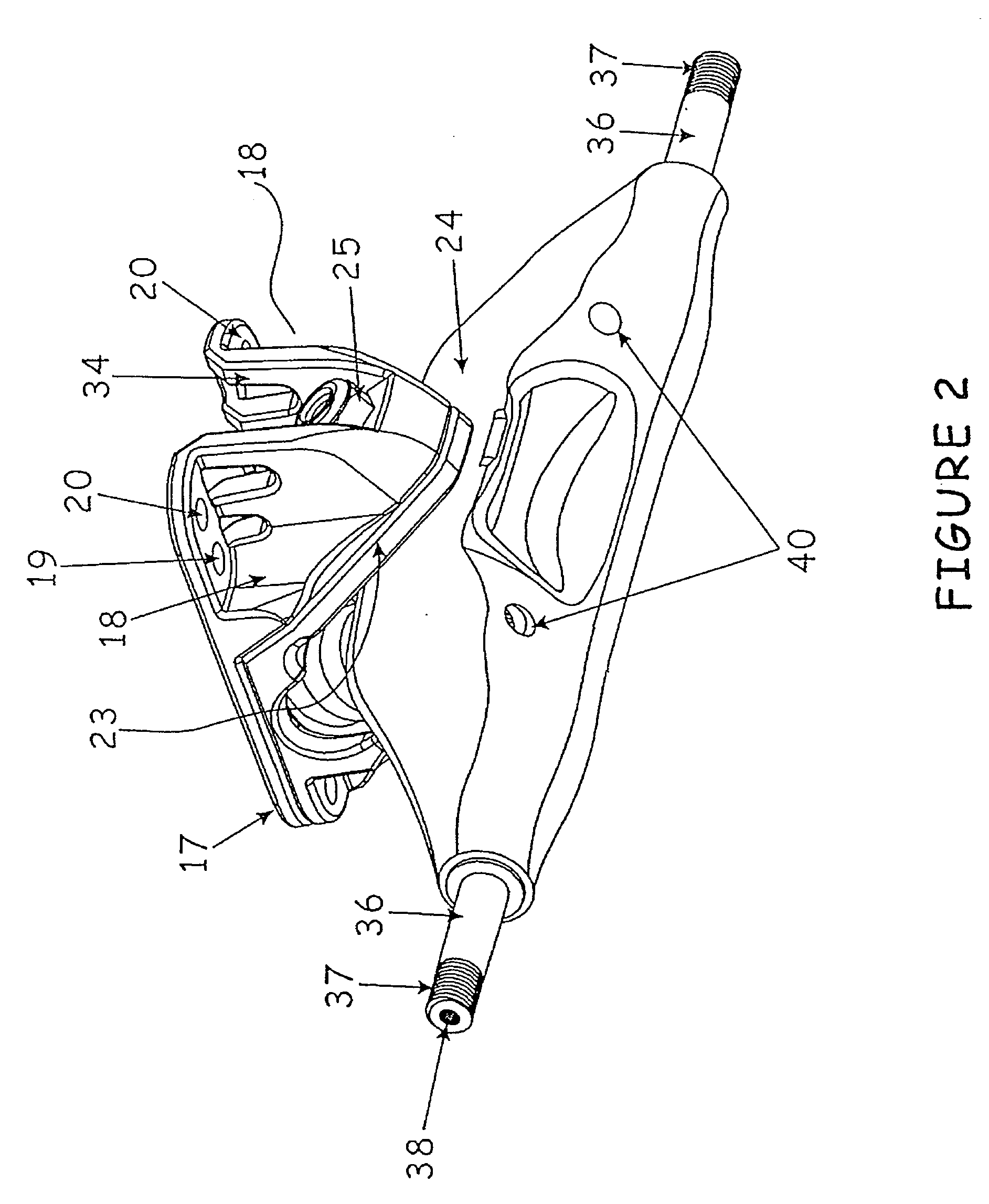

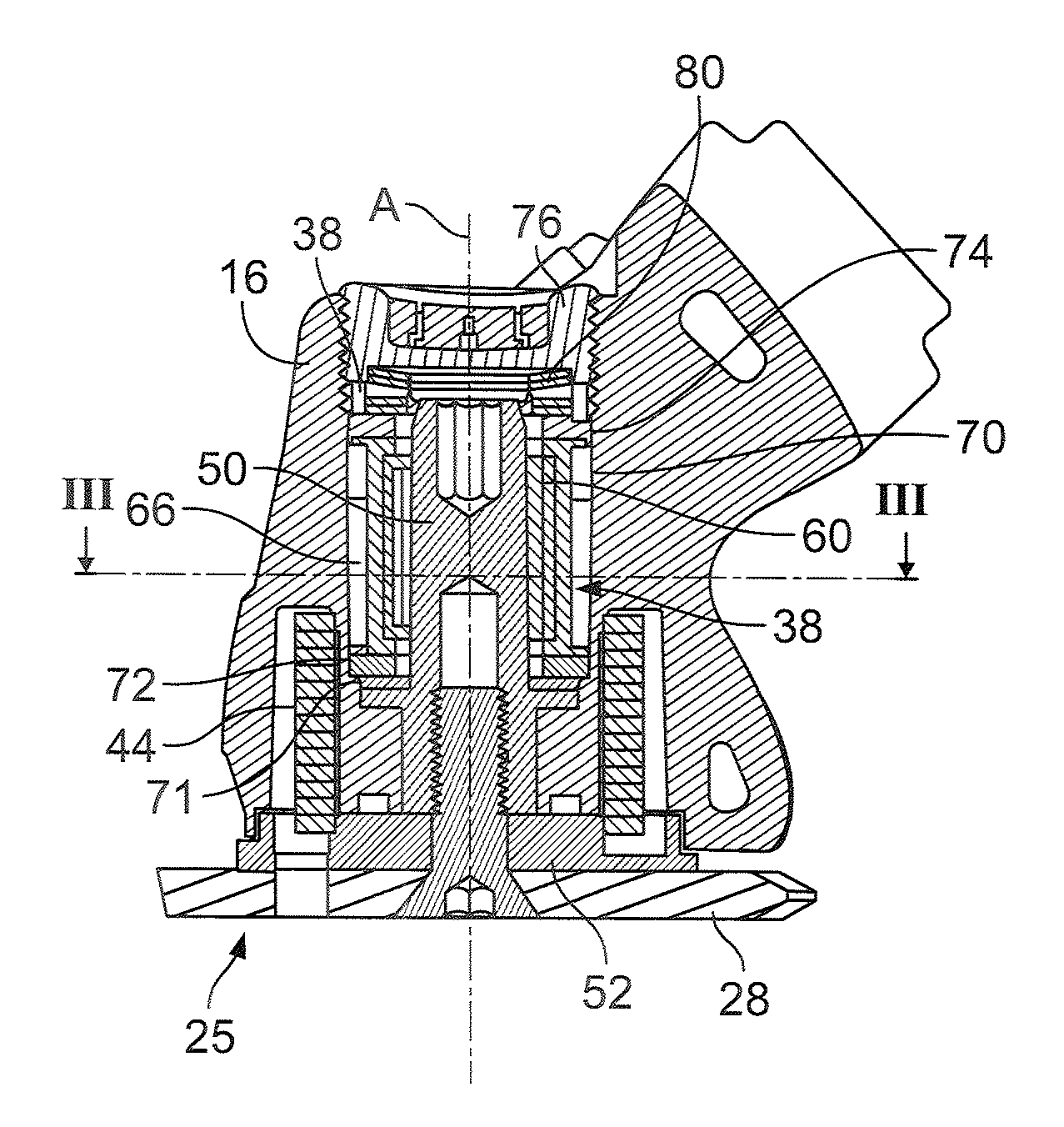

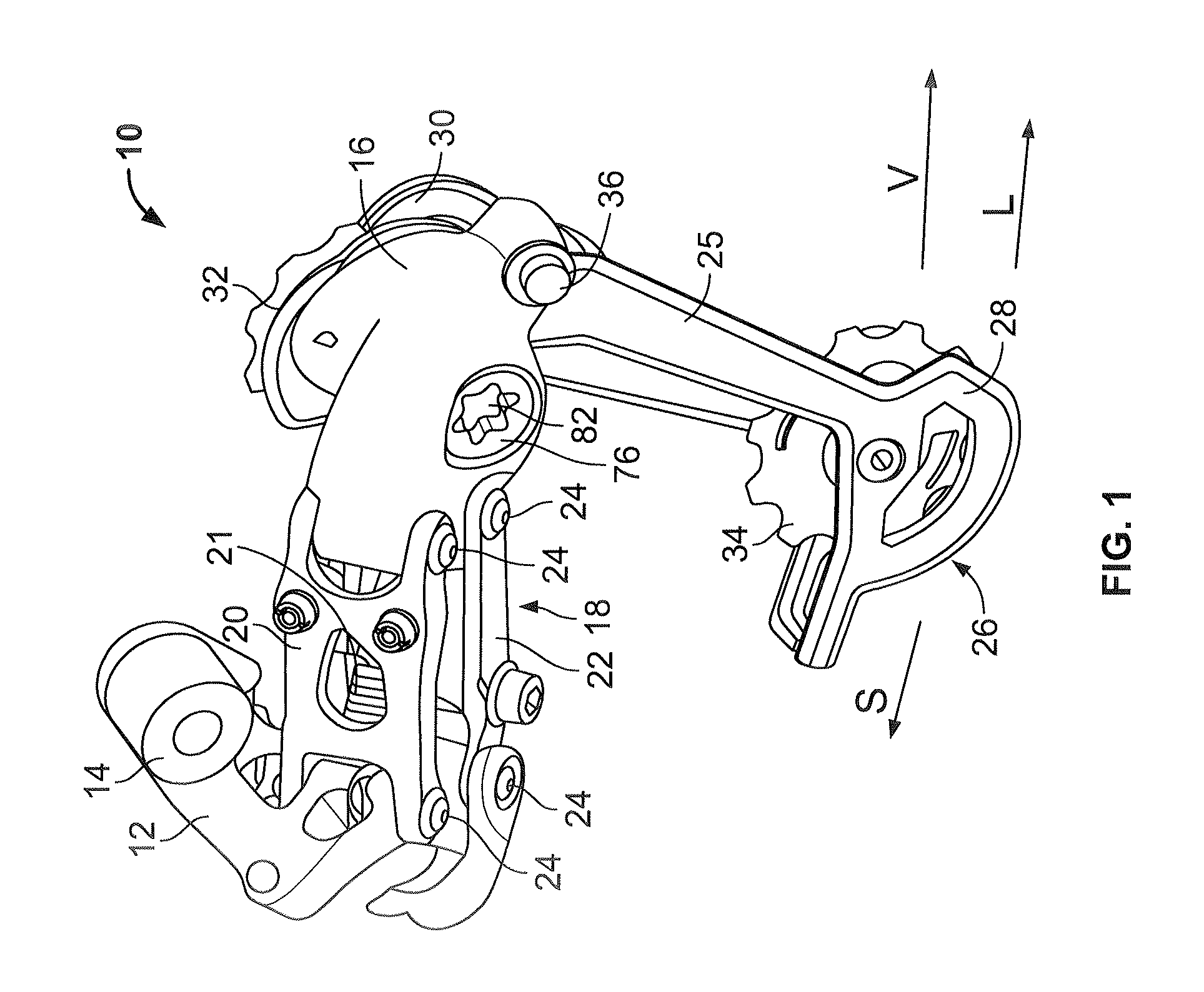

Motorized bicycle derailleur assembly

A motorized bicycle front derailleur assembly is provided that includes a motor unit, a front derailleur and a motor linkage. The motor unit is configured to rotate an output shaft in first and second opposite rotational directions. The front derailleur includes a fixing body configured to be mounted to a bicycle frame, inner and outer links pivotally coupled to the fixing body at first and second pivot points, and a chain guide pivotally coupled to the inner and outer links to move between an inner shift position and an outer shift position. The first pivot point is located laterally closer to a center plane of the bicycle frame than the second pivot point. The motor linkage is operatively coupled to the output shaft of the motor unit and the inner link to move the chain guide between the inner and outer shift positions upon rotation of the output shaft.

Owner:SHIMANO INC

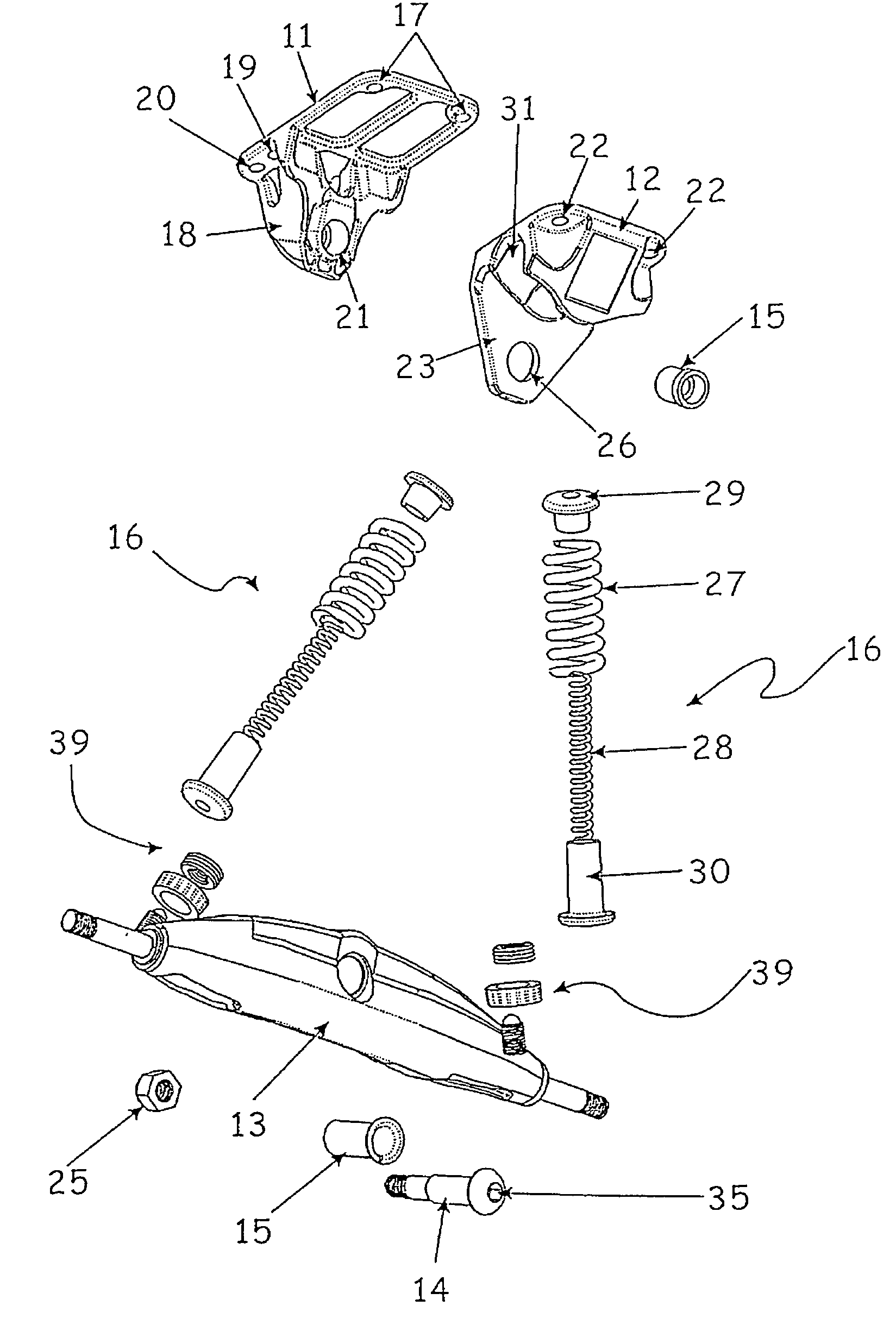

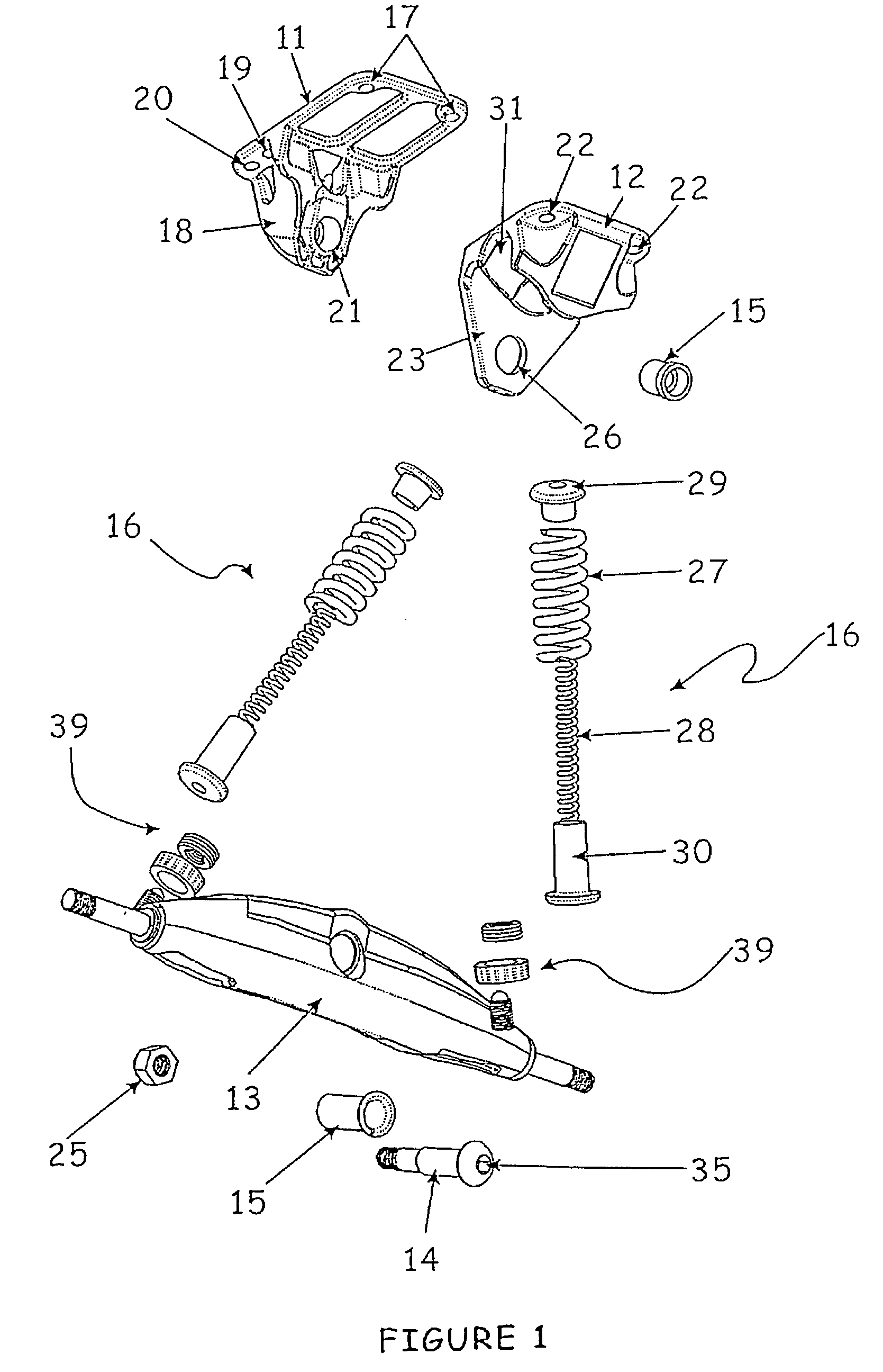

Turning frame for skateboard

InactiveUS20060006622A1Improve the lubrication effectSmall degree of flexibilityRider propulsionSkate-boardsTurning framesEngineering

A skateboard truck includes a first base part having a first pair of mounting holes through each of which respective ones of a pair of fasteners can extend to secure the truck to a deck. There are second and third pairs of mounting holes, through either pair of which respective ones of a further pair of fasteners can extend to secure the truck to the deck. A second base part is secured to the first base part and including a bearing plate. A hanger bears against the bearing plate and is attached pivotally to the first base part by a pivot pin extending through the second base part. A pair of springs is mounted to the second base part to suspend the hanger.

Owner:MARCO SKATES LTD

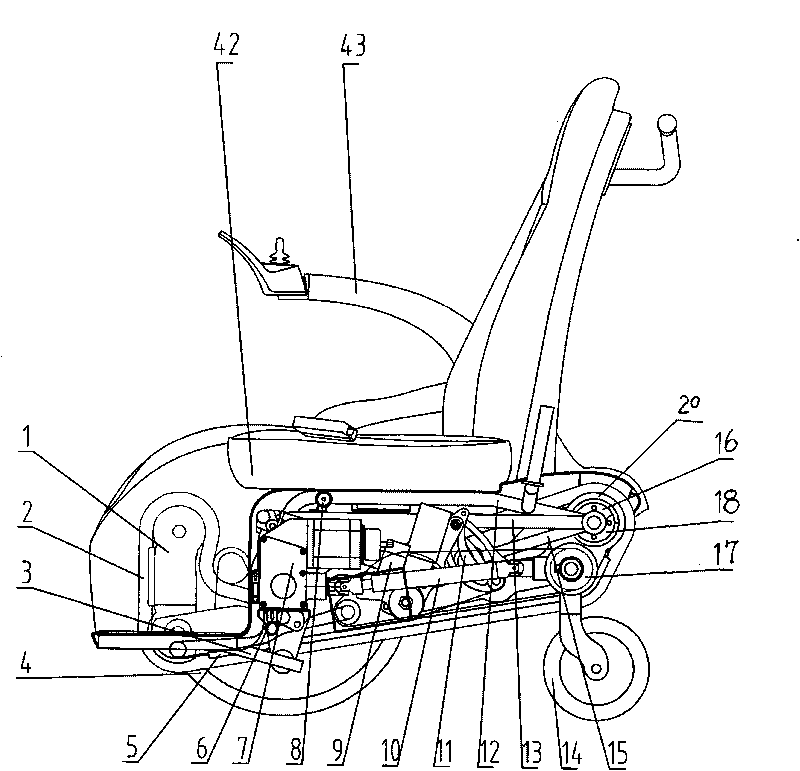

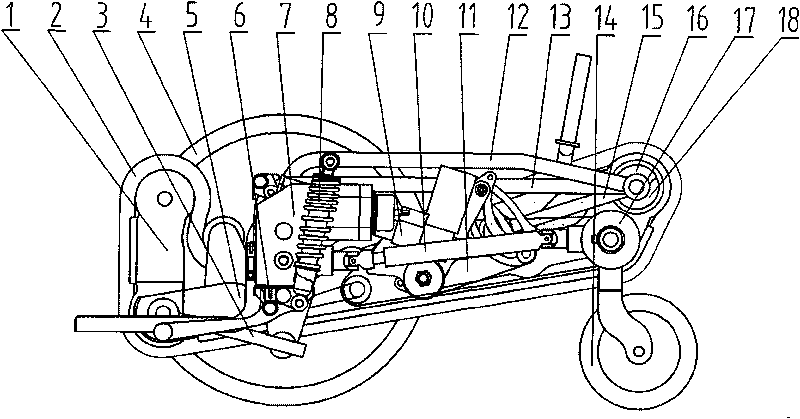

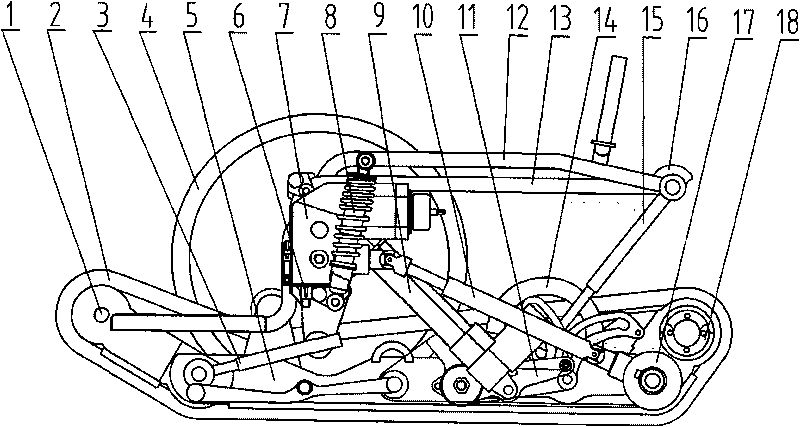

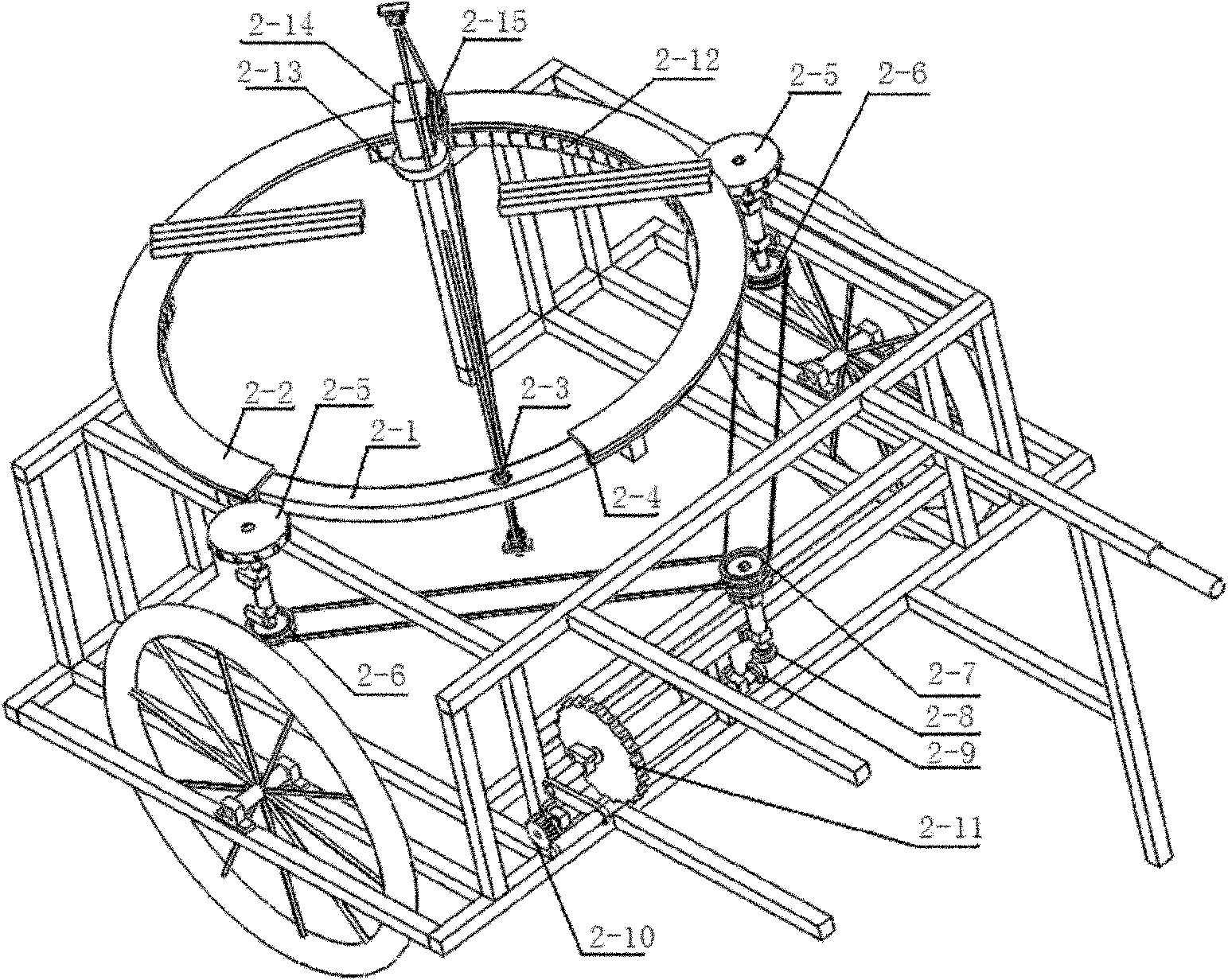

Electric stair climbing wheel chair

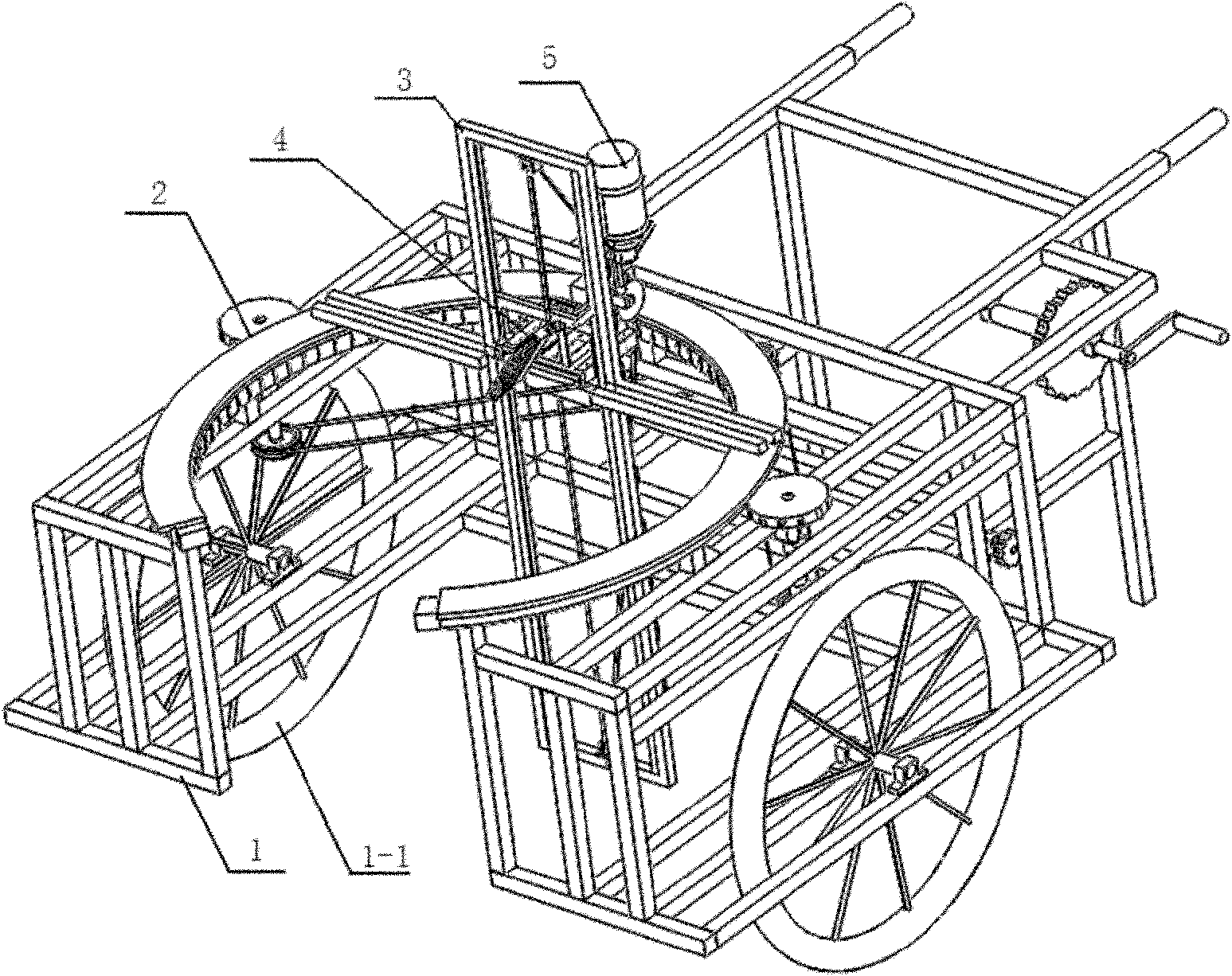

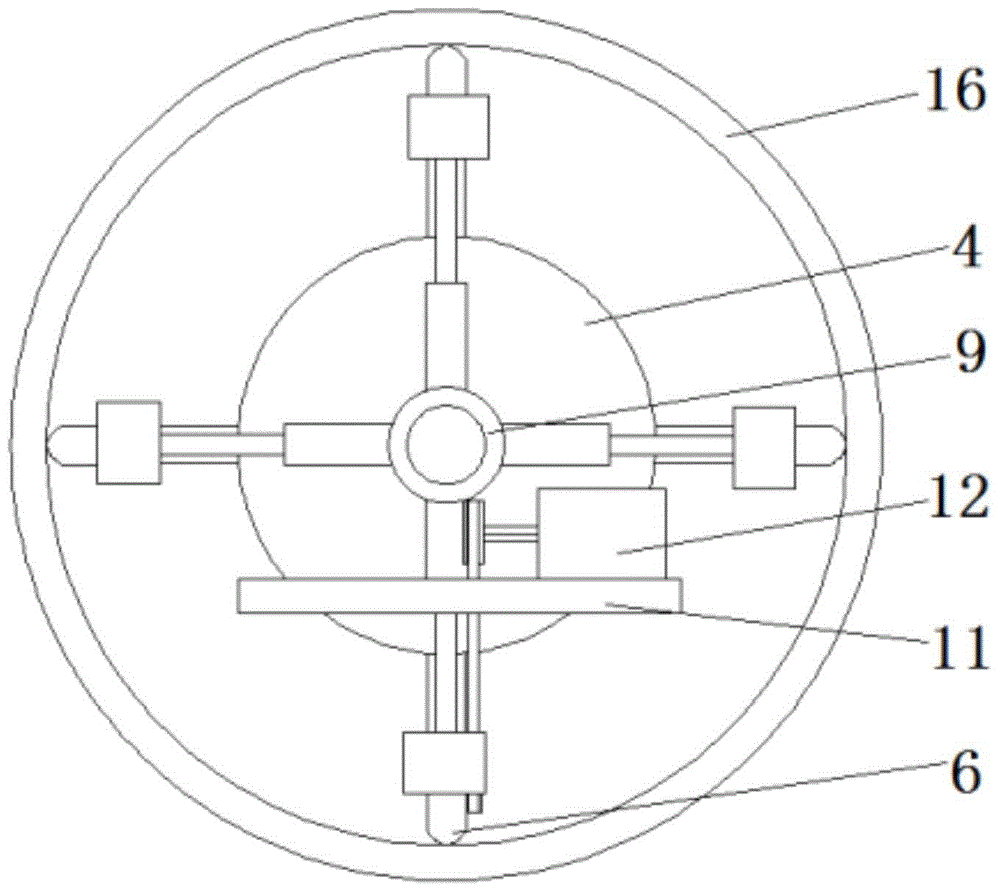

InactiveCN101703440AReduce volumeSimple and flexible operationWheelchairs/patient conveyanceWheelchairTurning frames

The invention relates to an electric stair climbing wheel chair which comprises a chair, armrests, front wheels, rear wheels and a composite chassis assembly, wherein a traveling output shaft of a power box is connected with the front wheels, and an obstacle crossing stair climbing output shaft is connected with a rear shaft gearbox; the rear shaft gearbox drives belt wheels of an obstacle crossing crawler belt, and a turning frame of the rear wheels is installed on a rear wheel shaft by a shaft sleeve; an accessory crawler belt frame is articulated with a crawler belt frame, and the accessory crawler belt frame is movably connected with the power box by a front connecting rod; the accessory crawler belt frame is connected with the turning frame of the rear wheels by a chain wheel; one end of an electric push rod is connected to a frame, and the other end drives the rear wheels to turn by a posture change mechanism; a carrying frame, the frame and one end of a rear connecting rod are coaxially fixed on a support shaft, luniform positioning blocks at both ends of the support shaft are matched with luniform buckled rings at the end parts of the crawler belt frames, and the other end of the rear connecting rod is articulated with the crawler belt frames. The invention has functions of traveling on the flat ground, crossing an obstacle and a ditch, climbing stairs up and down, and the like and has the advantages of compact structure, high automation degree, stable working, safe use and small size.

Owner:ZHEJIANG SAMPLE ELEVATOR

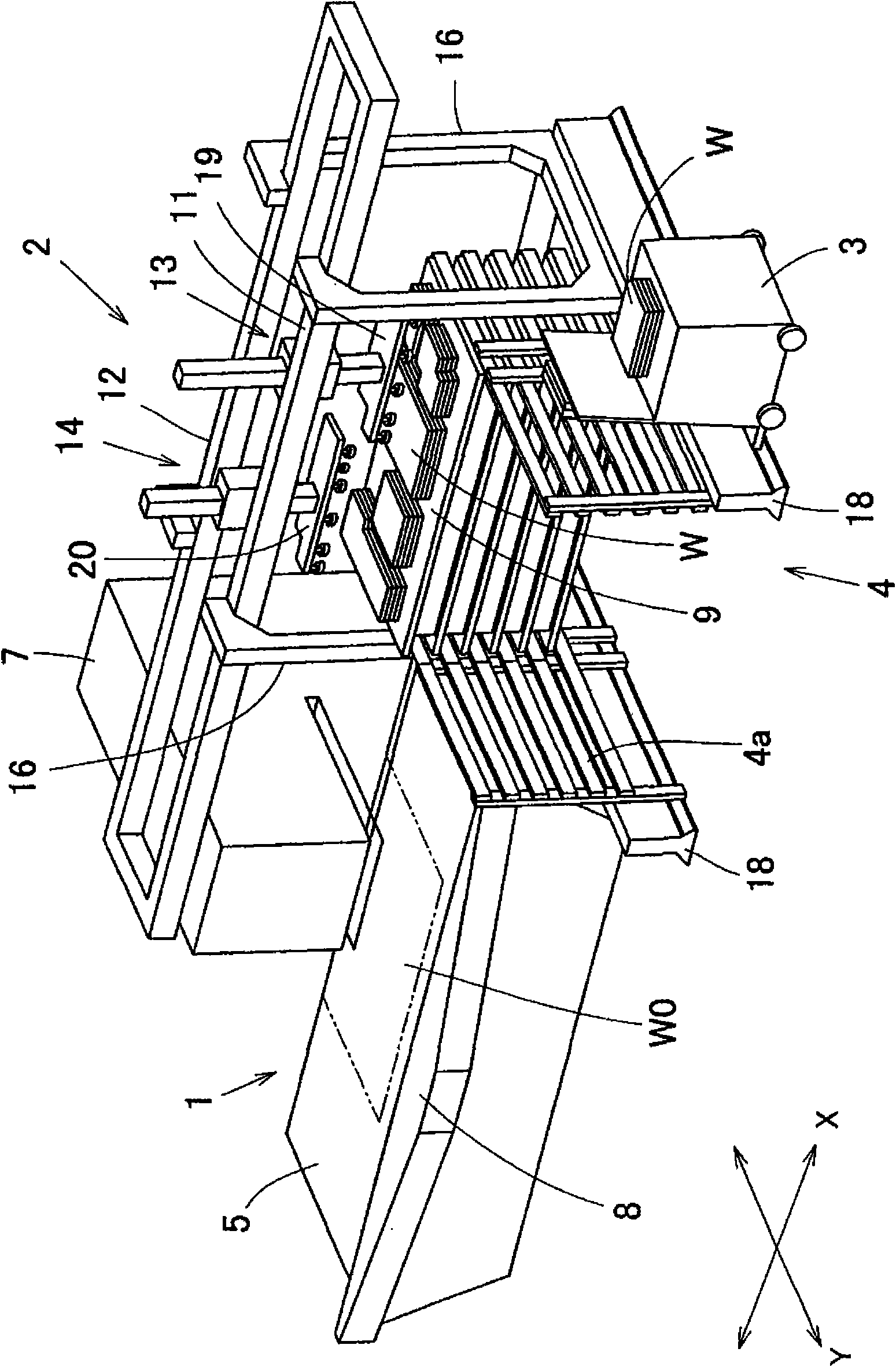

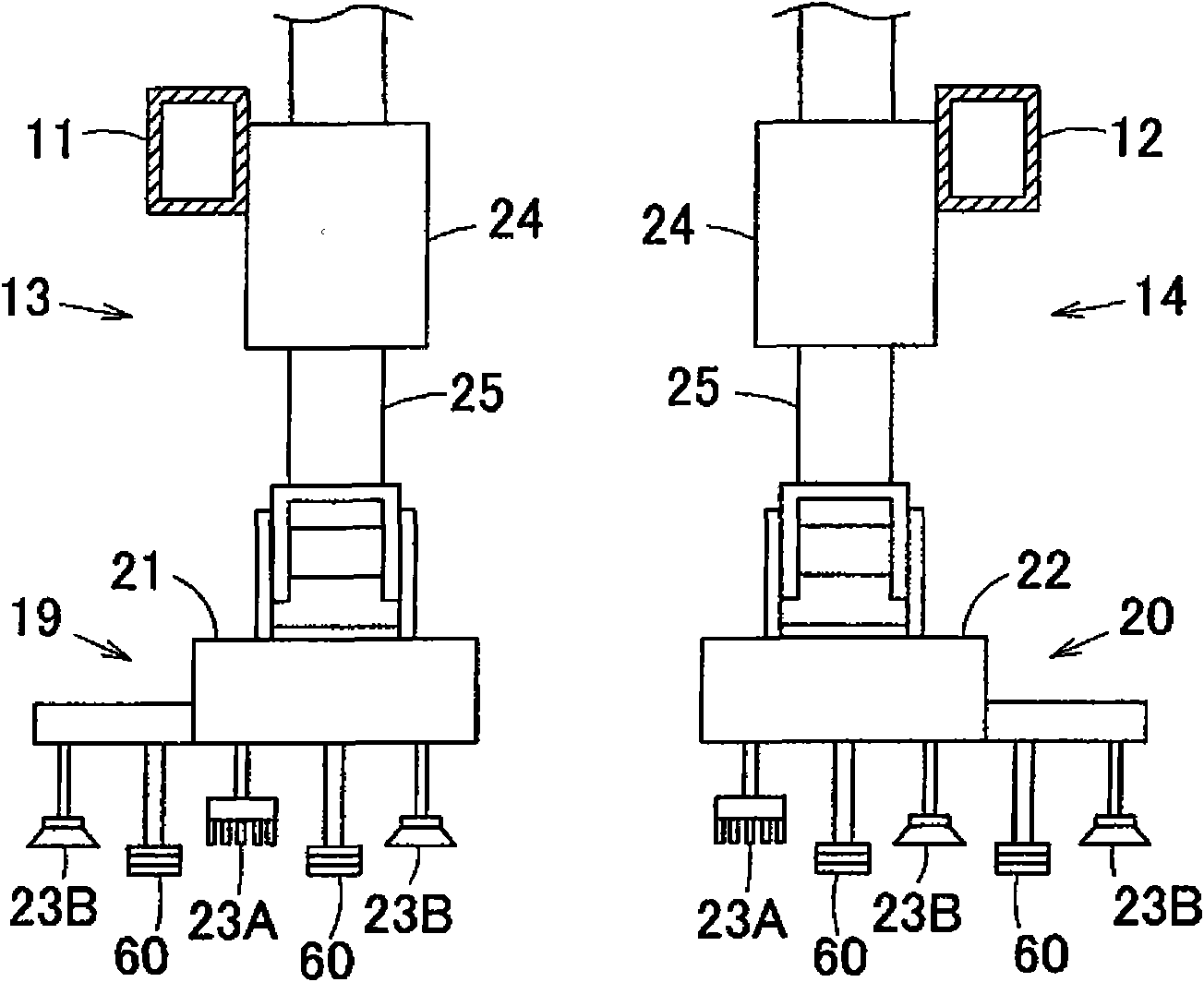

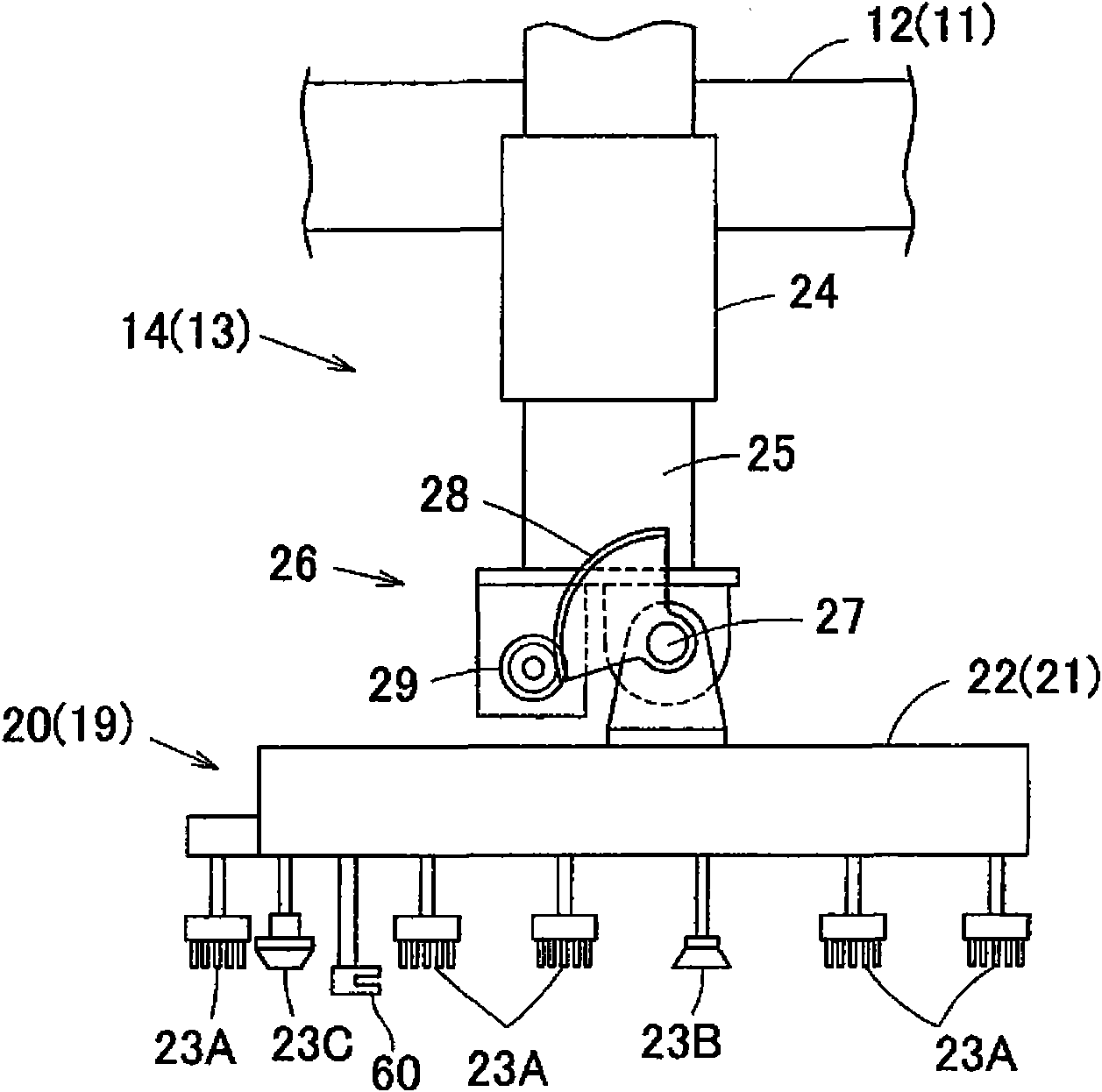

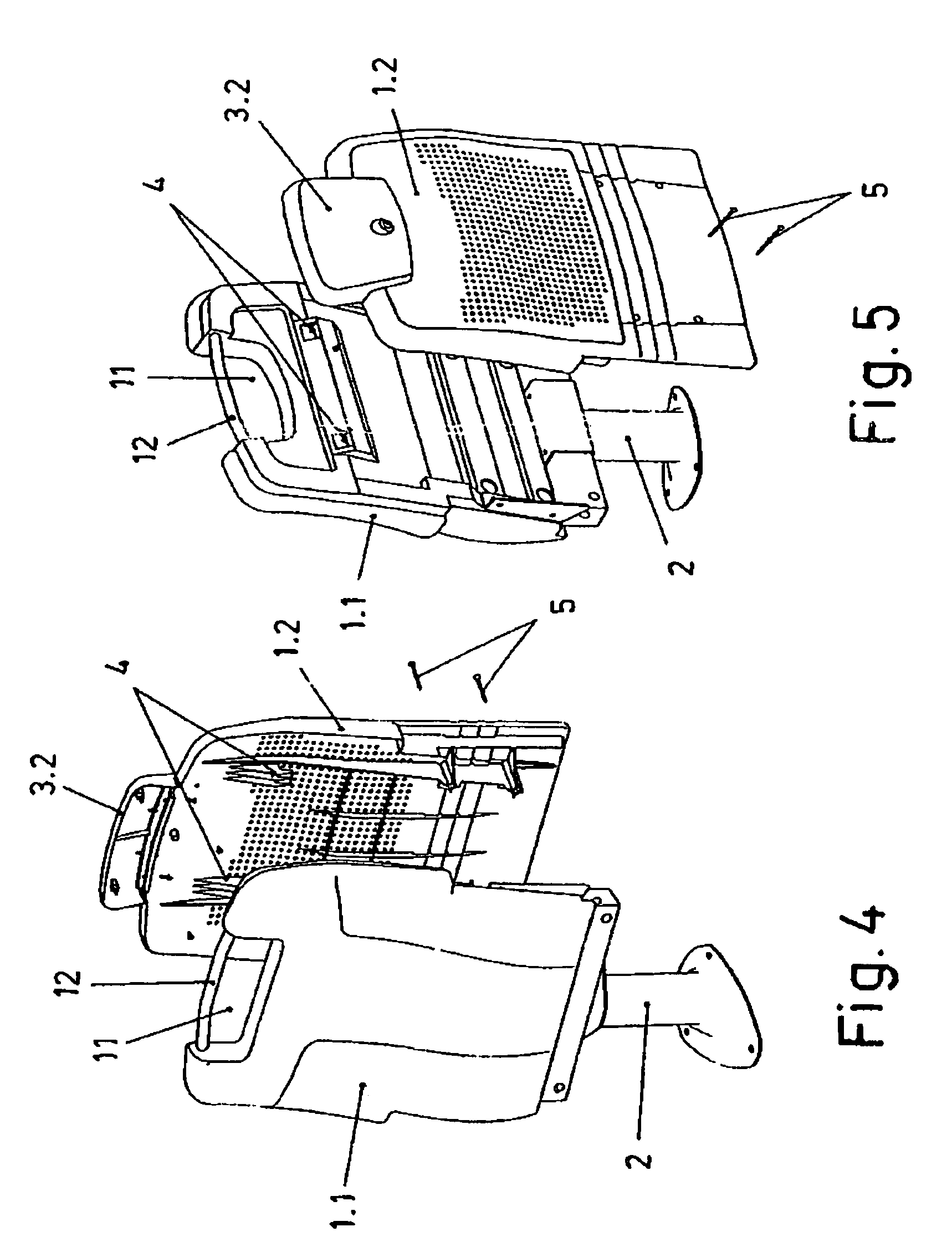

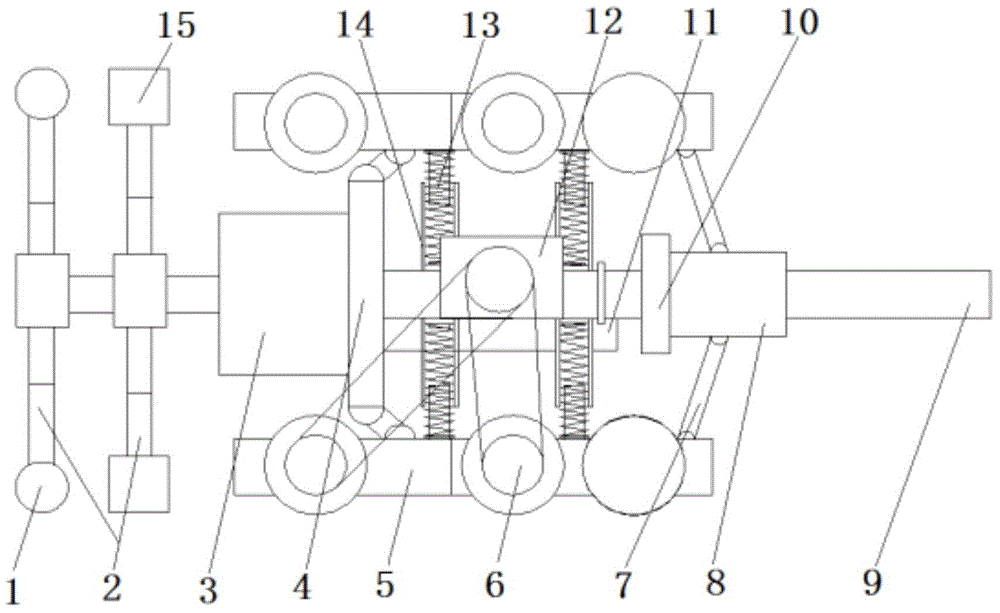

Plate material conveying device

InactiveCN101559880AIncreased conveying speedAcceleration and deceleration time is shortProgramme-controlled manipulatorMetal-working feeding devicesTurning framesEngineering

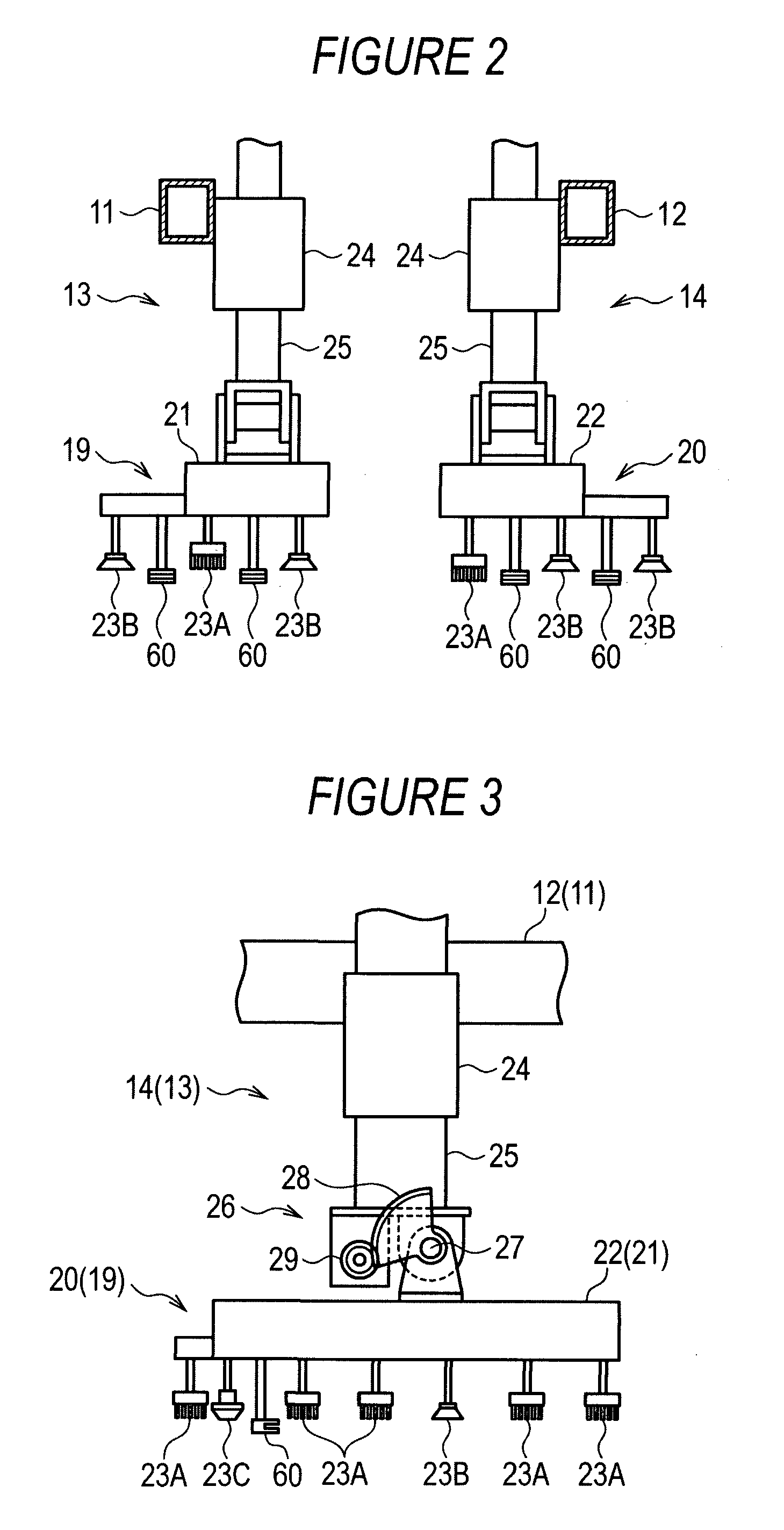

The present invention provides a plate material conveying device including a compact traveling member to enable an increase in plate material conveyance speed and a reduction in time required for acceleration and deceleration and to allow small plate materials to be more efficiently conveyed, the plate material conveying device further enabling one of a gripper and a suction type plate material holder to be selected for conveyance of a plate material. Traveling members (13, 14) are provided on respective tracks (11, 12) so as to travel freely along the respective tracks (11, 12). Each of the traveling members (13, 14) has a plate material holder support frame (21, 22) supporting suction type plate material holders (23A, 23B, 23C). The plate material holder support frame (21, 22) has a frame main body (21a, 22a), and a turning frame (21b, 22b) which is turnable in a substantially horizontal direction with respect to the frame main body (21a, 22a) and which is turnable to a position where the supported plate material planarly overlaps the adjacent track. Each of the turning frames (21b, 22b) has a gripper (60) gripping an end of the plate material. An opening of the gripper is configured to face a central side of the plate material.

Owner:MURATA MASCH LTD

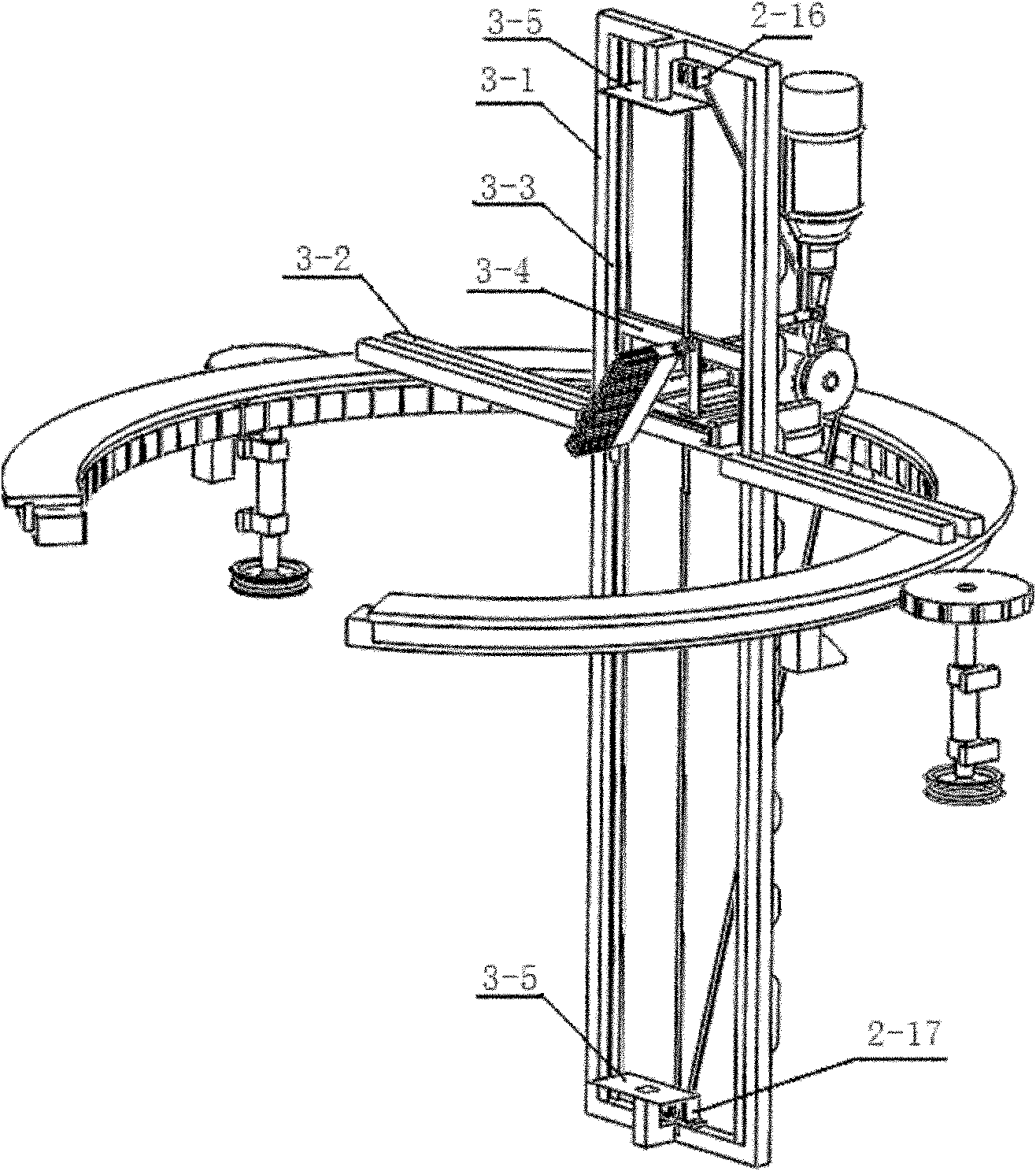

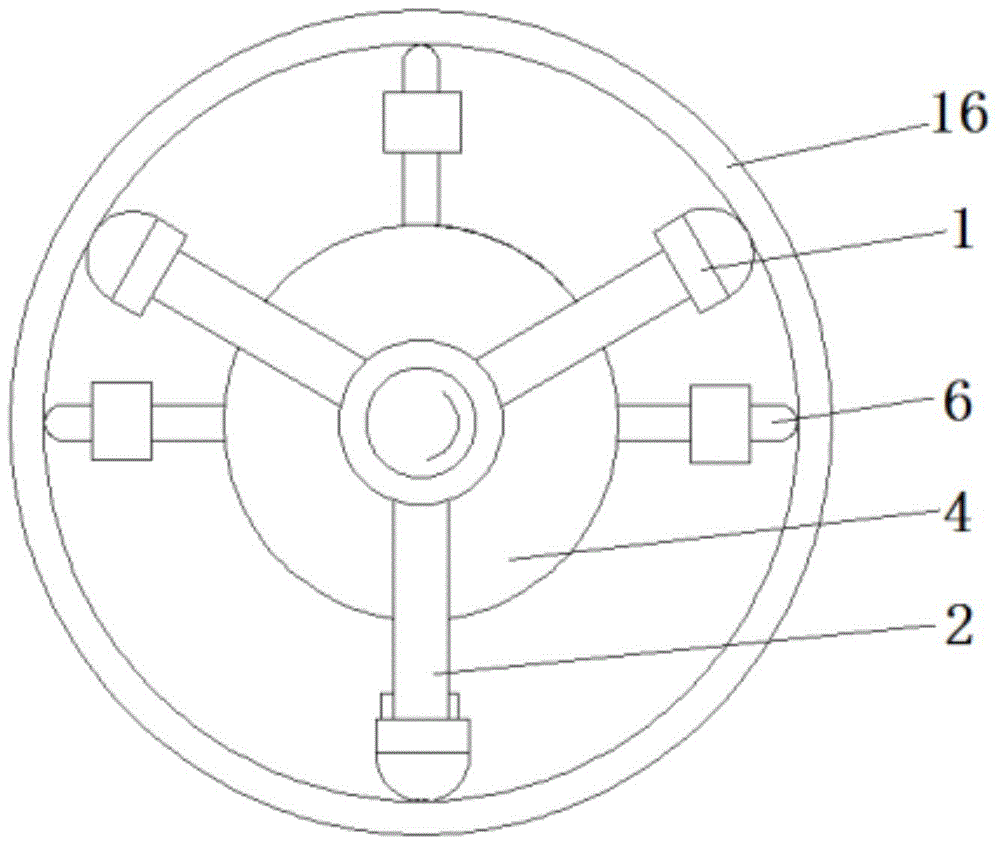

Novel tree whitewashing machine

ActiveCN102172187AEliminate working dead endsImprove paint qualityPlant protectionGear wheelFixed frame

The invention relates to a novel tree whitewashing machine which comprises a frame, a rotating transmission mechanism, a brush mechanism and a liquid feed mechanism. A guide pipe of the liquid feed mechanism is arranged on the brush mechanism; a fixed opening ring is installed on the frame; a rotation opening ring is rotatably installed outside the fixed opening ring in a winding manner; the outer side of the rotation opening ring is provided with a chain with a K-shaped accessory; the chain and a first chain wheel are in engaged transmission; the first chain wheel is in transmission connection with a manual handle through a transmission element; the inner side of the fixed opening ring is provided with an internal rack with an arc opening; a speed reducing commutator is fixed on the rotation opening ring; gears are installed on an input shaft of the speed reducing commutator; an output shaft of the speed reducing commutator is provided with a wire rope pulley; an external framework is fixed on the rotation opening ring through a fixed frame; guide grooves are installed at a left inner side and a right inner side of the external framework; a lifting block is installed on the guide grooves in a vertically-moving manner; and an upper fixed pulley and a lower fixed pulley are respectively fixed on the external framework. The novel tree whitewashing machine can be used for effectively eliminating dead angles and improving painting quality.

Owner:海宁市黄湾镇资产经营有限公司

Adjustable bed with sliding subframe for torso section

A sliding subframe mounted to the derriere-supporting section of an articulating bed is adapted to translate the rotational axis of the torso-supporting section of the bed toward the headframe as the torso-supporting section is raised to an inclined position, and back toward the footboard as the torso-supporting section is lowered to a level position. This mechanism reduces compression of the lumbo-sacral area of the patient during bed articulation.

Owner:BEDLAB

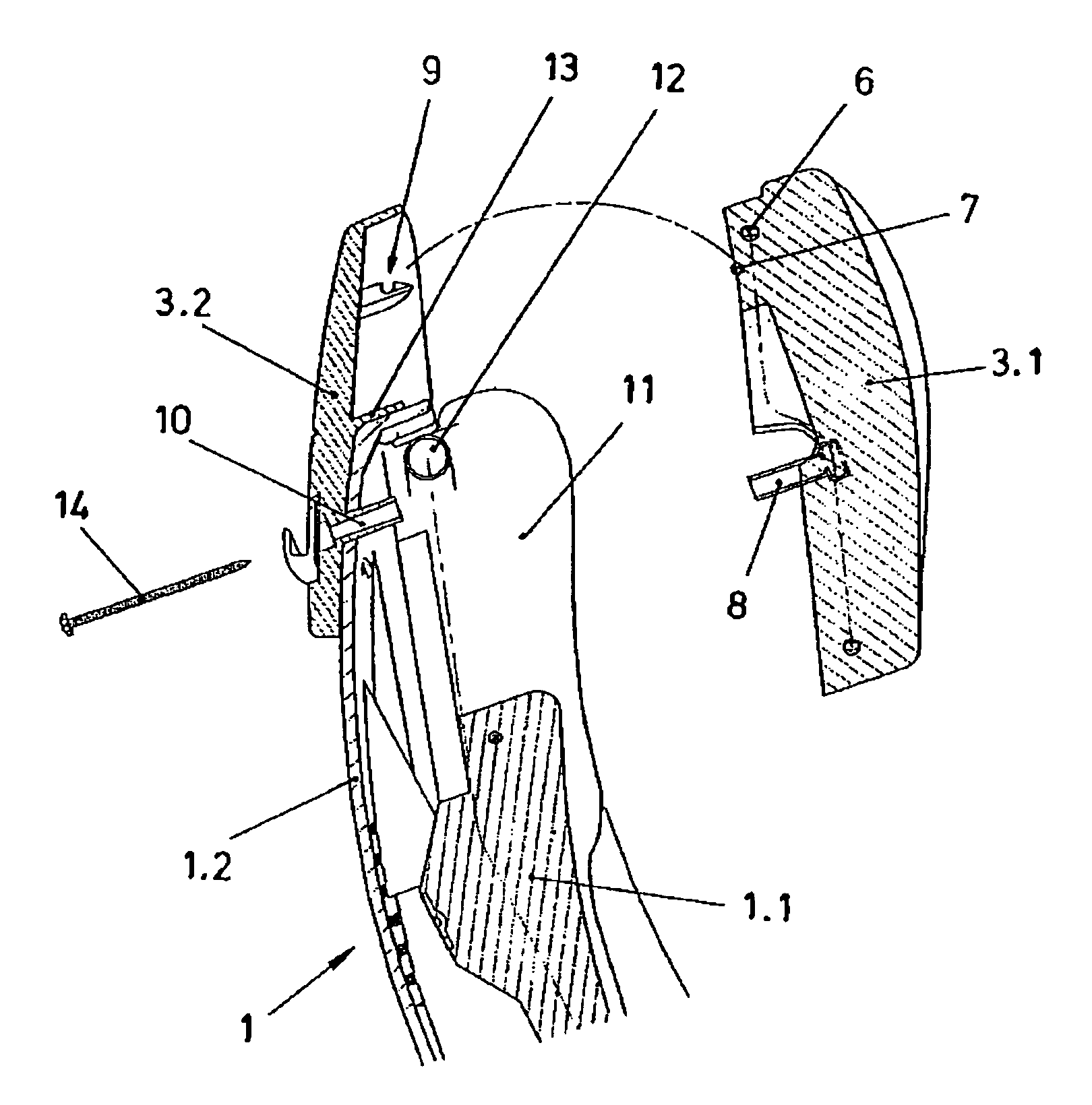

Backrest for armchairs

Backrest for armchairs, made up of a soft front body (1.1) and a rear frame (1.2), situating at the upper part a headrest made up of a respective soft front body (3.1) and a respective rear frame (3.2), fitting the soft body (3.1) of the headrest in a notch (11) of the upper part of the soft body (1.1) of the backrest, with fixing of the mentioned soft body (3.1) of the headrest over the hooks (9) of the corresponding rear frame (3.2) and a screwed anchoring (14) which passes through the frame (3.2) of the headrest and the frame (1.2) of the backrest.

Owner:FIGUERAS INT SEATING

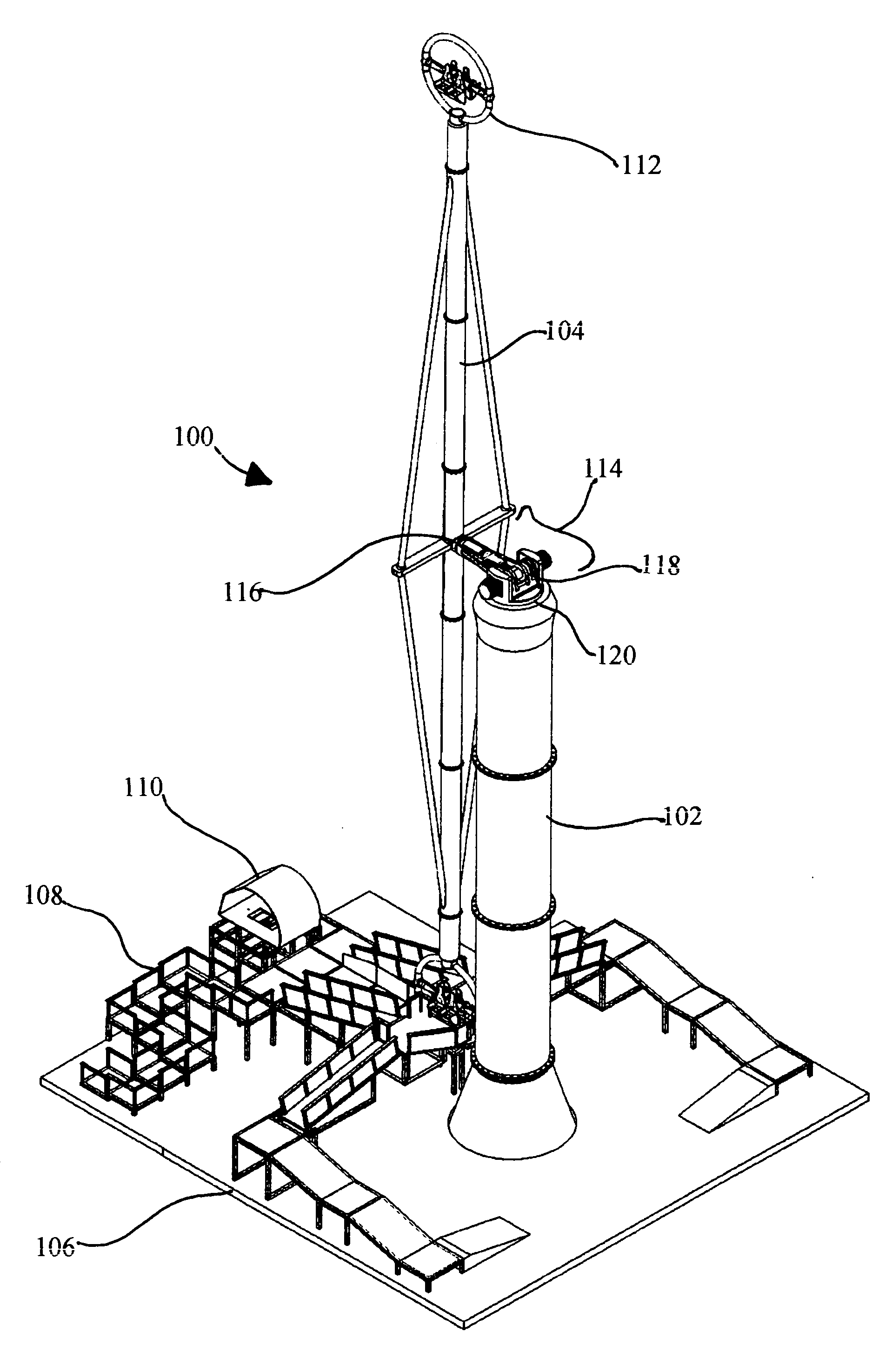

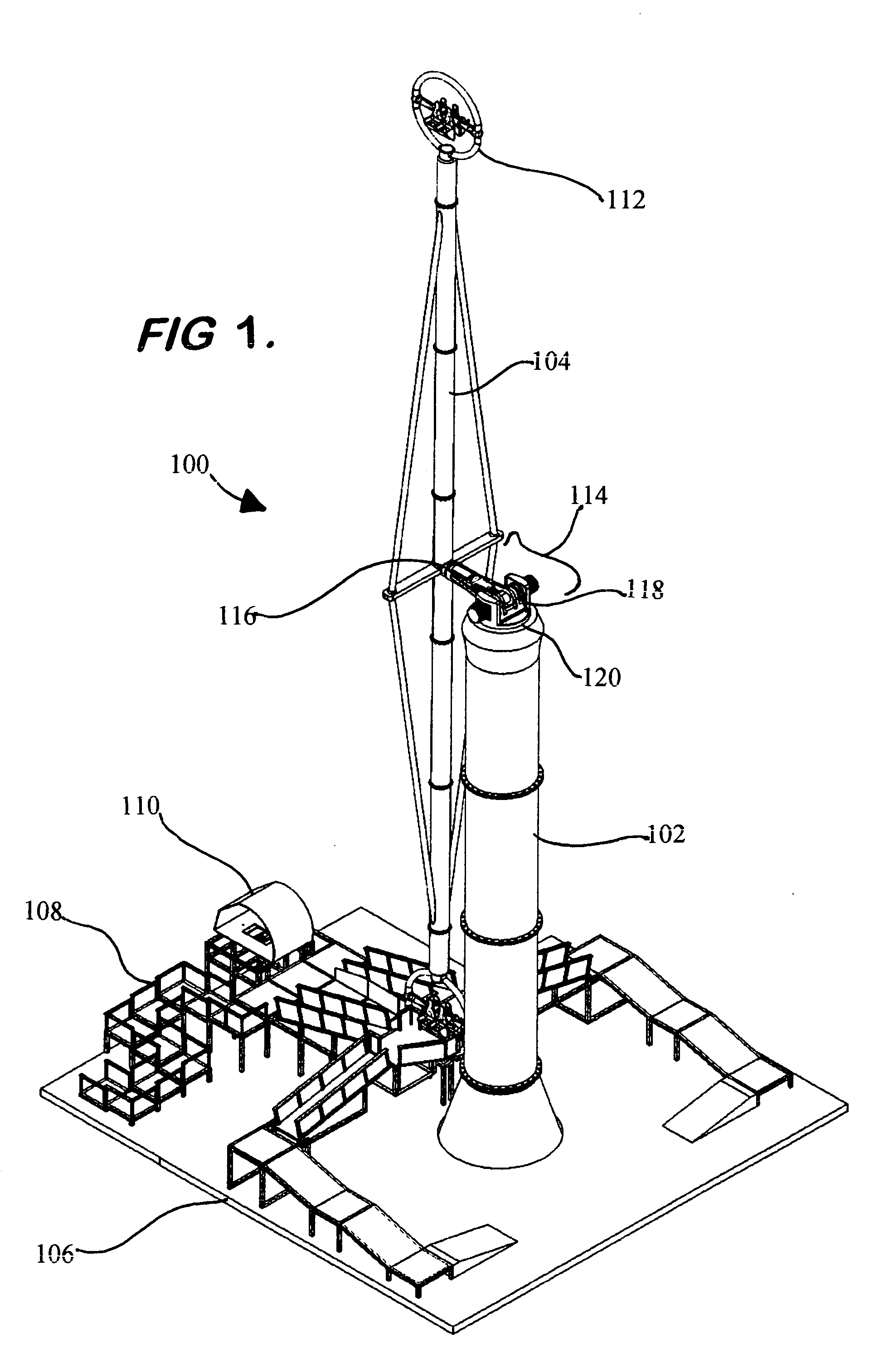

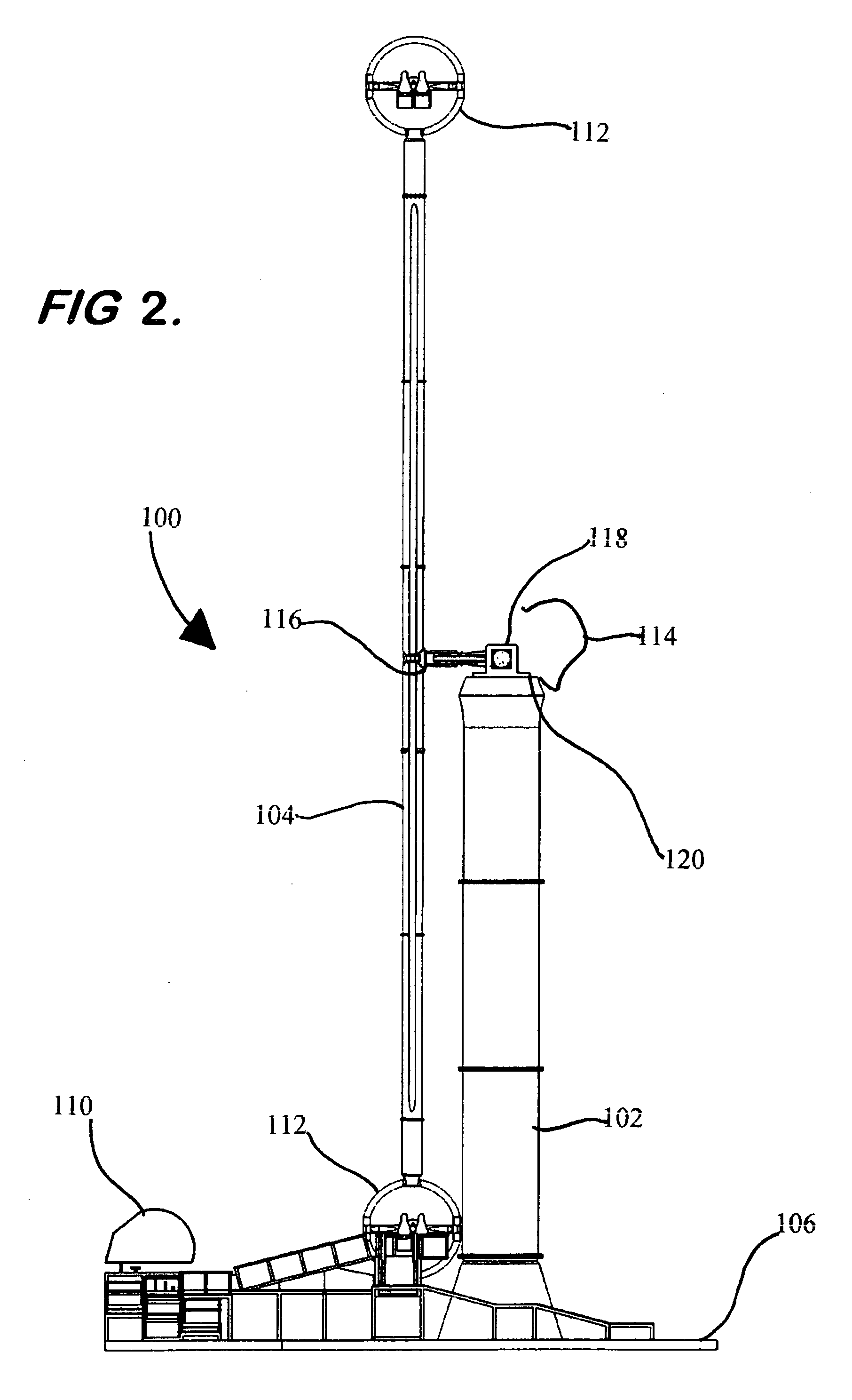

Amusement ride

An amusement ride including an elongated boom connected to a vertical tower so as to be selectively rotated and pivoted with respect to the tower. The tower includes a pitch actuator, a yaw actuator, and a roll actuator for pivoting or rotating the boom about three axes or degrees of motion. A rider carriage assembly is rotatably coupled to the elongated boom. The rider carriage assembly may include pitch actuators, yaw actuators, and roll actuators to impart selective rotating motion to the rider and rider carriage assembly and up to three axes or degrees of motion independent of the boom motion.

Owner:THRELKEL DAVID V

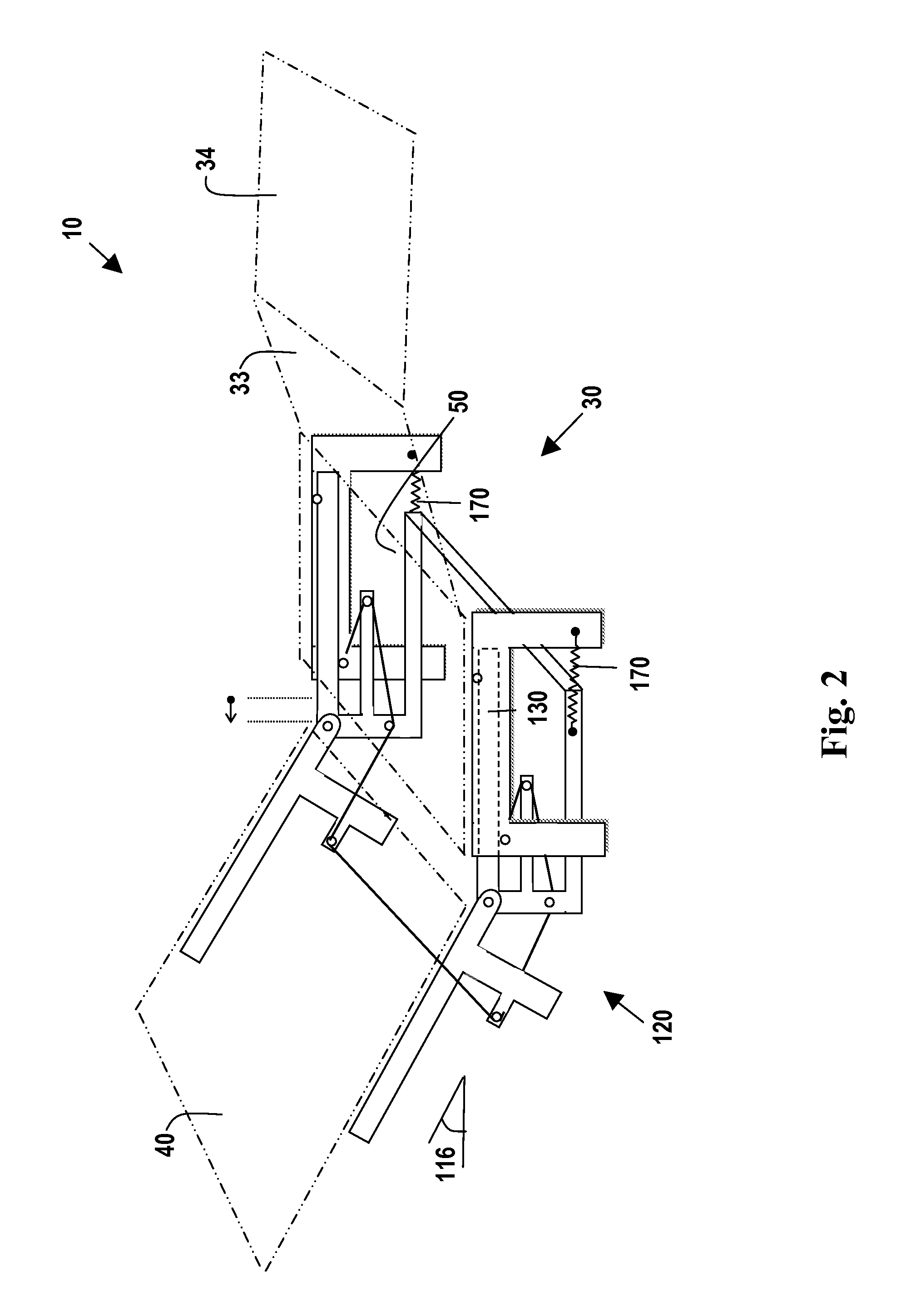

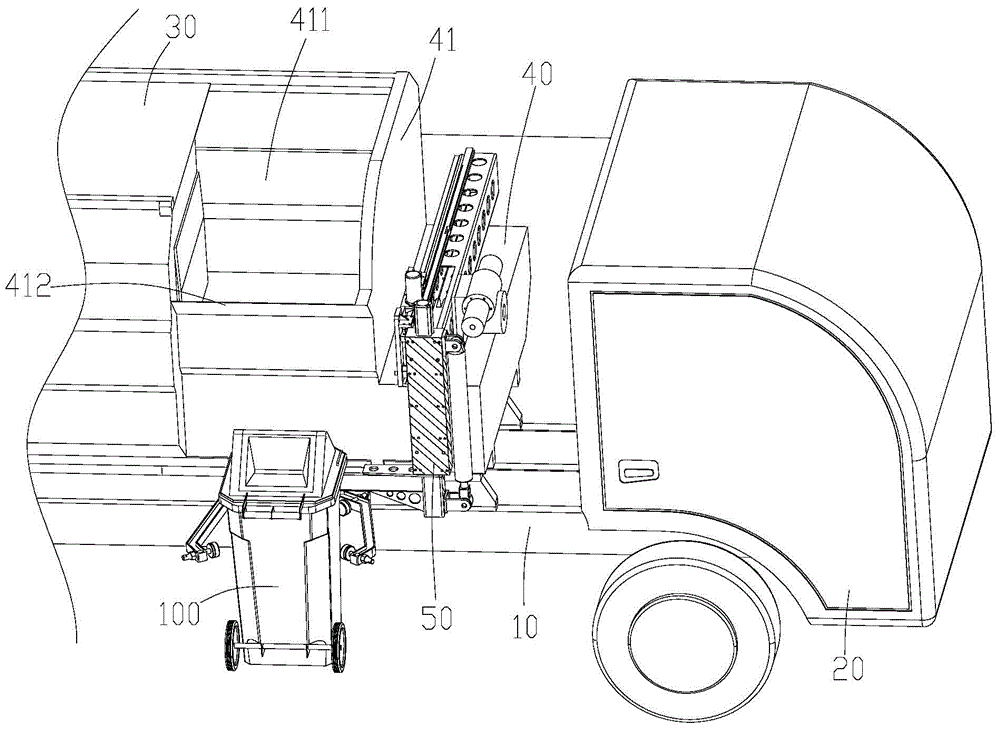

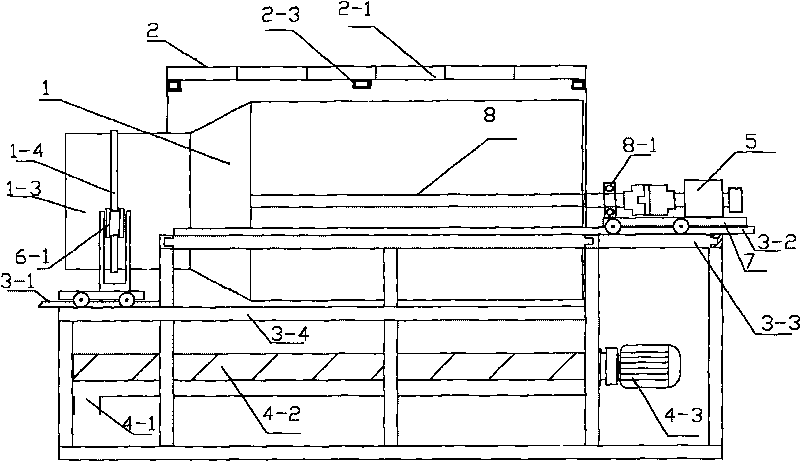

Intelligent self-loading and unloading-type garbage compression truck

ActiveCN105883275AAutomatic and flexible positioningAutomatic and flexible grabbingRefuse vehiclesWaste collectionTurning frames

The invention discloses an intelligent self-loading and unloading-type garbage compression truck. The intelligent self-loading and unloading-type garbage compression truck comprises a frame, a truck head arranged on the front end of the frame, a truck carriage and a material filling box arranged on the frame, an intelligent manipulator and a sewage collection device, wherein the material filling box is located between the truck carriage and the truck head and communicates with the front end of the truck carriage; a material inlet fame is arranged above the material filling box; the bottom of the material inlet frame communicates with the material filling box; the top of the material inlet frame is provided with a material inlet; the material inlet is provided with a material feeding side which is lower than the top surface of the truck carriage; the intelligent manipulator is arranged on the material filling box and is located between the material inlet frame and the truck head; the intelligent manipulator is used for positioning, grabbing, lifting, overturning and releasing a garbage can on the ground; and the sewage collection device is arranged on the rear end of the truck carriage, and is used for collecting sewage mixed in garbage in the truck carriage. By adopting the intelligent self-loading and unloading-type garbage compression truck, mechanical can hanging and overturning work can be performed on the garbage can; and work for hanging the garbage can on a frame or releasing the garbage can from the frame manually is omitted, so that labor intensity of workers is lowered, and garbage collection efficiency is improved.

Owner:长沙市蓝地环保科技有限公司

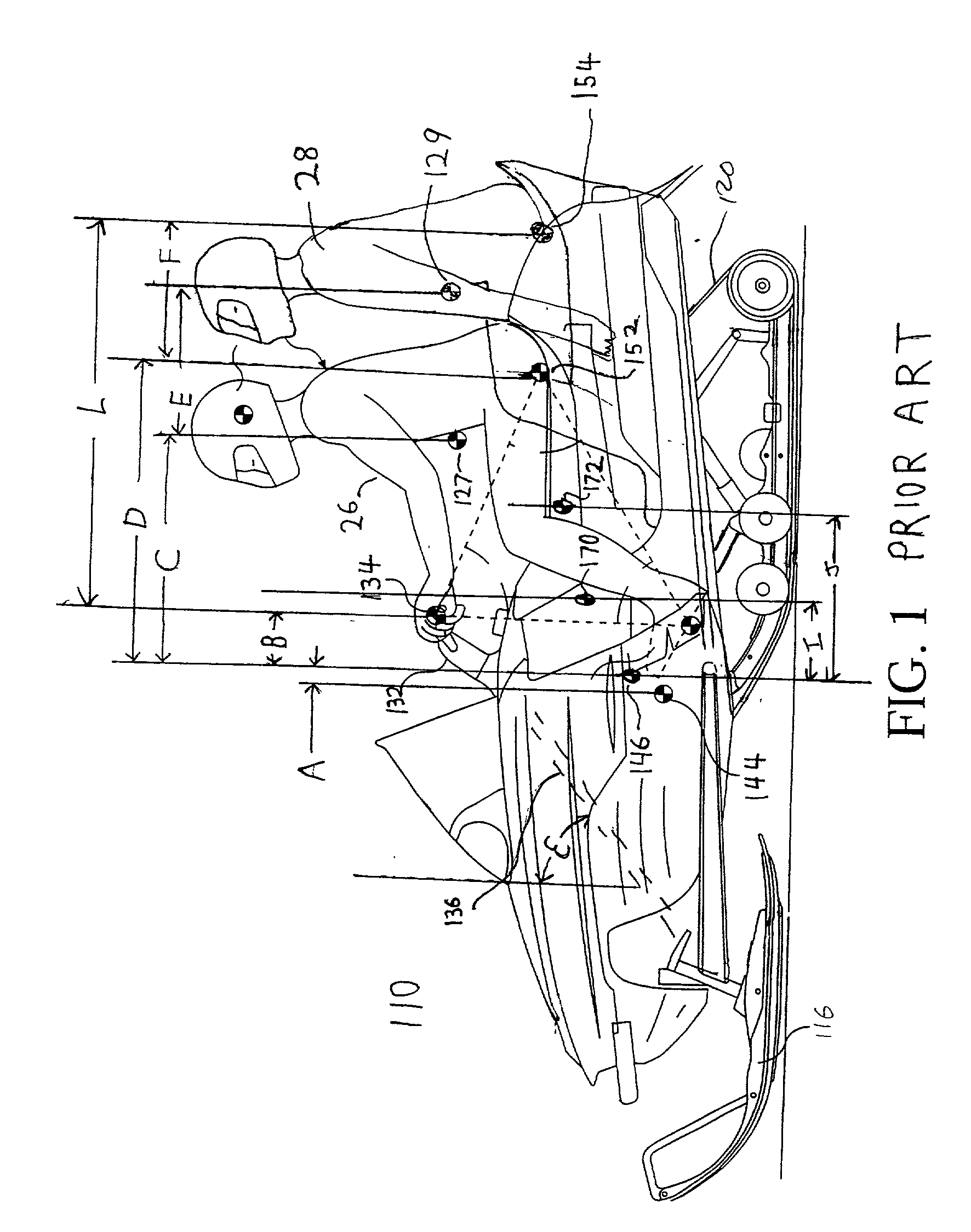

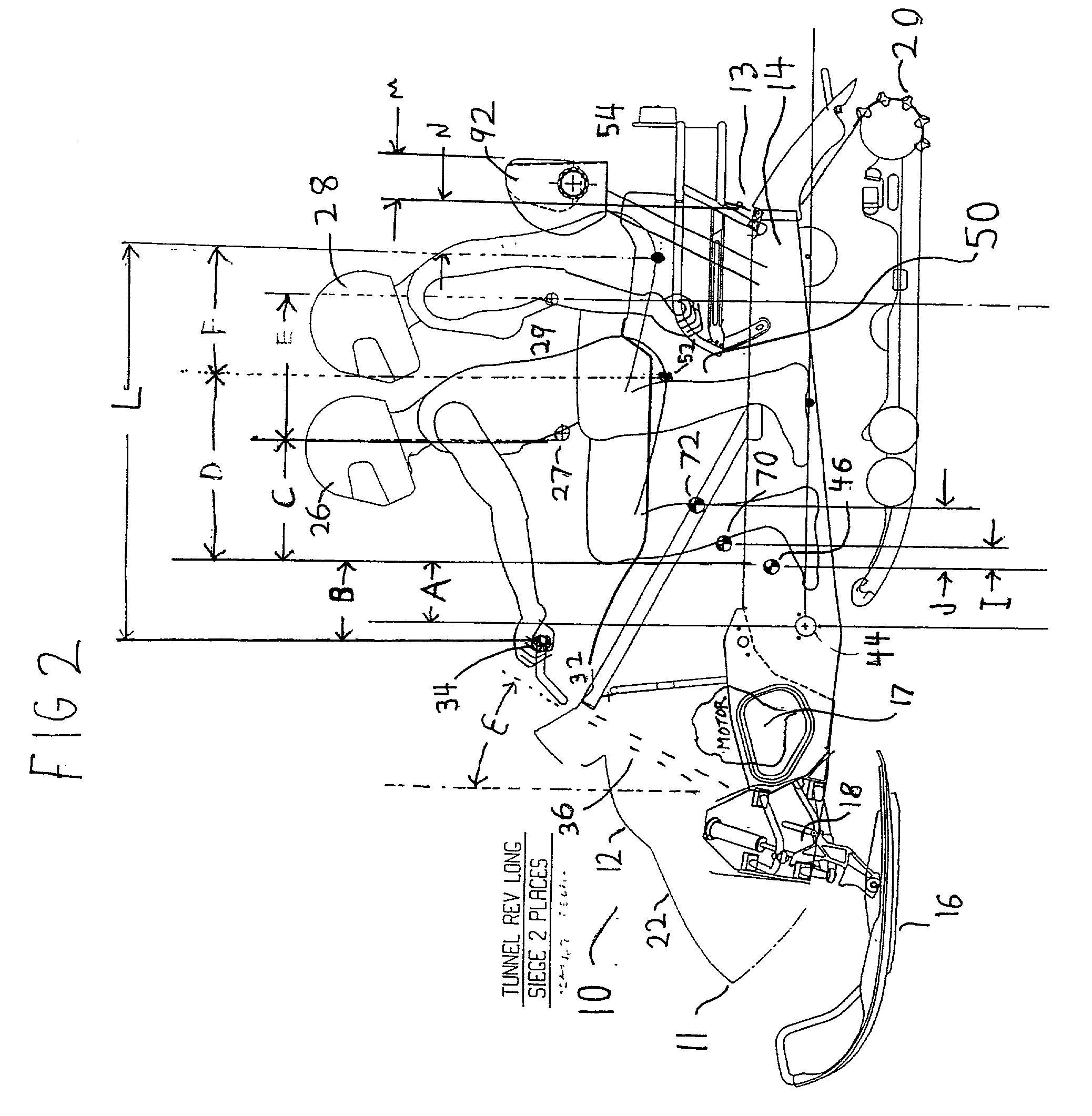

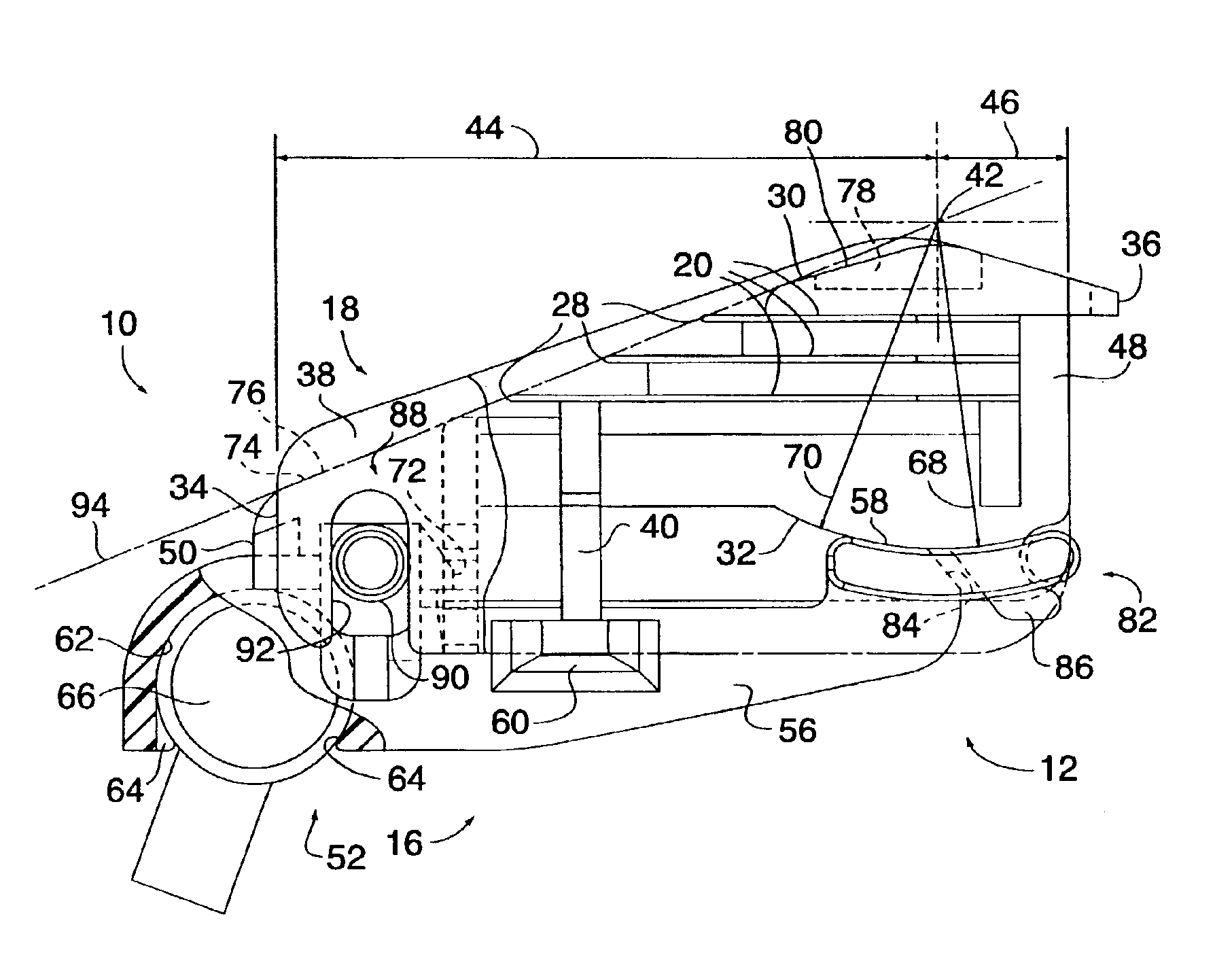

Snowmobile rider positioning

Owner:BOMBARDIER RECREATIONAL PROD INC

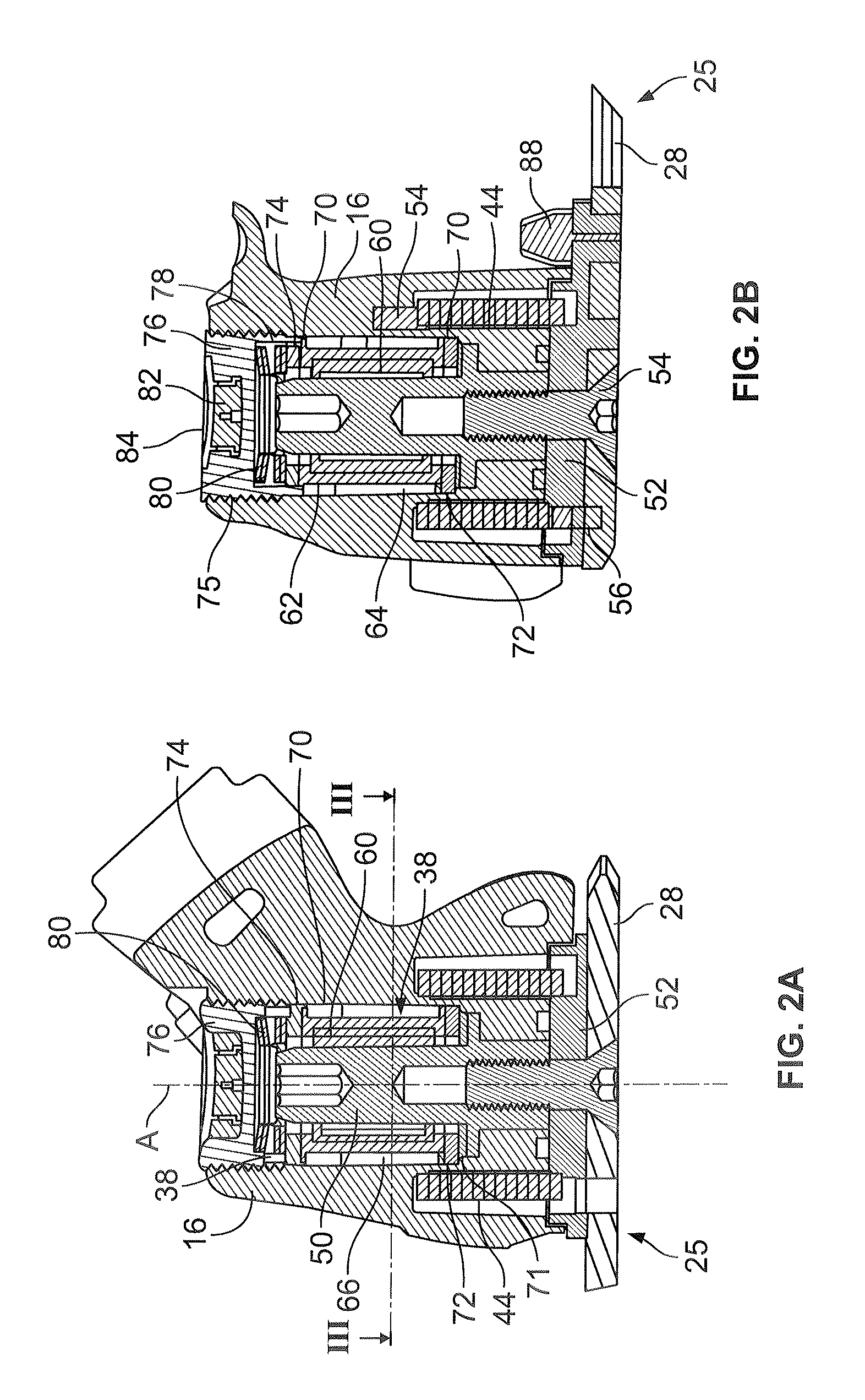

Bicycle rear derailleur with a damper assembly

ActiveUS9463846B2Compact structureSufficient contentChain/belt transmissionGearingRotational axisTurning frames

A bicycle rear derailleur includes a base member mountable to a bicycle frame. A movable member is movably coupled to the base member. A chain guide assembly is rotatably connected to the movable member for rotation about a rotational axis. A biasing device is configured to bias the chain guide assembly in a first rotational direction relative to the movable member. A damper assembly is disposed between the chain guide assembly and the movable member to apply a damping force to the chain guide assembly when the chain guide assembly rotates in a second rotational direction opposite to the first rotational direction. The damper assembly includes a one-way roller clutch assembly including radially inner and outer clutch members and roller elements acting between the inner and outer clutch members and a friction device including a friction biasing device and friction surfaces axially biased against and in frictional engagement with the one-way roller clutch assembly by the friction biasing device. The friction surfaces are axially offset with reference to the rotational axis relative to the roller elements.

Owner:SRAM +1

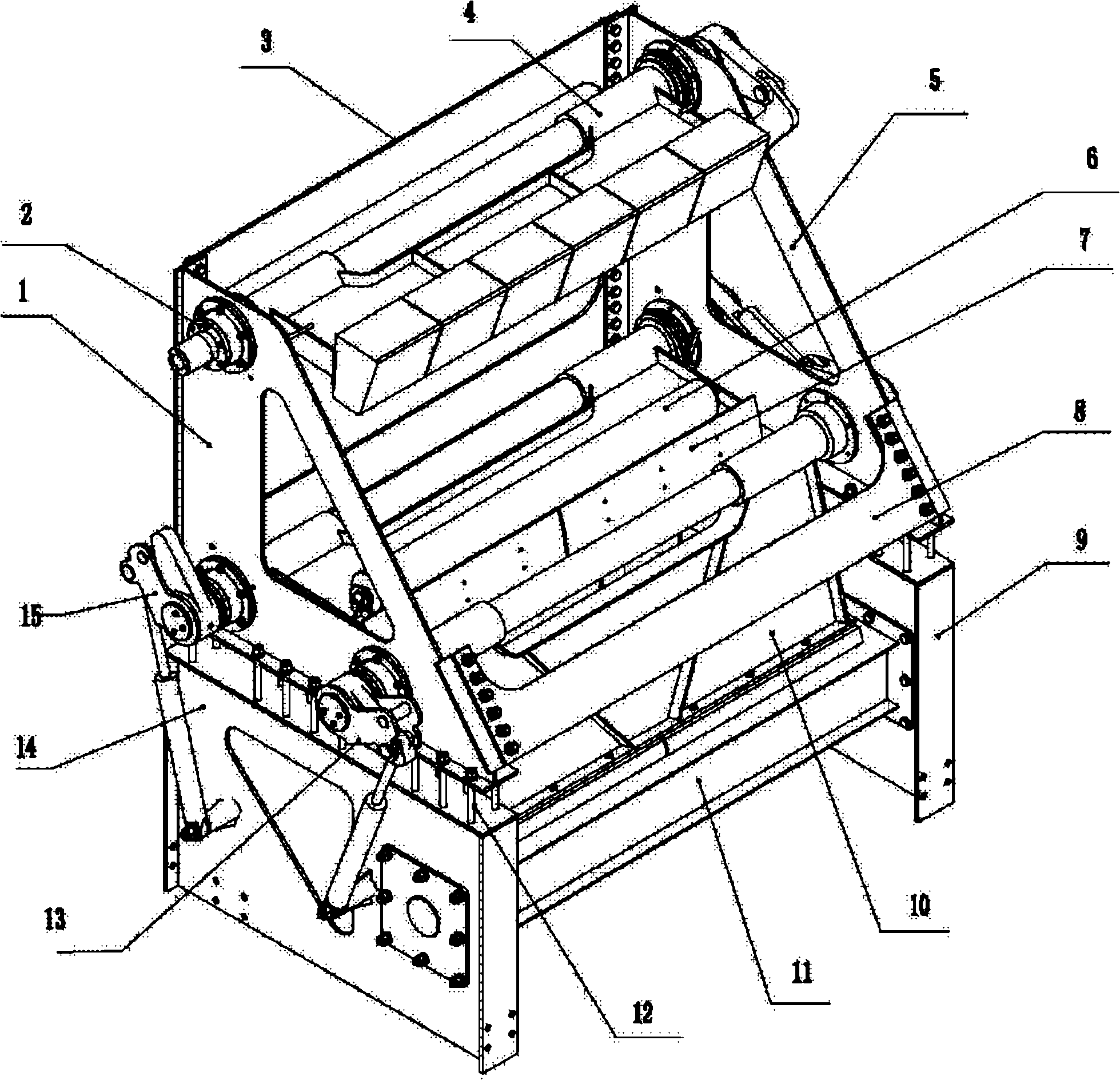

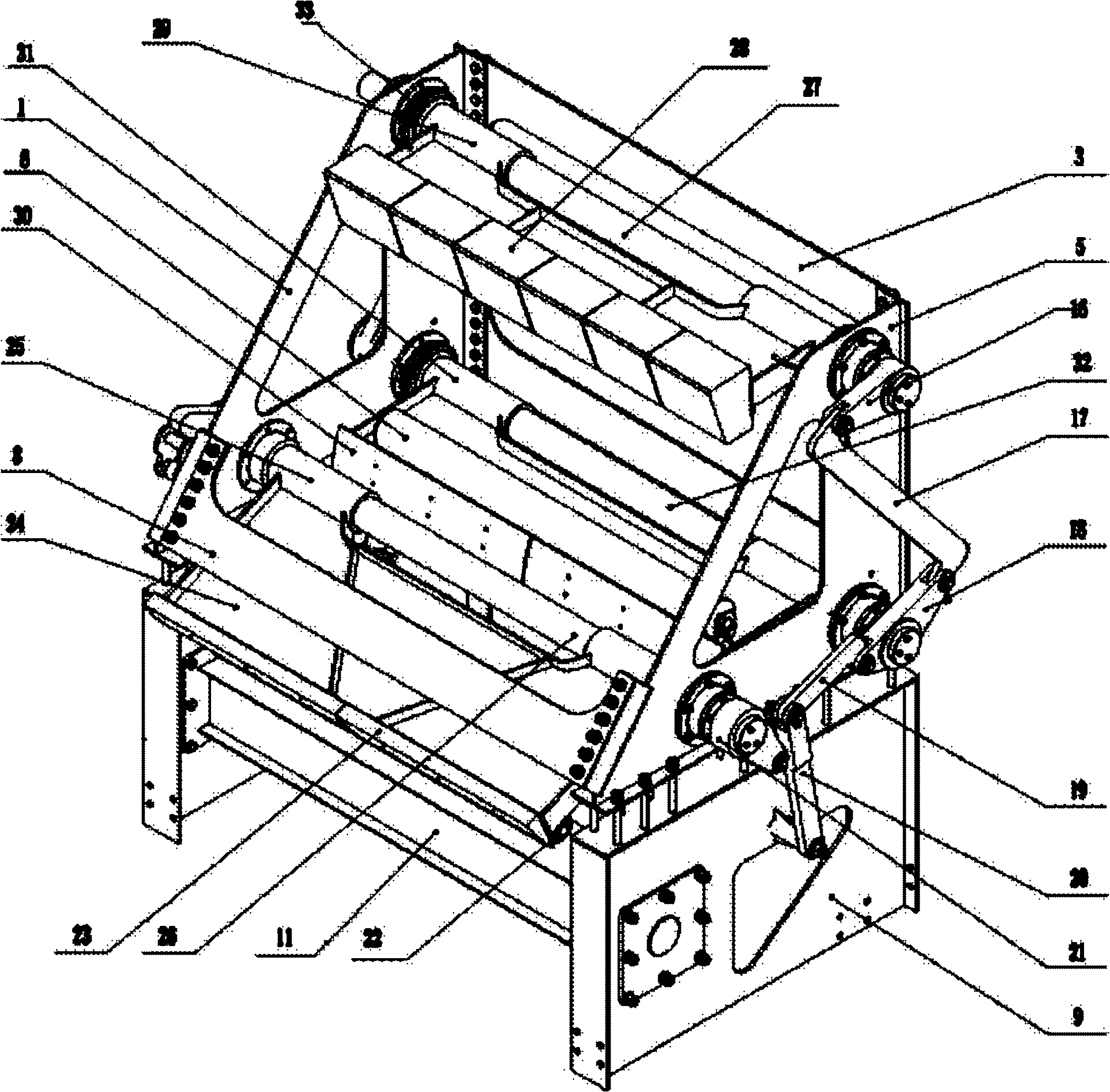

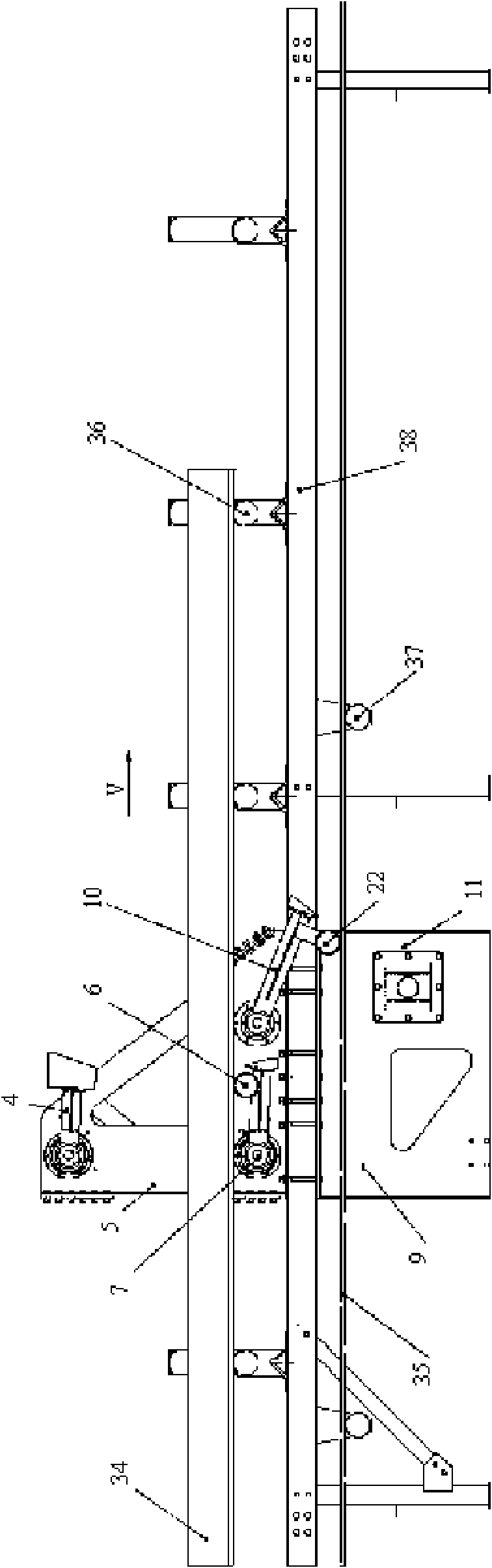

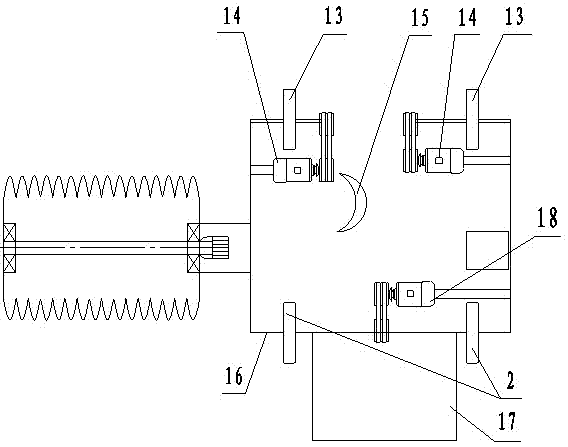

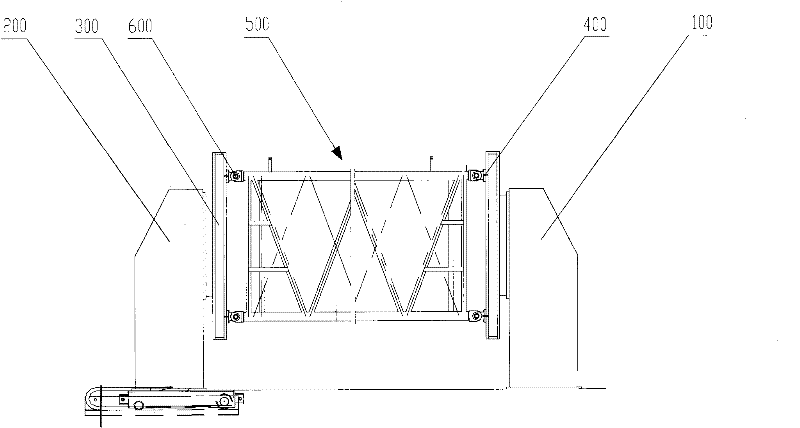

Capturing device for broken belt of belt conveyer

ActiveCN102381549ANo malfunctionLarge braking torqueControl devices for conveyorsTurning framesEngineering

The invention relates to a capturing device for a broken belt of a belt conveyer. A conveyer belt of the conveyer comprises a loading belt and a return belt. The capturing device comprises a frame, a loading rubber belt capturing mechanism, a return rubber belt capturing mechanism, an upper and lower linkage device and an adjusting unlocking mechanism, wherein the loading rubber belt capturing mechanism comprises an upper turning frame assembly and a lower turning frame assembly which are arranged in the frame, can be turned up and down and are located in a same upright position; the return rubber belt capturing mechanism comprises a return belt turning frame assembly and a cross beam; the return belt turning frame assembly is arranged in the frame, can be turned up and down and is in a same horizontal position of the lower turning frame assembly; the cross beam is located under the return belt turning frame assembly; the upper and lower linkage device is located on one outer side of the frame and comprises an upper linkage mechanism and a lower linkage mechanism; and the adjusting unlocking mechanism is located on the other outer side of the frame in the manner of being symmetrical to the upper and lower linkage device and comprises an upper capturing adjusting mechanism and a lower capturing adjusting mechanism. The capturing device provided by the invention has the advantages of compact structure, big braking force, capability of realizing the capturing linkage of the loading belt and the return belt, few malfunctions and capturing reliability, and is free from damagingthe conveyer belt.

Owner:山西慧达澳星科技有限公司

Self-propelled air suction comb tooth type lycium barbarum picking harvester

The invention provides a self-propelled air suction comb tooth type lycium barbarum picking harvester which comprises a trolley, a gasoline engine generator, a comb tooth picking device and a collecting box. A thrust handle is mounted on a frame, walking land wheels are arranged on the same end face with the thrust handle, and a steering wheel is arranged on the other end face. The gasoline engine generator and the collecting box are arranged on a platform, a sorting screen and a two-channel fan are arranged in the collecting box, and the gasoline engine generator provides a power source for a motor and the fan. The comb tooth picking device comprises a picking comb and a picking comb motor, and an induced draft fan is arranged at the end, close to the comb tooth picking device, of a conveying bag. A movable handle is held in hands to enable the comb tooth picking device to press close to lycium barbarum branches, the induced draft fan sucks air to enable lycium barbarum fruit stems to be changed to deviate from a plumb line and form an included angle of 30-90 degrees with the plumb line from being in a plumb line state, the picking comb motor drives the picking comb to rotate, lycium barbarum fruits fall off from the branches to enter the conveying bag and then enter a strip rod, and the lycium barbarum fruits drop into the collecting box after being sorted by the fan.

Owner:SHANDONG UNIV OF TECH

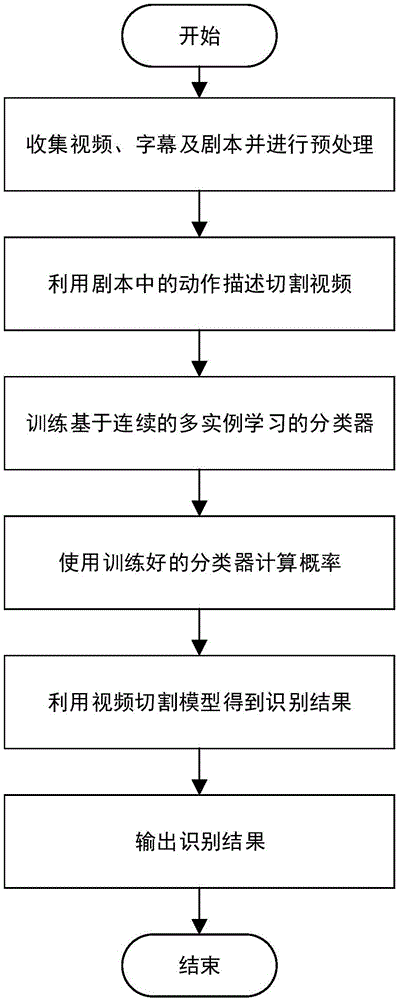

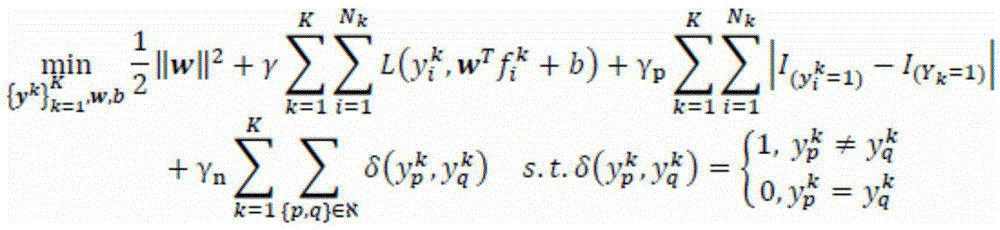

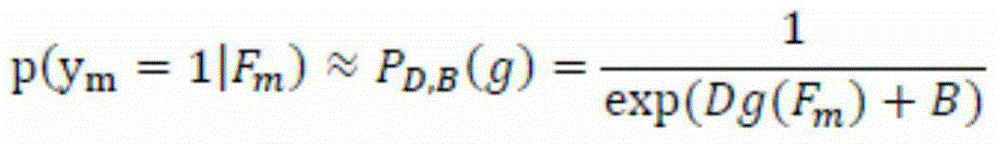

Method for identifying actions in video based on continuous multi-instance learning

ActiveCN105138953AImprove accuracyReduce ambiguityCharacter and pattern recognitionUser inputTurning frames

The invention discloses a method for identifying actions in a video based on continuous multi-instance learning. The method comprises the following steps that: 1, film data used as training data sample sets are collected from video websites, pre-processing is simultaneously carried out on subtitles and scripts collected on the websites, and action description in the scripts is used as video grade weak marks of training data; 2, a video is cut into a plurality of video fragments through the weak marks, each video fragment is composed of one action, and for each action, action classifiers based on the continuous multi-instance learning are trained by means of the video fragments; 3, a user inputs a video to be identified into the plurality of trained action classifiers, and the probability that each frame of the video to be identified belongs to the action is calculated; and 4, the action type of each frame is obtained by a video cutting model, and the action types are returned to the user. The method solves the problem that manual marking wastes time and labor, and ambiguity problem caused by the weak marks and turning frames is simultaneously relieved.

Owner:ZHEJIANG UNIV

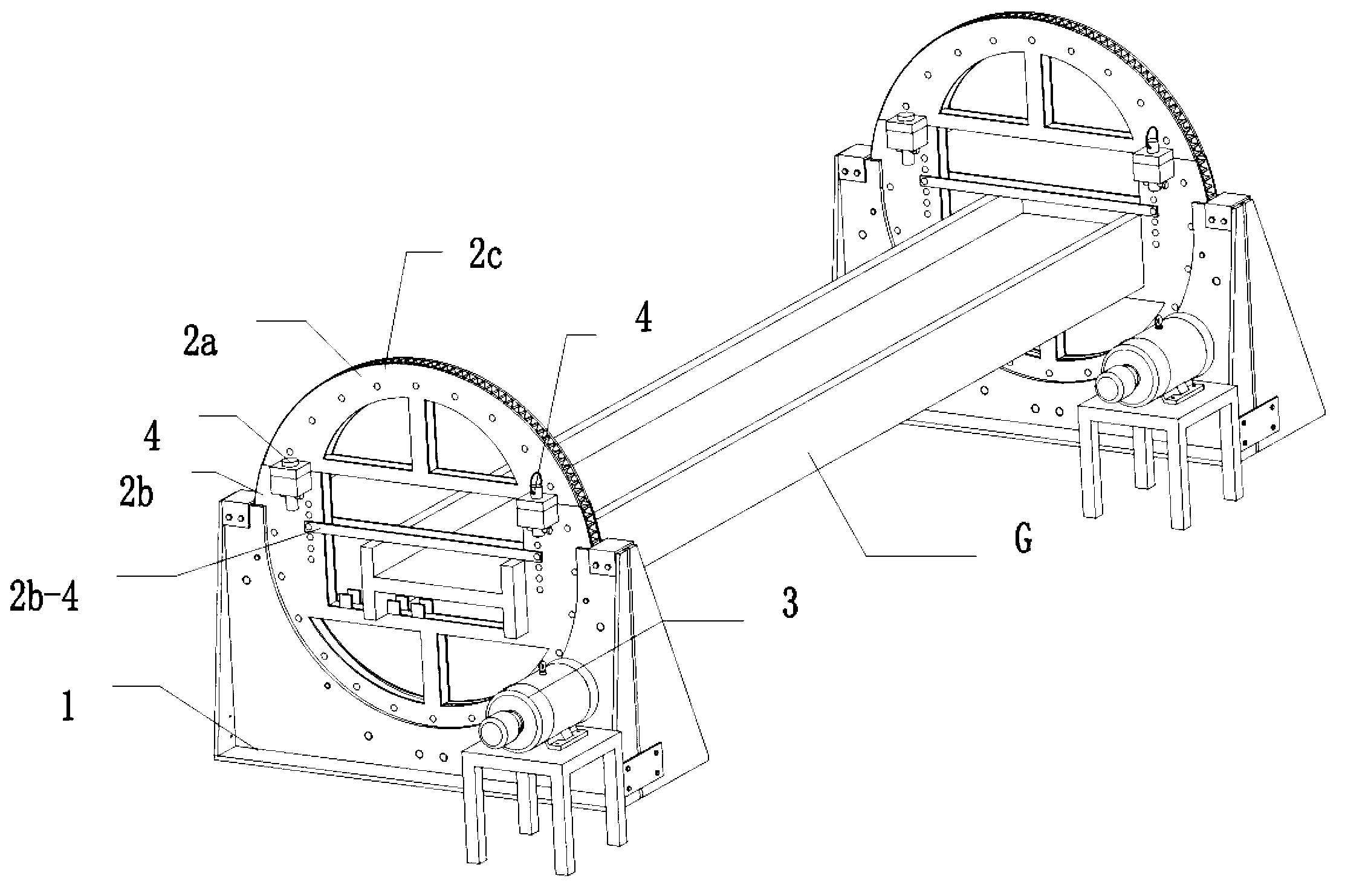

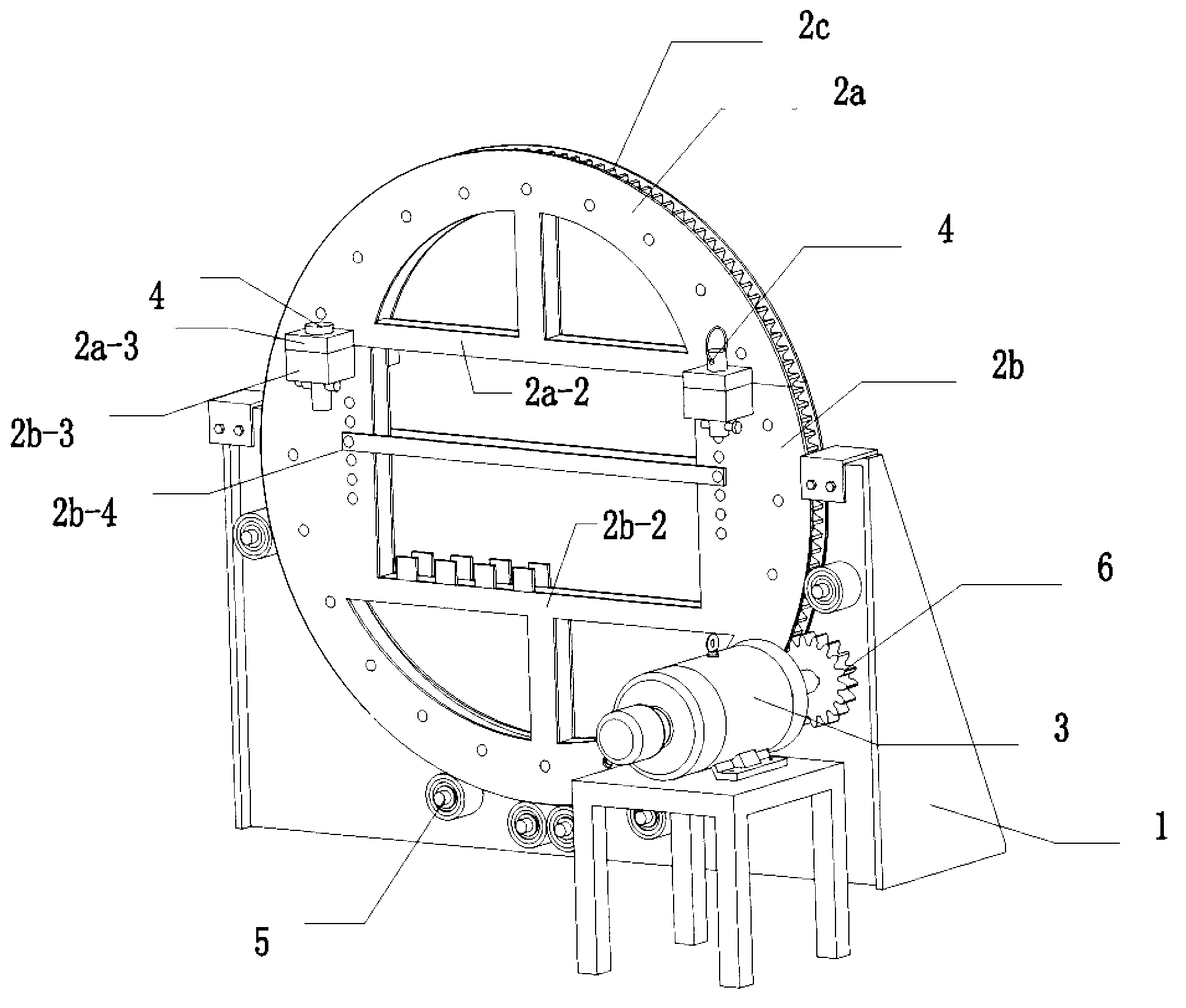

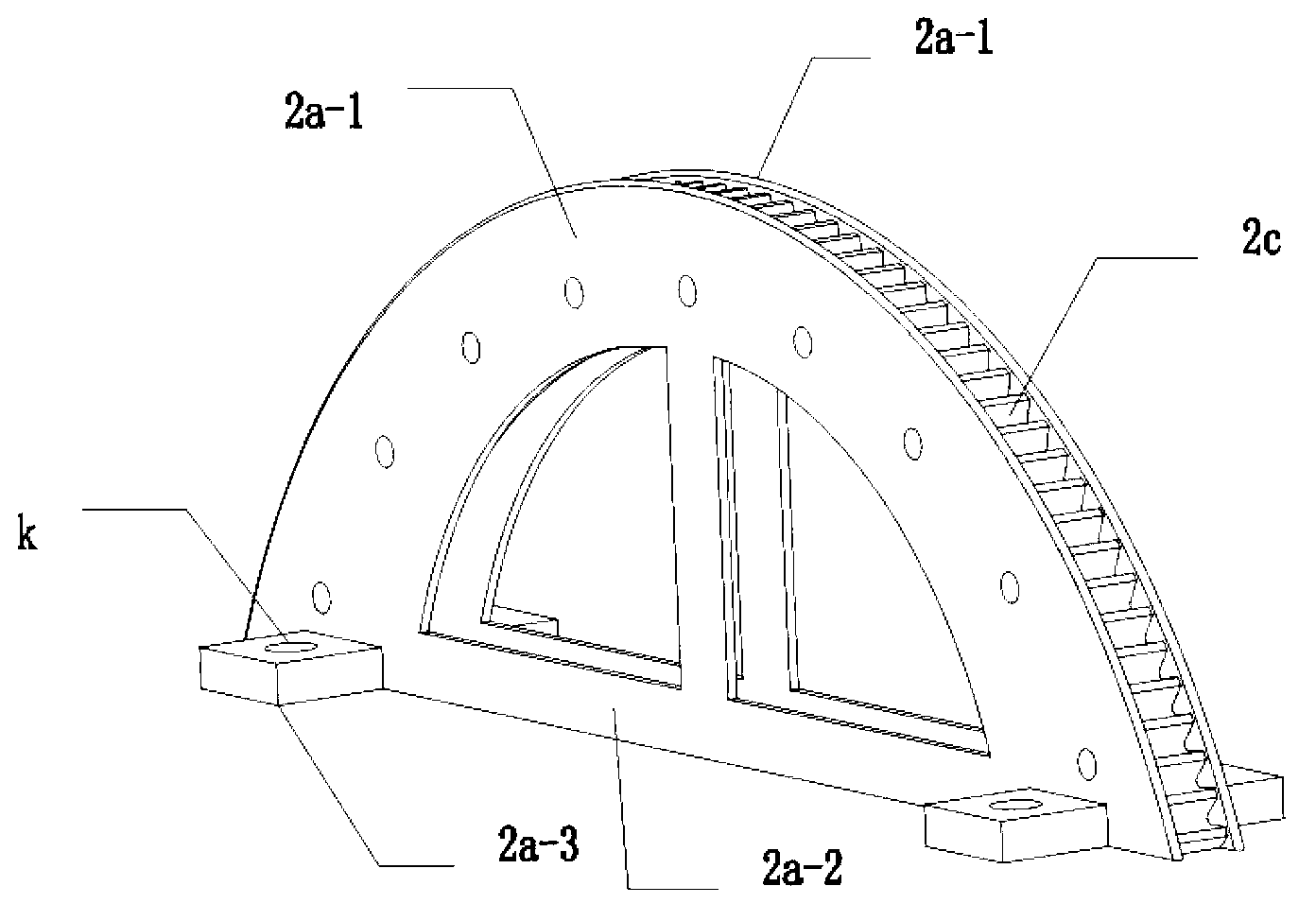

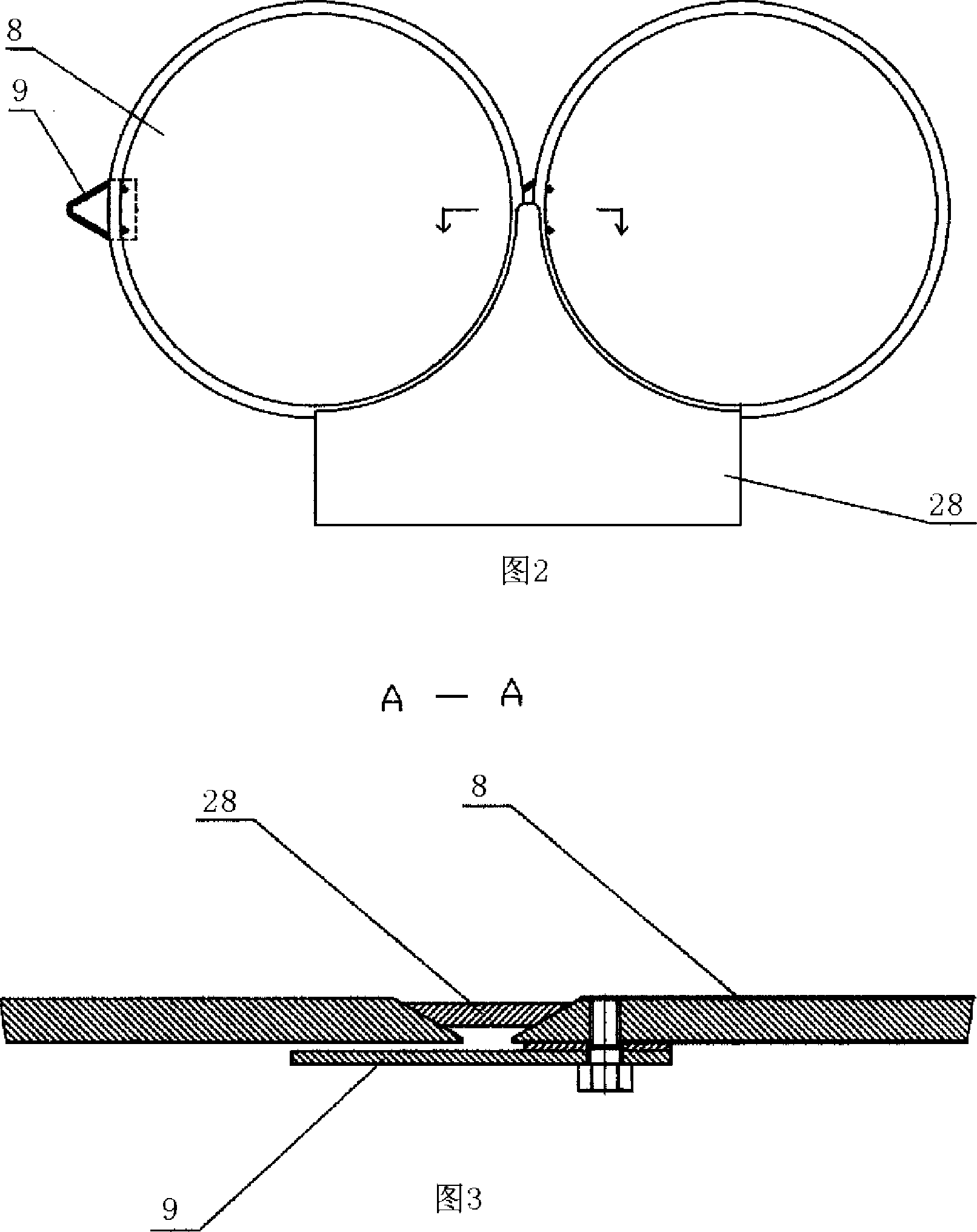

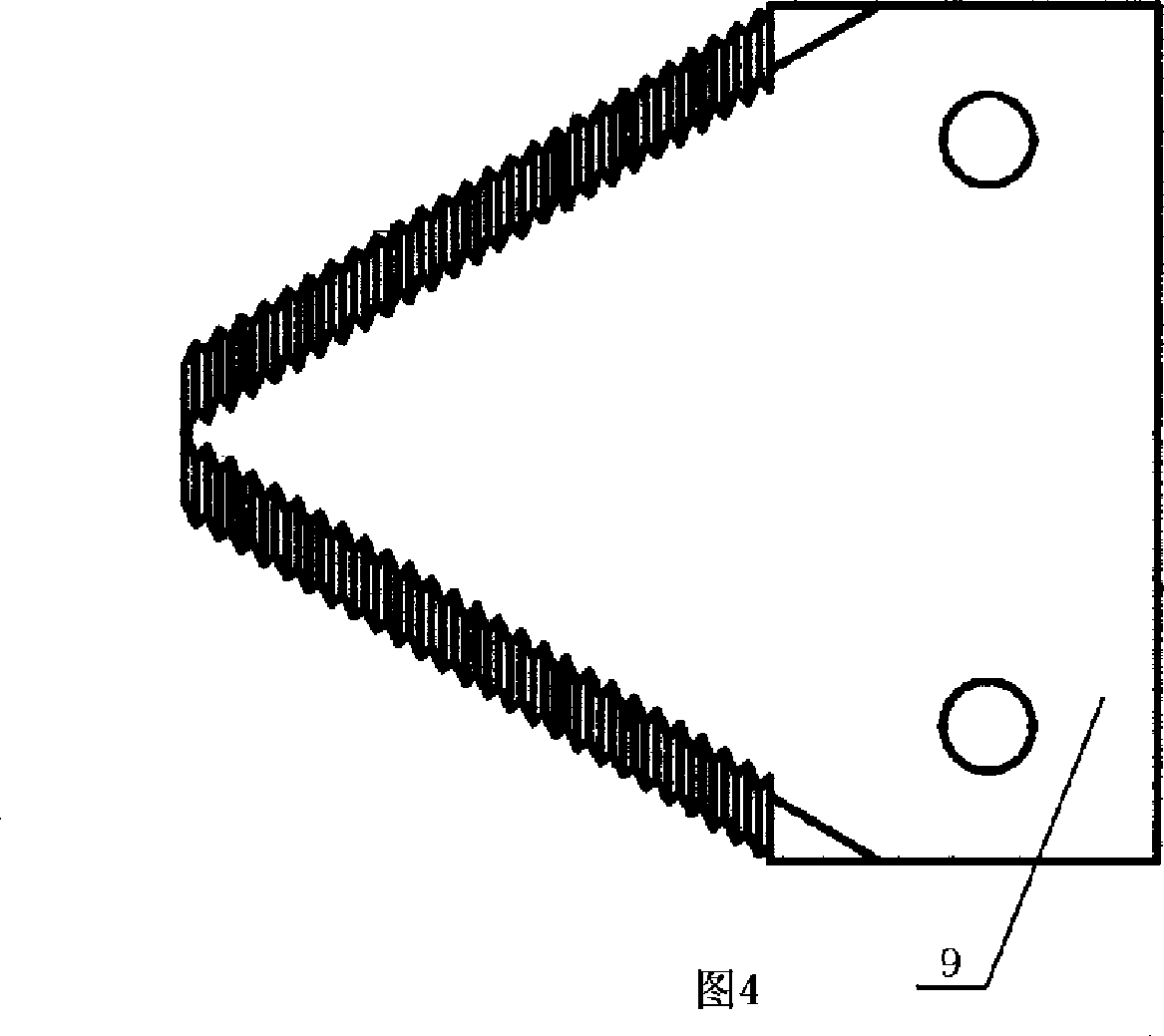

H-shaped steel turning device

InactiveCN102794591AHigh turnover efficiencyLabor savingWelding/cutting auxillary devicesAuxillary welding devicesSynchronous motorGear wheel

The invention discloses an H-shaped steel turning device and belongs to the field of a frock machine tool of a machine. The H-shaped steel turning device comprises two same turning machines, wherein the turning machine comprises a base, a turning frame and a motor; the turning frame is an open-close type round turning frame comprising an upper frame body and a lower frame body connected through a pin shaft; racks are embedded along the arc peripheries of the upper frame body and the lower frame body respectively; an H-shaped steel frame position is formed between the upper frame body and the lower frame body; the periphery of the turning frame is arranged in an arc-shaped track of the base in a matched way; the motor is engaged with the racks on the periphery of the round turning frame through a small gear of an output shaft of the motor so as to drive the turning frame to rotate; the two ends of H-shaped steel are respectively mounted in the H-shaped steel frame positions of the two turning machines; and the two turning machines adopt synchronous motors and drive the two turning frames to synchronously rotate with the H-shaped steel. The H-shaped steel can be turned through the device without a travelling crane and large quantities of auxiliary labors, so that the turning efficiency is high, the labor force and the operation time are saved, the operation is safe and convenient, and the production efficiency of products is improved.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

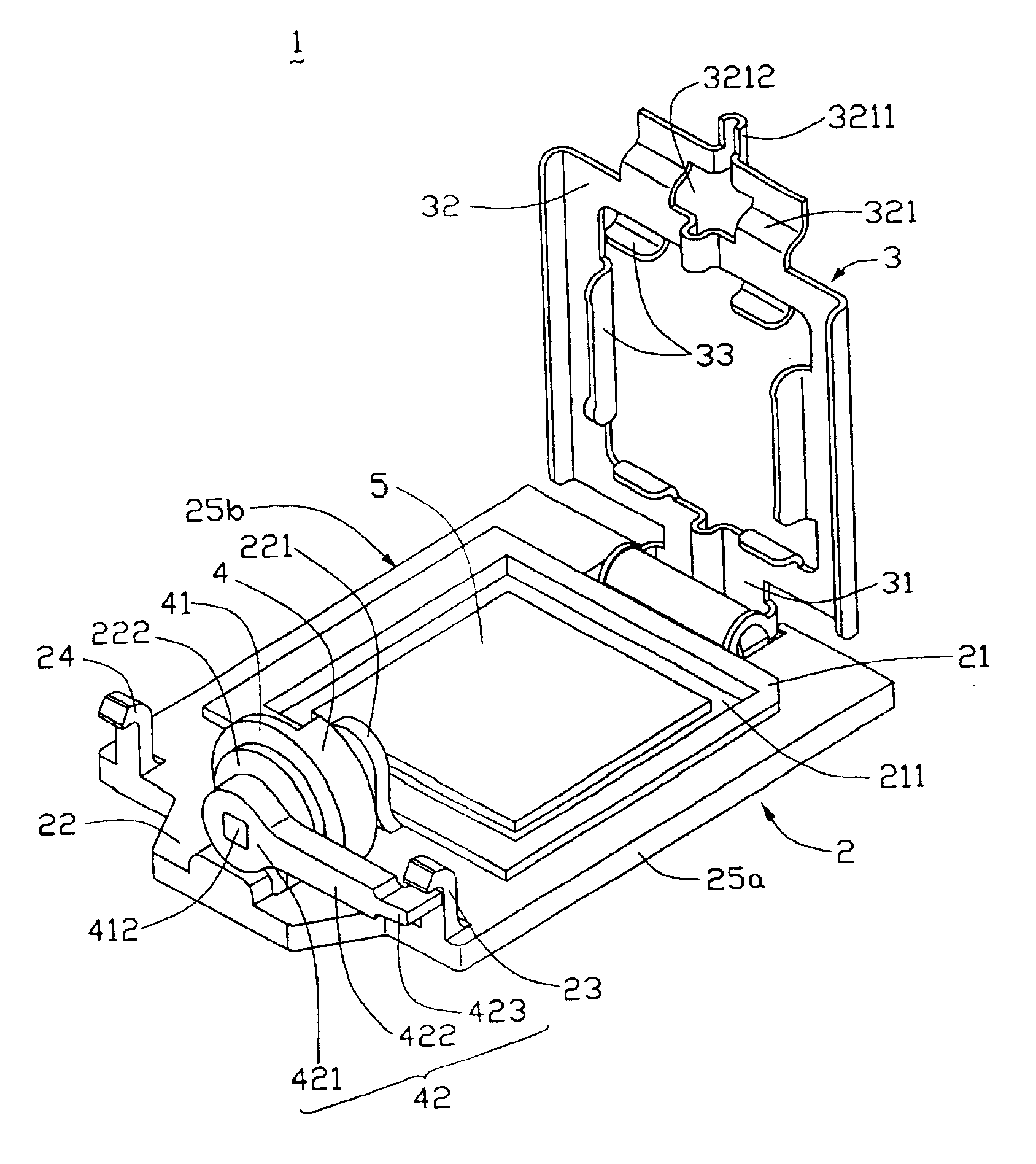

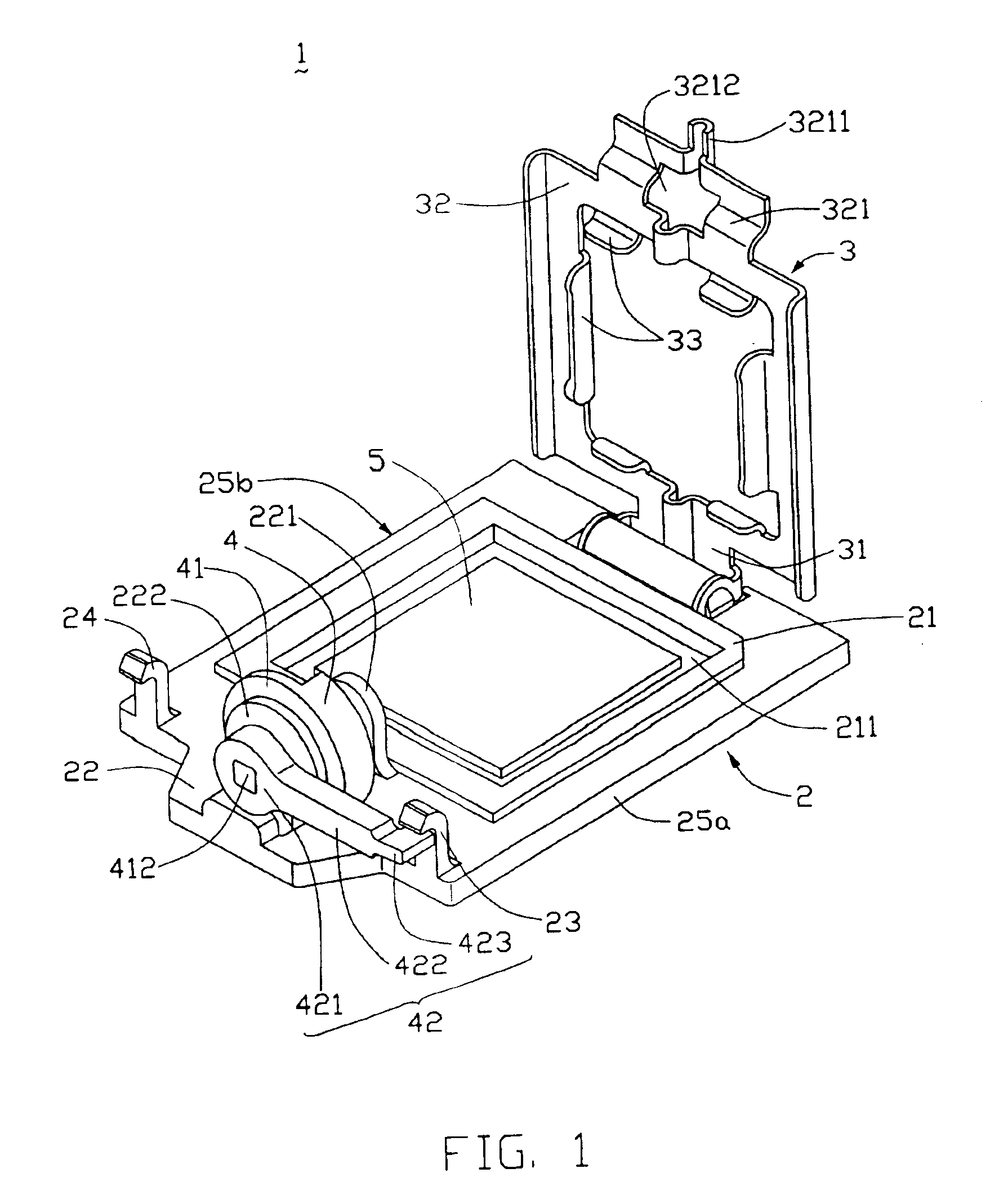

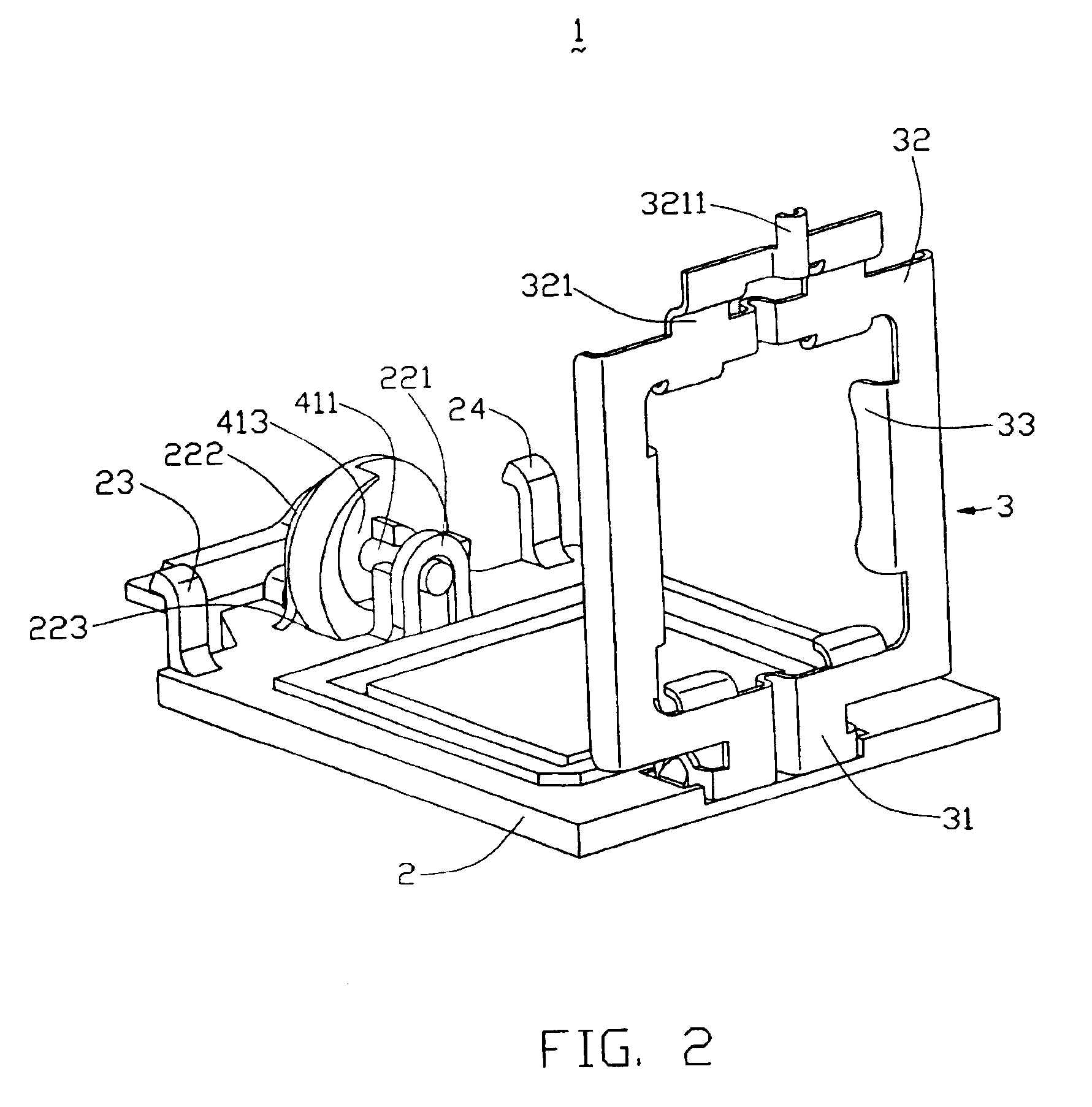

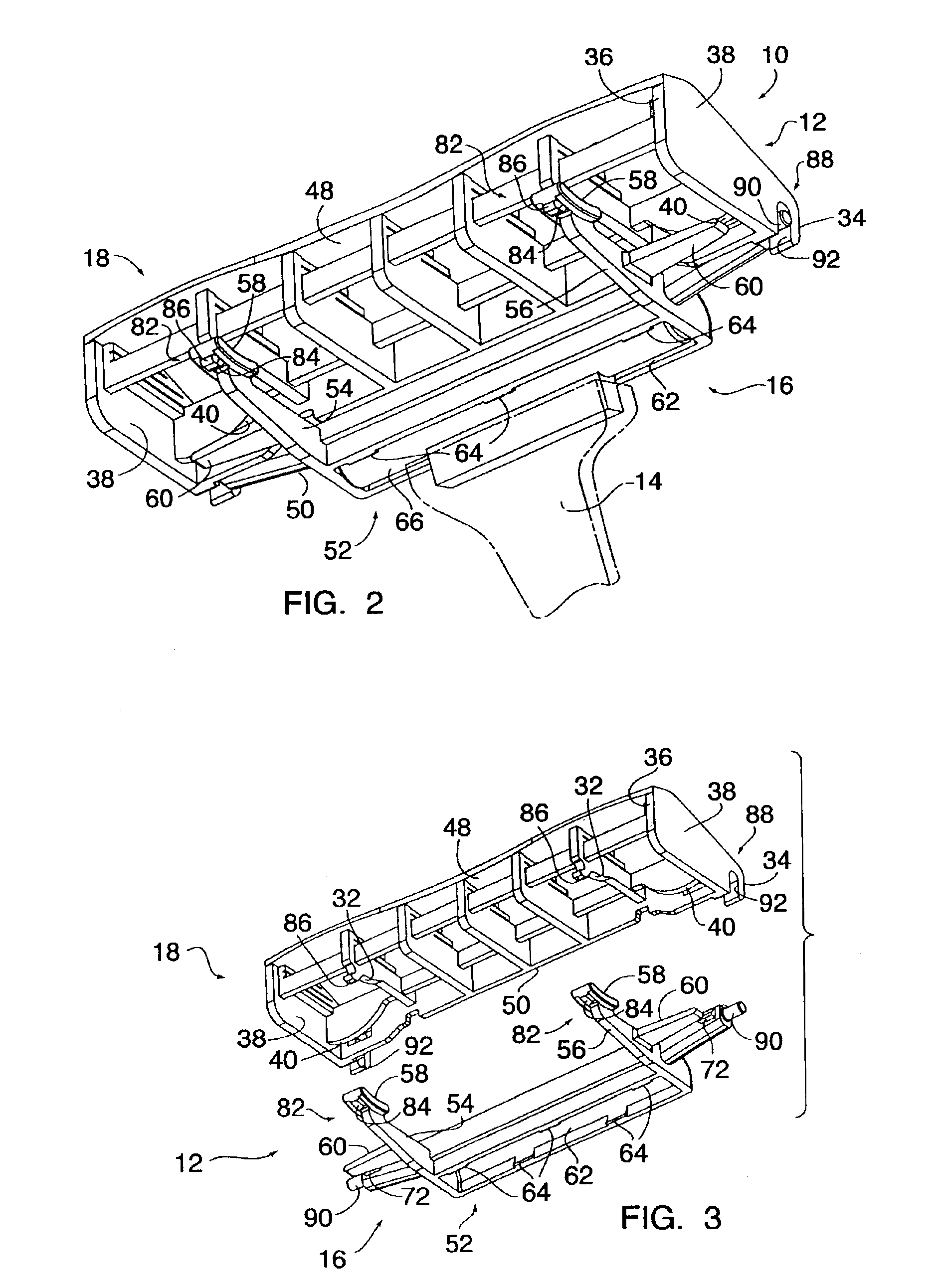

Land grid array connector assembly with compact cam driver

InactiveUS6875038B1Engagement/disengagement of coupling partsCoupling contact membersDriver/operatorTurning frames

Owner:HON HAI PRECISION IND CO LTD

Portable steel tube inner wall de-rusting vehicle

The invention discloses a portable steel tube inner wall de-rusting vehicle. Steel wire wheels and polishing wheels are arranged on motor shaft brackets of a de-rusting motor of a vehicle body through a frame, so that the de-rusting motor can rotate to drive the steel wire wheels and the polishing wheels to de-rust and polish the interior of a steel tube; springs in limiting grooves perform tensioning on limiting supporting beams, so that wheels on the limiting supporting beams are attached to the inner wall of the steel tube; meanwhile, the limiting supporting beams are connected to the frame and a sleeve through connecting rods, and the sleeve is adjusted by an adjusting nut, so that the distance between the limiting supporting beams and a central shaft is adjusted, and the vehicle body can adapt to more steel tubes with different inner diameters. Thus, the de-dusting vehicle can effectively remove rust and dust on the inner wall of the steel tube, does not raise the dust, and is good in using effect; the inner wall of the steel tube is cleanly de-rusted, and the treated inner wall of the steel tube is brighter; meanwhile, the dust is prevented from floating in a using process, and the environmental pollution is avoided.

Owner:河北德瑞环保设备有限公司

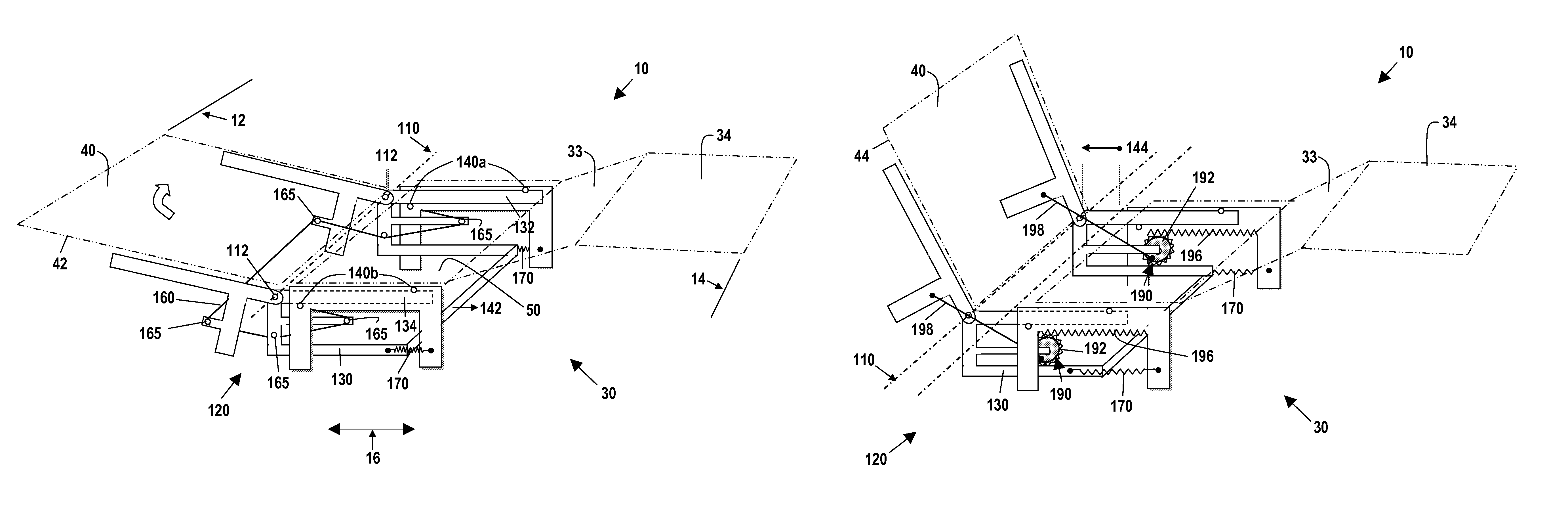

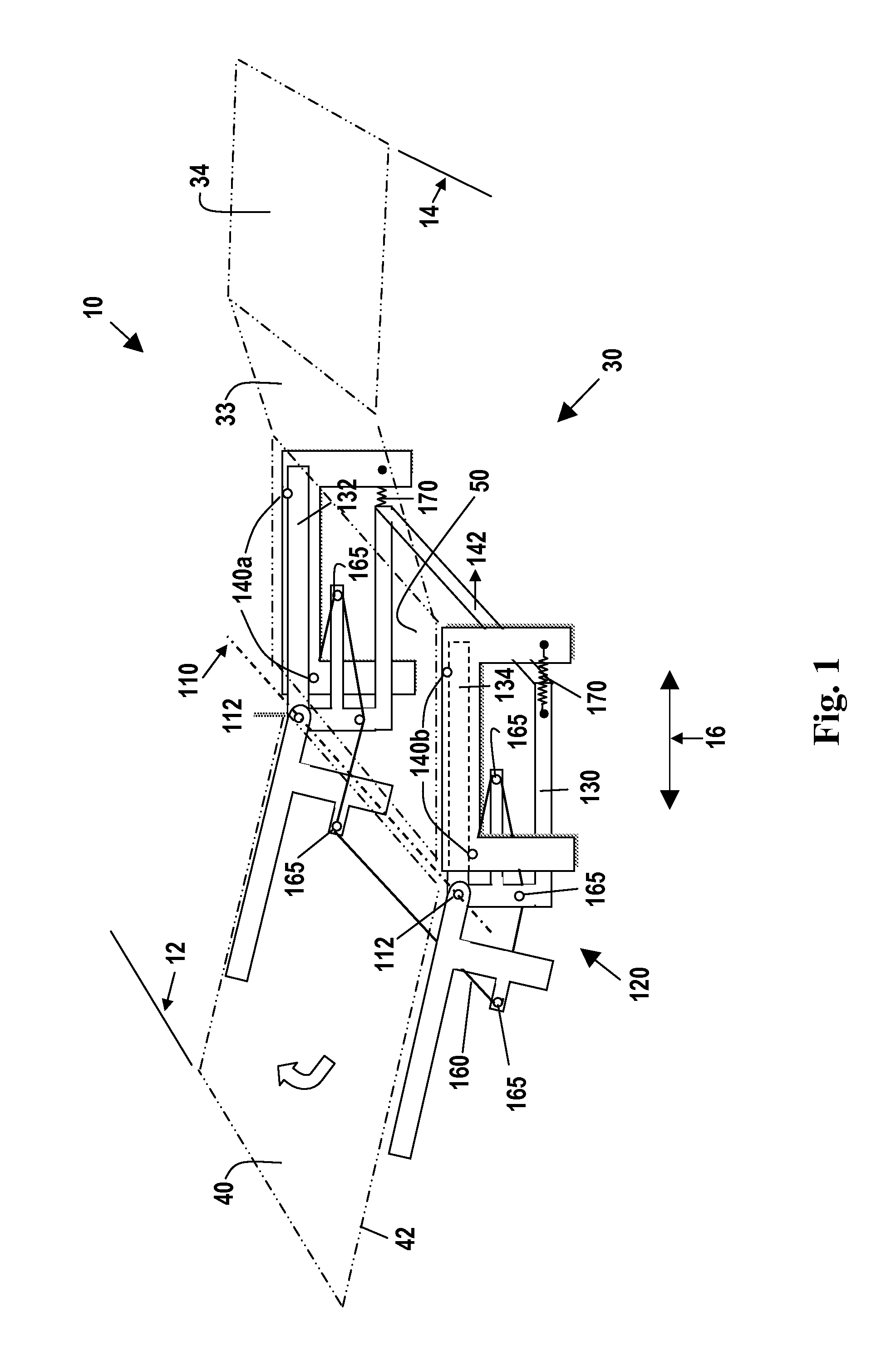

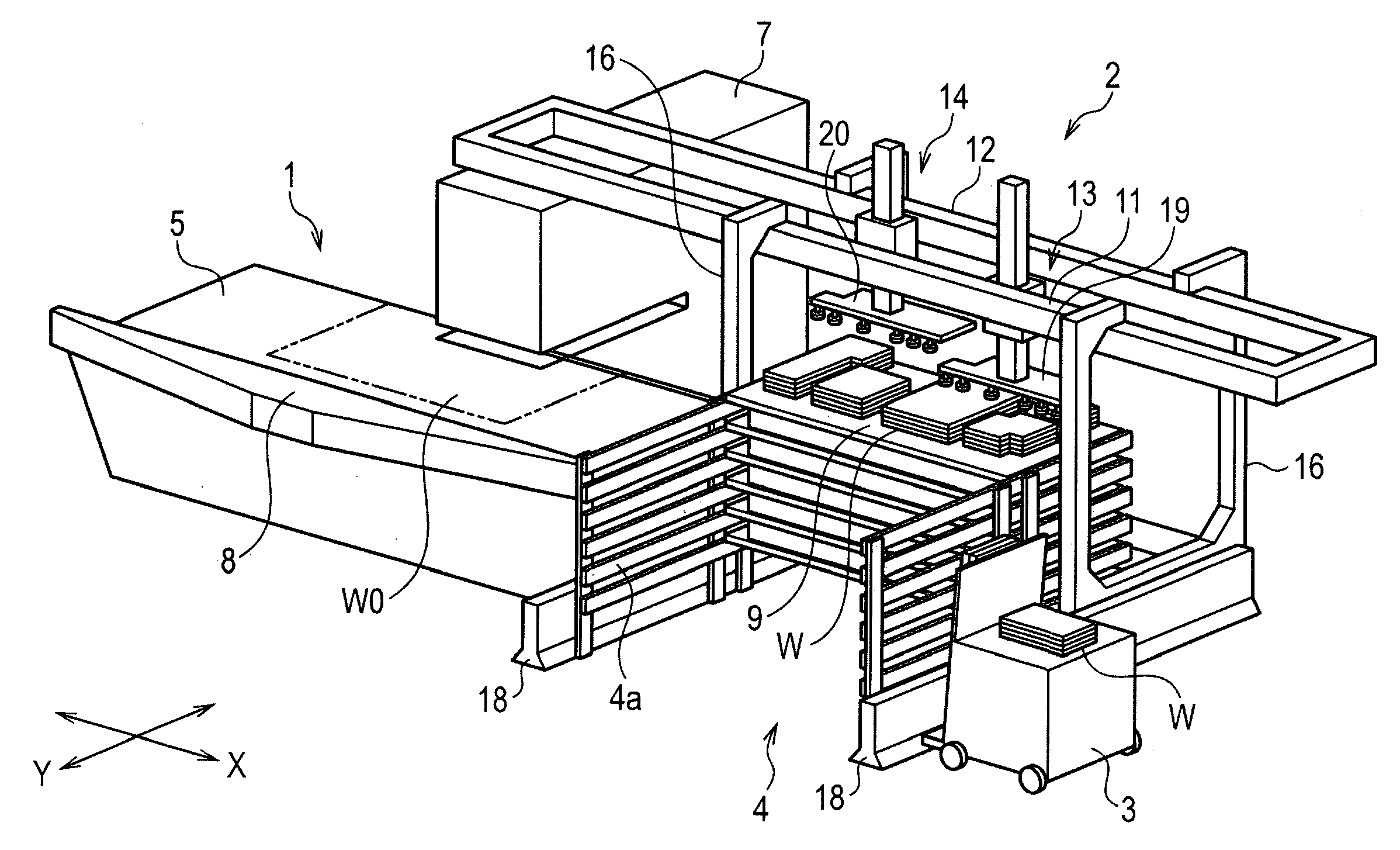

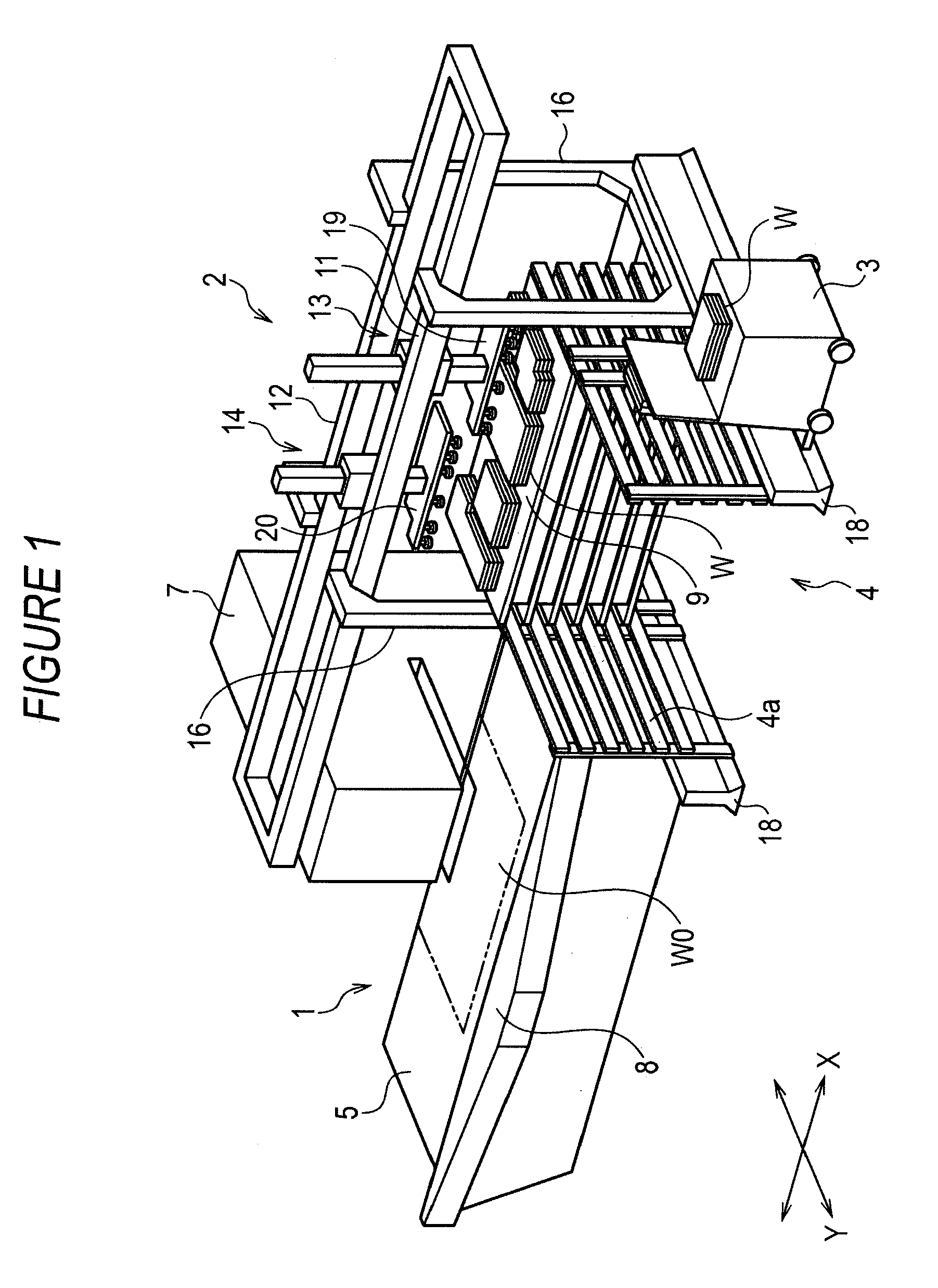

Plate material conveying device

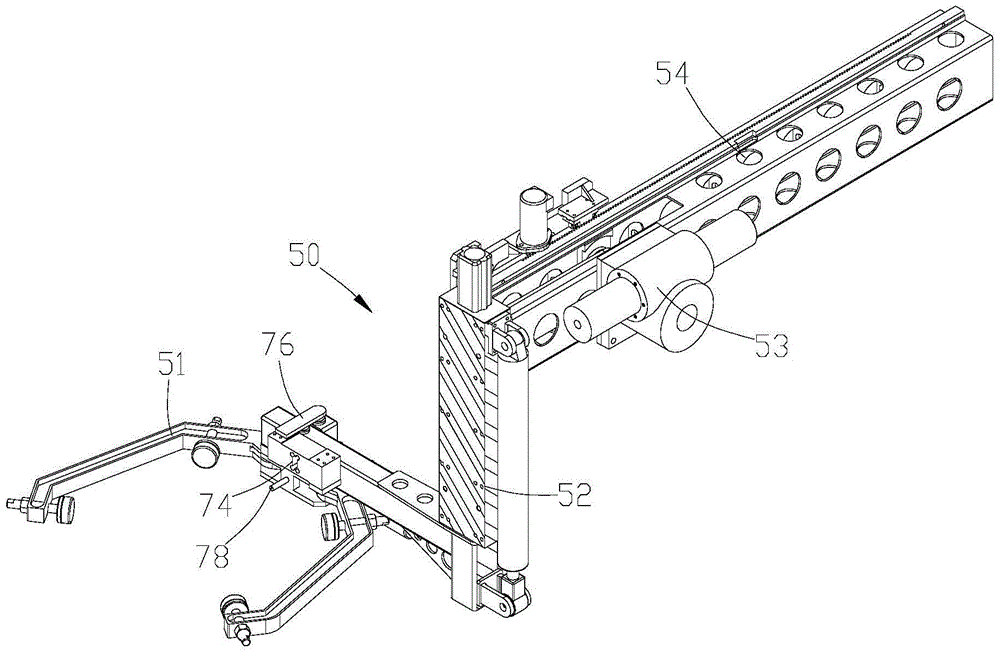

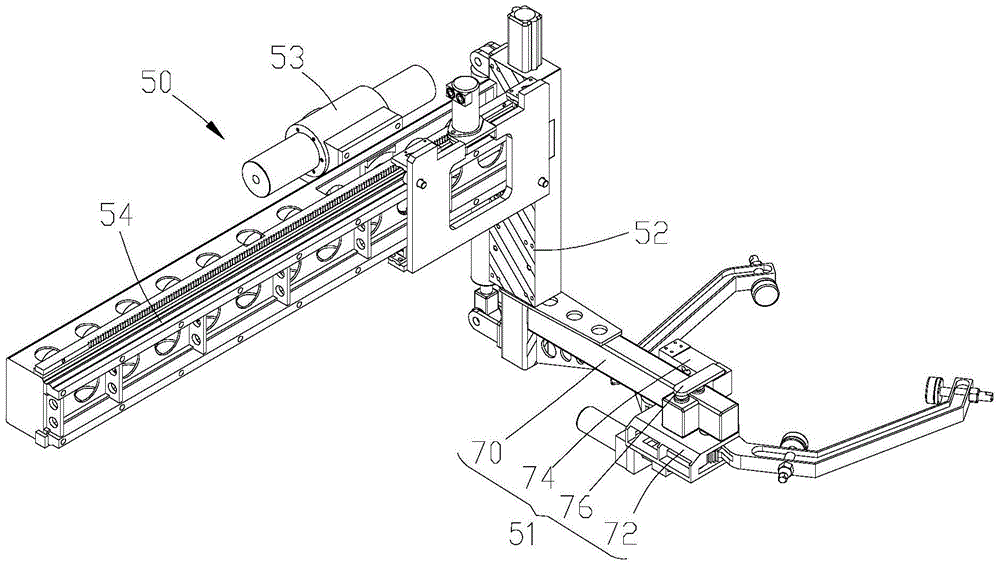

InactiveUS20090263218A1Efficiently conveyedSimple materialProgramme-controlled manipulatorGripping headsTurning framesEngineering

The present invention provides a plate material conveying device including a compact traveling member to enable an increase in plate material conveyance speed and a reduction in time required for acceleration and deceleration and to allow small plate materials to be more efficiently conveyed, the plate material conveying device further enabling one of a gripper and a suction type plate material holder to be selected for conveyance of a plate material. Traveling members 13, 14 are provided on respective tracks 11, 12 so as to travel freely along the respective tracks 11, 12. Each of the traveling members 13, 14 has a plate material holder support frame 21, 22 supporting suction type plate material holders 23A, 23B, 23C. The plate material holder support frame 21, 22 has a frame main body 21a, 22a, and a turning frame 21b, 22b which is turnable in a substantially horizontal direction with respect to the frame main body 21a, 22a and which is turnable to a position where the supported plate material planarly overlaps the adjacent track. Each of the turning frames 21b, 22b has a gripper 60 gripping an end of the plate material. An opening of the gripper is configured to face a central side of the plate material.

Owner:MURATA MASCH LTD

Dump truck

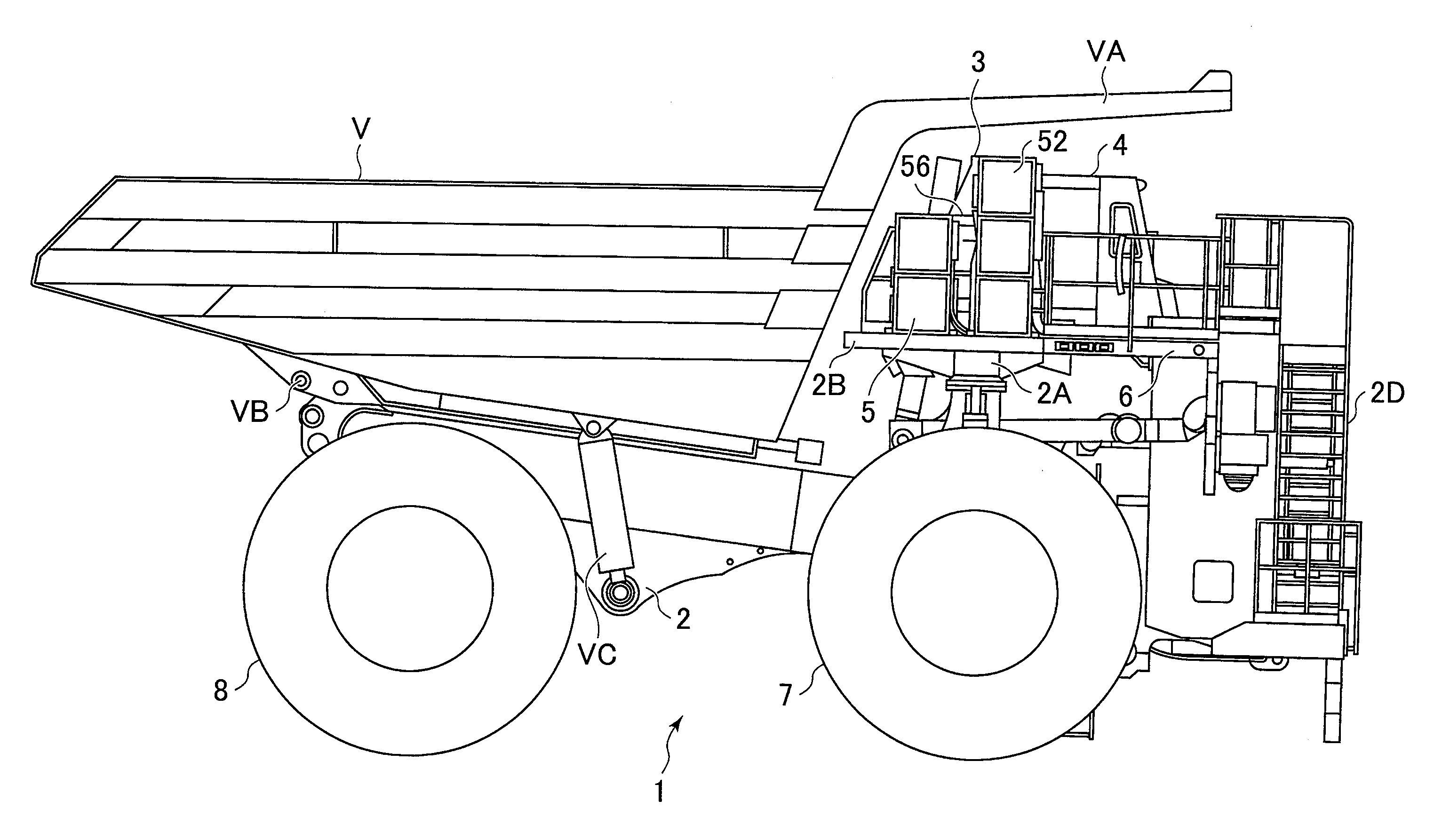

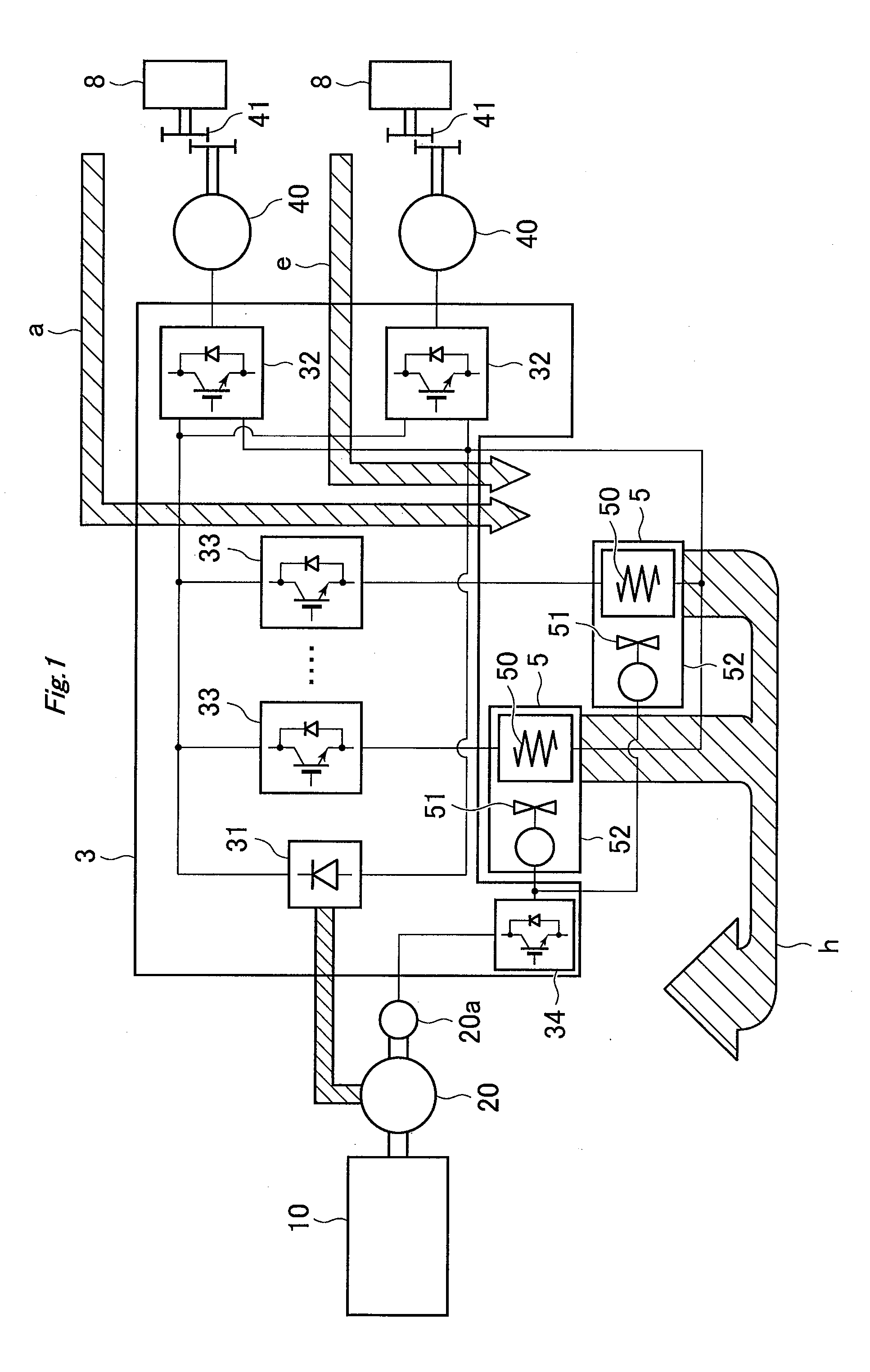

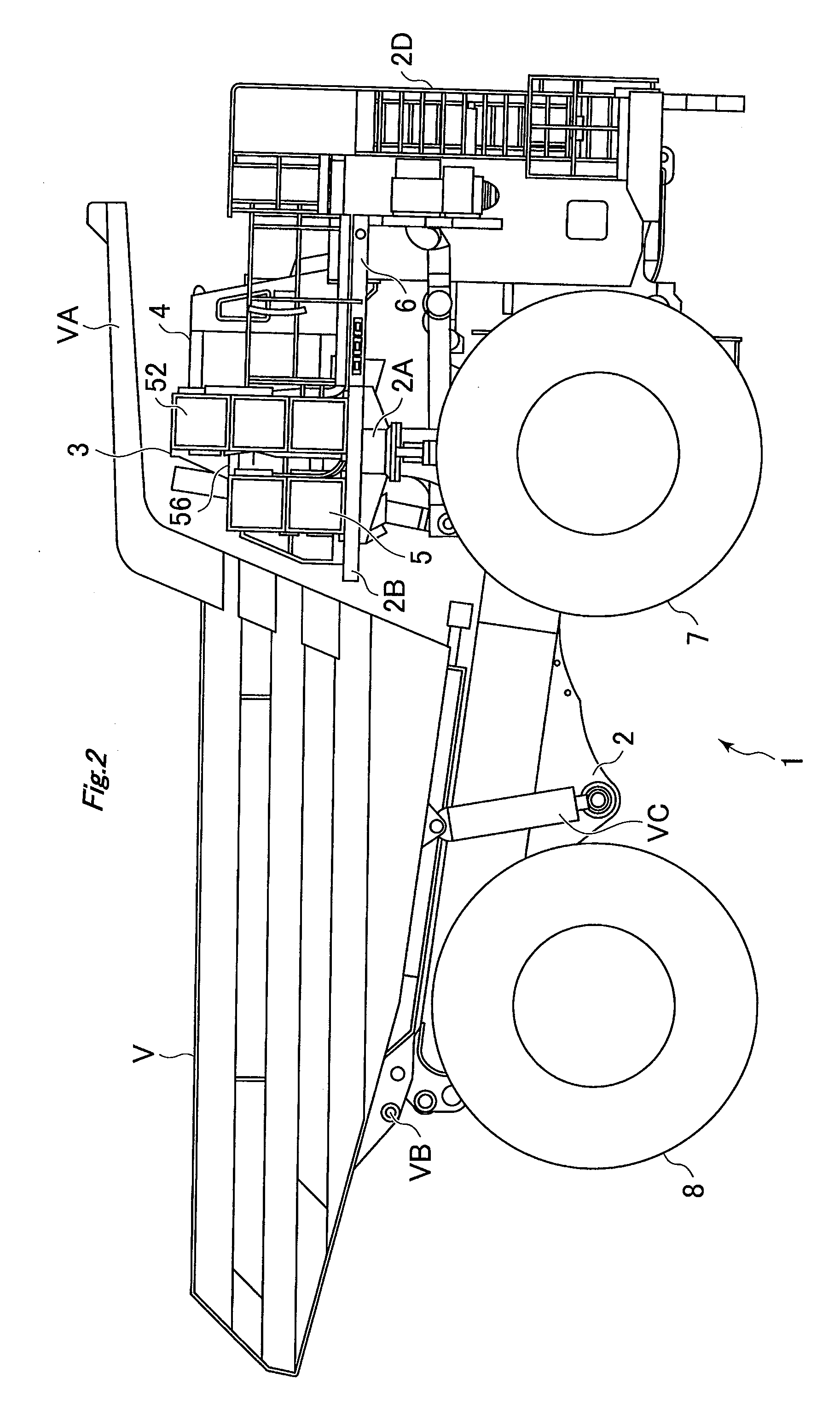

ActiveUS20100051359A1Easily propagatedImprove noise levelDC motor speed/torque controlTemperatue controlVisibilityTurning frames

An electrically-driven dump truck 1 uses resistors to convert electric power generated during retarder braking operation into heat energy. A body frame 2 has front and rear wheels, a support base 2A, a cab 4 mounted on an upper left surface of the support base, and a control cabinet 3 mounted on an upper surface of the support base. A plurality of resistor boxes 5 are mounted on an upper base plate 2B and are arranged in a stacked manner such that the plurality of resistor boxes 5 are located to the right of the control cabinet 3 in order to secure right side visibility from the cab 4. Each resistor box has a casing with plural resistors connected in parallel, an inlet port and an outlet port. A fan for cooling the resistors is housed in the casing.

Owner:NIHON KENKI CO LTD +1

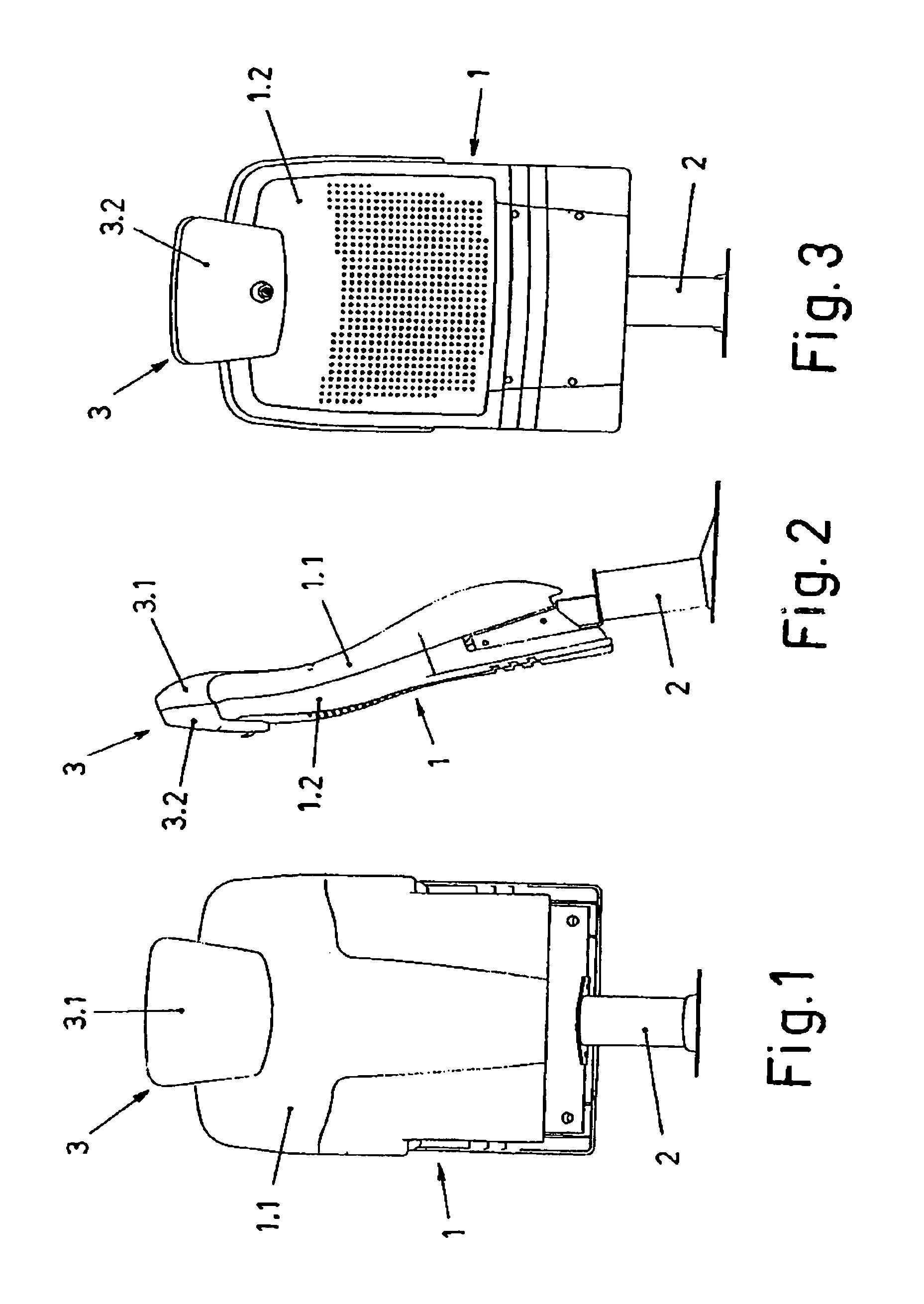

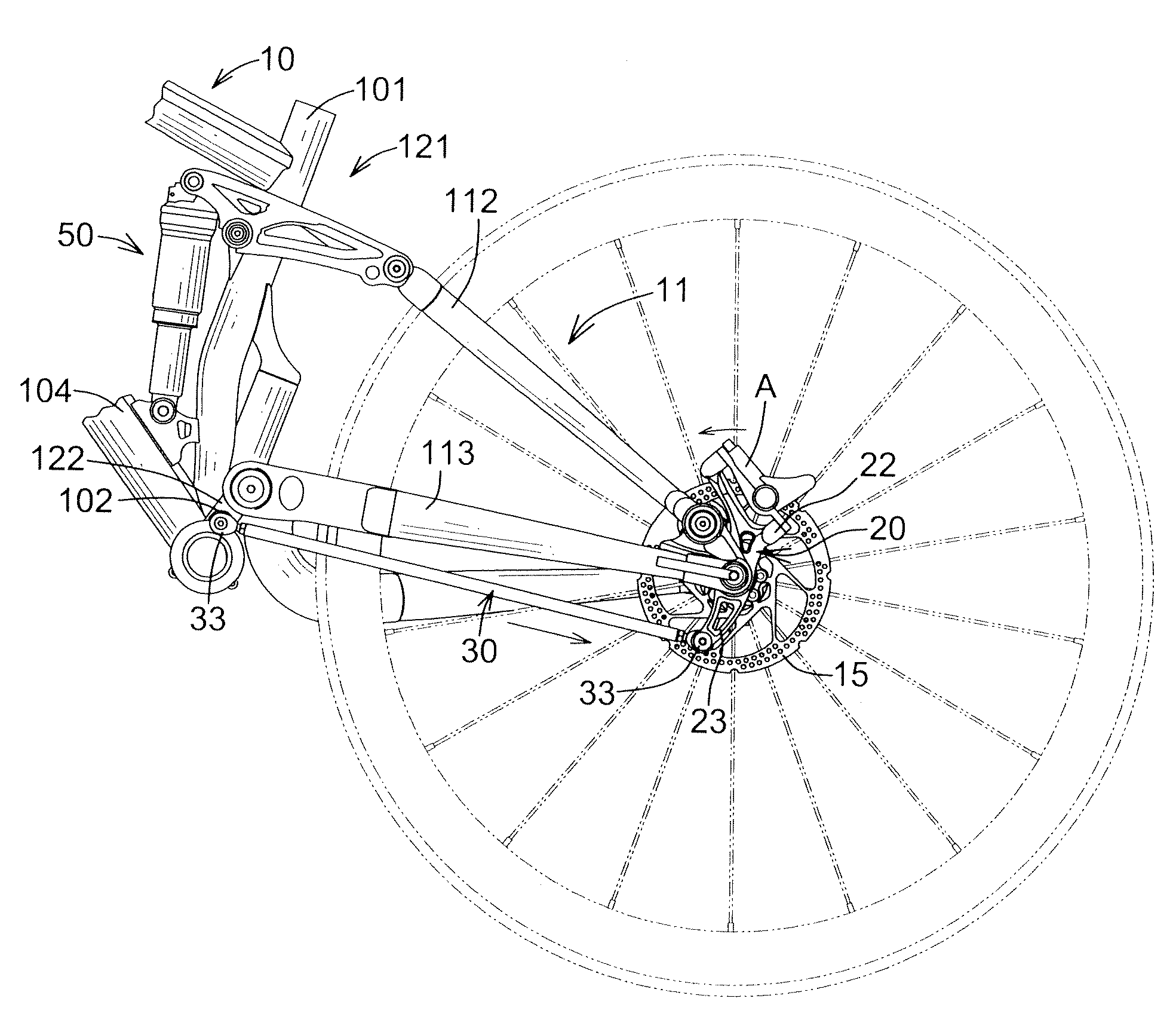

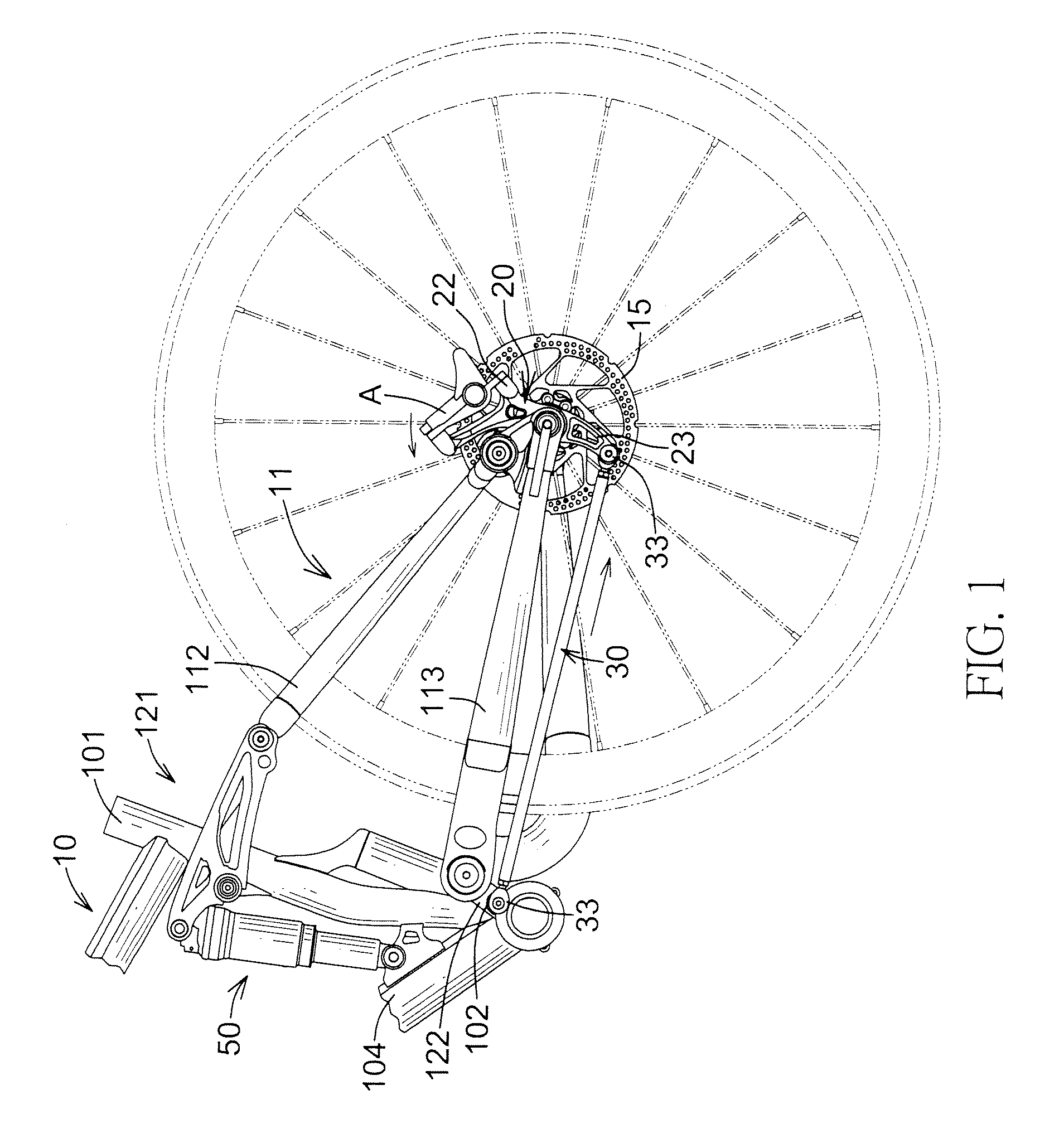

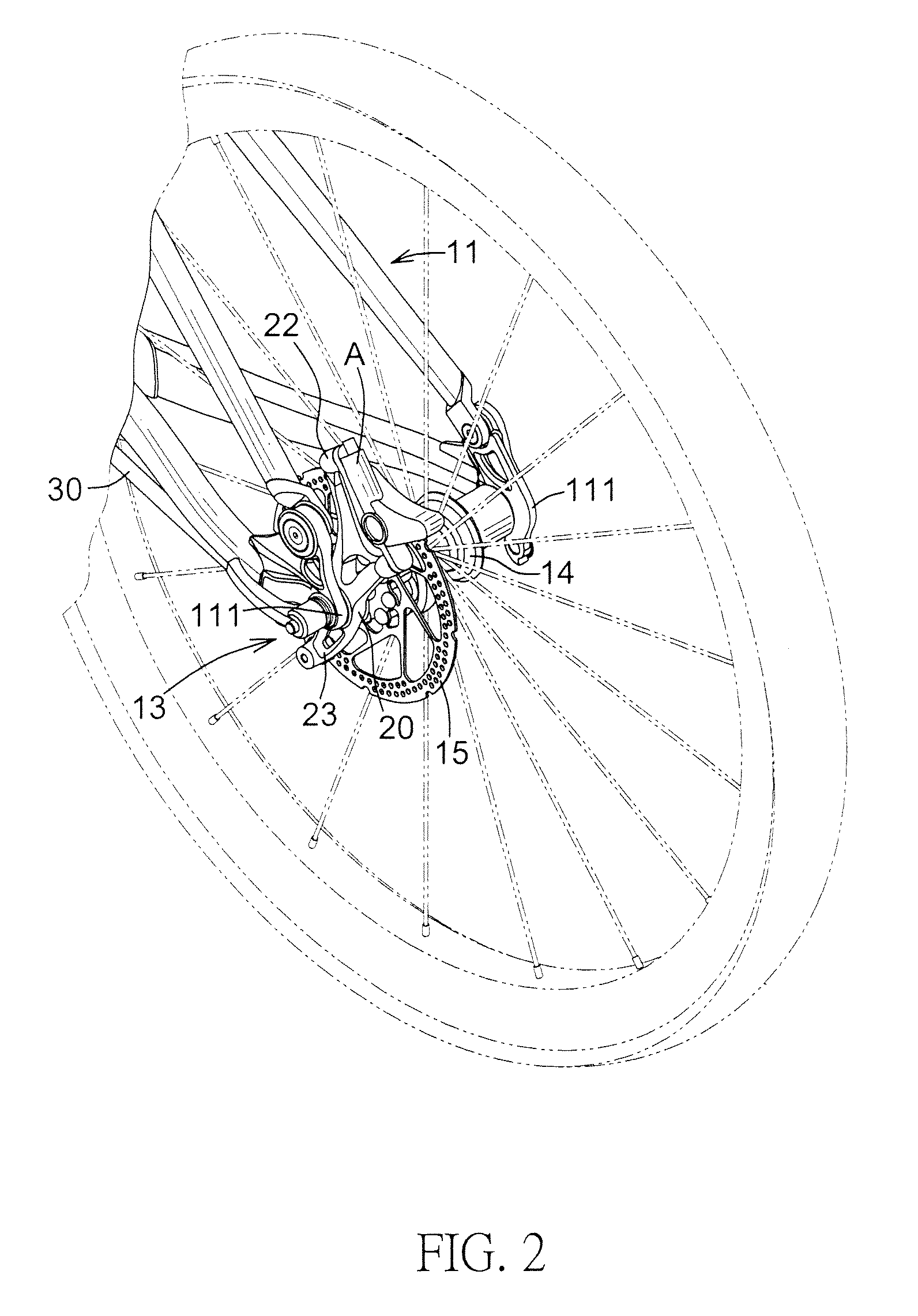

Rear fork

A rear fork for a rear suspension bicycle having a ground link, the rear fork has a front frame, a rear frame, input links, a shock absorber, coupler links, follower links, a brake mount and a connecting shaft. The input links are mounted pivotally on the ground link and are connected to the shock absorber that is mounted on the ground link. The coupler links are connected to the input links and terminate in dropouts being mounted thereon. The followers are mounted rotatably on the dropouts and pivotally to at least one link mount being connected to the ground link. The brake mount is pivotally mounted adjacent to a non-drive side dropout and has a caliper mounted thereon. The connecting shaft is connected to the ground link and the brake mount to prevent a shock absorbing force of the rear fork from interfering with a braking force of the caliper.

Owner:MERIDA IND

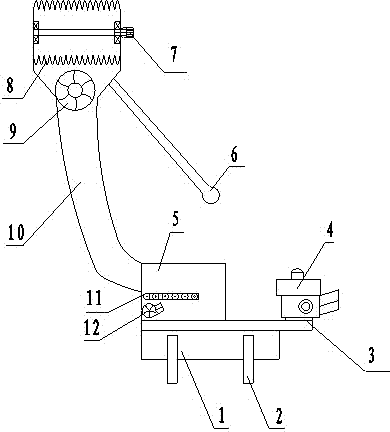

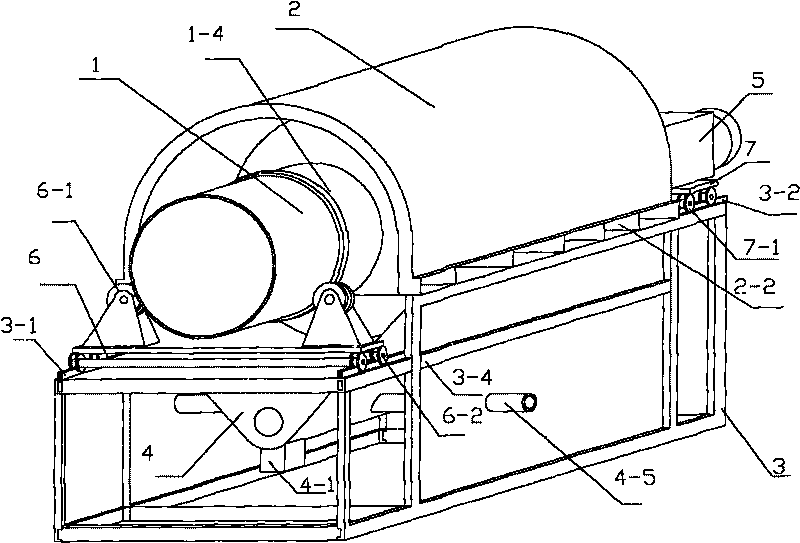

Coptis chinensis drying and tassel removing method and equipment

InactiveCN101721501AAvoid thermal decompositionIncrease profitPlant ingredientsTemperature controlWorking environment

The invention discloses coptis chinensis drying and tassel removing method and equipment. A drying chamber is formed by an inverted U-shaped heating cover fixed on a framework and a V-shaped deslagging screw conveyer; a roller is erected on a front frame and a rear frame of the framework and can slide in / out of the drying chamber through the front frame and the rear frame; the roller wall on the lower part of the roller consists of a screen mesh; and the roller can rotate. The invention has the advantages that coptis chinensis is dried under a temperature control condition, thereby avoiding that coptis chinensis alkaloid is heated and decomposed and ensuring that the quality of the coptis chinensis conforms to the requirement of the Chinese pharmacopoeia; meanwhile, the primary processing of the coptis chinensis is carried out in a hermetic system, thereby improving the energy utilization rate and the drying efficiency and reducing influences of smoke and silt on the working environment; and the automatic sample inlet (outlet) improves the working efficiency.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

Turning mechanism

InactiveCN102452014APlace stableSimple processWelding/cutting auxillary devicesAuxillary welding devicesTurning framesEngineering

Owner:XCMG CONSTR MACHINERY

Paper high speed synchronization butt joint device for photogravure press units

InactiveCN101033044AAchieve connectionGuaranteed reliabilityRotary pressesWebs handlingButt jointAdhesive

This invention provides a high speed synchronous paper but-joint device of an unit gravure machine including a turning frame, a turning big arm, a cutting unit, a frame, a swing-roller, a paper-end cutter fixed on the frame, a large roller and a paper roller with back-adhered glue, in which, the paper-end cutter is under the large roller driven by an executing cylinder, a test photoelectric eye is set on the cutter, a steel strip is set on the head of a paper roll, a coder is set on the big roller and the back-adhered paper roll is driven by the executing cylinder and the steel strip is adhered on the head of a new material with a double-side adhesive tape.

Owner:SHAANXI BEIREN PRINTING MACHINERY

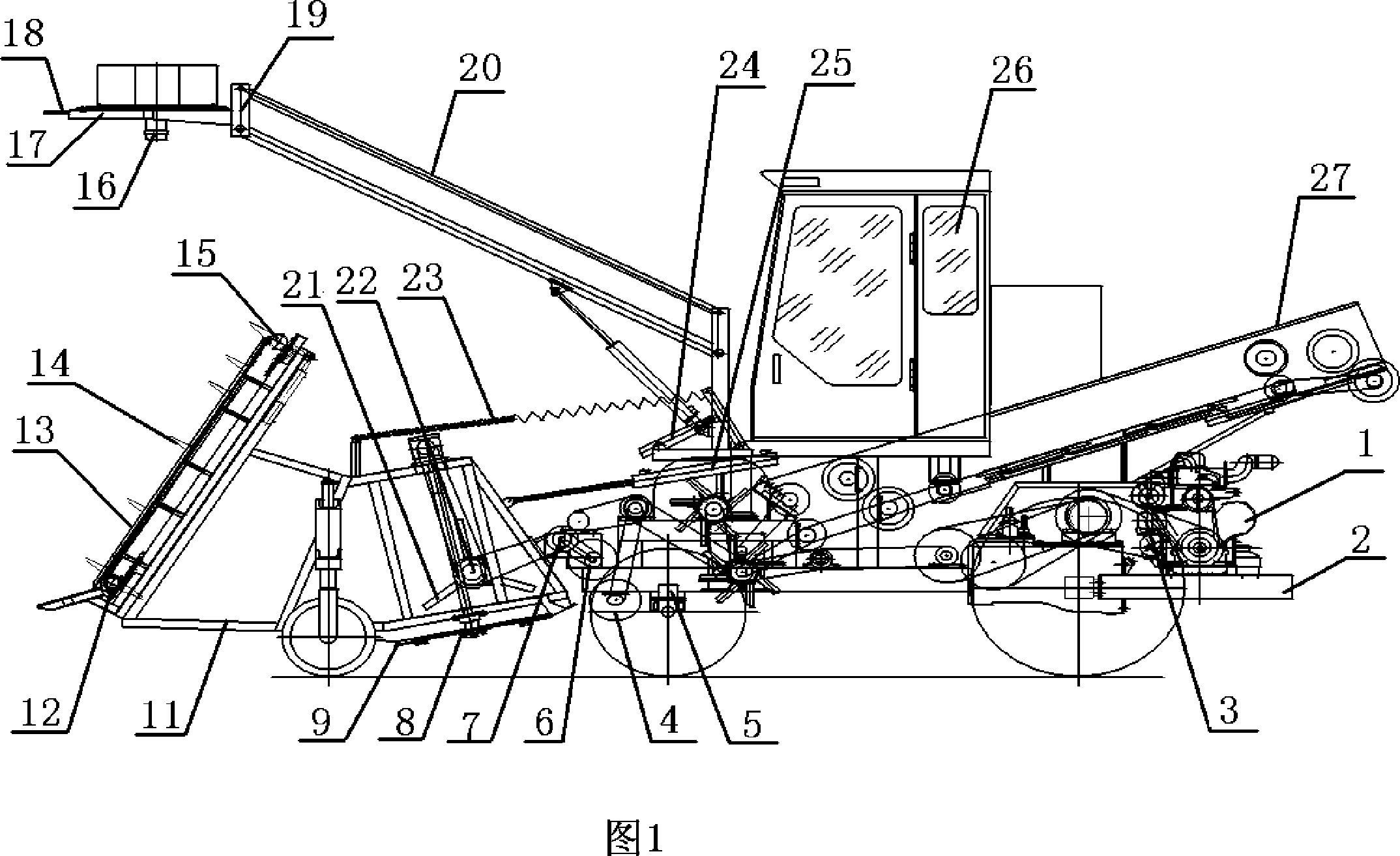

Machinery for harvesting sugarcane

InactiveCN101002526ALower the altitudeRealization of small size and light weightMowersAgricultural lifting devicesTurning framesEngineering

A sugar cane harvester is composed of a main frame assemblage with a rockerarm and a cane tip cutting unit, a harvesting platform assemblage in the front of said main frame assemblage and with two cane-holding units, a comb-shaped can pushing bar between two cane-holding units, a tooth-shaped cutting unit and a guide plate, and a leaf-stripping assemblage with a pair of horizontal delivering roller.

Owner:柳州市汉森机械制造有限公司

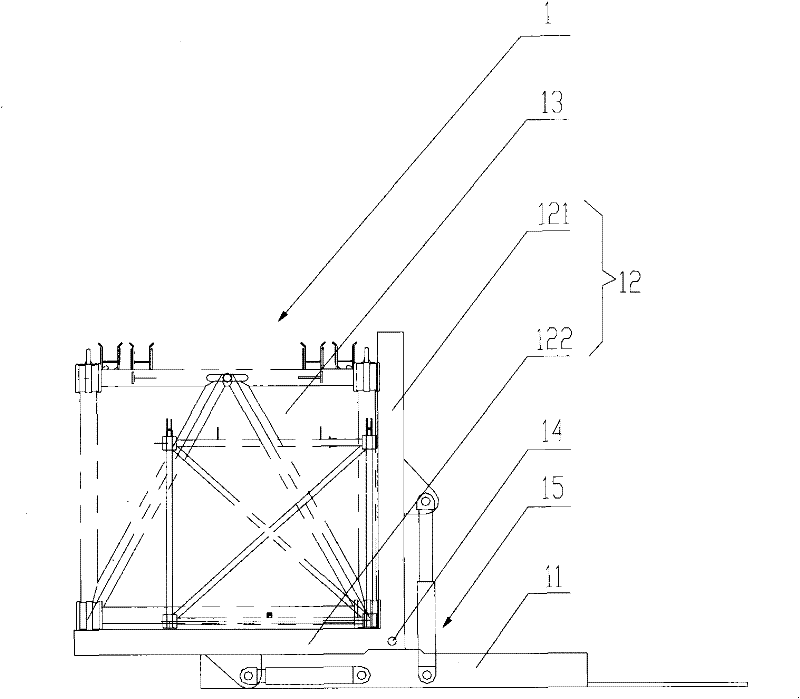

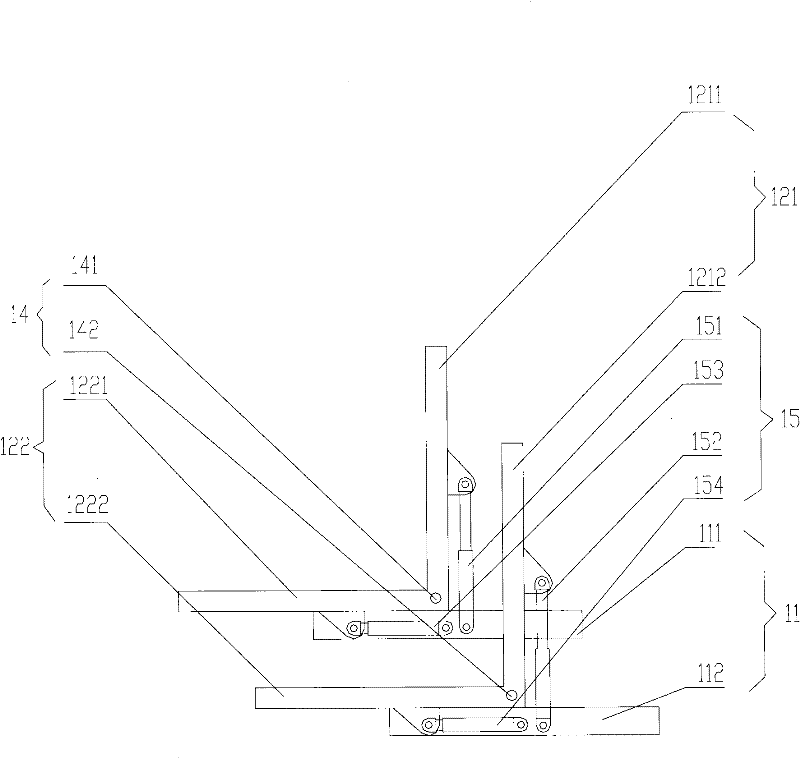

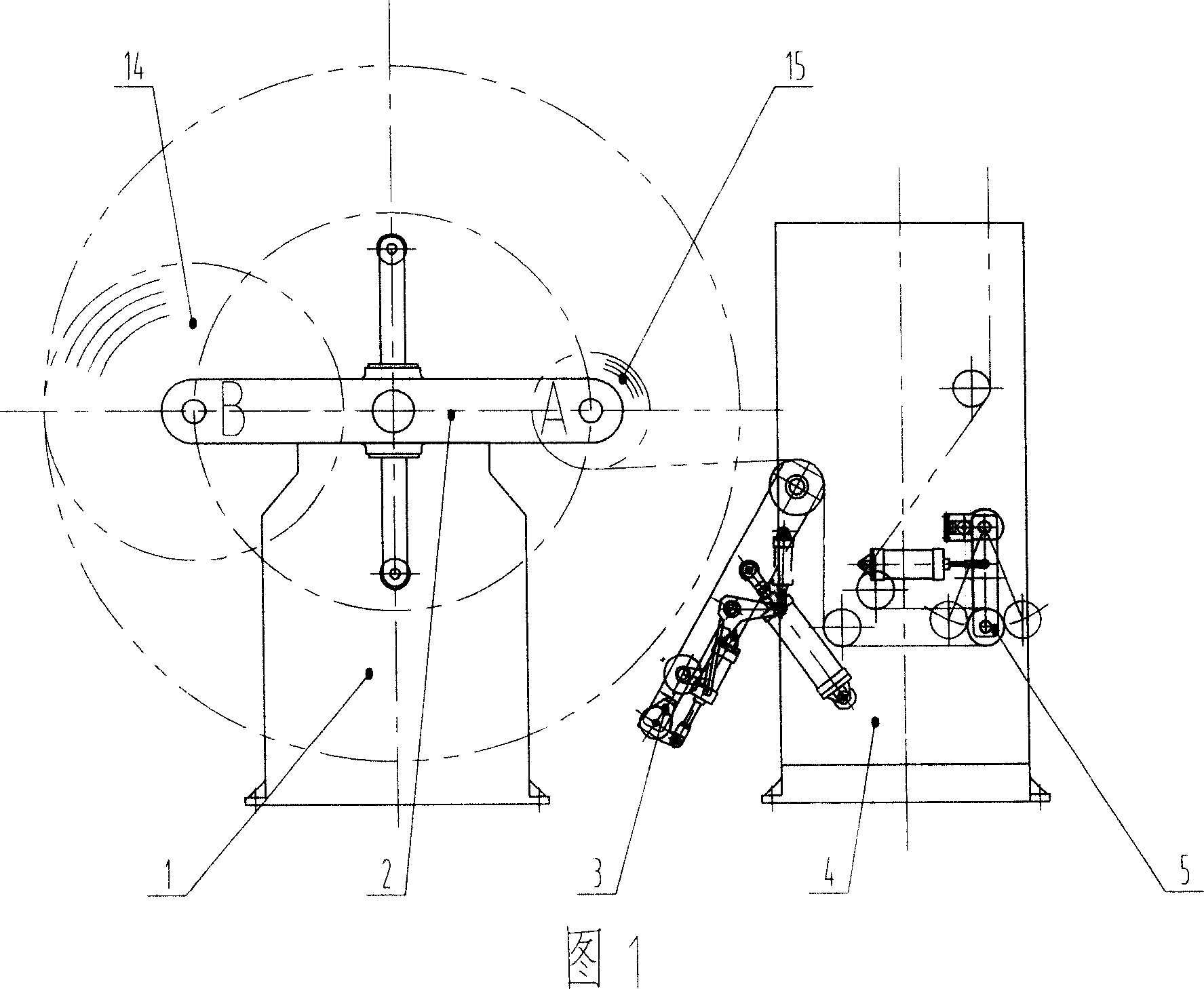

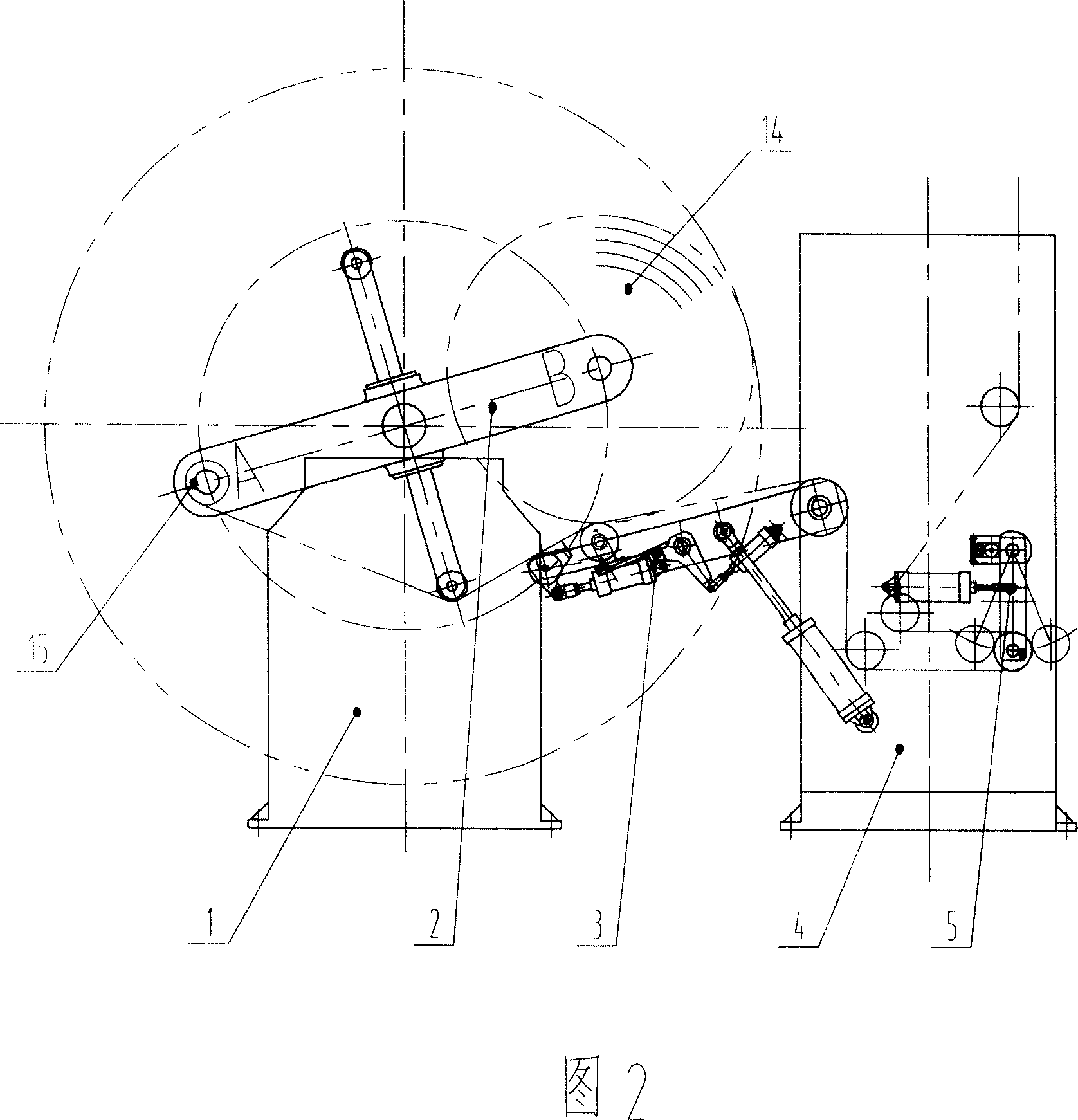

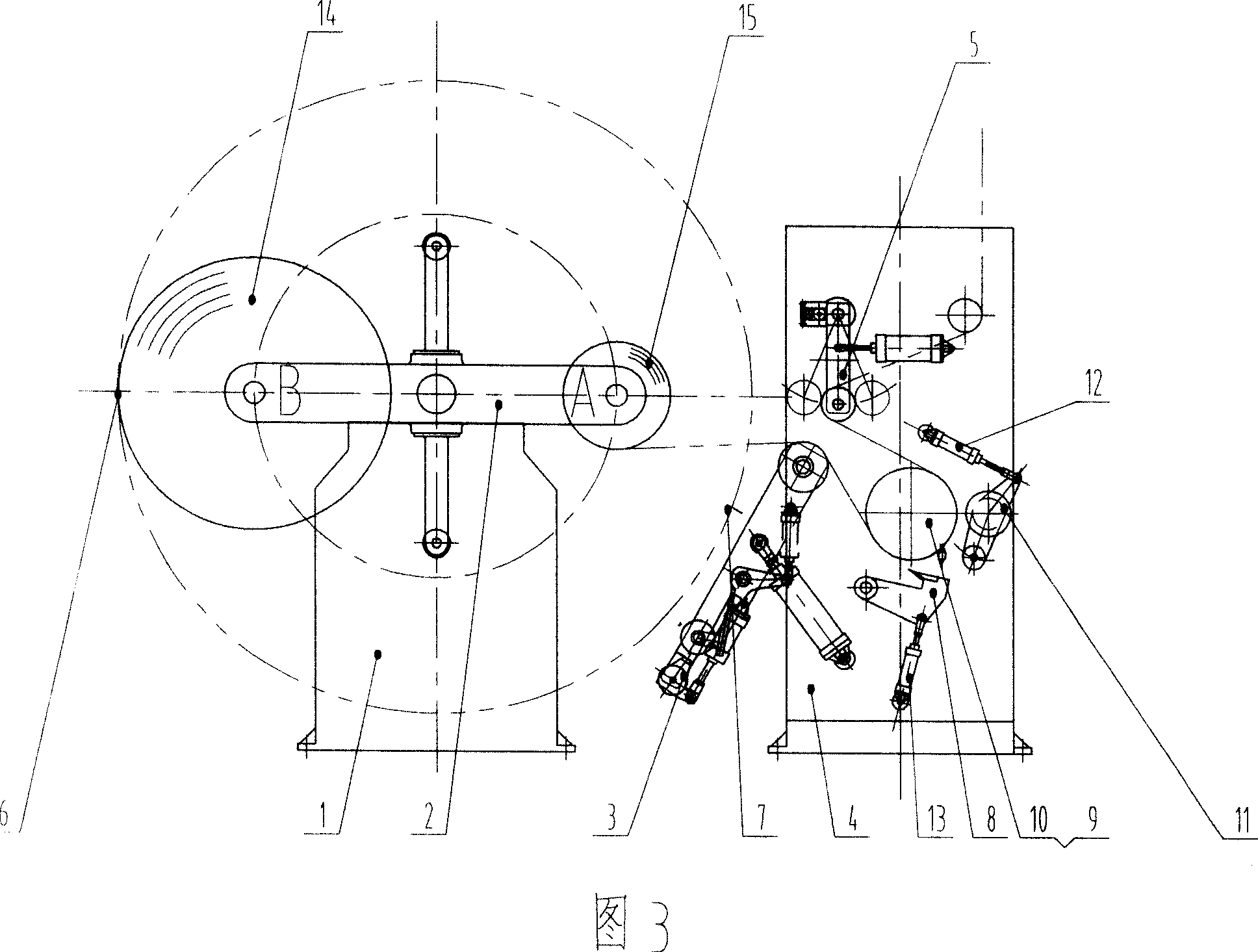

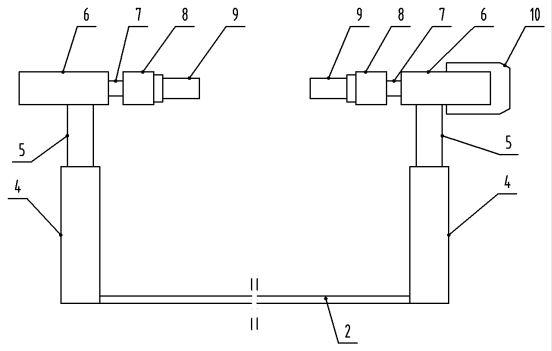

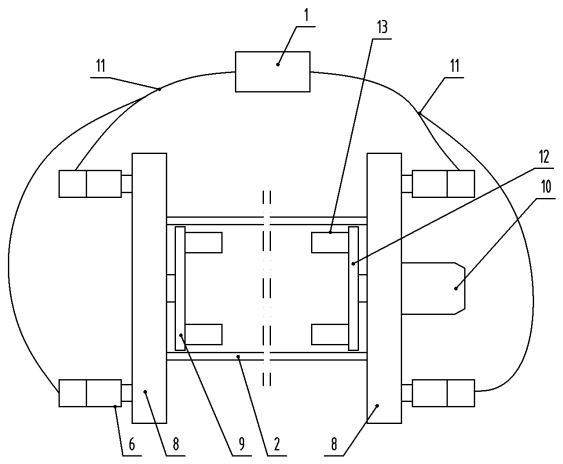

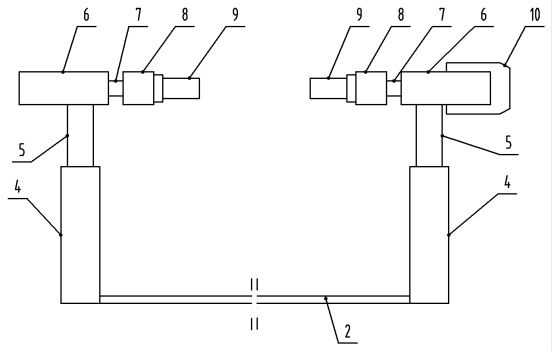

Frame turning device

InactiveCN102000938AEnsure assembly welding qualityEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderTurning frames

The invention discloses a frame turning device which comprises a hydraulic station and four vertical hydraulic cylinders which are arranged in a rectangle, wherein a horizontal hydraulic cylinder which is parallel with a track is arranged on an upward vertical piston rod in each vertical hydraulic cylinder; a fixed plate is respectively arranged between two horizontal piston rods of two horizontal hydraulic cylinders at the same end; the inner side of each of the two fixed plates is respectively connected with a turning frame in a rotating mode; a motor for controlling the rotation of the turning frame is arranged at the outer side of one fixed plate; and each vertical hydraulic cylinder and each horizontal hydraulic cylinder are respectively connected with the hydraulic station through hydraulic oil pipes. In the invention, the frame at one side is already welded by adopting a horizontal and symmetrical turning method, so that the whole frame can not be deformed because of turning, the assembling and welding quality of the whole frame is ensured, and the production efficiency is greatly improved.

Owner:HENAN HUANGMA VEHICLE

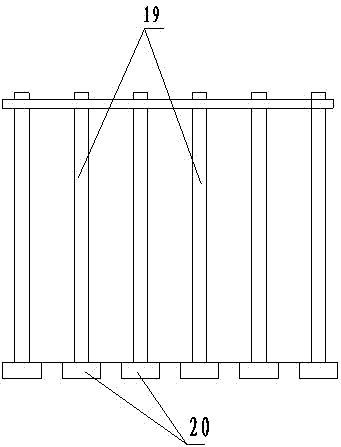

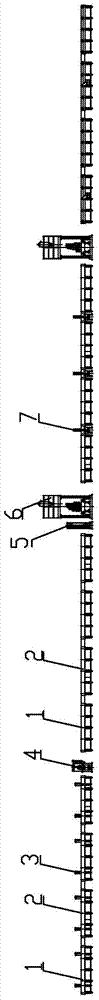

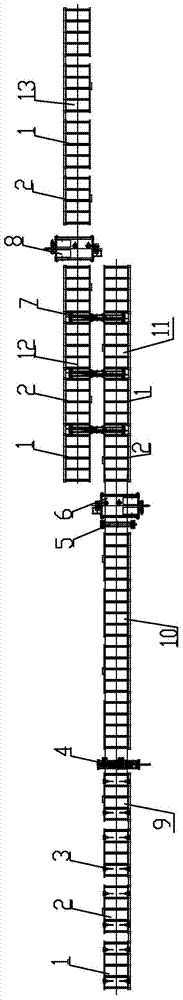

Horizontal production line for welding H-shaped steel

ActiveCN103567678AImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesProduction lineTurning frames

The invention belongs to the technical field of welding equipment, and particularly relates to a horizontal production line for welding H-shaped steel. The horizontal production line comprises conveying rollers, sideward-turning devices, an end portion assemblage machine, an assistant positioning device, a front end assembling and welding machine, a turning frame and a rear end assembling and welding machine. The sideward-turning devices are used for turning an H-shaped steel wing plate on the conveying rollers in front of the end portion assemblage machine by 90 degrees and enabling the H-shaped steel wing plate to be attracted to perpendicular guide pillars through magnetic rings, the end portion assemblage machine is used for assembling a web and the wing plate into the H-shaped steel, and the assistant positioning device is used for conducting further positioning before the spliced H-shaped steel enters the front end assembling and welding machine. According to the horizontal production line for welding the H-shaped steel, transverse assembling and welding are conducted on the web and the wing plate of the H-shaped steel, splicing and welding of the H-shaped steel are simultaneously completed through one-time work, and work efficiency is greatly improved.

Owner:无锡洲翔成套焊接设备有限公司

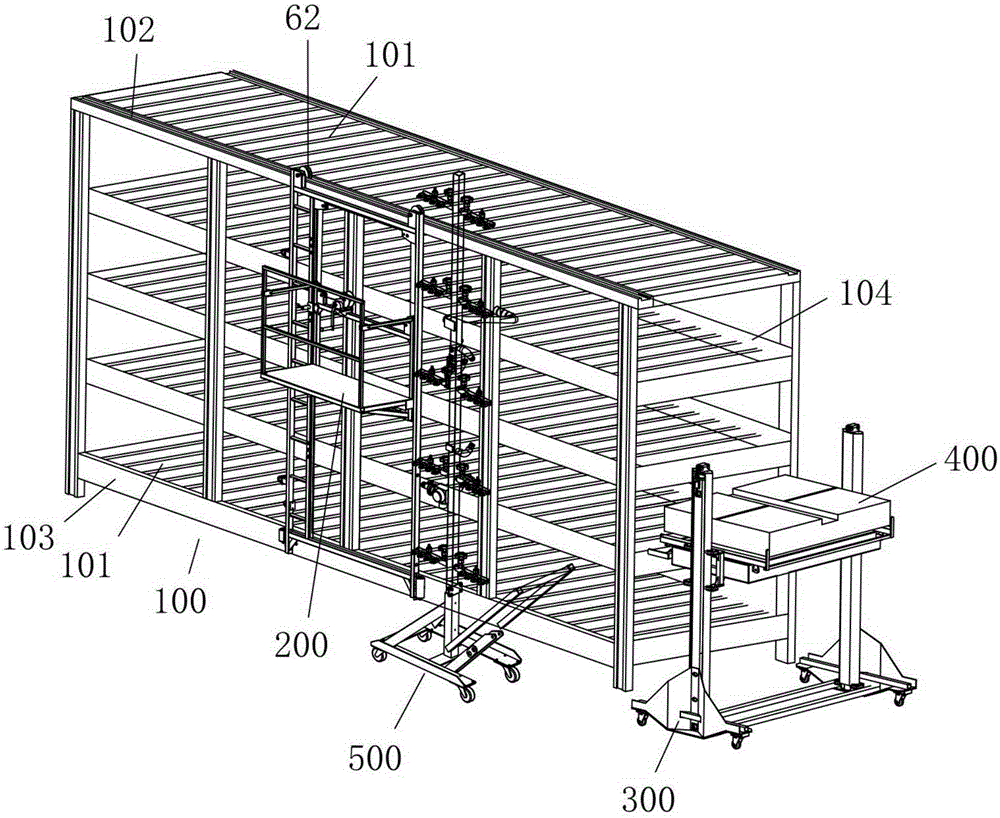

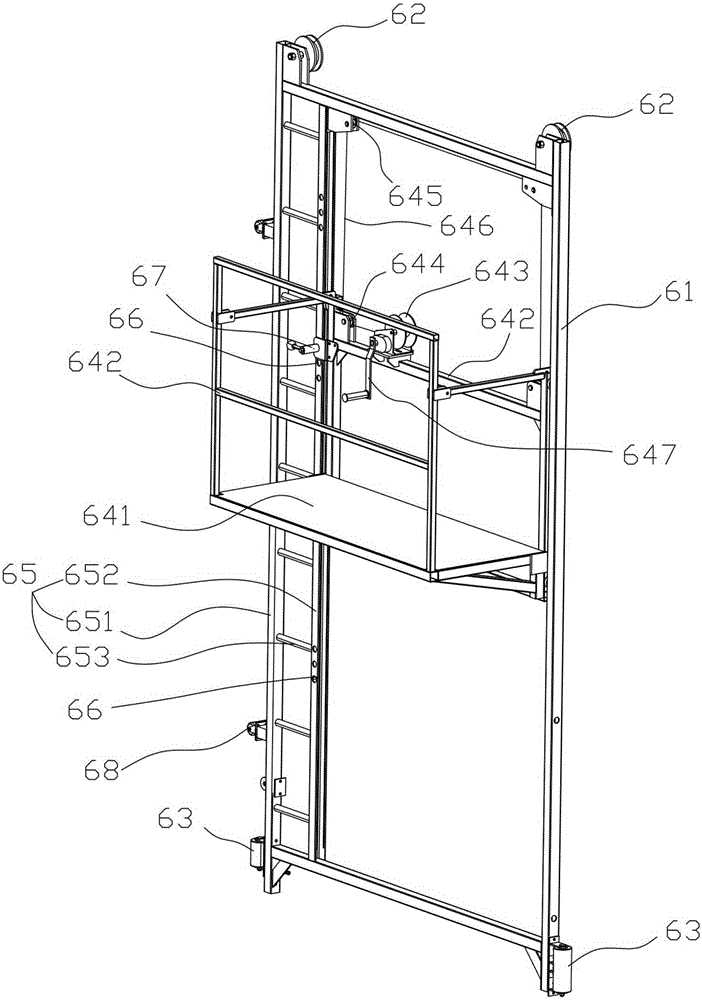

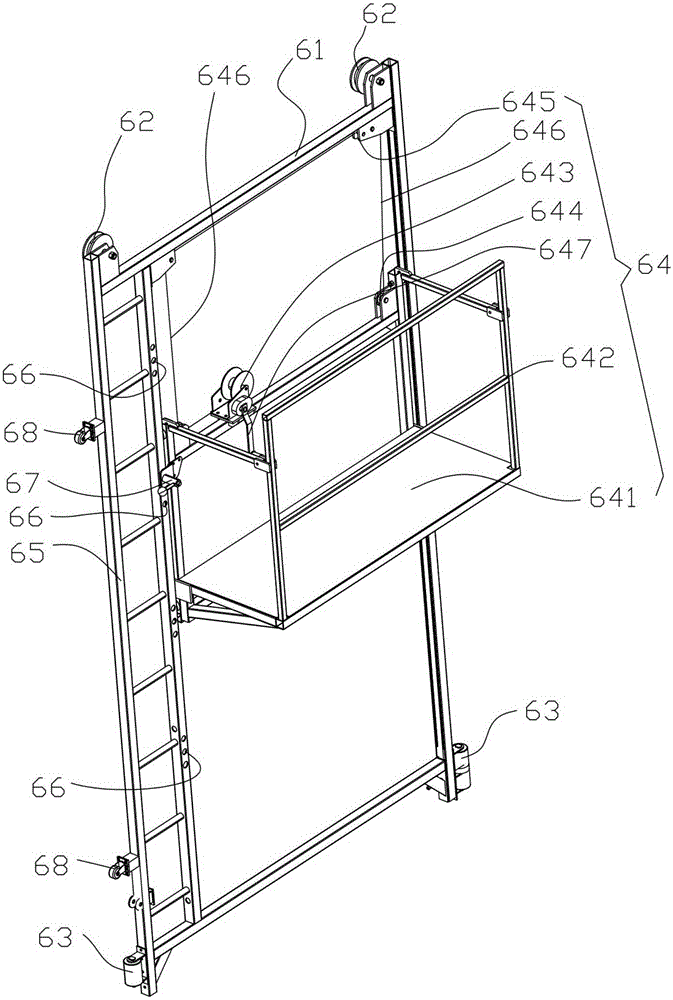

Mushroom bed planting system

The invention belongs to the technical field of mushroom planting, and particularly relates to a mushroom bed planting system. Multiple planting layers are arranged in a mushroom bed, and a mushroom picking car is arranged on the left side or the right side of the mushroom bed; a frame of the mushroom picking car is provided with sliding wheels, auxiliary wheels and a safe lifting platform, and a ladder is arranged beside the safe lifting platform; the mushroom picking car not only lowers the mushroom farmer working difficulty of daily mushroom cultivation management such as watering and soil loosening, but also lowers the working difficulty of mushroom picking, and therefore not only is the working efficiency significantly improved, but also the safety of workers is guaranteed. A walking lifting mechanism is matched with a mycelium scratching machine, and material soil on the mushroom bed can be extremely conveniently trimmed and turned, so that mycelia in the material soil can grow smoothly, the manpower demands of mushroom planting are lowered, and the yield of mushroom planting is improved. Mushrooms can get enough water in the growing process due to the design of a water spraying tree, and use is convenient.

Owner:ZHEJIANG HONGYE EQUIP TECH

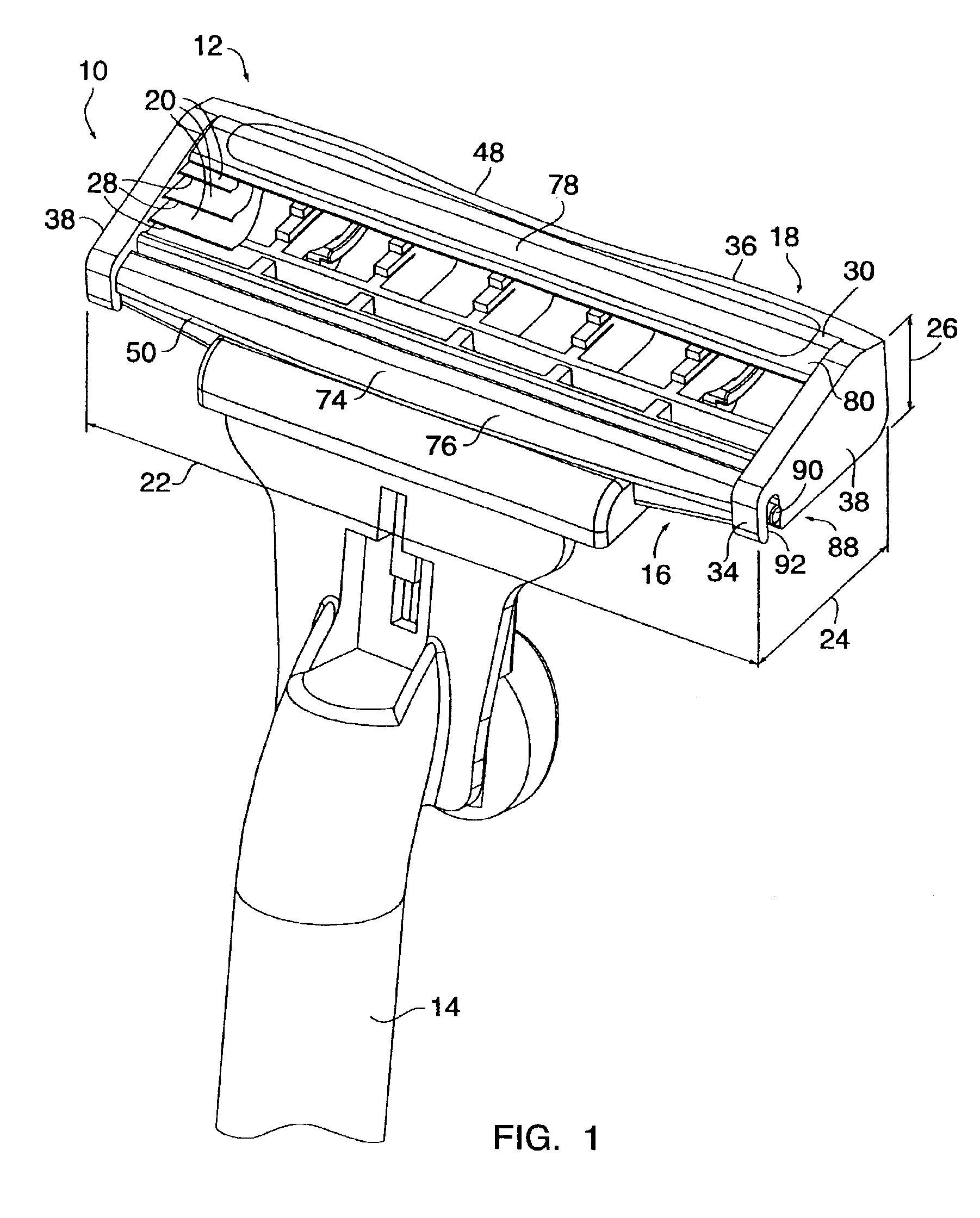

Razor cartridge

InactiveUS6935032B2Reduce the angleReducing undesirable interactionMetal working apparatusTurning framesEngineering

A razor cartridge is provided that includes a subframe, a frame, and one or more razor blades attached to the frame. The frame includes a cap, a forward end, and a cap end. The frame is mounted on coengaging bearing surfaces on the frame and the subframe to pivot about an imaginary pivot line that is positioned adjacent the cap, above the bearing surfaces, and aft of the cutting edges of the one or more razor blades. The razor cartridge preferably further includes a spring mechanism that acts between the frame and the subframe.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

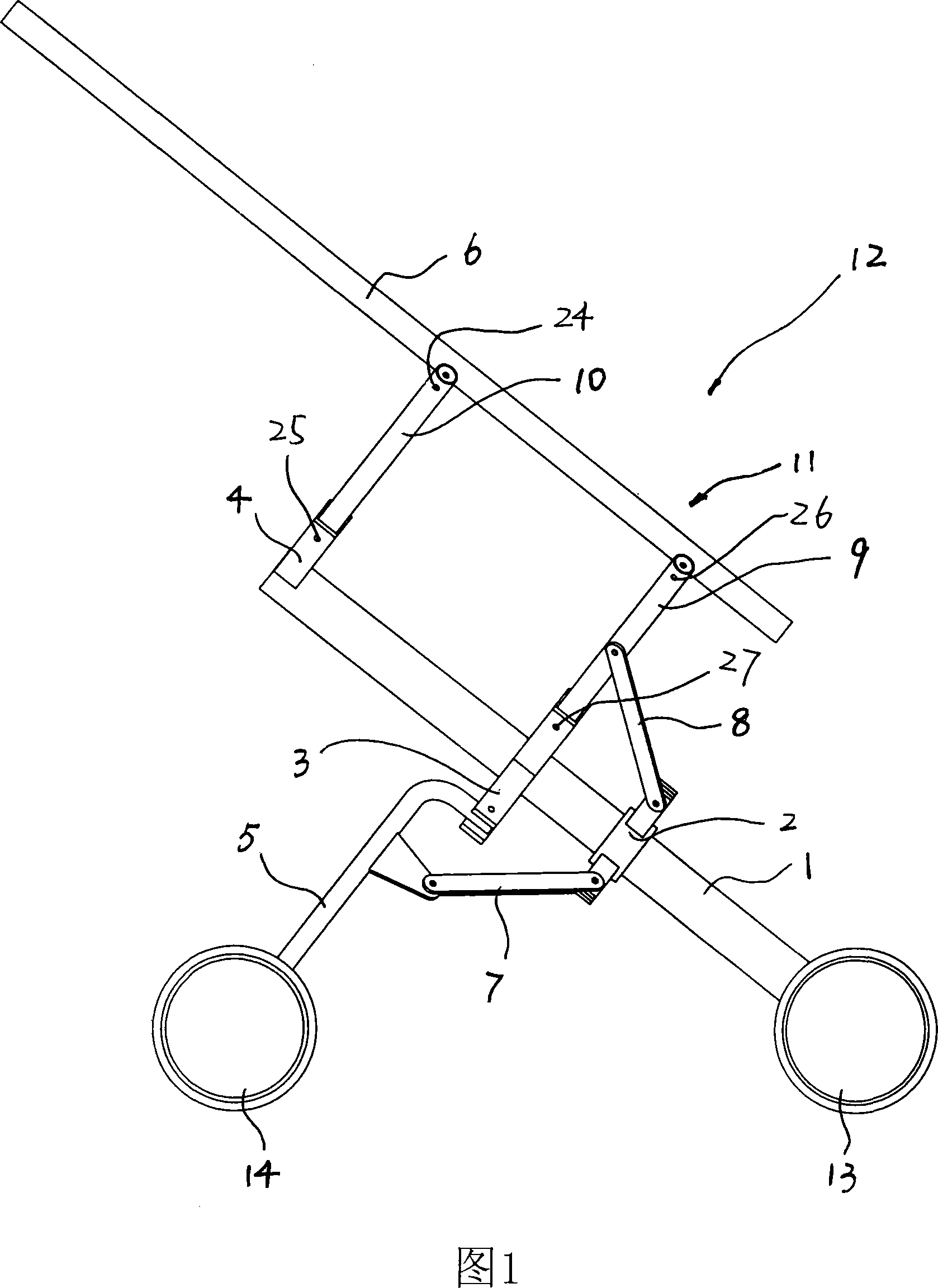

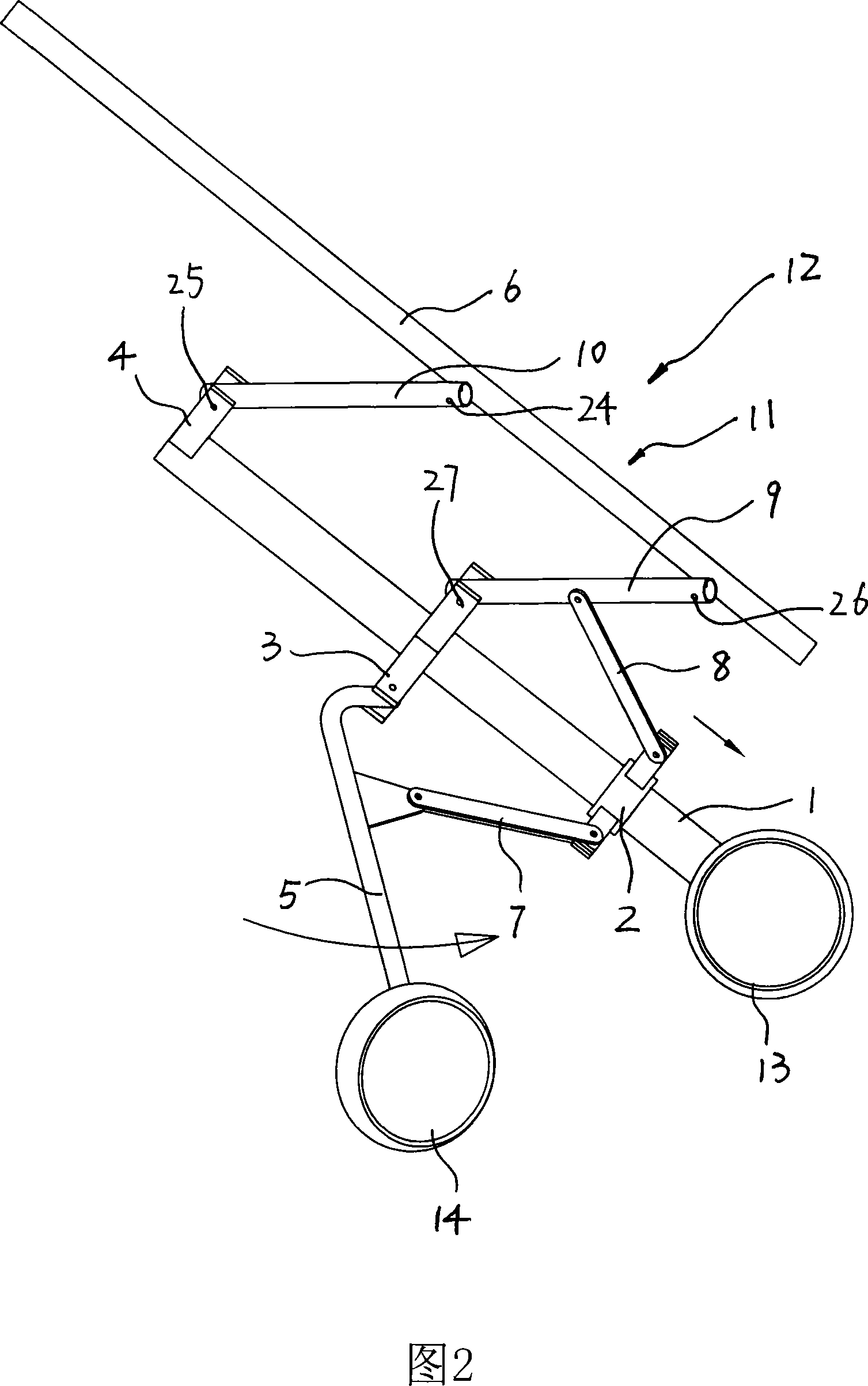

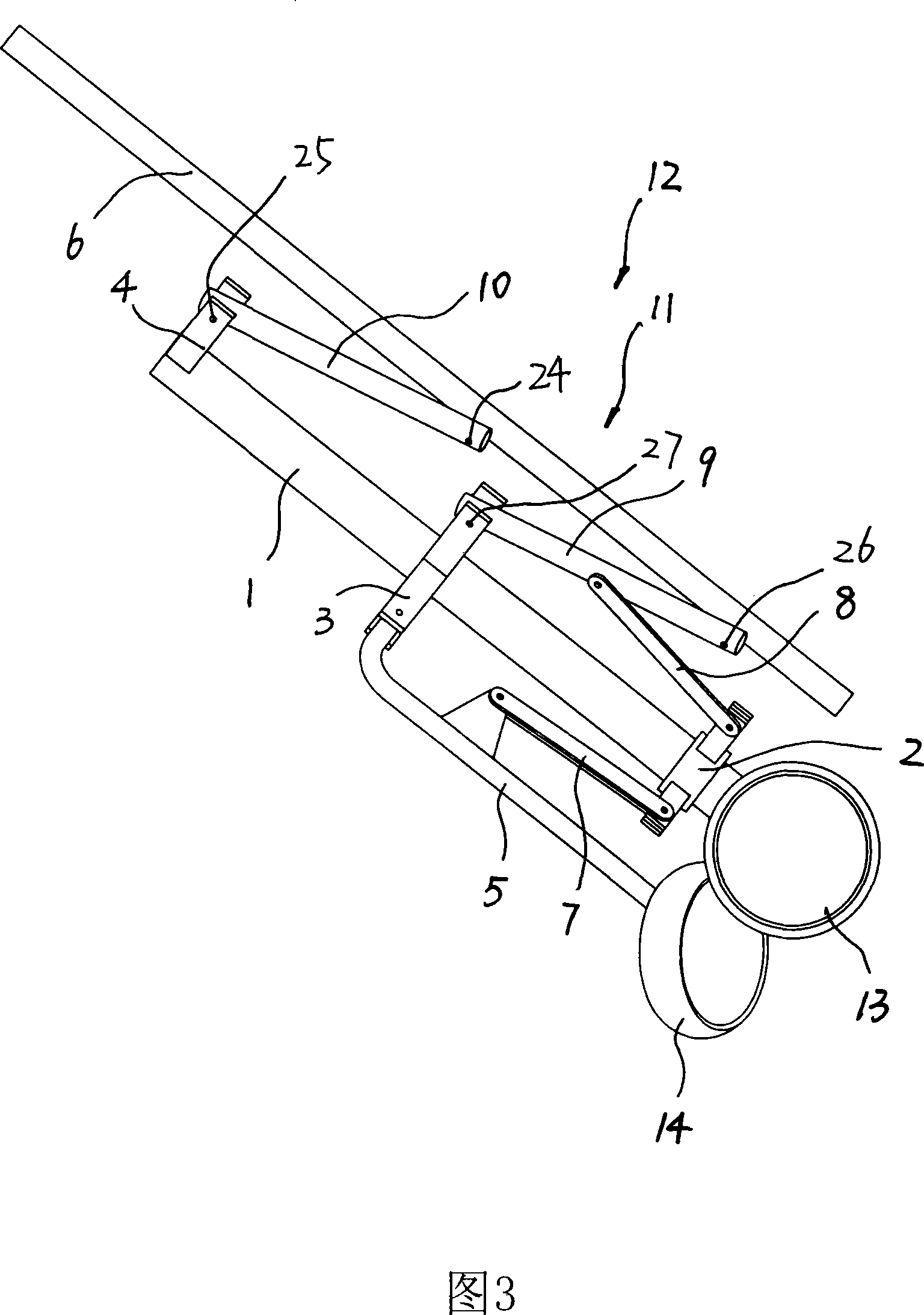

Children's barrow

ActiveCN101138986AEasy accessAchieve self-relianceCarriage/perambulator with multiple axesLocking mechanismTurning frames

The present invention provides a children trammer, a frame of which includes a front wheel bracket, a slip seat that is slip and arranged at the front wheel bracket and lateral brackets which are placed at two sides of the front wheel bracket. The lateral bracket at each side all includes a back wheel bracket, a top part of which is rotationally connected with the front wheel bracket, a handspike, a lower link lever, one end part of which is rotationally connected with the back wheel bracket and another end part is rotationally connected with the slip seat, a third upper link lever, one end part of which is rotationally connected with the handspike and another end part is rotationally connected with the back of the front wheel bracket, a second upper link lever, one end part of which is rotationally connected with the lower part of the handspike and another end part is rotationally connected with the front wheel bracket, a first upper link lever, one end part of which is rotationally connected with the second upper link lever and another end part is rotationally connected with the slip seat, and a locking mechanism. The front wheel bracket, the second upper link lever, the handspike and the third upper link lever form a quadrangle mechanism. Because the trammer can realize self standing after being folded, and the top part of the handspike is still placed at the upside, the trammer is convenient for the operator to take, and the operation is quite convenient.

Owner:GOODBABY CHILD PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com