Capturing device for broken belt of belt conveyer

A broken belt capture device and belt conveyor technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the large amount of work and difficulty in the installation, adjustment and maintenance of the catcher, and the broken With problems such as secondary damage and misoperation of the catcher, it can achieve the effect of facilitating the recovery of the catch state, reducing the lifting height of the load, and facilitating maintenance or repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

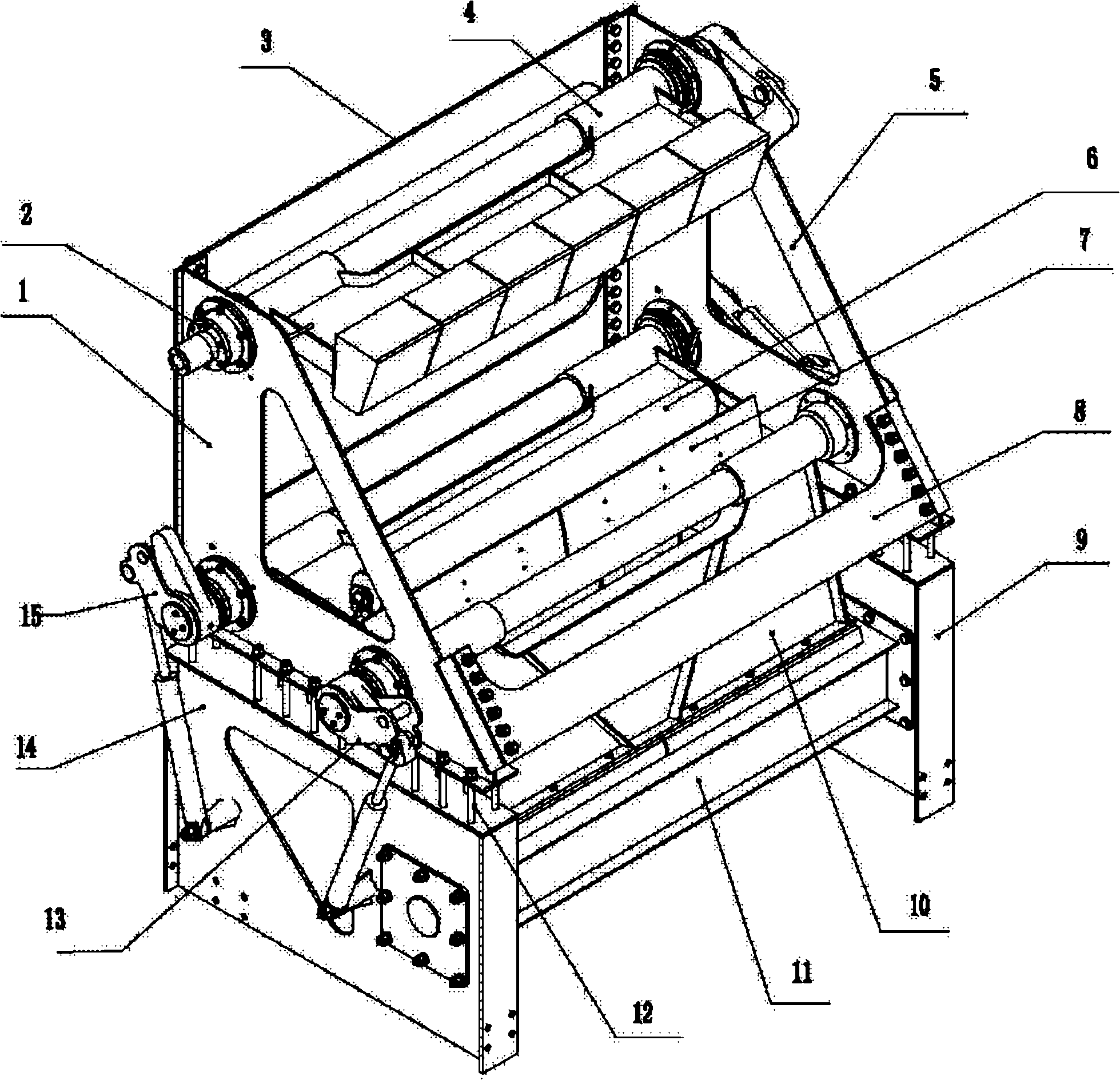

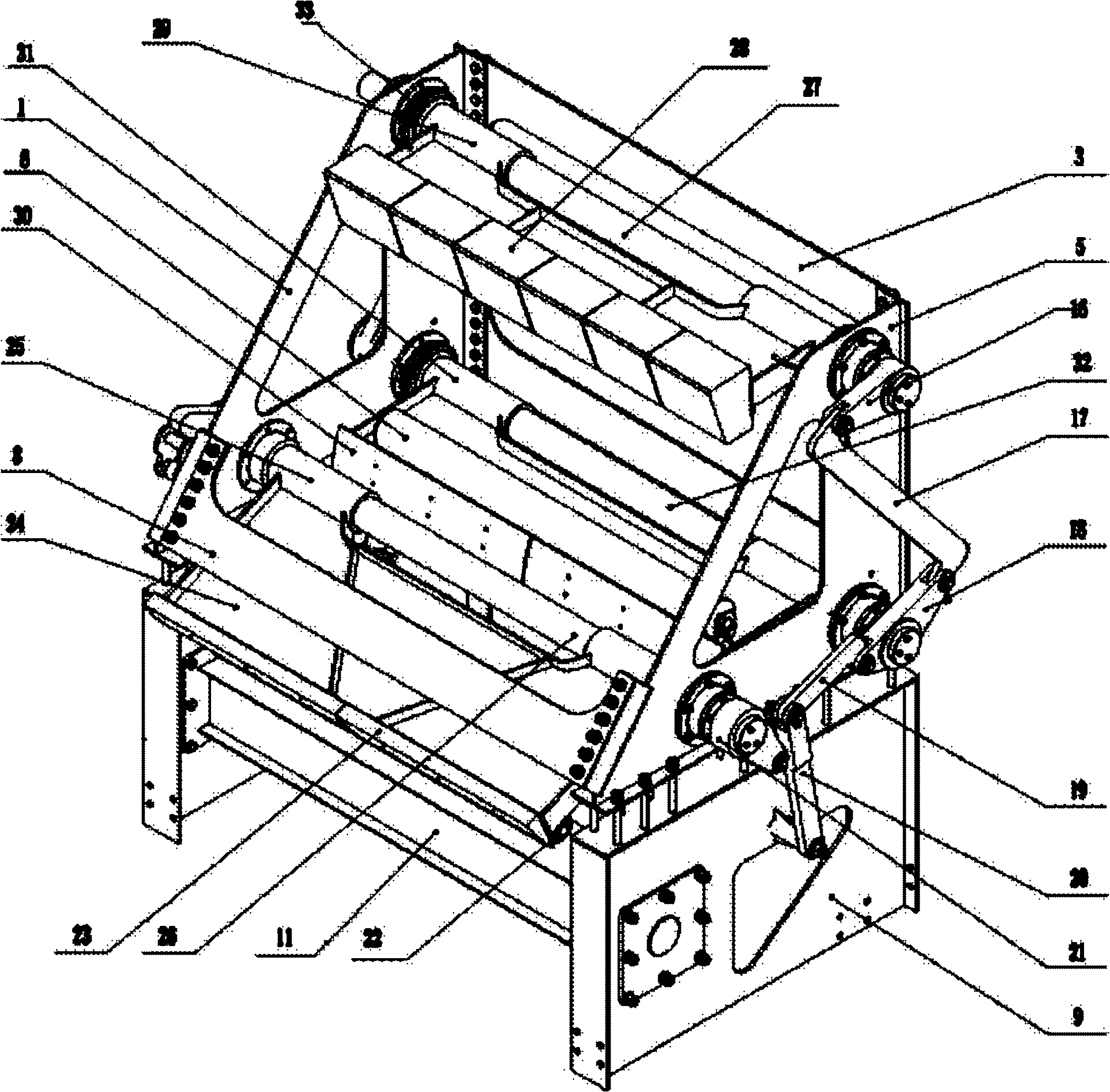

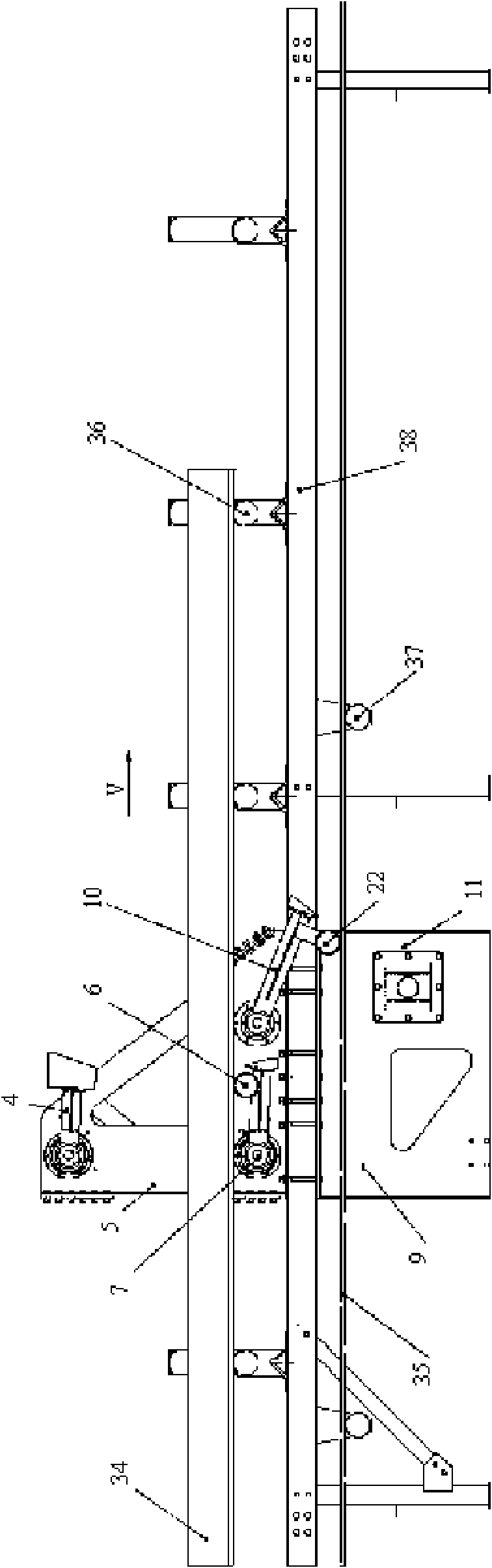

[0068] see Figure 1 to Figure 8 , the present invention, that is, a broken belt arresting device for a belt conveyor, comprising a frame, a carrying tape (ie upper belt) arresting mechanism, a return tape (i.e. lower belt) arresting mechanism, an upper and lower linkage device and an adjustment and unlocking mechanism, Used to catch the broken conveyor belt installed on the frame 38 , the conveyor belt includes a carrier belt 34 supported by a trough-shaped upper roller assembly 36 and a return belt 35 supported by a flat idler roller assembly 37 .

[0069] The frame consists of upper and lower parts connected as a whole, of which:

[0070] The upper part includes a left vertical board 5 and a right vertical board 1 arranged in parallel, and a back board 3 and a front guard board 8 for connecting the left and right vertical boards 5 and 1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com