Machinery for harvesting sugarcane

A harvester and sugarcane technology, applied in harvesters, headers, cutters, etc., can solve the problems of high root breaking rate of sugarcane, clogging of sugarcane in the machine, easy damage of cutting knives, etc., to achieve good adaptability and prevent harvesting. Loss, solve the effect of cutting too high and too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

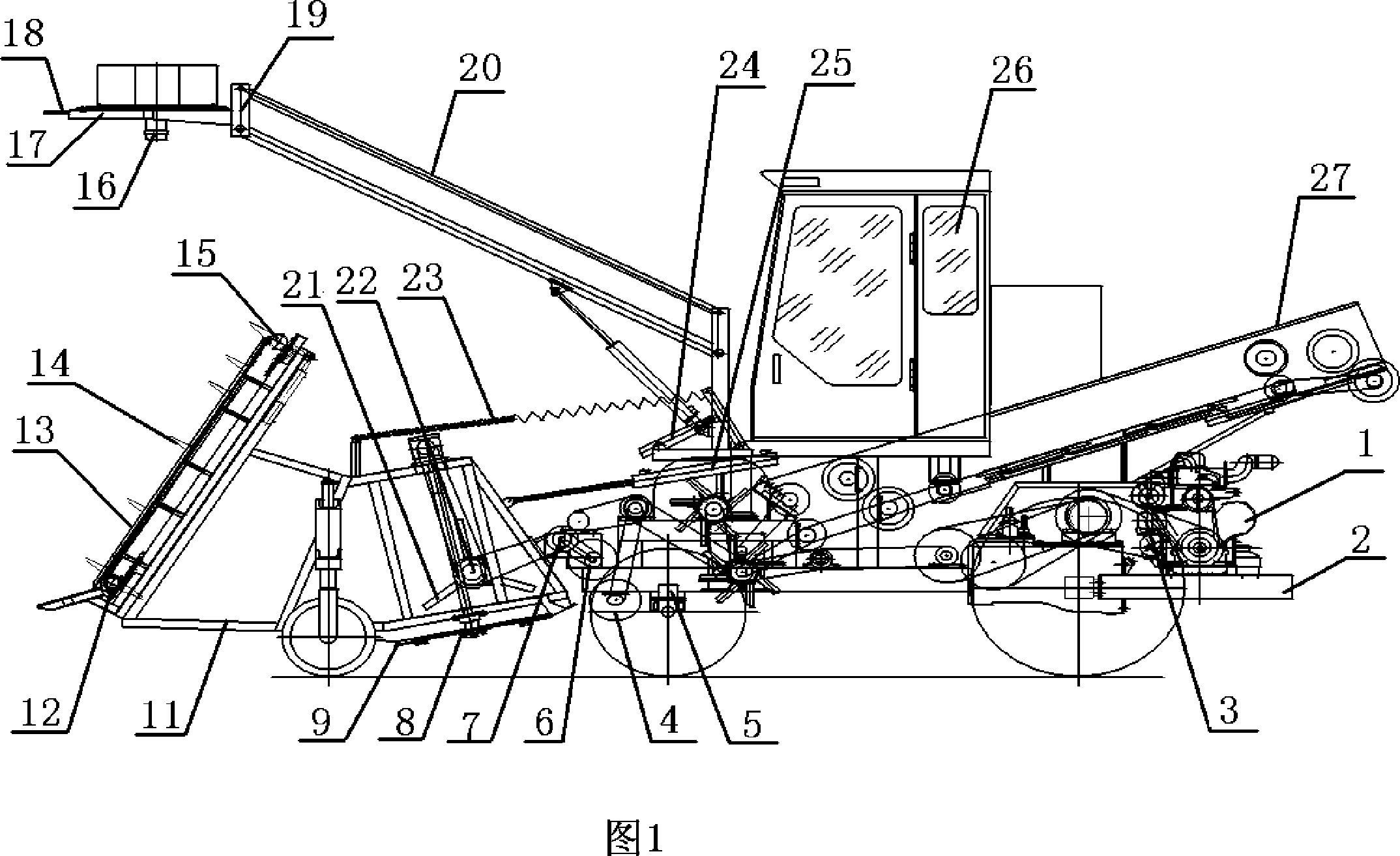

[0033] Below in conjunction with accompanying drawing example, structure of the present invention is described in further detail:

[0034]The sugarcane harvester described in Fig. 1 is equipped with an internal combustion engine 1, a cab 26 and a leaf stripping assembly 27 etc. on a vehicle frame assembly 2 with steering, walking, and braking functions. In addition to providing rotational power for the whole machine, the internal combustion engine 1 also drives the oil pump 3 of the hydraulic system to provide motion force for the plungers of each hydraulic cylinder on the machine. The front end of the vehicle frame assembly 2 is connected with the header assembly through the hinge shaft 7, so that the header assembly is located in front of the front axle 5 of the vehicle frame assembly 2, between the frame 11 of the header assembly and the vehicle frame assembly 2 Lifting oil cylinder 25 is housed between. In this way, the harvester can raise and lower the header assembly, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com