H-shaped steel turning device

A turning device and H-shaped steel technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated H-shaped steel process, low production efficiency, casualties, etc., and achieve high turning operation efficiency and improved Effects of productivity, labor saving and operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now further illustrate how the present invention is implemented in conjunction with the accompanying drawings:

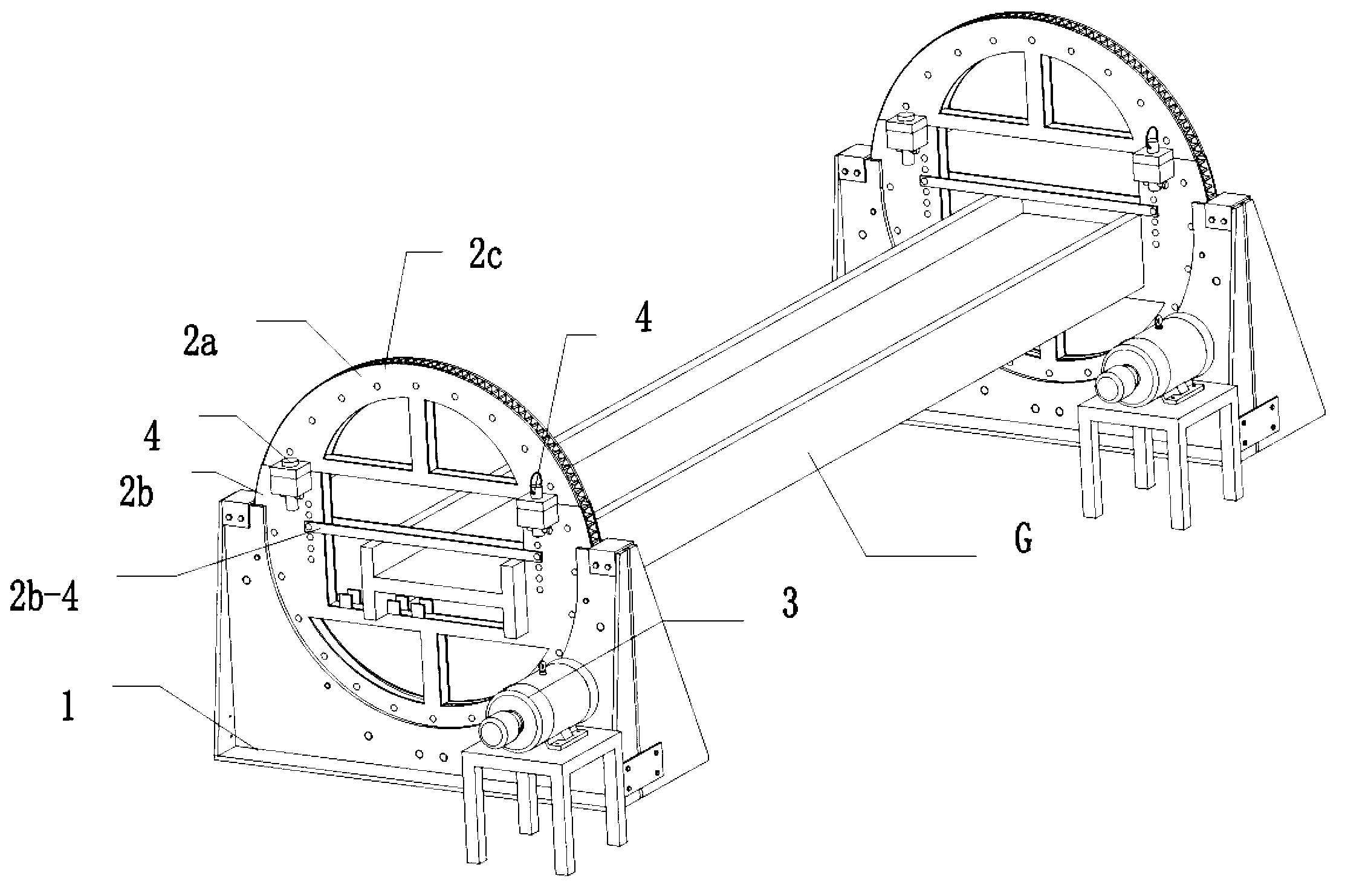

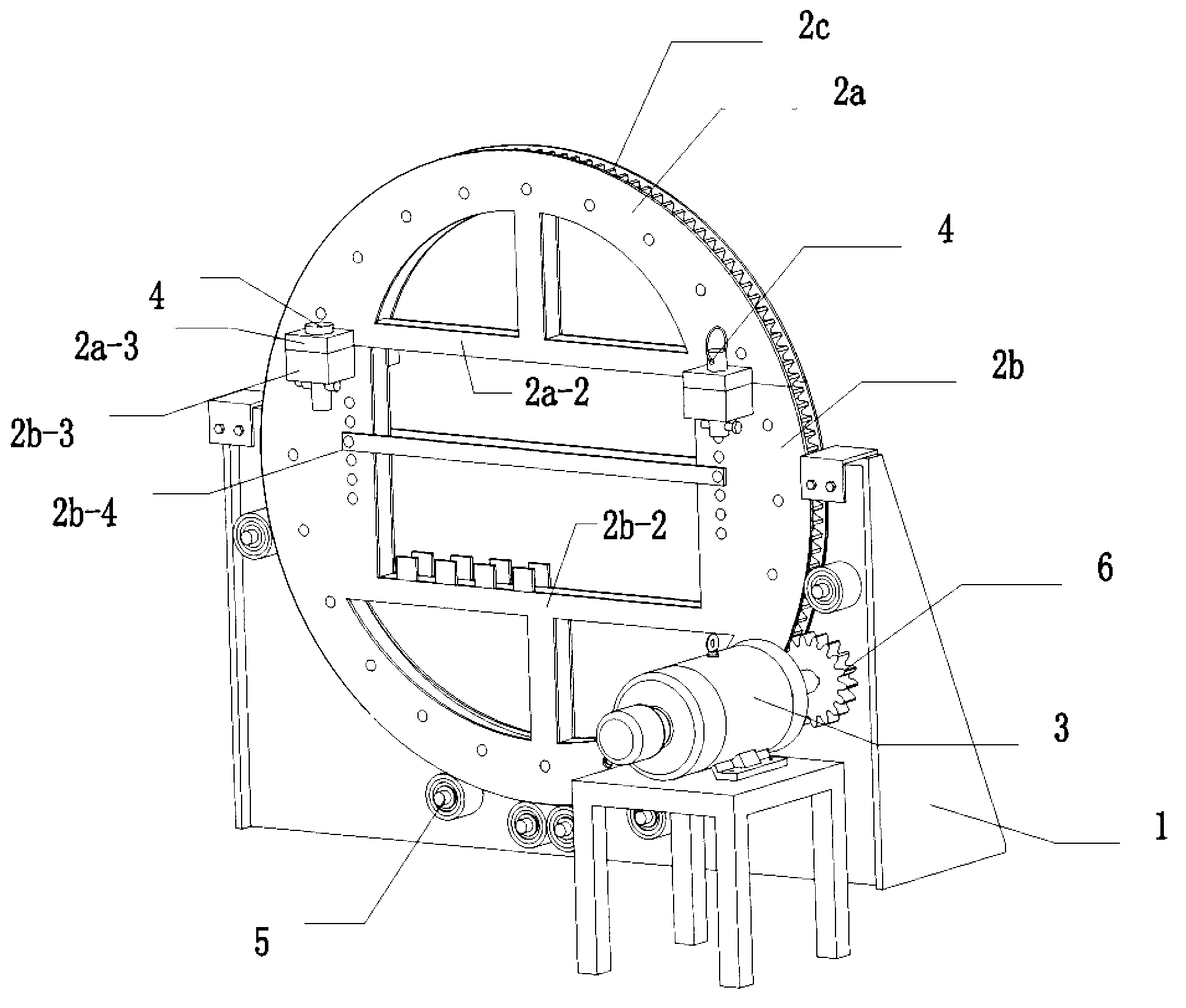

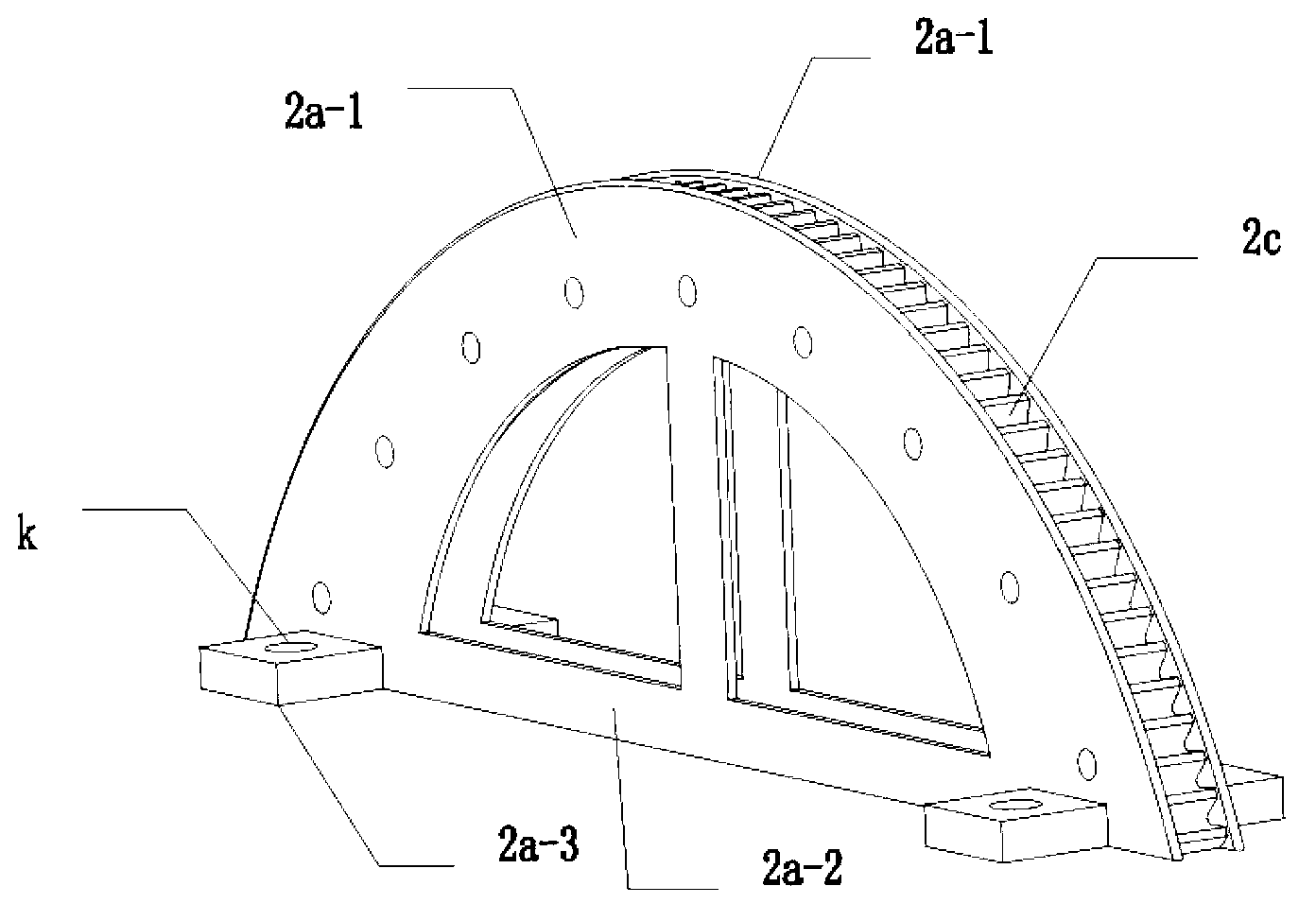

[0018] The turning machine of the H-beam turning device of the present invention is composed of a base 1, a turning frame 2 and a motor unit 3. The turning frame is an arc-shaped turning frame composed of an upper frame 2a and a lower frame 2b, and the rack 2c of the upper frame is embedded and clamped The two arc splints 2a-1 are fixedly connected to form an integral body between the arc peripheries of the two arc splints. The two arc splints 2a-1 on the upper frame correspond to the chord beam 2a-2 and the pin shaft connecting platform 2a-3 respectively; The rack 2c is embedded and fixed between the arc circumferences of the two arc splints 2b-1 to form a whole, and the two arc splints 2b-1 of the lower frame 2b respectively correspond to the bottom beam 2b-2 and the pin shaft connection platform. 2b-3, the movable outer baffle 2b-4, on the bottom beam 2b-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com