Frame turning device

A frame flipping and flipping frame technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting product quality and production efficiency, frame deformation, frame tilting, etc., to ensure assembly Improvement of welding quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

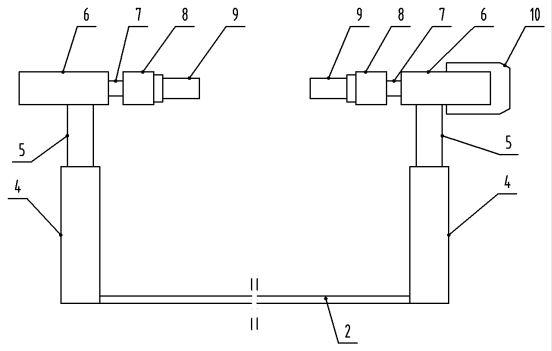

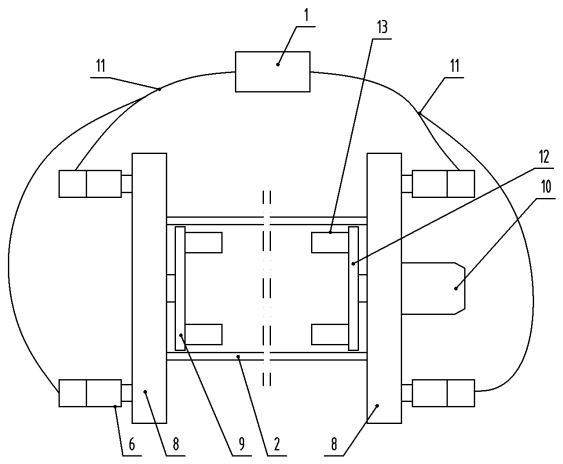

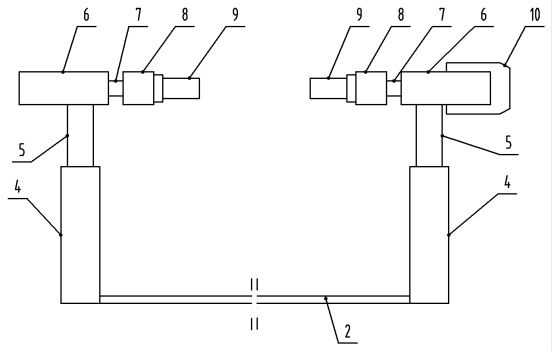

[0009] like figure 1 and figure 2 As shown, a frame turning device of the present invention includes a hydraulic station 1 arranged on one side of the track 2, four vertical hydraulic cylinders 4 arranged in a rectangular shape along both sides of the track 2, and two ends of the track 2 are respectively provided with Two, the upward vertical piston rod 5 in the vertical hydraulic cylinder 4 is provided with a horizontal hydraulic cylinder 6 parallel to the track 2, and a block is arranged between the two horizontal piston rods 7 of the two horizontal hydraulic cylinders 6 at the same end. Fixed plate 8, the inner sides of two fixed plates 8 are respectively rotated and connected with an overturning frame 9, and the outer side of one of the fixed plates 8 is provided with a motor 10 for controlling the rotation of the overturning frame 9, and the vertical hydraulic cylinder 4 and the horizontal hydraulic cylinder 6 are connected with the hydraulic station 1 respectively. Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com