Mushroom bed planting system

A planting system and mushroom bed technology, applied in botany equipment and methods, horticulture, agricultural machinery and tools, etc., can solve problems such as high difficulty, low work efficiency, and low safety factor of staff, so as to improve yield and facilitate The effect of trimming and turning soil and reducing manpower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

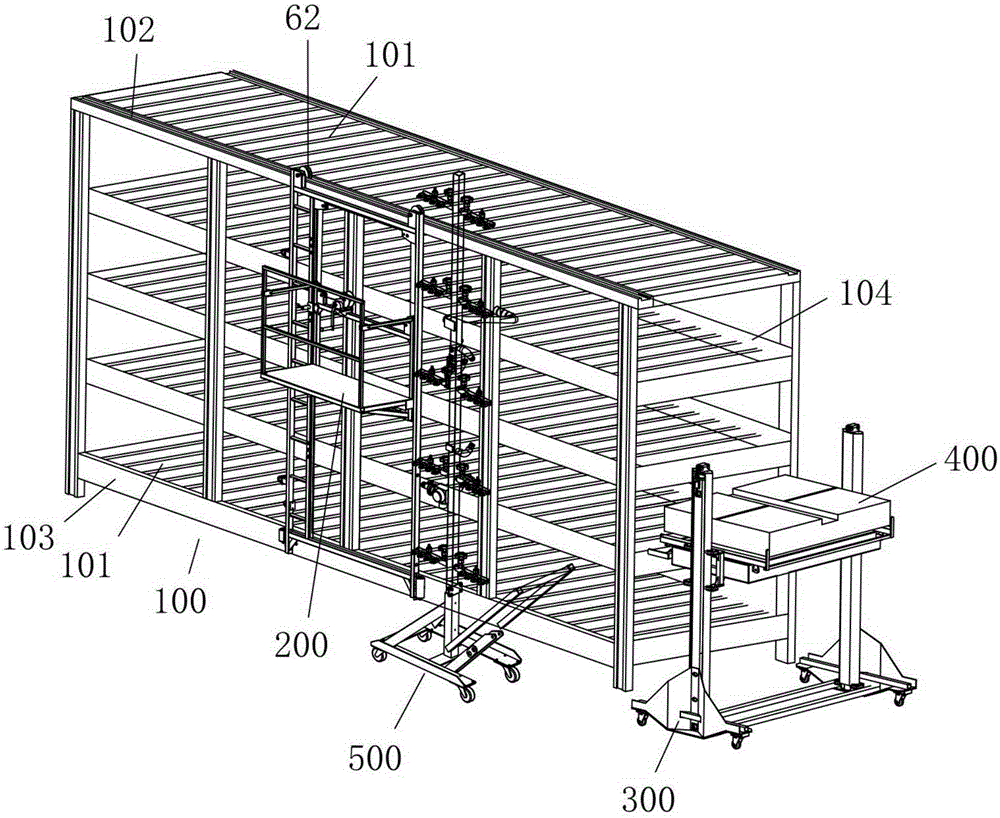

[0057] The mushroom bed planting system includes a mushroom bed 100, and a number of planting layers 101 are arranged in the mushroom bed, and the planting layers 101 are arranged from top to bottom; a mushroom picking vehicle 200 is set on the left or right side of the mushroom bed 100;

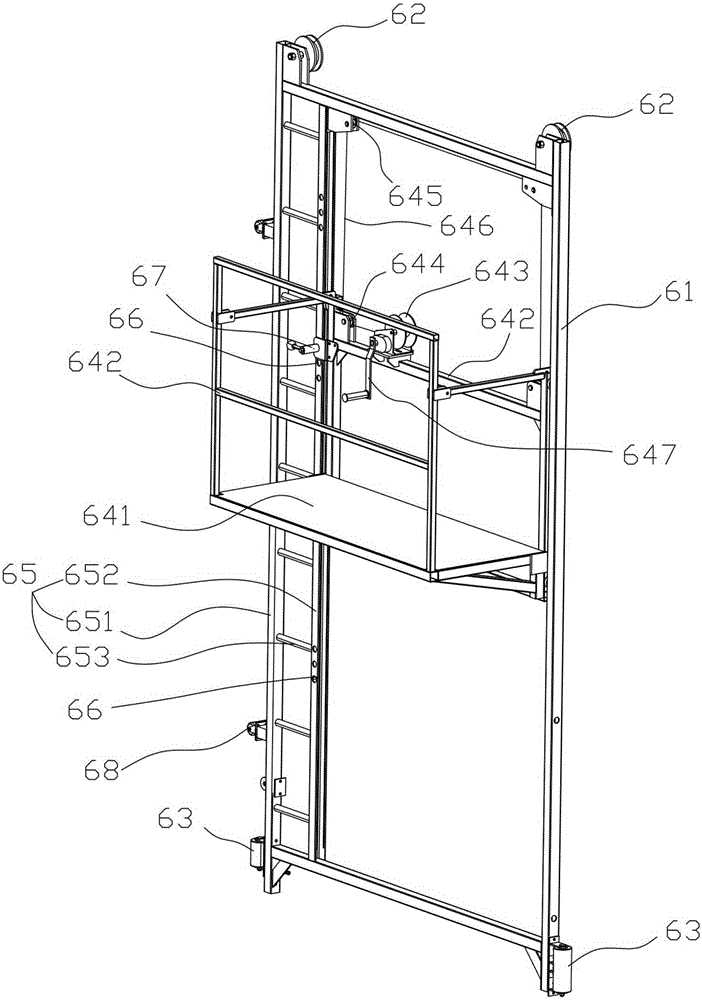

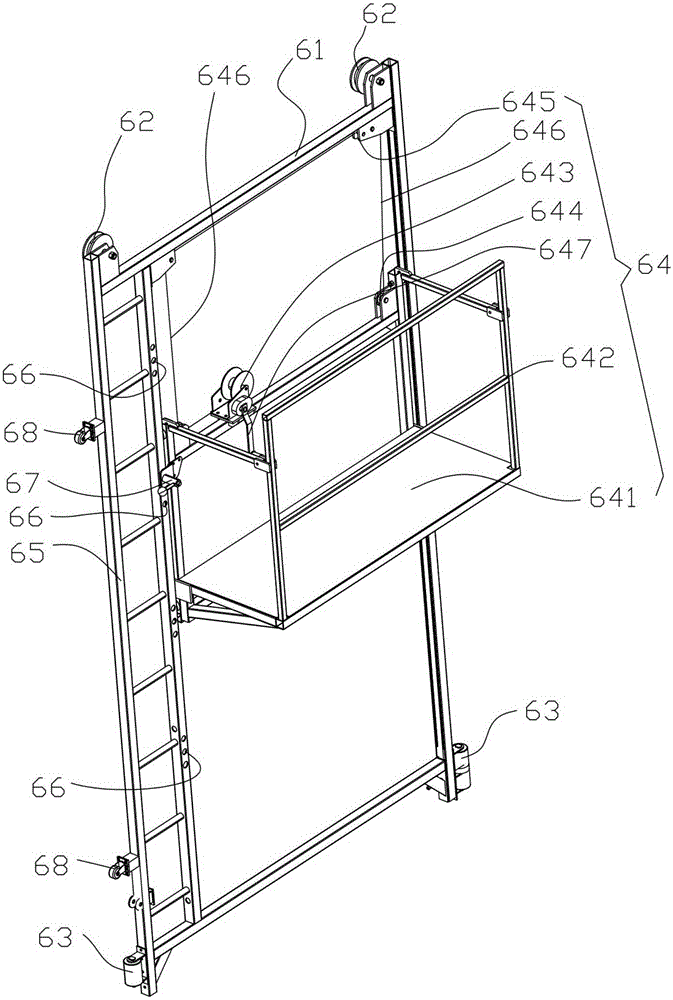

[0058] Mushroom picking vehicle 200 comprises vehicle frame 61, is provided with sliding wheel 62, auxiliary wheel 63 and safety lifting platform 64 on vehicle frame 61, is provided with ladder 65 on the side of safety lifting platform 64; Described safety lifting platform 64 includes Platform 641, a guardrail 642 is provided on the platform 641, a driving wheel 643 and a lower driven wheel 644 are arranged on the upper edge of the guardrail 642, an upper driven wheel 645 is arranged on the upper end of the vehicle frame 61, the driving wheel 643, the lower driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com