Plate material conveying device

A technology for conveying devices and plates, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of difficulty in increasing the speed of the walking body, shortening the time of acceleration and deceleration, and increasing the weight of the device, so as to shorten the time of acceleration and deceleration, Effects of increasing sheet conveying speed and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

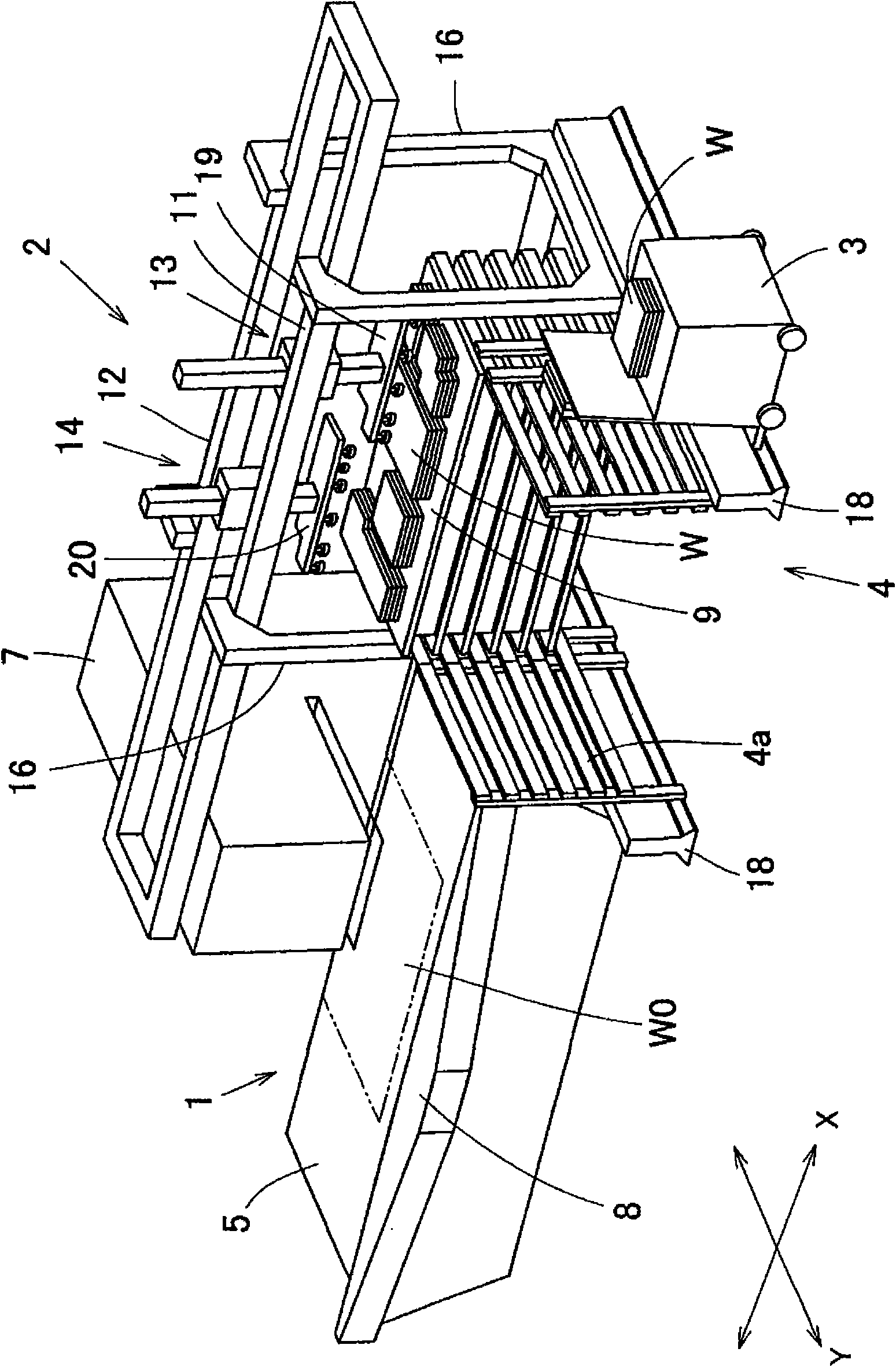

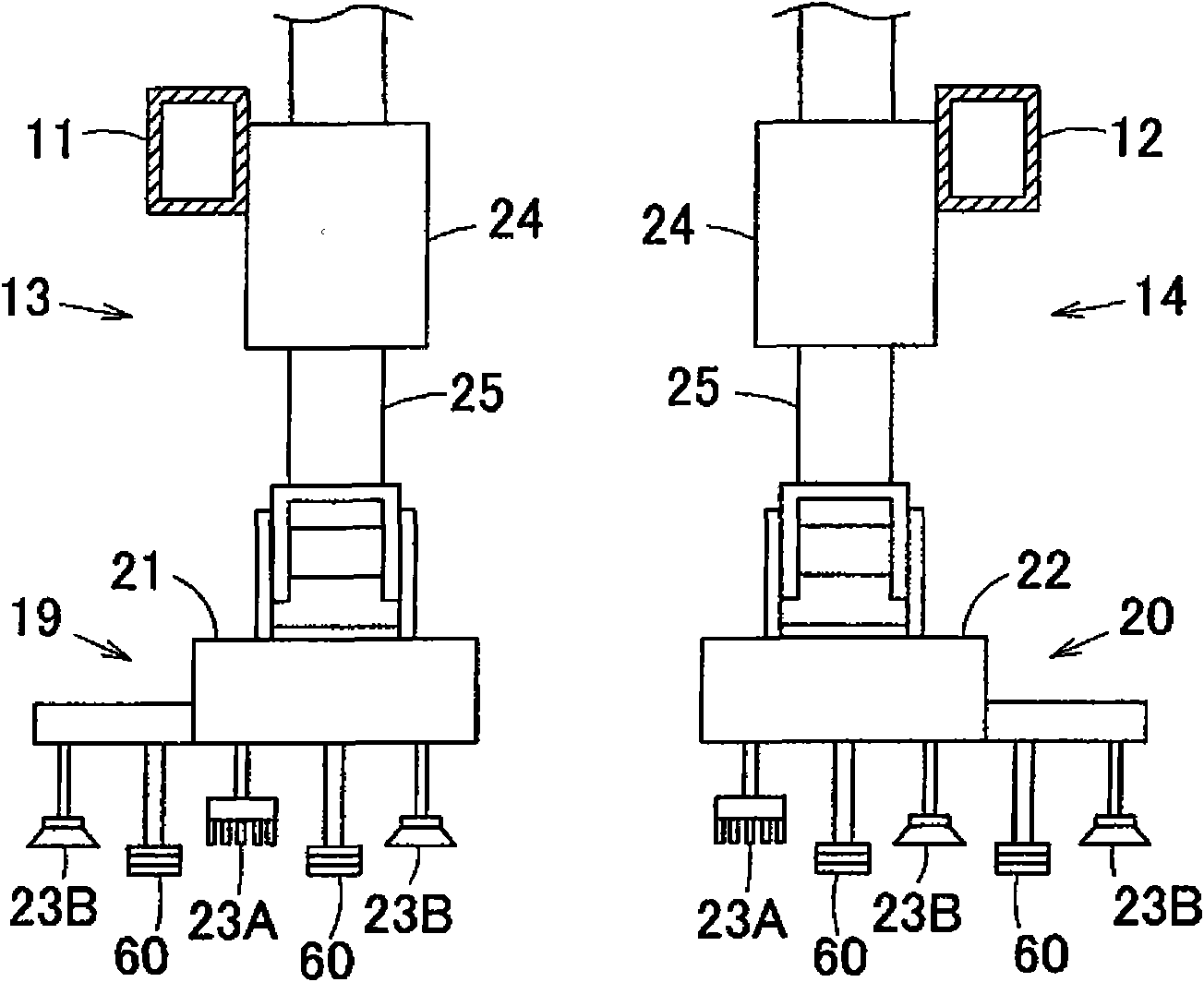

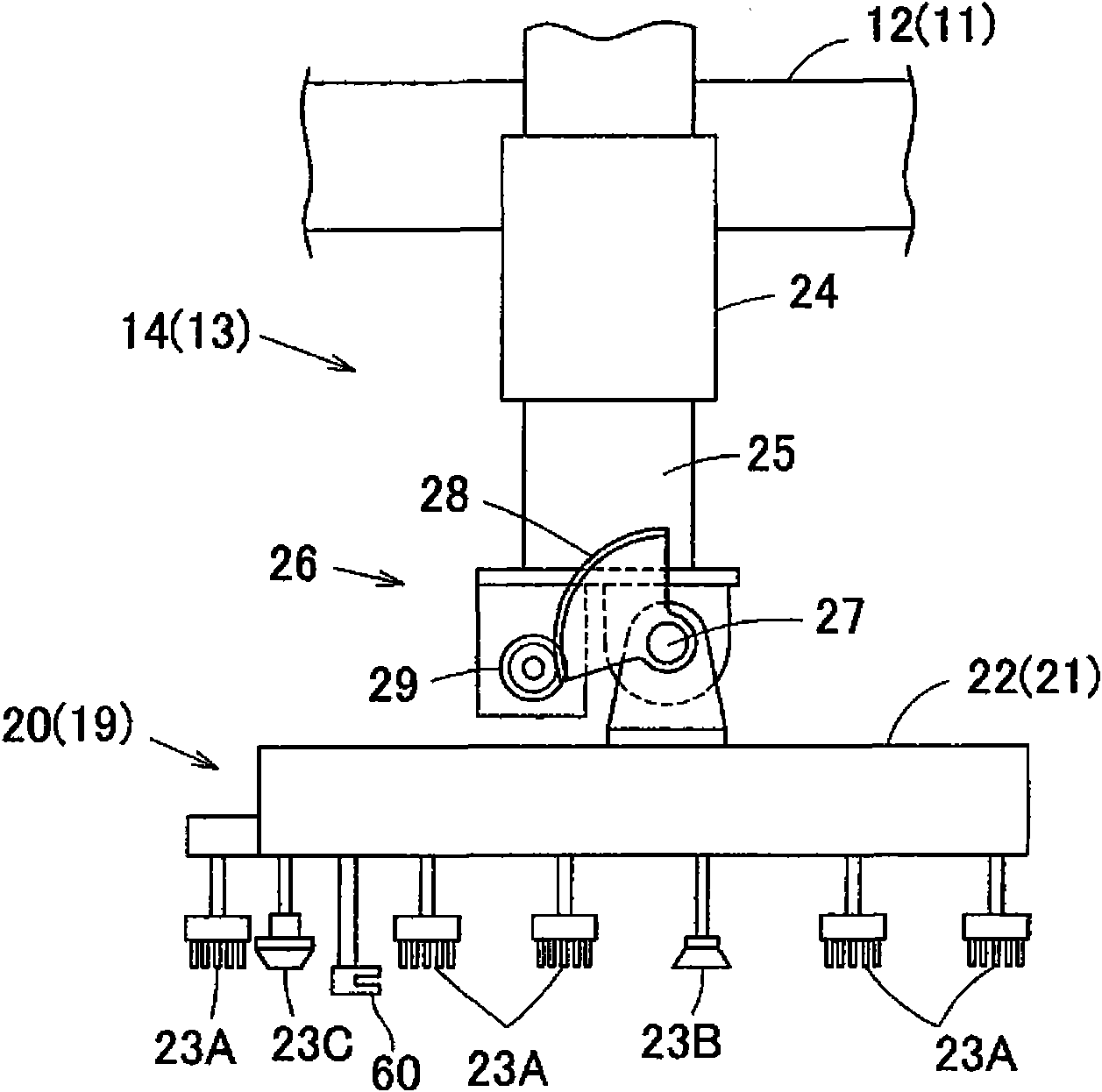

[0038] and Figure 1 to Figure 13 Embodiments of the present invention will be described together. figure 1 It is an overall perspective view of a board processing system, which includes: a board processing machine 1; In addition, this work sheet processing system includes a sheet material carrying device (not shown) for carrying the raw material sheet WO into the work sheet processing machine 1 , but description of the work sheet carrying device is omitted. The sheet material processing machine 1 and the sheet material conveyance device 2 are controlled by a computer-type processing machine control device and a conveyance control device (not shown) according to respective control programs.

[0039] The sheet metal processing machine 1 has a function of cutting a plurality of finished sheet materials W from the raw material sheet WO on the table 5 by punching or the like, and is constituted by a punch press or a laser processing machine or the like. In this example, the shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com