Carrying apparatus and hot-rolling apparatus, and carrying method and hot-rolling method

A conveying device and conveying roller technology, applied in forging and pressing devices, workpiece heating devices, furnace control devices, etc., can solve the problems of conveying roller impact, bending or warping of workpieces, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

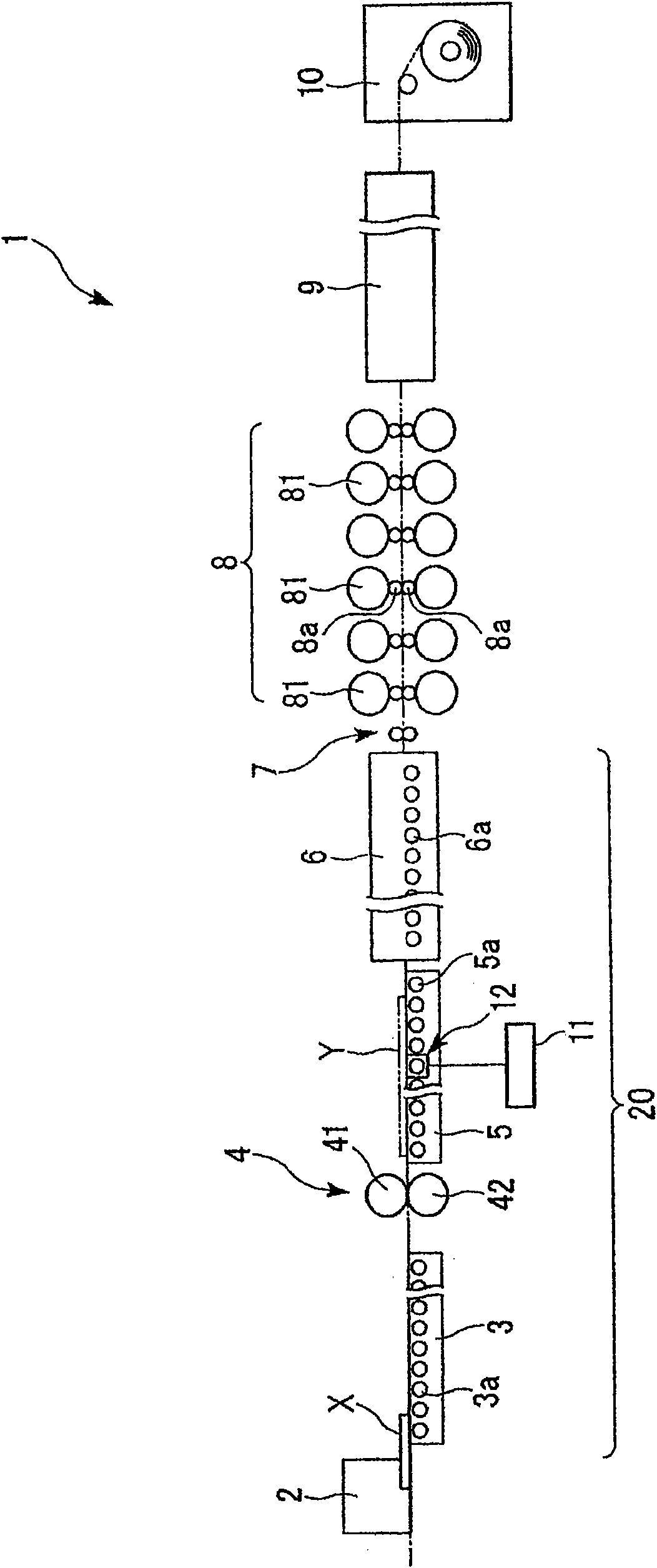

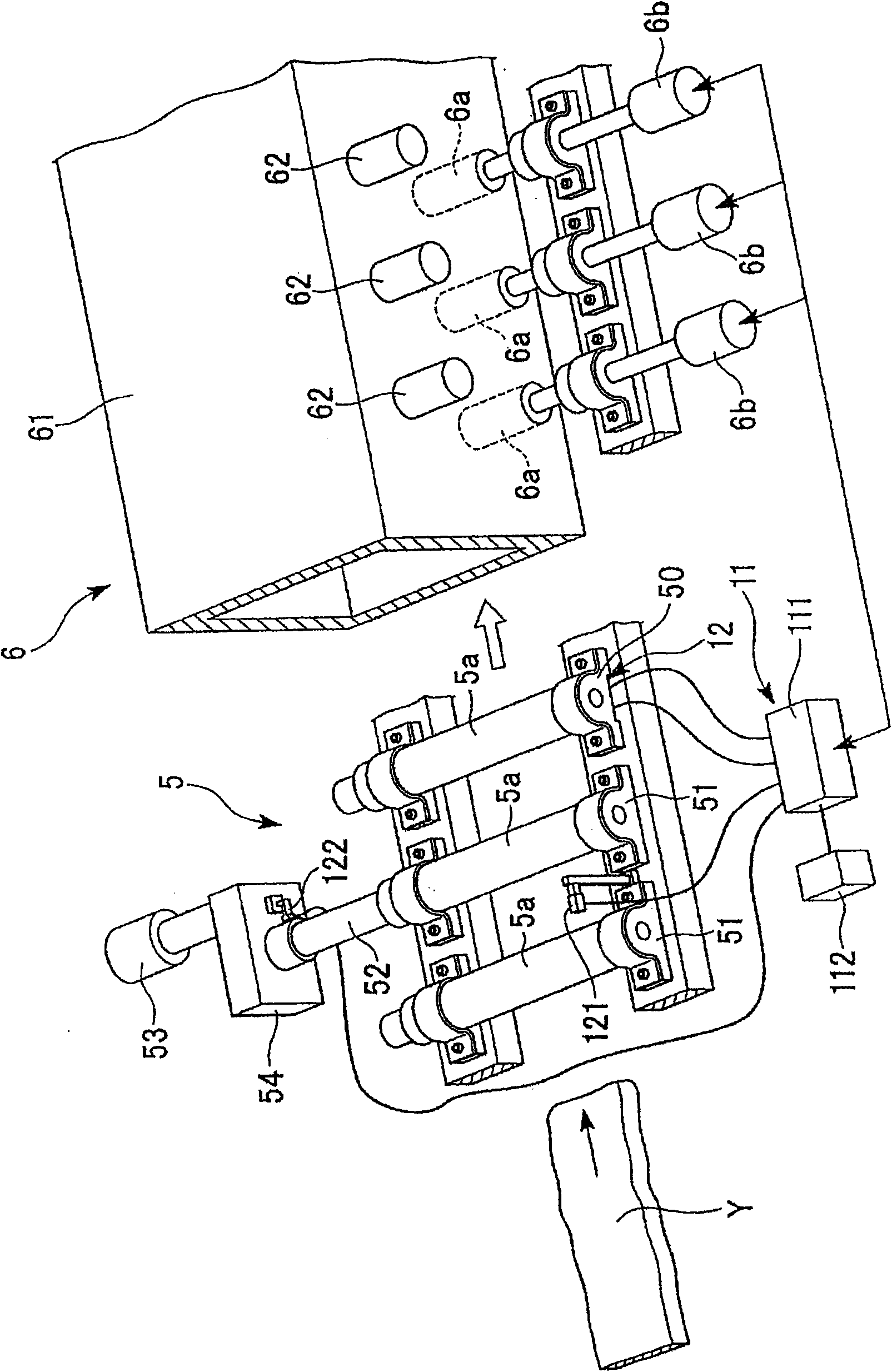

[0052] figure 1 It is a figure which shows the schematic structure and functional structure of the conveying apparatus 20 which is one embodiment of this invention, and the hot rolling apparatus 1 provided with this conveying apparatus 20.

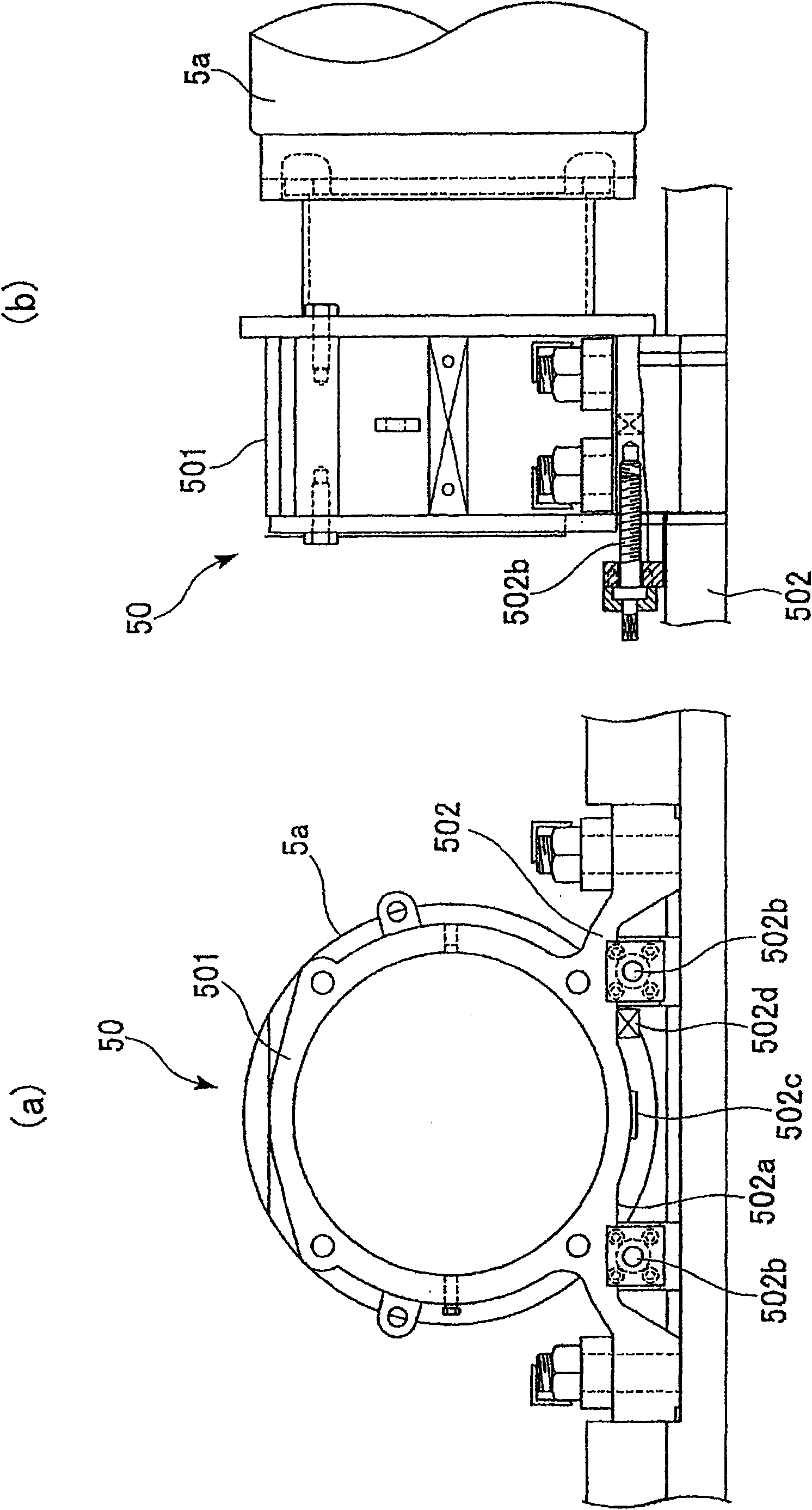

[0053] As shown in the figure, the hot rolling apparatus 1 of this embodiment includes a heating furnace 2, a front roller table 3, a rough rolling mill 4, a rear roller table 5, a heating and holding furnace 6, a shearer 7, a finishing mill 8, and a cooling device 9. , a winding machine 10, a control unit 11, and a data acquisition unit 12 for impact prediction.

[0054] The heating furnace 2 heats a slab X (workpiece) containing copper and mainly composed of steel to a temperature suitable for the rough rolling process before rolling by the rough rolling mill 4 .

[0055] The front roller table 3 is arranged in the rear stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com