Vehicle element size quality control system and method

A quality control method and technology for auto parts, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as non-discovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

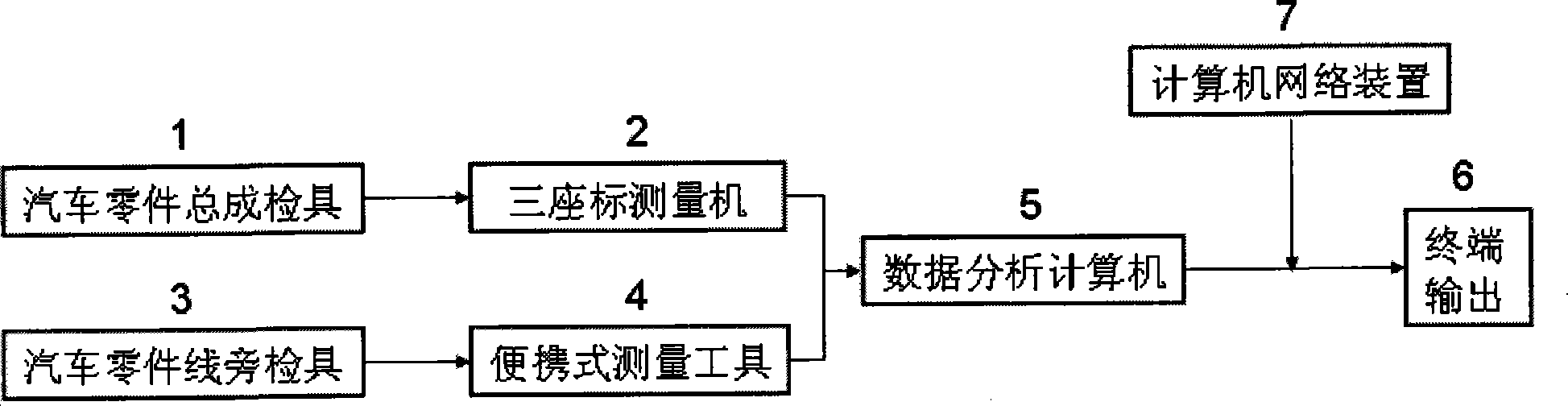

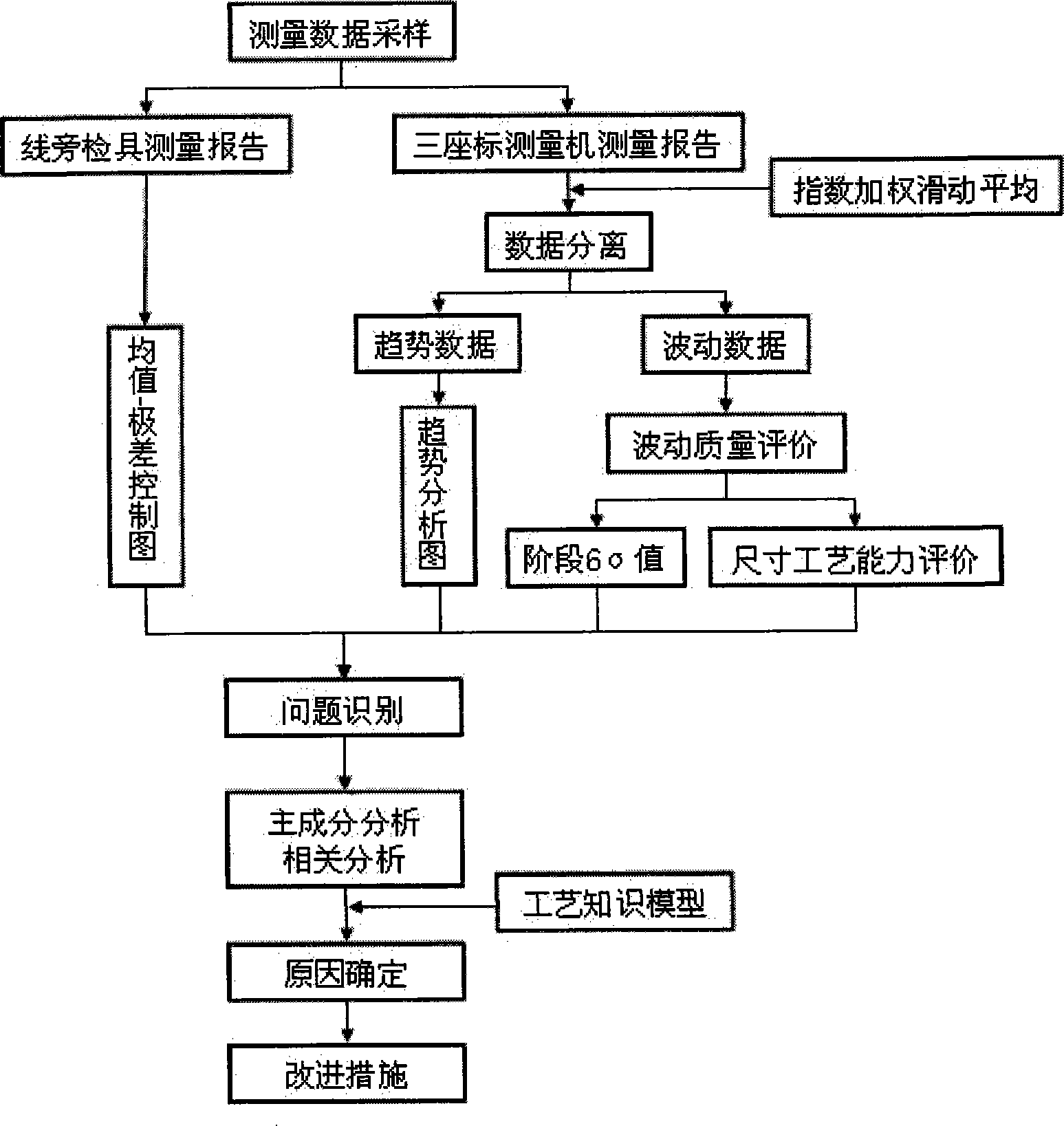

Method used

Image

Examples

Embodiment

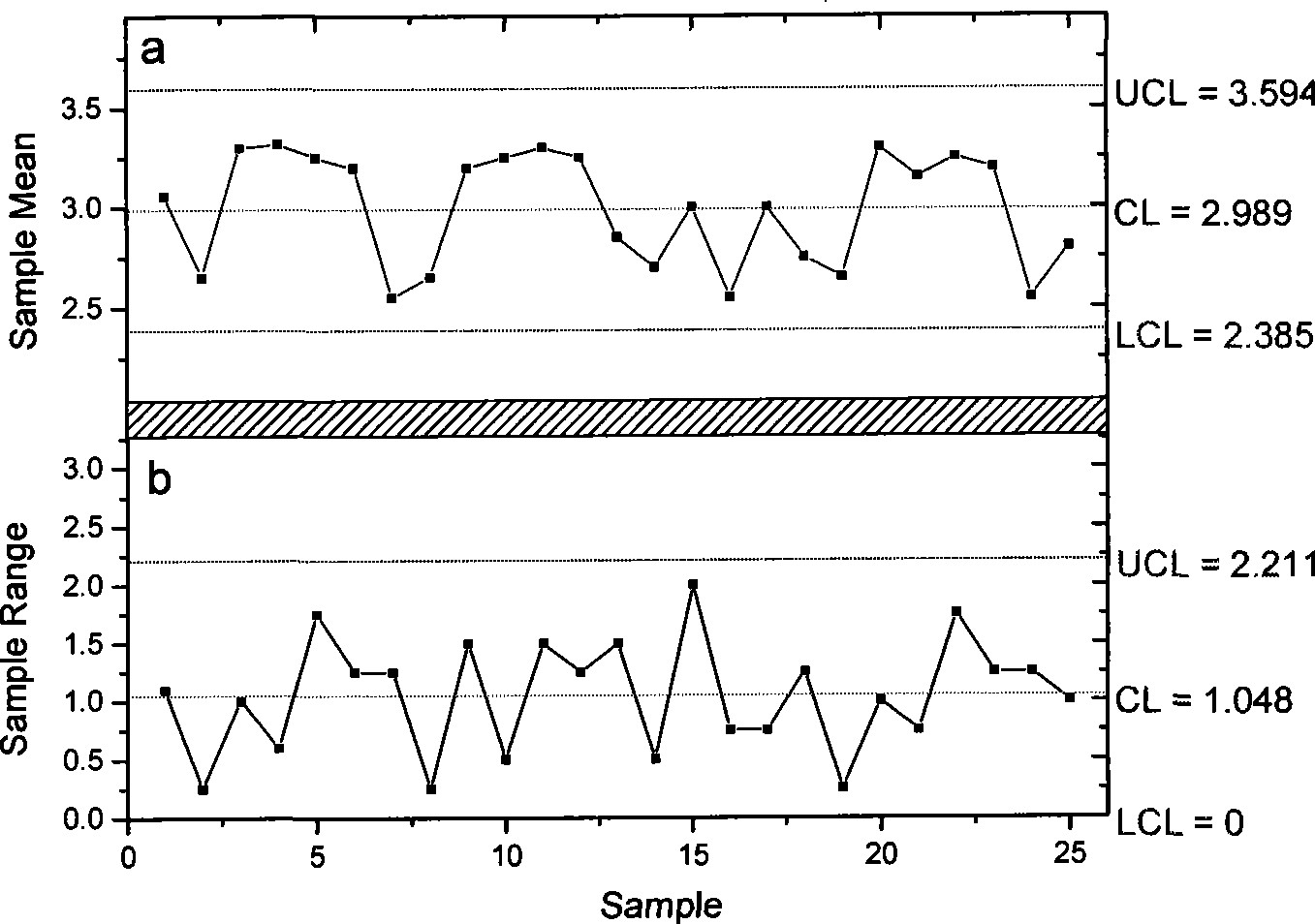

[0085] Embodiment: 1. Sampling: In this example, the sampling frequency of the line-side inspection tool for auto parts is 5 pieces / time, and each production shift is sampled 4 times at a fixed time every day, and double-shift production is implemented, that is, 8 pieces are obtained every day Sample, take 25 samples, and analyze the measured value of a measuring point on the part;

[0086] The sampling frequency of the three-coordinate measuring machine measurement of parts is 2 pieces per day, and 45 days of data are taken, and a total of 90 pieces are analyzed.

[0087] 2. Data analysis:

[0088] (1) Analysis of the mean-range control chart of lineside gauge measurement

[0089] 1) Generate the measurement report of the lineside gauge, as shown in Table 1.

[0090]

[0091] 2) Calculate the sample mean For example for the first sample x 1 ‾ = 3.06 , The rest and so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com