Patents

Literature

171results about How to "Reduce conveying speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

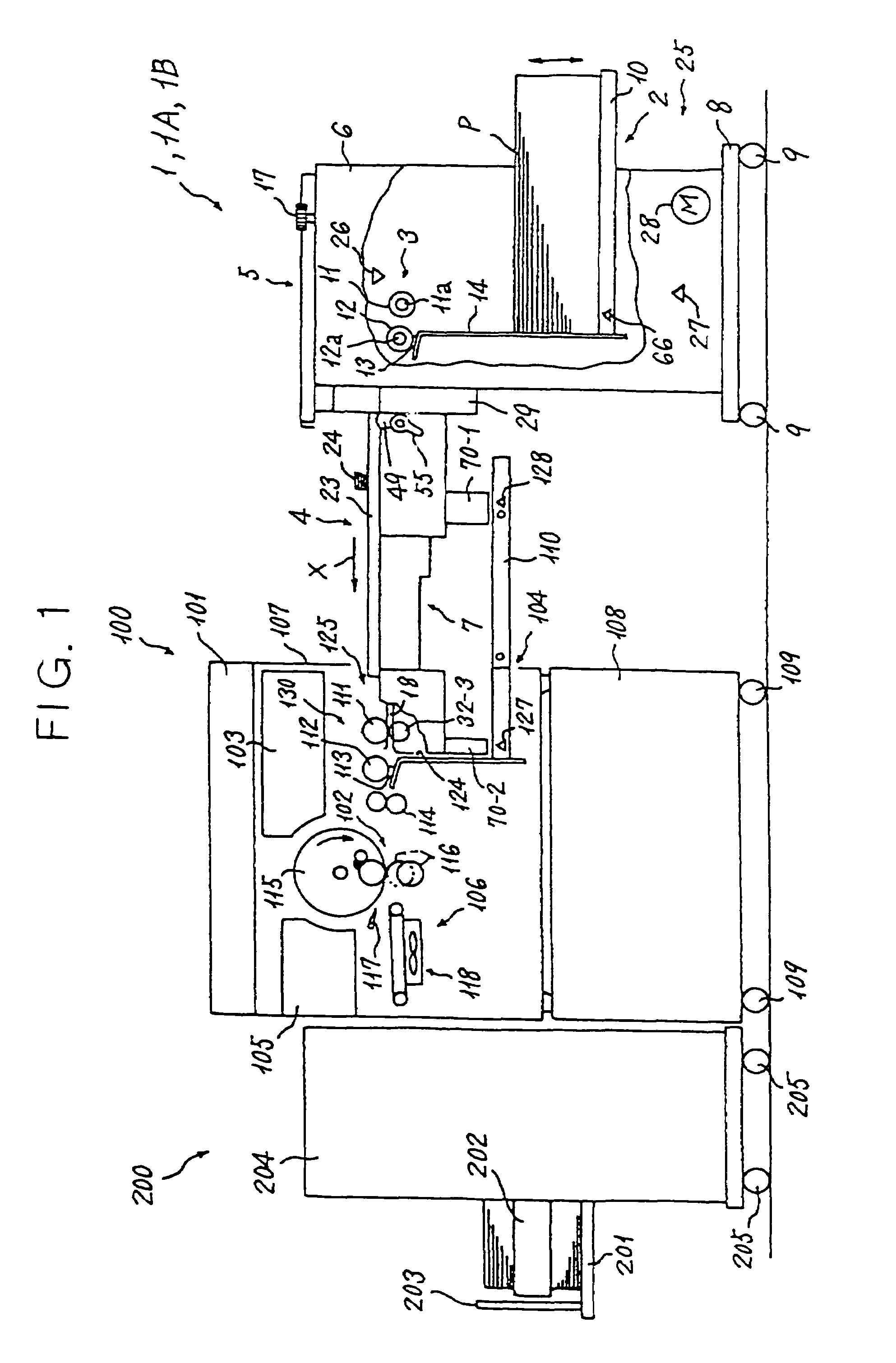

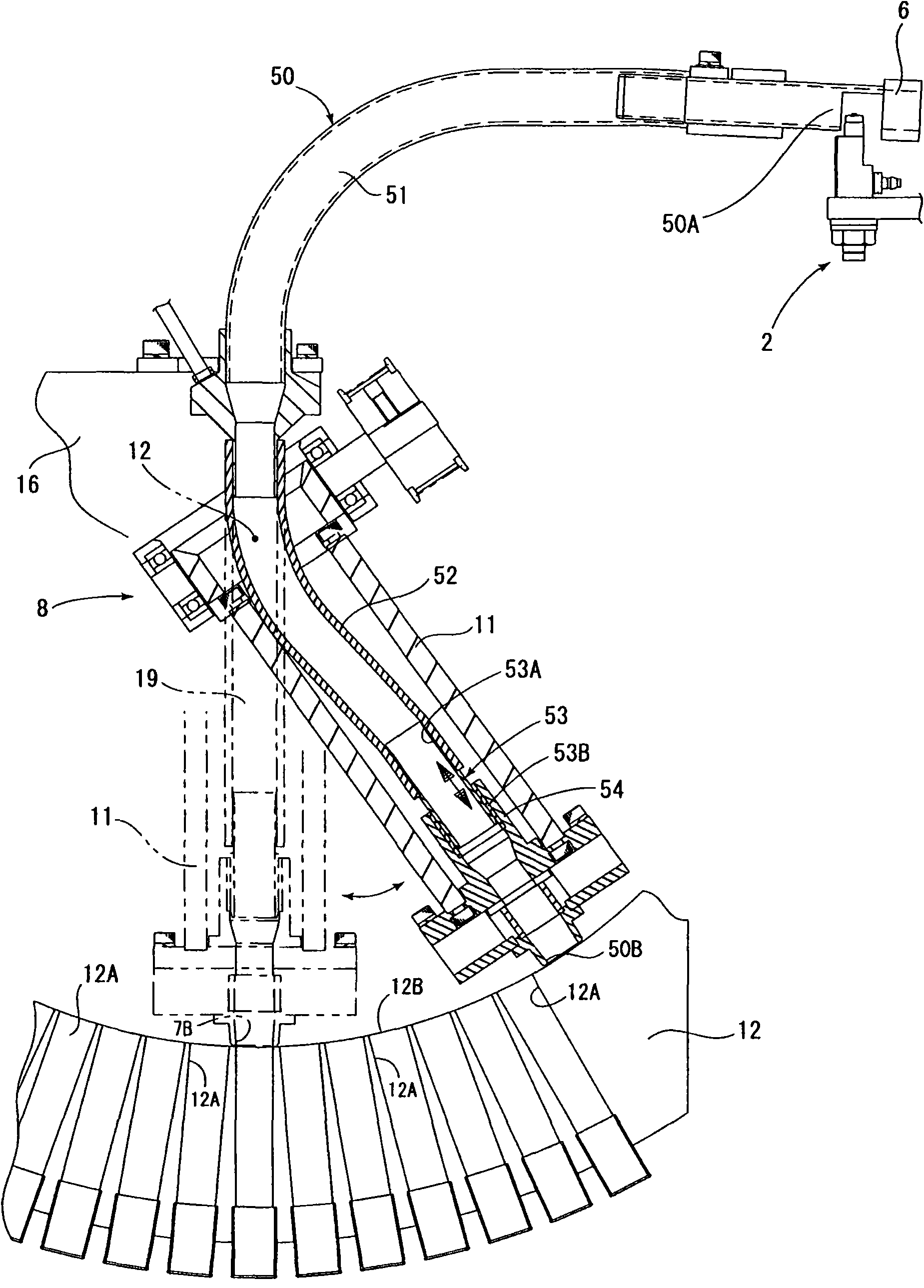

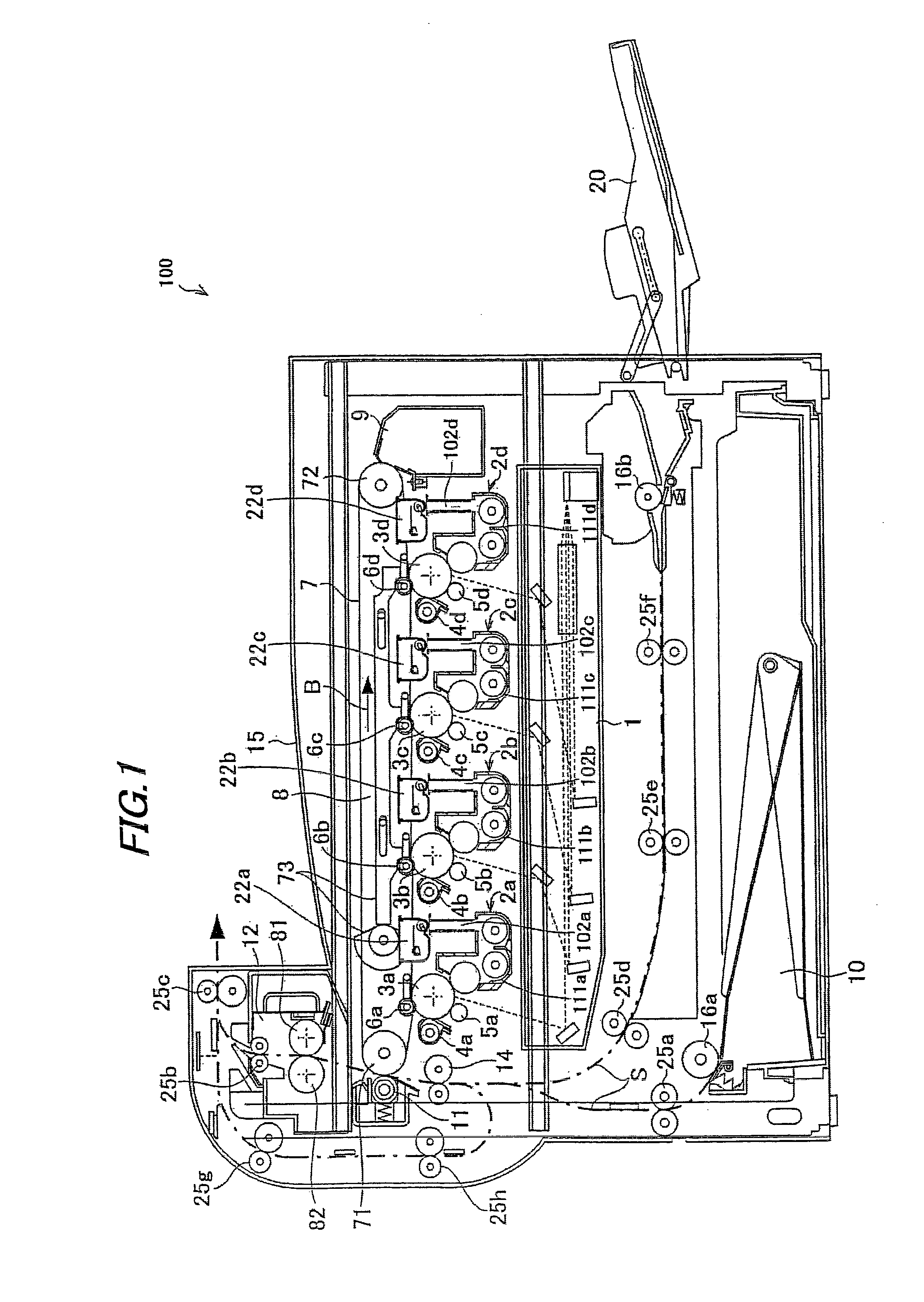

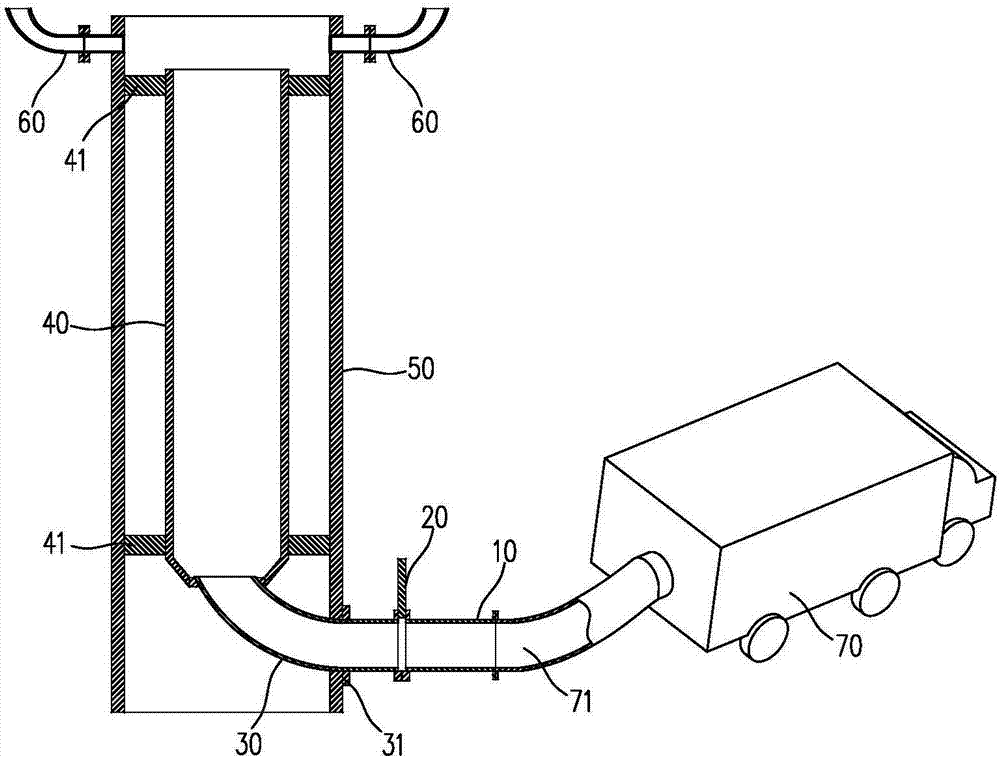

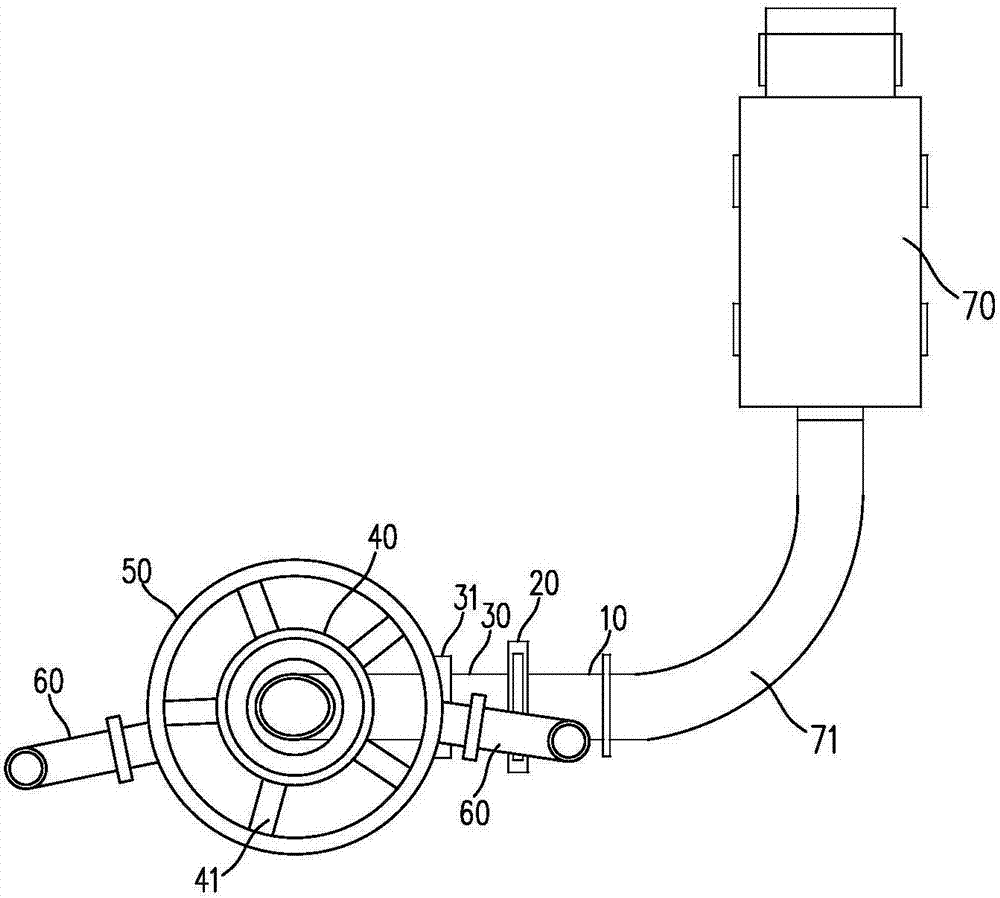

Pebble-bed module type high-temperature gas cooled reactor fuel loading and unloading system

ActiveCN103474113AGuaranteed purityImprove securityNuclear energy generationReactor fuel elementsVacuum pumpingNuclear engineering

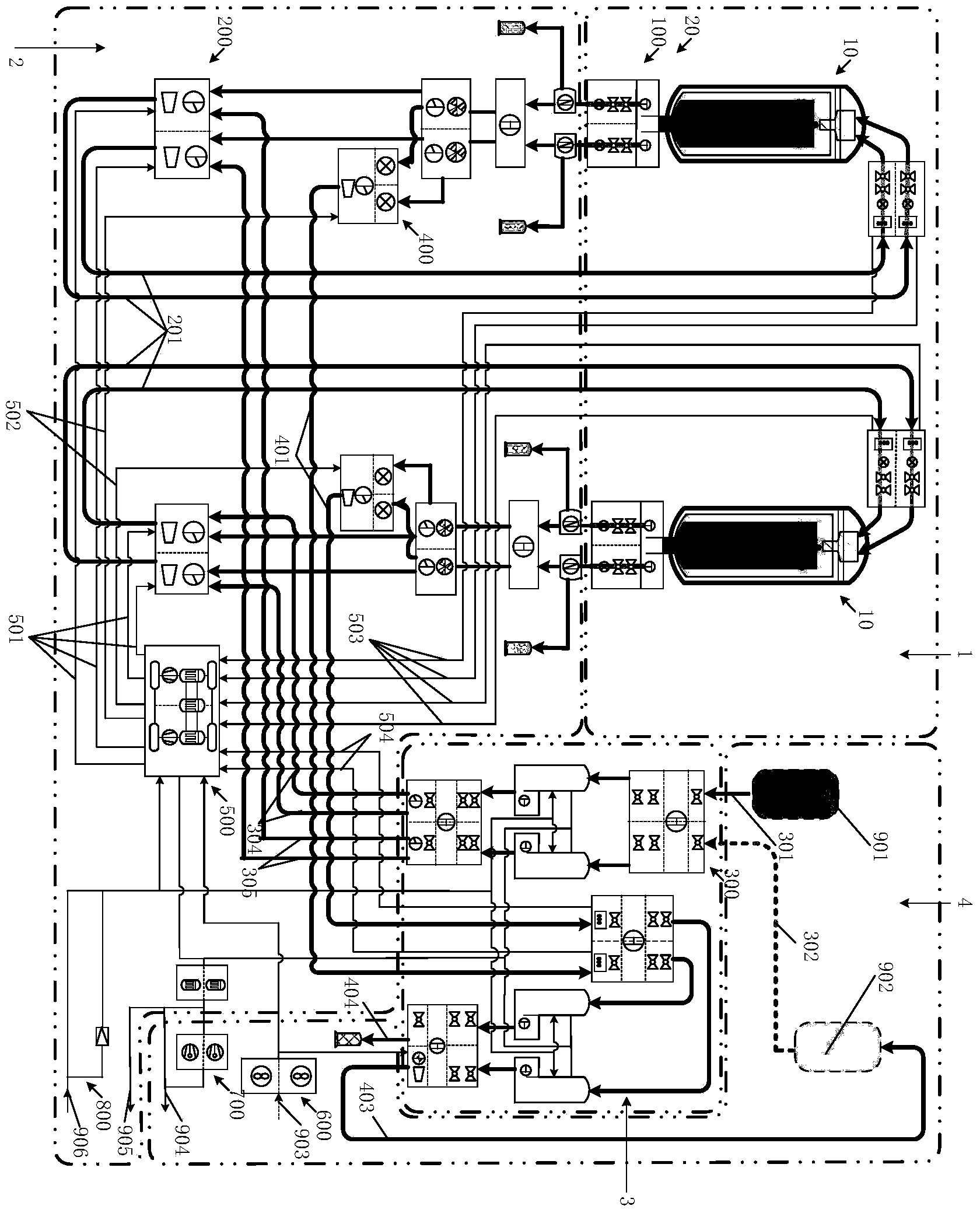

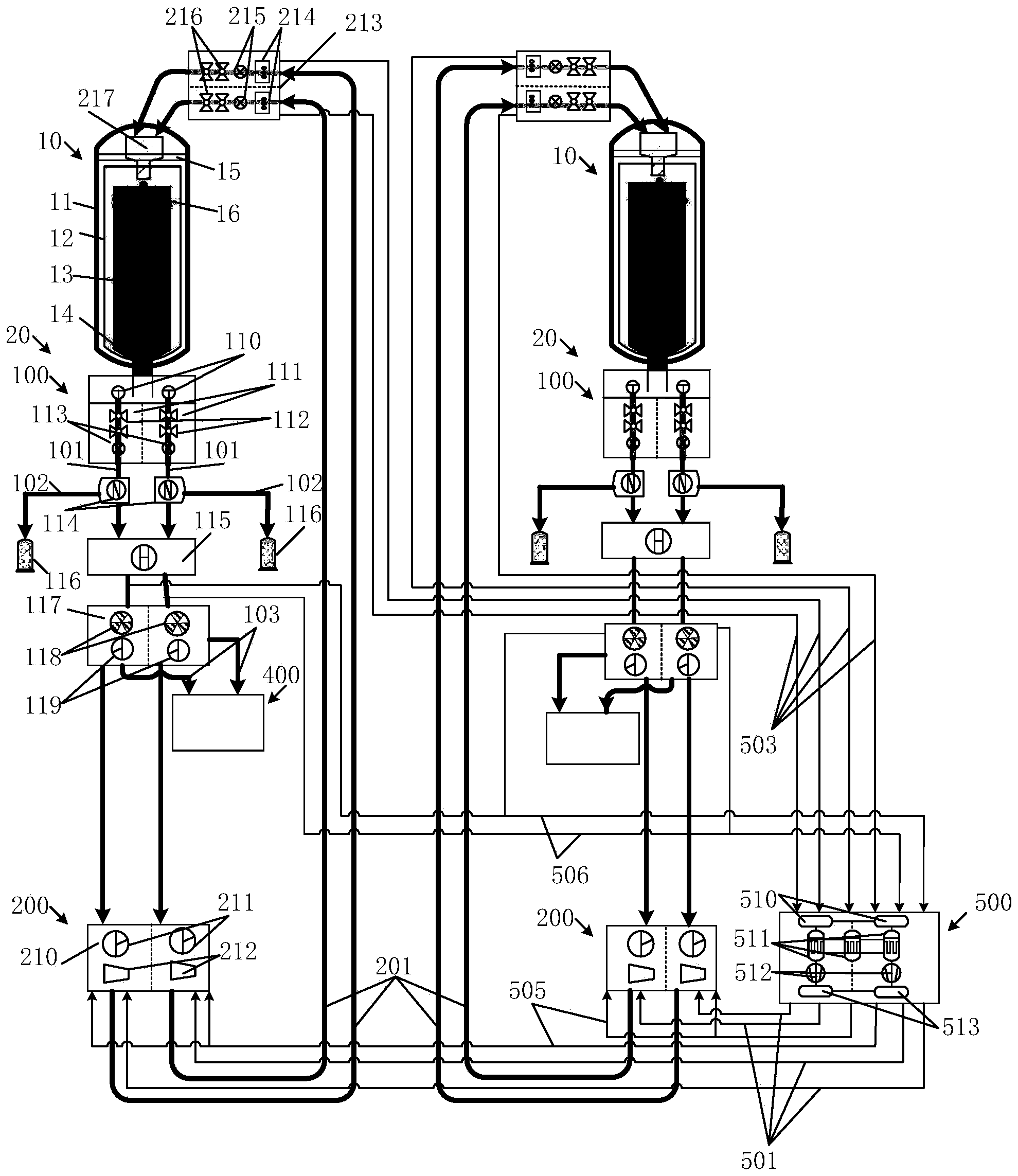

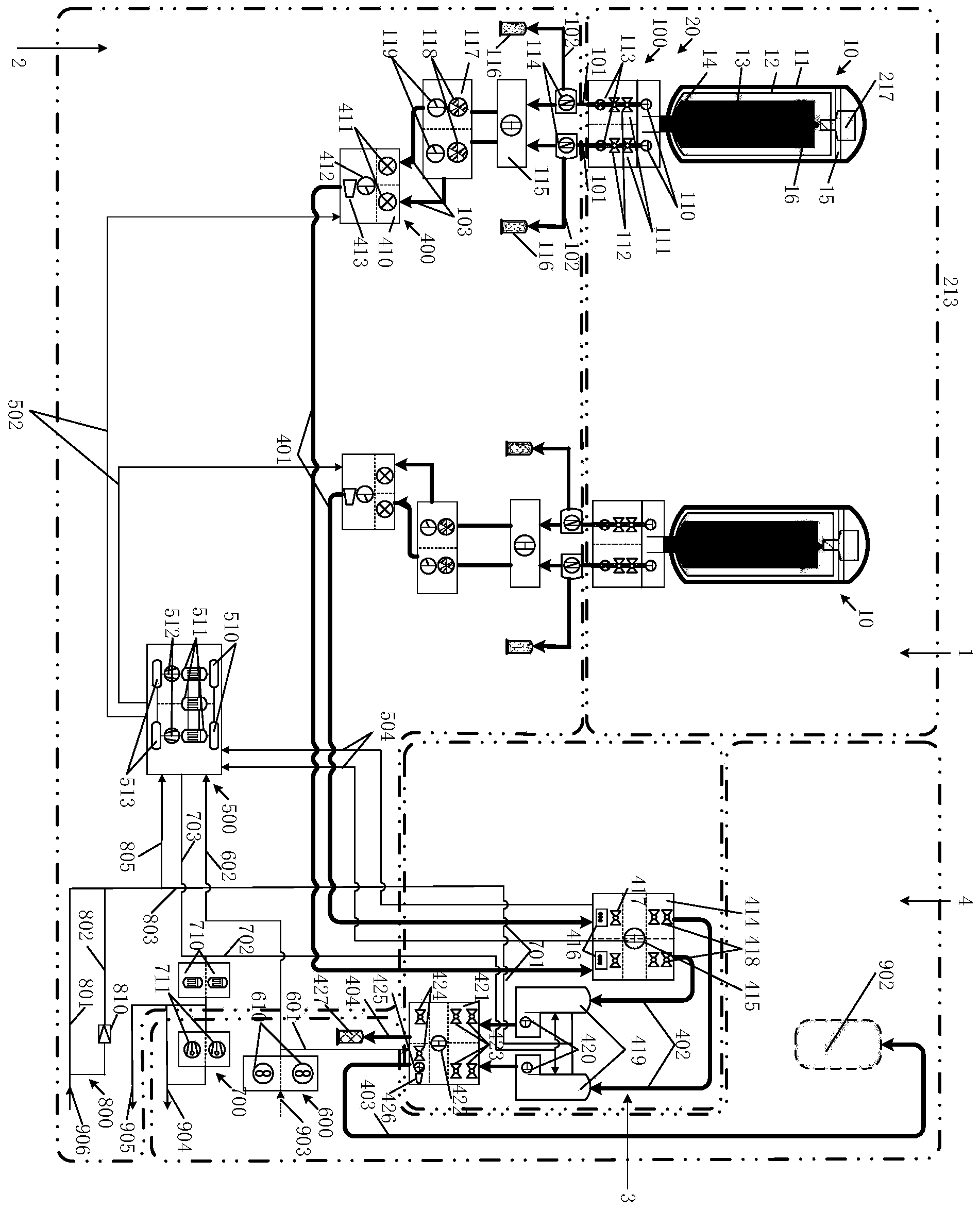

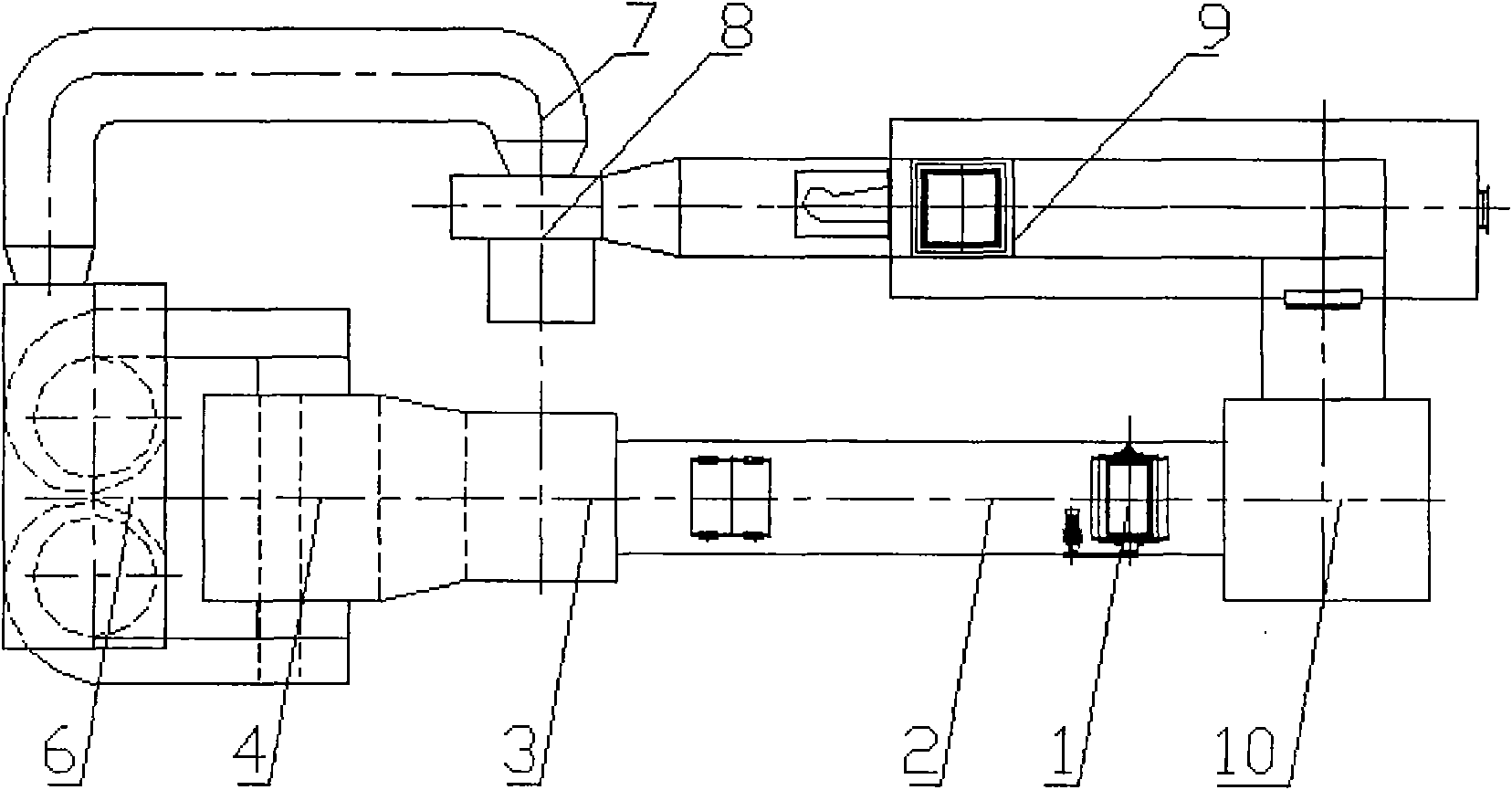

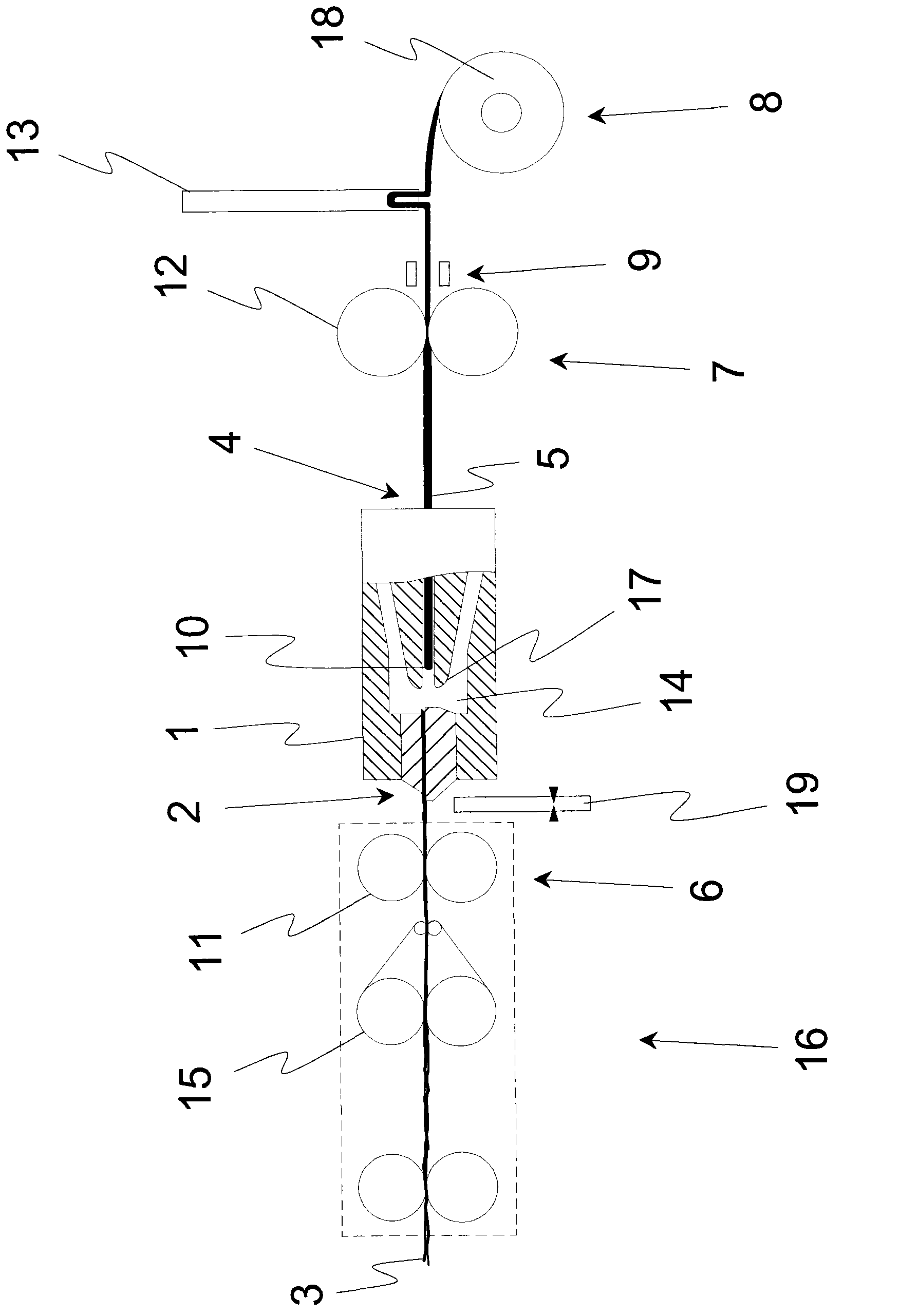

The invention relates to a pebble-bed module type high-temperature gas cooled reactor fuel loading and unloading system which comprises a reactor (10), a reactor core fuel circulating system (20), a new fuel loading system (300) and a spent fuel unloading system (400). The reactor (10) comprises a reactor pressure container (11), a graphite coating reactor internal component (12), a central reactor core cylinder (13), a metal reactor internal component (15) and an unloading pipe (14), the reactor core fuel circulating system (20) comprises a reactor core unloading system (100) and a reactor core loading system (200) and further comprises a helium pneumatic conveying system (500), a compressed air pneumatic conveying system (600), a vacuum pumping system (700) and a helium supplying and recycling system (800), and the compressed air pneumatic conveying system (600), the vacuum pumping system (700) and the helium supplying and recycling system (800) are all connected with the helium pneumatic conveying system (500). The helium pneumatic conveying system (500) is further respectively connected with the reactor (10), the reactor core fuel circulating system (20), the new fuel loading system (300) and the spent fuel unloading system (400).

Owner:CHINERGY CO LTD

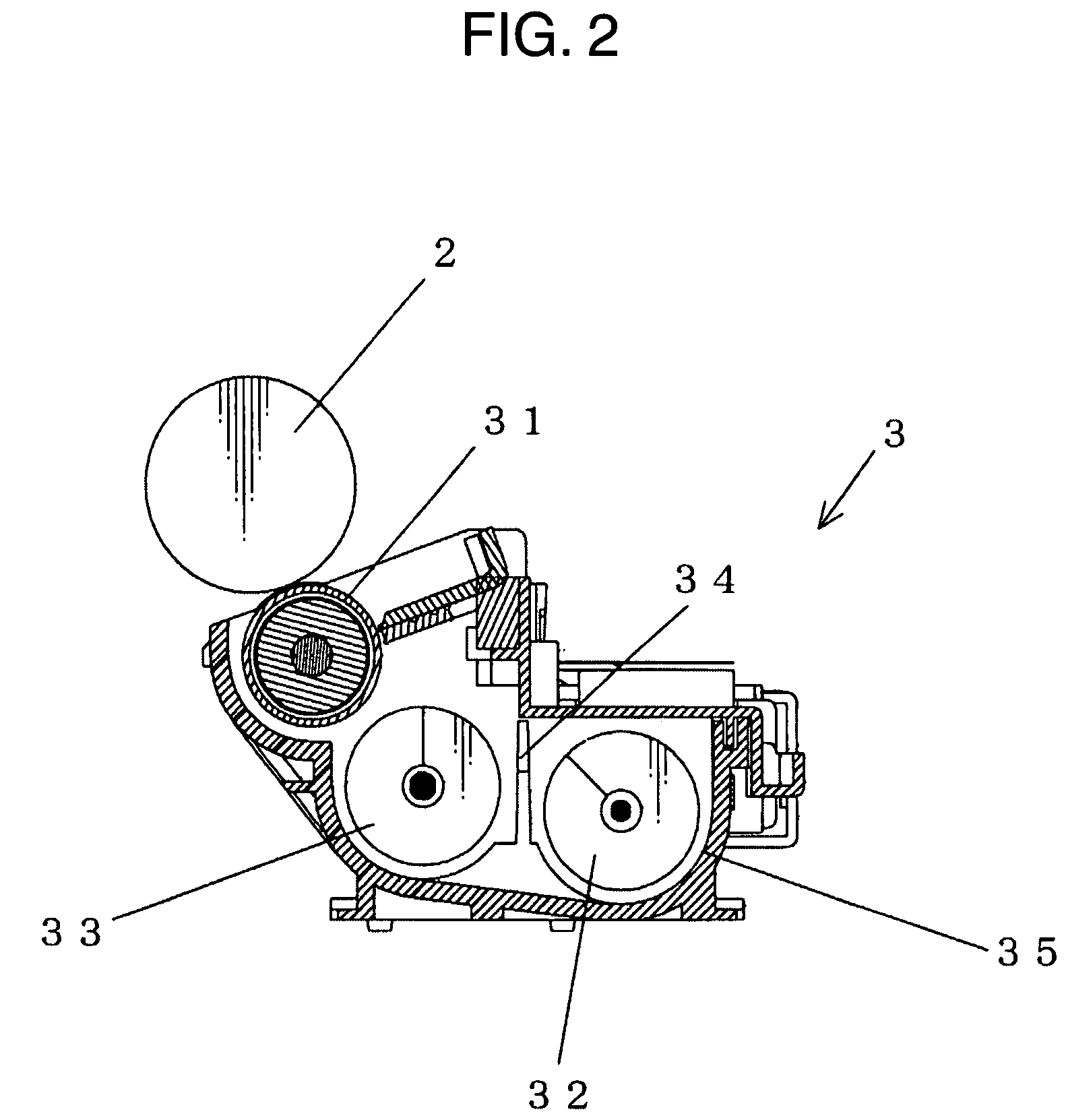

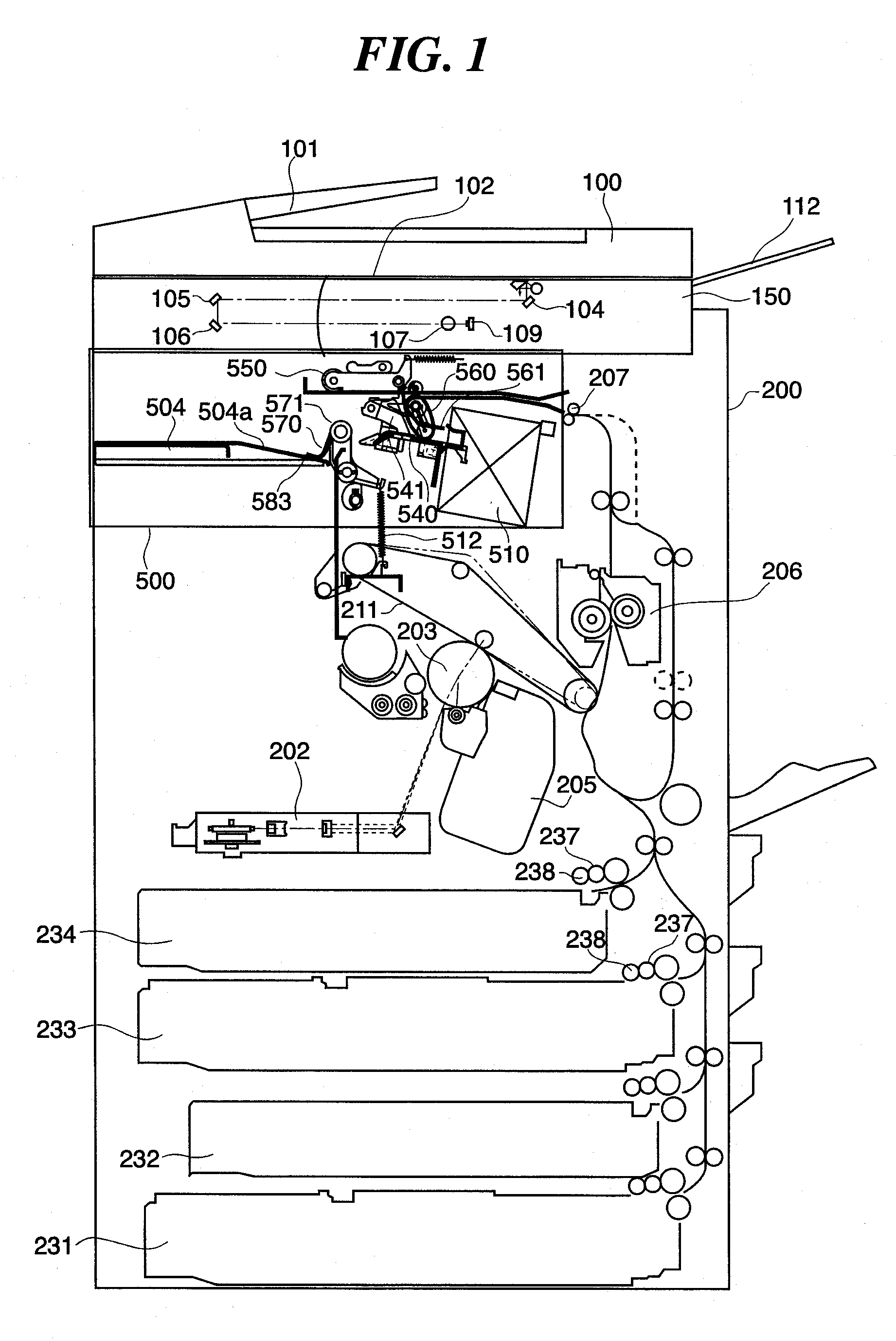

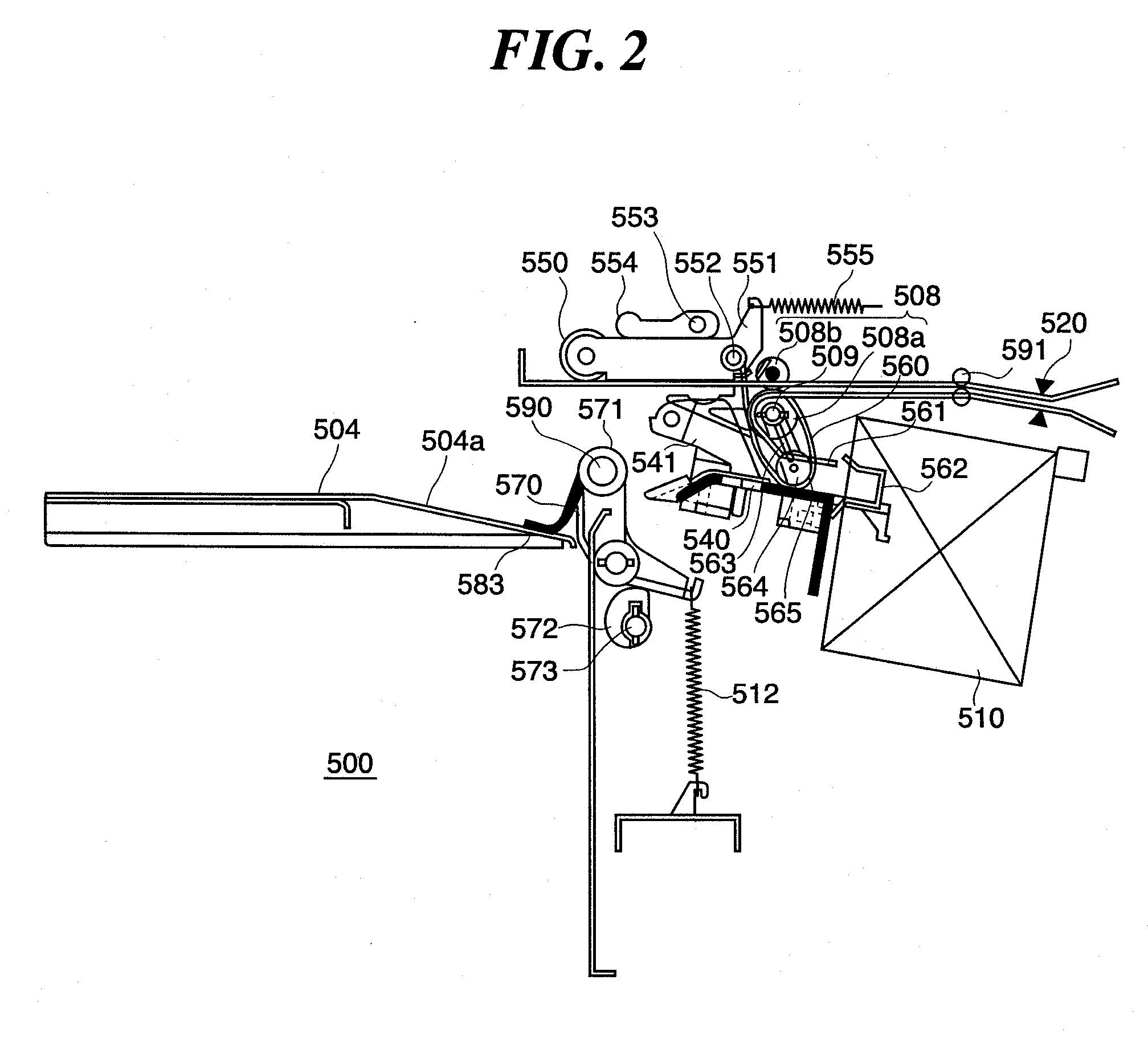

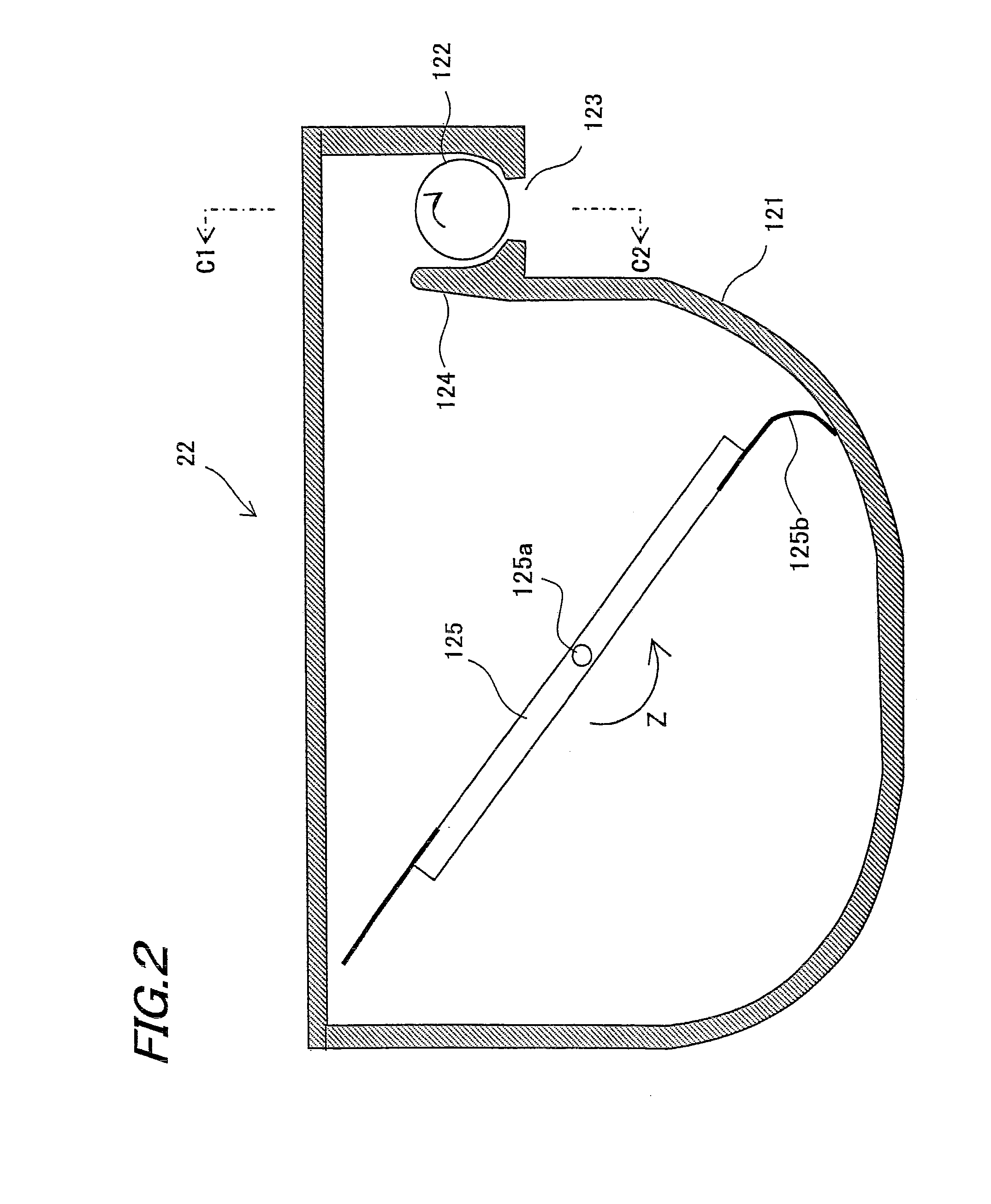

Powder conveying apparatus

ActiveUS20080025763A1Stir wellReduce conveying speedElectrographic process apparatusMaterials science

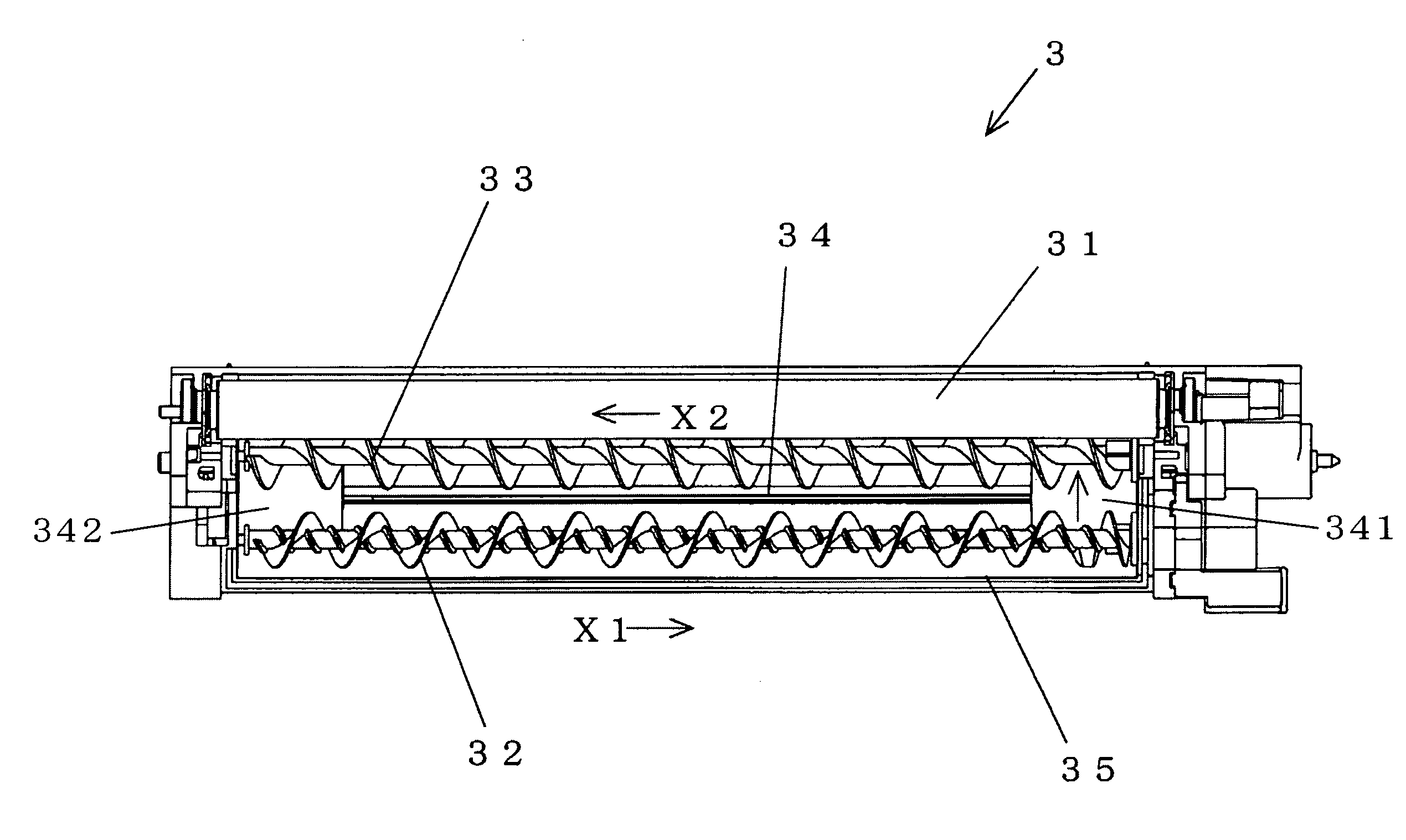

A powder conveying apparatus, comprising a powder container for storing powder and a powder agitating / conveying member provided in the powder container, wherein the powder agitating / conveying member includes: a shaft revolving around the axis; a primary conveying blade provided on the external surface of the shaft in such a manner that the powder is conveyed in the first direction toward one side of the axial direction, by revolution in one rotational direction around the axis of the shaft; and a secondary conveying element provided on the external surface of the shaft and located radially inner than a radially outer end of the primary conveying blade in the diameter direction in such a manner that conveying force is applied to part of the powder, which is conveyed in the first direction by the primary conveying blade, in the second direction toward the other side of the axial direction.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

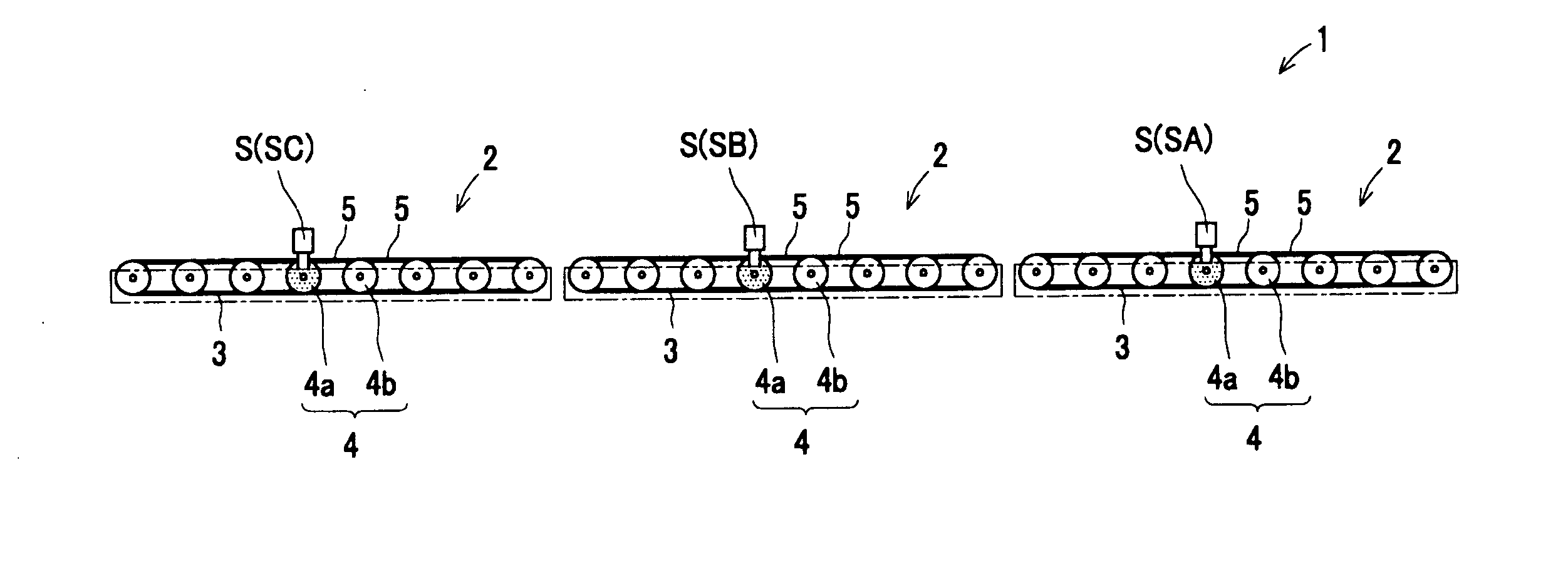

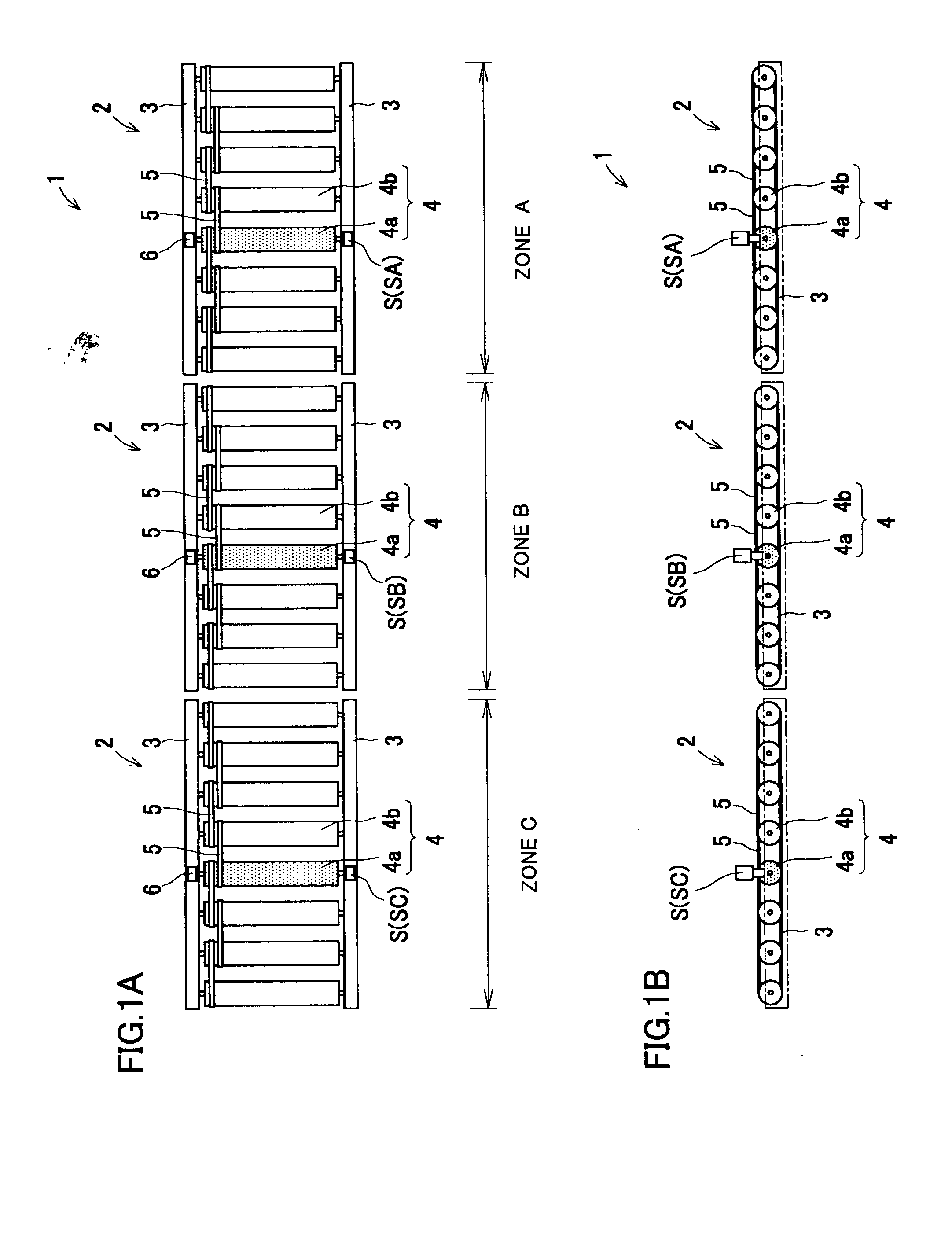

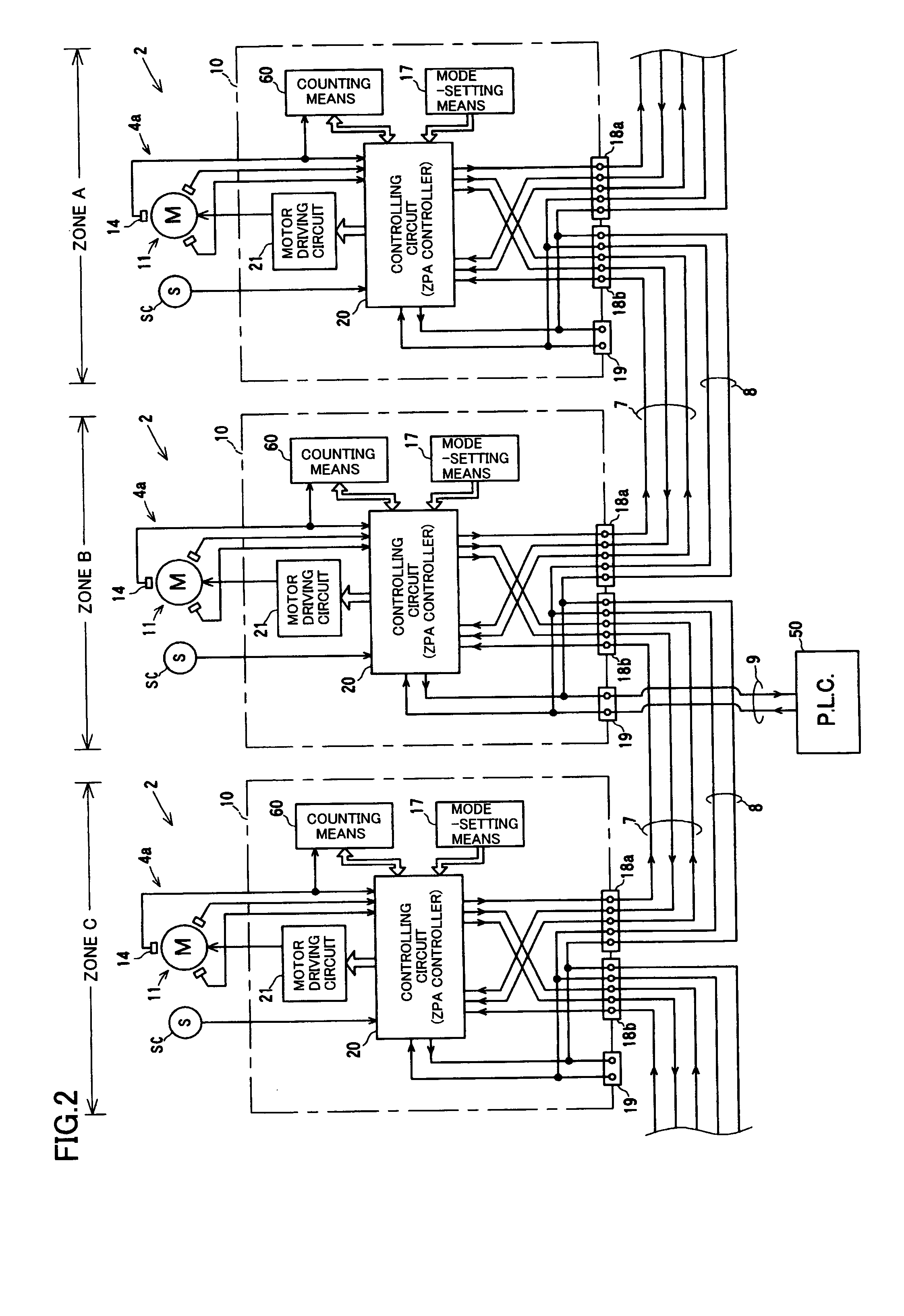

Zone controlled conveyor system and a zone controller for use therein

ActiveUS20050065641A1Good adhesionIncreased durabilityDigital data processing detailsControl devices for conveyorsEngineeringDelivery system

The invention aims to provide a zone controlled conveyor system including a plurality of zones for control. A zone controlled conveyor system, while conveyance of any article from a zone to a downstream zone is forbidden, (a) starts operation of a driving roller in the zone at a first conveying speed slower than a prescribed standard conveying speed upon detection of a presence of an article from an immediately upstream zone of the zone, (b) operates the driving roller at a second conveying speed slower than the first conveying speed after arrival of the article at a predetermined position in the zone, and (c) halts operation of the driving roller upon detection of a presence of the article in the zone. Thereby, the system enables to stop articles at a target position accurately.

Owner:ITO DENKI KK

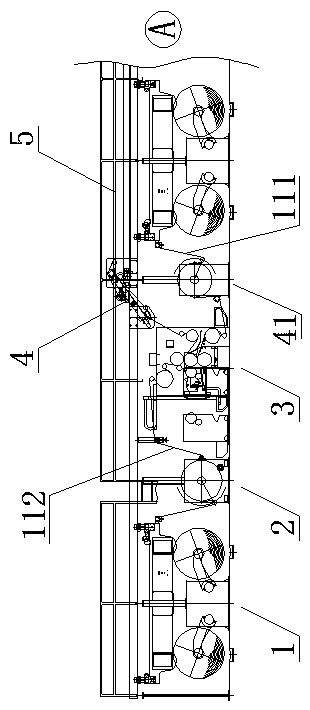

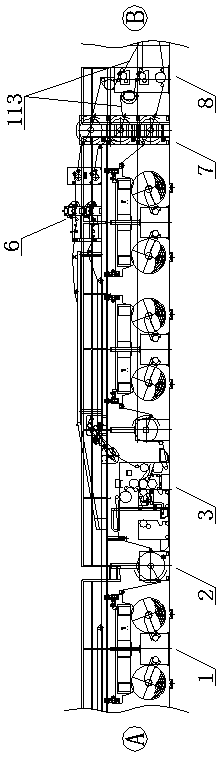

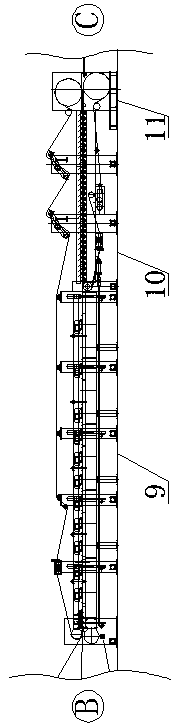

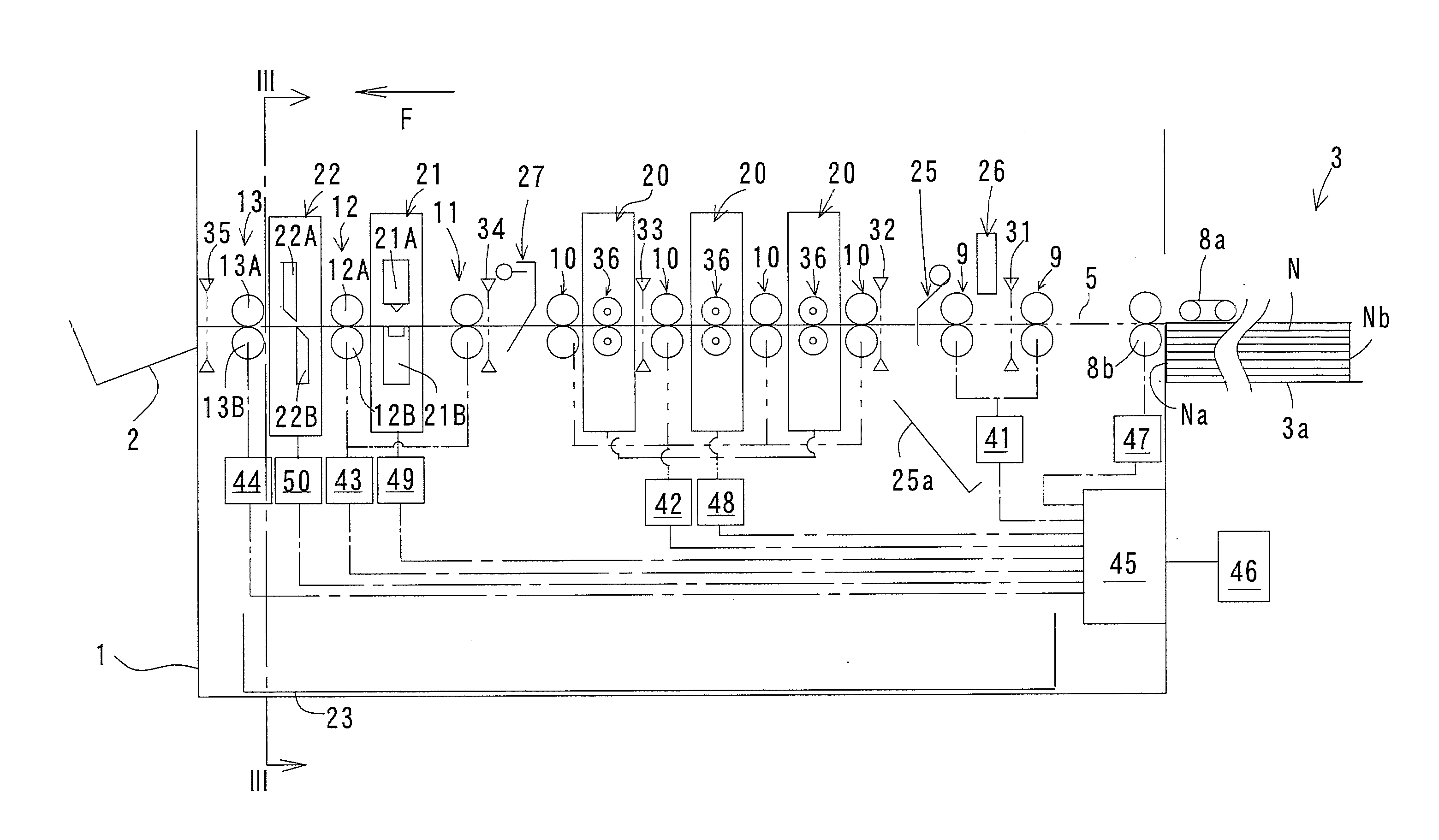

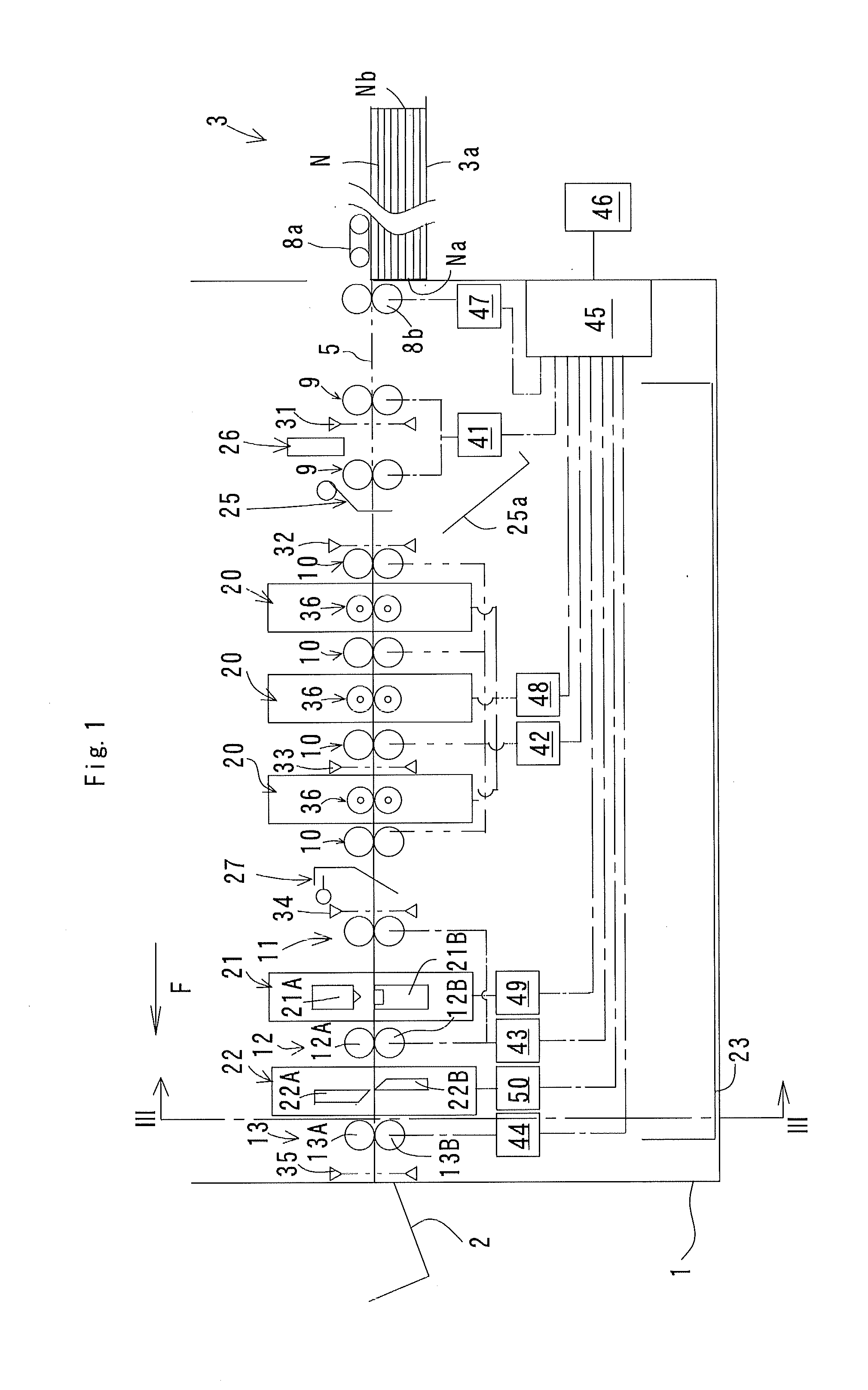

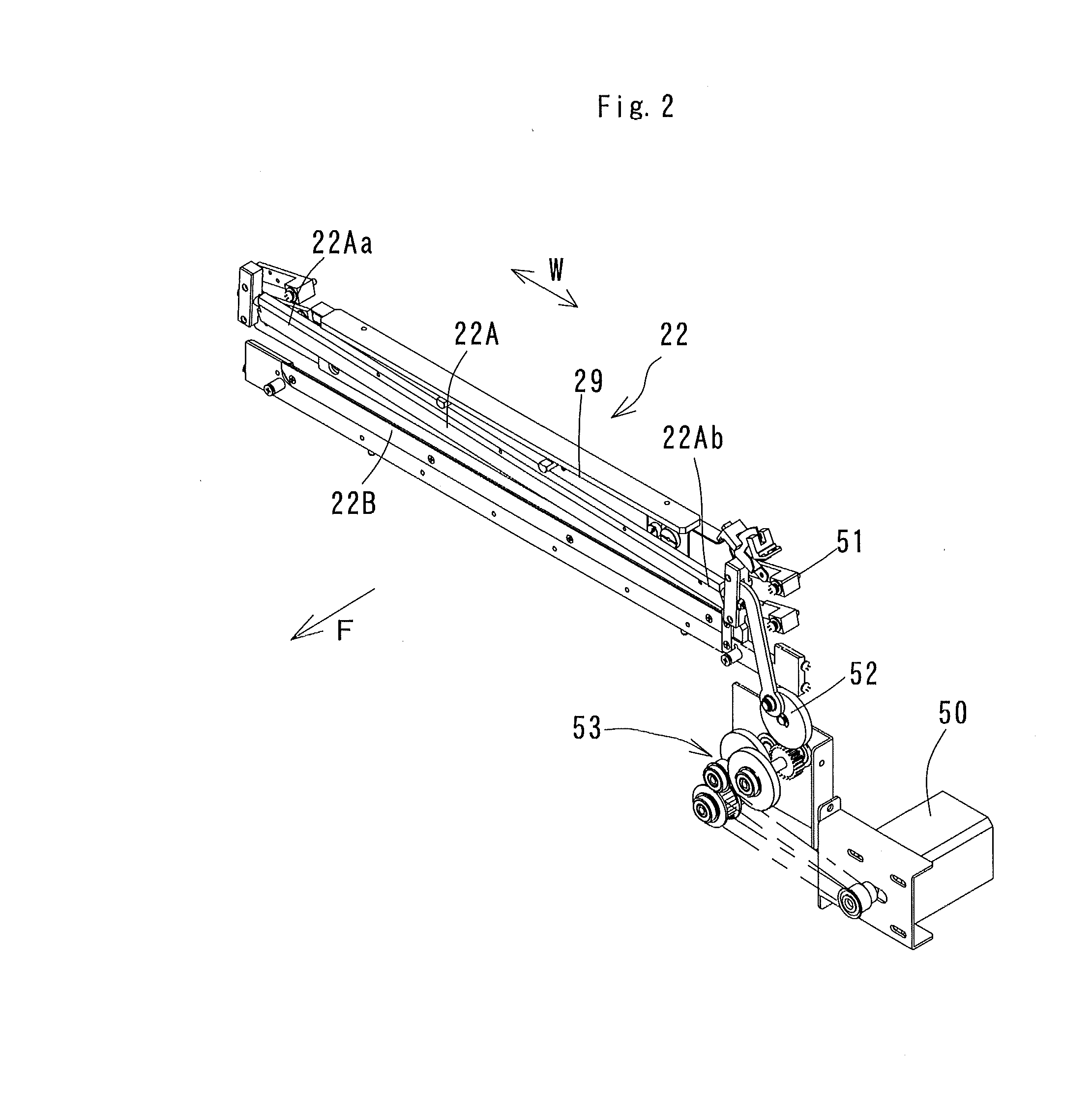

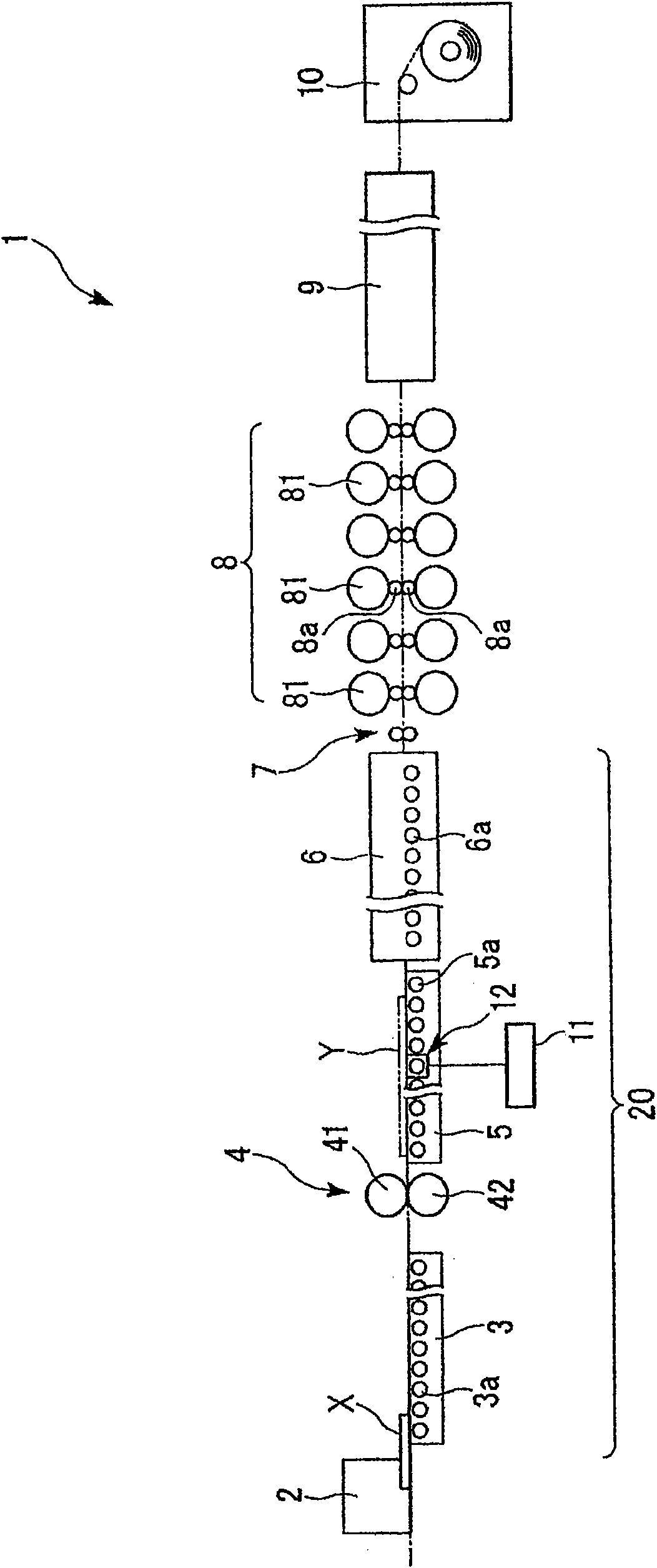

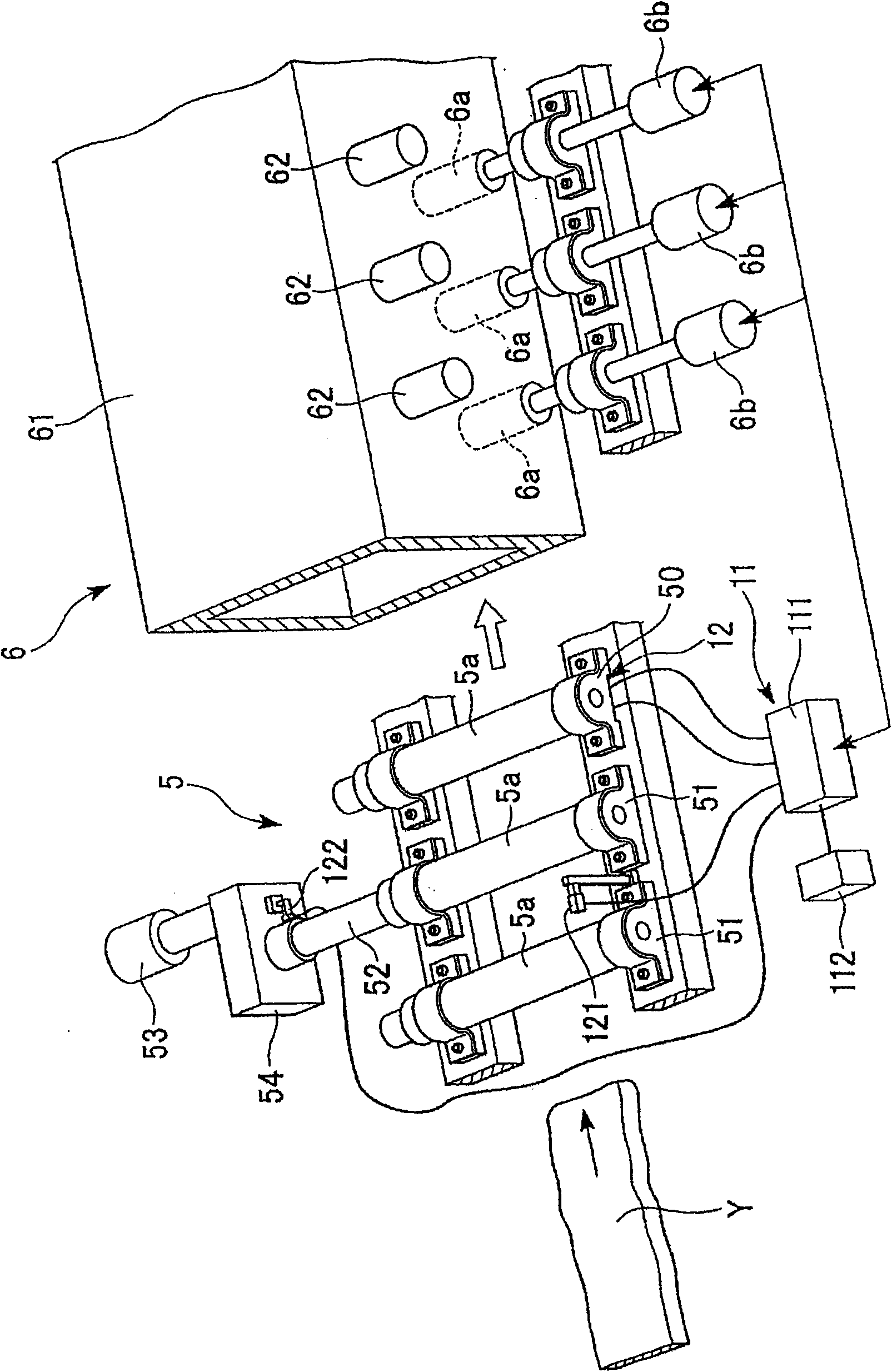

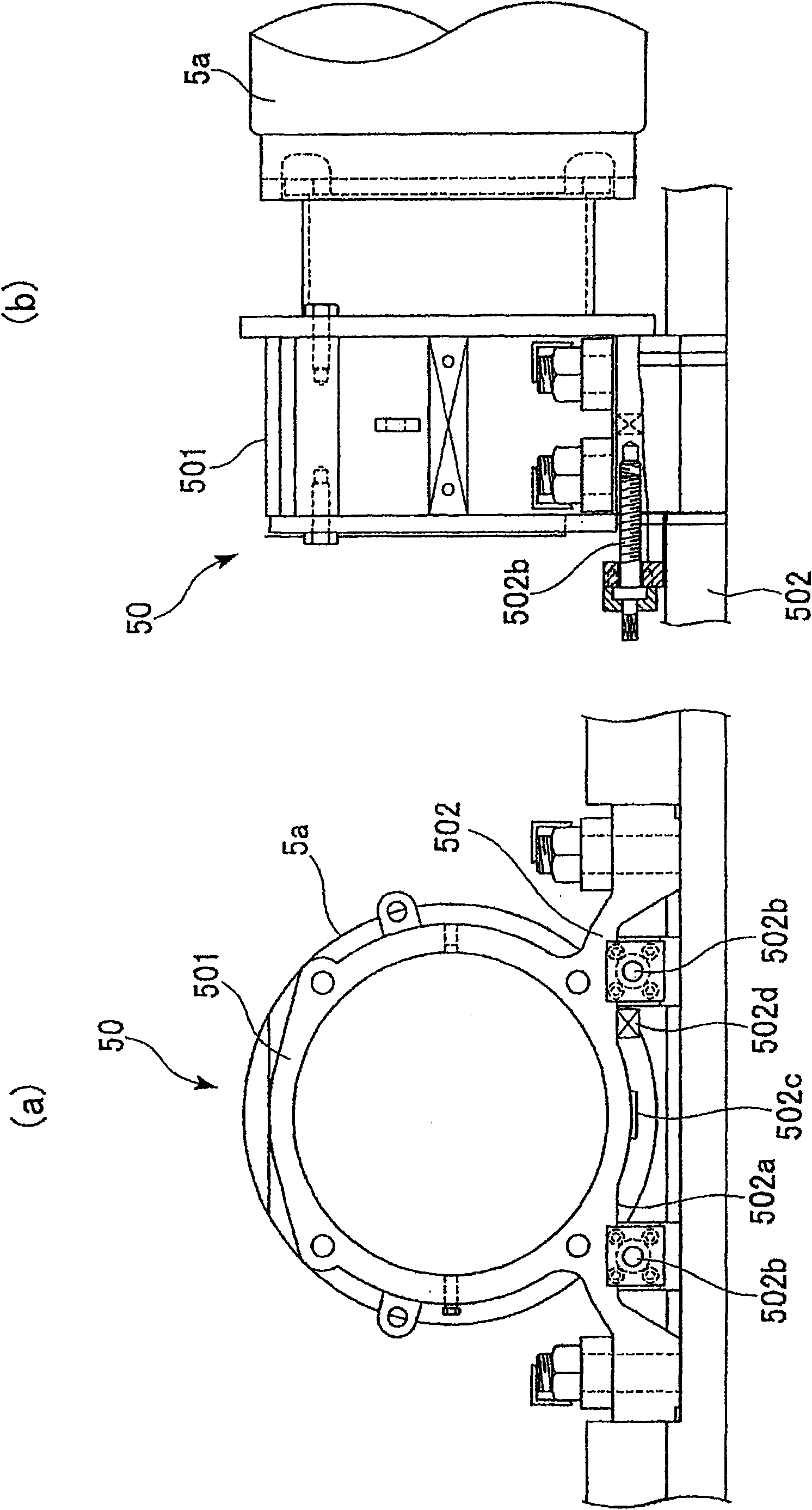

Five-layered corrugated paper production line

ActiveCN109130329AMeet functional needsPrecise position of fixed-point machiningMechanical working/deformationBox making operationsCardboardPaper production

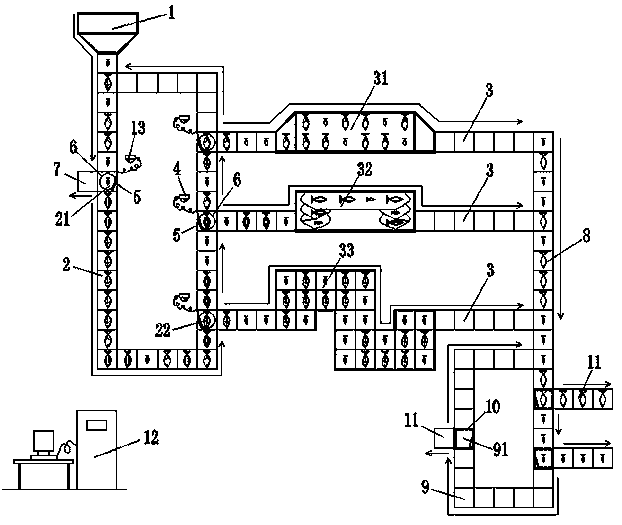

The invention discloses a five-layered corrugated paper production line. The five-layered corrugated paper production line comprises a plurality of body paper racks used for unreeling body paper, facepaper preheating wheels, core paper preheating wheels, a single corrugated paper machine, an upward leading device, a double-layered paper rack, a conveying device, a triple preheating wheel, a pasting machine, a paper board forming machine, a driving device and an N.C. cutting and line pressing edge trimmer, wherein the face paper preheating wheels and the core paper preheating wheels are arranged between every two body paper racks; the single corrugated paper machine is used for roller forming of core paper and further compounding the core paper and face paper into single corrugated paper boards; the upward leading device and the double-layered paper rack are arranged above the single corrugated paper machine; the conveying device is used for conveying the single corrugated paper boards; the triple preheating wheel is used for preheating the single corrugated paper boards and the face paper; the pasting machine is used for pasting the face paper and two layers of the single corrugated paper boards; the paper board forming machine is used for compounding the face paper and the two layers of the single corrugated paper boards into a five-layered corrugated paper board; the drivingdevice is used for conveying the five-layered corrugated paper board; and the N.C. cutting and line pressing edge trimmer is used for shaping the five-layered corrugated paper board. By adoption of the five-layered corrugated paper production line, the corrugated paper board of a five-layered structure can be produced, and fixed-point notching treatment of the five-layered corrugated paper boardcan be conducted; and the automatic detecting and waste discharging functions are further achieved, and the number of discarded products in finished corrugated paper board products is decreased.

Owner:晋江市新达纸箱包装有限公司

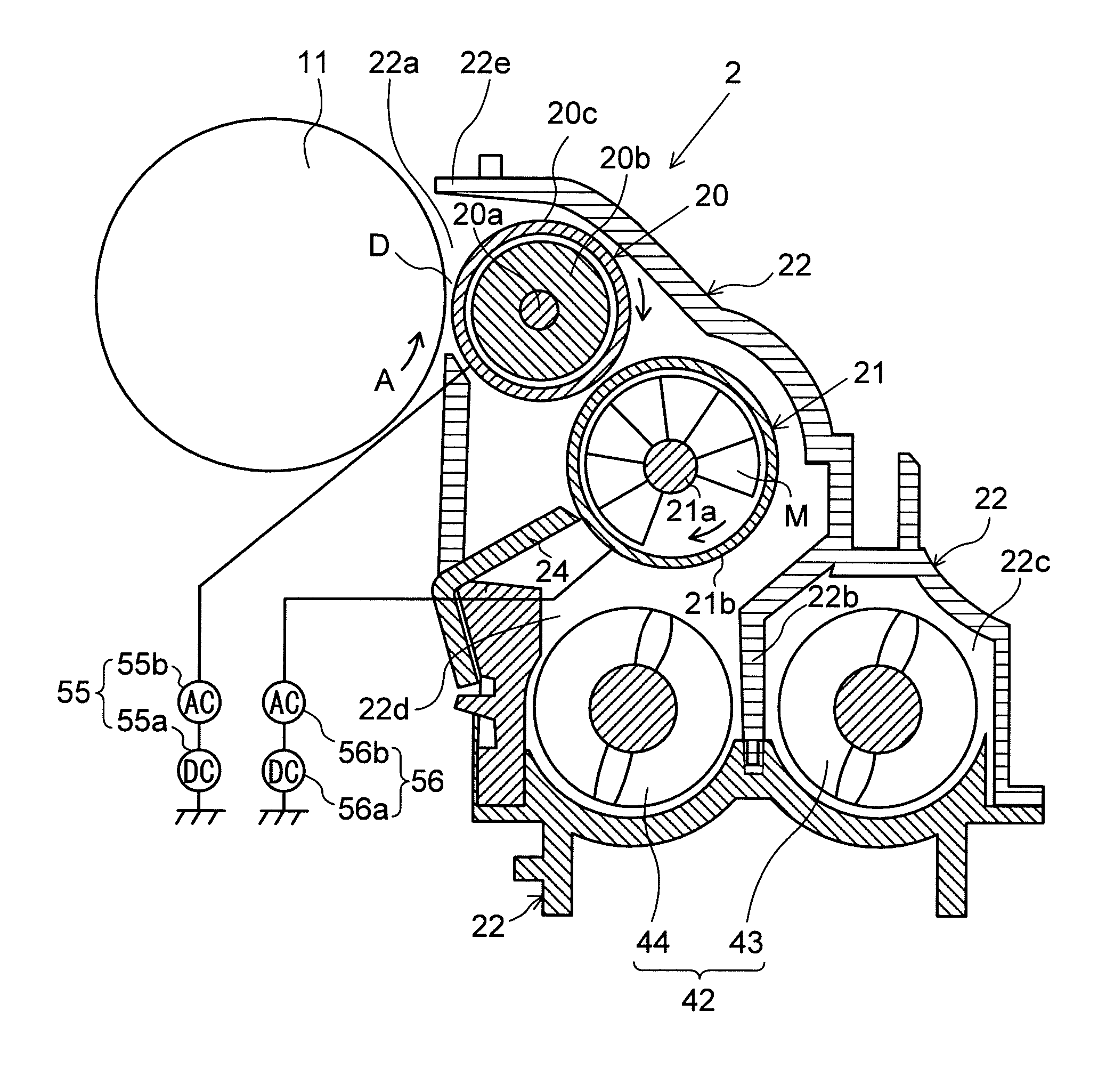

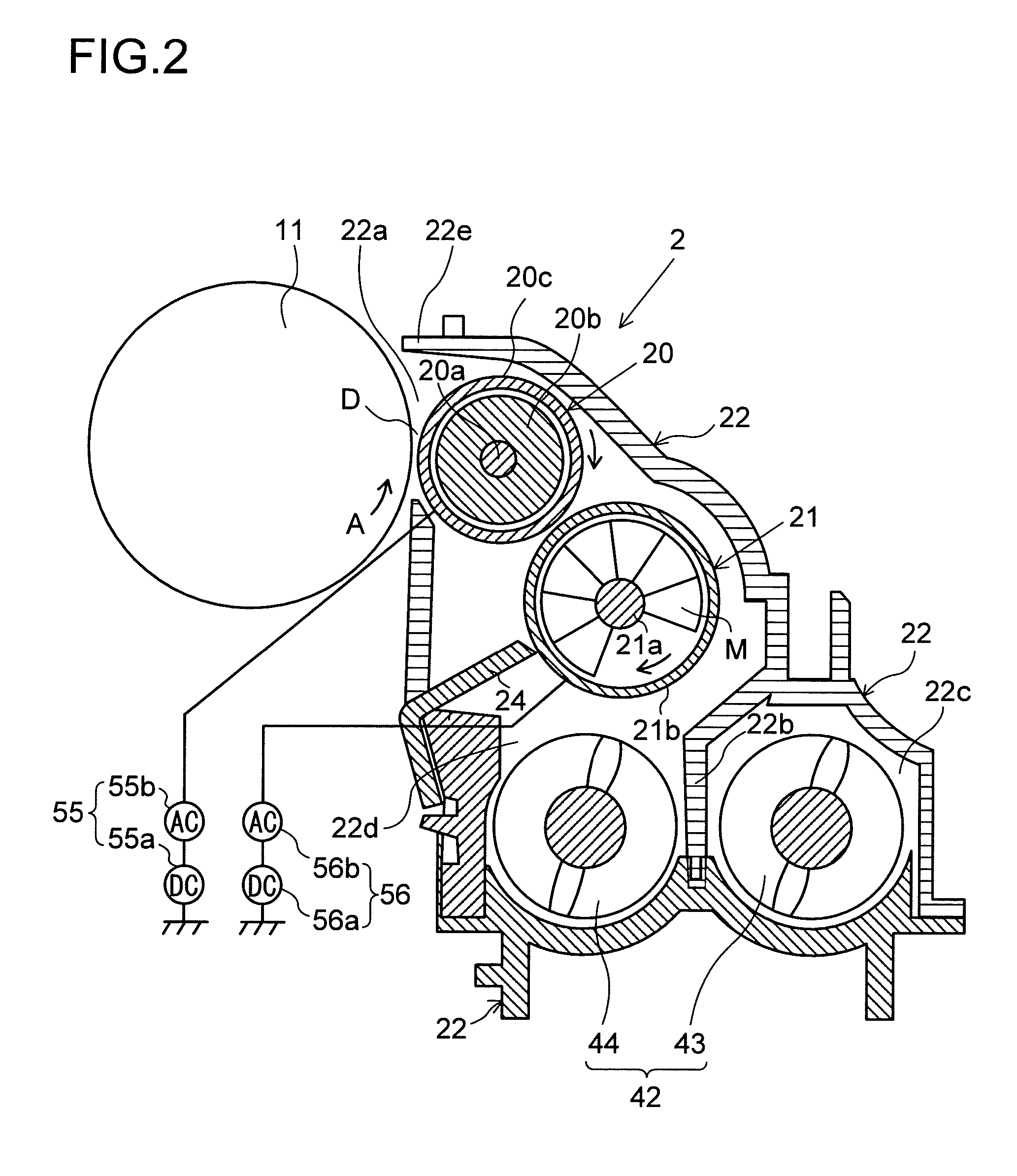

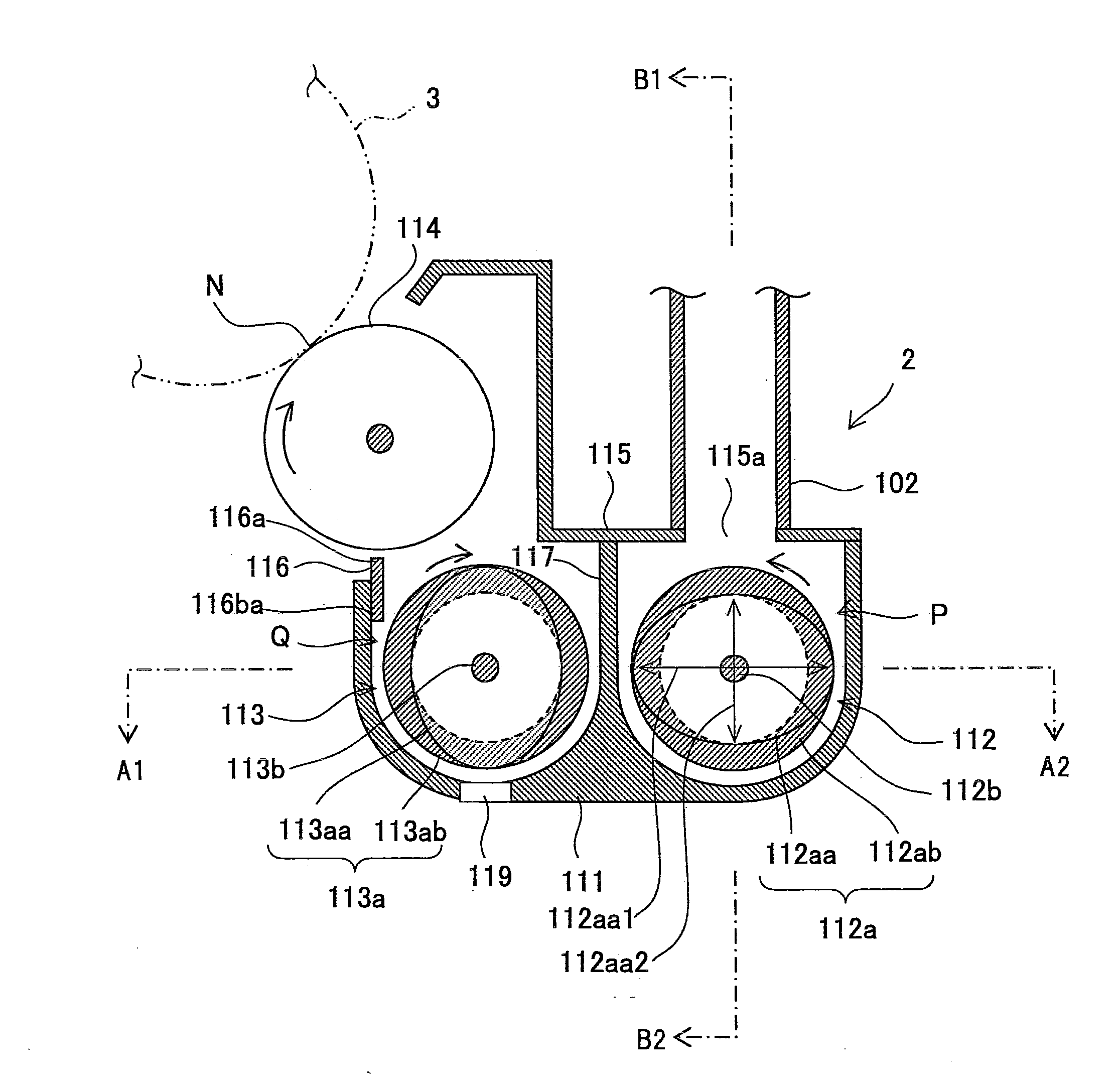

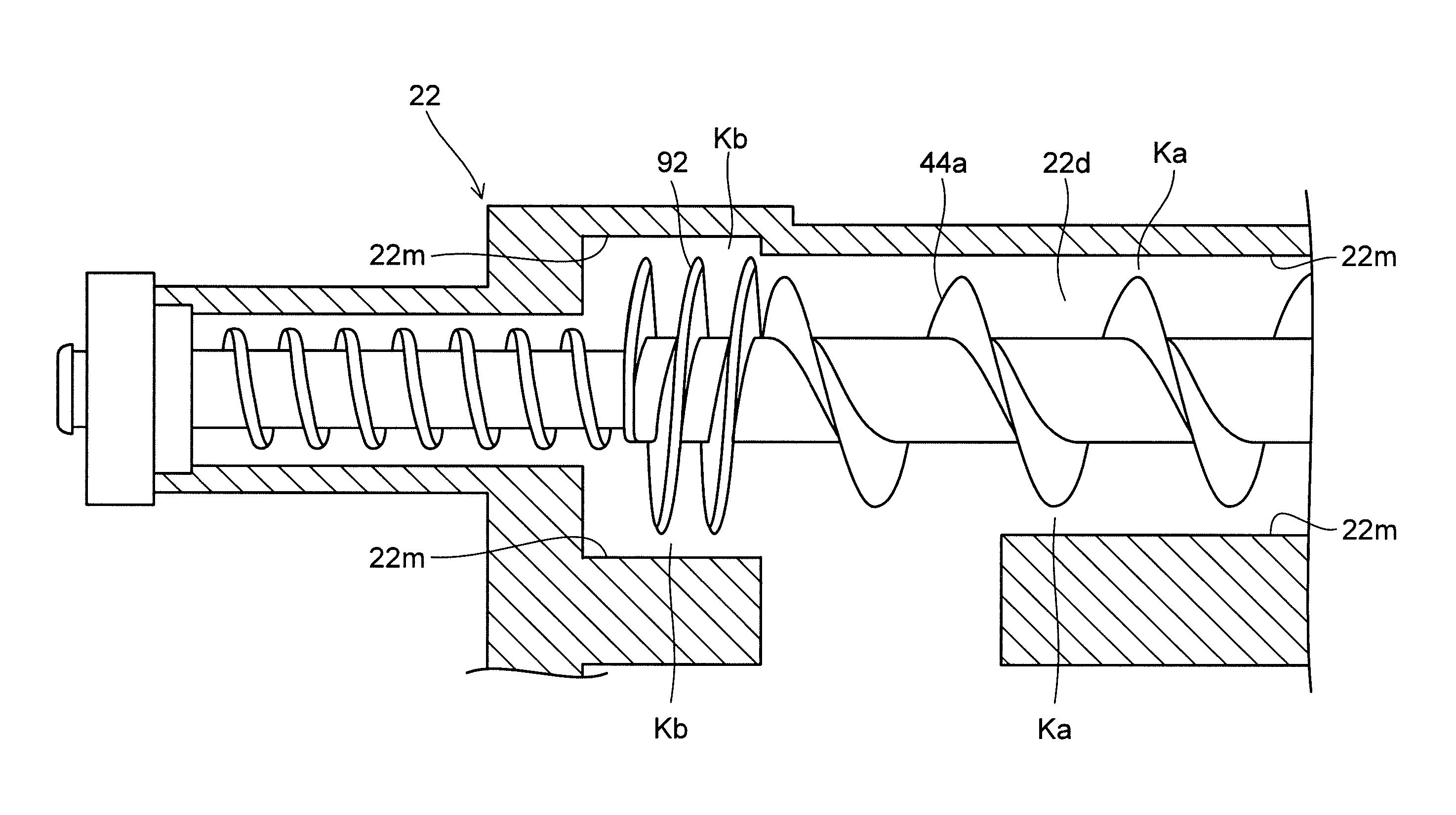

Developing device and image forming apparatus provided therewith

ActiveUS20110150537A1Simple structurePrecise maintenanceElectrographic process apparatusHelical bladeImage formation

Provided is a developing device including: a developing container including a developer replenishing port from which the developer is replenished, and a developer discharge port which is provided on a downstream side of one of the conveyance paths and from which surplus developer is discharged; and a discharge regulating portion provided to one of the plurality of stirring members which is arranged in the one of the conveyance paths, in which the discharge regulating portion includes a regulating member arranged so as to face the developer discharge port, for regulating movement of the developer to the developer discharge port side, and a decelerating conveyance member arranged between the helical blade and the regulating member, for partially reducing a conveying speed of the developer in the one of the conveyance paths.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

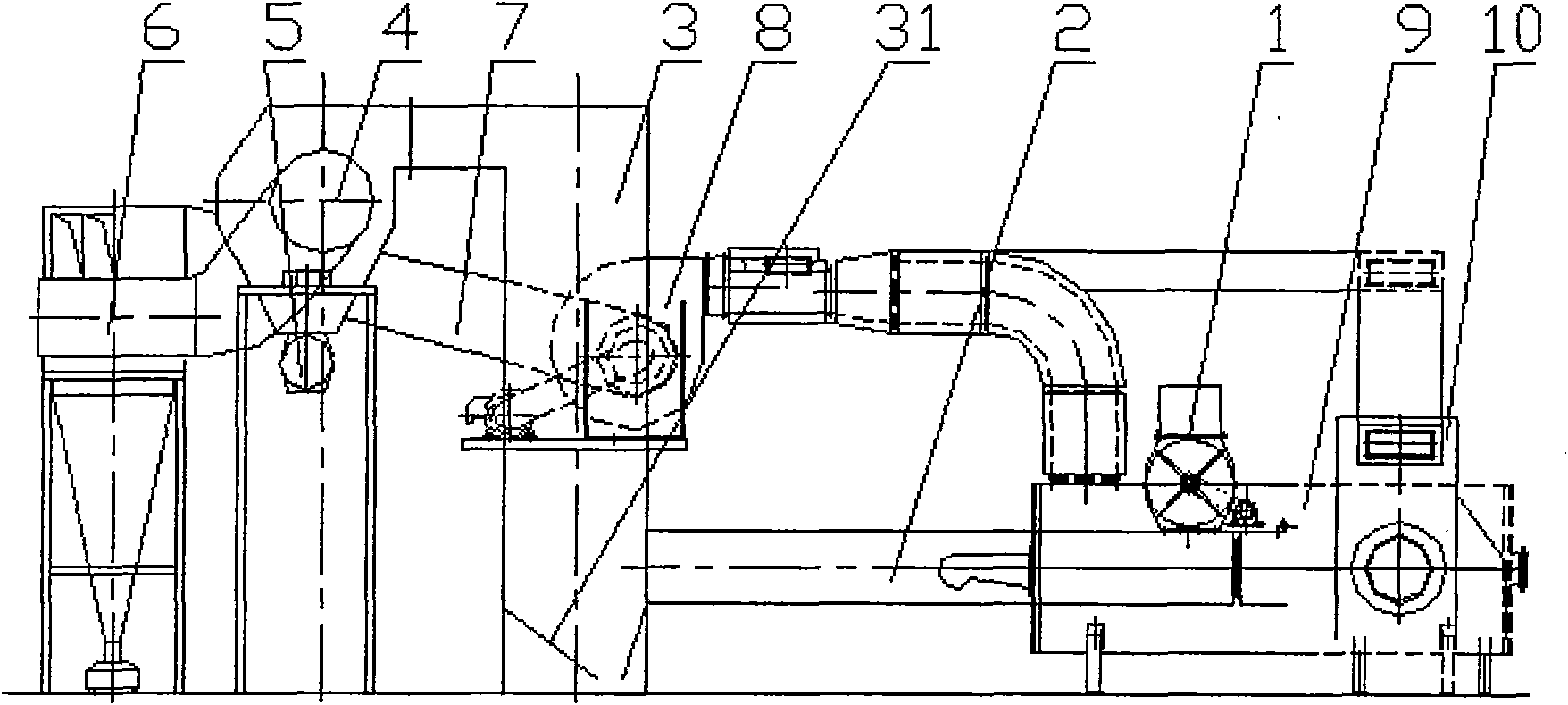

Tobacco material pneumatic drying process and equipment

ActiveCN101601500AShorten speedExtended drying timeTobacco preparationVolumetric Mass DensityEngineering

The invention provides a pneumatic drying method and equipment thereof for realizing large-flow tobacco material puffing drying treatment; the method comprises the following steps: puffed tobacco material is conveyed to a drying pipe for being dried by hot air flows, and then the tobacco material is separated from hot sir; the drying pipe is composed of a horizontal drying pipe and a vertical drying pipe of which the cross section is more than the cross section of the horizontal drying pipe; hot air with the temperature at 100-250 DEG C and air flow speed of10-50m / s of is sent in the horizontal drying pipe, wherein the air flow feeding direction is vertical to the material feeding direction; the material driven by hot air flows enters in the vertical drying pipe and is ascended in a suspension way, and the ascending speed of the material is reduced to 0.5-5m / s; meanwhile, sundries such as slivers with large density in the material can not be suspended and are separated pneumatically under the wind speed. By arranging the vertical drying pipe with large caliber, the speed of the material, moving upwards along the air flow direction, is reduced, on the premise of not increasing the drying route, the drying time of the material is prolonged, heat-transferring and mass transferring coefficient is improved, and the drying time of the material is improved.

Owner:ZHISI HLDG GRP

Automatic fish identifying and sorting system and running method thereof

PendingCN109332207ALabor intensiveReduce production efficiencySortingClimate change adaptationEngineeringFish species

The invention provides an automatic fish identifying and sorting system and a running method thereof. An automatic fish identifying function and an automatic fish sorting function are combined, therefore, automatic continuous running can be achieved, the labor intensity is reduced, the error rate is decreased, and the identifying and sorting time is shortened. An inlet system is connected with anidentifying and sorting circular conveying line; the identifying and sorting circular conveying line is provided with a quality identifying area and fish species identifying areas; a fish species identifier and a fish pusher are installed in each fish species identifying area; a quality identifier and a fish pusher are installed in the quality identifying area; an unqualified product conveying line is connected with the quality identifying area; classifying conveying lines are connected with the fish species identifying areas; a transition conveying line is connected with the classifying conveying lines and a weighing and sorting circular conveying line; the weighing and sorting circular conveying line is provided with weighing areas, and a fish pusher and a weighing device are installed in each weighing area; output conveying lines are connected with the weighing areas; and an analytical controller is connected with the fish species identifiers, the quality identifier, the fish pusherand the weighing devices.

Owner:CHINA UNITED ENG

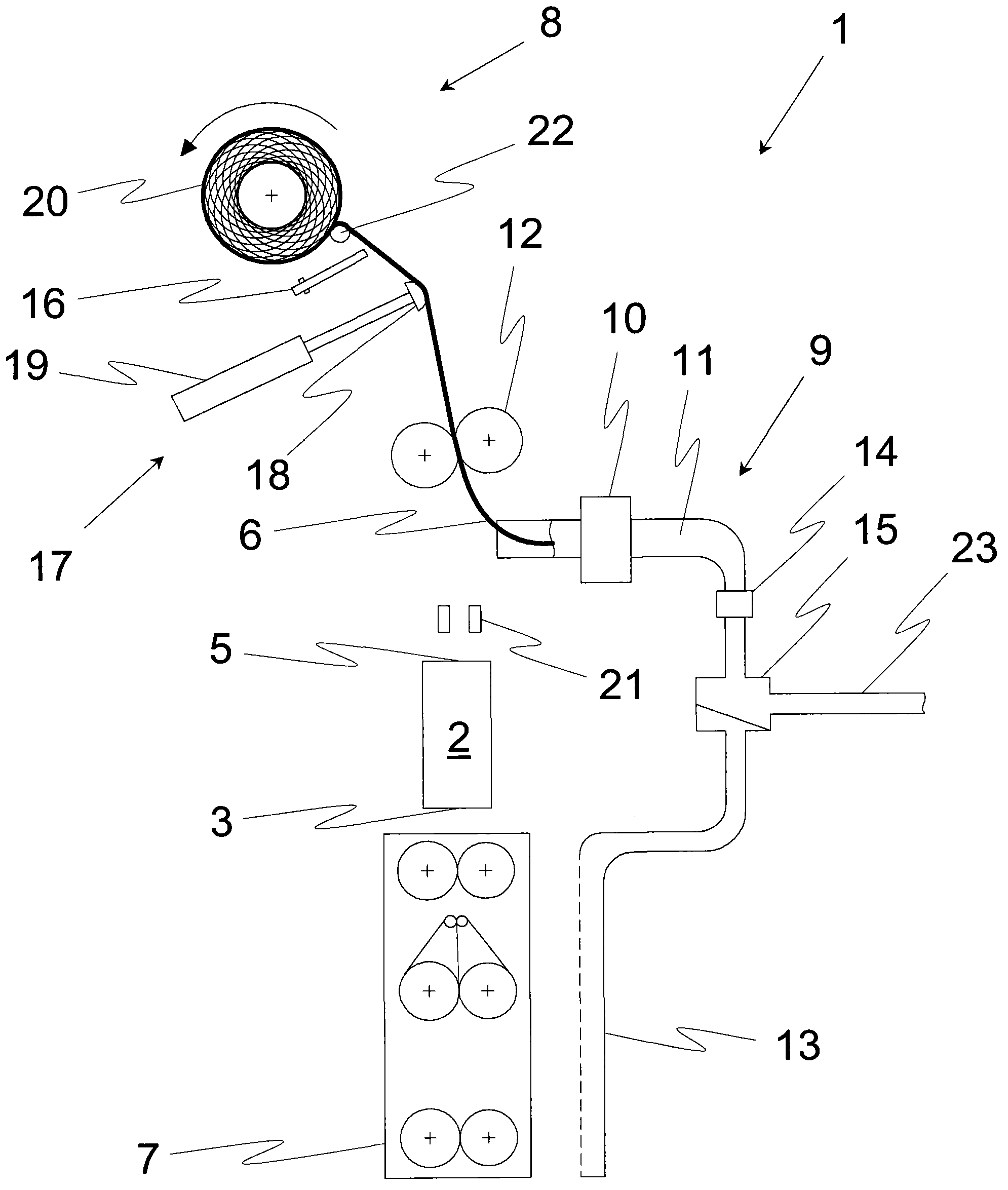

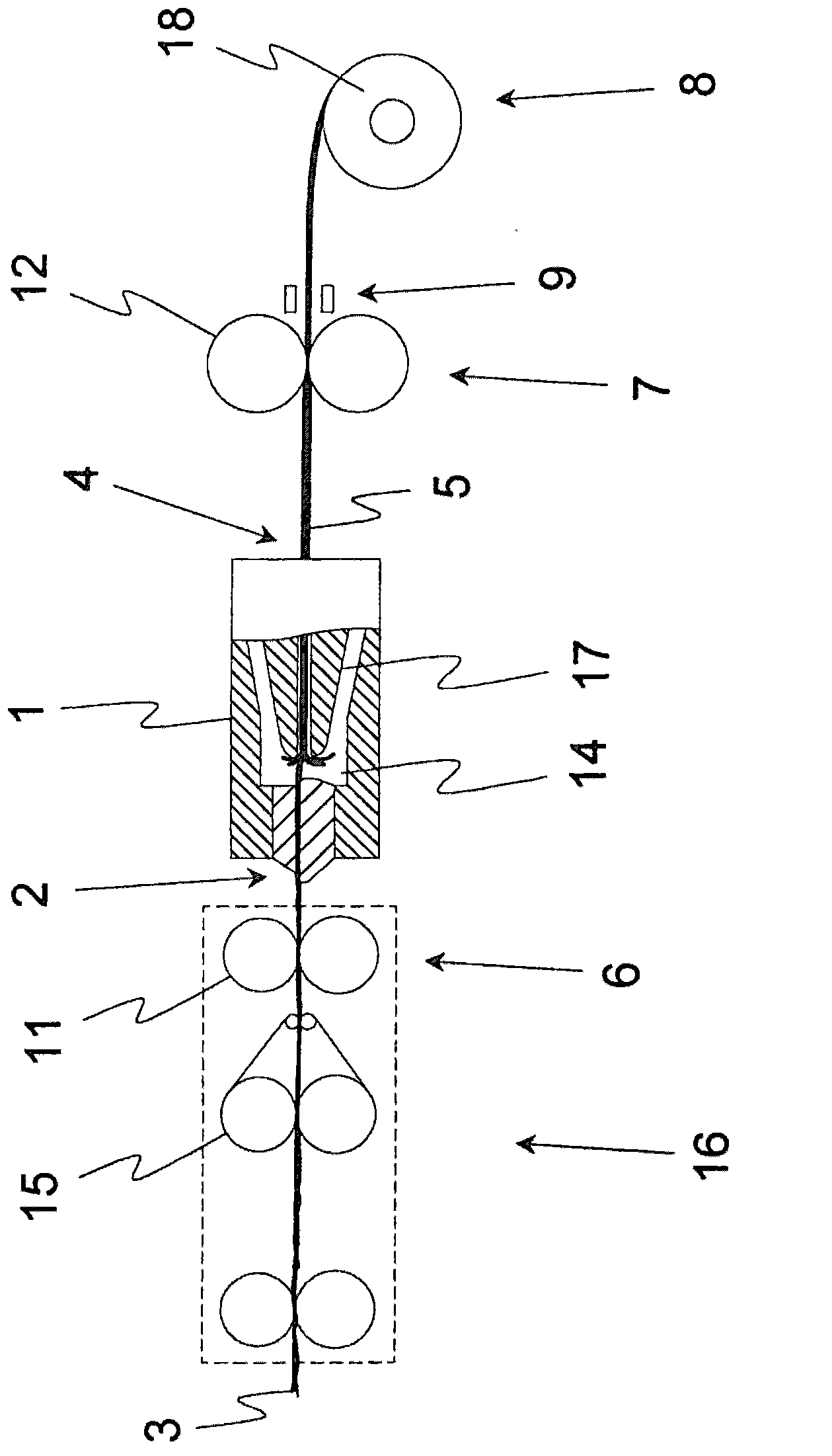

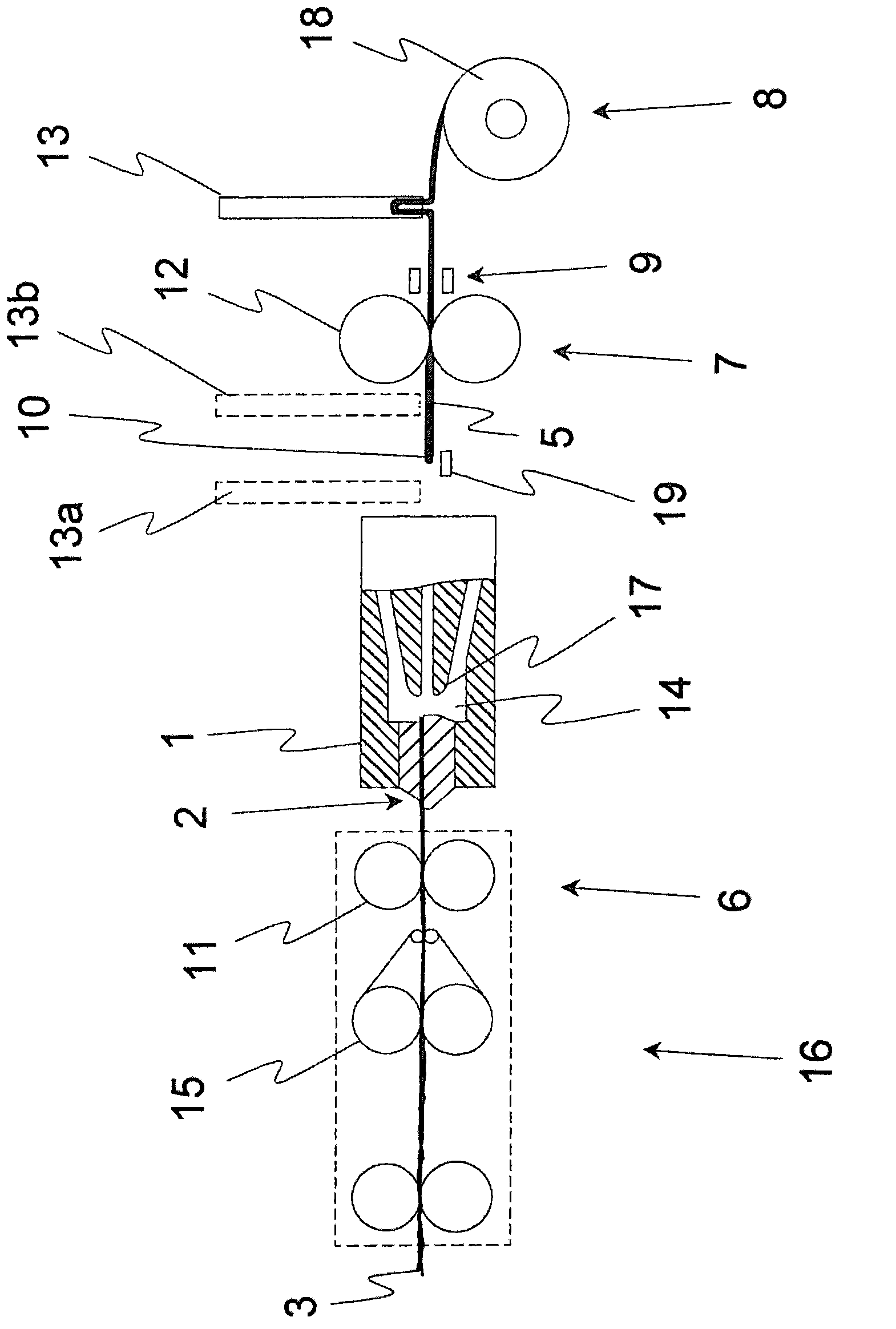

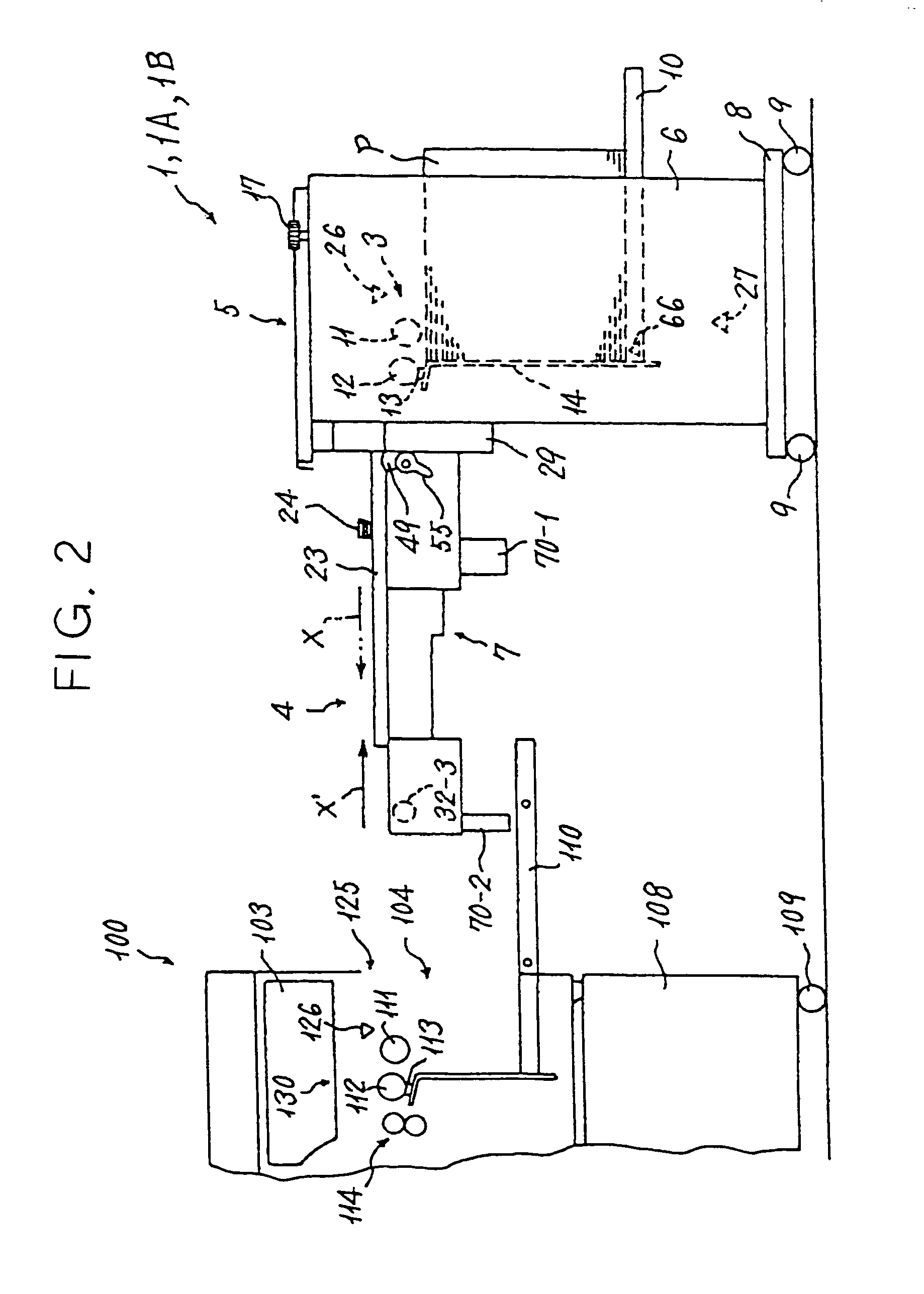

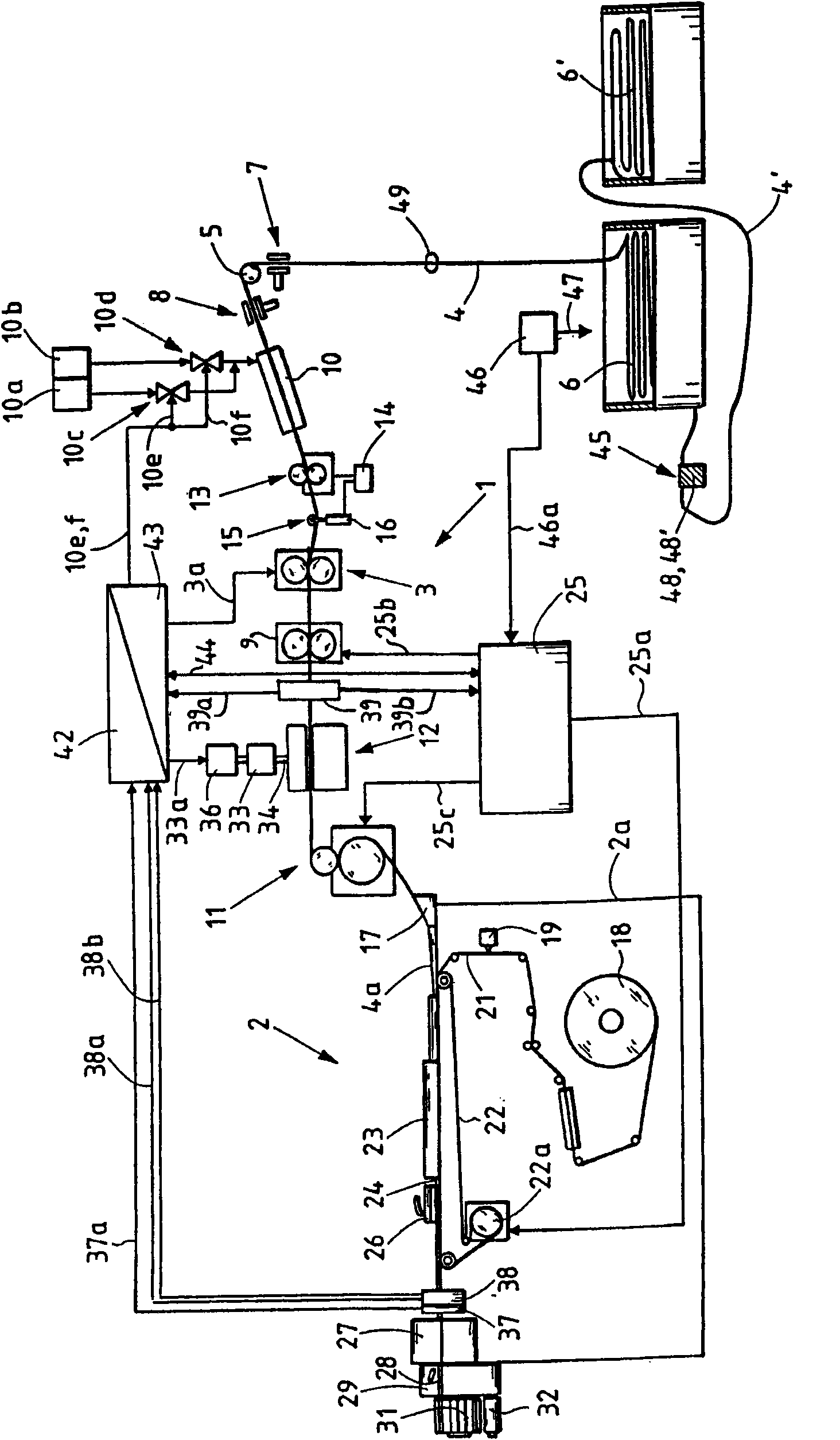

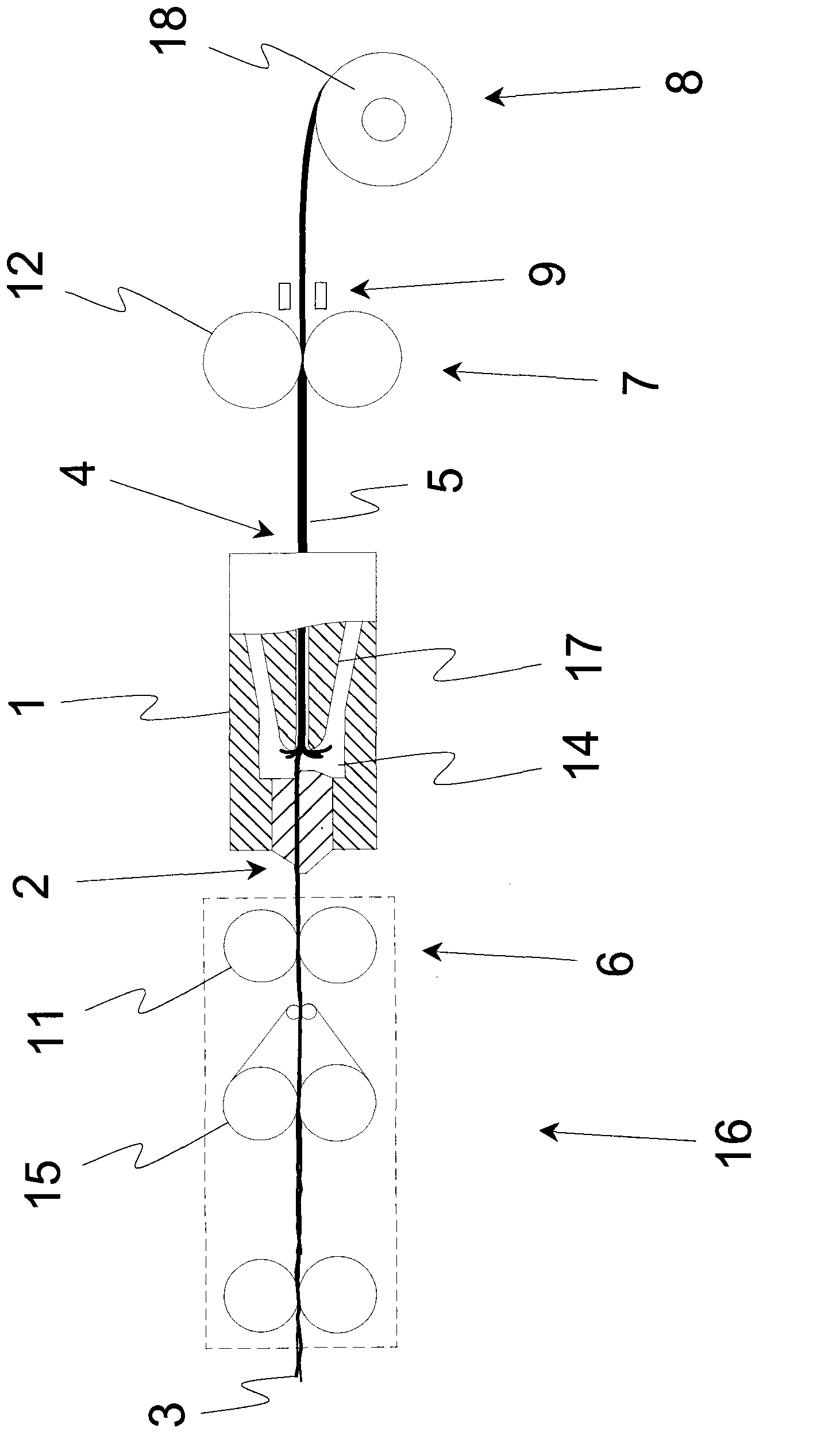

Spinning machine and method for discharging an end section of a thread on a spinning machine

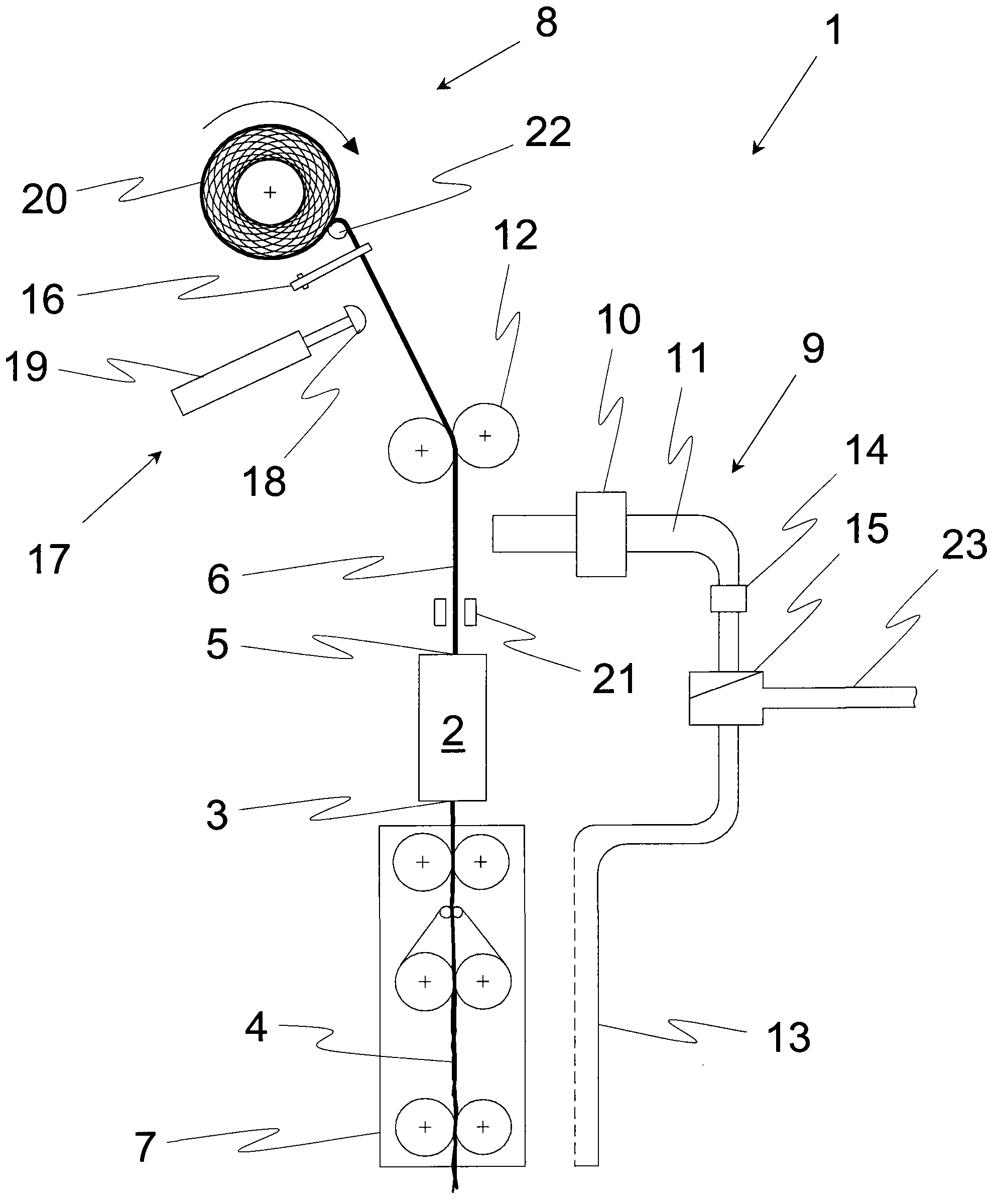

ActiveCN103014945AReliable reverse deliveryReduce conveying speedPiercing arrangementsFilament handlingYarnFiber

The invention relates to at least one spinning machine of a spinning table. The spinning point comprises a spinning device which has an input end for fiber material, an output end for yarn manufactured in the spinning device with the fiber material, a conveyance device used for guiding the fiber material to the spinning device, and a winding device for winding the manufactured yarn. The spinning point comprises a yarn end disposal means partly arranged between the input end of the yarning device and the winding device, and with the aid of which an end section of the produced yarn is able to be separated from the rest of the yarn and eliminated. Furthermore, a method for removing an end section of a yarn at a spinning point of a spinning machine prior to the subsequent piecing process is proposed. An end section of a yarn is obtained with the aid of the yarn end disposal means which is a constituent part of the spinning point. The end sections of yarn is disposed from an area of the spinning point after end sections of the rest yarns are separated, and the yarn end disposal means is at least partly arranged between the output end of the spinning device and the winding device.

Owner:MASCHINENFABRIK RIETER AG

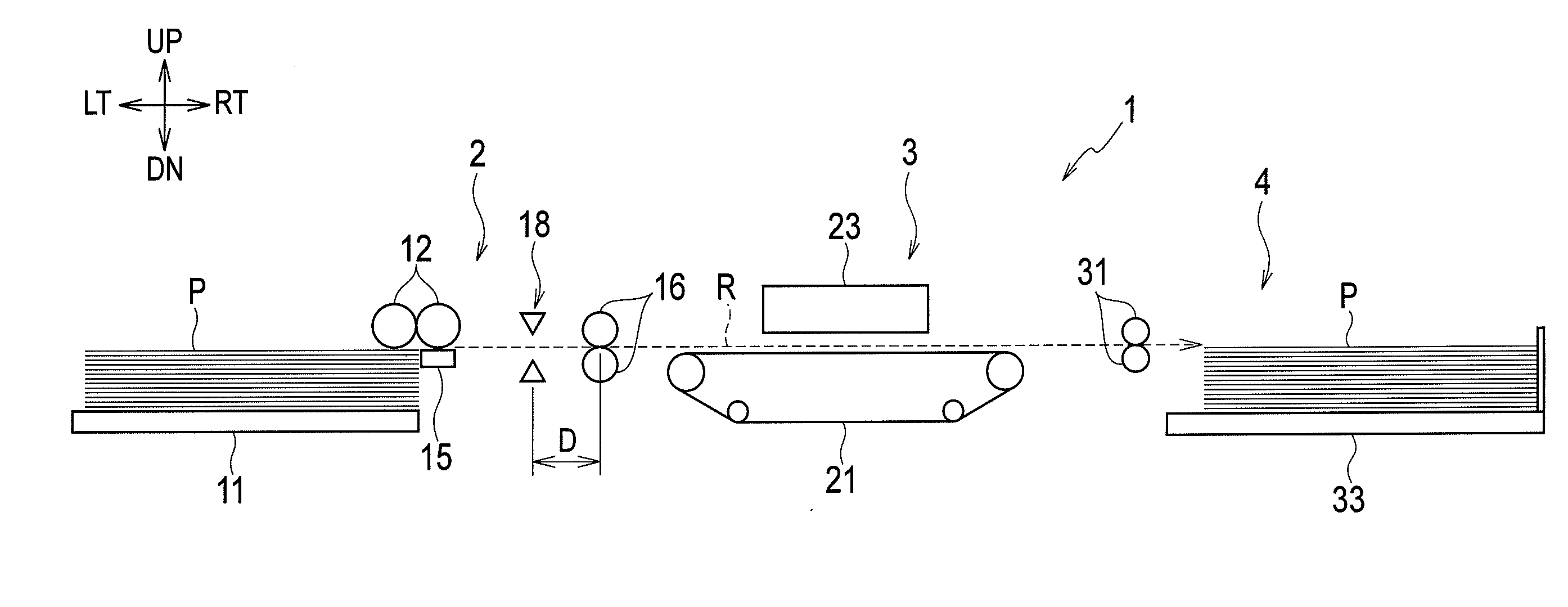

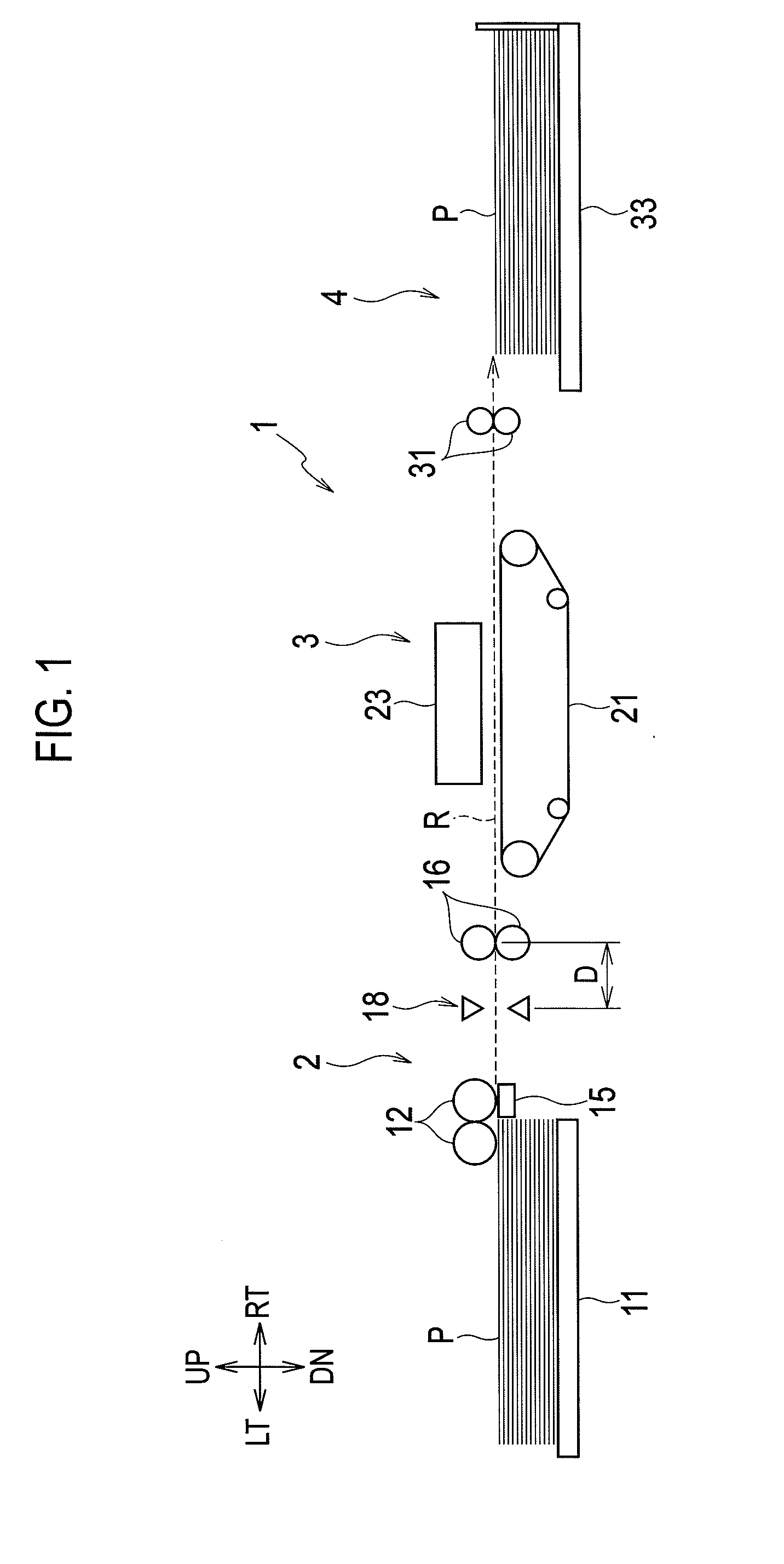

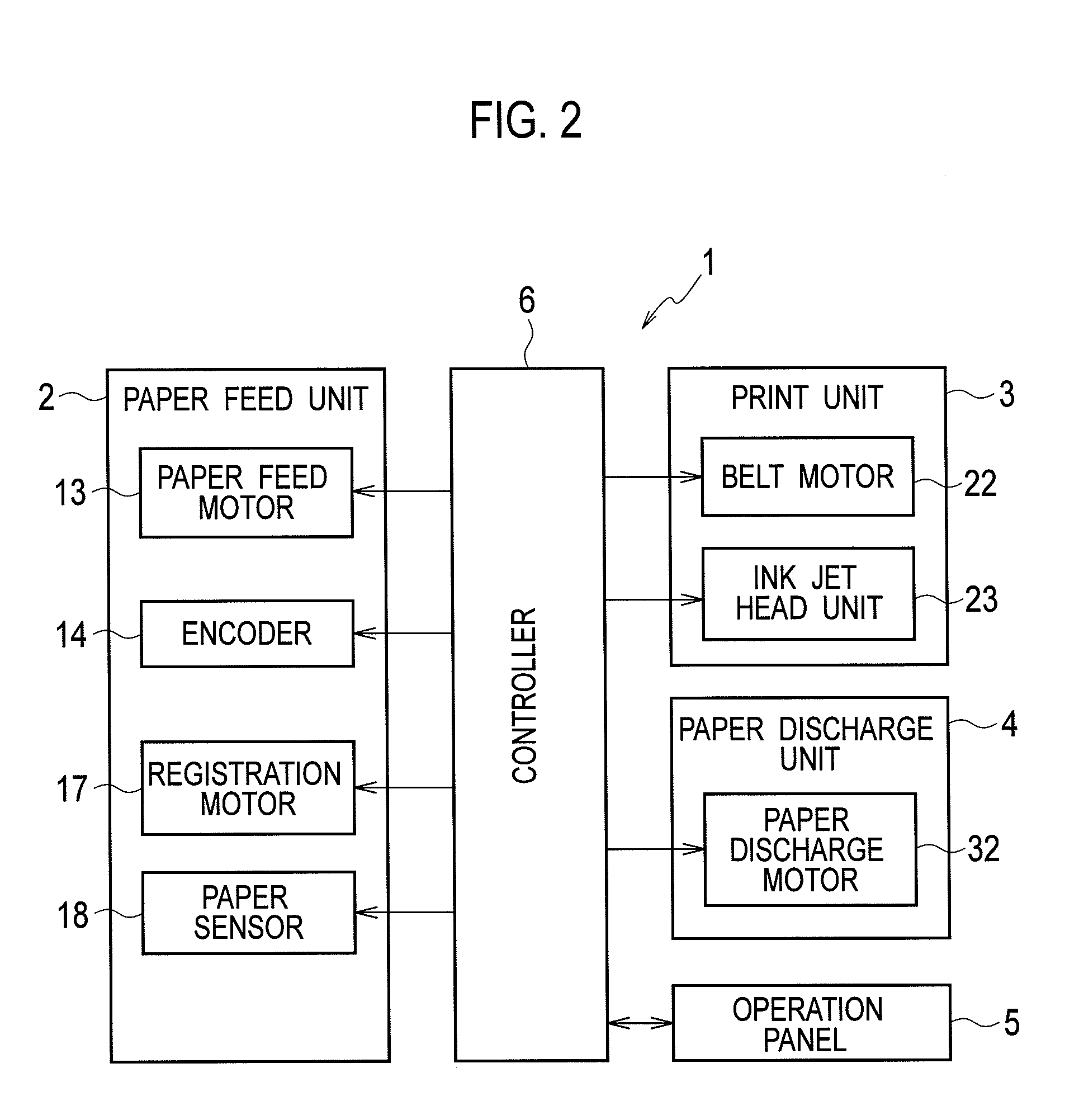

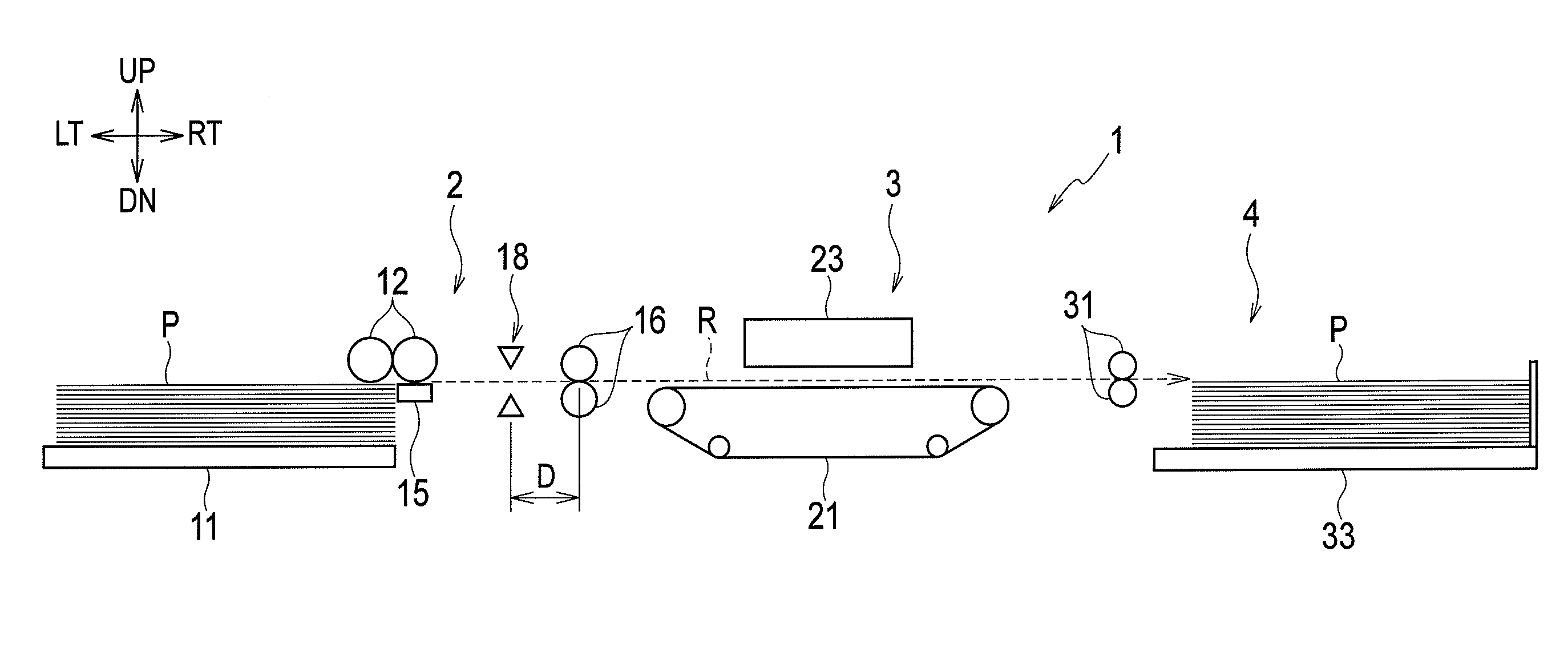

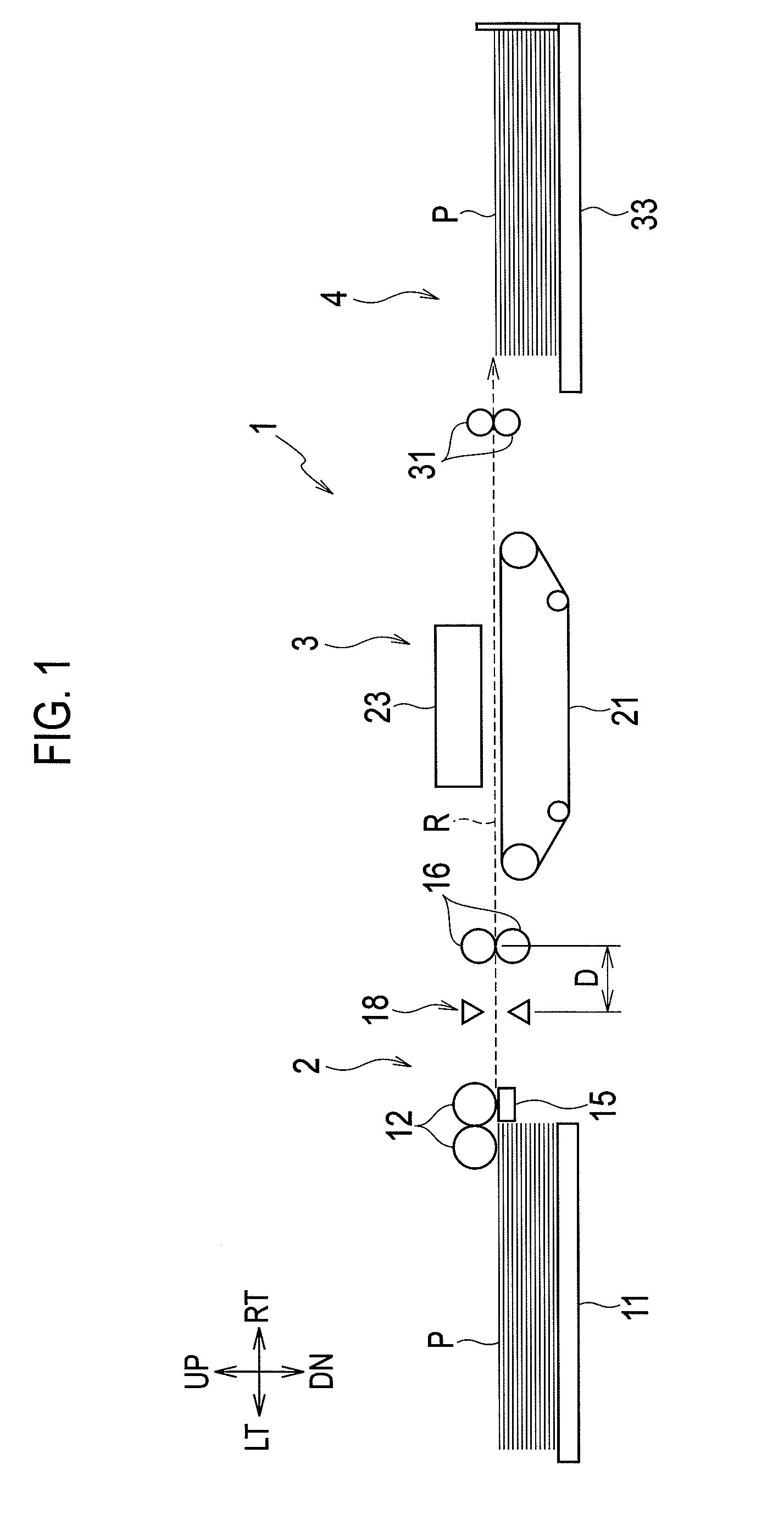

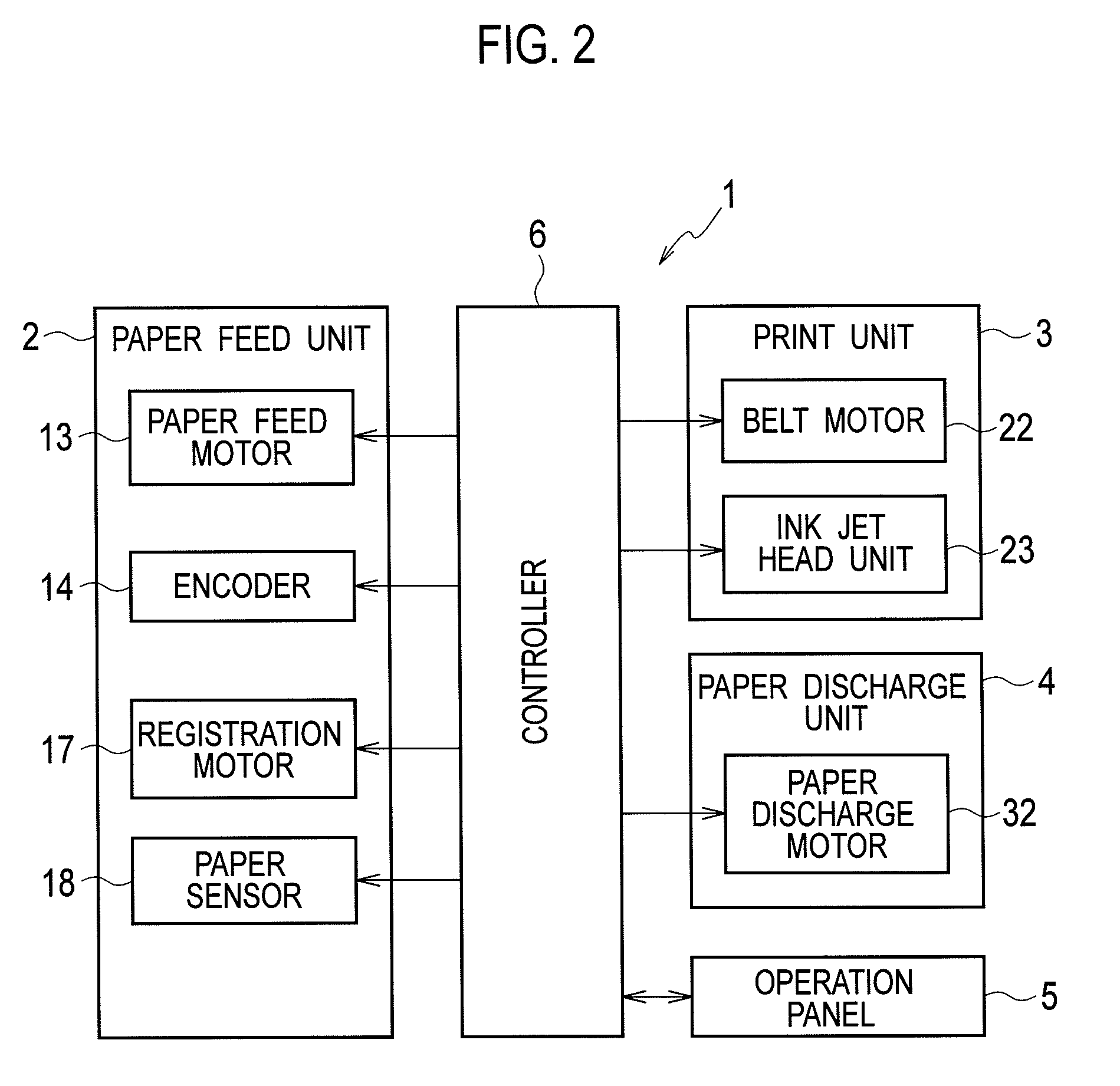

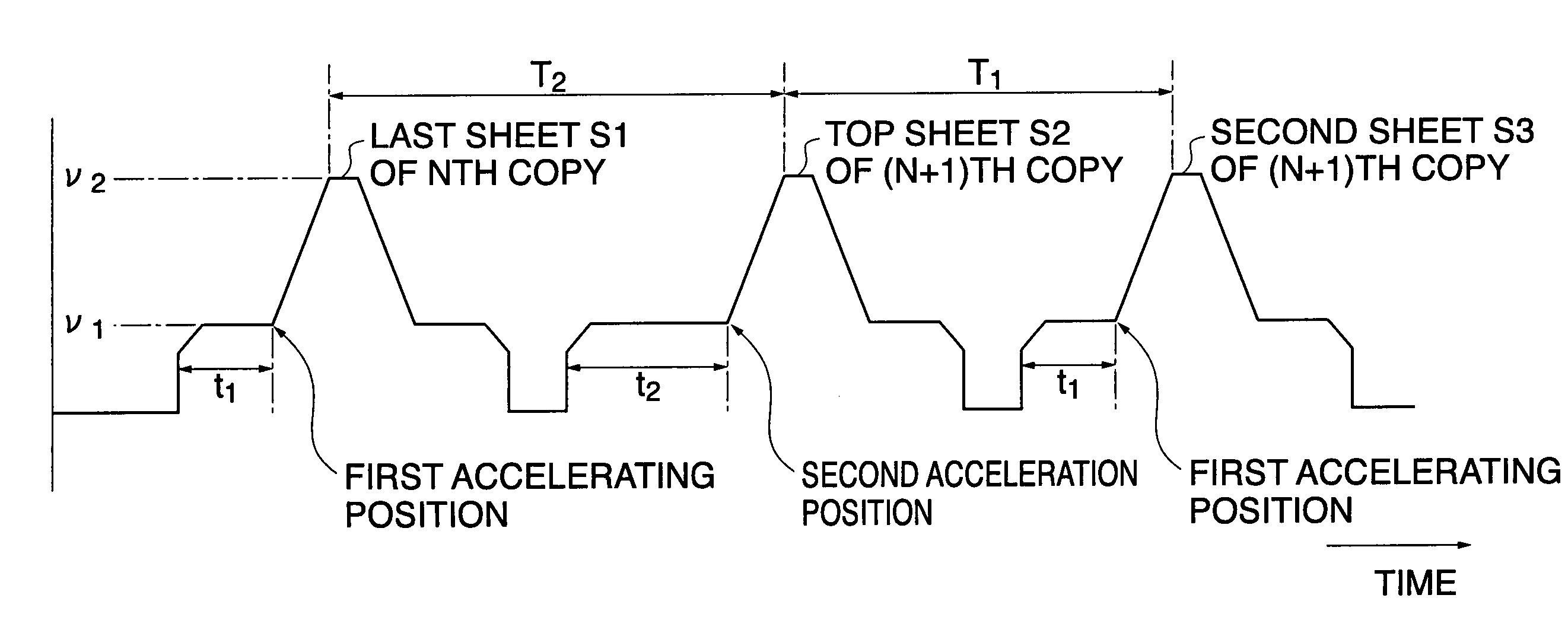

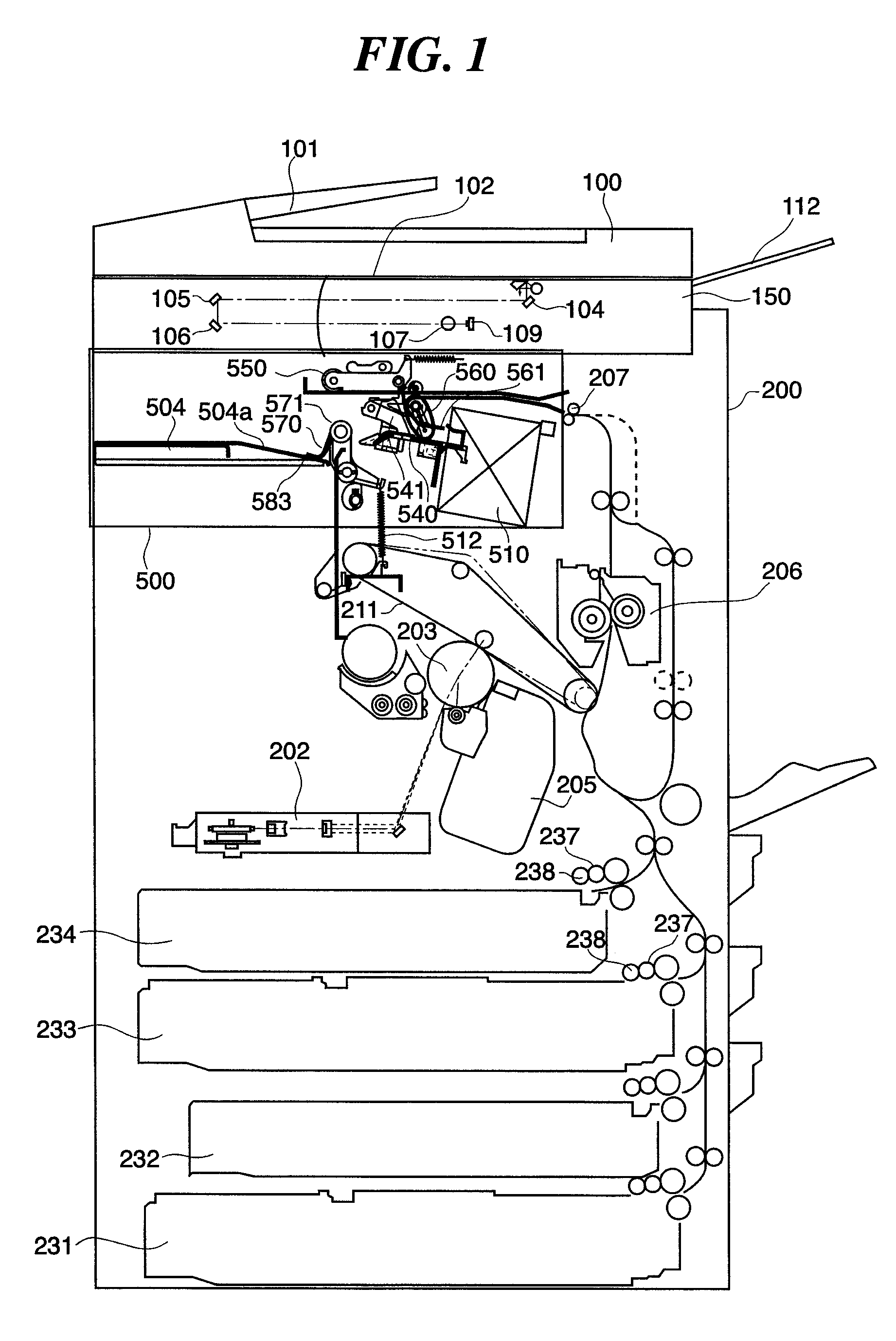

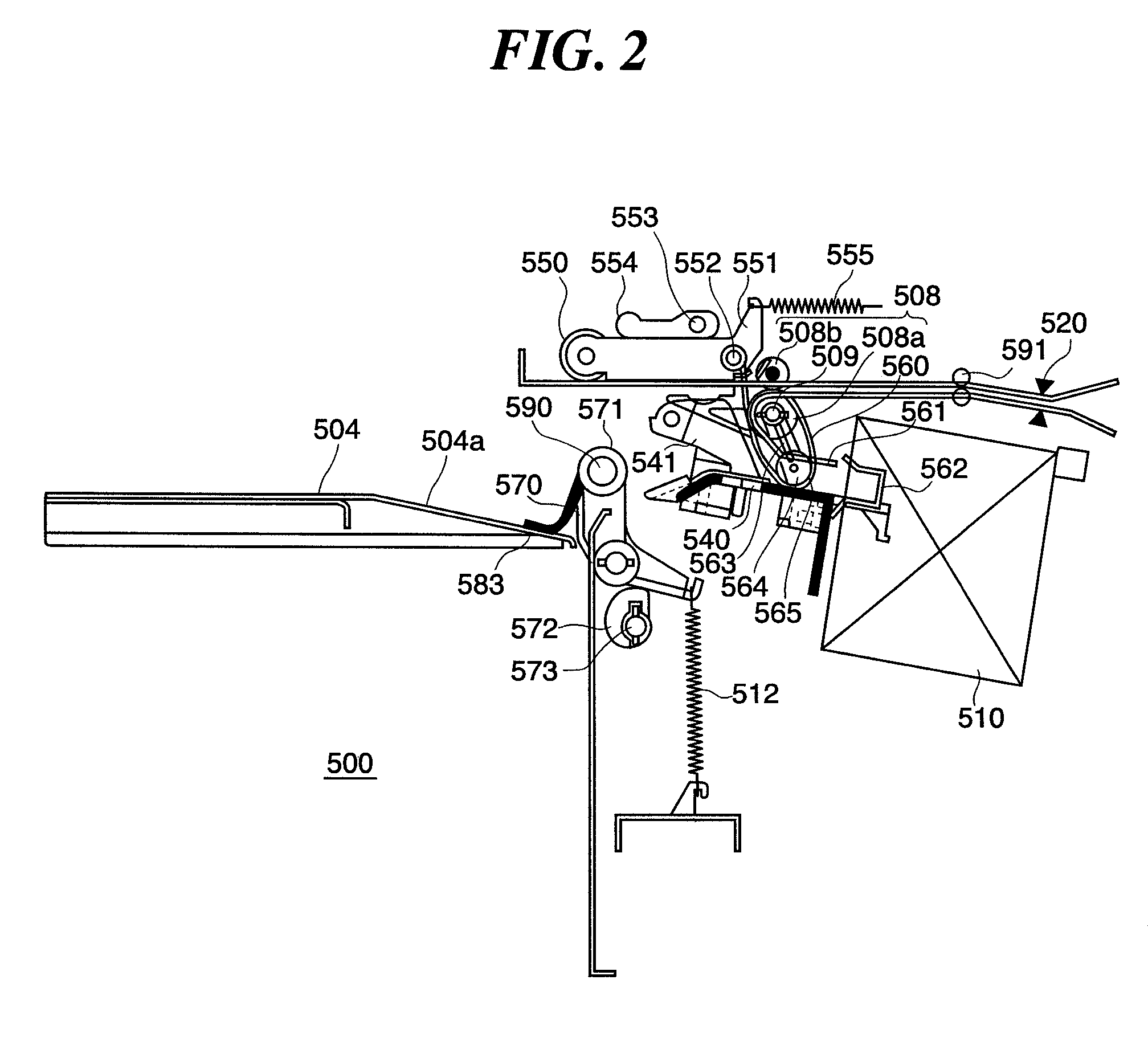

Paper feeder and printer

ActiveUS20140232055A1Avoid registrationReduce conveying speedRegistering devicesFunction indicatorsComputer printingPulp and paper industry

Upon continuous feeding of a plurality of sheets and upon detection of a leading end of a sheet by a detection unit before an elapse of a first time after a start of a paper feed roller, a controller performs control such that a paper conveyance speed of the paper feed roller is set lower than a paper conveyance speed of a registration roller, and the paper feed roller is stopped after conveying the sheet having the leading end detected for a specified conveyance distance before a next timing of starting the registration roller.

Owner:RISO KAGAKU CORP

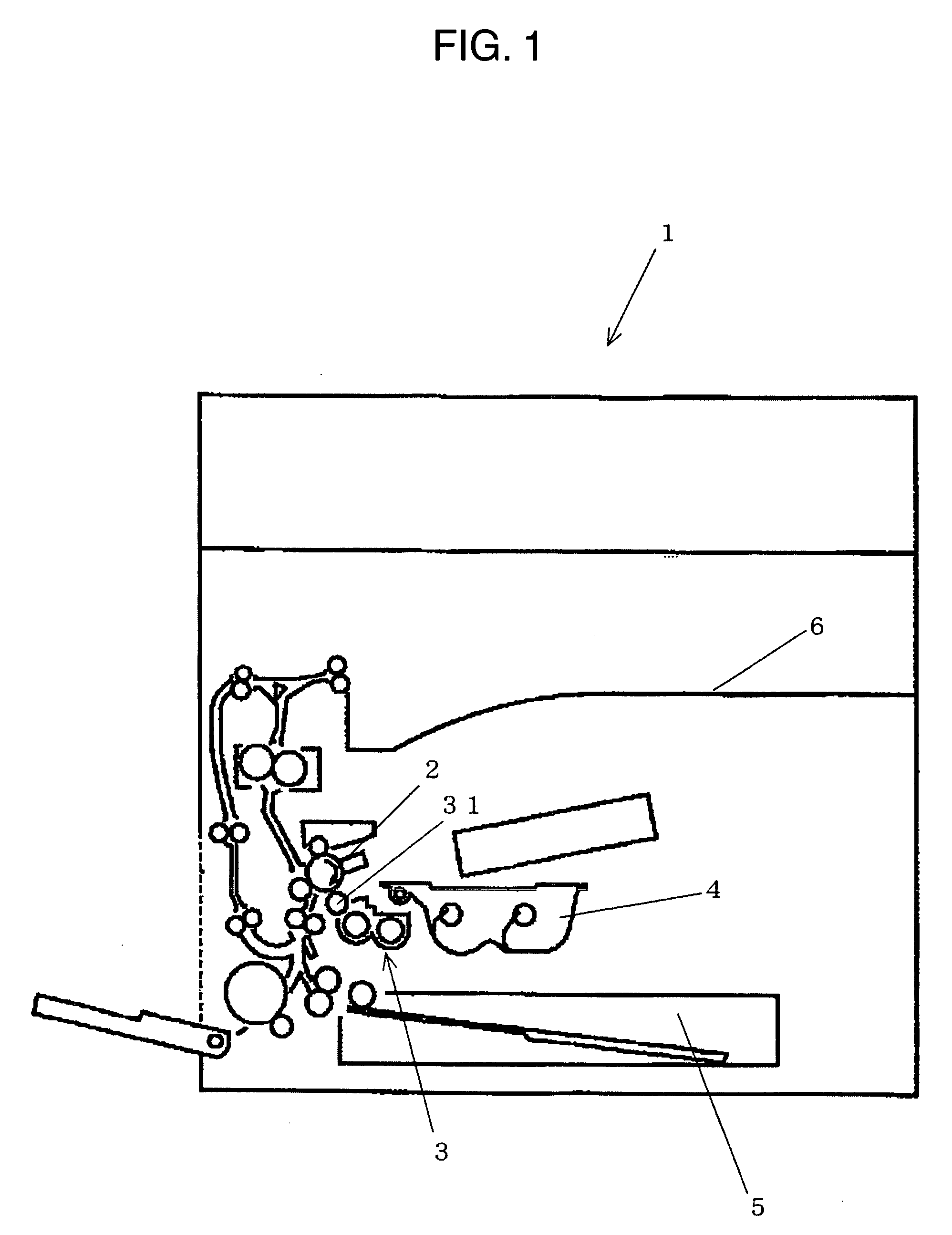

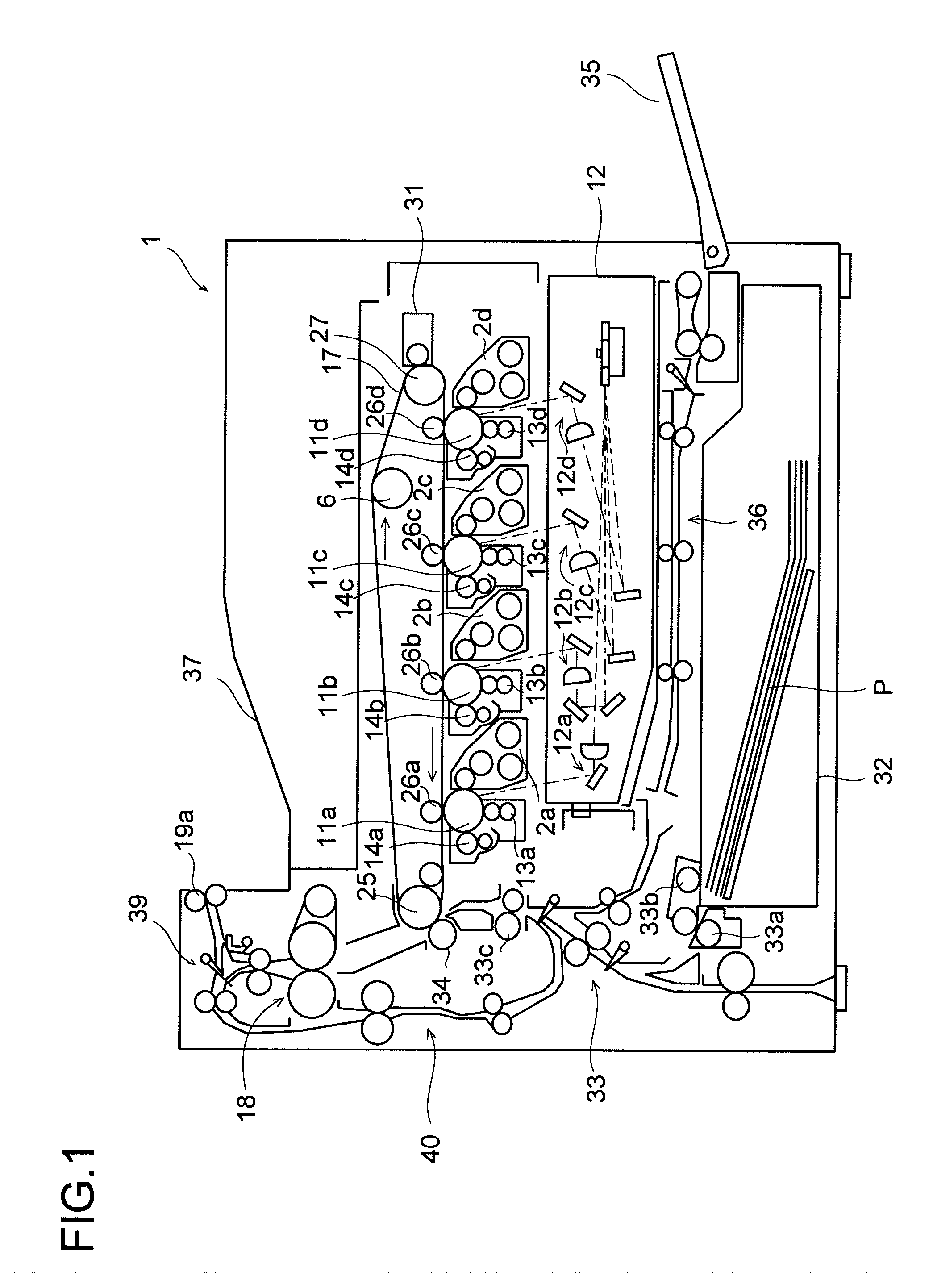

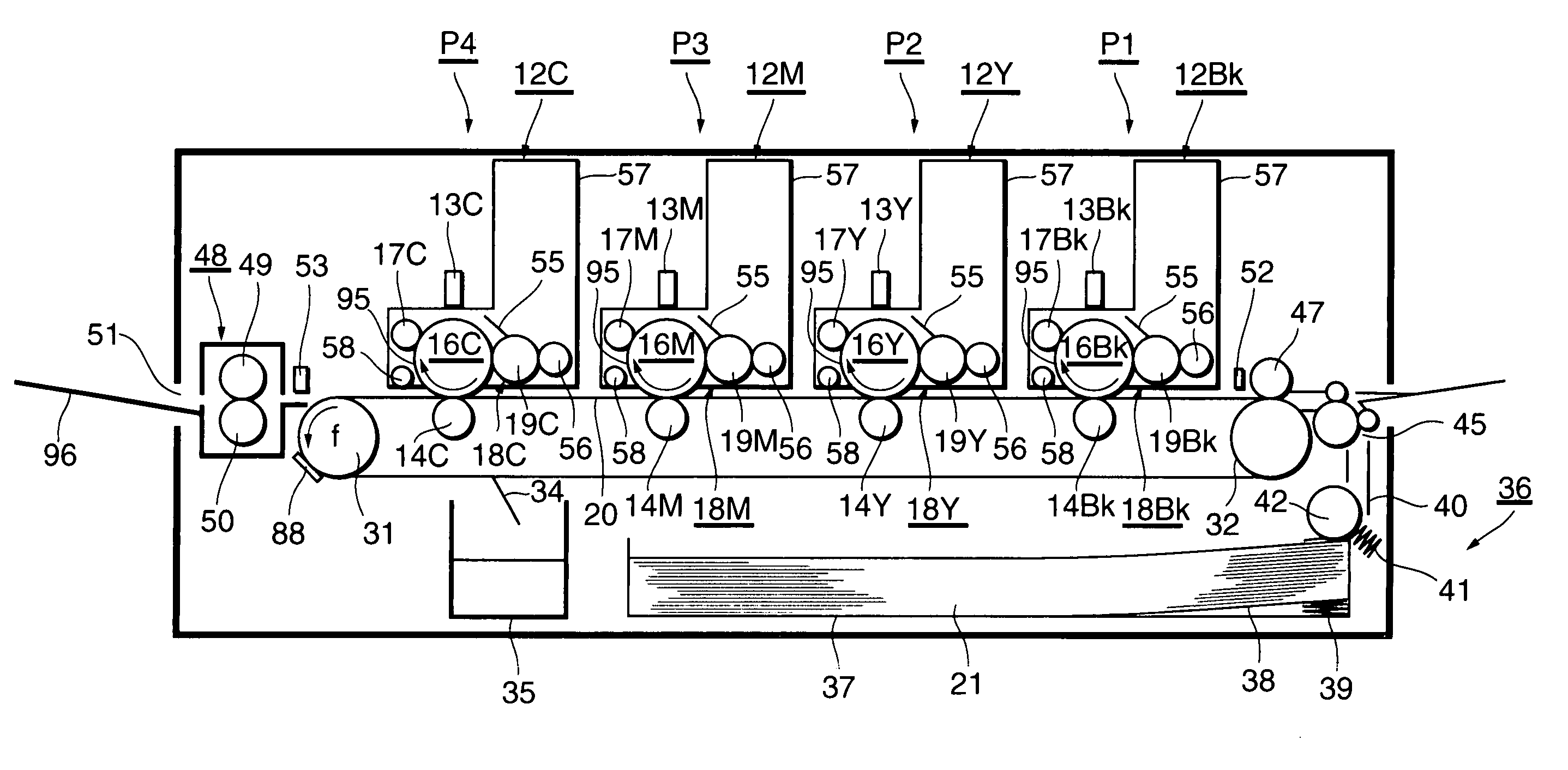

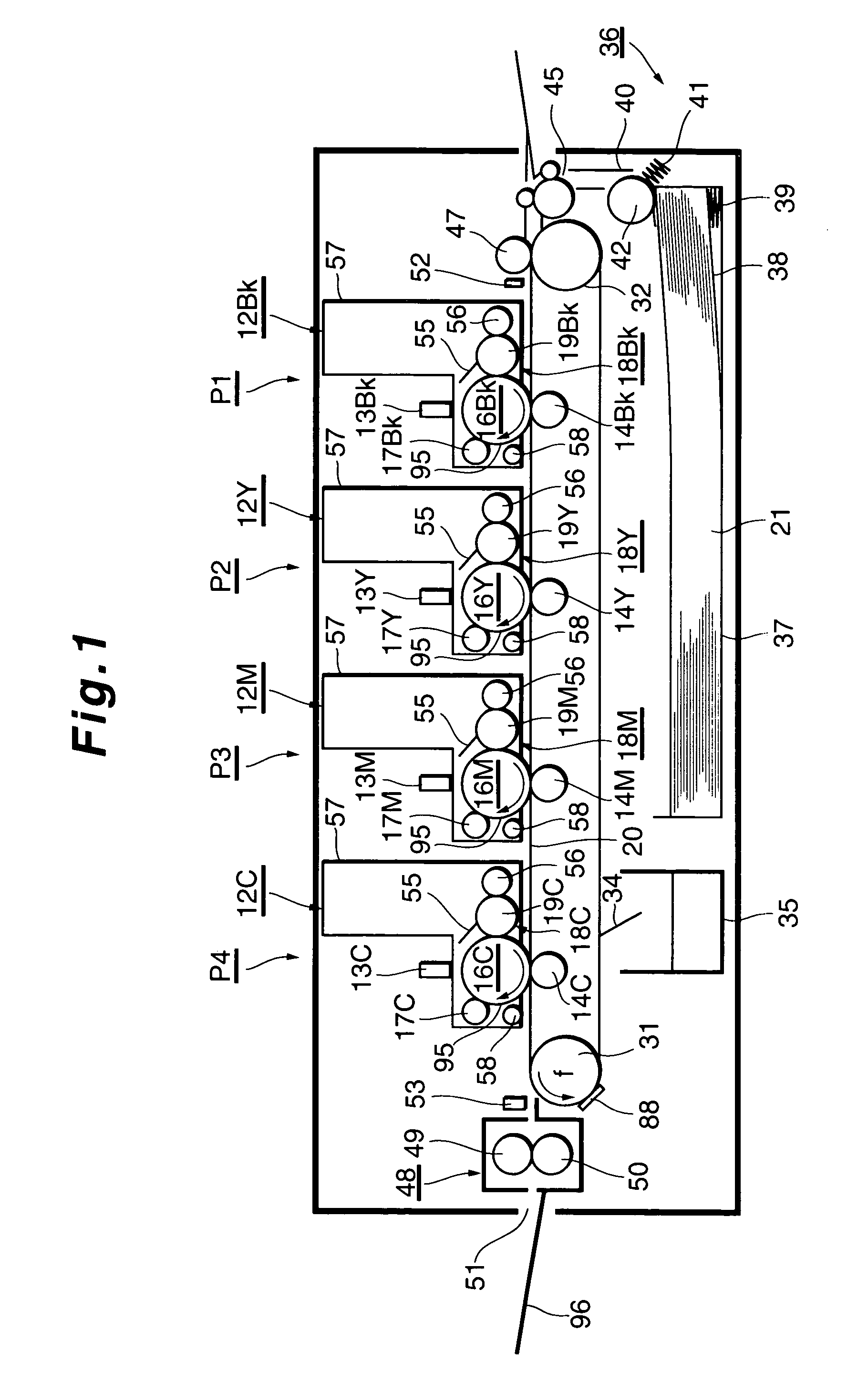

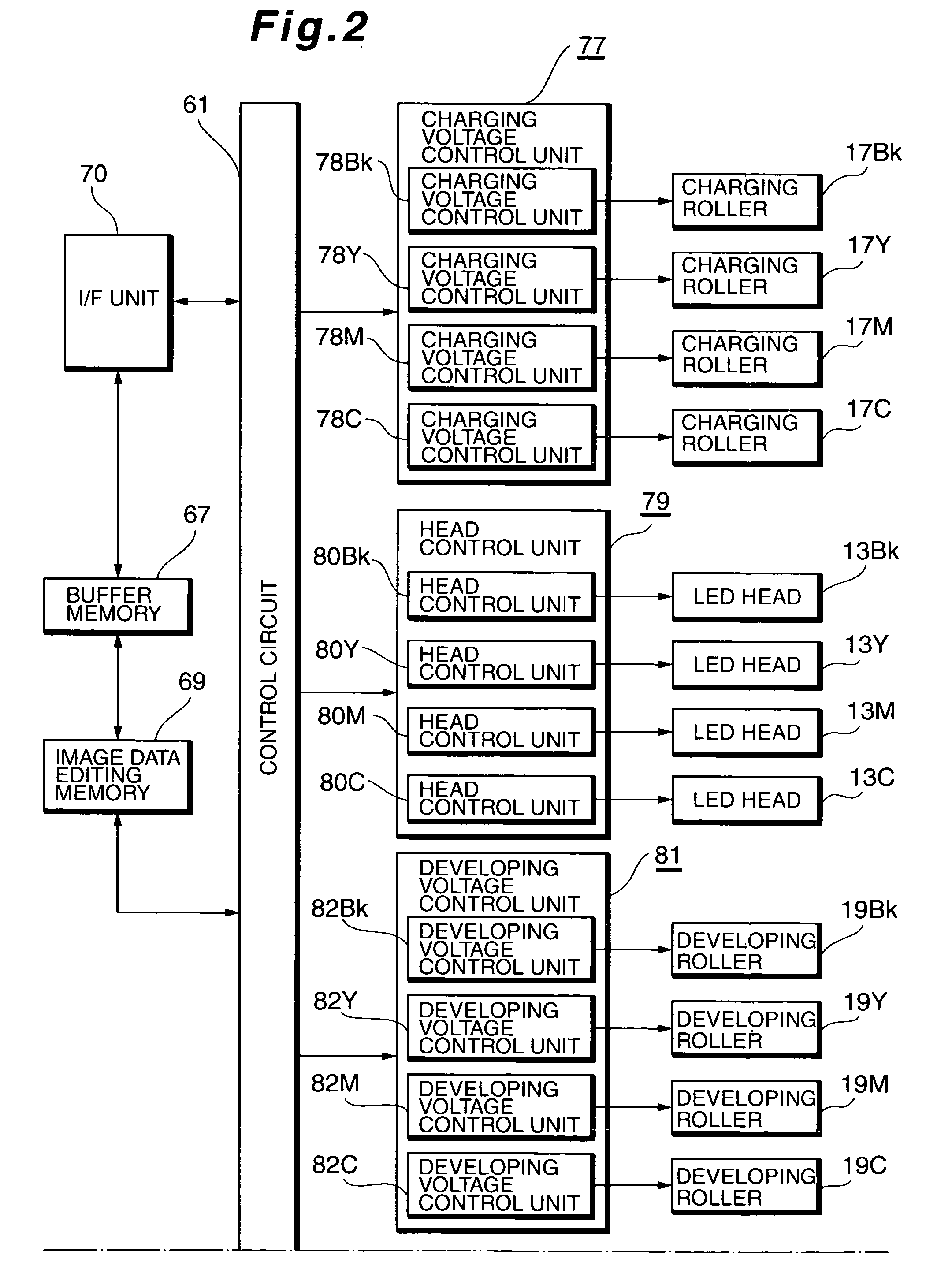

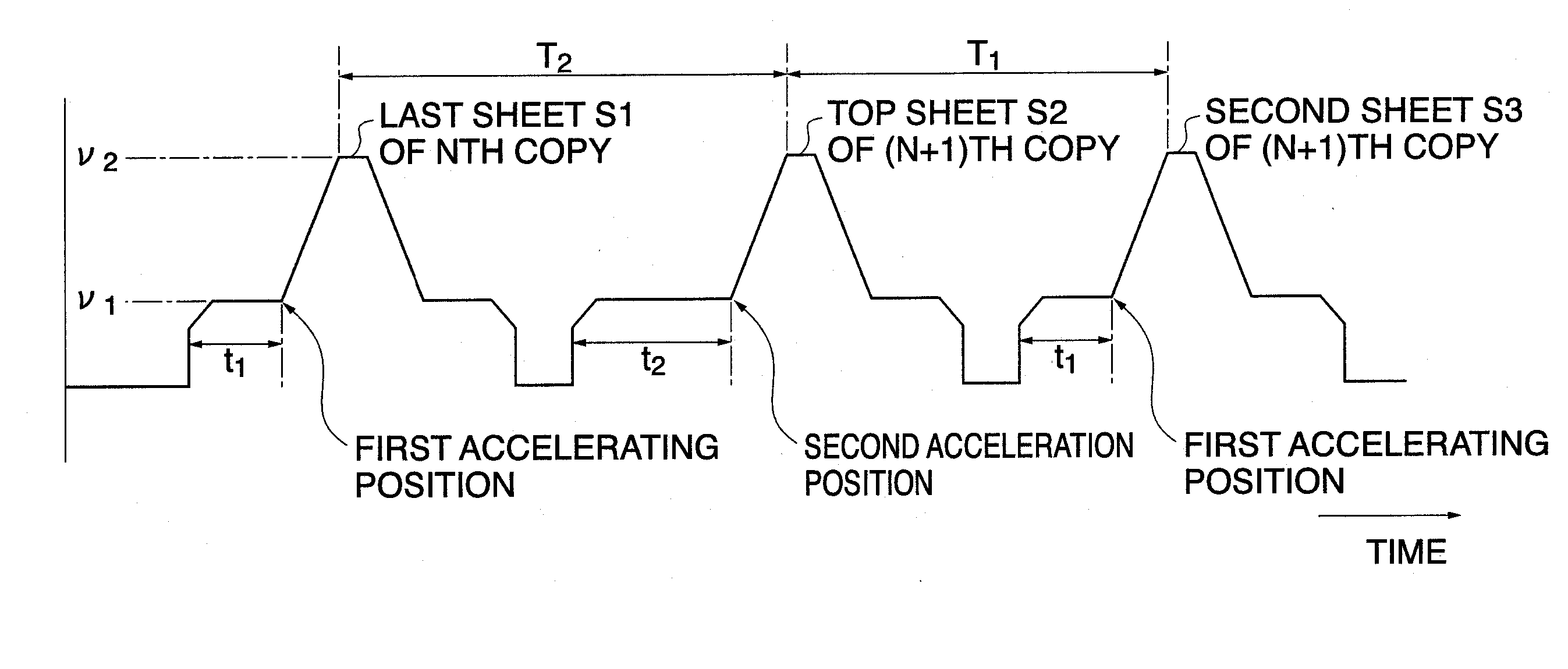

Image forming apparatus that controls image forming process based on temperature of conveying belt

ActiveUS7167657B2Suppresses internal temperature riseImprove image qualityElectrographic process apparatusTemperature controlImaging quality

An image forming apparatus such as a printer has: an image forming unit which forms an electrostatic latent image onto a charged photosensitive drum, deposits toner onto the image, and forms a visible image; a belt arranged so as to run freely in contact with the image forming unit; a temperature sensor which detects a temperature of the belt; and a controller which controls an image forming process on the basis of the detected temperature. Since the belt temperature is detected and the printing process is controlled on the basis of the detected temperature, an increase in temperature of the drum and an increase in temperature in the printer can be suppressed. Thus, the flowability of the toner in each image forming unit does not deteriorates and image quality can be improved.

Owner:OKI ELECTRIC IND CO LTD

Sheet processing apparatus and sheet processing method

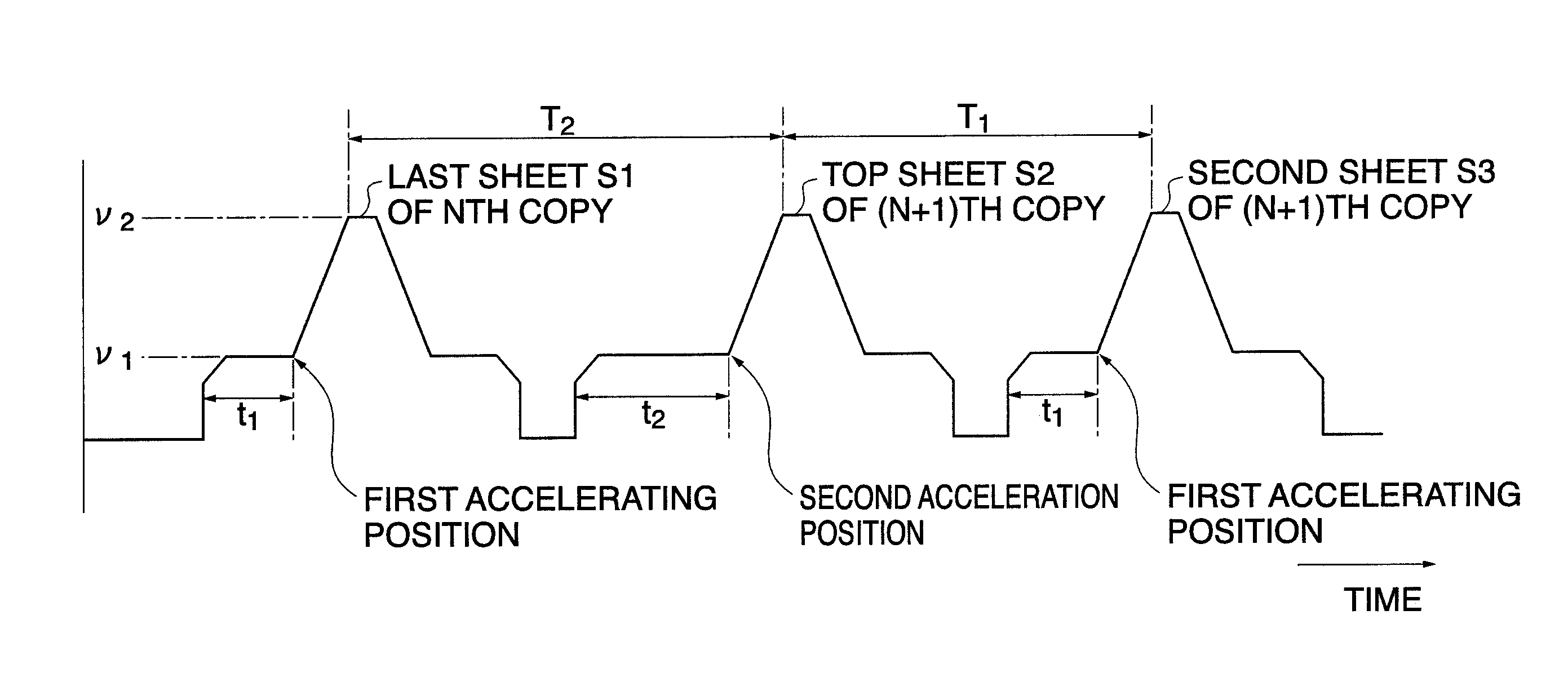

ActiveUS20070194521A1Increase delivery speedReduce conveying speedFunction indicatorsPile receiversEngineeringProcess time

A sheet processing apparatus which is capable of securing a sufficient sheet bundle processing time period even with a short sheet conveying path to thereby maintain required capability of processing sheets conveyed at constant intervals. Rollers that convey sheets are controlled such that the conveyance speed of a sheet being conveyed by the rollers is increased in first timing so as to set the sheet at an increased distance from a succeeding sheet being conveyed by the rollers. When a sheet preceding the sheet being conveyed is the last sheet of a set of sheets to be processed by the sheet processing apparatus, the rollers are controlled to increase the conveyance speed of the sheet being conveyed in second timing later than the first timing.

Owner:CANON KK

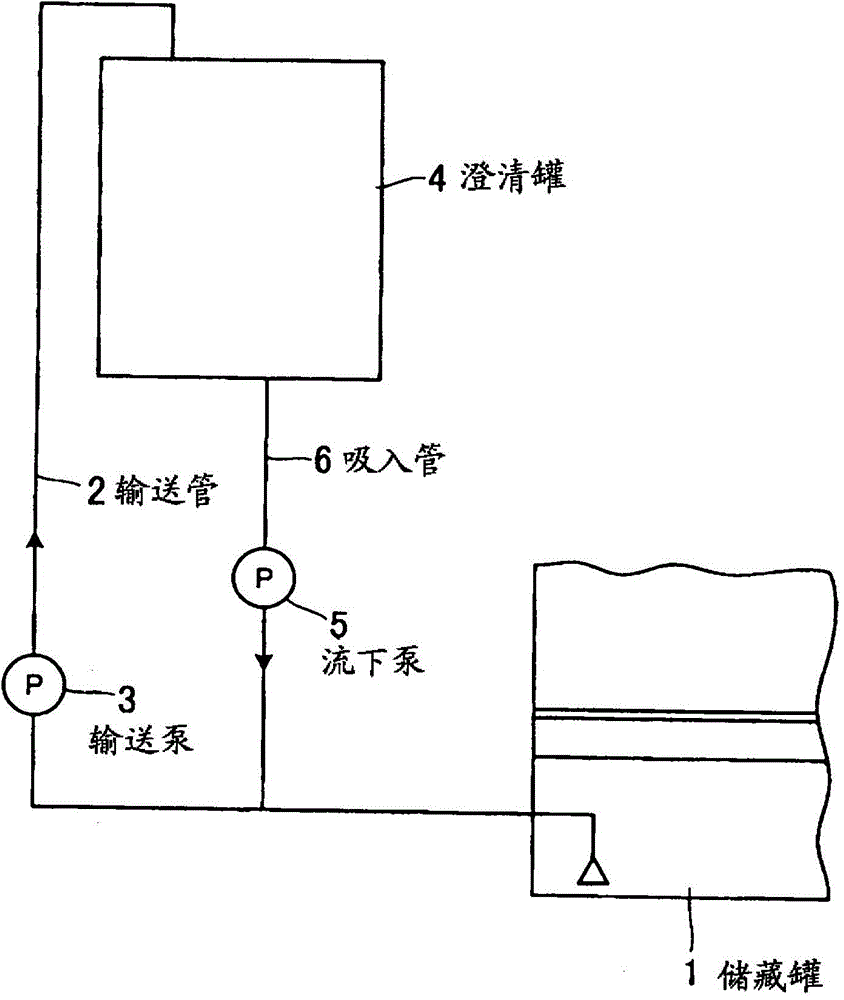

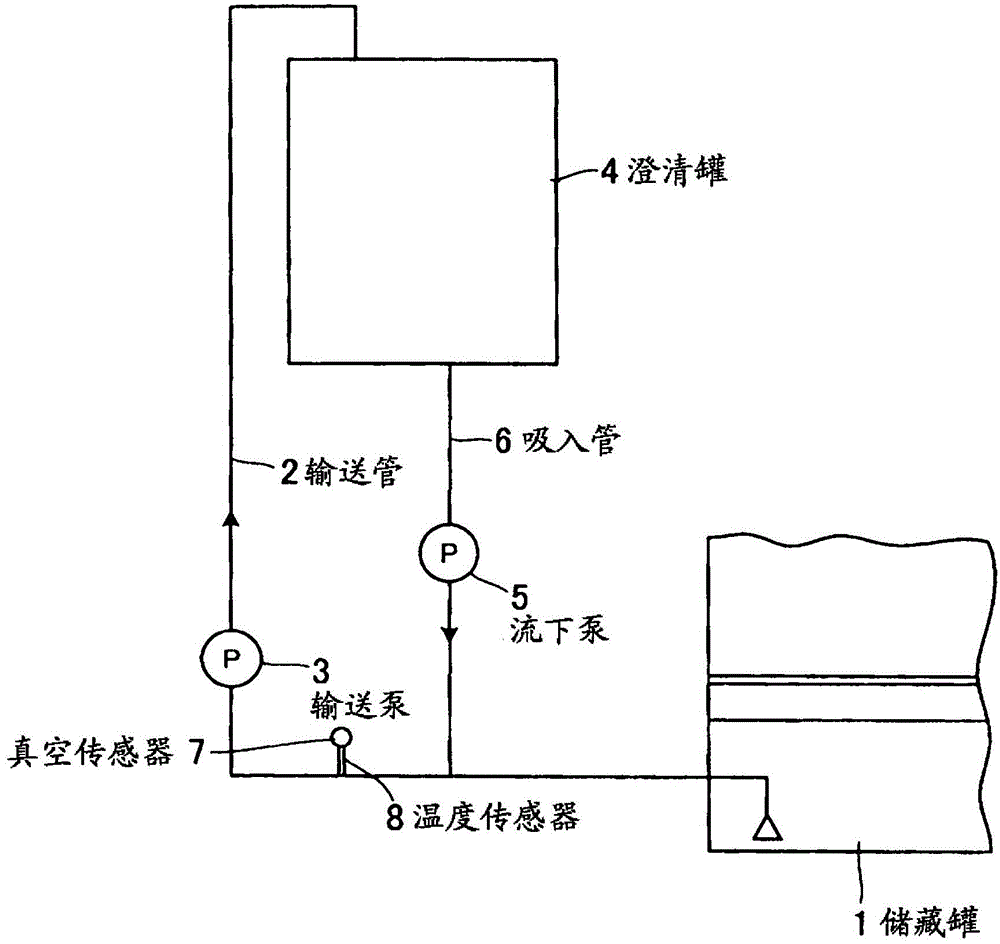

Heating method of fuel oil

ActiveCN104443339AImprove power loadReduce conveying speedPropulsion power plantsMachines/enginesEngineeringFuel oil

The present invention aims for improving power load of a delivery pump and reducing absorbing resistance of a delivery pipe. When the delivery pump (3) of the fuel oil is used for delivering, a downflow pump (5) is kept to operate continuously, so that the high temperature oil form the downflow pump (5) is mixed and delivered to the fuel oil form a storage tank (1) and absorbed by the delivery pump (3) so that the viscosity of the fuel oil is reduced, and therefore the power load of the delivery pump (3) is improved, the delivery amount of the fuel oil form the storage tank (1) is reduced as much as the amount of the downflow oil, the delivery speed of the storage tank is reduced and the absorbing resistance is reduced.

Owner:HOKUSHIN ENG

Method for controlling sheet processing apparatus

ActiveUS20140011654A1Increase delivery speedEasy to operateAutomatic control devicesMechanical working/deformationEngineeringKnife blades

In the control of a cutting mechanism of a sheet processing apparatus, when rear end cut region of a sheet is finely cut and divided into predetermined fine-cutting unit length, if sheet conveying direction length of rearmost end divided region is equal to or more than minimum reference length corresponding to the distance between cutting position of the cutting mechanism and nipping position of a pair of first conveying rollers and is less than maximum reference length in which predetermined fine-cutting unit length is added to minimum reference length, upper and lower blades of the cutting mechanism are held opened immediately after the downstream edge of rearmost end divided region is cut and the pair of first conveying rollers are driven at limited conveying speed lower than normal conveying speed.

Owner:DUPLO SEIKO CORP

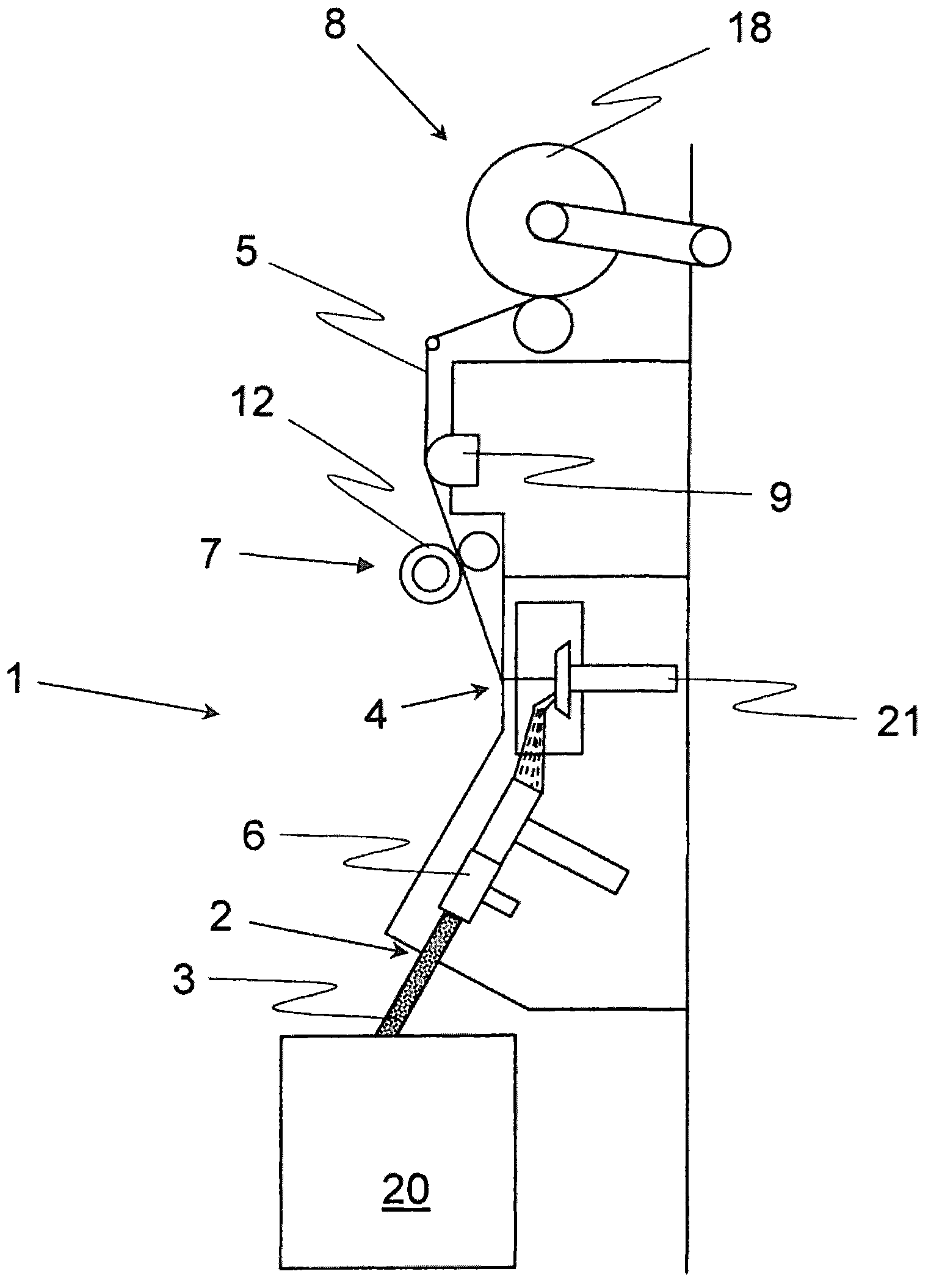

Spinning machine and method for interrupting yarn production on a spinning machine

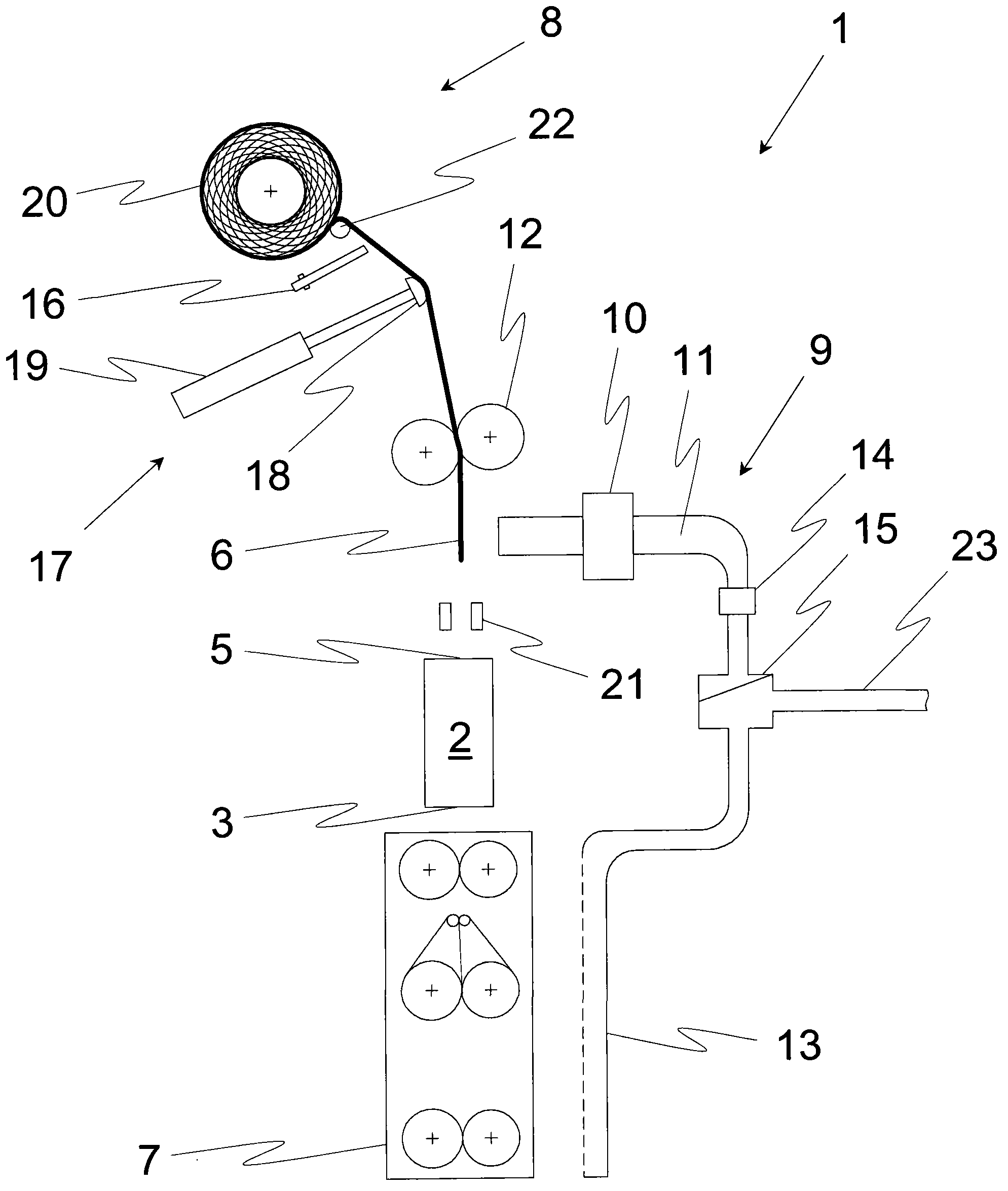

ActiveCN103014960AImplementation returnsFixed earlyContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a spinning machine and a method for interrupting yarn production on a spinning machine. The spinning machine comprises at least one spinning point (1) having an inlet for a fiber material (3) and an outlet for the yarn (5) produced from the fiber material (3), wherein the spinning machine comprises a delivery device (6) for feeding the fiber material (3) into the spinning point (1), a take-off device for drawing off the yarn from the spinning point, a winding device for winding up the produced yarn, and a yarn monitoring unit for monitoring at least one yarn parameter. The feed speeds of the delivery device, the take-off device, and the winding device are gradually reduced to a stop in order to interrupt the yarn production, wherein the reducing takes place such that the end (10) of the produced yarn (5) is located between the outlet (4) of the spinning point (1) and the winding device (8) after the reducing is completed.

Owner:RIETER INGOLSTADT GMBH

Paper feeder and printer

ActiveUS8864132B2Avoid registrationReduce conveying speedRegistering devicesFunction indicatorsPulp and paper industryContinuous feeding

Upon continuous feeding of a plurality of sheets and upon detection of a leading end of a sheet by a detection unit before an elapse of a first time after a start of a paper feed roller, a controller performs control such that a paper conveyance speed of the paper feed roller is set lower than a paper conveyance speed of a registration roller, and the paper feed roller is stopped after conveying the sheet having the leading end detected for a specified conveyance distance before a next timing of starting the registration roller.

Owner:RISO KAGAKU CORP

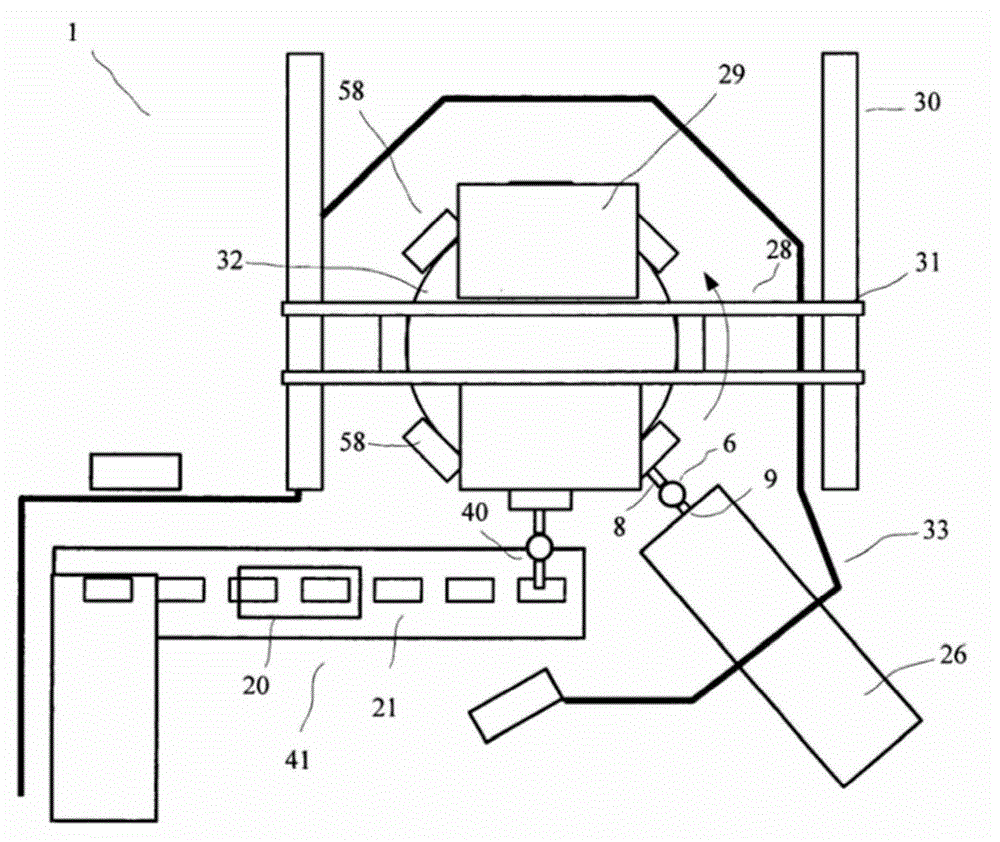

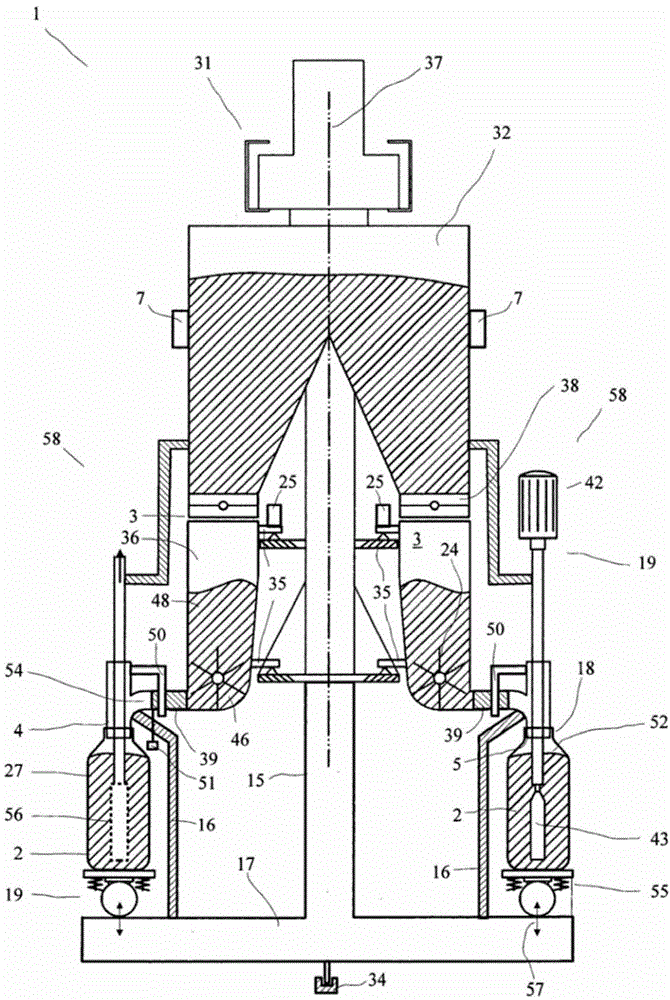

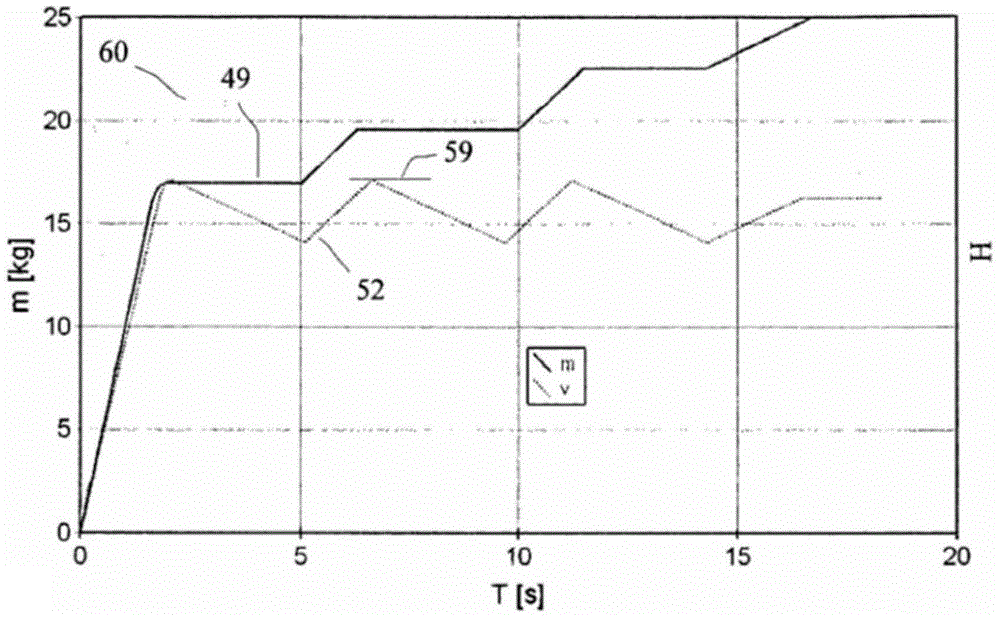

Packaging machine and method for filling pouches

ActiveCN104039653AVariable conveying speedConveying speed is variably controlledPackaging automatic controlSolid materialEngineeringPackaging machine

A packaging machine and method for filling bags with a supporting structure to which at least one filling box is fastened which includes a conveyor element and to which a weighing device and a filling spout are assigned. A control device is provided. The filling box is retained non-communicating with the supporting structure and the assigned filling box and is weighed separately by the assigned weighing device to discharge from the filling box a predefined quantity of intended fill product by way of differential weighing and to fill it into the bag through the tilling spout. The control device controls the strength of a volume flow into the bag over the time of the filling process so that the intended fill product is maintained at a high fill height while overflow is simultaneously prevented.

Owner:HAVER & BOECKER

Sheet processing apparatus and sheet processing method

InactiveUS7240901B2Increase delivery speedReduce conveying speedDigital data processing detailsFunction indicatorsProcess timeSheet material

A sheet processing apparatus which is capable of securing a sufficient sheet bundle processing time period even with a short sheet conveying path to thereby maintain required capability of processing sheets conveyed at constant intervals. Rollers that convey sheets are controlled such that the conveyance speed of a sheet being conveyed by the rollers is increased in first timing so as to set the sheet at an increased distance from a succeeding sheet being conveyed by the rollers. When a sheet preceding the sheet being conveyed is the last sheet of a set of sheets to be processed by the sheet processing apparatus, the rollers are controlled to increase the conveyance speed of the sheet being conveyed in second timing later than the first timing.

Owner:CANON KK

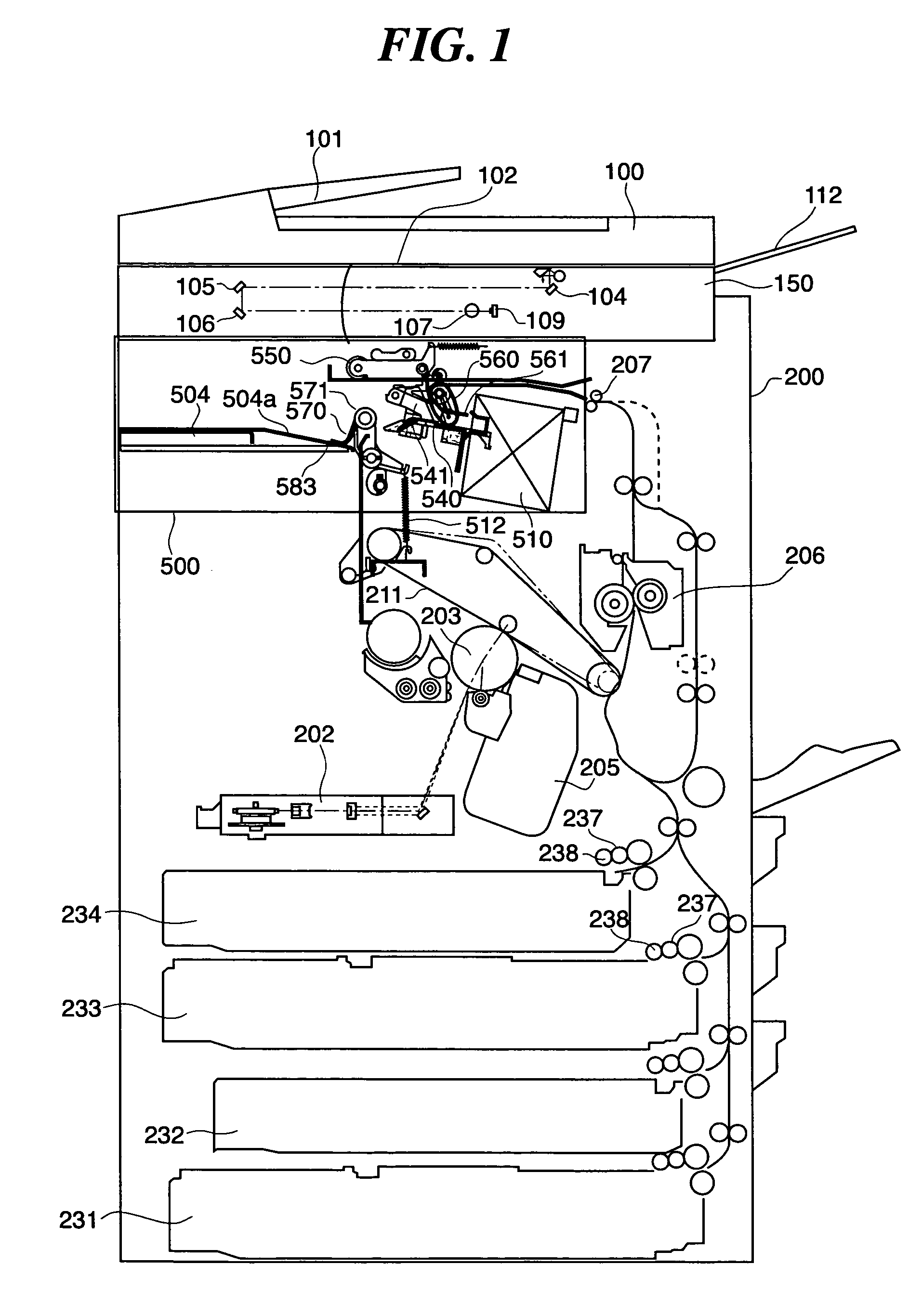

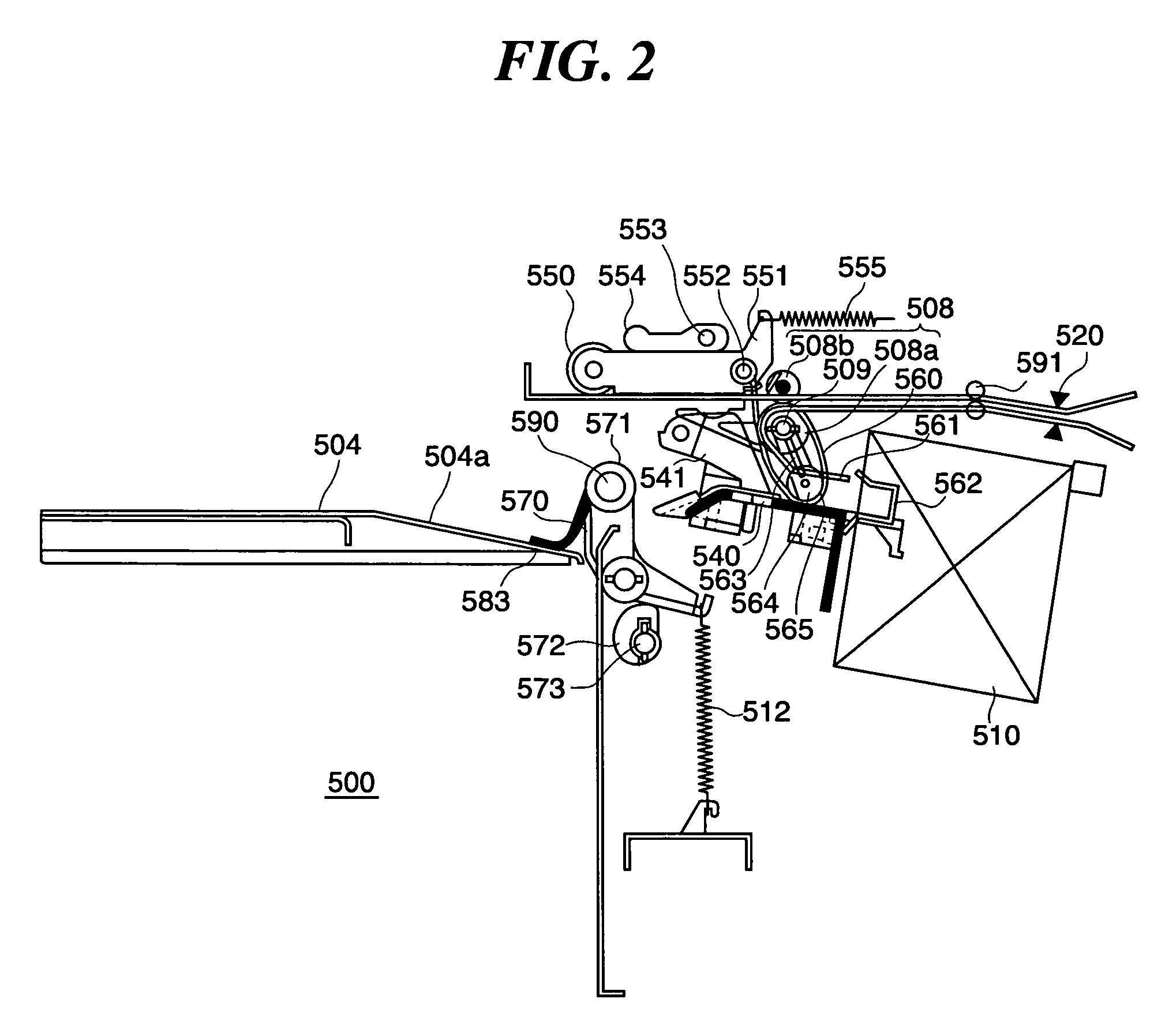

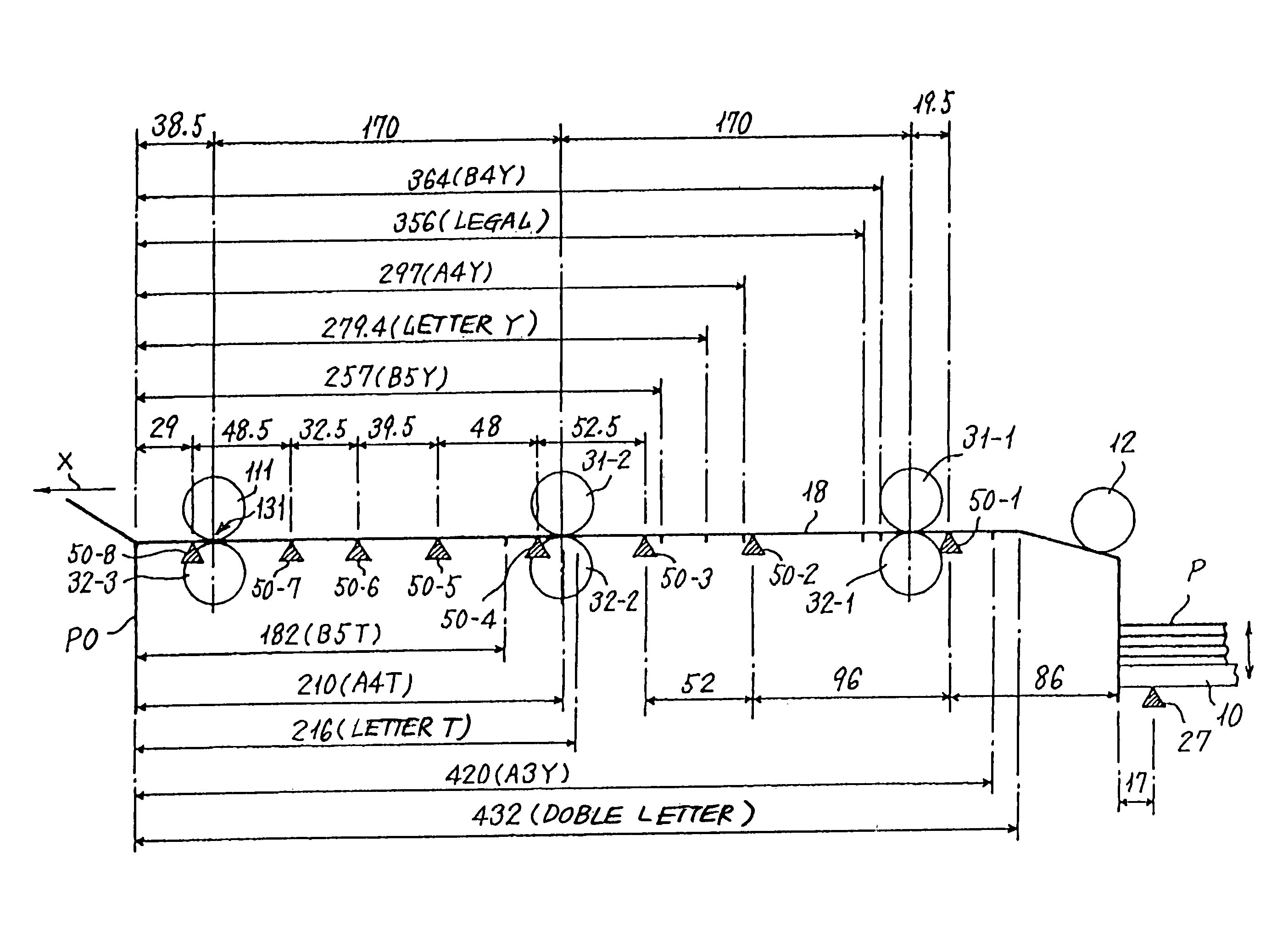

Paper conveyance apparatus

InactiveUS7651090B2Little changeGood quality feedFunction indicatorsArticle feedersLeading edgeMechanical engineering

A paper conveyance apparatus includes a stacking portion; a feeding mechanism to extract and feed paper from the stacking portion one sheet at a time; and an intermediate portion for conveying the fed paper to the vicinity of a feeding port or feeding device of a main body of an image forming apparatus. The intermediate portion includes a plurality of conveyance devices and a plurality of paper detecting devices disposed from the upstream side to the downstream side of a conveyance path. The paper conveyance apparatus further includes a control device for reducing the conveyance speed of the plurality of conveyance devices when the leading edge of the paper is detected by a detecting device disposed at least one device further toward the upstream side than a paper detecting device disposed furthest downstream of the plurality of detecting devices.

Owner:RICOH KK

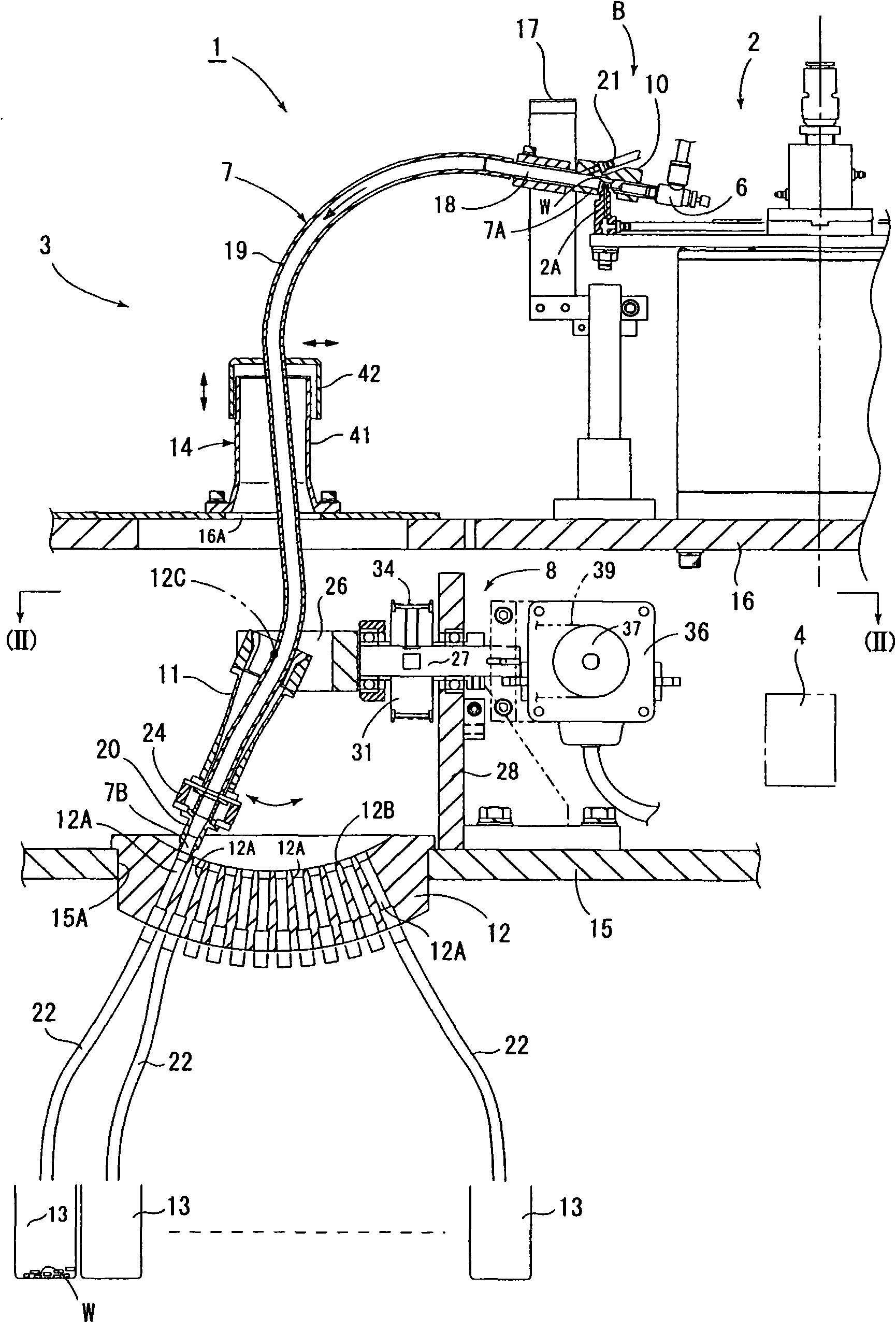

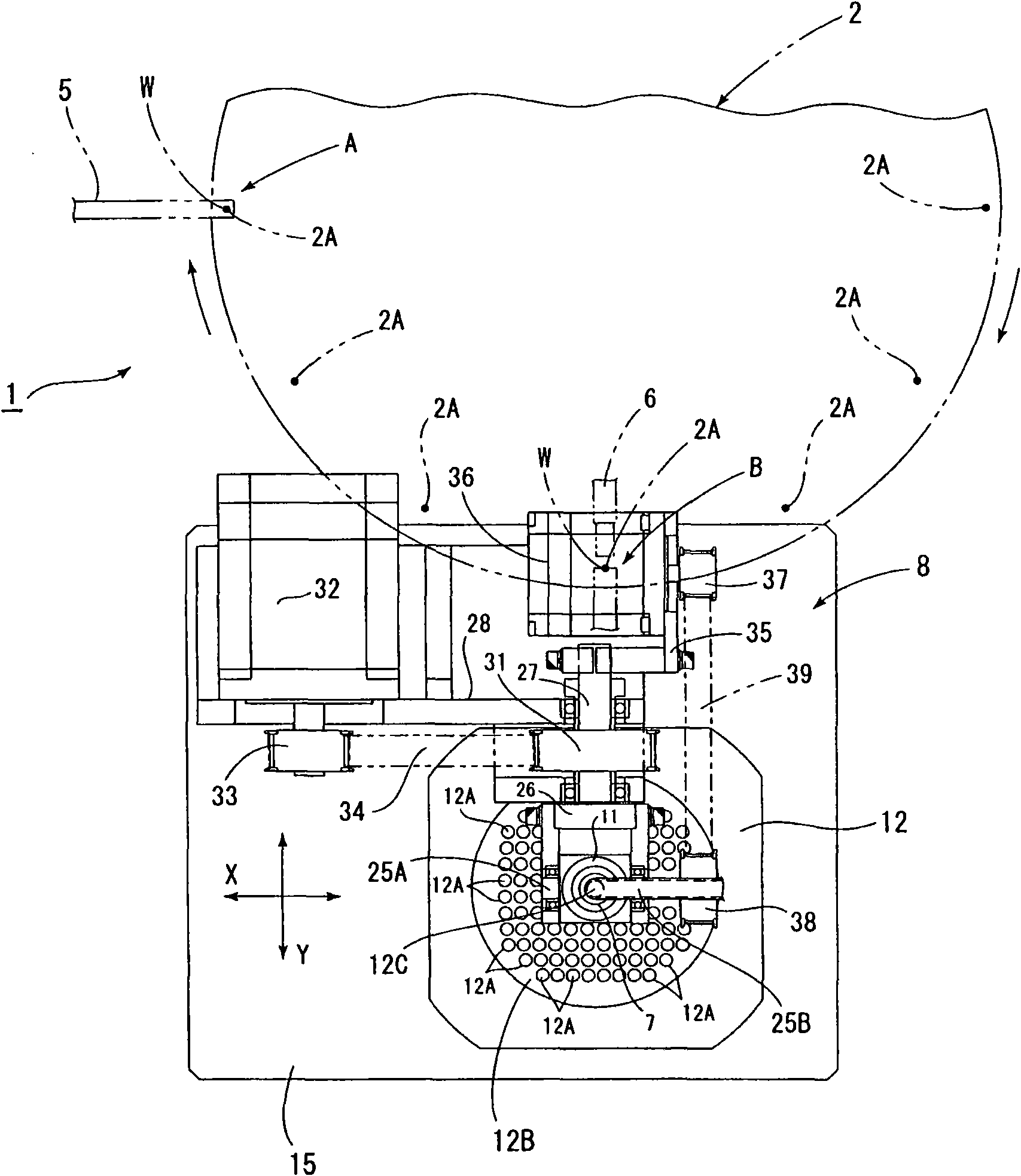

Distribution device of electronic component

ActiveCN101890410AReduce conveying speedProcessing speedElectrical testingSortingEngineeringElectronic component

The invention provides a distribution device of an electronic component; an inputting slideway (7) of the distribution device (3) comprises flexible tubes; the lower end of the inputting slideway (7) is held at the lower end of a swinging component (11). The swinging component (11) is driven by a driving mechanism (8) to swing so that an exhausting port (7B) of the inputting slideway (7) moves to a position adjacent to the upper part of a specific distribution port (12A). The flow area in the inputting slideway (7) is in the whole area, which can prevent the flowing speed of the compressed air flowing into the inputting slideway (7) from reducing. Therefore, the distribution device (3) of the electronic component with a higher processing is provided.

Owner:SHIBUYA IND CO LTD

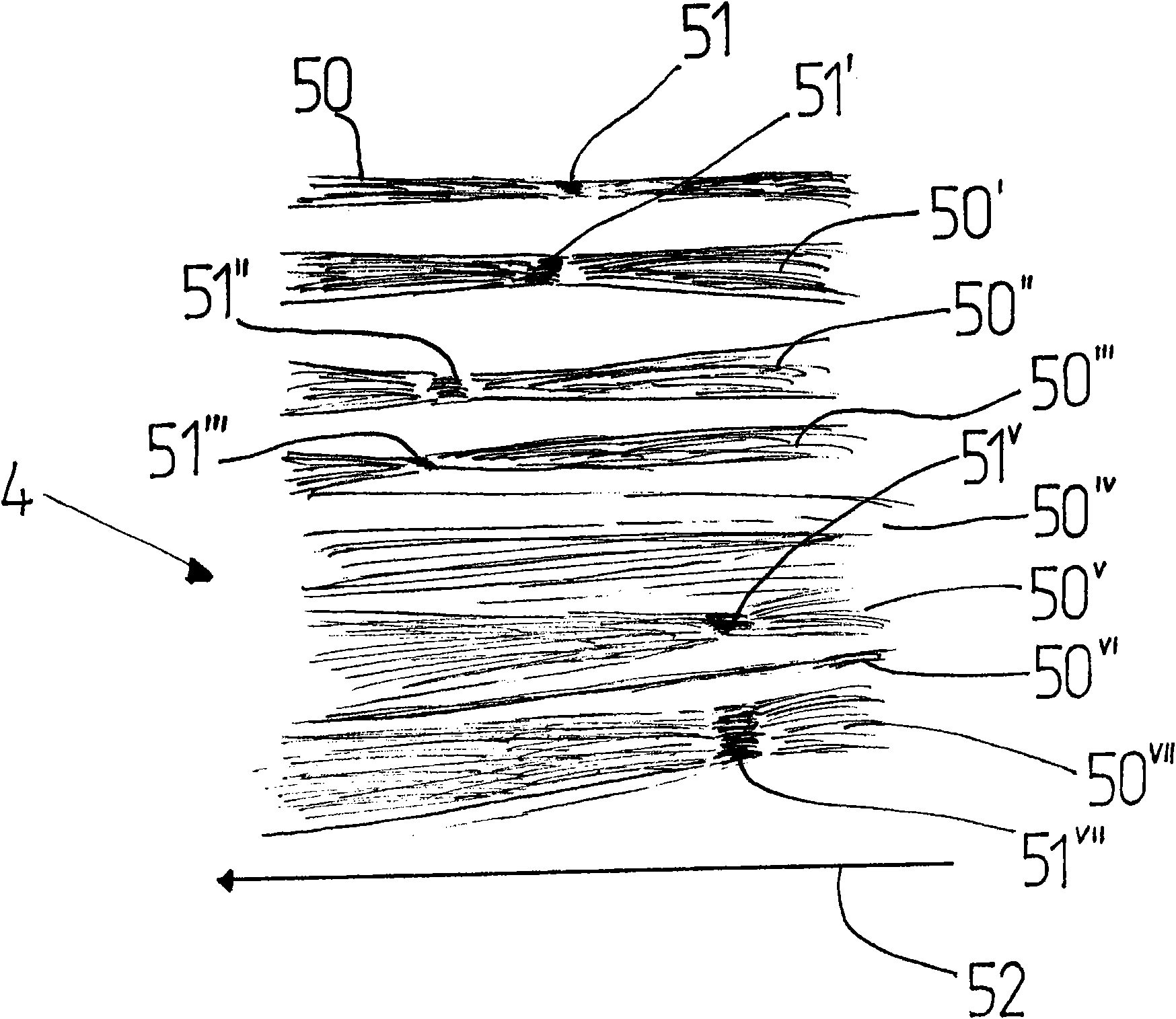

Method for operating a filter rod machine and filter rod machine

ActiveCN101856148AIncrease widthGood location resolutionCigarette manufactureTobacco smoke filtersEngineeringFilter material

This invention relates to a method for operating a filter-tip rod machine and a filter-tip rod machine, wherein the filtering material is extracted from a storage, spread, extended and transmitted through the coating device, then provided to the forming apparatus, furthermore, a filtering material strip is formed to be a filter-tip rod. It is characterized in that at least one sensor identifies the default part and produces at least one signal after the extension of the filtering material strip and before the coating device, therefore, at least the area of the filter-tip rod with default parts will be excluded by the next process; the filter-tip rod has a filtering material output station, a spreading apparatus, a extending apparatus a coating device and a rod forming apparatus which helps making the filter-tip rod, wherein the apparatus comprises at least one sensor for identifying the default part of the filtering material strip, being characterized in that the sensor is arranged at the position of the extending apparatus or arranged at the lower part of the extending apparatus and the upper part of the coating device.

Owner:KOERBER TECH GMBH

Carrying apparatus and hot-rolling apparatus, and carrying method and hot-rolling method

InactiveCN101939119AIncrease delivery speedReduce conveying speedForging/pressing devicesCharge manipulationThermodynamicsProcess engineering

Disclosed is a carrying apparatus, which comprises a plurality of carrying rollers supported in parallel at a predetermined spacing, so that a workpiece is carried from a rolling machine to the inside of a heat keeping-applying furnace by the carrying rollers. The carrying apparatus is characterized by further comprising a shock-predicting data collection unit for acquiring such data upstream of the heat keeping-applying furnace as to predict the magnitude of shocks to be applied by the workpiece to that one of the carrying rollers, which is disposed in the heat keeping-applying furnace, and a control unit for predicting the magnitude of the shocks from that data acquired by the shock-predicting data collection unit, thereby to adjust the carrying speed of carrying the workpiece in the heat keeping-applying furnace in accordance with the magnitude of the shocks.

Owner:IHI CORP

Spinning machine and method for interrupting the production of thread on a spinning machine

ActiveCN103014946AYarn clampingReliable clampingContinuous wound-up machinesOpen-end spinning machinesYarnFiber

A method for interrupting yarn production on a spinning machine is provided. The spinning machine has at least one spinning point having an inlet for a fiber material and an outlet for the yarn made from the fiber material, as well as a delivery device for feeding the fiber material into the spinning point, a take-off device for drawing off the yarn out of the spinning point, a winding device for winding up the produced yarn, and a yarn monitoring unit for monitoring at least one yarn parameter. The yarn production is interrupted upon detecting a defined deviation of the monitored yarn parameter from a target value, upon changing bobbins at the winding device, and / or prior to switching off the spinning machine. The feed speeds of the delivery device, the take-off device, and the winding device are gradually reduced to a stop in order to interrupt the yarn production. In addition, a spinning machine, a control and / or adjusting unit of which is driven in the invented method, is described.

Owner:RIETER INGOLSTADT GMBH

Sheet processing apparatus and sheet processing method

InactiveUS7717422B2Increase delivery speedReduce conveying speedFunction indicatorsPile receiversProcess timeSheet material

A sheet processing apparatus which is capable of securing a sufficient sheet bundle processing time period even with a short sheet conveying path to thereby maintain required capability of processing sheets conveyed at constant intervals. Rollers that convey sheets are controlled such that the conveyance speed of a sheet being conveyed by the rollers is increased in first timing so as to set the sheet at an increased distance from a succeeding sheet being conveyed by the rollers. When a sheet preceding the sheet being conveyed is the last sheet of a set of sheets to be processed by the sheet processing apparatus, the rollers are controlled to increase the conveyance speed of the sheet being conveyed in second timing later than the first timing.

Owner:CANON KK

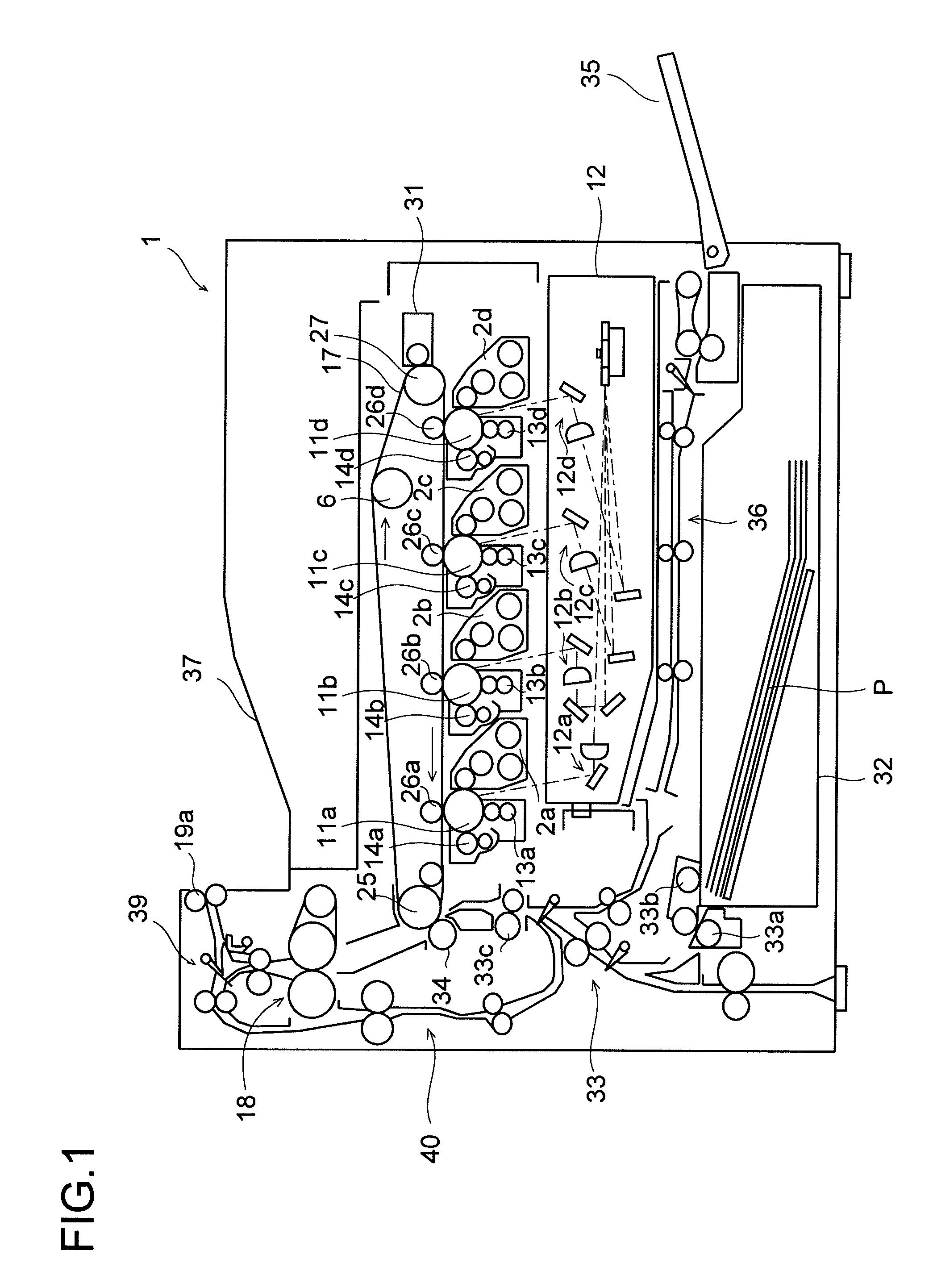

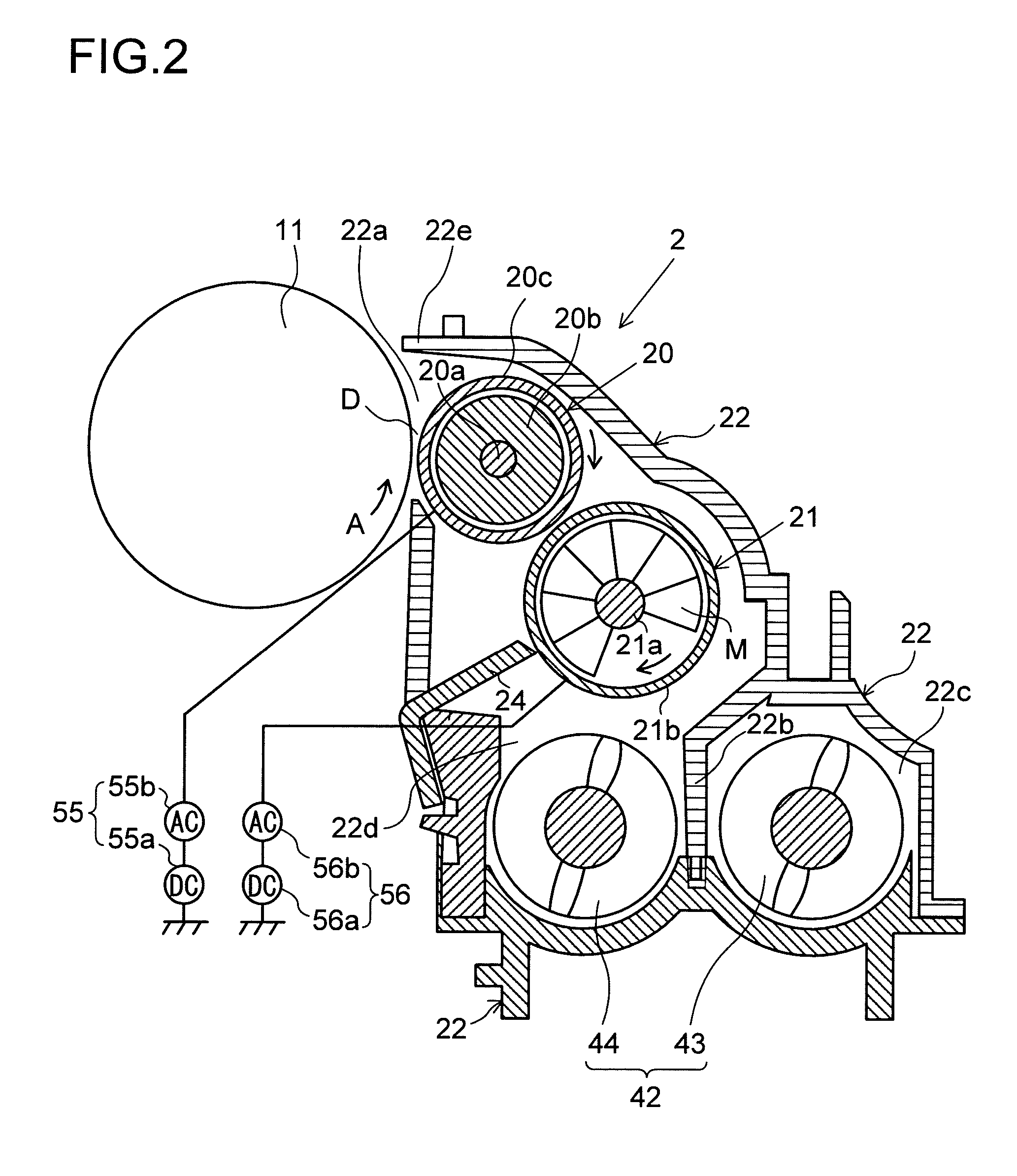

Developing device and image forming apparatus using the same

ActiveUS20100226689A1Improve performanceReduction of developer conveying performanceElectrographic process apparatusHelical bladeImage formation

A developing device includes a developing vessel for storing a developer, a first conveying passage, a second conveying passage, a first conveying member and a second conveying member to supply toner to a photoreceptor drum. The first conveying member includes a first rotary shaft and a first multi-helically structured blade. The first multi-helically structured blade includes a first inner helical blade and ring-shaped first outer helical blade. The first inner helical blade is formed so that the radius of the helical blade varies cyclically. The second helical pitch of the first outer helical blade is smaller than the first helical pitch of the first inner helical blade. The first outer helical blade inscribes the outer periphery of the first inner helical blade at its minimum radius portions.

Owner:SHARP KK

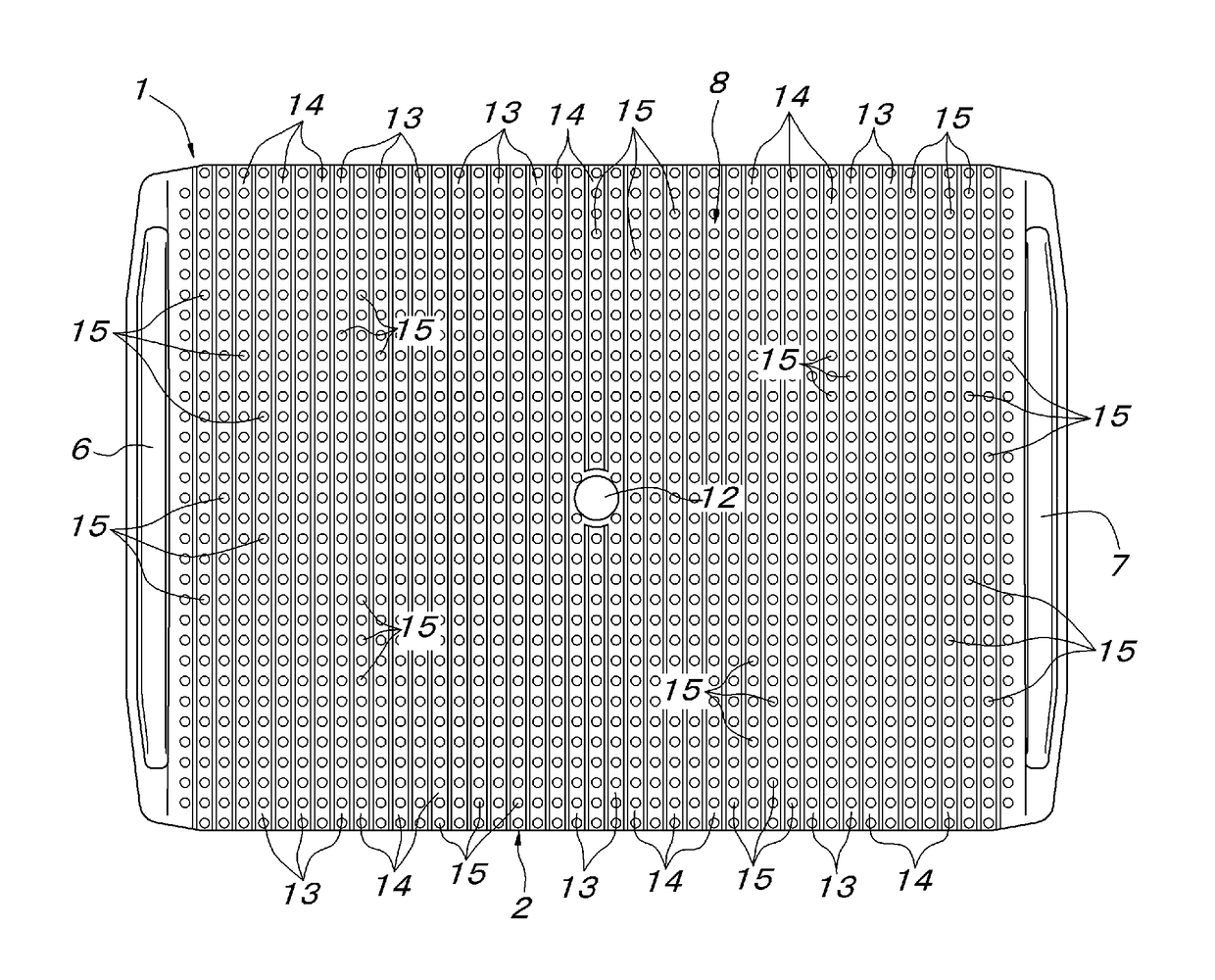

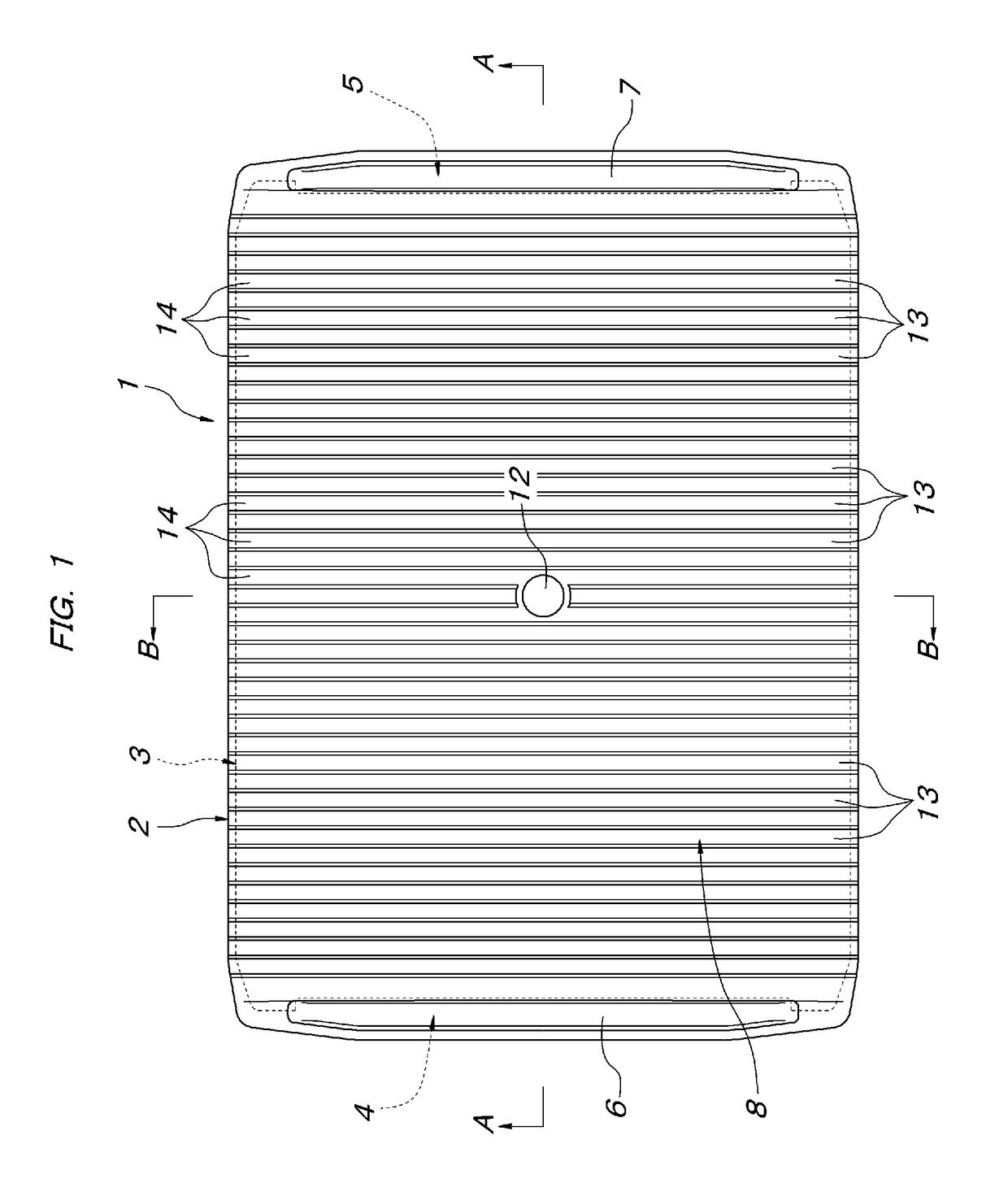

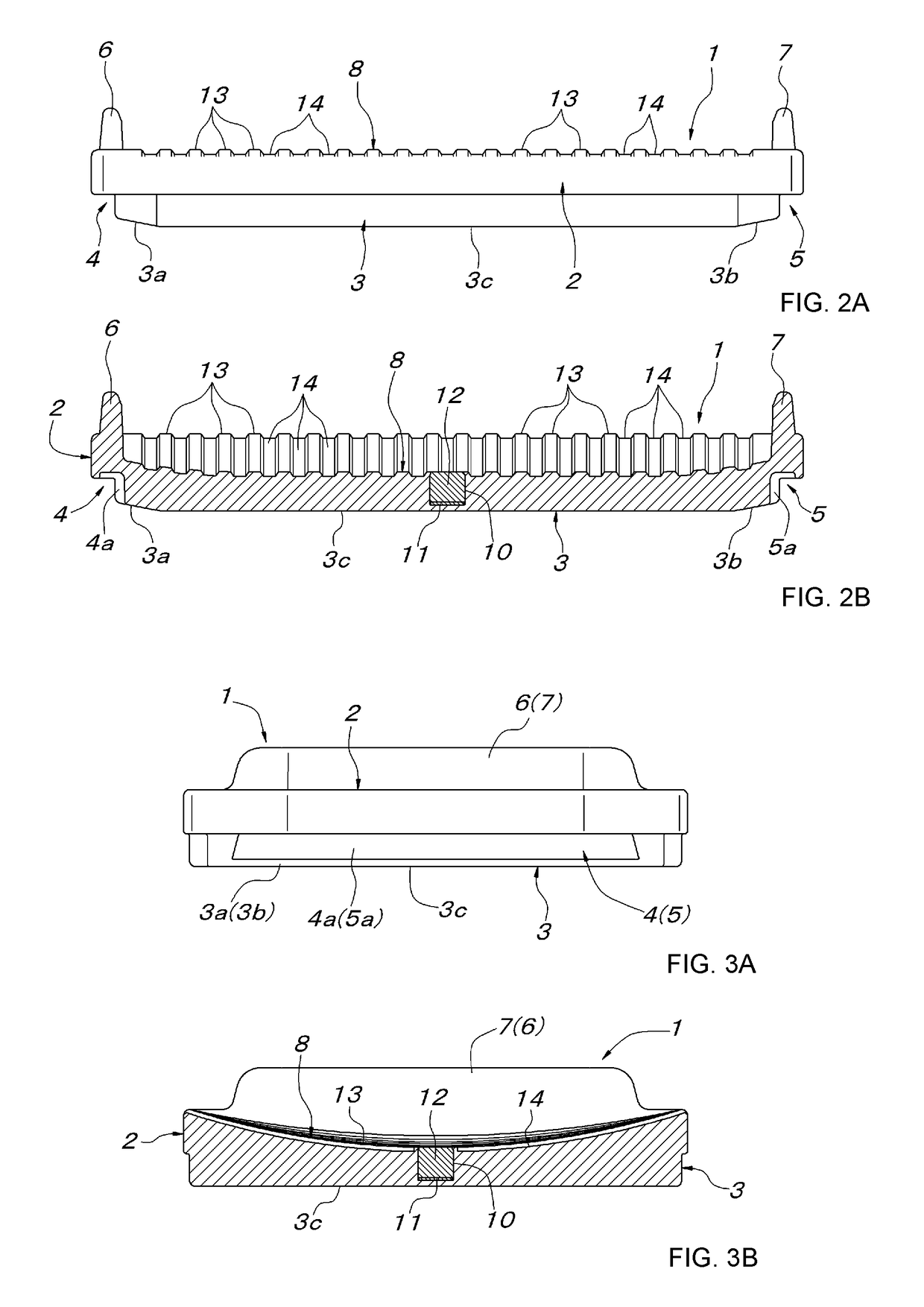

Baggage conveyance tray

ActiveUS9950828B2Increase speedImprove delivery efficiencyShow cabinetsContainer decorationsWall plateConveyor system

A baggage conveyance tray suitable for a sorting conveyor system for conveying baggage at airports has raised wall plate portions protruding on the front and rear both end portions of the tray in the length (conveyance) direction thereof extending in the right-left width direction of the tray. A baggage placement surface located between the front and rear both raised wall plate portions is concave along the length direction such that the central portion in the right-left width direction is lowered while the right and left both sides are raised. Elongated protrusion portions extending along the right-left width direction of the tray are disposed on the baggage placement surface at intervals in the length direction of the tray.

Owner:DAIFUKU CO LTD

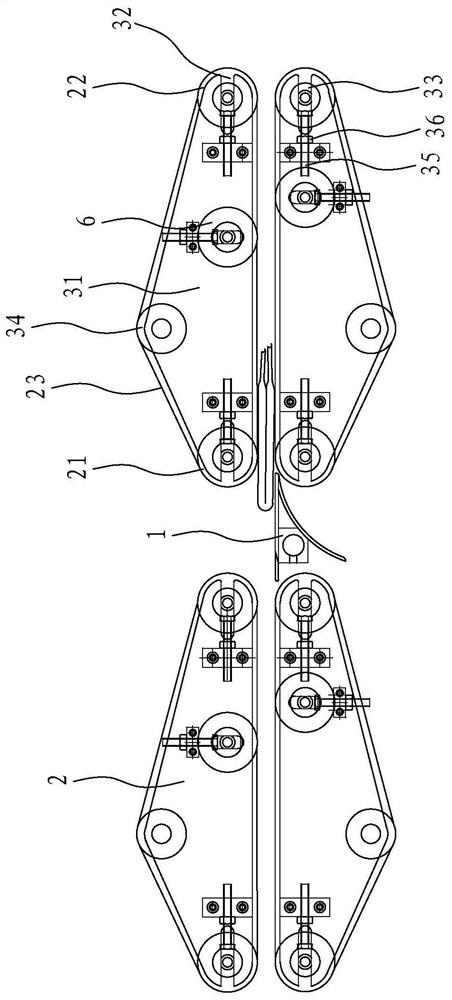

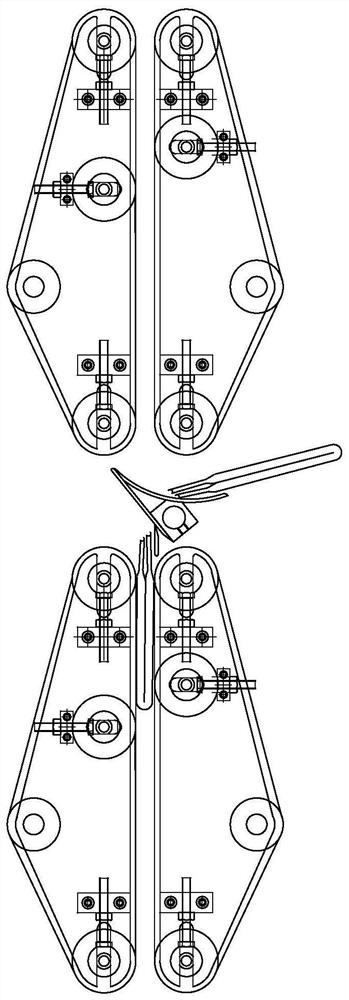

Rotational waste removing mechanism

PendingCN111717595AEasy to adjustAchieve regulationConveyorsSortingEnvironmental engineeringMechanical engineering

The invention relates to the field of disposable hygiene products, in particular to a rotational waste removing mechanism. The mechanism comprises two clamping transportation devices which are arranged on a rack; a waste removing device is arranged between the two clamping transportation devices; the waste removing device comprises a rotary shaft, a servo motor, and a waste removing plate; the waste removing plate comprises a clamping installation part, a horizontal plate, and an arc-shaped guiding plate; and the upper surface of the horizontal plate is not higher that the lower end face of atransportation channel. When the horizontal plate rotates upwardly around the rotary shaft, an angle between the upper end of and a vertical surface of the arc-shaped guiding plate is smaller than 20degree, and the rotating angle of the horizontal plate is not larger than 45 degree; a first inclined surface is formed in the horizontal plate, a supporting plate is arranged between the waste removing device and the clamping transportation device, and a second inclined surface is formed in the supporting plate; and when the horizontal plate is at a horizontal position, the second inclined surface abuts against the first inclined surface. The provided rotational waste removing mechanism solves the technical problem of lower accuracy of existing waste removing mechanisms.

Owner:QUANZHOU HANWEI MACHINERY MFG

Developing device and image forming apparatus provided therewith

ActiveUS8750765B2Simple structurePrecise maintenanceElectrographic process apparatusHelical bladeImage formation

Provided is a developing device including: a developing container including a developer replenishing port from which the developer is replenished, and a developer discharge port which is provided on a downstream side of one of the conveyance paths and from which surplus developer is discharged; and a discharge regulating portion provided to one of the plurality of stirring members which is arranged in the one of the conveyance paths, in which the discharge regulating portion includes a regulating member arranged so as to face the developer discharge port, for regulating movement of the developer to the developer discharge port side, and a decelerating conveyance member arranged between the helical blade and the regulating member, for partially reducing a conveying speed of the developer in the one of the conveyance paths.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

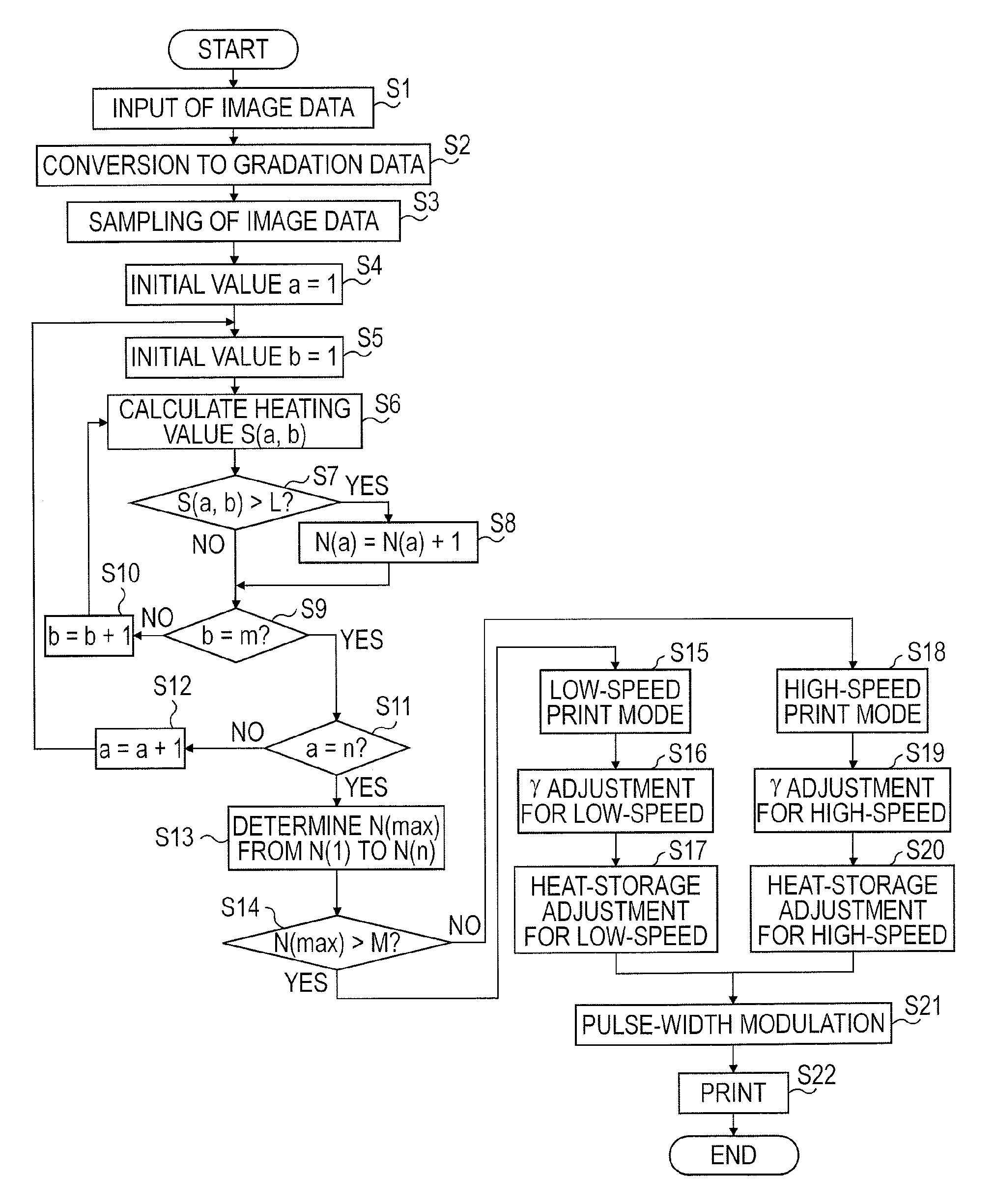

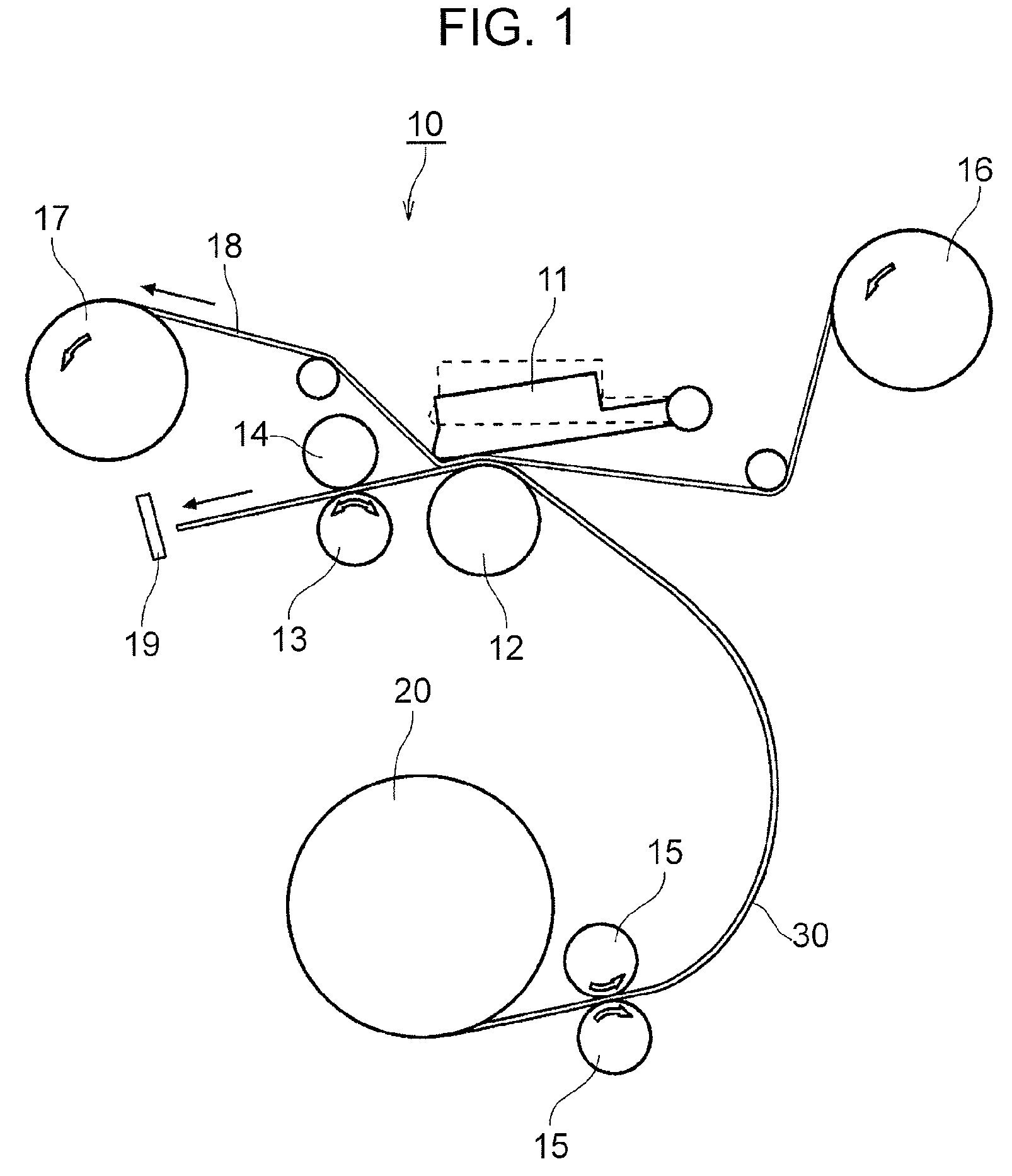

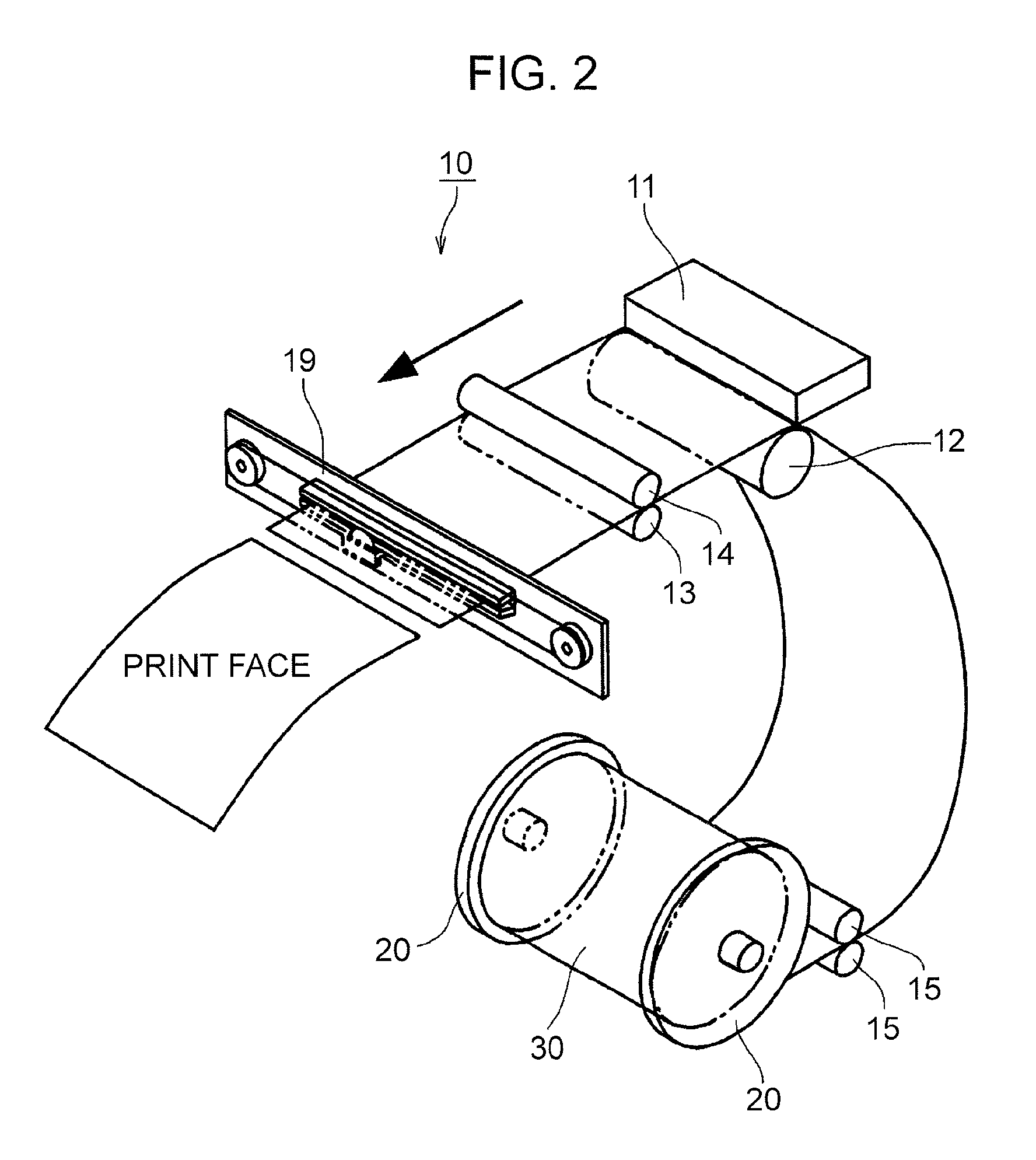

Thermal head printer and printing method in thermal head printer

InactiveUS7352380B2Low densitySubjected to scratchingRecording apparatusKitchen equipmentEngineeringThermal aware

A thermal head printer includes a platen, a thermal head having a heating element, a heating-value arithmetic unit, a heating-value comparator, an excess-value counter, and a heating-value controller. The thermal head printer performs a printing operation by conveying a recording medium between the platen and the thermal head and heating the heating element on the basis of image data to be printed. The heating-value arithmetic unit calculates heating values for the heating element corresponding to the image data. The heating-value comparator compares each calculated heating value with a reference heating value of the heating element. The excess-value counter counts the number of calculated heating values that exceed the reference heating value so as to determine an excess-value number. The heating-value controller limits the heating values of the heating element if the excess-value number exceeds a reference number.

Owner:SONY CORP

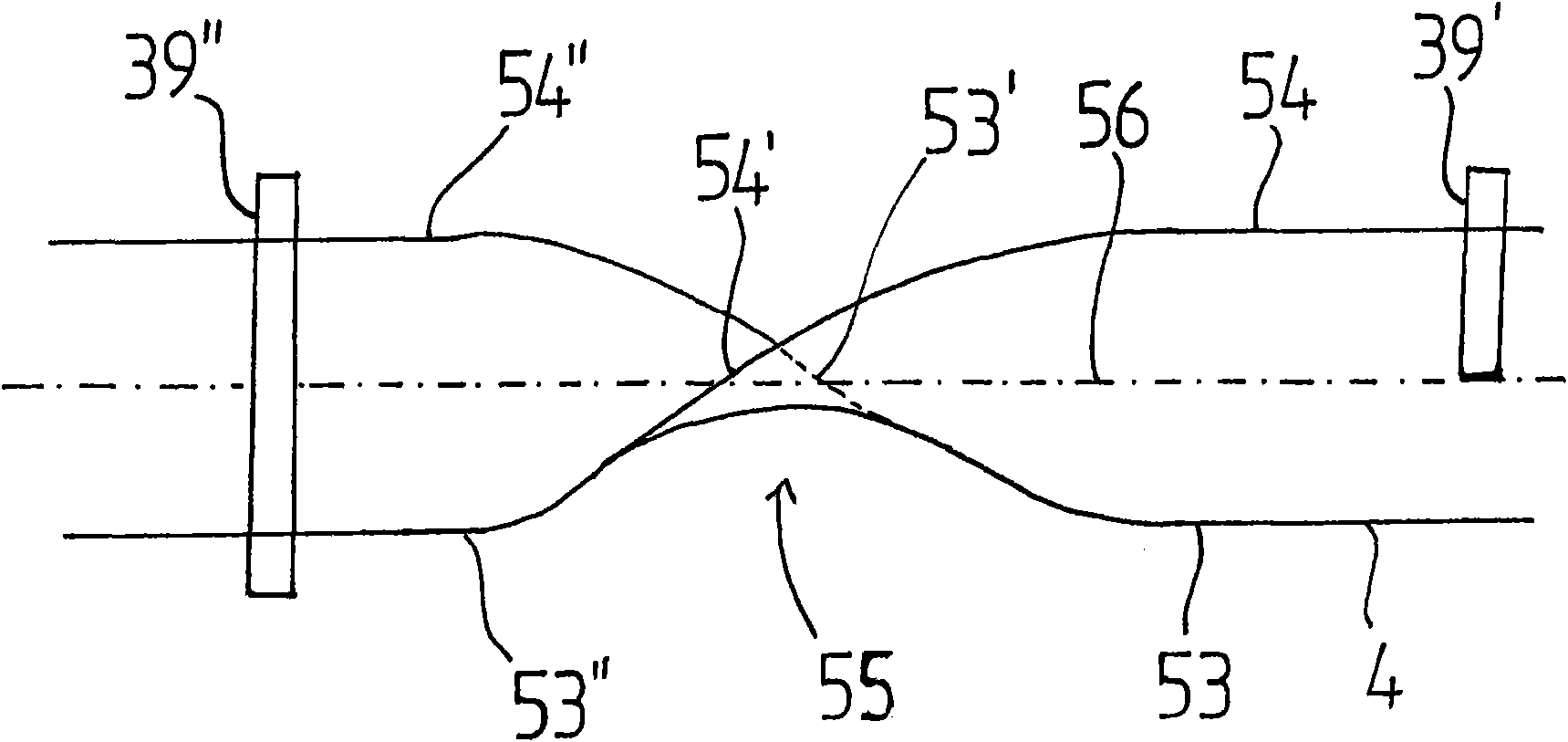

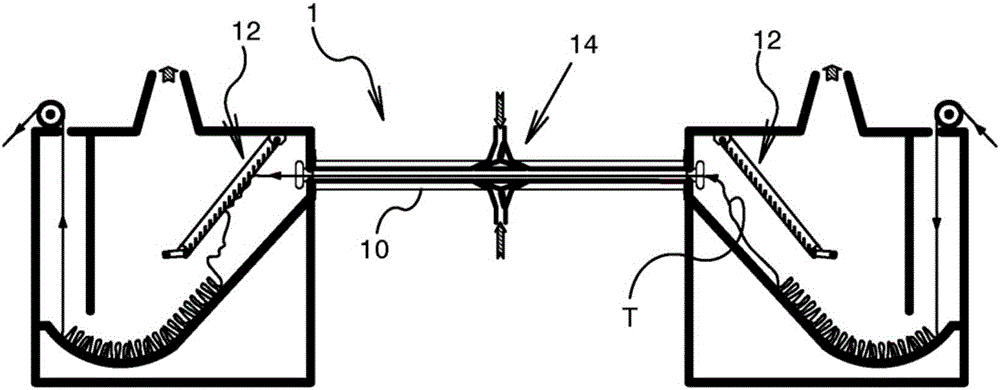

Method and machine for treating textile fabrics with an adjustable air flow

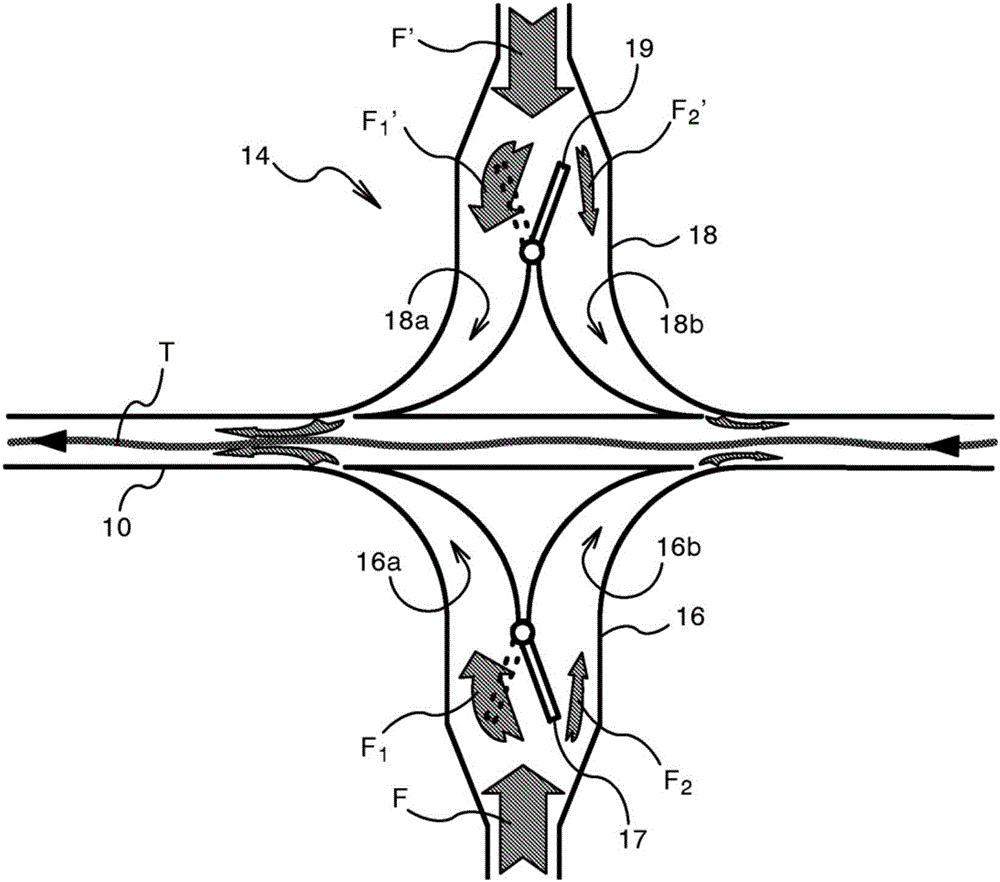

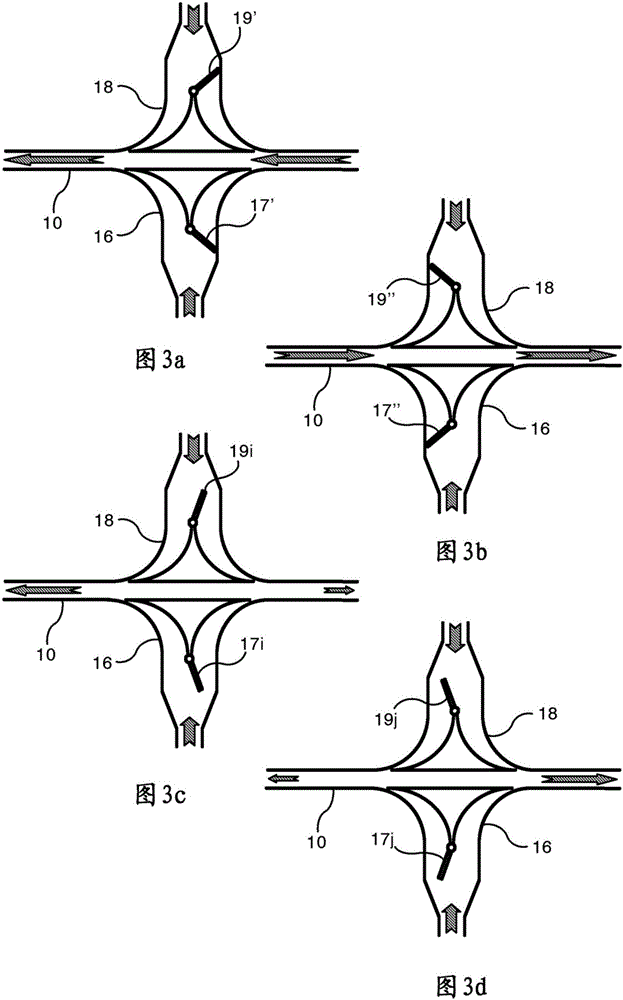

ActiveCN106460277AReduce intensityUninterrupted alternating movementFabric breaking/softeningLiquid/gas/vapor treatment of propelled fabricsAir treatmentAirflow

A machine for treating a fabric (T) with air, comprises a tunnel (10) for pneumatically transporting the fabric and means for injecting the air into the tunnel above and / or below the fabric and comprising at least one diverting valve (16; 18) located substantially half way along the tunnel and having two channels (16a, 16b; 18a, 18b) which are oriented to direct the air flow entering the tunnel in one direction or the other. The valve comprises an adjustable baffle (17; 19) adapted to shut off access to the channels (16a, 16b; 18a, 18b) either wholly or partly. In the treatment method of the invention, the air flow (F;F') entering the tunnel is divided into two unequal components (F1, F2; F1', F2') directed towards opposite ends of the tunnel.

Owner:BIANCALANI SRL

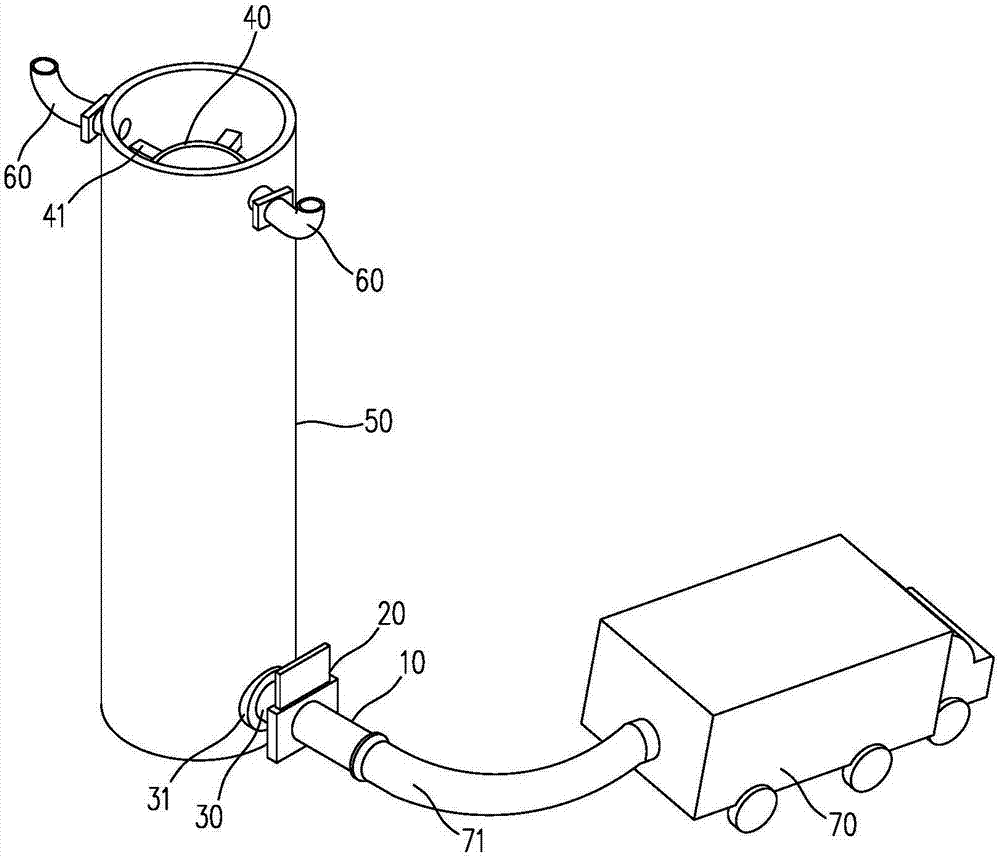

Steel pipe concrete pillar concrete jacking pouring device and construction technique thereof

PendingCN107217851AReduce shockReduce conveying speedStrutsBuilding material handlingArchitectural engineeringPipe

The invention relates to a steel pipe concrete pillar concrete jacking pouring device and a construction technique thereof. The device comprises a horizontal conveying pipe, and the horizontal conveying pipe is connected with a vertical conveying pipe arranged in a steel pipe pillar through a connecting elbow; a central axis of the vertical conveying pipe is overlapped with the central axis of the steel pipe pillar; a horizontal end opening of the connecting elbow is extended out at the outside of the steel pipe pillar and connected with the horizontal conveying pipe together through a plug board valve; a vertical end opening of the connecting elbow is arranged at inside of the steel pipe pillar and connected with the bottom part of the vertical conveying pipe; the connecting elbow is connected with the steel pipe pillar together, the top part of the steel pipe pillar is provided with an overflow pipe; the horizontal conveying pipe, the connecting elbow and the vertical conveying pipe are connected mutually and formed to be a sealed and leakage-free delivery channel. The conveying channel formed by the horizontal conveying pipe, the connecting elbow and the vertical conveying pipe can bear big pumping impact. The device can effectively reduce and even avoid uncompact concrete in the steel pipe pillar, thereby greatly improving the construction efficiency.

Owner:ANHUI ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com