Spinning machine and method for interrupting the production of thread on a spinning machine

A technology for yarn manufacturing and spinning machines, applied in the field of spinning machines and yarn manufacturing for interrupting spinning machines, which can solve problems such as time-consuming spinning ends, delays in the spinning process, and affecting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

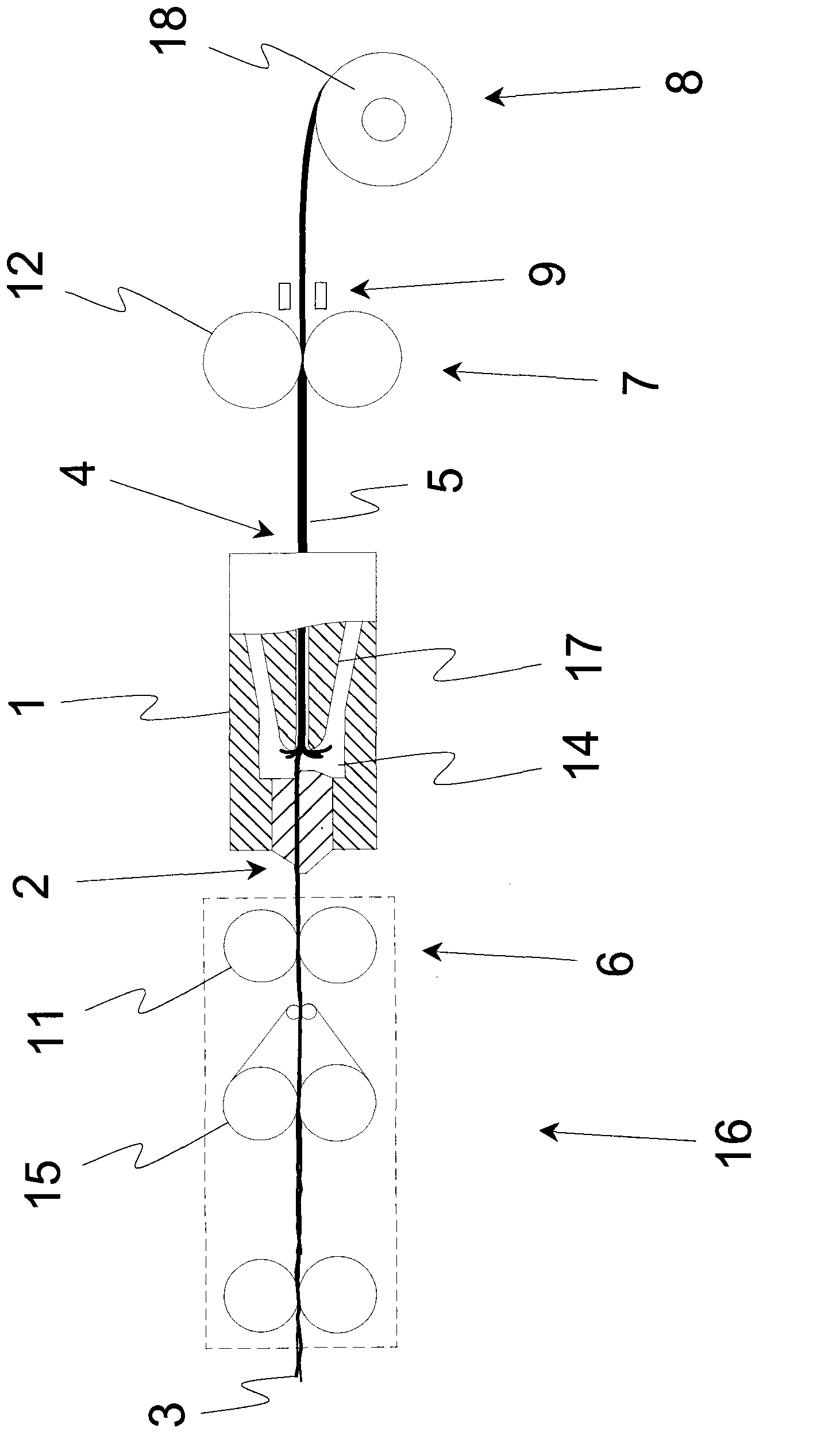

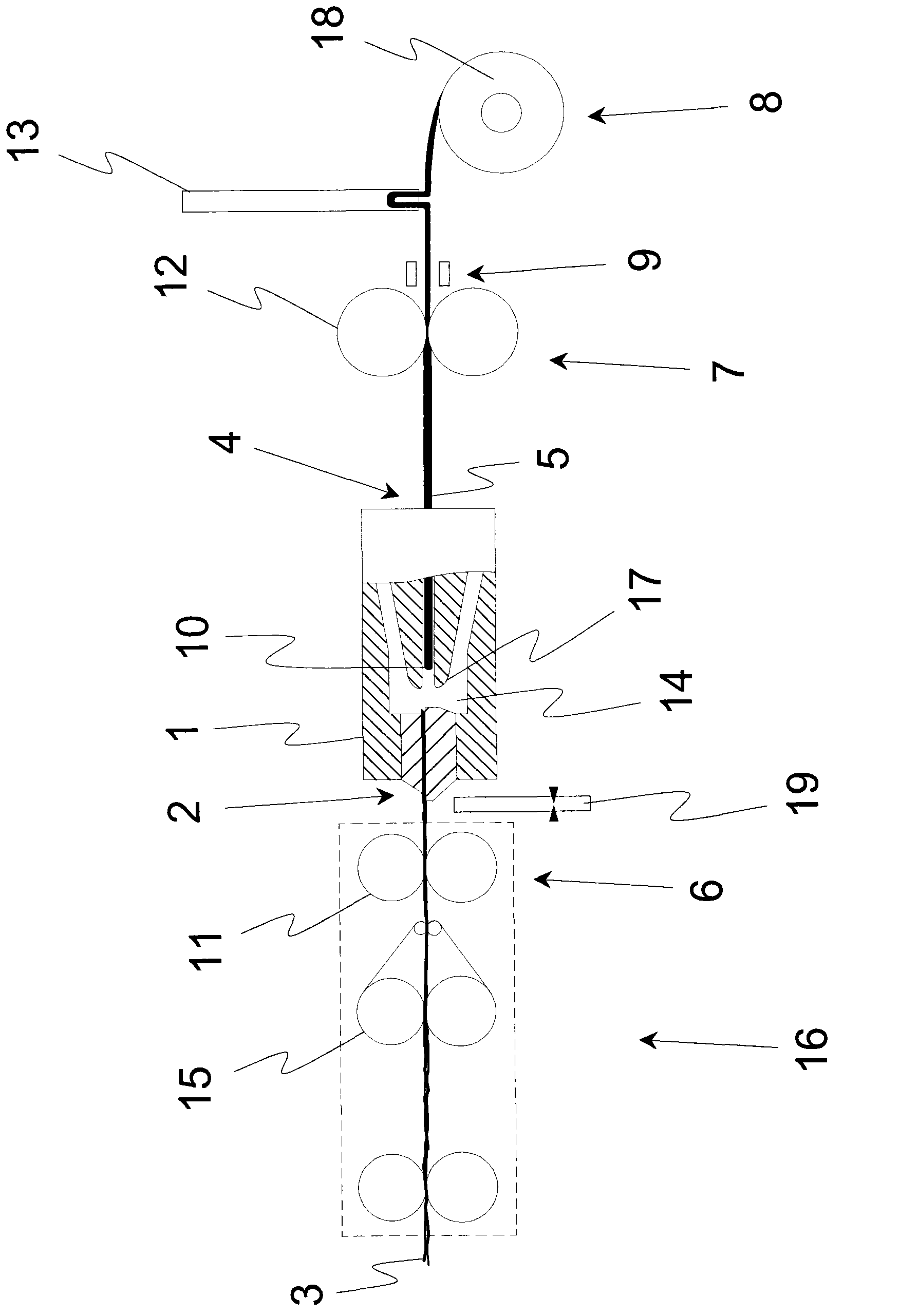

[0027] figure 1 Schematic diagram of a section of a dry spinning machine according to the invention. The dry-laid spinning machine generally comprises a drafting device 16 to which the yarn material 3 is supplied, for example in the form of a double draft strip. In addition, the shown dry spinning machine basically comprises a spinning table 1 spaced apart from the drafting device, said spinning table having an input 2 for the yarn material 3 and a built-in air vortex Room 14.

[0028] The introduction of the yarn material 3 to the spinning table 1 takes place by means of a transfer device 6 designed as a pair of transfer rollers 11 , which in turn can be part of the drafting device 16 . Finally inside the air vortex chamber 14 the yarn material 3 or at least a part of the fibers of the yarn material 3 are set in rotation in order to produce the desired yarn 5 . In this case, the rotation is produced by a targeted air flow in the region of the spindle 17 , the air flow bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com