Patents

Literature

702results about How to "Avoid winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

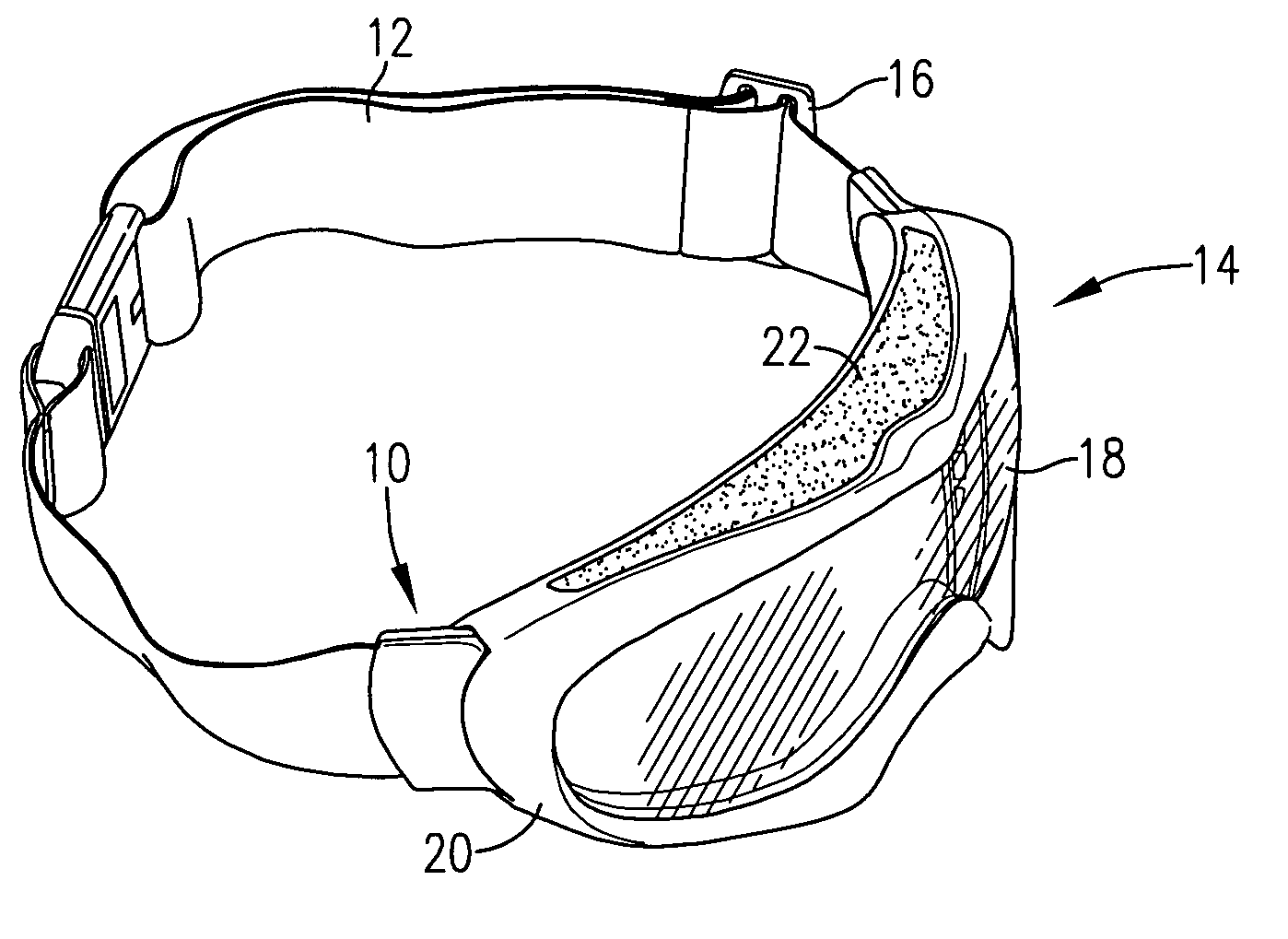

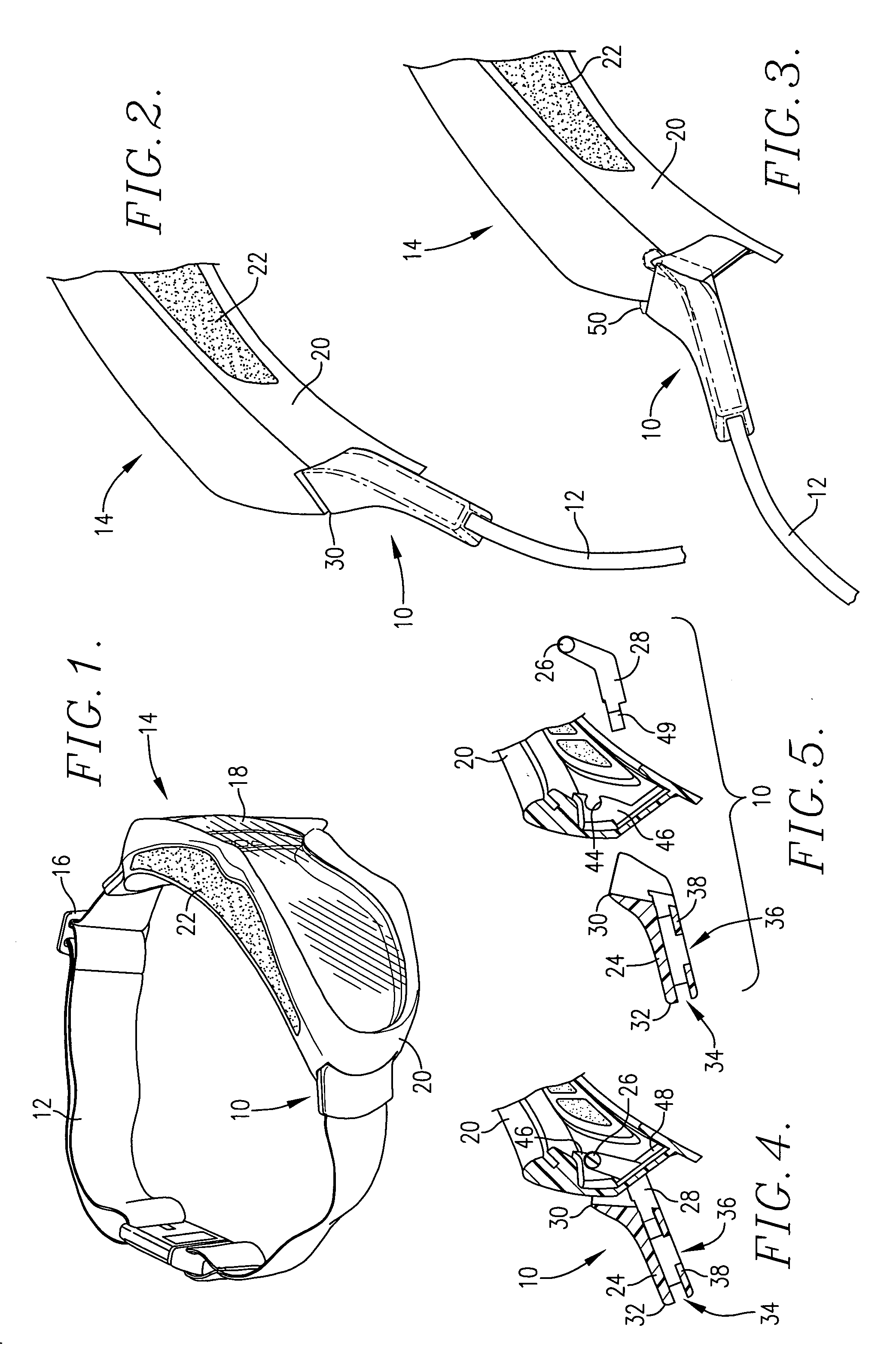

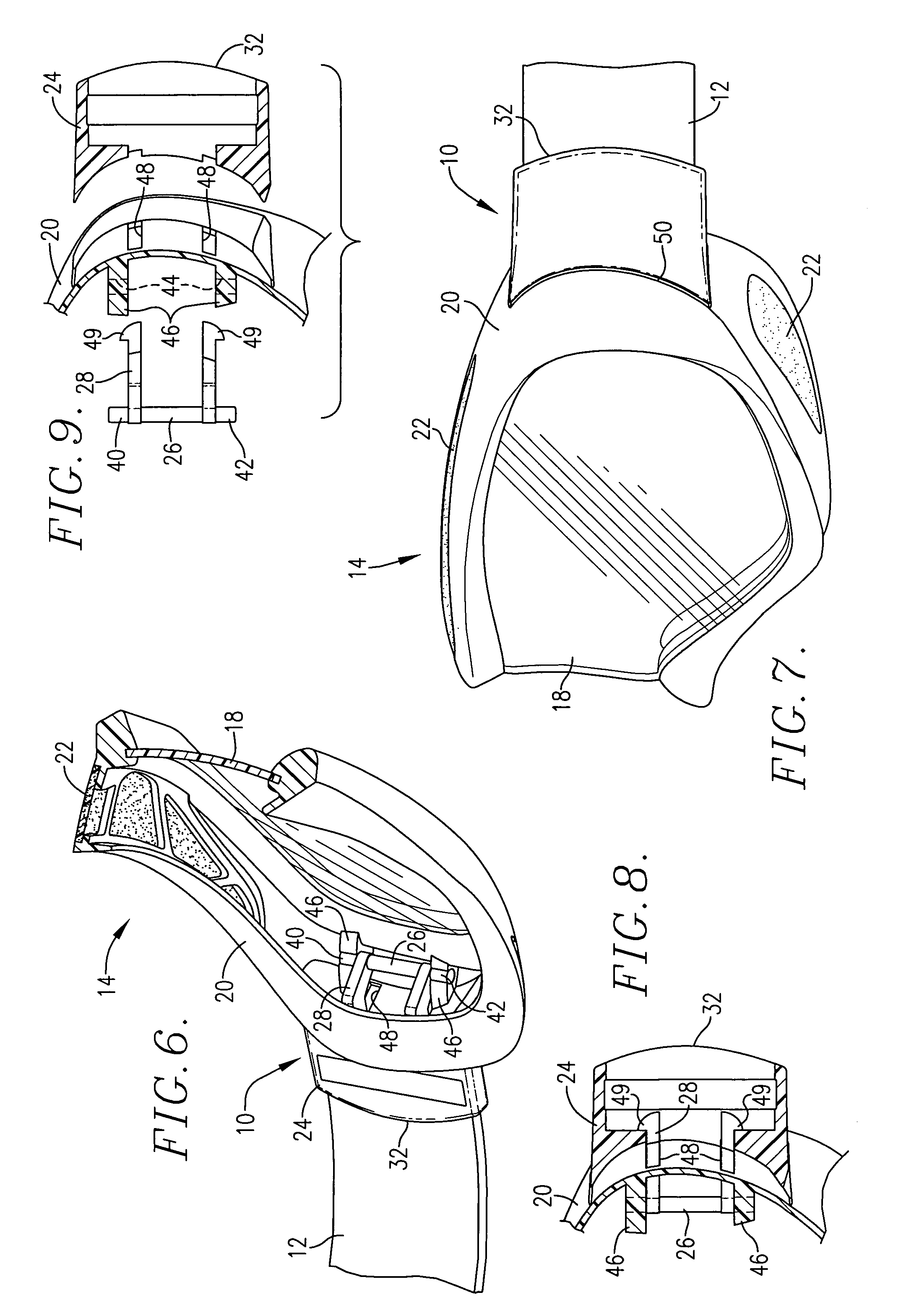

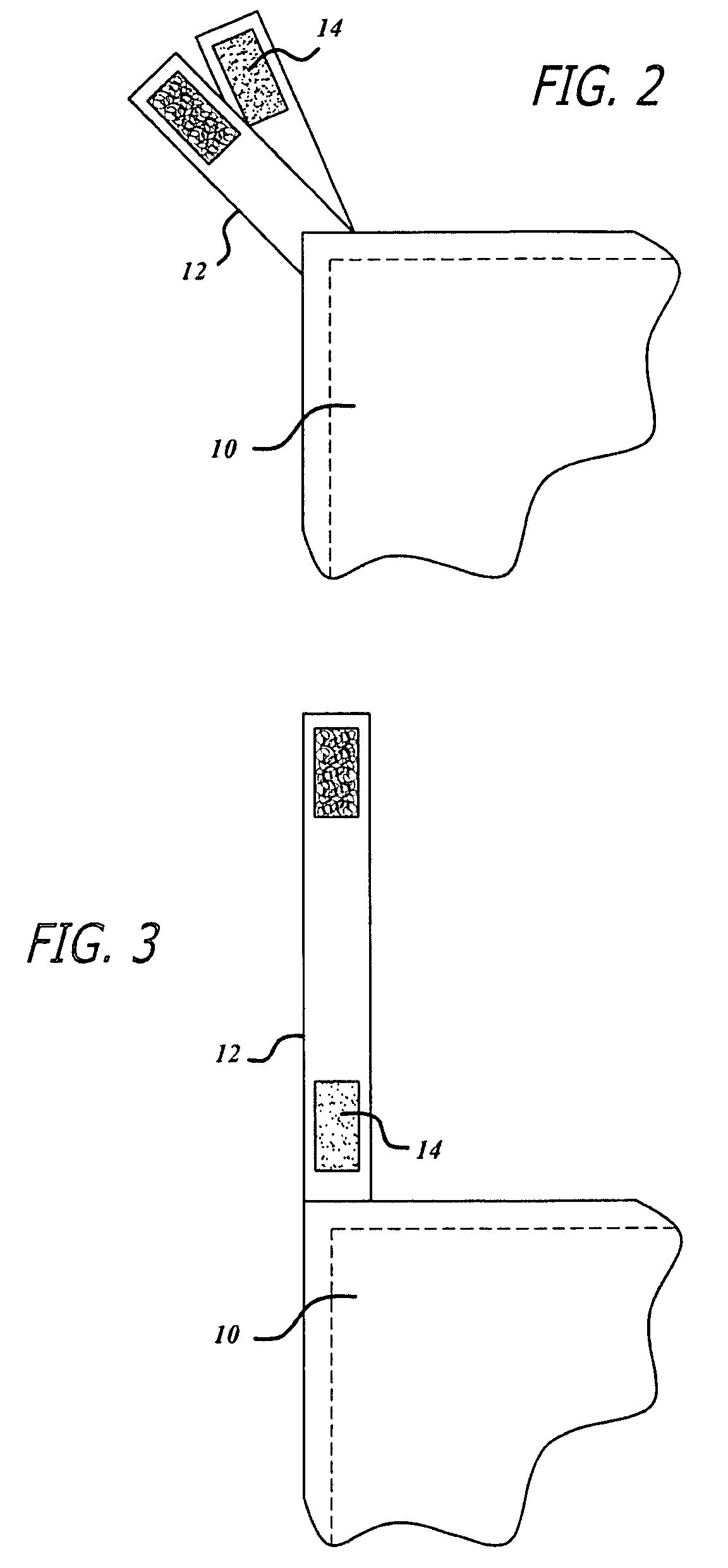

Goggle clip

ActiveUS6928663B1Without sacrificing functionalityGap minimizationGogglesProtective garmentEngineering

A goggle clip (10) that may be used to rotatably or pivotally secure a strap (12) to a goggle (14) with a concealed hinge. The clip (10) broadly comprises a main body (24) located outside a shroud (20) of the goggle (14) and secured to the strap (12), an axle (26) located inside the shroud (20), and a forwardly extending skirt (30) that substantially conforms to the shroud (20). The skirt (30) preferably maintains close proximity to the shroud (20) during rotation of the clip (10). Thus, the skirt (30) forms an aerodynamic seal with the shroud (20), thereby diverting airflow away from the hinge and preventing wind, dust, dirt, and other contaminants from interfering with the hinge's operation. Furthermore, the skirt (30) and the location of the axle (26) conceal the hinge, thereby providing a more aesthetically appealing goggle (14).

Owner:BOLLE BRANDS INC

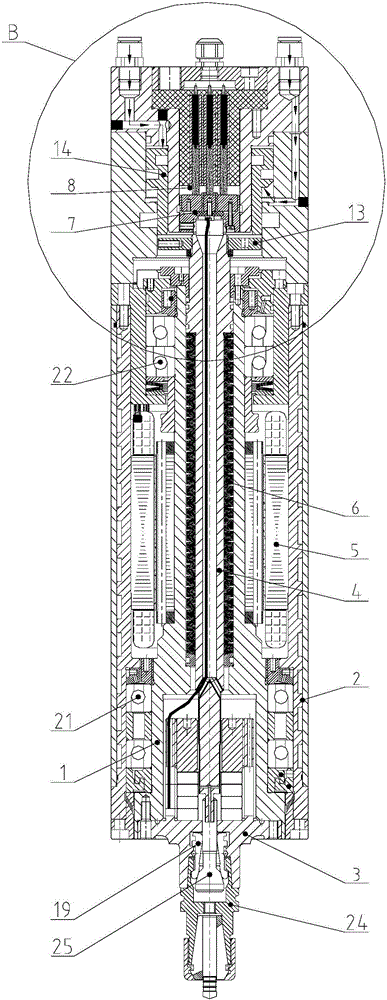

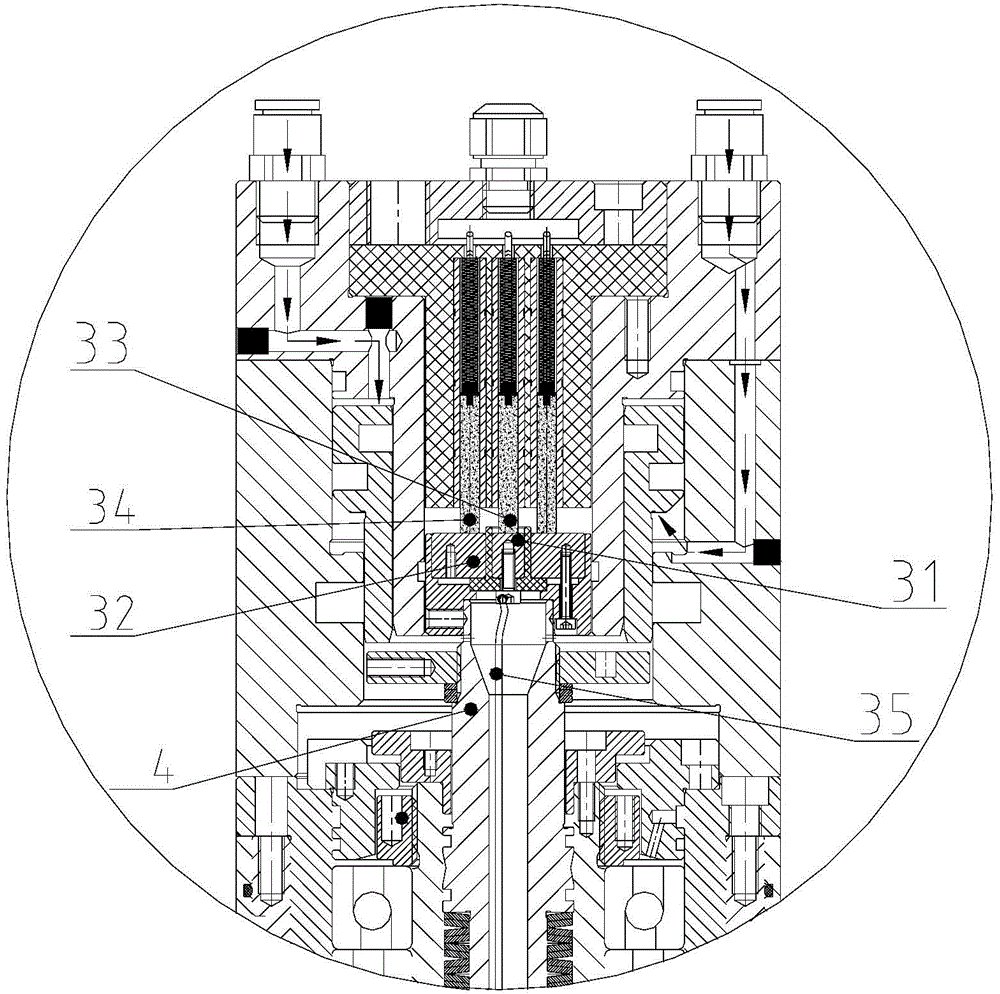

Improved electric spindle

ActiveCN104439298AAvoid windingReduce wearLarge fixed membersPositioning apparatusElectricityUltrasonic sensor

The invention discloses an improved electric spindle which comprises a machine body, a stator and a central spindle assembly mounted in the machine body. The central spindle assembly is provided with a rotor matched with the stator. The central spindle assembly comprises a hollow central spindle and a pull rod located in the central spindle. An ultrasonic transducer is fixedly arranged at the lower end of the central spindle, a mounting cavity is formed in the ultrasonic transducer, and a pull claw is arranged in the mounting cavity. The electric spindle further comprises an amplitude-change pole which is provided with a cutter, and the upper end of the amplitude-change pole is mounted between the ultrasonic transducer and the pull claw. The pull claw is movably arranged at the lower end of the pull rod in a sleeving mode, and a strutting part is arranged on the pull rod. A driving part which is used for driving the pull rod to move downwards and driving the strutting part to be away from the pull claw to enable the pull claw to be automatically contracted is mounted in the machine body. An elastic element is mounted between the pull rod and the central spindle. The improved electric spindle can improve the processing effect, and further can prolong the service life of the cutter. Moreover, the abrasion of a center carbon brush and an outer carbon brush can further be reduced, and assembling is easy.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

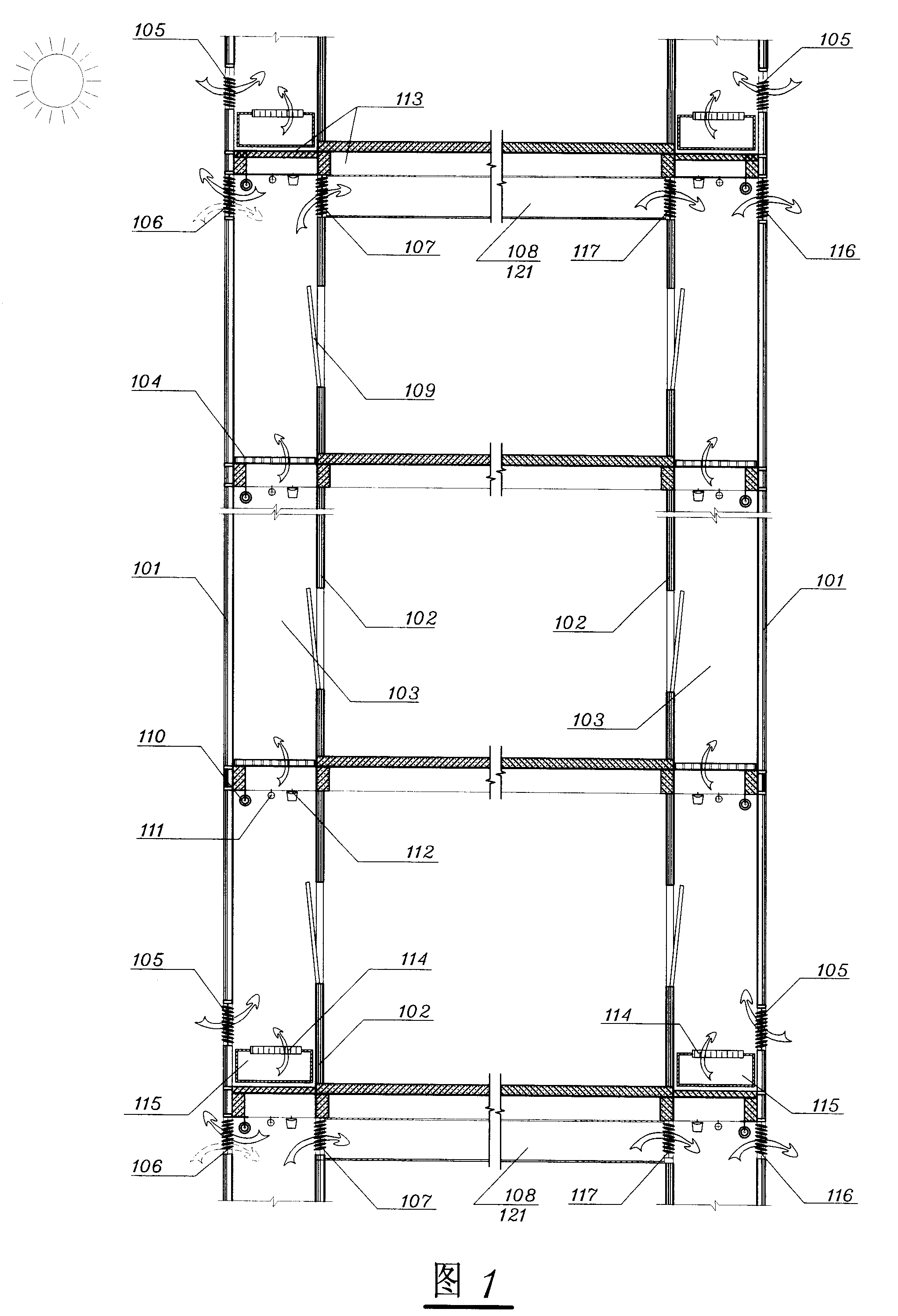

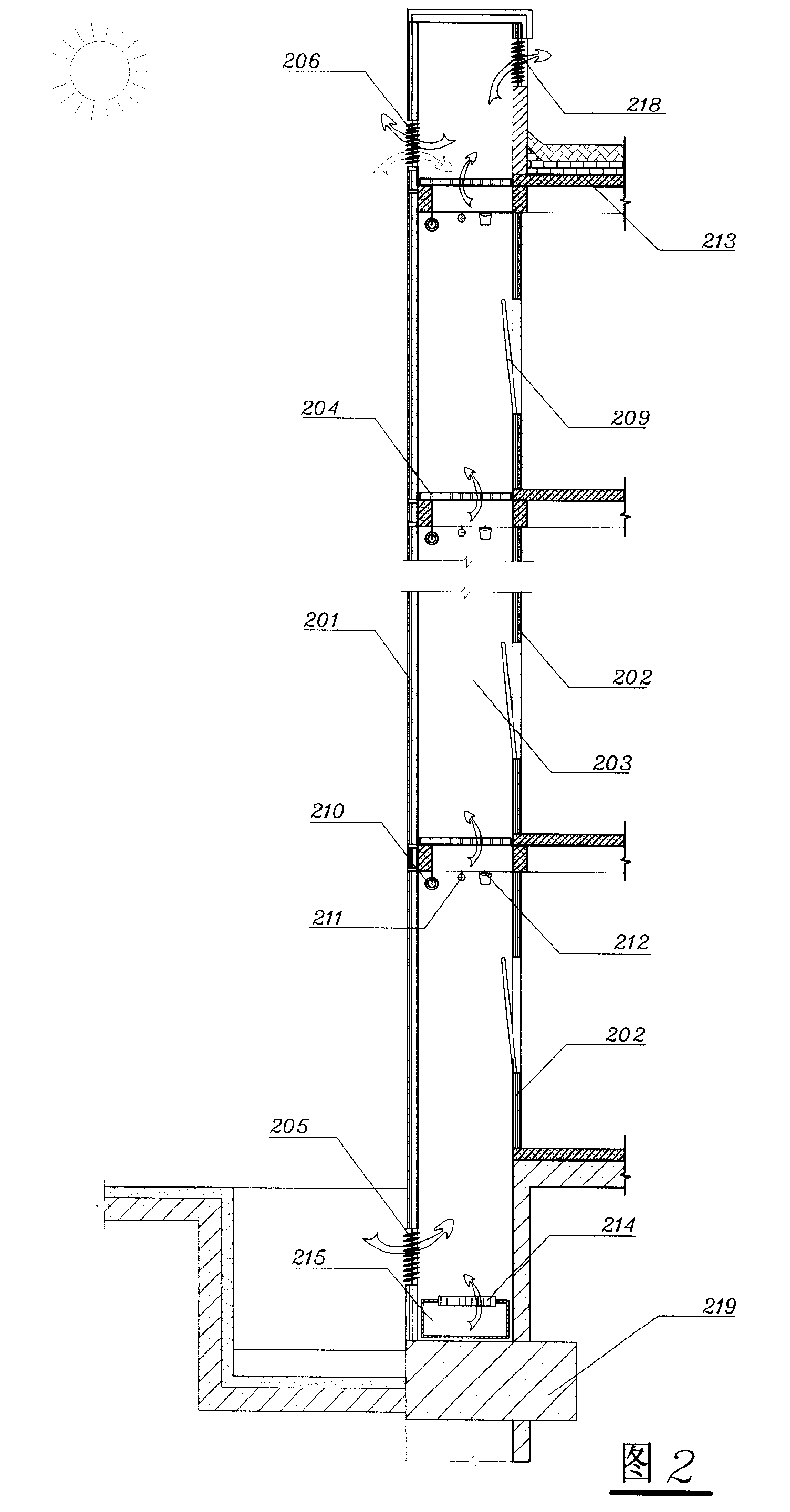

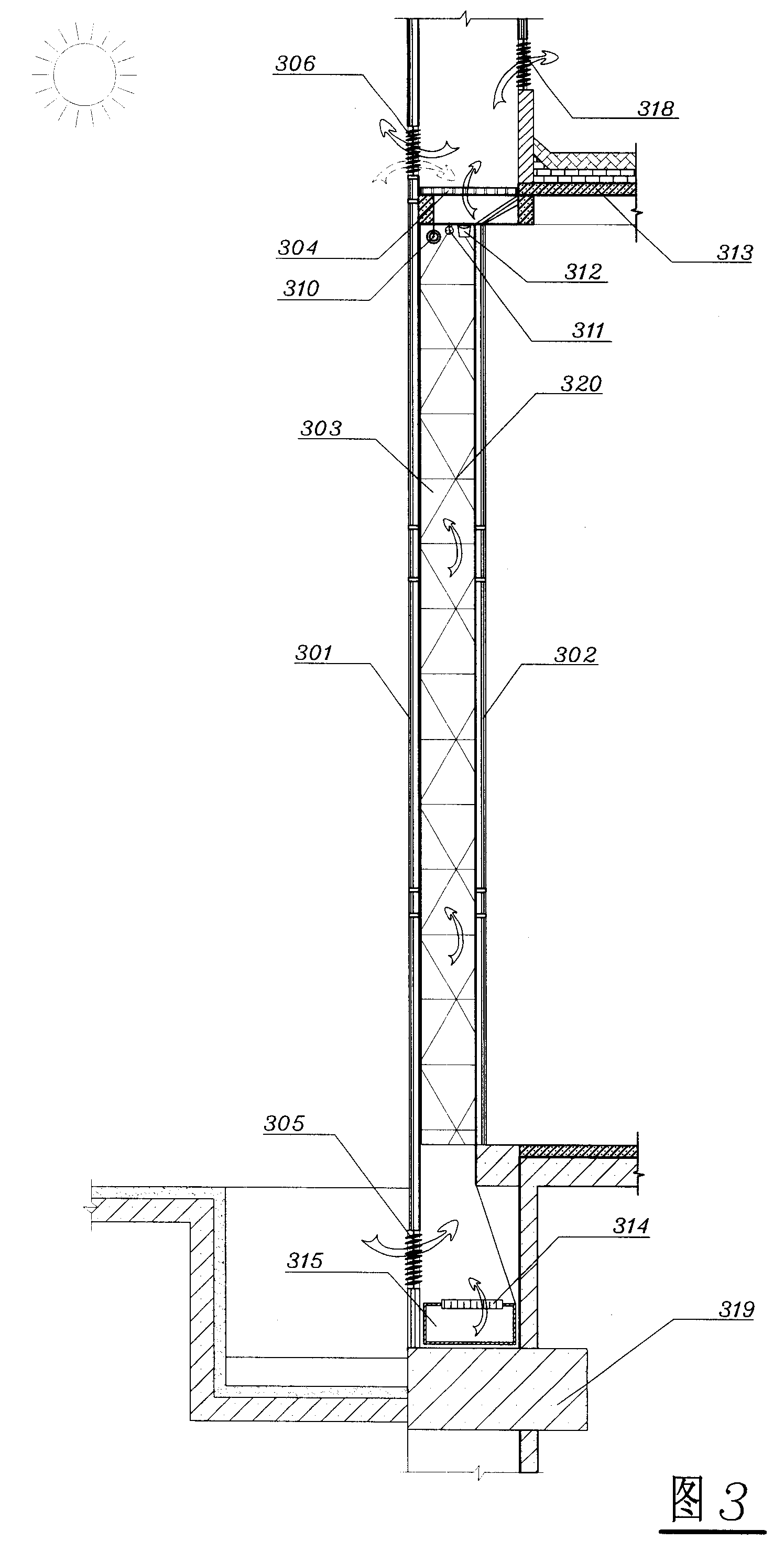

Double layer glass curtain aeration technology and method and structure

InactiveCN101187488ASolve the problem of unstable liquidityReduce the temperatureLighting and heating apparatusWallsSmoke detectorsDifferential pressure

The invention relates to a novel energy-saving glass curtain wall, wherein the shortcoming of natural wind is compensated through mechanical assisted air supply mode, and the problem of unsustainable and unstable airflow is solved. An air inlet is arranged on the windward side, an air outlet is arranged on the leeward side, the air inlet and the air outlet are connected through a ventilating duct or 'an architectural layer ventilating duct' to ensure the air flow smoothly. The distance between the air inlet and the air outlet is increased, the differential pressure of air can be realized, and the effect of 'a chimney effect' is improved. A fireproof grade of an outside curtain wall is lower than a fireproof grade of an inside curtain wall, and the fireproof capacity of a double layer curtain wall is basically same as a single layer curtain wall, the fireproof capacity can be improved through a smoke detector and a spray system. In summer, the invention adopts the mode of spray desuperheating through a fire-fighting spray system, and in daytime pollution-free power supply is supplied to an air supply system and a draught fan through solar energy. According to the improvement, the integrated effect of the double layer glass curtain wall and 'a climate adaptive capacity' is hoped to be improved, and a new idea is provided to the development of the curtain wall and the technological innovation.

Owner:周嘉陵 +2

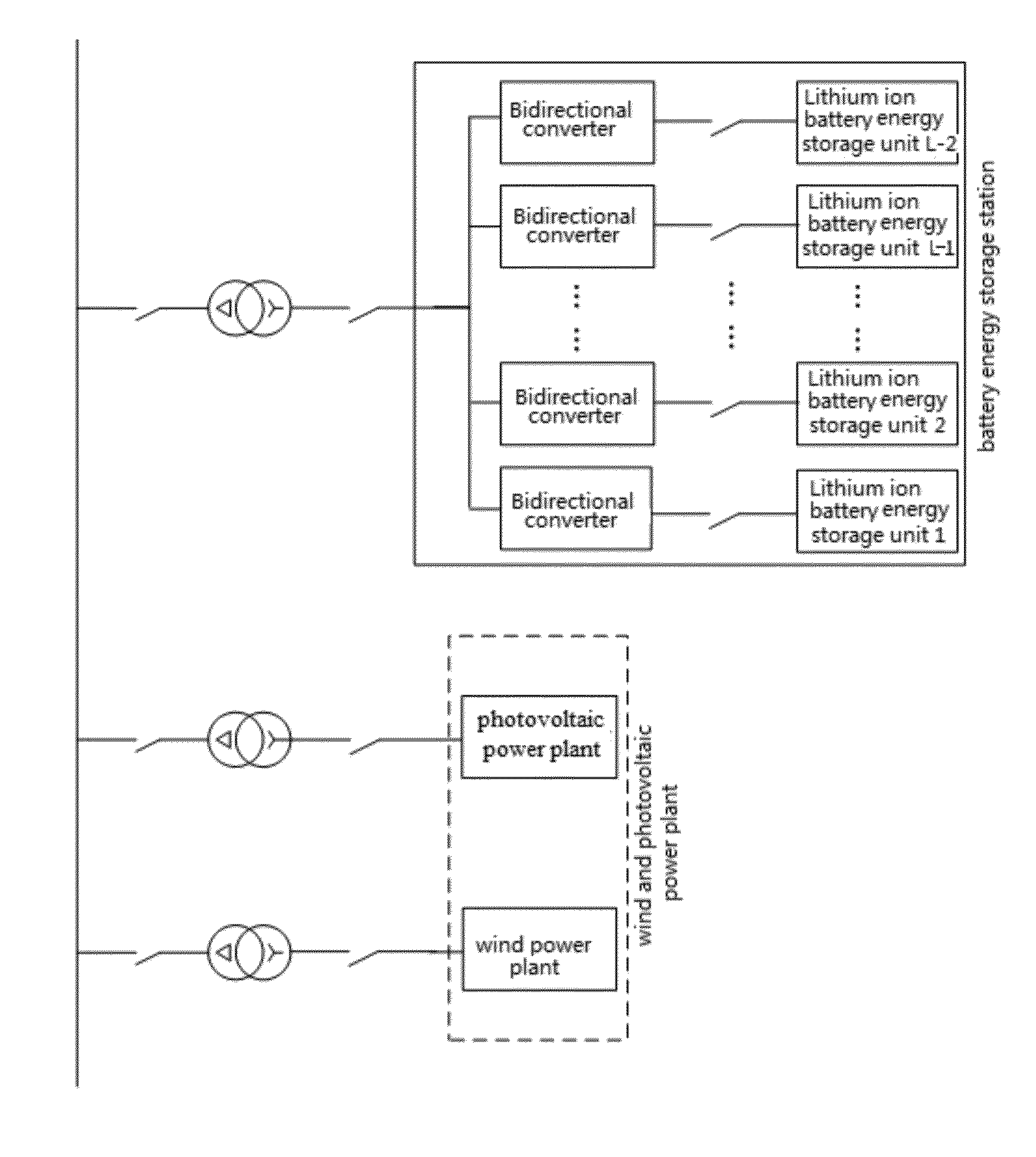

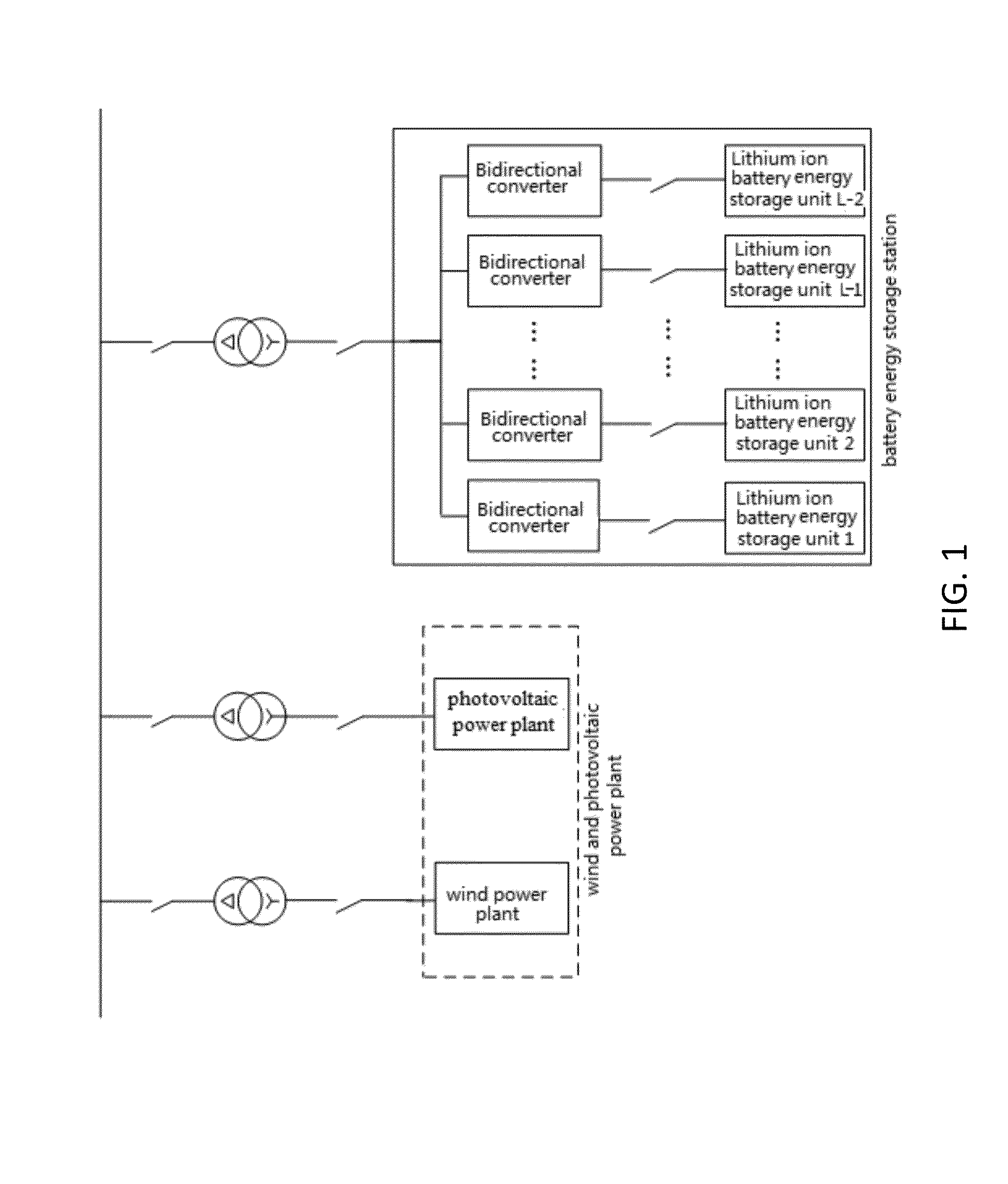

A method and system for control of smoothing the energy storage in wind phtovolatic power fluctuation based on changing rate

InactiveUS20160233679A1Wind evenlyAvoid windingWind motor with solar radiationWind motor controlEngineeringLimit value

The invention relates to a method and system for smoothing the energy storage wind and photovoltaic power fluctuation based on rate control, including: reading and processing data; determining the signal change rate of the dynamic slope limiter; calculating the smoothing target value of the wind and photovoltaic total power; calculating total power demand of battery energy storage power station; and outputting data. The invention can effectively suppress wind and photovoltaic power fluctuation under the fluctuation rate limited value, can effectively smooth wind and photovoltaic power output. Thus it smoothens wind and photovoltaic power output, reduces the energy storage battery burden, and effectively controls battery energy storage power station system.

Owner:STATE GRID CORP OF CHINA +1

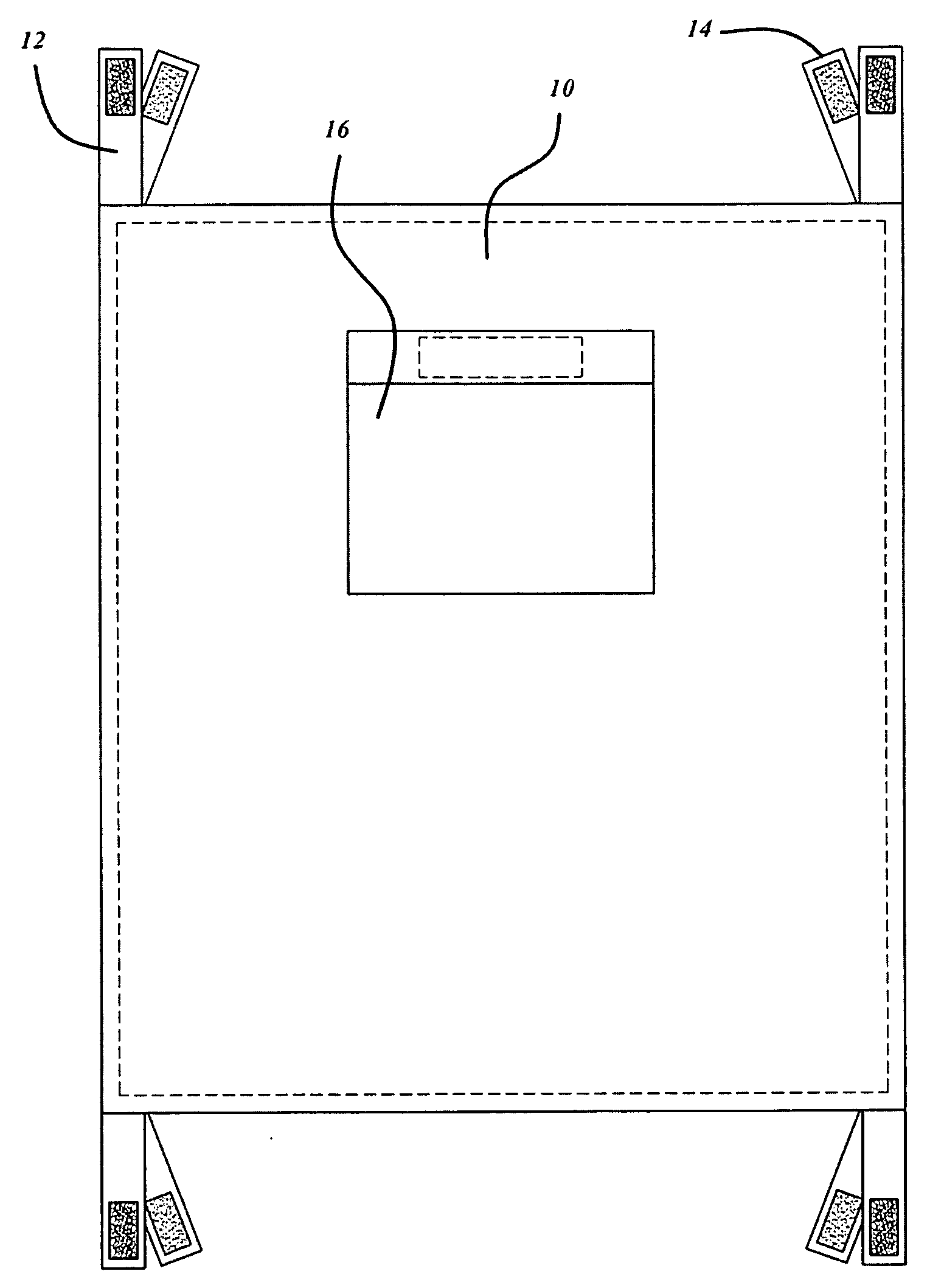

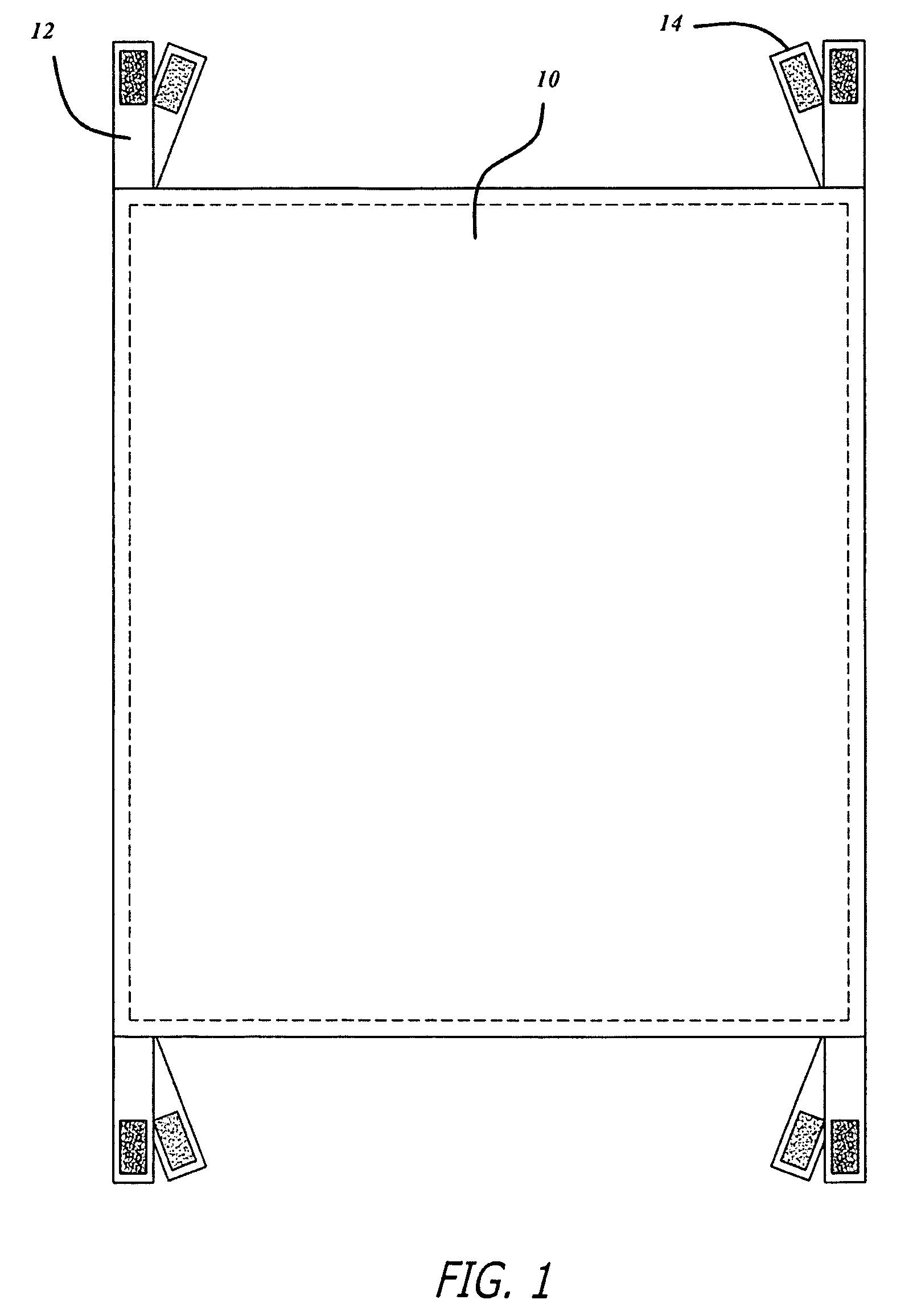

Blanket With Tie Straps

InactiveUS20080235870A1Reduce amountSecurely placedCarriage/perambulator accessoriesTravelling rugFastenerEngineering

A multipurpose baby blanket with integrated straps and storage pocket. The blanket is composed of several materials, and is therefore suitable for many tasks. Integrated straps with hook and loop fasteners provide an easy method of securing the blanket in place. An integrated pocket provides storage for baby supplies and paraphernalia.

Owner:HEIDE LISA

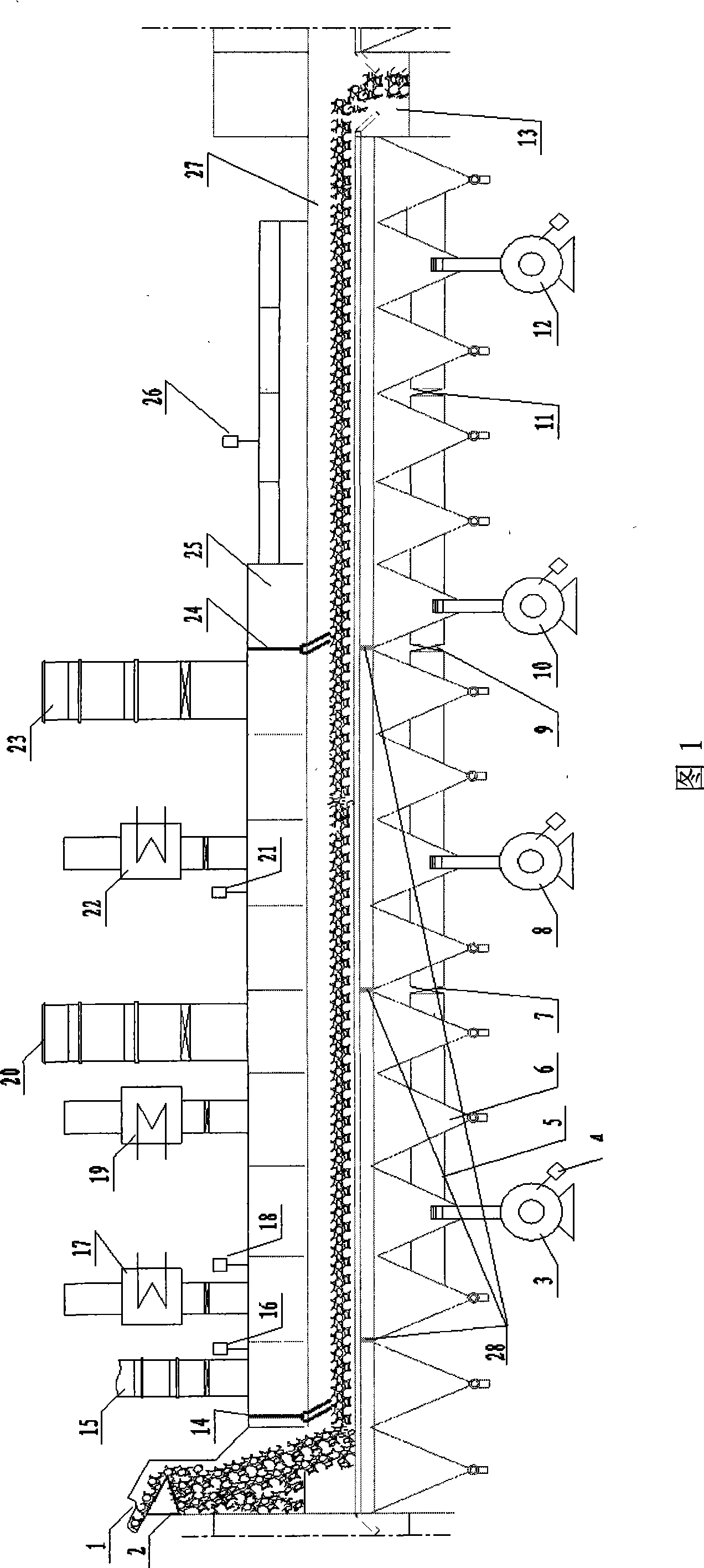

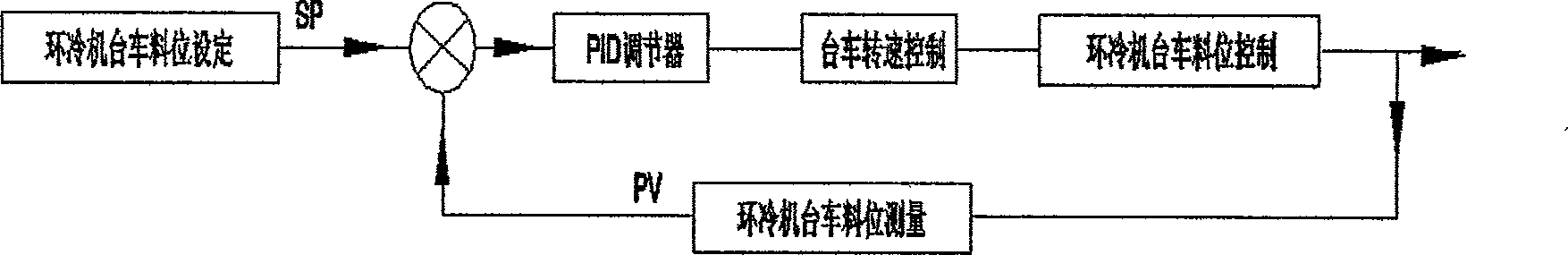

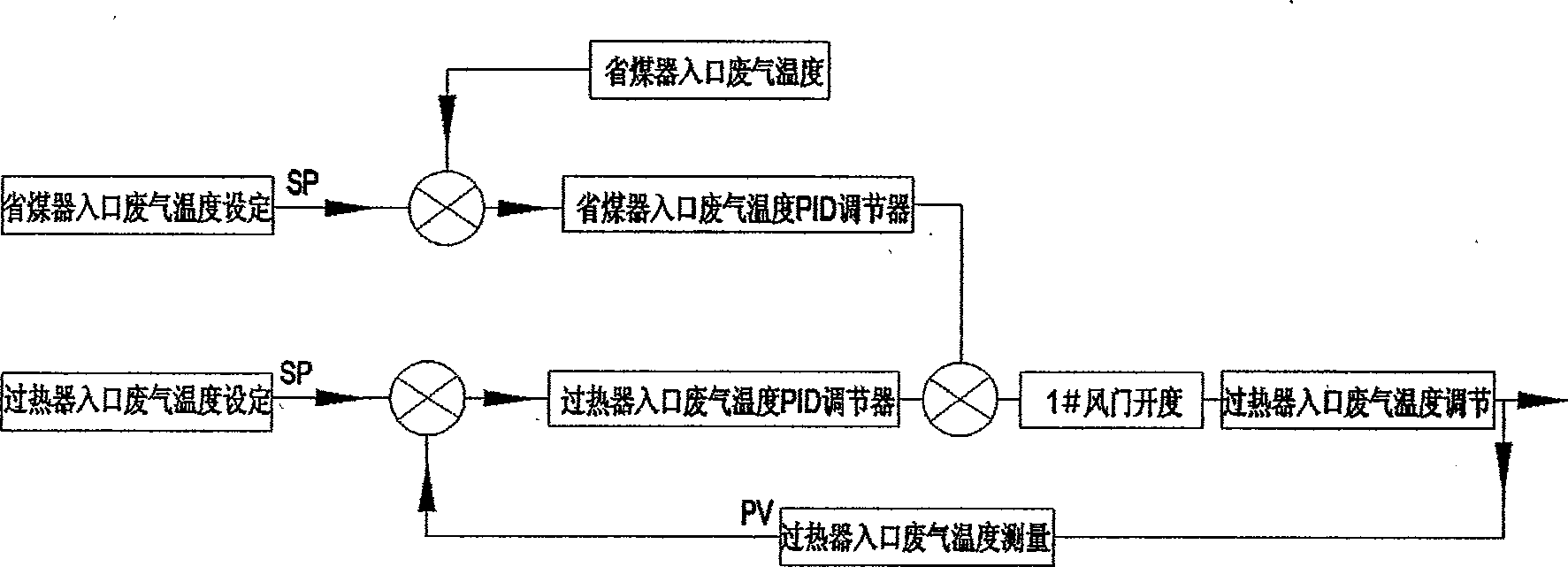

Control method for stabilizing and enhancing sintered ring cooling wind temperature while smelting steel

InactiveCN101424484AEasy to controlGuaranteed uptimeTemperature control with auxillary non-electric powerFurnace typesTaking temperaturesMaterials science

The invention relates to the field of reclaiming of waste gas and waste heat in the steel industry and power generation by the waste gas and the waste heat, in particular to a control method and a device for stabilizing and improving air taking temperature of a sintered ring in steel smelting. The device and the method are characterized in that the device and the technical method can achieve relative stabilization and moderate improvement of the temperature of the waste gas at the upper part of an inner batch layer of a cooling trolley through increasing and adjusting speed and cooled air of a circular cooler and uniformity for transversely feeding at a feed opening; and at the same time, under the premise that the temperature of the waste gas reaches the technical requirement of a waste heat generating technique, flow of the waste gas at the upper part of the batch layer is increased by properly increasing blown air amount at the lower part of the cooling trolley, so as to ensure relative stabilization and moderate improvement of air inlet temperature and flow of a waste heat boiler, and promote stabilization and improvement of vapor yield of the waste heat boiler and generated energy of a generating system.

Owner:昆明阳光基业股份有限公司

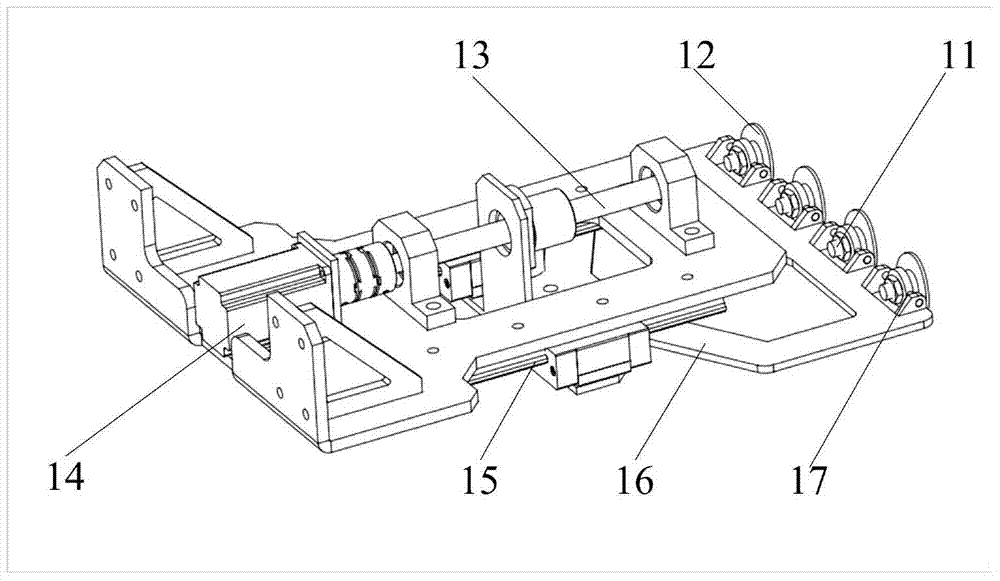

Chuck gripper device of stacking robot for complex surface

InactiveCN104493822AAchieve opposite motionGuaranteed gripping stabilityProgramme-controlled manipulatorGripping headsSymmetric designMotor drive

The invention provides a chuck gripper device of a stacking robot for a complex surface. The device comprises a connecting flange, a mounting frame, a transverse adjusting mechanism, longitudinal adjusting mechanisms, an absorbing mechanism, a human-computer control interface and an electrical protection device; the transverse adjusting device is used for adjusting the width of the absorbing mechanism through a motor driving a bidirectional rotating lead screw; the longitudinal adjusting mechanisms are of a symmetric design and are respectively mounted at two sides of the bidirectional rotating lead screw to lift and lower down the absorbing mechanism; the absorbing mechanism is connected with a sponge chuck by a hinging manner, which effectively avoids the phenomenon of failure of absorbing on an uneven surface; the absorbing mechanism can be in match with the transverse and longitudinal moving mechanisms to adapt to the change on the size of materials. The device is suitably used for gripping objects with different size and surface forms and has the characteristics of being simple in structure, convenient to drive, steady and reliable, high in generality, and flexible to operate.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH +1

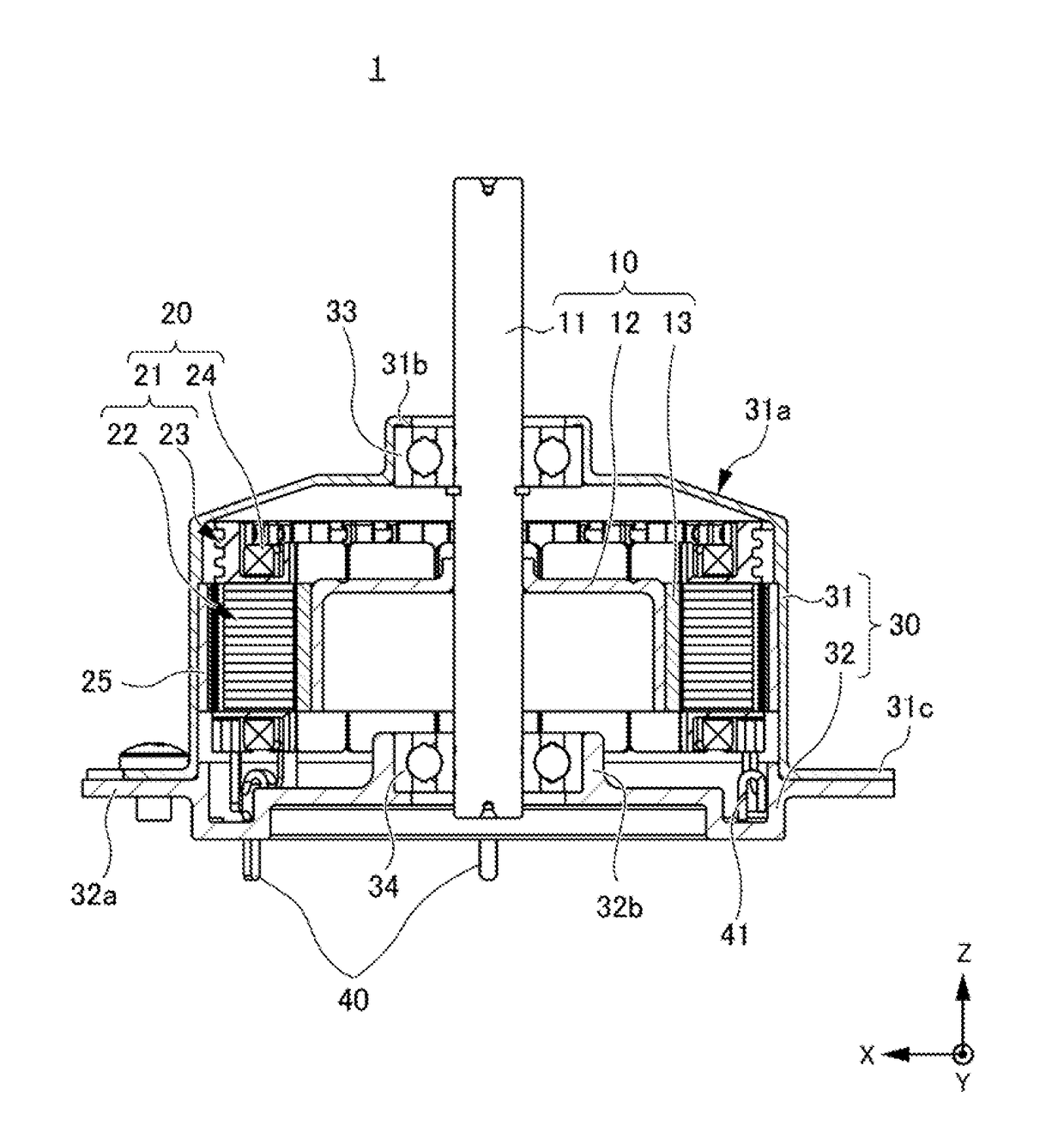

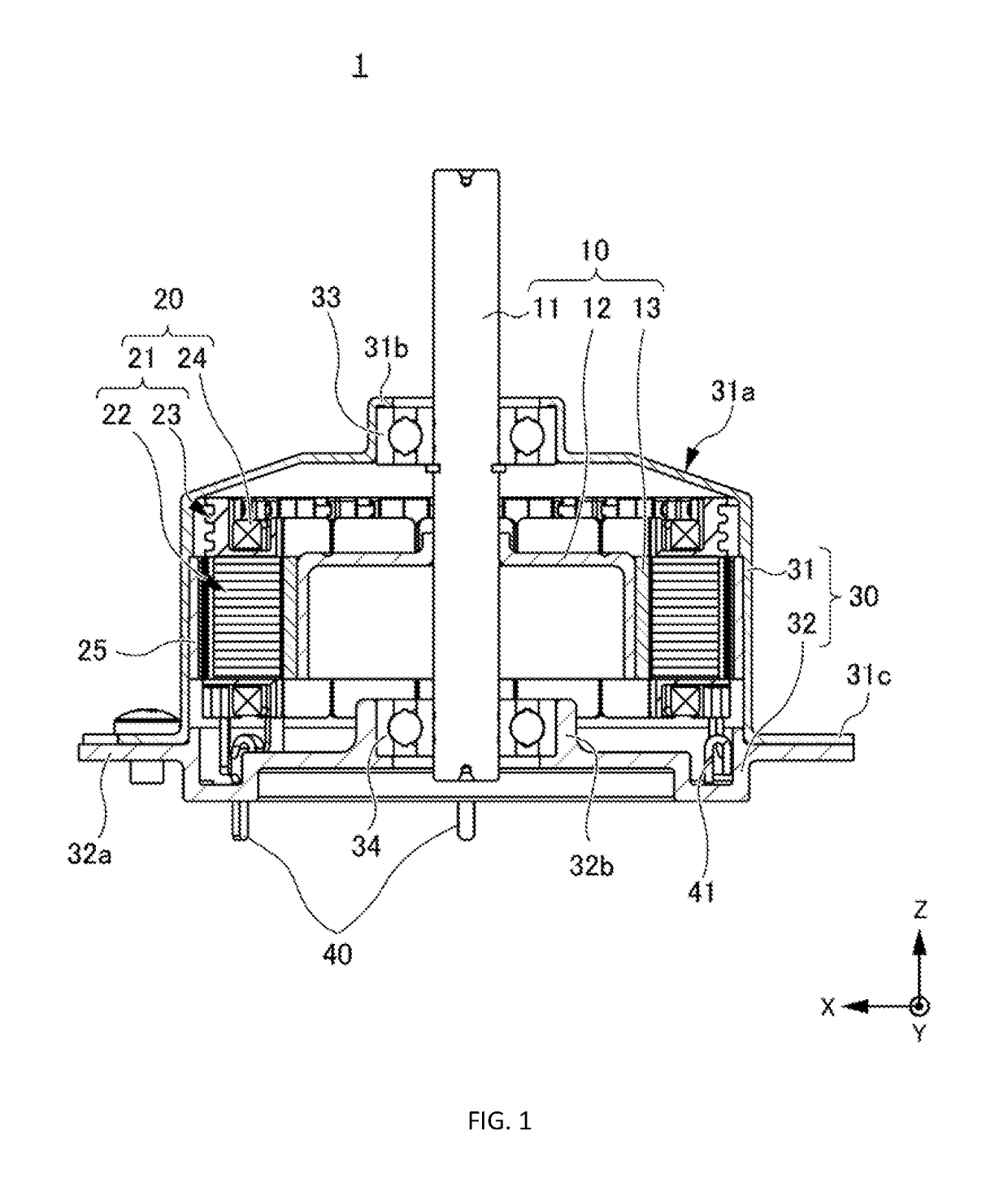

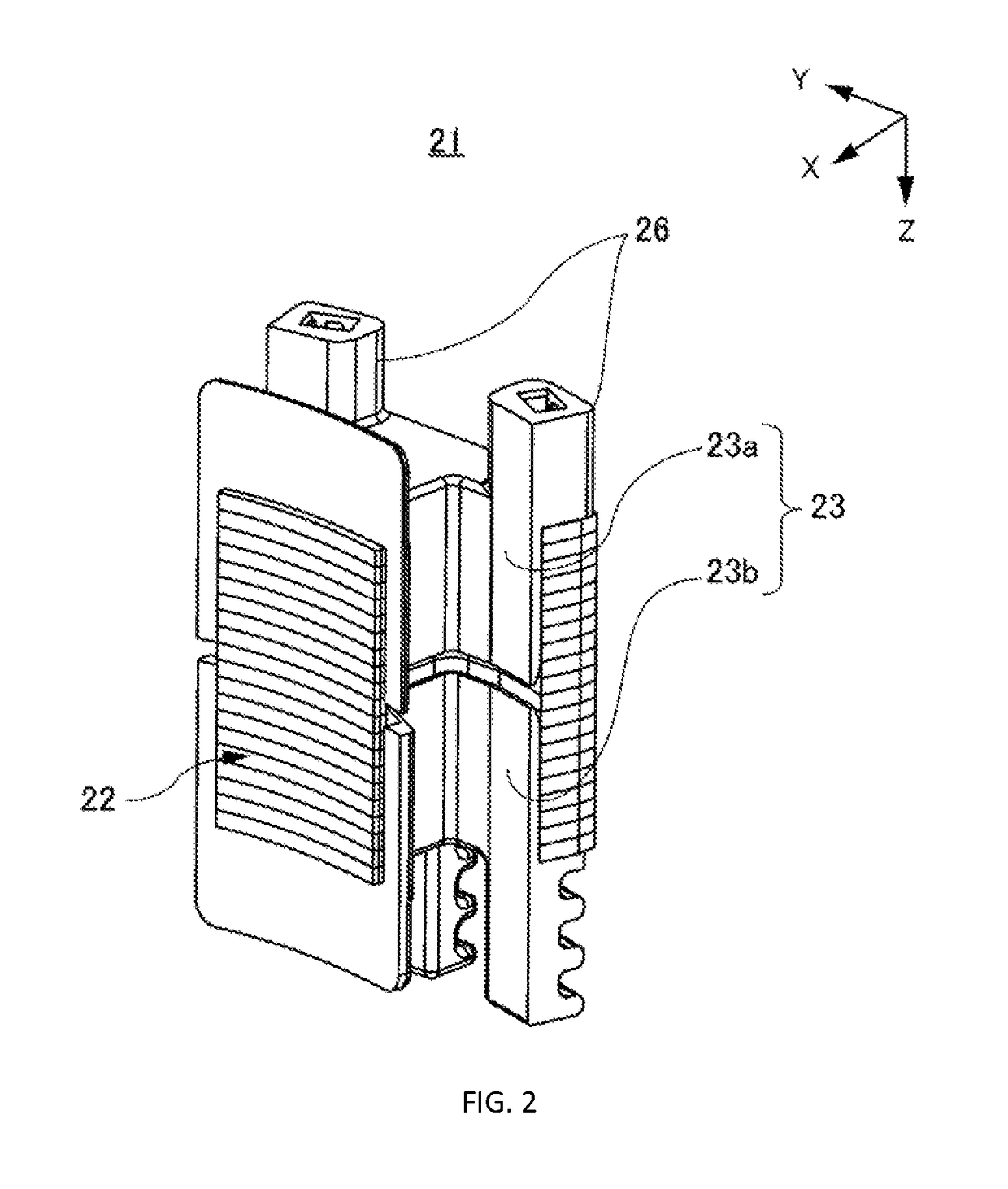

Stator of motor and inner rotor-type motor including stator

ActiveUS20170163118A1Reduce motor sizeIncrease productionWindings insulation materialMagnetic circuit rotating partsCouplingElectric machine

A stator of a motor comprises a core section including a core outer circumference part forming an annular shape and a plurality of core tooth parts projecting radially inward from the core outer circumference part; an insulator covering at least an outer circumference of each of the core tooth parts and an end face in an axial direction of the core outer circumference part; a coil wound on each of the core tooth parts via the insulator; and a terminal attached to the core outer circumference part via the insulator, an end portion of the coil being connected to the terminal, wherein the terminal includes: a leg portion extending in the axial direction; a hook portion including an open end opened in the axial direction and disposed on the core outer circumference part at a position corresponding to one of the core tooth parts in a circumferential direction, the end portion of the coil being connected to the hook portion; and a coupling portion extending from the leg portion in the circumferential direction along the core outer circumference part and connected to the hook portion, the insulator includes a terminal holding portion, to which the leg portion is attached, at a position in the end face of the core outer circumference part in a position not corresponding to the core tooth parts in the circumferential direction and a position corresponding to the leg portion of the terminal, the hook portion includes: a base end portion located on an outer side in the radial direction; a side piece portion located on the inner side in the radial direction to be arranged side by side with the base end portion; and a connecting portion connecting an end portion of the base end portion and an end portion of the side piece portion located on an opposite side of the open end side and forming a closed end, and the coupling portion of the terminal is bent to locate the hook portion radially outside the core tooth parts.

Owner:MINEBEAMITSUMI INC

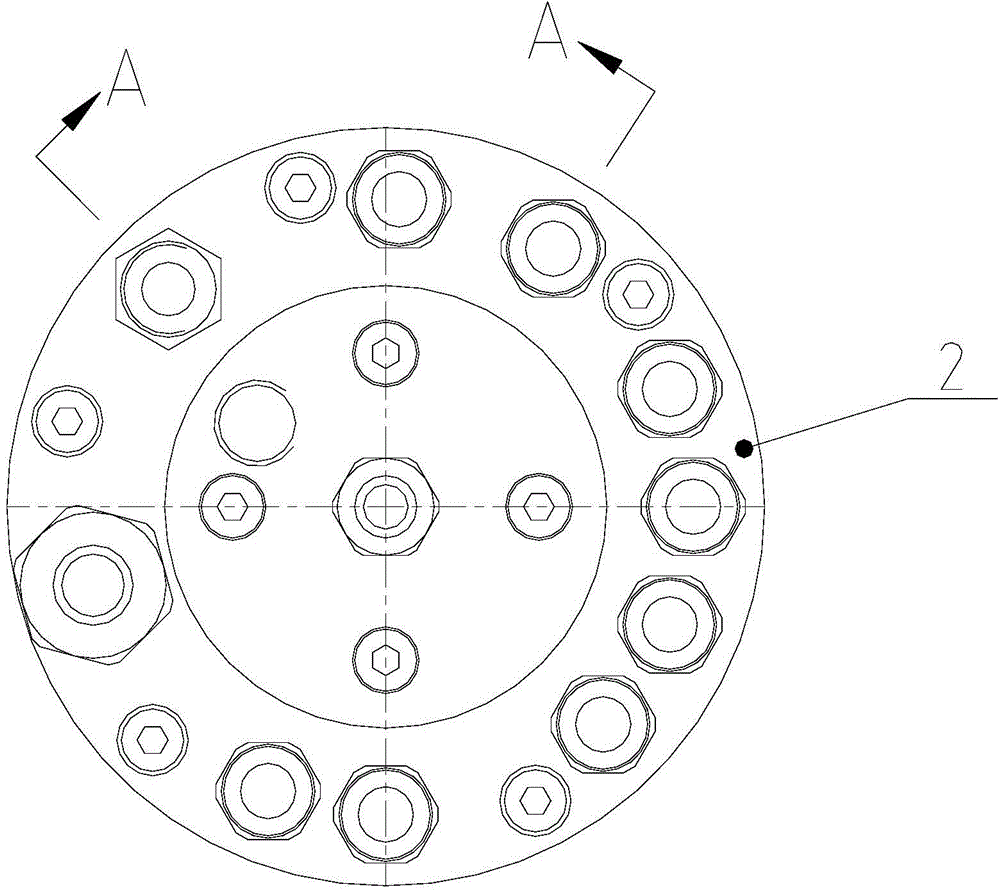

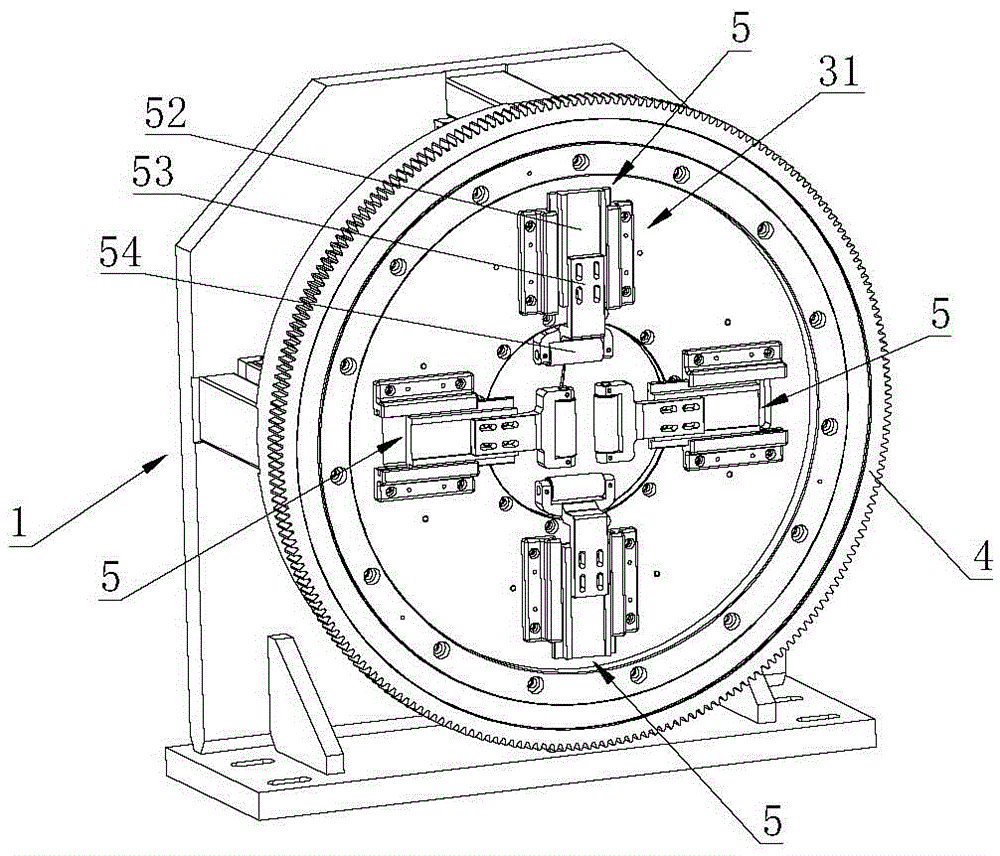

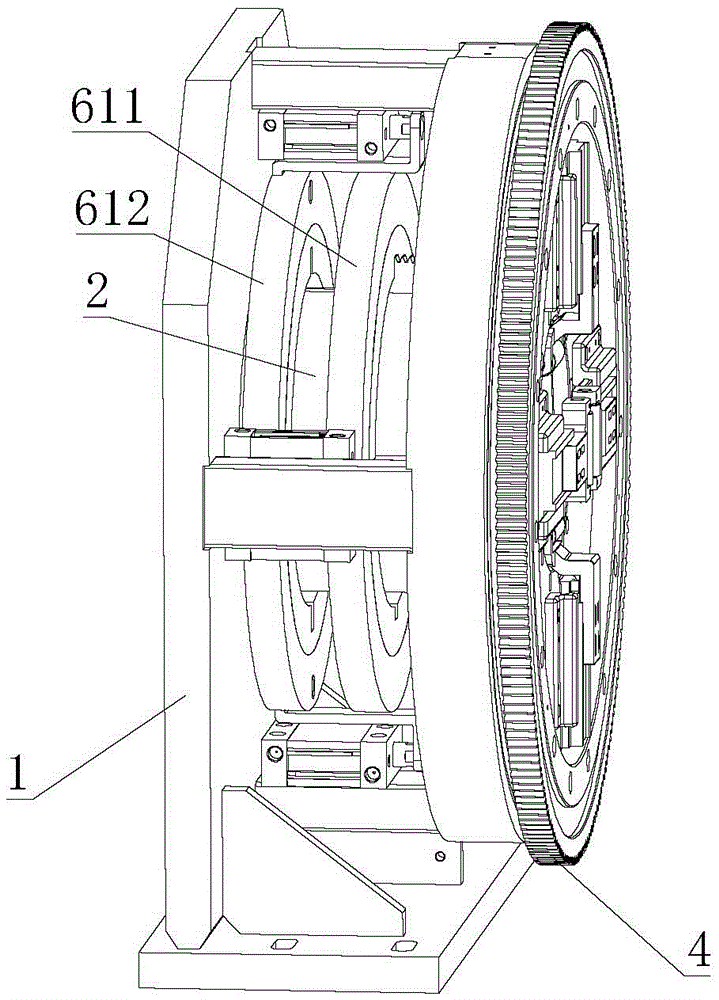

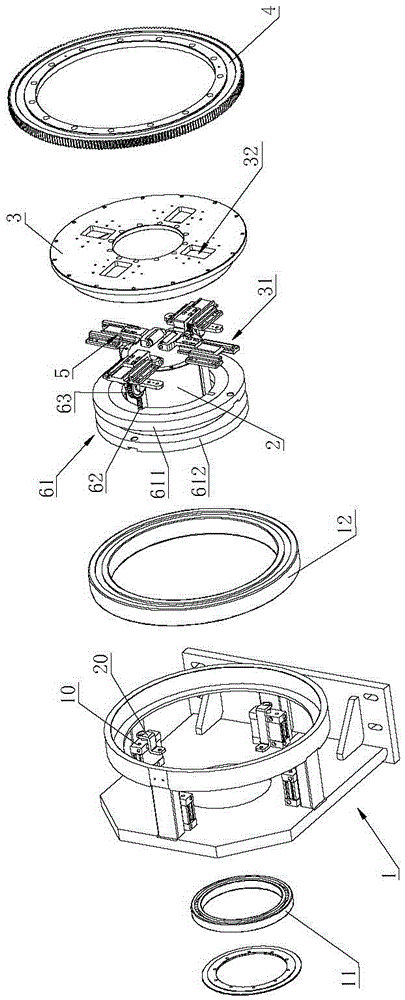

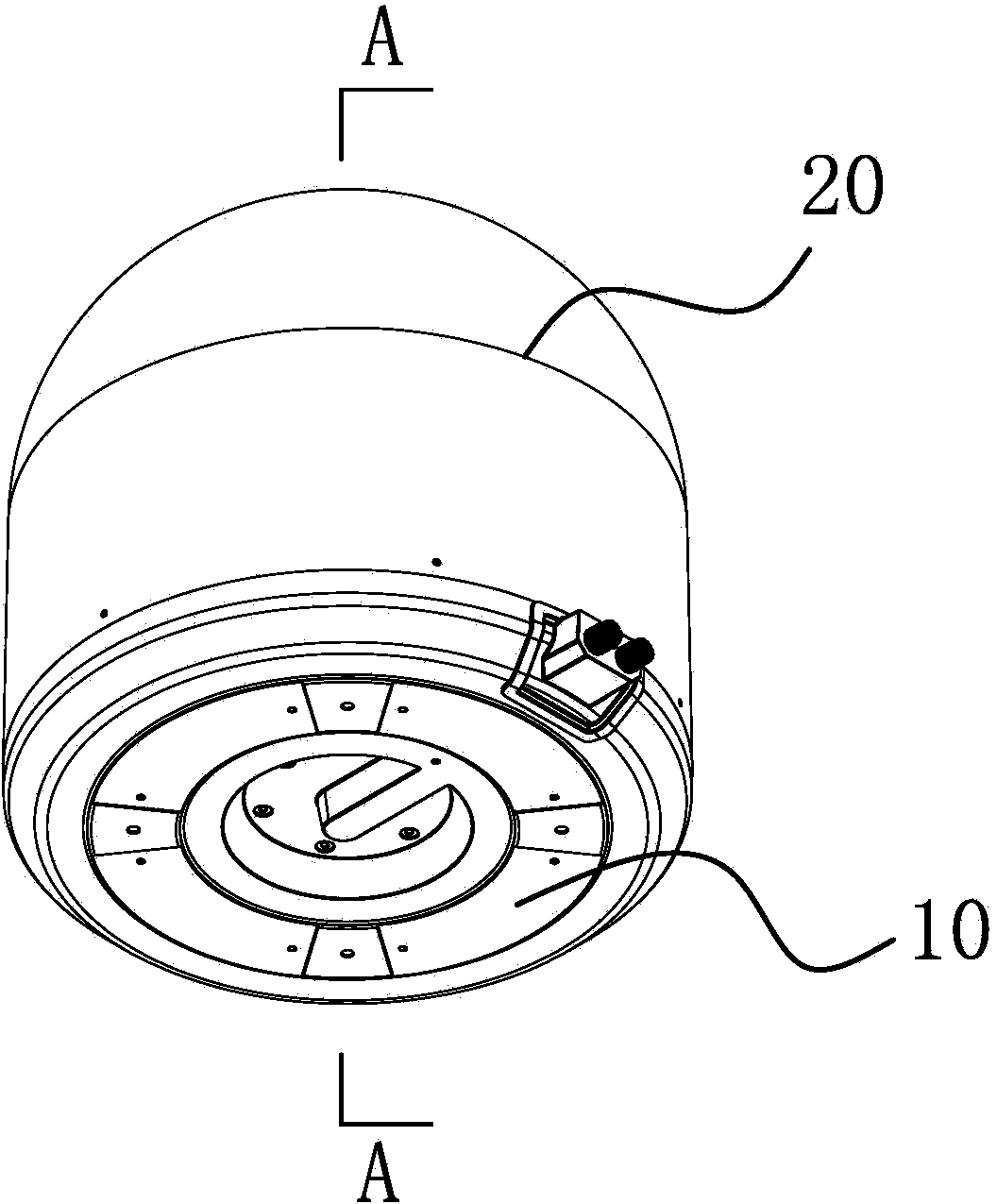

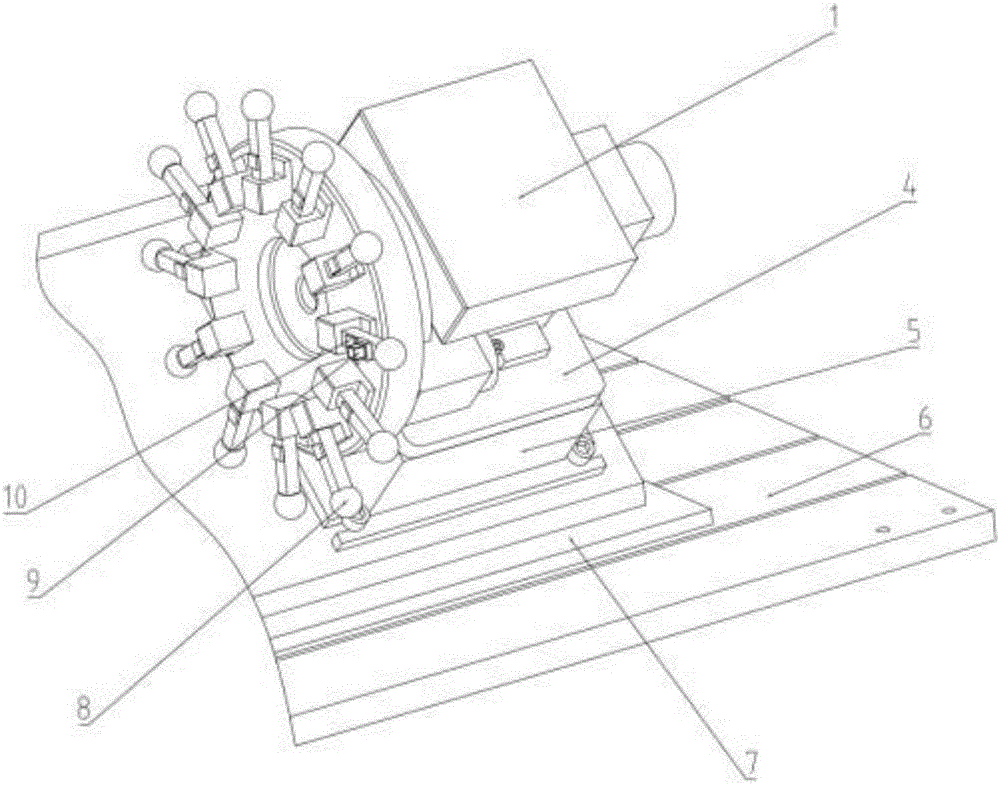

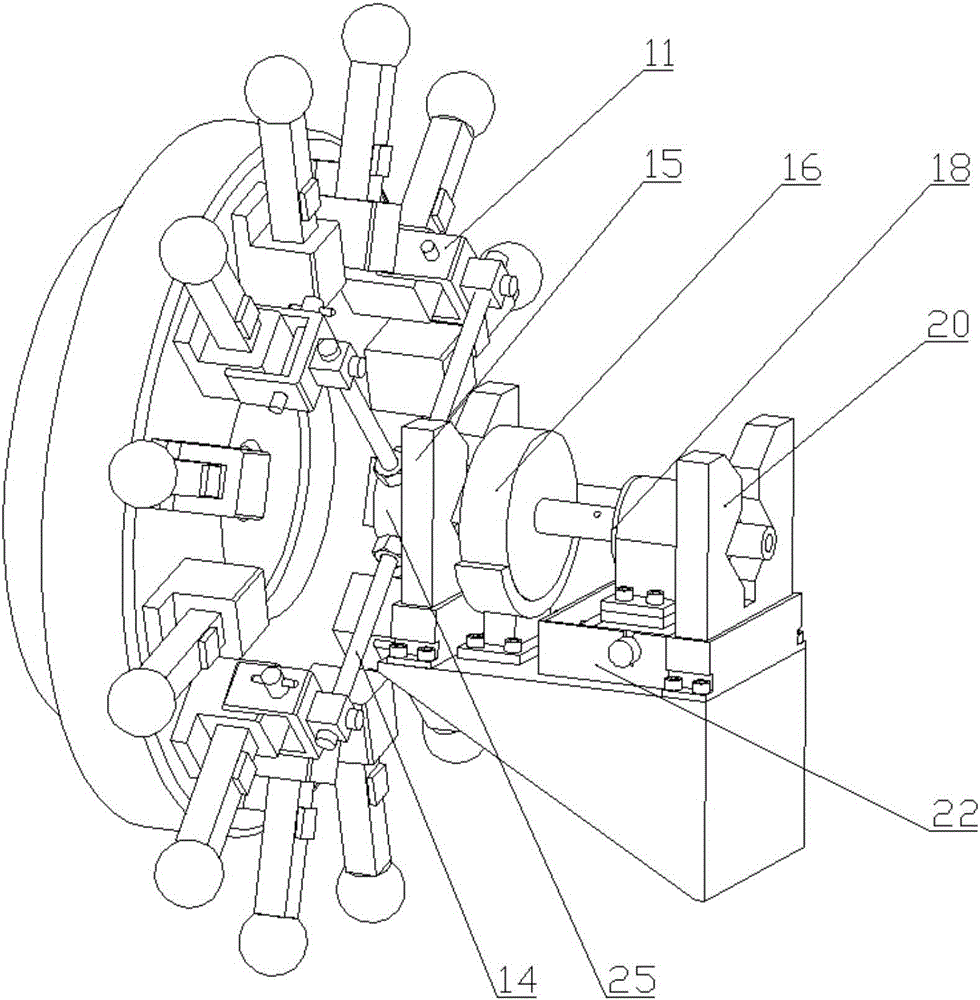

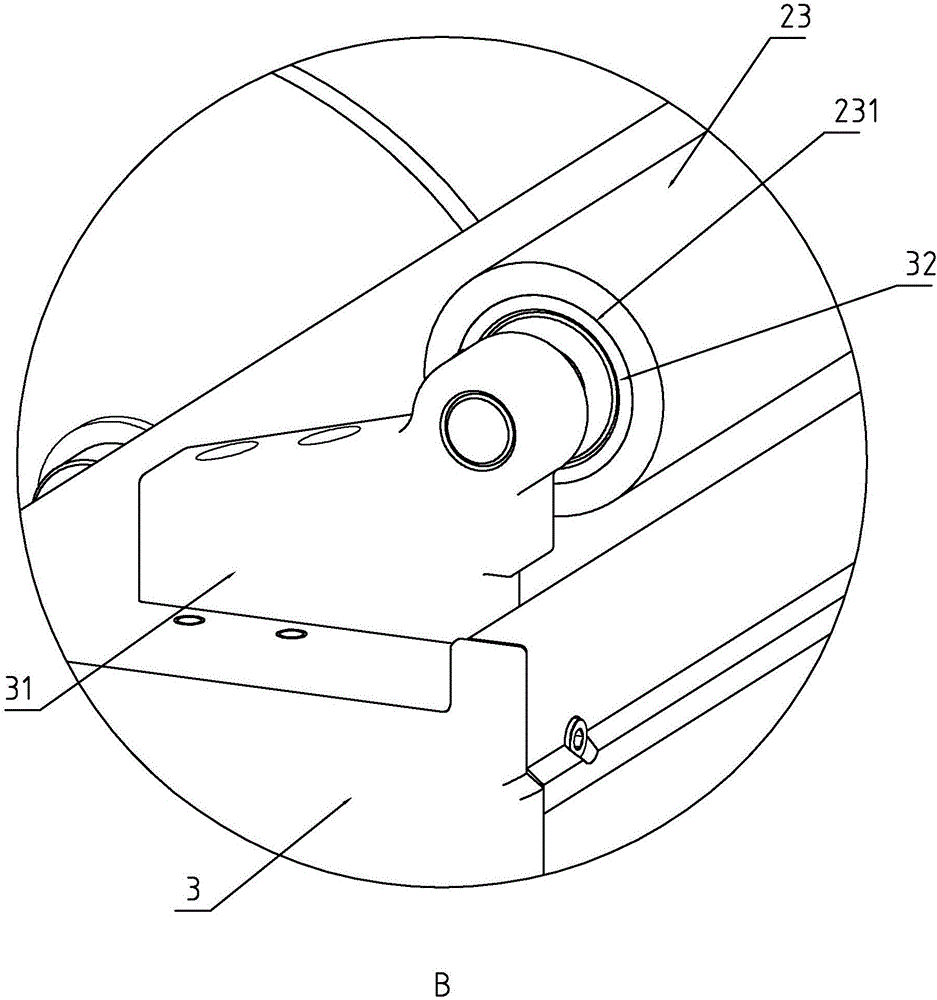

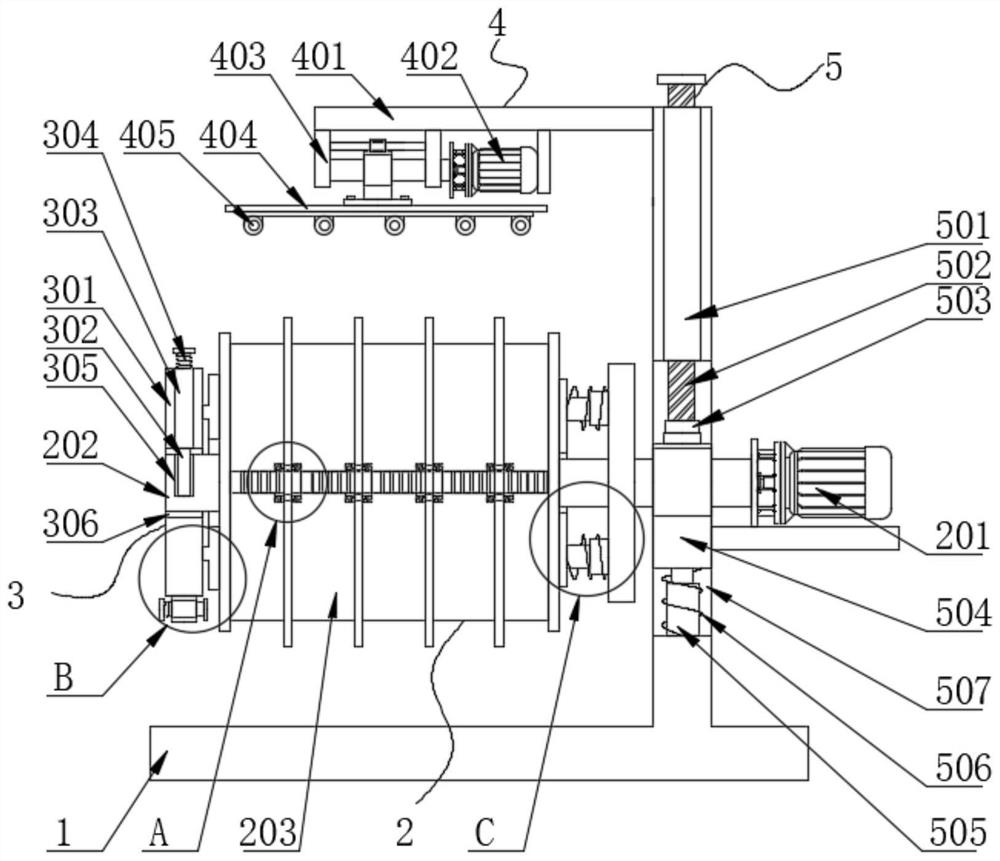

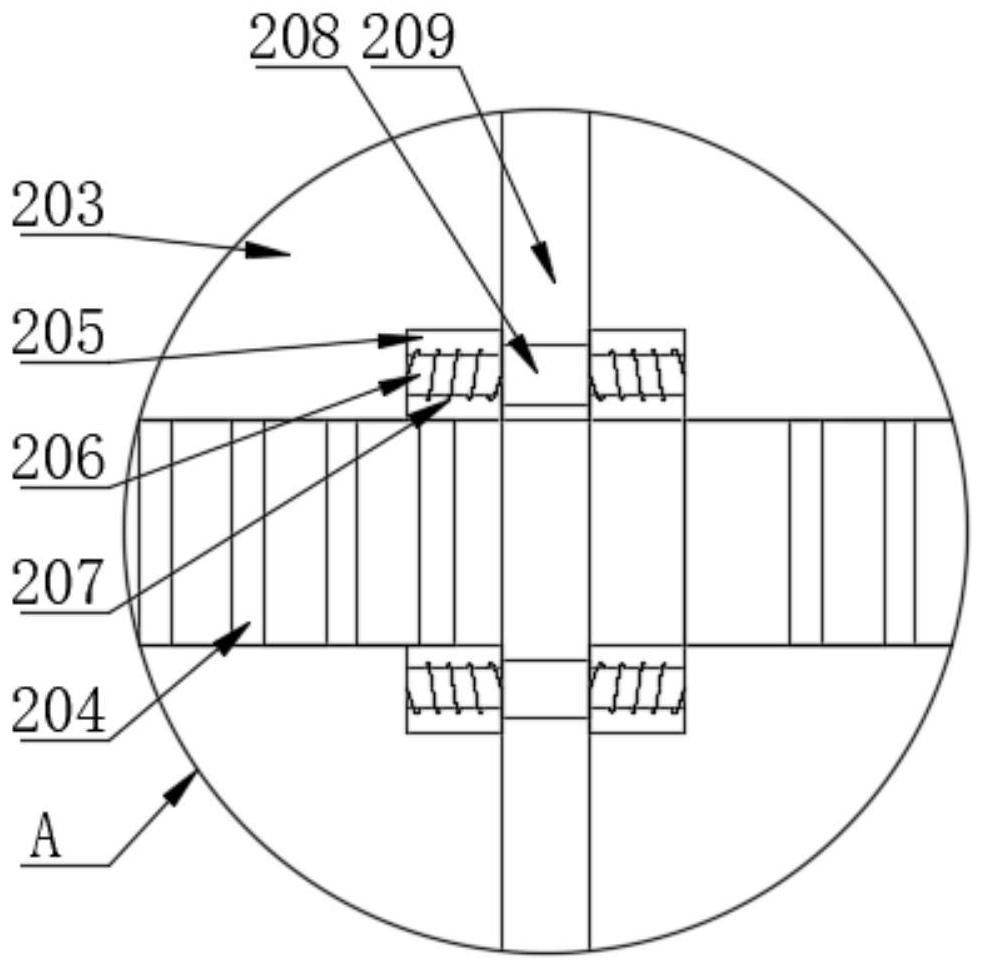

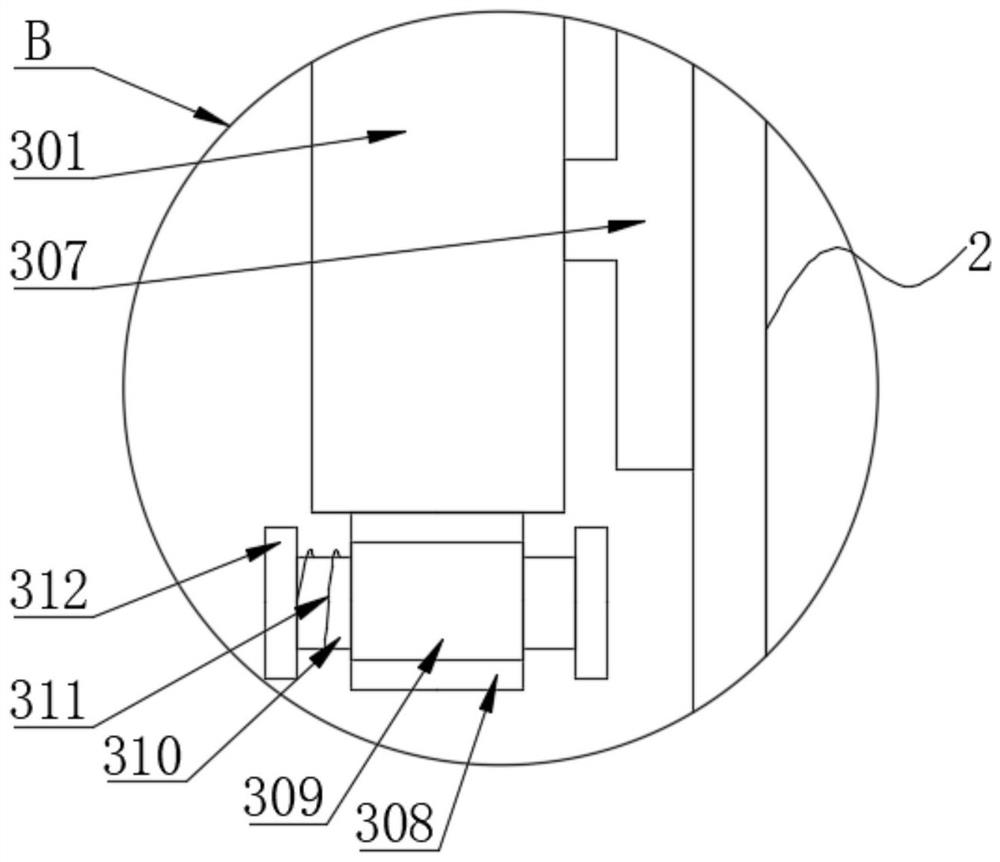

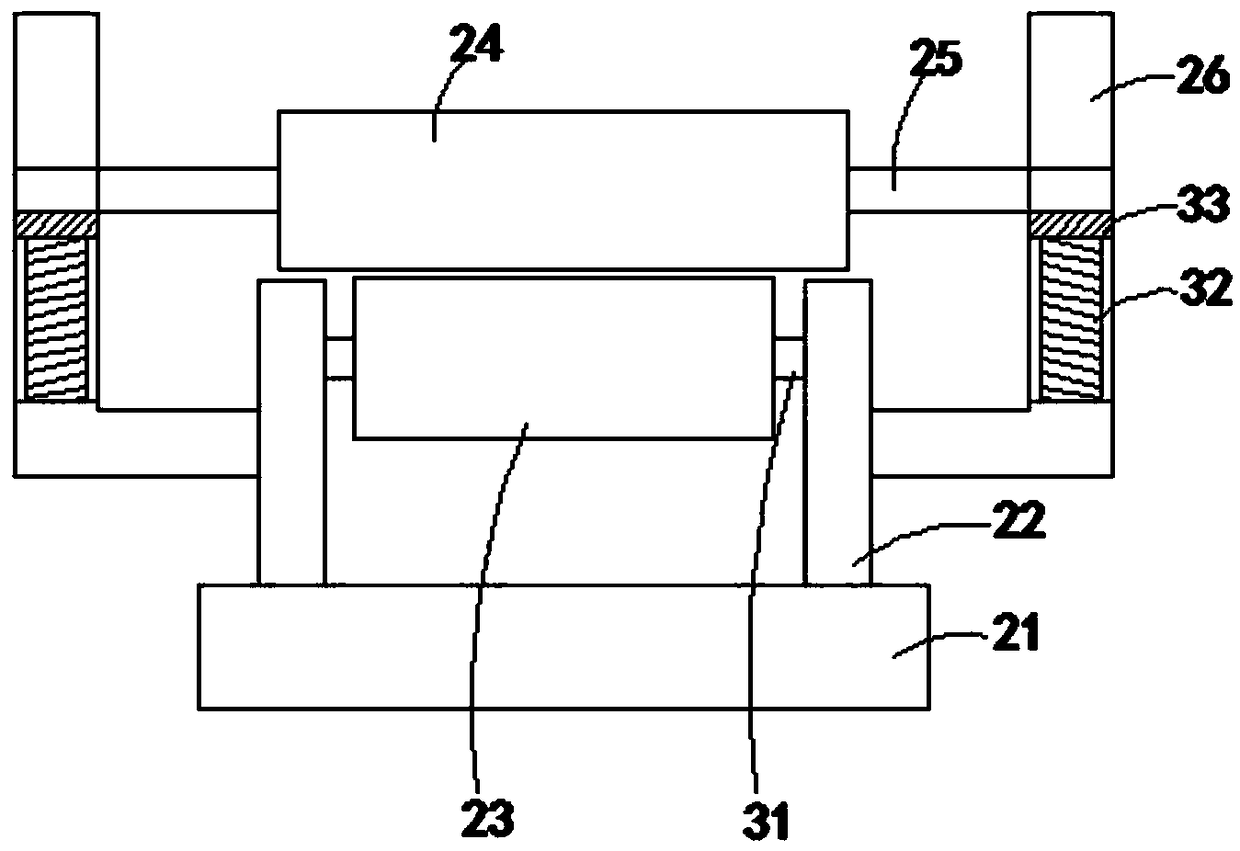

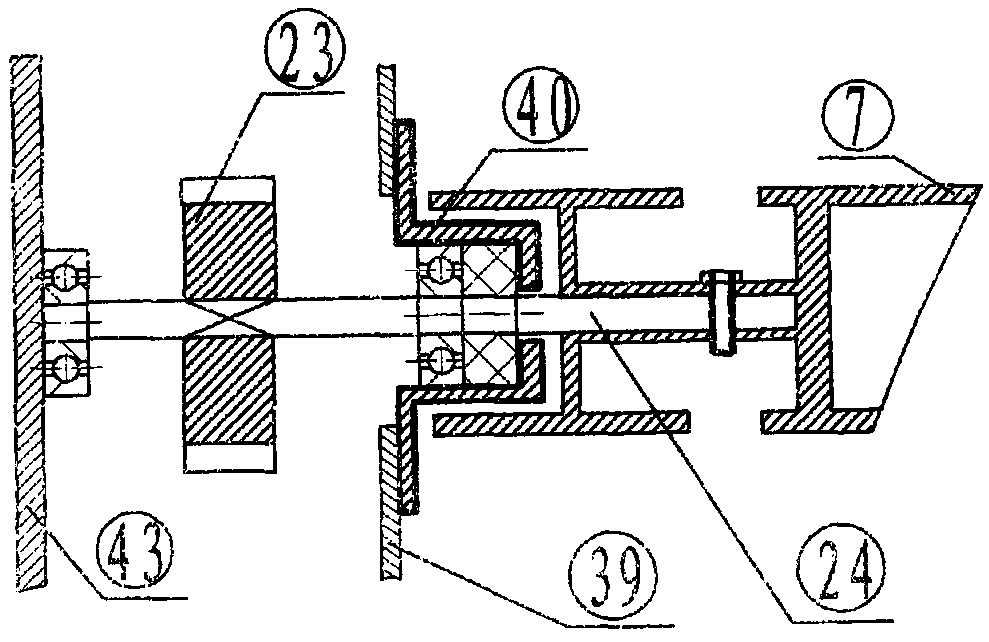

Self-centering chuck

The invention relates to the technical field of clamps, in particular to a self-centering chuck. The self-centering chuck comprises a chuck bracket, a rotating sleeve, a chuck claw disc, a driving wheel, at least two chuck claws and a chuck claw driving mechanism; the chuck claw driving mechanism comprises a driving bearing, a straight line driving mechanism connected with the outer circle of the driving bearing, first racks connected with the inner circle of the driving bearing and gears engaged with the first racks; each chuck claw is provided with second racks; and the second racks are engaged with the corresponding gears. According to the ingenious application of the self-centering chuck, the inner circle of the driving bearing rotates along with the rotating sleeve, and the straight line driving mechanism is connected with the outer circle of the driving bearing, so that the whole driving bearing is driven to move; and the straight line driving mechanism is fixed and does not rotate along with the rotating sleeve, so shat the problem that a cable or an air pipe or an oil pipe or the like of the straight line driving mechanism is wound or loosened or abraded is effectively avoided, clamping of the chuck claws is reliable, the maintenance cost of the self-centering chuck is reduced, and the service life is prolonged.

Owner:东莞市凌美激光科技有限公司 +1

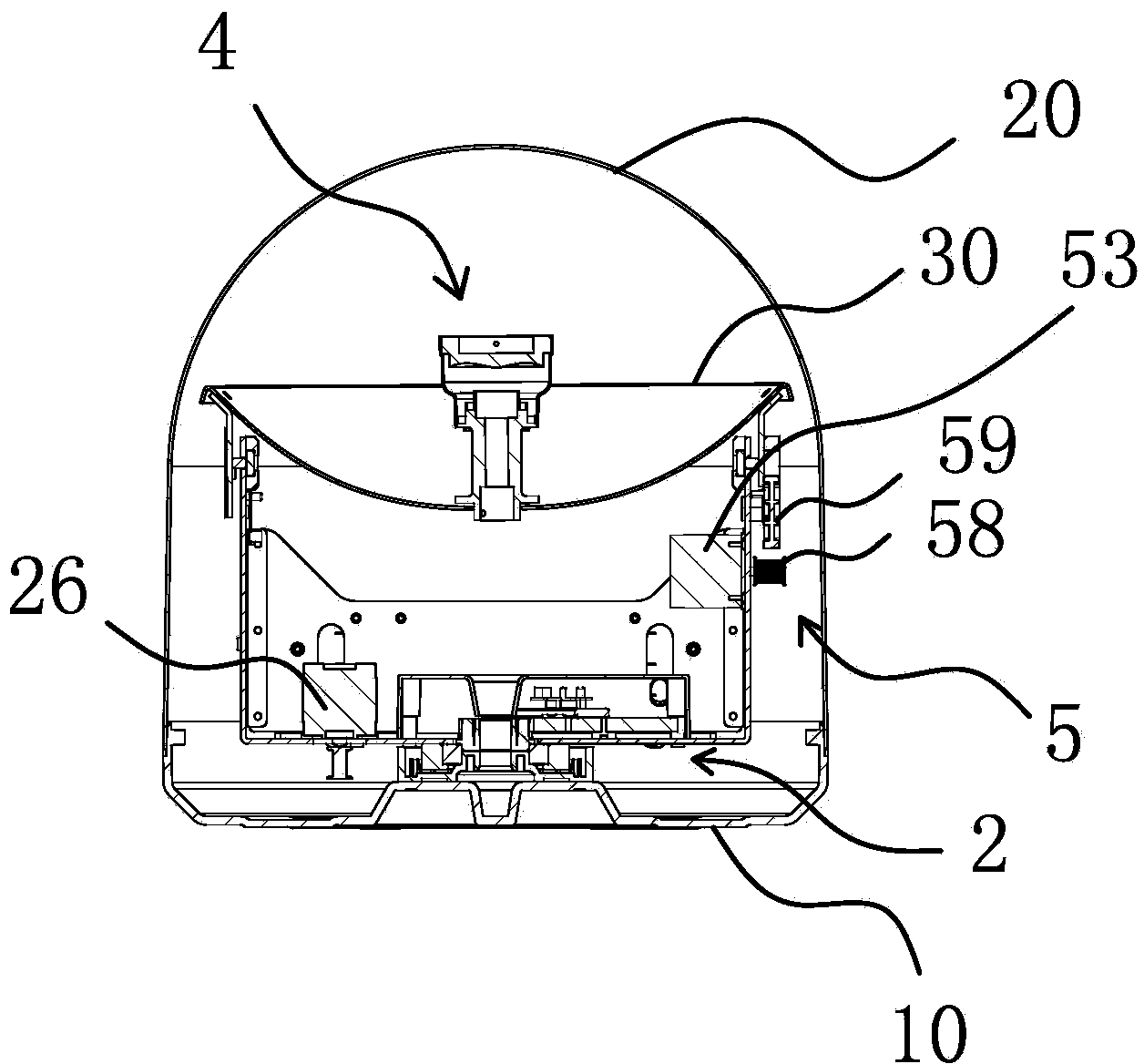

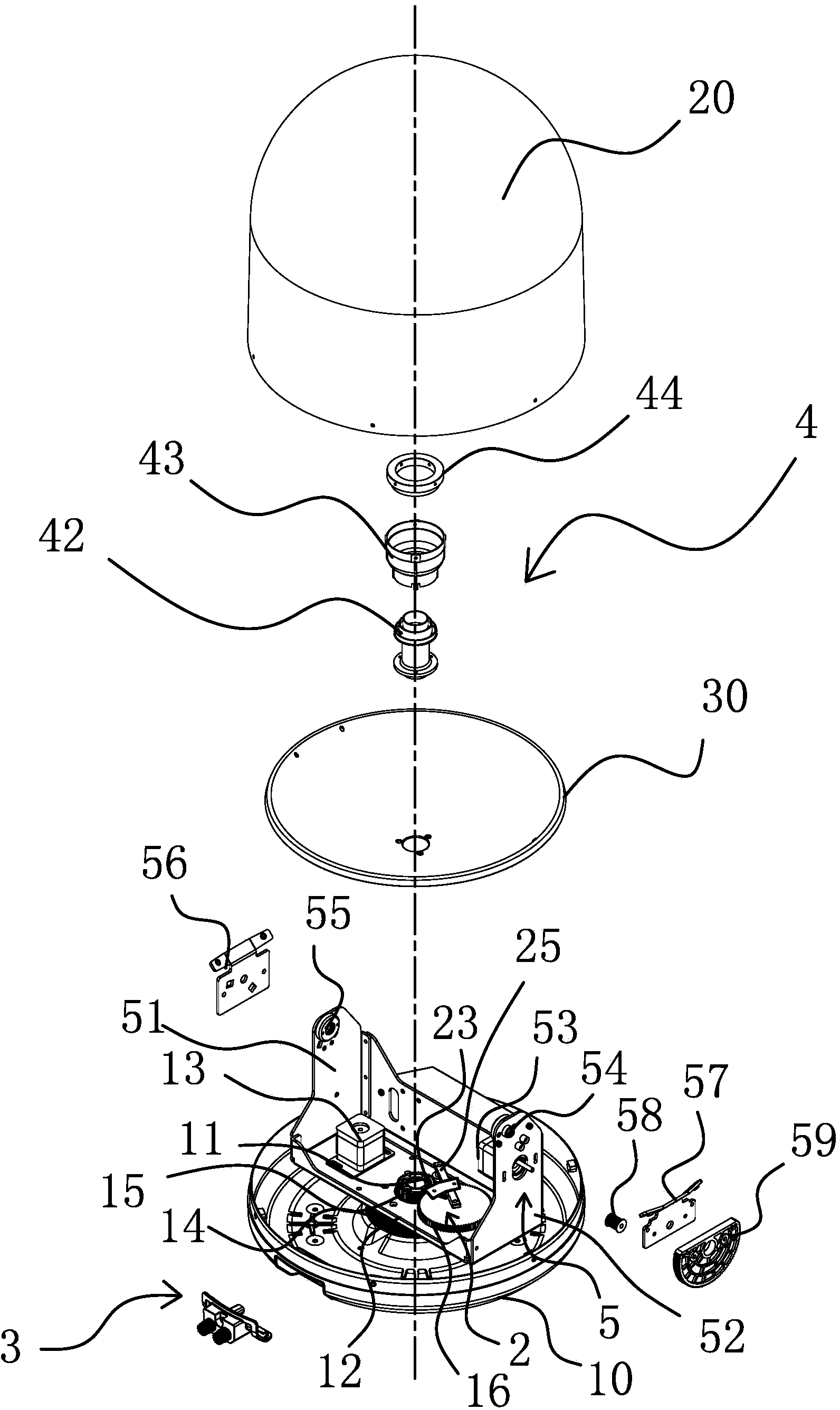

Marine satellite antenna

The invention provides a marine satellite antenna, and belongs to the technical field of electronic communication. The marine satellite antenna solves the technical problem that in the prior art, when a satellite antenna finds stars, electric wires in the antenna are wound due to the unlimited rotation of the antenna. The marine satellite antenna comprises a base and an antenna outer shell which is detachably connected with the base. A center shaft is fixed on the base, a base plate capable of rotating around the center shaft penetrating through the center shaft, a center gear located on the lower side of the base plate is fixed on the center shaft, a first drive motor is fixed on the base plate, a first planetary gear is fixed on an output shaft of the first drive motor, the first planetary gear is meshed with the center gear, the antenna is movably connected to the base plate, and the marine satellite antenna further comprises a rotation limiting device. The marine satellite antenna can find the stars and limit the rotation in an all-around mode, and meanwhile a satellite signal can be enhanced.

Owner:宁波迪泰科技股份有限公司

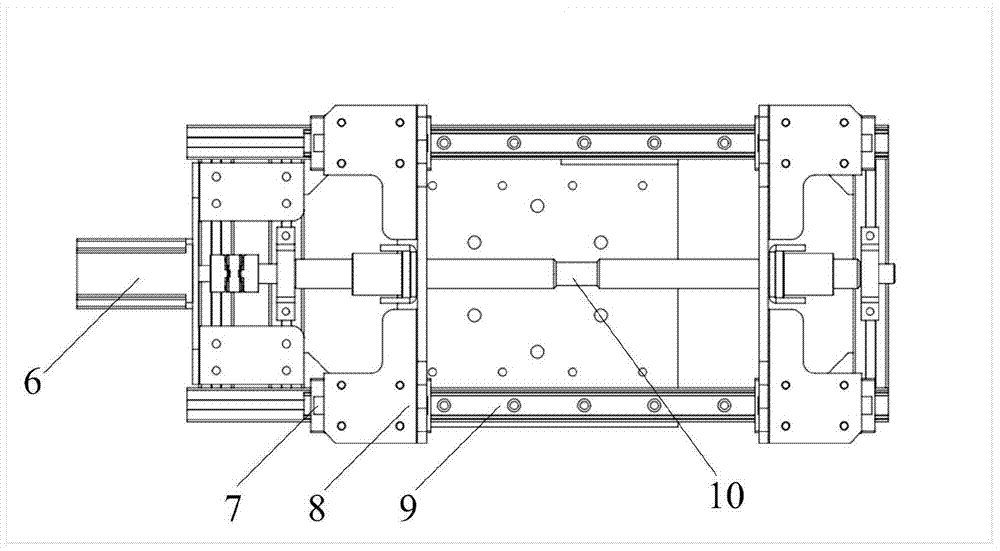

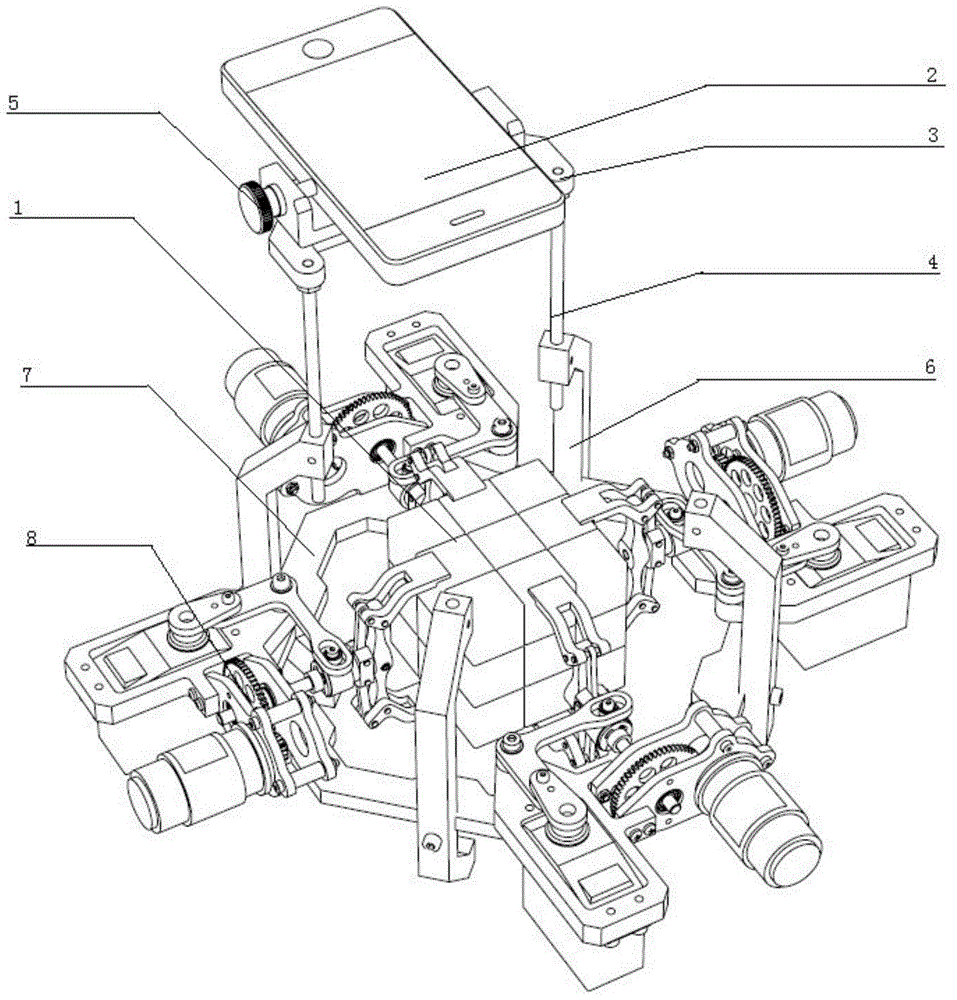

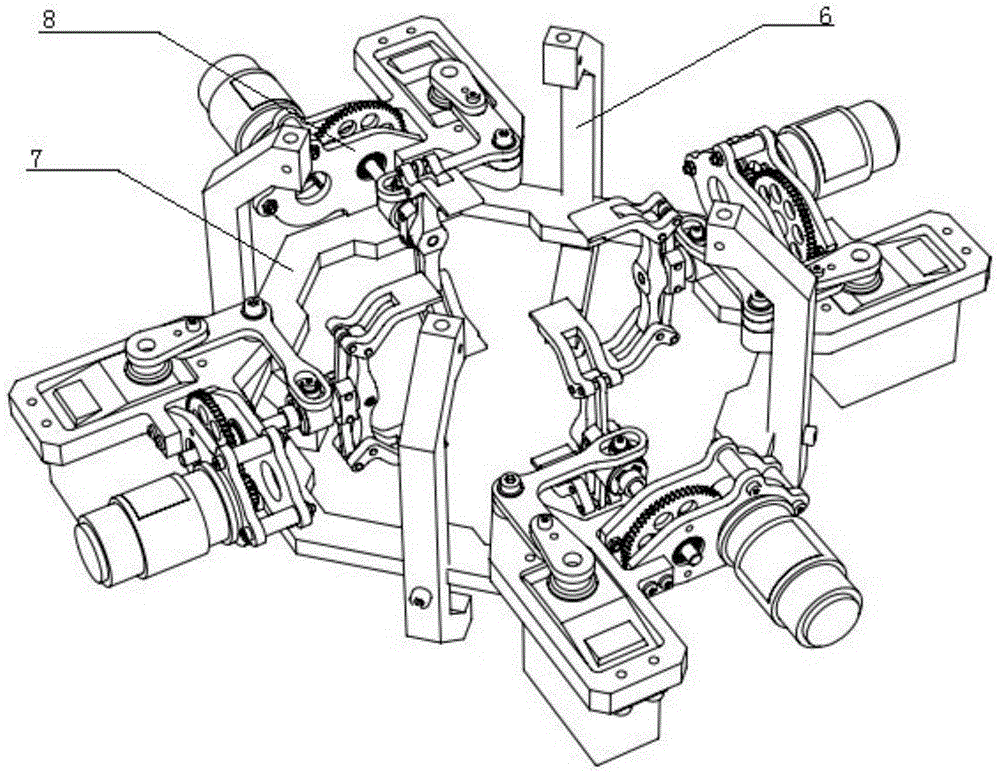

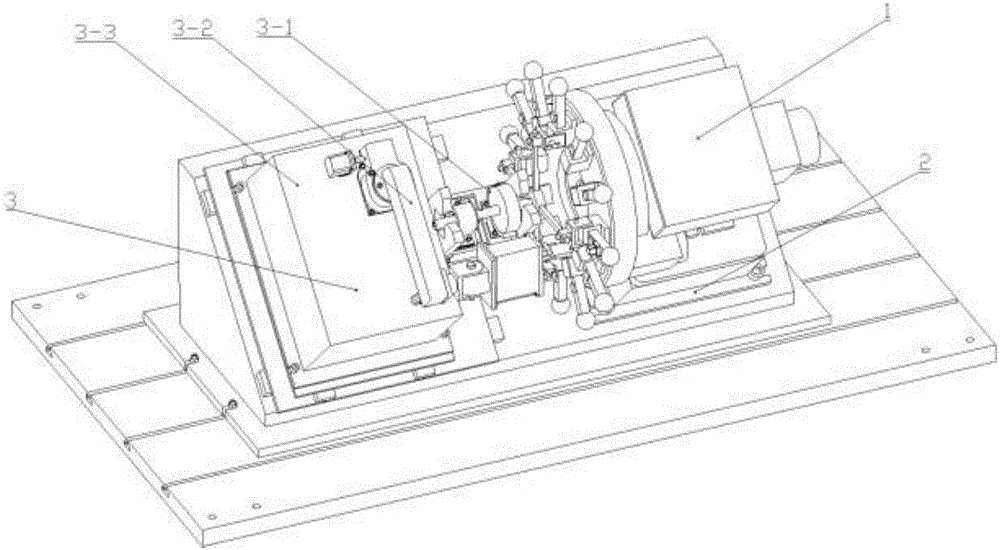

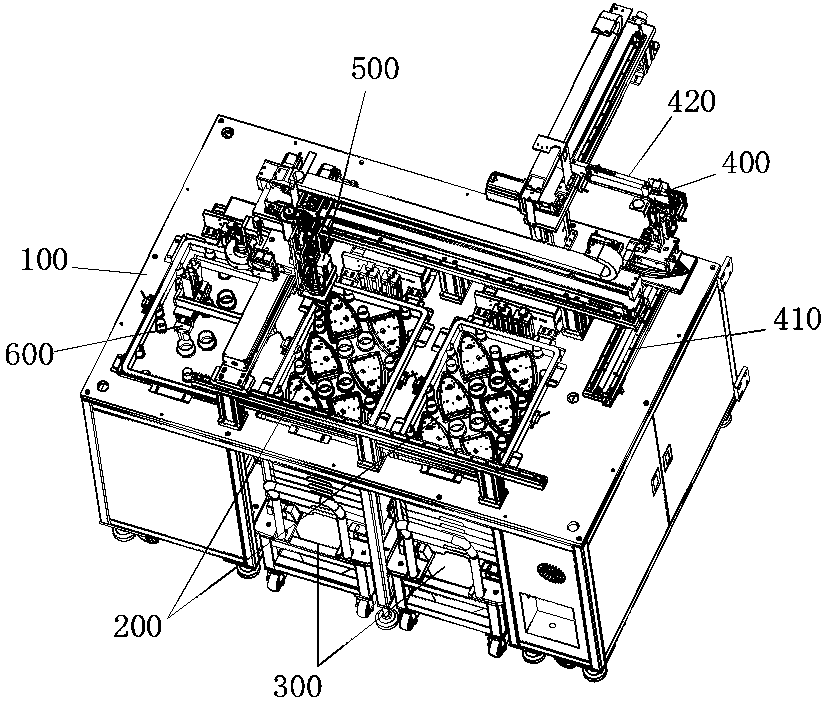

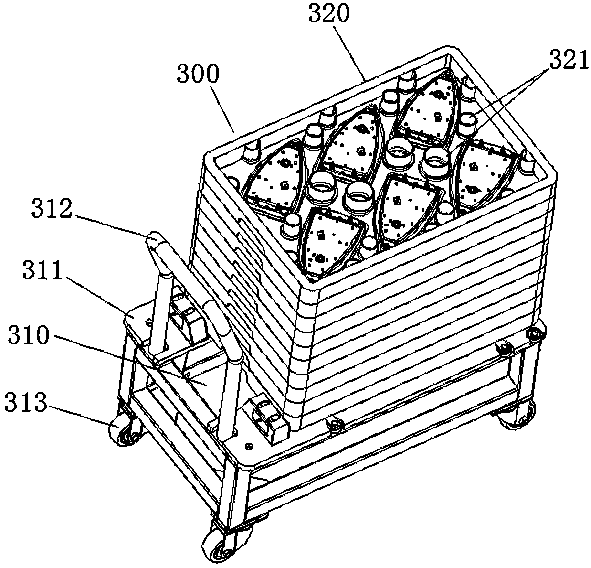

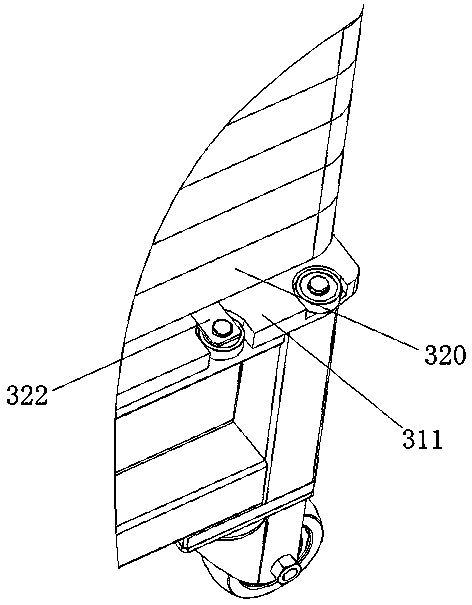

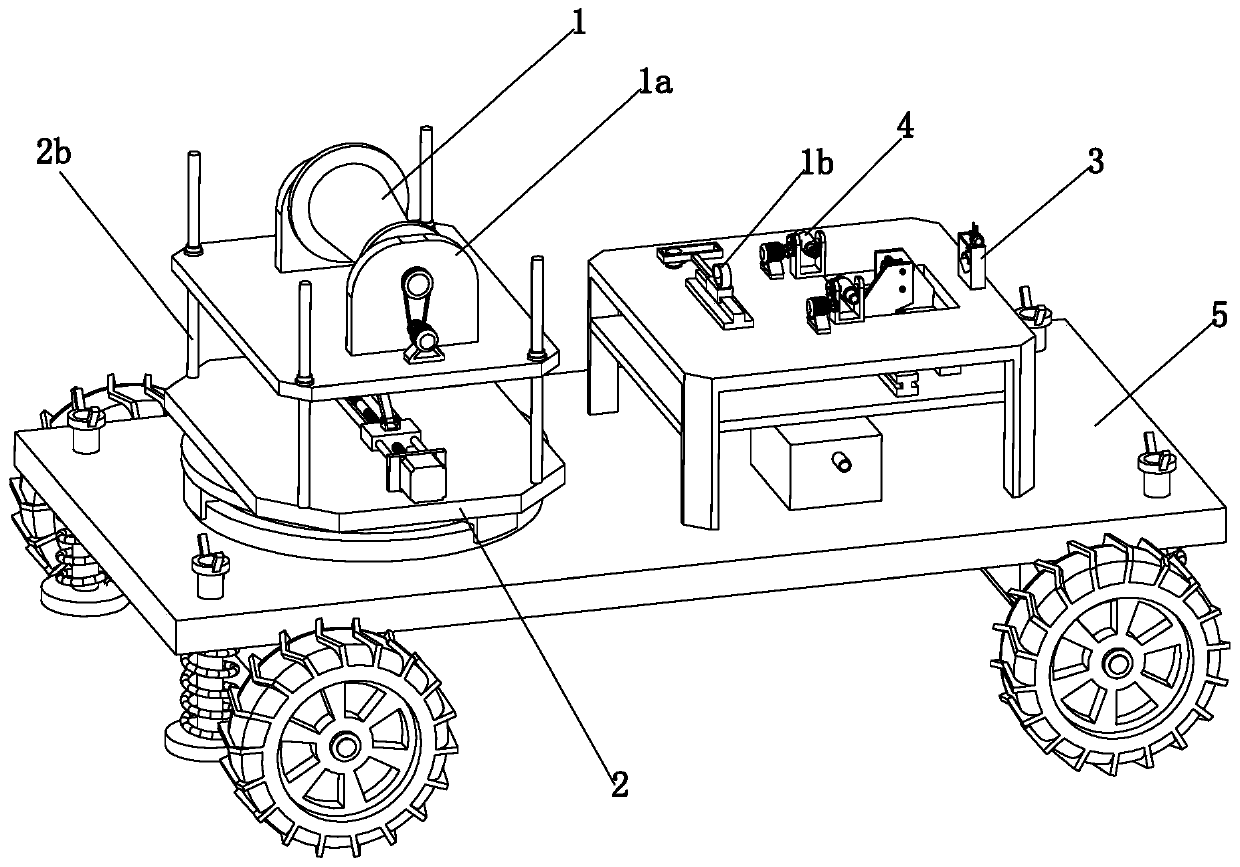

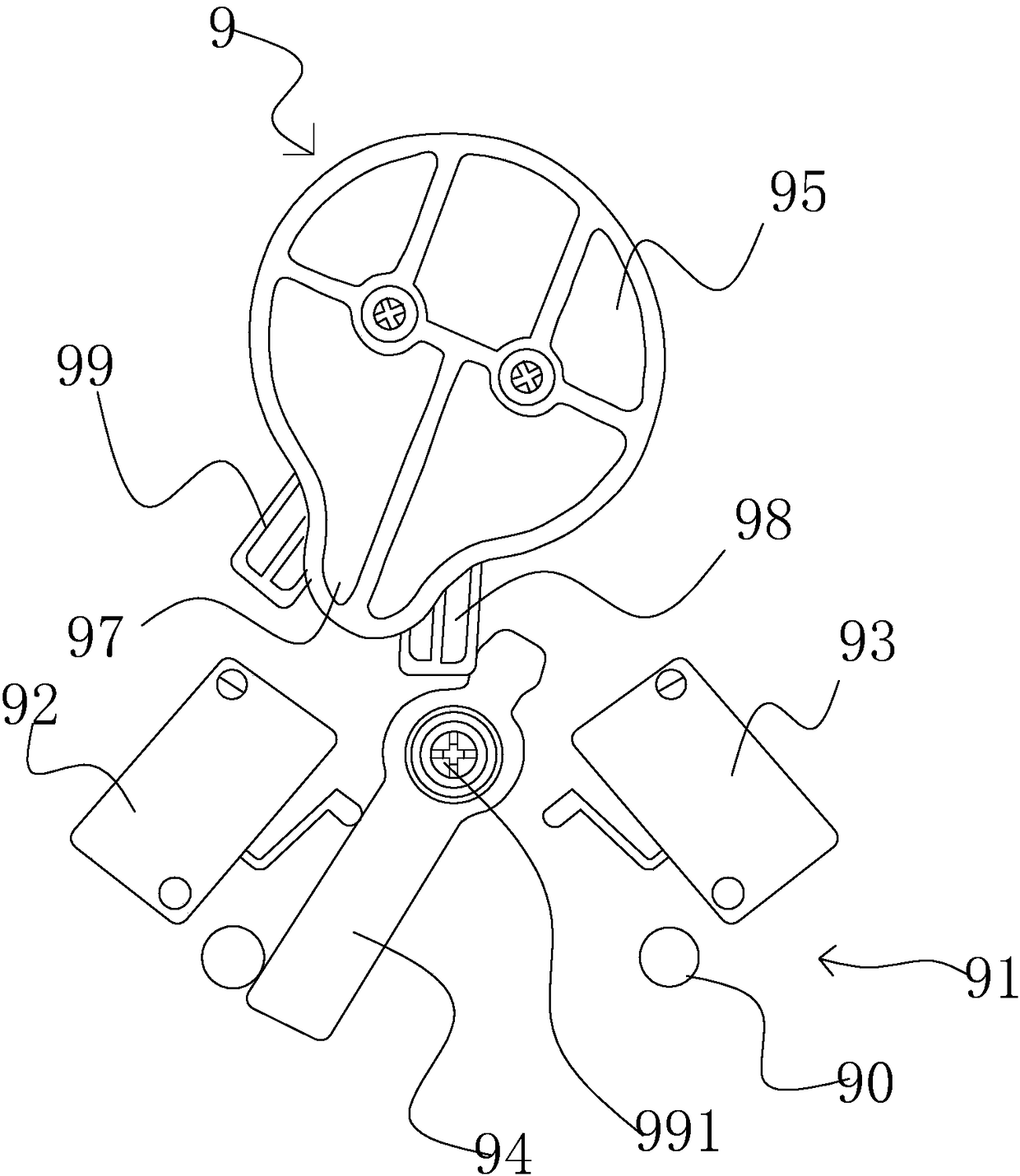

Magic-cube-solving robot with symmetrical structures in four surfaces

ActiveCN104552308AImprove execution efficiencyHigh precisionProgramme-controlled manipulatorExecution unitEngineering

Owner:BEIJING UNIV OF TECH

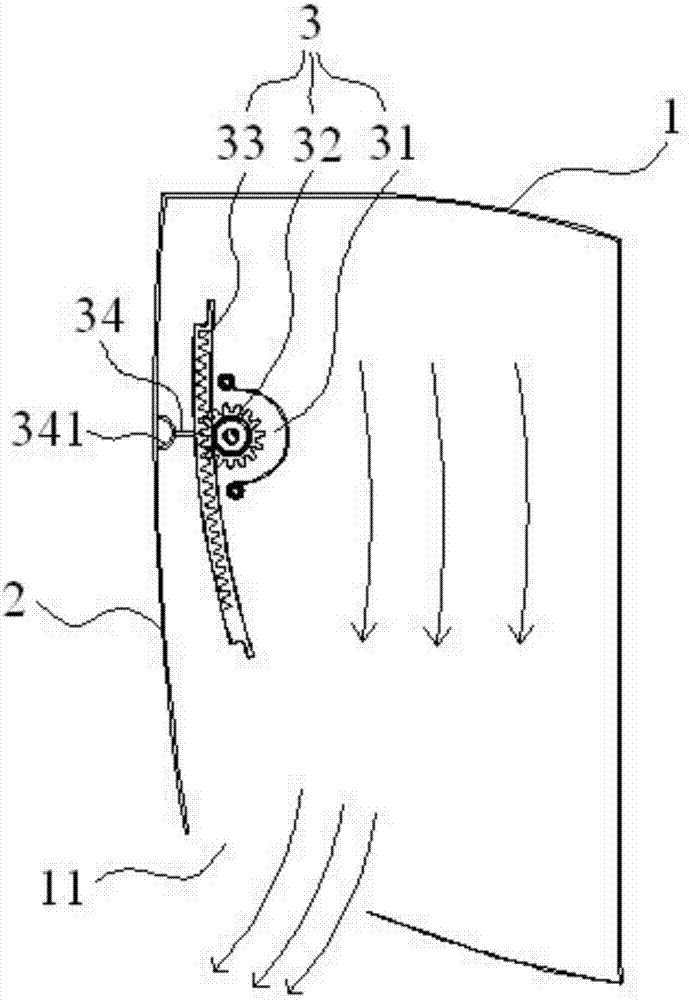

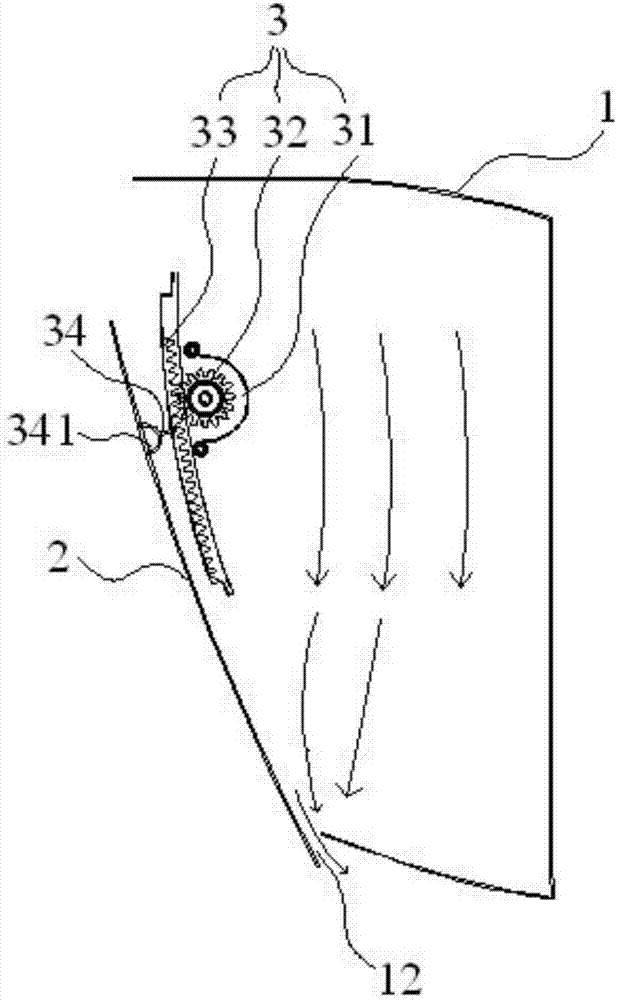

Air-conditioner with wind-feeling-free function and control method thereof

ActiveCN106895568AAvoid condensationImprove comfortCondensate preventionSpace heating and ventilation safety systemsOperation modeMoisture sensor

The invention discloses an air-conditioner with the wind-feeling-free function and a control method thereof, and relates to the technical field of air-conditioners. The air-conditioner with the wind-feeling-free function is invented in order to solve the problem that an air deflector of an air-conditioner in the prior art can generate condensation easily in the wind-feeling-free mode. The air-conditioner with the wind-feeling-free function comprises a shell, a wind screen assembly, a humidity sensor and a control unit. An air outlet is formed in a front panel of the shell. The wind screen assembly comprises a wind screen and a driving device. The driving device can drive the wind screen to move between a retracted position and an extended position. The humidity sensor is used for detecting the humidity of indoor air. The control unit is connected with the humidity sensor and the driving device, and can control the driving device to operate and further control the operation mode of the air-conditioner. The air-conditioner with the wind-feeling-free function and the control method thereof can be used for indoor air adjustment.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

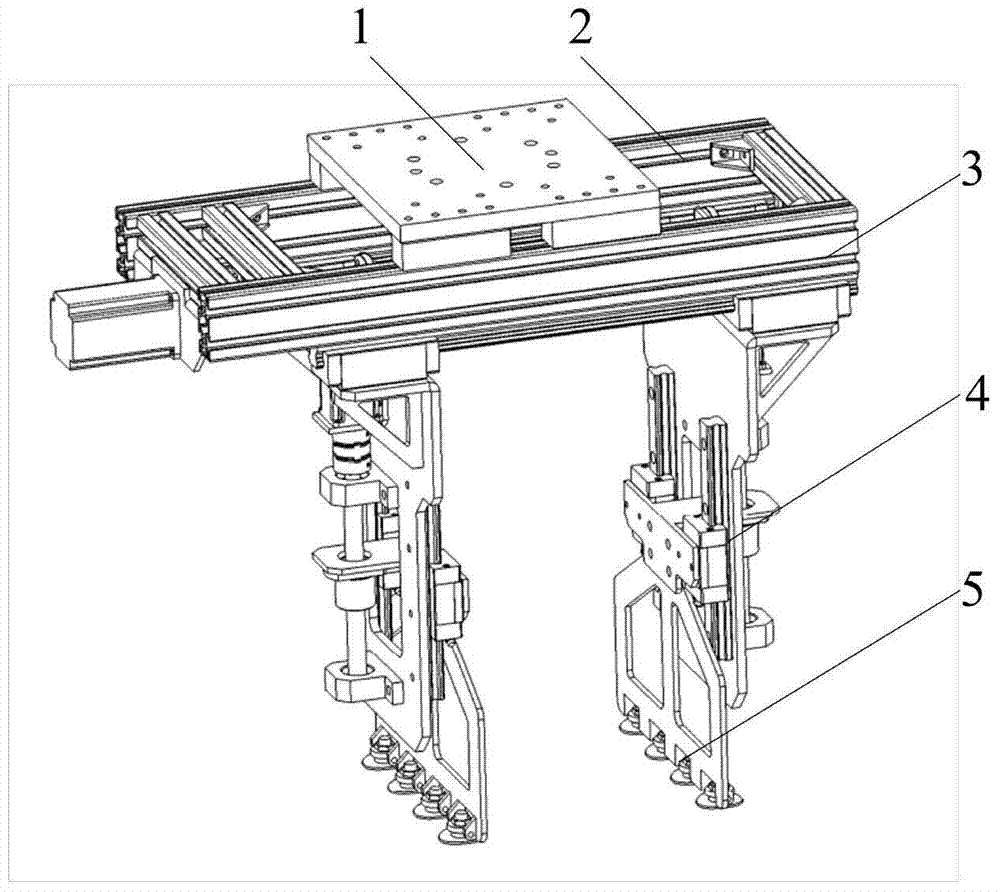

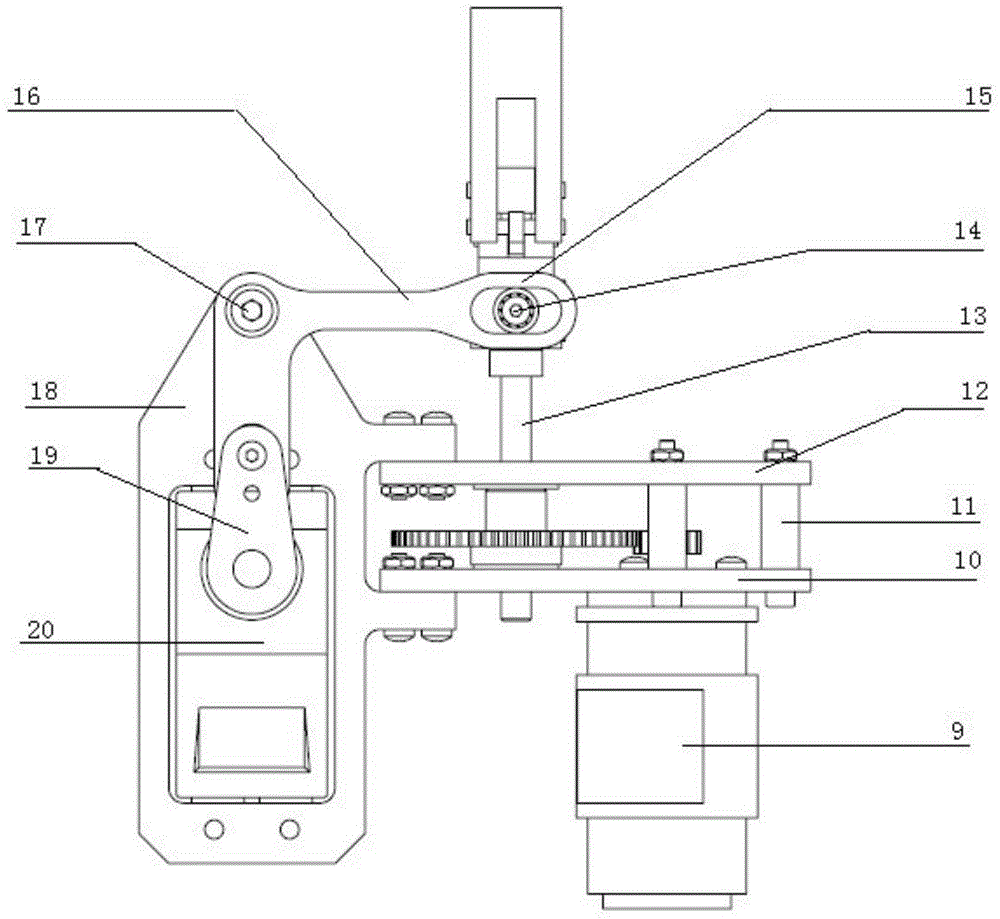

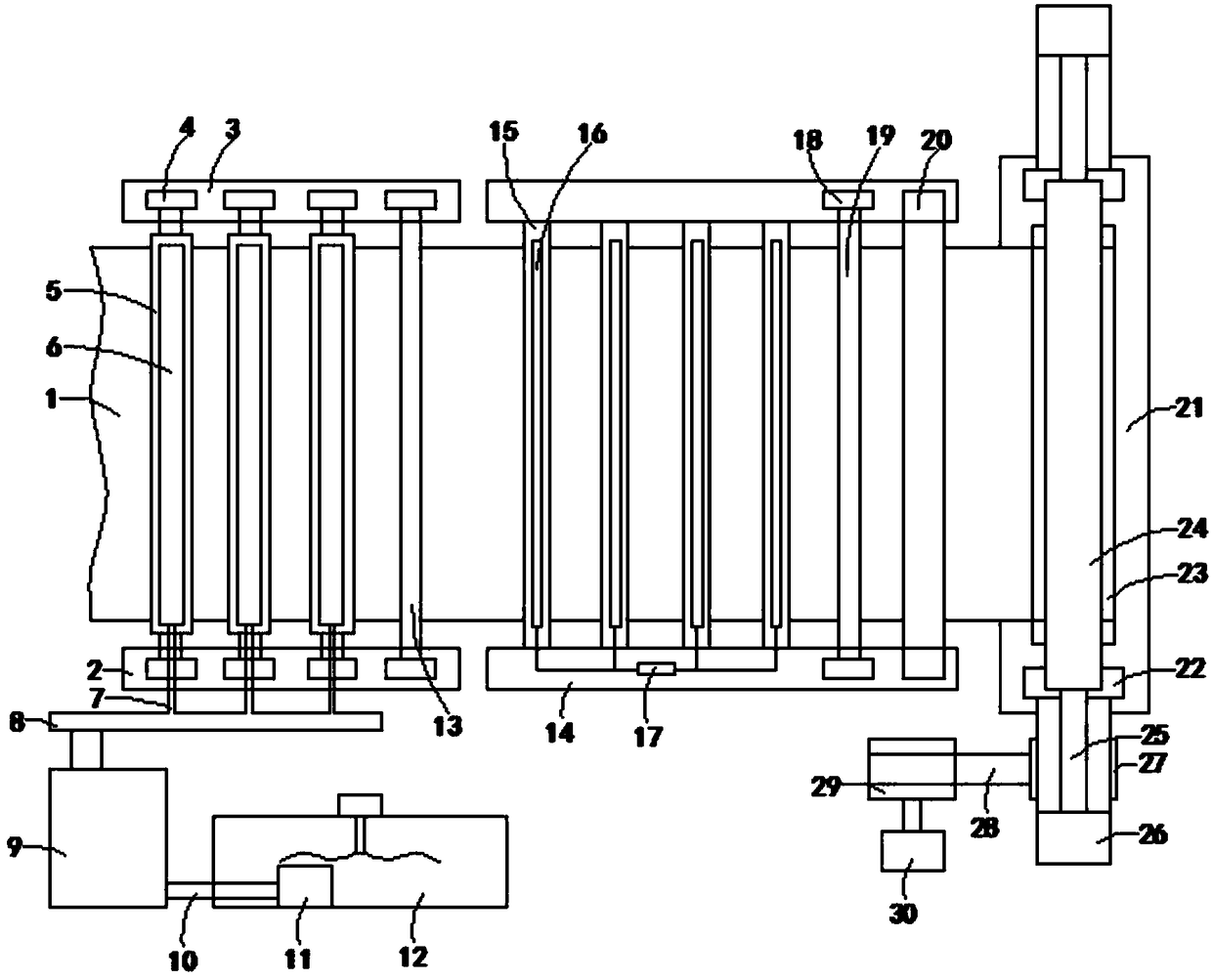

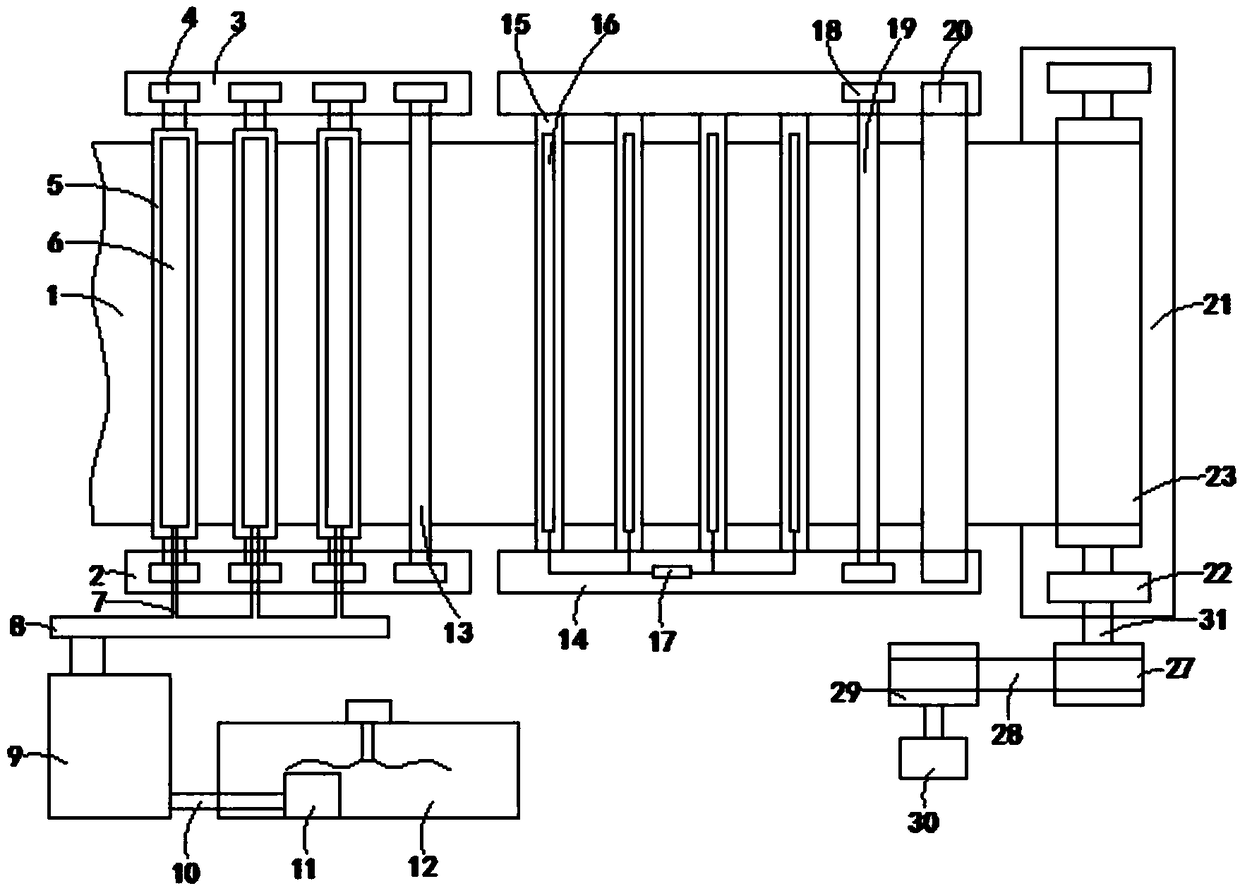

Online detection device for performance parameters of numerical control knife rest

ActiveCN106736860AEasy to installStrong applicabilityMeasurement/indication equipmentsEngineeringKnife holder

The invention belongs to the technical field of knife rest performance detection and discloses an online detection device for performance parameters of a numerical control knife rest. The problems that during current detection of performance parameters of a knife rest, it is needed to manually switch sensors, and the detection efficiency is low are solved. The online detection device for the performance parameters of the numerical control knife rest comprises a servo knife rest, an installing platform and a knife rest performance parameter online detection device; the knife rest performance parameter online detection device is composed of a knife rest detection device body and a vibration sensor automatic replacing device; the knife rest detection device body comprises a knife disk positioning precision and knife changing speed detection device, a knife disk vibration detection device, a knife rod vibration detection device, a knife rest running noise detection device, a knife rod deformation detection device, a centering performance detection and adjustment module and a synchronous rotation module; and the vibration sensor automatic replacing device comprises electromagnetic clamping claws, a servo motor and a worm gear and worm rotation table. According to the online detection device for the performance parameters of the numerical control knife rest, sensors for detection are designed onto the complete online detection device and are adjusted according to different knife rests, installing is convenient and flexible, and adaptability is high.

Owner:JILIN UNIV

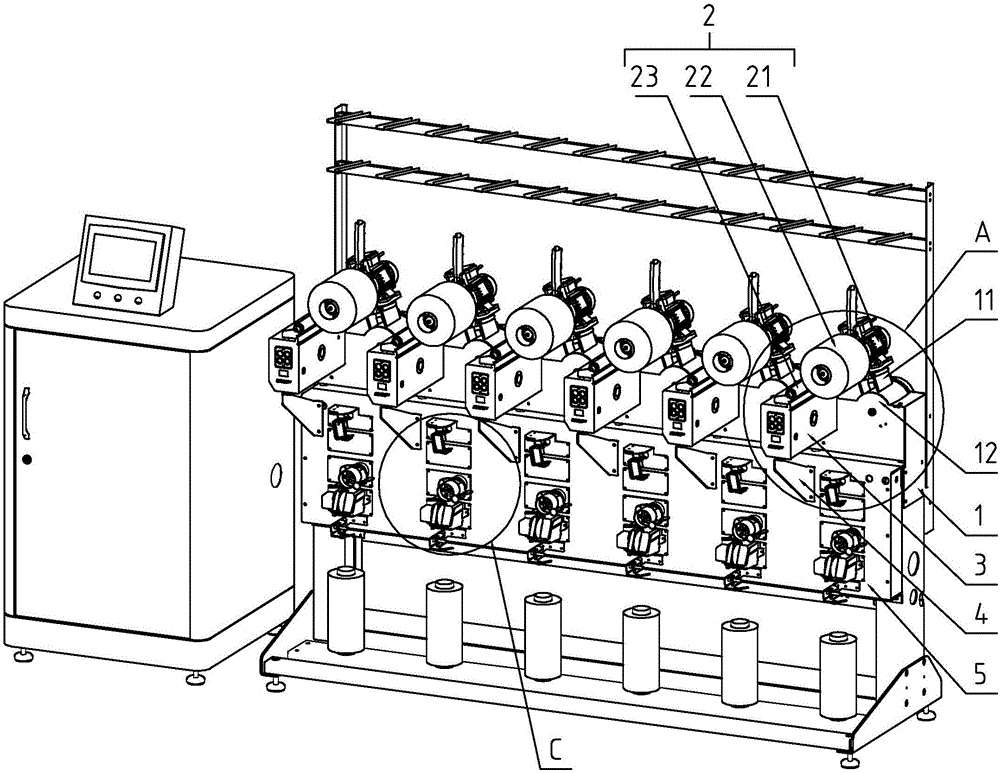

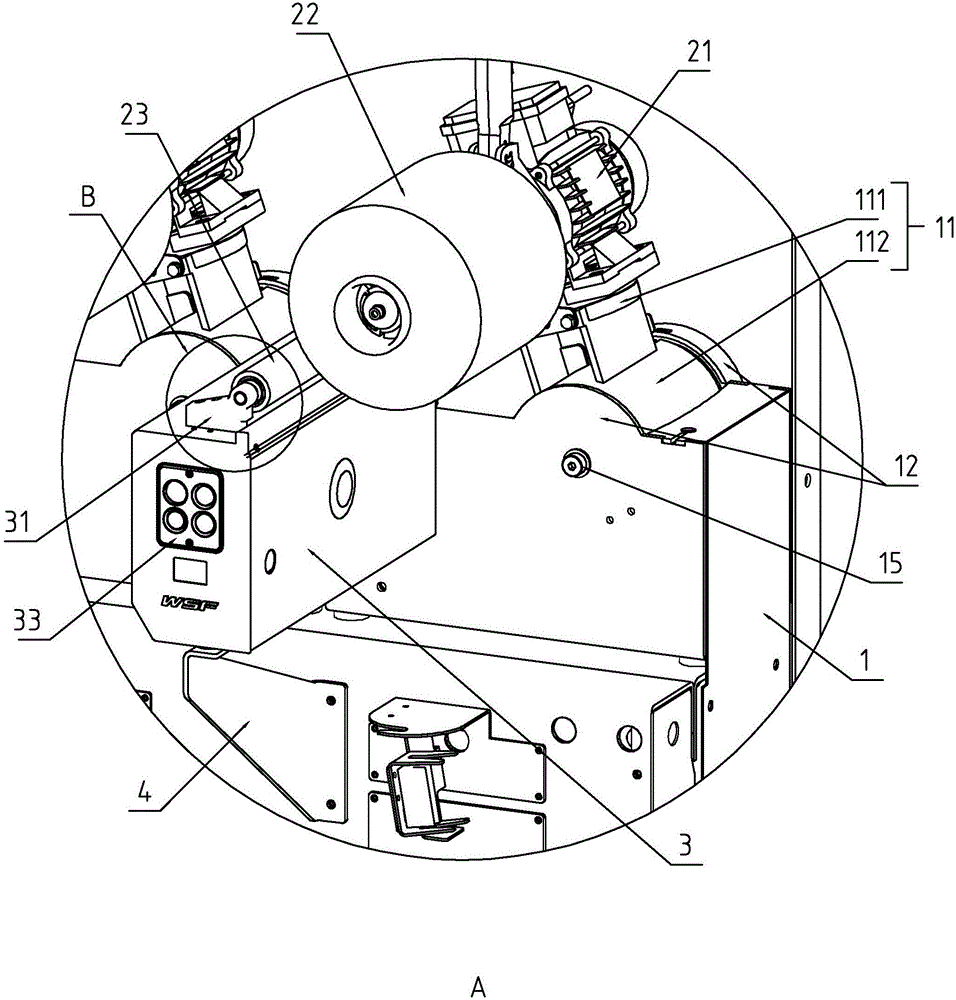

Automatic winder

The invention discloses an automatic winder. The technical scheme has the key points that the automatic winder comprises a rack and a wind-up device, as well as a yarn guiding transmission device, wherein the wind-up device comprises a winding motor and a spool; the yarn guiding transmission device comprises a tension meter, a super feeding wheel and a refueling mechanism, as well as a yarn guiding hook; yarns sequentially pass through the yarn guiding hook, the refueling mechanism, the super feeding wheel and the tension wheel and then are wound on the spool which is driven to rotate by the winding motor, the tension meter, the super feeding wheel and the yarn guiding hook all belong to the prior art, and therefore, unnecessary details are not given; the wind-up device further comprises a propping wheel which always presses one side of the spool to press the yarns on the outer side wall of the spool; the propping wheel can be arranged on the rack in an axial rotating manner; a rotating shaft of the propping wheel is parallel to a rotating shaft of the spool; the propping wheel is positioned on the yarn feeding side of the spool; and when the winding motor drives the spool to wind, the propping wheel always presses the yarns on the outer side wall of the spool. The automatic winder can improve the uniformity of the yarns wound on the spool.

Owner:XINCHANG WANSHIFA TEXTILE MACHINERY

Take-up structure with anti-winding effect for textile operation

The invention discloses a take-up structure with an anti-winding effect for textile operation, and belongs to the technical field of textile assistive devices. The take-up structure comprises a rack,one side of the rack is movably connected with a winding mechanism, one side of the winding mechanism is provided with a clamping mechanism, and the top of the winding mechanism is movably connected with the rack through a lifting mechanism; and the top of one side of the rack is fixedly connected with a wire arranging mechanism, the winding mechanism comprises a first motor, and an output shaft of the first motor is fixedly connected with a first rotating shaft. According to the take-up structure, by the arrangement of the winding mechanism and the wire arranging mechanism, wire harnesses canbe effectively prevented from being wound with one another during winding, the multiple wire harnesses can be taken up at the same time, the separation effect during simultaneous winding of the multiple wire harnesses can be guaranteed through a baffle connected to the outer wall of a winding drum, and burrs of the wire harnesses during pulling can be avoided through a smooth guide sleeve; and the winding efficiency is remarkably improved while winding of thread bodies is avoided, and the requirement for adapting to the textile operation is met.

Owner:青岛富思特纺织股份有限公司

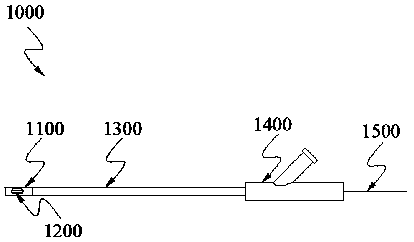

Bottom plate feeding equipment

PendingCN109879012AImprove stabilityLocation judgmentConveyor partsPulp and paper industryVisual detection

The invention discloses bottom plate feeding equipment. The bottom plate feeding equipment mainly comprises a working platform, a feeding mechanism, a visual detection positioning and vacuum suction mechanism, and a transfer secondary positioning and suction transfer loading mechanism, wherein the feeding mechanism is used for feeding, the visual detection positioning and vacuum suction mechanismis used for positioning and sucking a bottom plate, and the transfer secondary positioning and suction transfer loading mechanism is used for transferring, positioning and discharging the bottom plate. According to the bottom plate feeding equipment, the feeding mechanism feeds the required feeding bottom plate into a feeding channel, then the visual detection positioning and vacuum suction mechanism visually detects and positions the bottom plate located in the feeding channel and sucks the transferring bottom plate to the transfer position in vacuum, and the transfer secondary positioning and suction transfer loading mechanism secondary positions the bottom plate and transfers the bottom plate to the next process. According to the bottom plate feeding equipment, automatic operation is realized in the feeding process of the bottom plate from feeding, visual detection and positioning, vacuum suction and transferring, transfer and secondary positioning, suction and transferring loadingto the next station, automatic feeding and taking ensure the appearance and position of the bottom plate, the production efficiency is high, and the consistency of the product quality is good.

Owner:FORYOU MULTIMEDIA ELECTRONICS

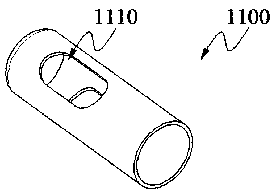

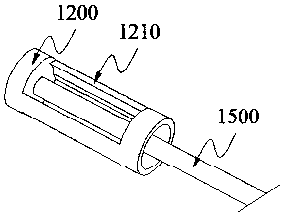

Arterial embolectomy catheter

ActiveCN108013918AAvoid entanglementAvoid windingExcision instrumentsEndoscopic cutting instrumentsMedicineThrombus

The invention discloses an arterial embolectomy catheter which comprises an arterial embolectomy head, an embolism breaking knife, a transmission cable, a partition tube, an outer sheathing canal anda tail connecting piece, wherein the arterial embolectomy head is of a tubular hollow structure with at least one arterial embolectomy hole; the embolism breaking knife is of a tubular hollow structure with at least one blade point; the embolism breaking knife is installed inside the arterial embolectomy head; the embolism breaking knife is fixedly connected with the far end of the transmission cable; the near end of the arterial embolectomy head is fixedly connected with the far end of the outer sheathing canal; the near end of the outer sheathing canal is fixedly connected with the tail connecting piece; the partition tube is arranged outside the transmission cable in a sleeving manner; the near end of the partition tube is fixedly connected with the tail connecting piece; the embolism breaking knife is arranged outside the partition tube in a sleeving manner; a side hole is formed in the tail connecting piece; and the side hole is communicated with a cavity formed between the partition tube and the outer sheathing canal. According to the arterial embolectomy catheter provided by the invention, the partition tube is arranged outside the transmission cable, and the thrombus is prevented from winding with the transmission cable; and rapid and continuous arterial embolectomy is realized.

Owner:SHANGHAI BLUEVASCULAR MEDTECH CO LTD

Wall cloth spraying, drying and rolling device

The invention provides a wall cloth spraying, drying and rolling device and relates to the technical field of wall cloth production equipment. The wall cloth spraying, drying and rolling device comprises wall cloth, a left bracket, a right bracket, a fixed seat, a spraying cavity, a coating supply pipe, a feeding pipe, a material supply pipe, a liquid suction machine, a discharge pipe, a filter, amaterial storage box, an extrusion strike plate, a heating cavity bracket, a heating cavity, a heating rod, a power supply interface, a pressure shaft bracket, a pressure shaft, an air cooler, a rolling rack, a bearing pedestal, a rolling roller, a pressure roller, a connecting rod, a support, a driven flywheel, a transmission belt and the like. By arranging the air cooler to heat and dry the wall cloth, cold air blown by the air cooler can cool the cloth wall, so that the wall cloth is prevented from being rolled at a relatively high temperature; by arranging the pressure roller and a tension spring, when the wall cloth is rolled, the pressure roller is in tight contact with the rolling roller all the way under the action of tension spring; as the pressure roller levels the wall cloth, the condition that the rolled wall cloth is wrinkle is prevented, and the levelness of the wall cloth is improved.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

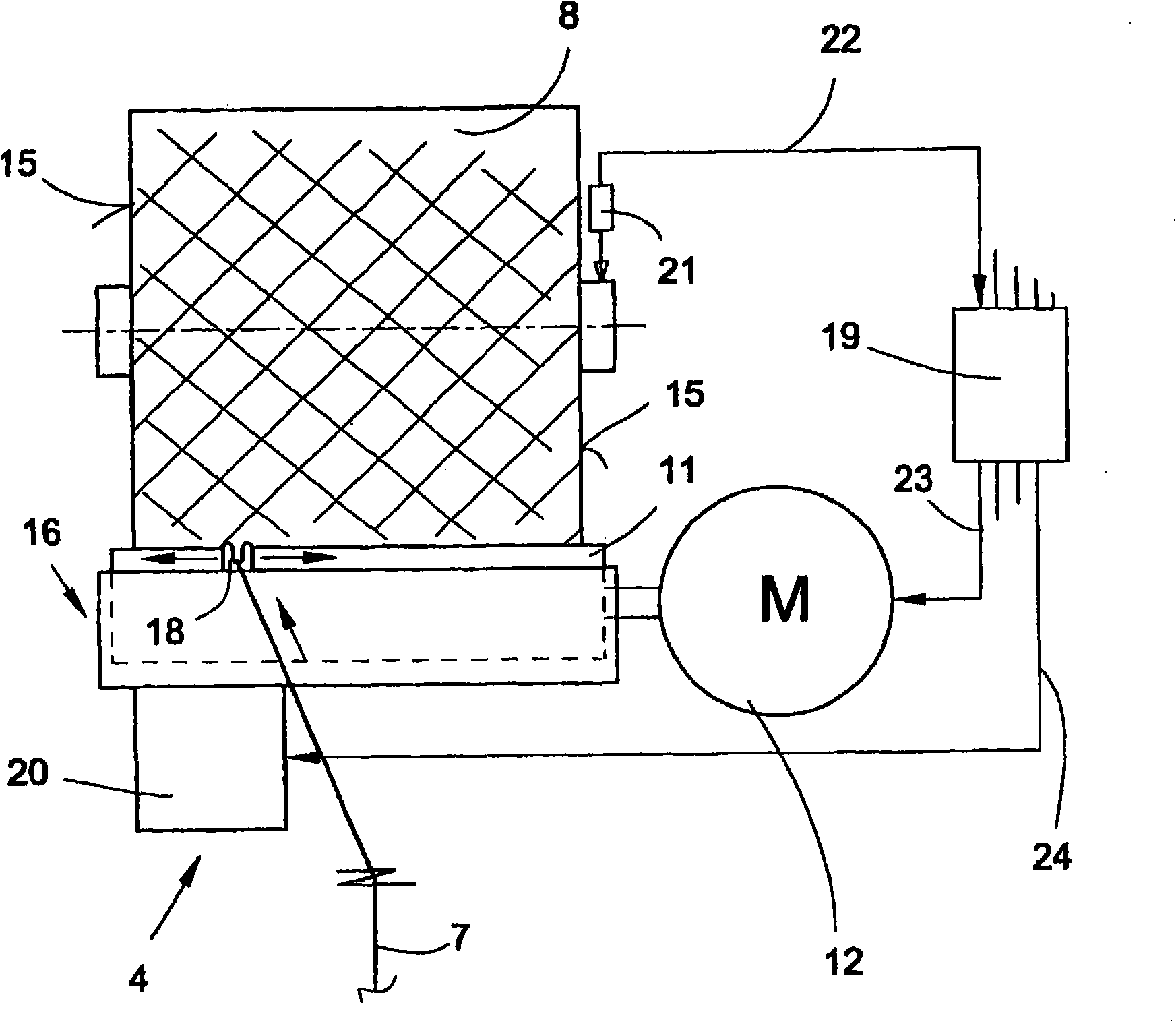

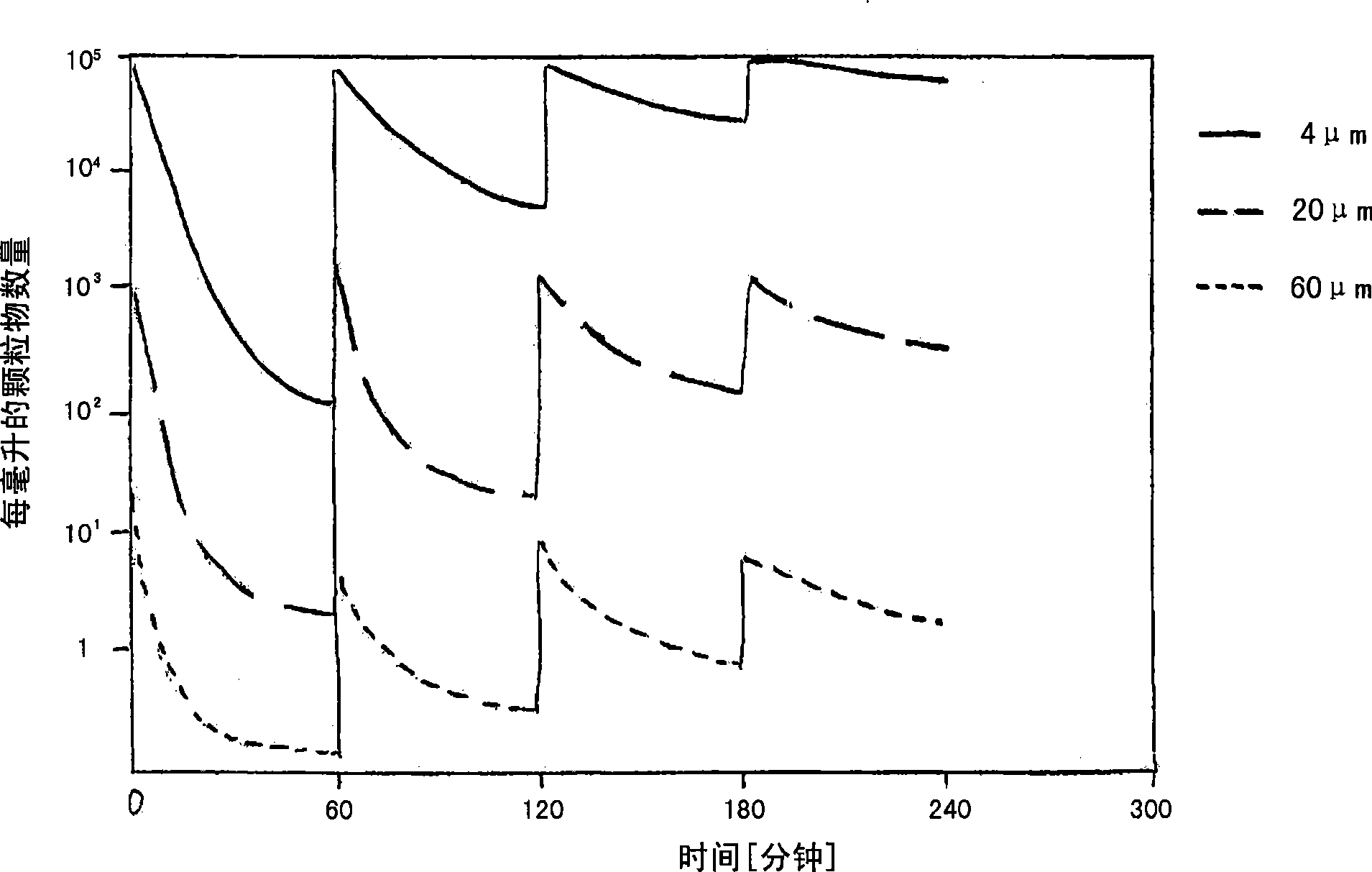

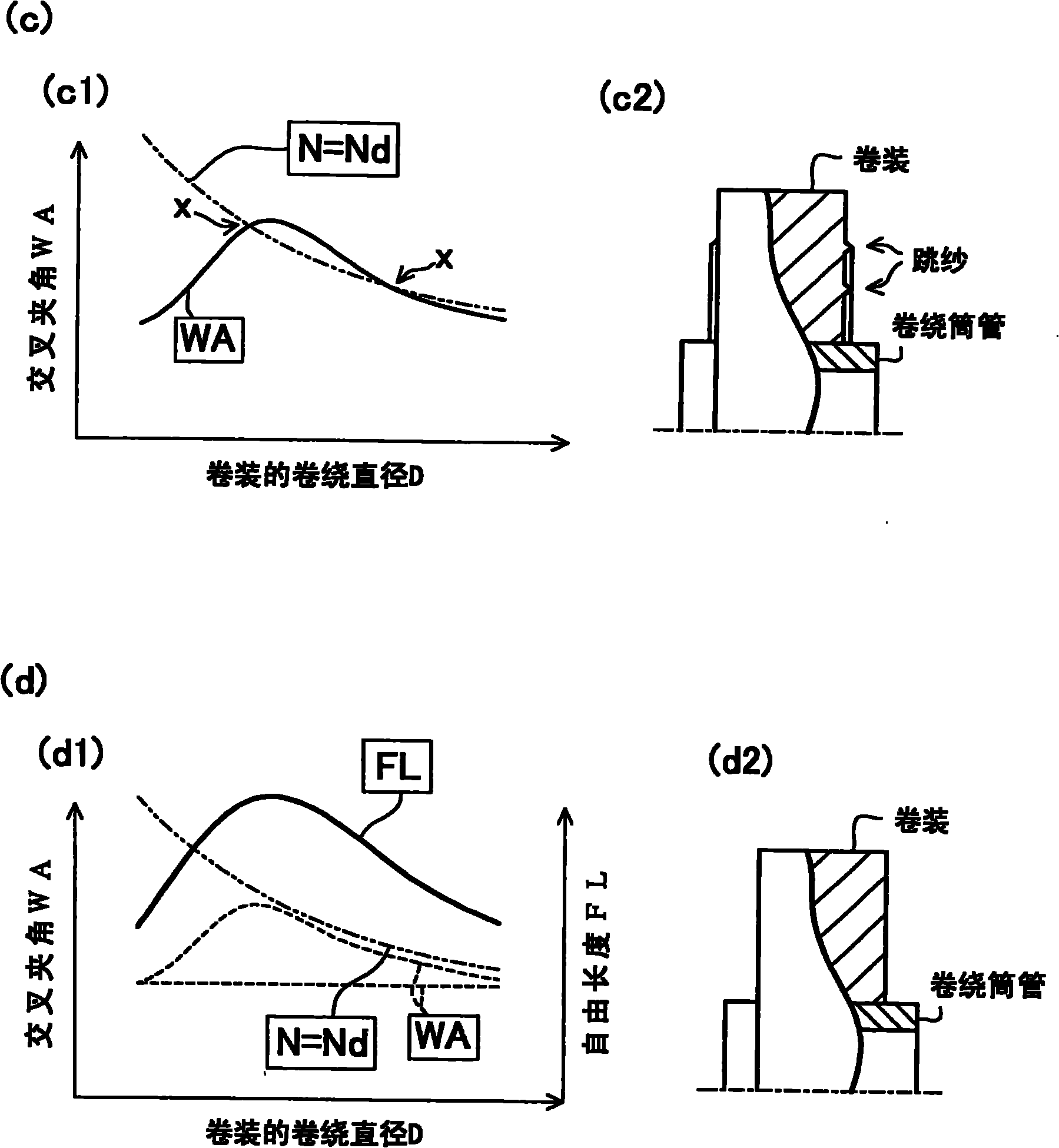

Method for avoiding ribbon windings

The invention relates to a method for avoiding ribbon windings in the production of winding-on bobbins which are wound as a 'randomly wound package' type on the workstations of textile machines which manufacture crosswound bobbins, by changing the crosswinding, with which the thread is wound onto the winding-on bobbin, wherein the workstations have in each case a single-motor drive which can be actuated in a defined manner for rotating the crosswound bobbin and a single-motor drive which can be actuated in a defined manner for an oscillating thread guide. According to the invention, there is provision for the diameters (DSP

Owner:OERLIKON TEXTILE GMBH & CO KG

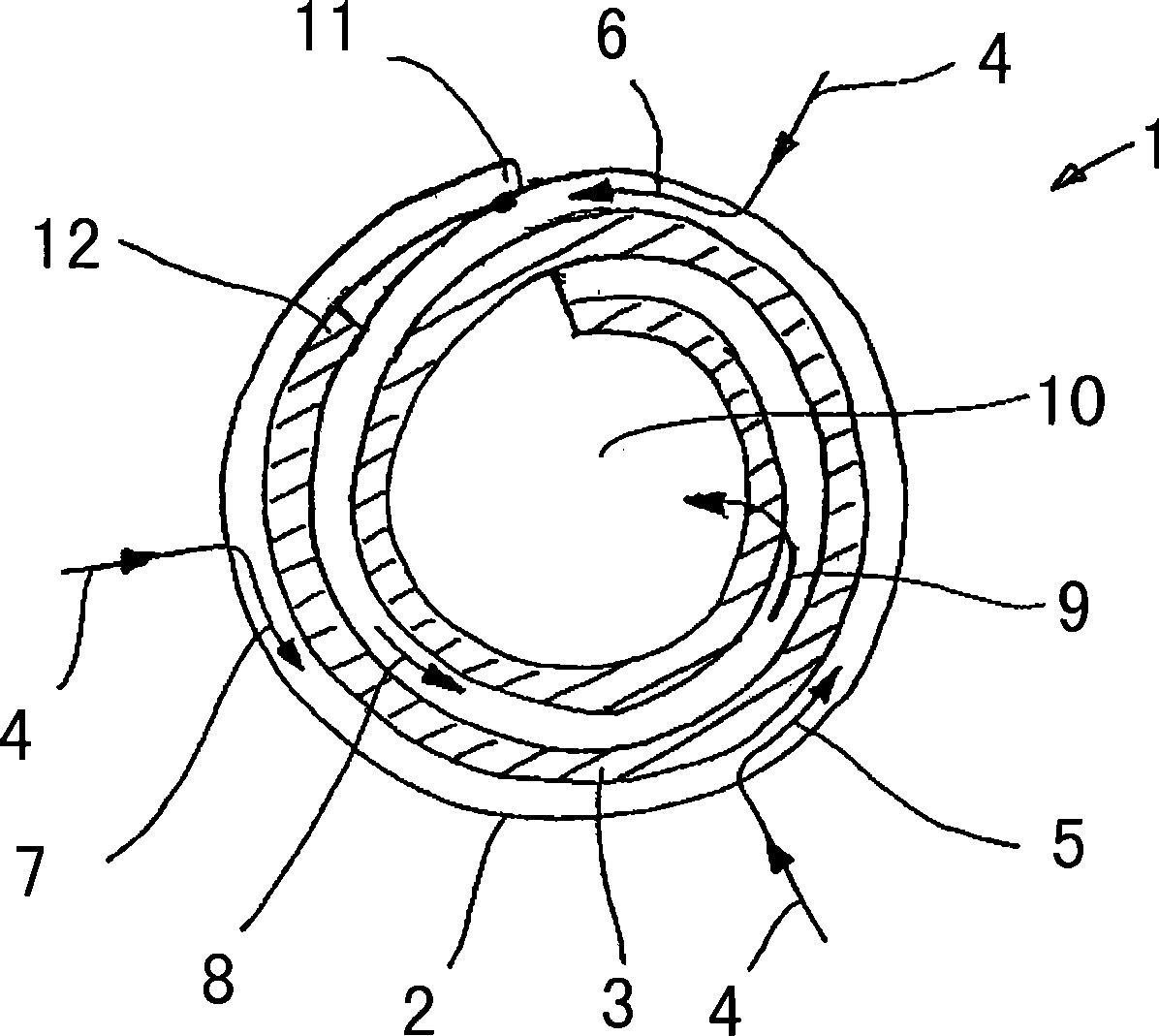

Filter element

InactiveCN101439242AUniform loadLow differential pressure riseStationary filtering element filtersAbsorption capacityFilter media

The invention relates to a filter element for filtering fluid for a motor or gearing, comprising a first filter medium which is arranged in a cylindrical way, with the fluid impinging in a perpendicular way on the circumferential surface of the first medium for filtering in an associated filter apparatus, then penetrating and passing through the same. The filter element comprises a second filter medium with a filter density differing from the first filter medium, the first filter medium and the second filter medium being stacked upon each other as filter layers and being jointly wound in a spiral manner. A desired purity of the fluid can thus be achieved more quickly than in filter elements which exclusively allow a radial passage of the fluid through the filter elements. The spiral configuration also achieves a higher dirt absorption capacity.

Owner:IBS菲尔特兰塑料金属产品有限责任公司

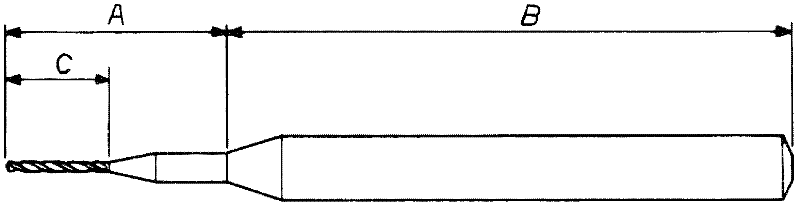

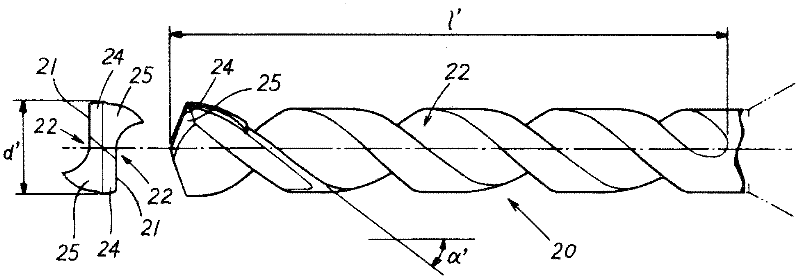

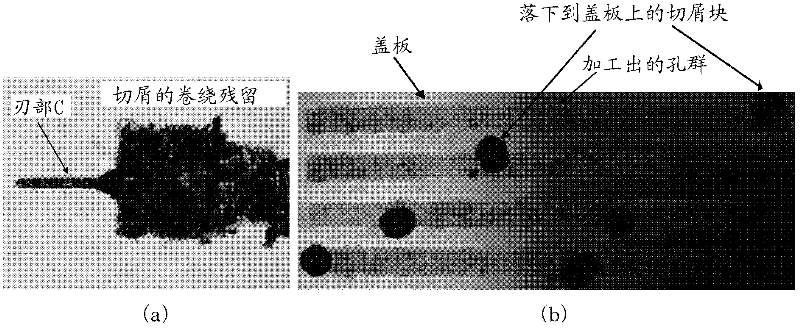

Drilling tool

ActiveCN102476209AAvoid windingLong breakage lifeTransportation and packagingPrinted circuit manufactureEngineeringDrill bit

Provided is a drilling tool, capable of preventing the cuttings from coiling. Even a drill with a small diameter can have a relatively long anti-damaging lifetime and realize excellent hole-site precision, stable drill processing, and excellent practical applicability. The tail end of the tool body is provided with one or a plurality of cutting edges. The periphery of the tool body is provided with a plurality of helical chip rooms in the direction toward base end side from tail end of the tool. The chip rooms comprise one main groove and more than one auxiliary grooves, wherein the auxiliary grooves are connected with the main groove at the midway section of the main groove. Moreover, the helical angles of the main groove and the auxiliary grooves are designed to have roughly equal angles from the connection setting section set by the connection between the main groove and the auxiliary grooves. The length of the auxiliary grooves is designed to be 50% to 95% of the length of the main groove. Also, the auxiliary grooves are set to be parallel to the main groove within a range from the connection setting section to a predetermined position away from the terminal of the main groove.

Owner:UNION TOOL

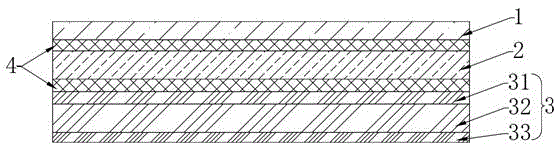

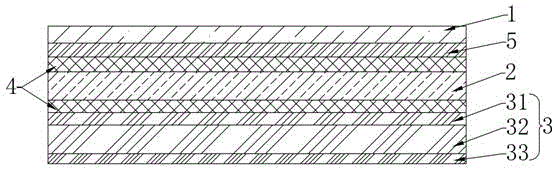

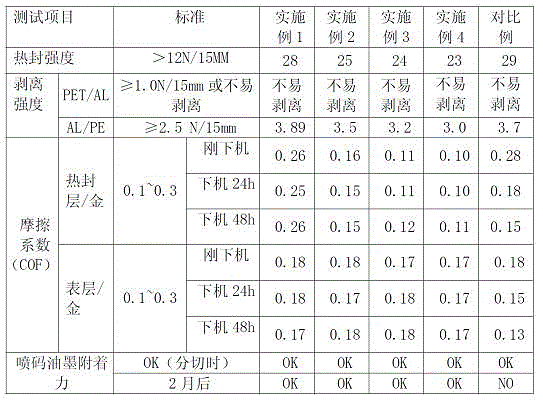

Composite membrane having stable friction coefficient and capable of being spurted with codes and preparation method of composite membrane

InactiveCN105667011AReduce coefficient of frictionImprove stabilityLamination ancillary operationsSynthetic resin layered productsSurface energySilicone resin

The invention discloses a composite film with a stable friction coefficient and which can be coded. It includes an outer layer, a barrier layer and a polyethylene co-extrusion film layer from the outside to the inside, and the polyethylene co-extrusion film layer includes a corona treatment layer from the outside to the inside. , a core layer and a heat-sealing layer. The material composition of the heat-sealing layer mainly includes polyethylene resin and a slip agent. The slip agent is a silicone slip agent masterbatch with polyethylene as a carrier. In the present invention, silicone slippery agent is added to the polyethylene co-extrusion film heat-sealing layer located inside the film, and it is extruded to the surface and evenly distributed during processing by utilizing its incompatibility with the main material to achieve The purpose of reducing the friction coefficient, and the molecular weight is large. Under the high temperature conditions during the film aging, storage and use, the silicone resin with low surface energy will not migrate and precipitate, and improve the stability of the friction coefficient of the inner surface of the film. Unwinding The speed meets the requirements of high-speed packaging machines. The invention discloses a method for preparing a composite film suitable for stable friction coefficient and capable of coding.

Owner:JIANGYIN SHENLONG PACKAGING MATERIALS CO LTD

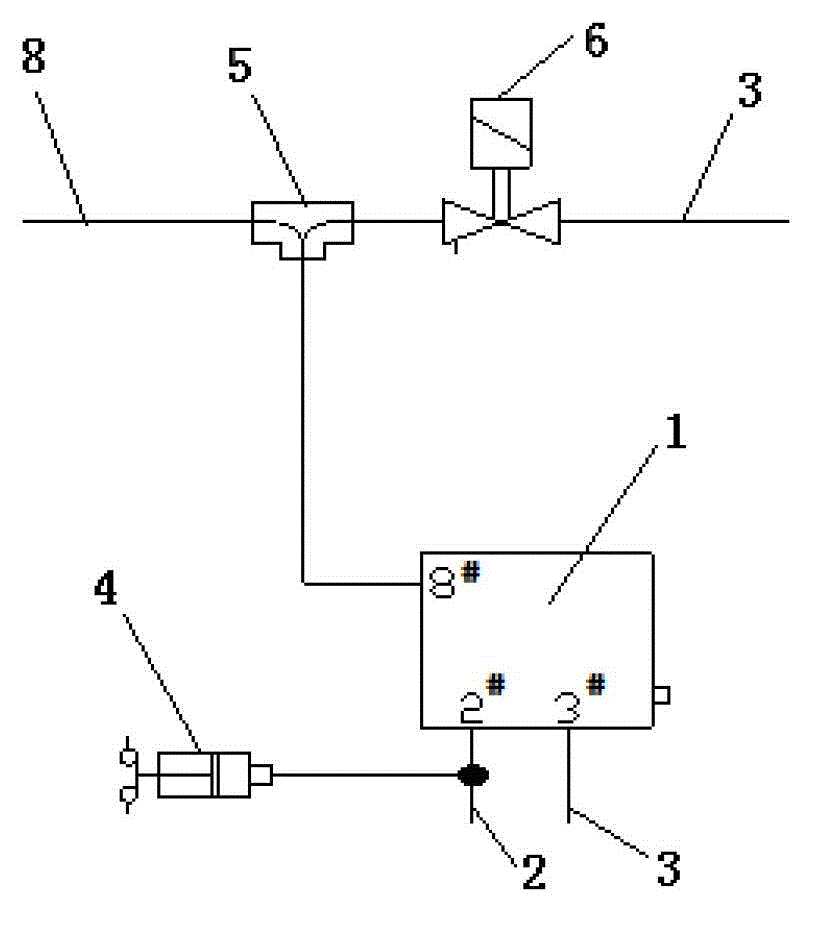

Automatic interruption device for emergent braking of relay valve of locomotive brake

The invention relates to an automatic interruption device for emergent braking of a relay valve of a locomotive brake. The automatic interruption device comprises a brake pipe, a train pipe and a relay valve of a blast pipe, air pressure of the brake pipe can interrupt aeration of the blast pipe to the train pipe, a pressure switch is installed on the train pipe, a makeshift valve is arranged between the brake pipe and the relay valve, the output end of the makeshift valve is connected with a relay valve port, one input end of the makeshift valve is connected with the brake pipe, and the other input end of the makeshift valve is connected with the blast pipe through an electromagnetic valve. A set of simple parts are matched with a locomotive to control a computer to enable the JZ-7 type brake to achieve automatic interruption effect under the condition that a non-brake valve triggers emergent braking. The automatic interruption device improves functions of the brake, improves brake safety, simplifies driver operation, avoids long-time air hitting of an air compressor and saves energy.

Owner:CRRC DALIAN CO LTD

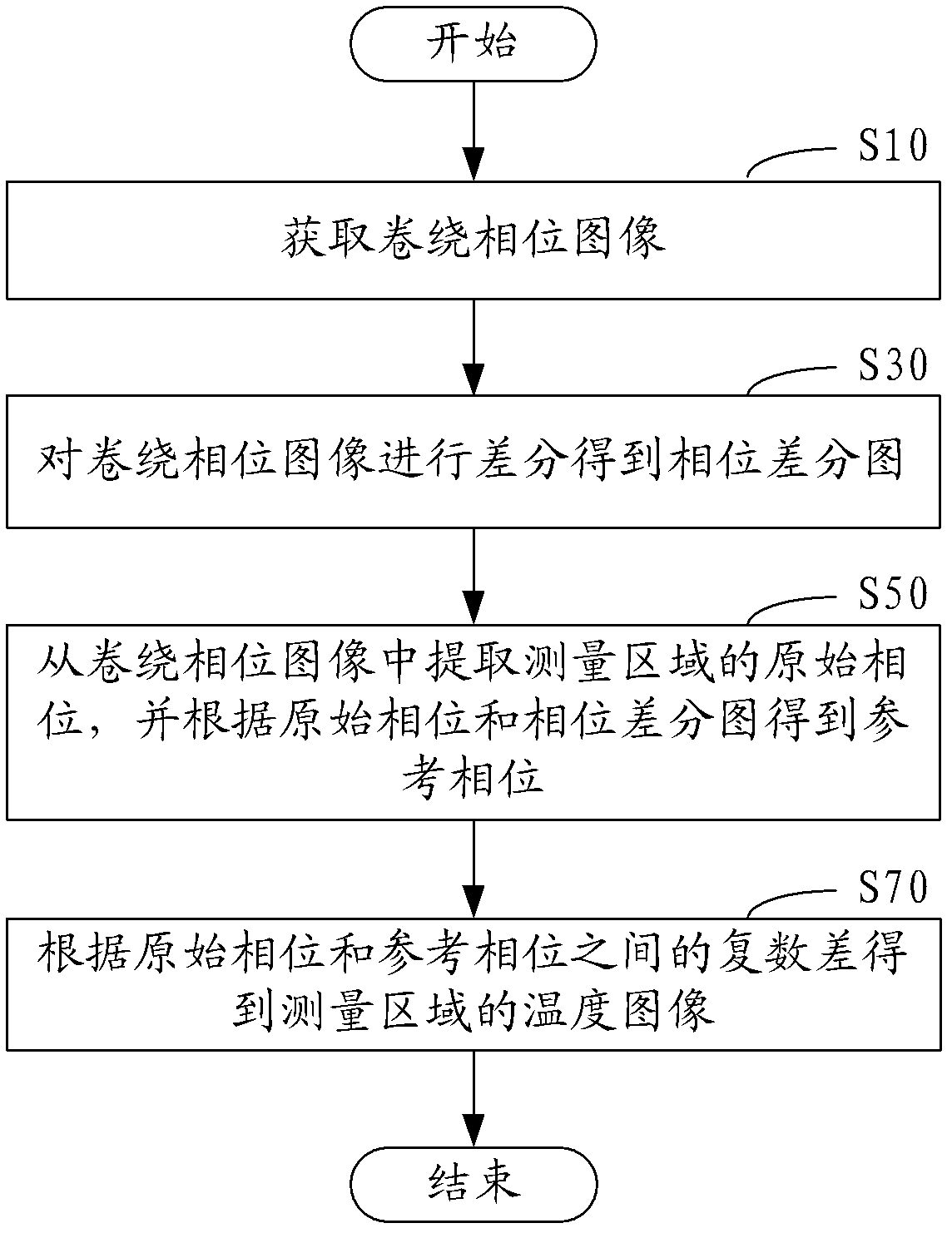

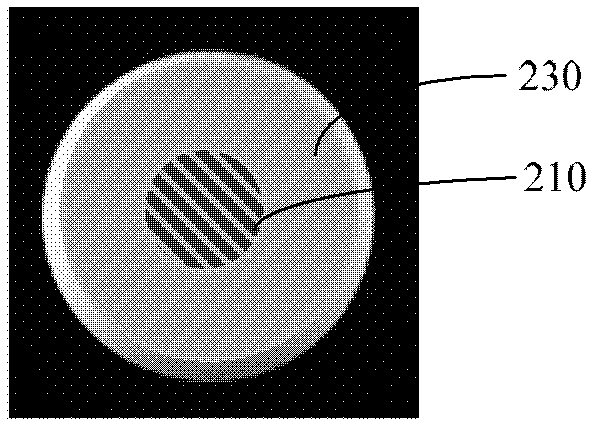

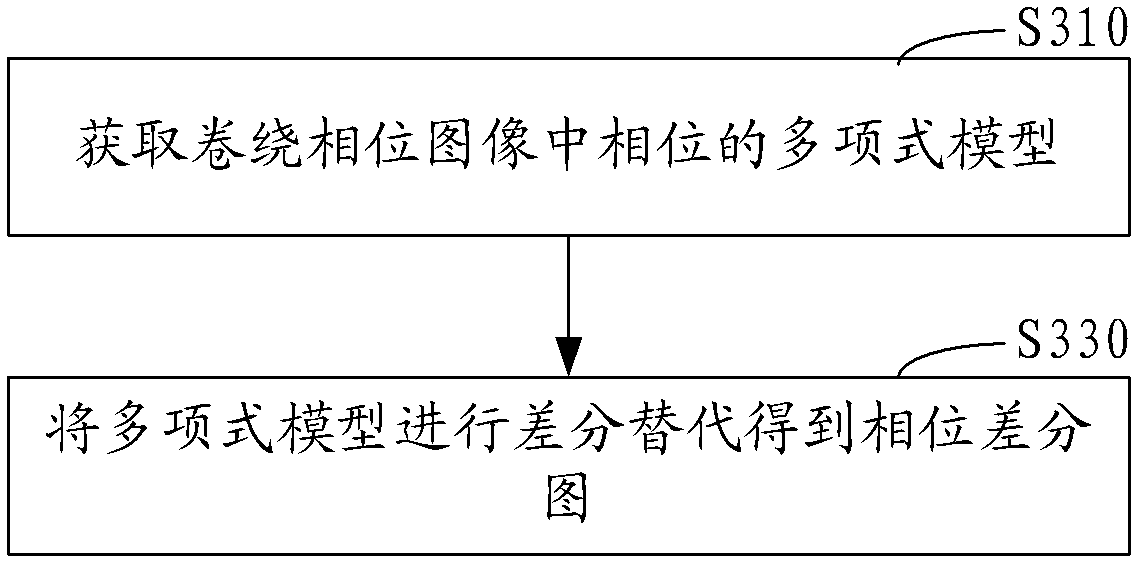

Temperature imaging method and system

InactiveCN102579015AAvoid windingCalculation speedDiagnostic recording/measuringSensorsPhase differencePhase unwrapping

The invention relates to a temperature imaging method which comprises the steps of acquiring a wrapping phase image; carrying out difference on the wrapping phase image to obtain a phase difference image; extracting an original phase of a measurement region from the wrapping phase image and obtaining a reference phase according to the original phase and the phase difference image; and obtaining a temperature image of the measurement region according to a complex difference between the original phase and the reference phase. According to the temperature imaging method and the temperature imaging system, the phase difference image is obtained by carrying out difference on the wrapping phase image, and the two-dimensional phase unwrapping is avoided, so that the computation speed is greatly improved, and the requirement of temperature imaging on the real-time property is further met on the premise of not losing the accuracy.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

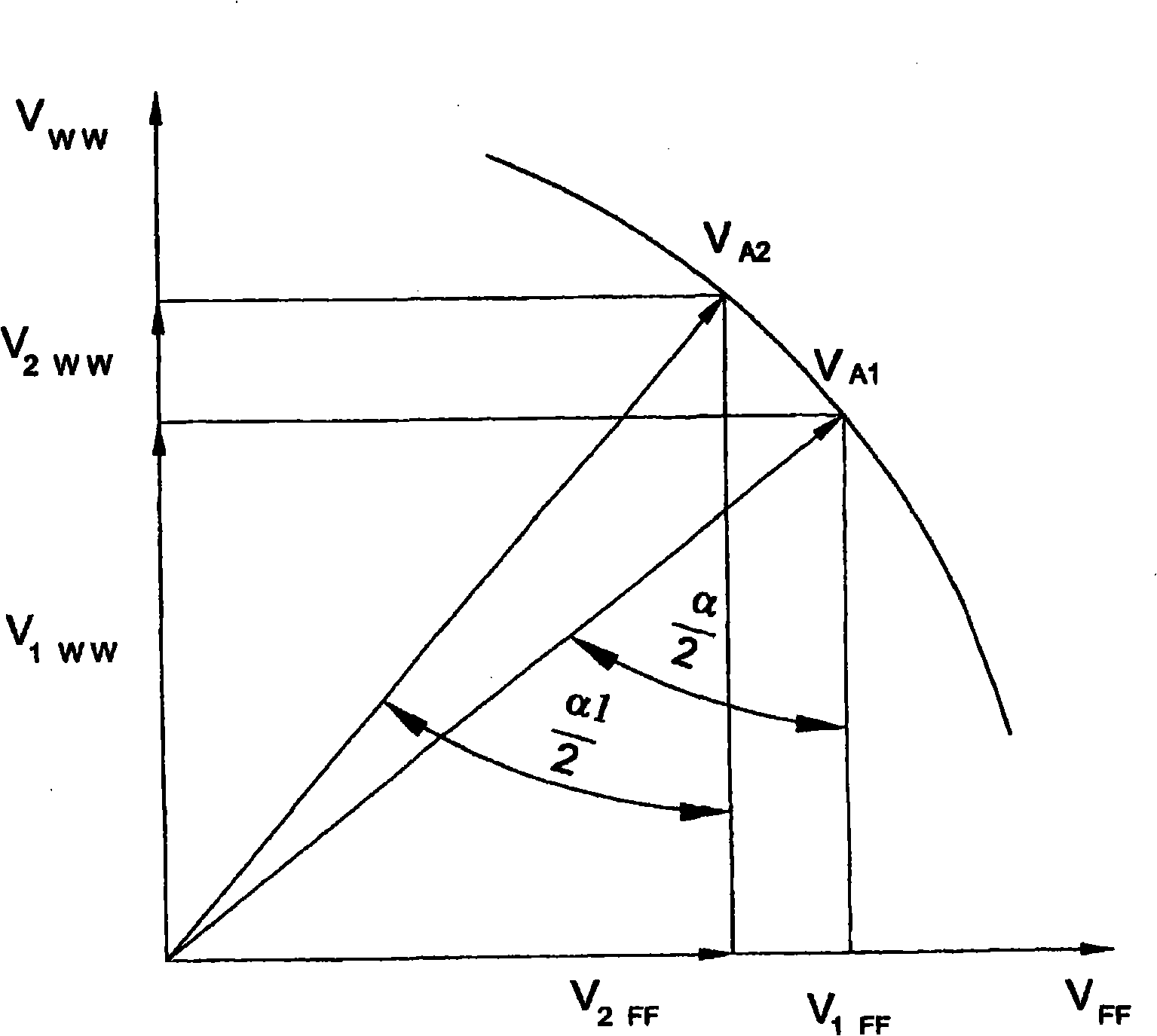

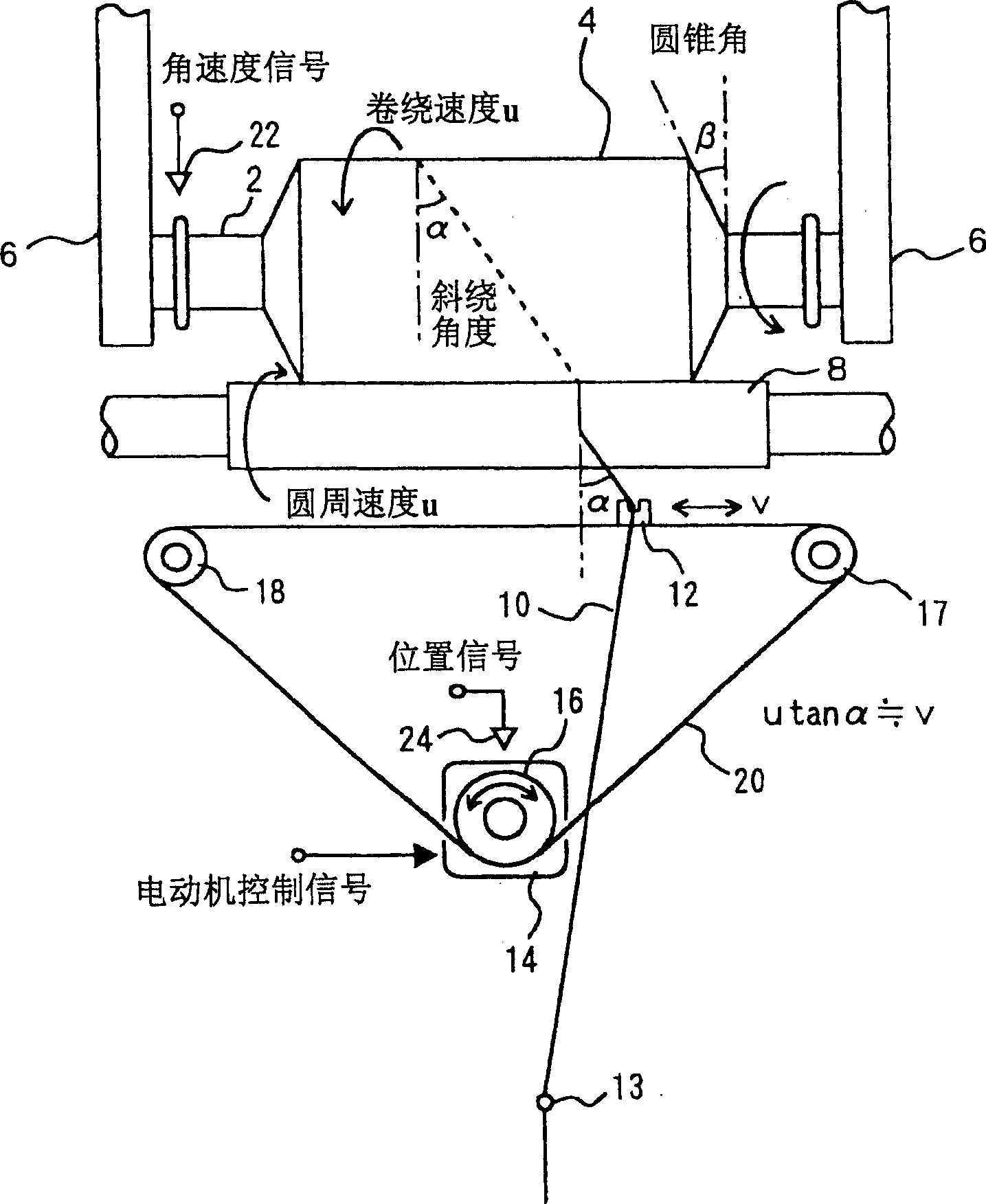

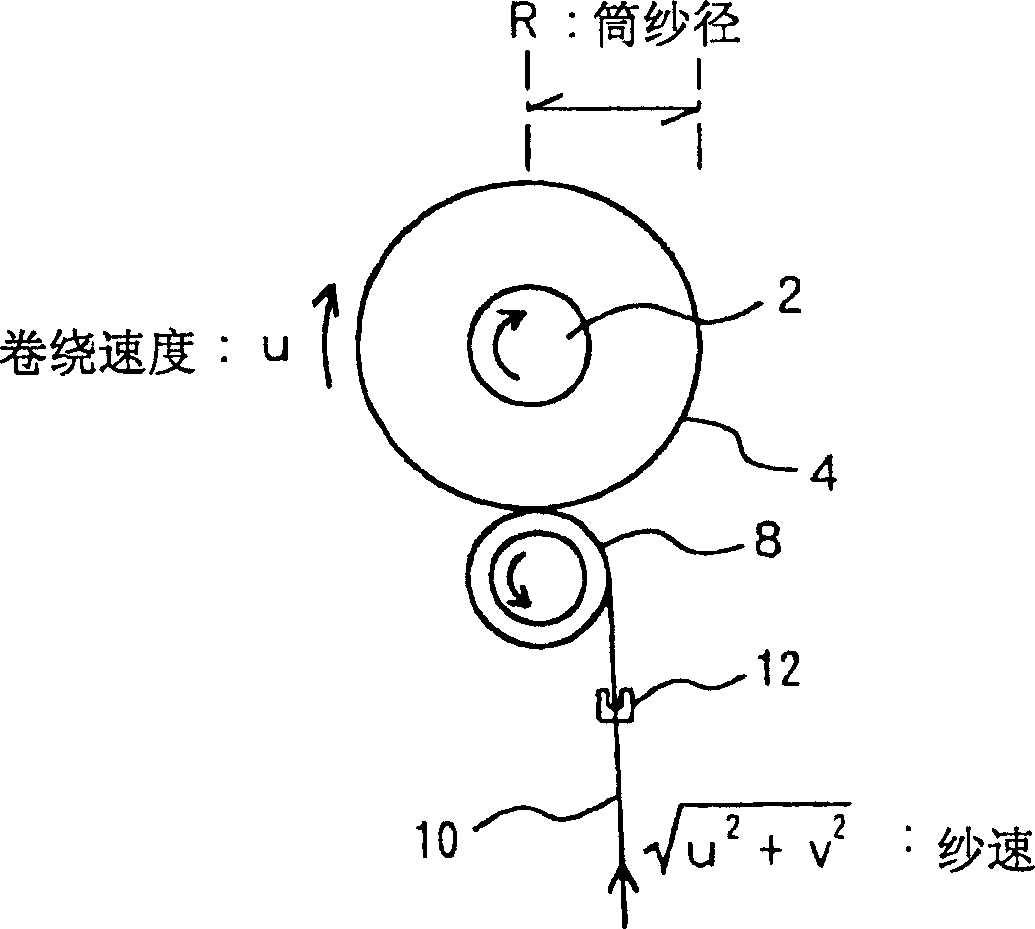

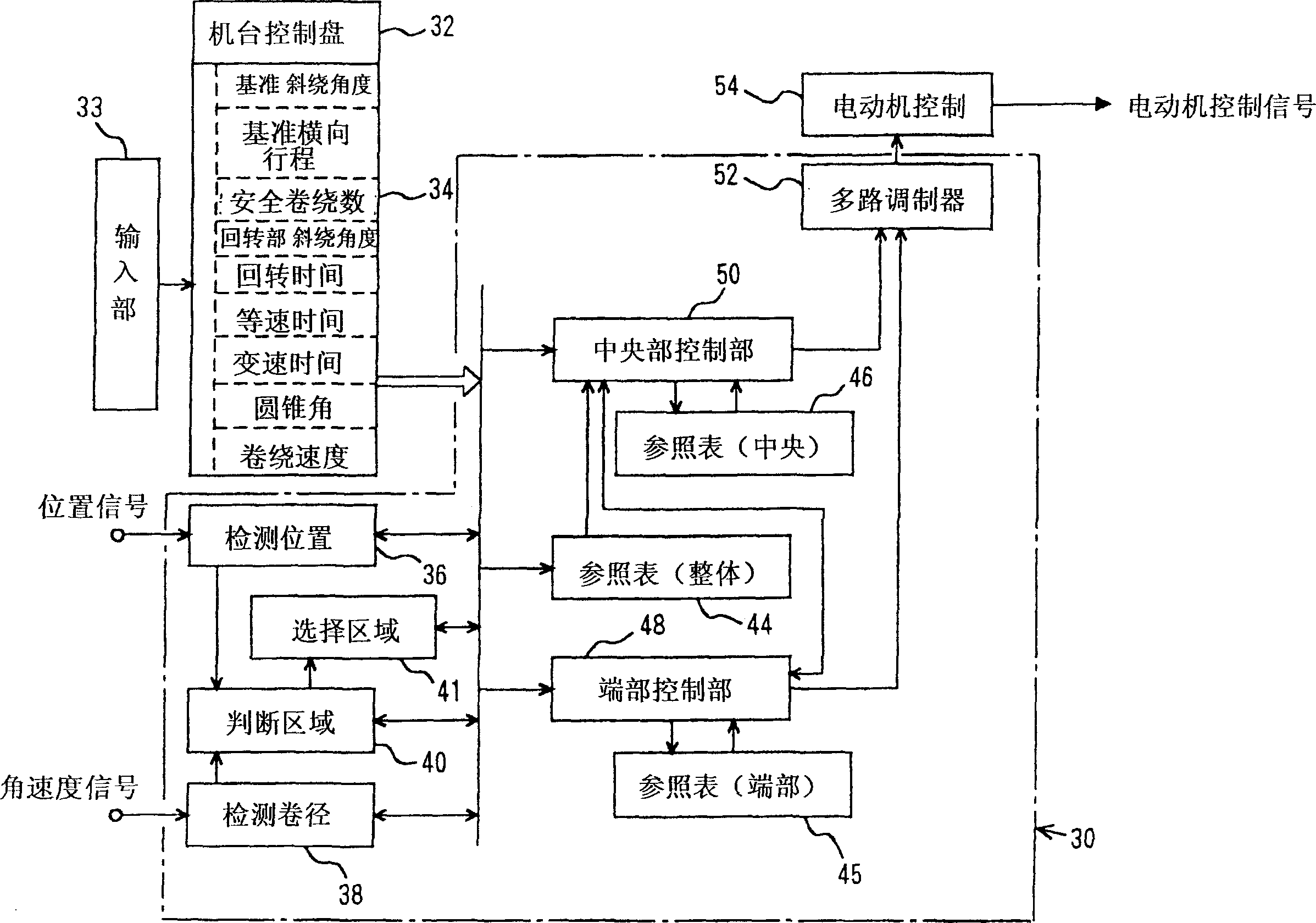

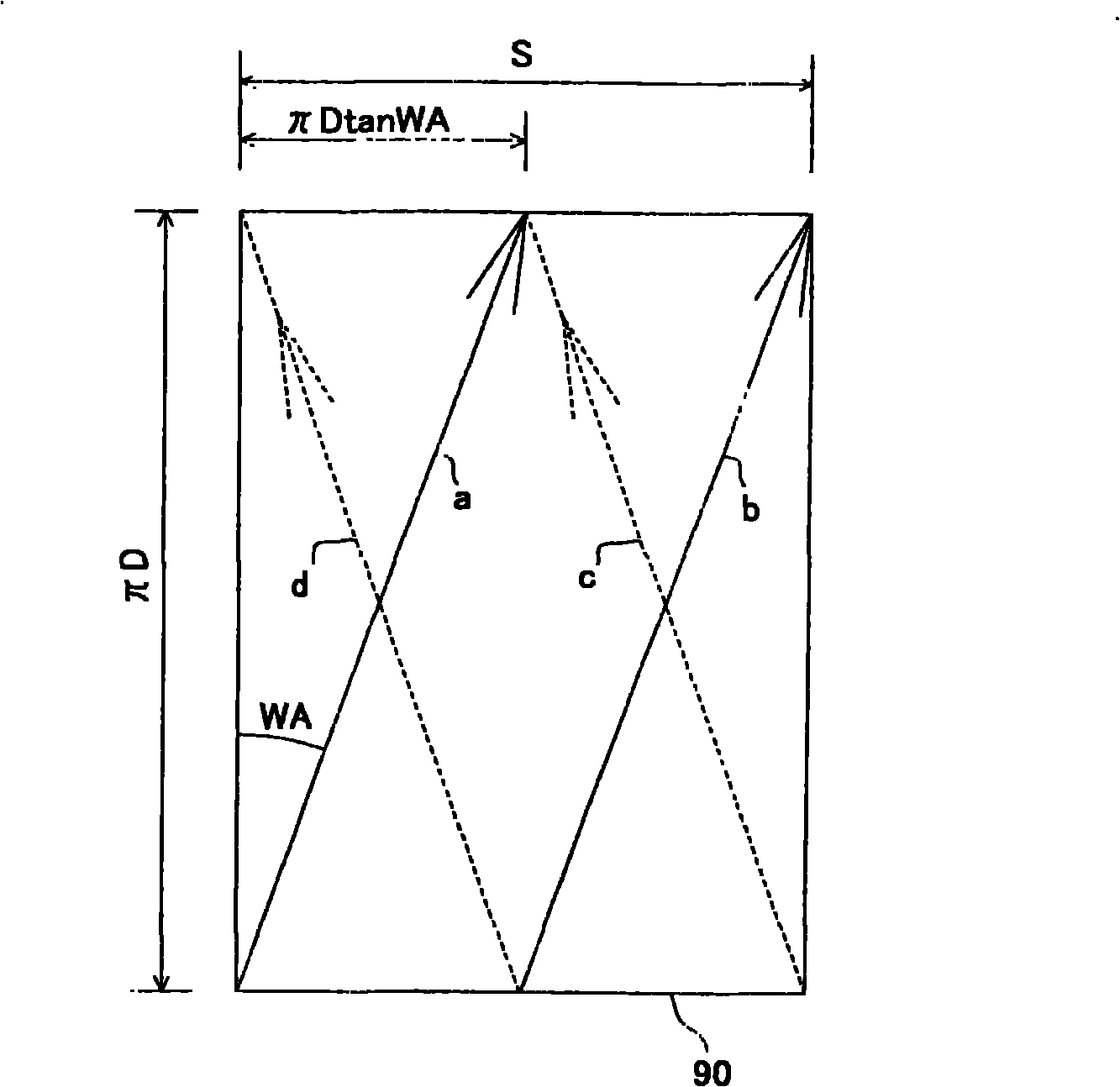

Method and device for winding yarn

Control the oblique winding angle curve of the central part when the bobbin is wound by segmental precision winding, etc., so that the trajectory of the yarn path on the rotary part is constant, and the curve is wound with a specified oblique winding angle to obtain the desired Desired number of windings.

Owner:MURATA MASCH LTD

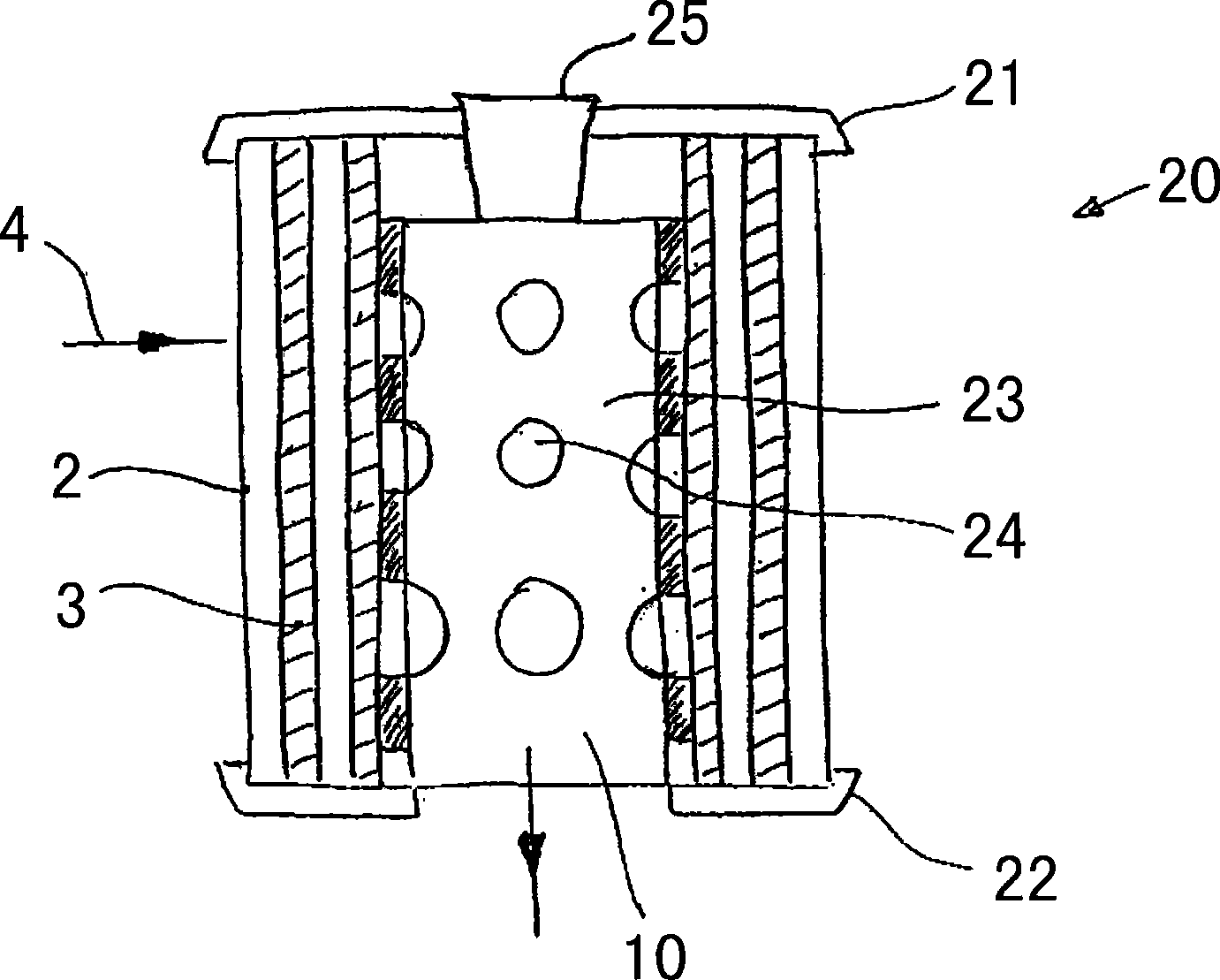

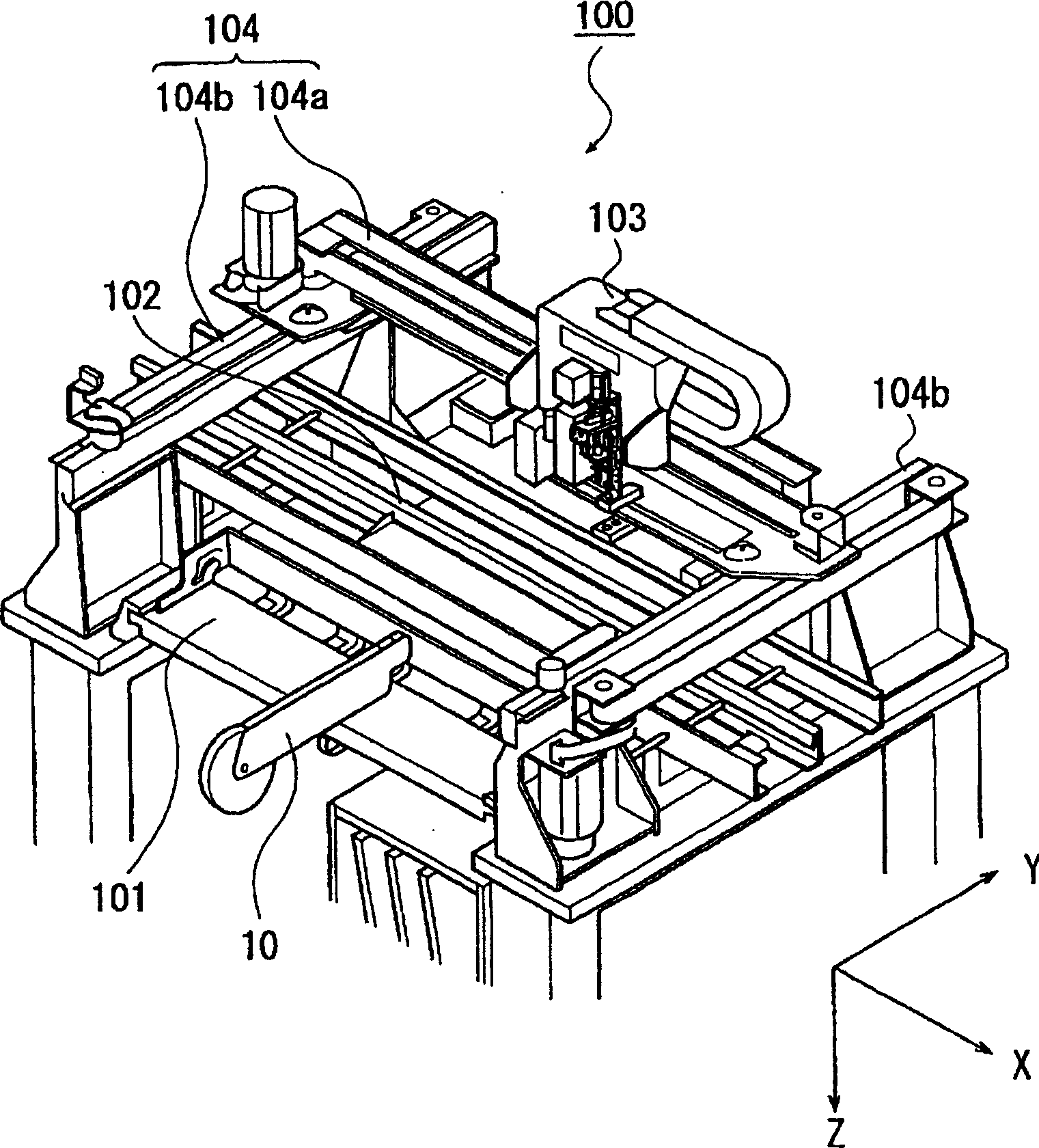

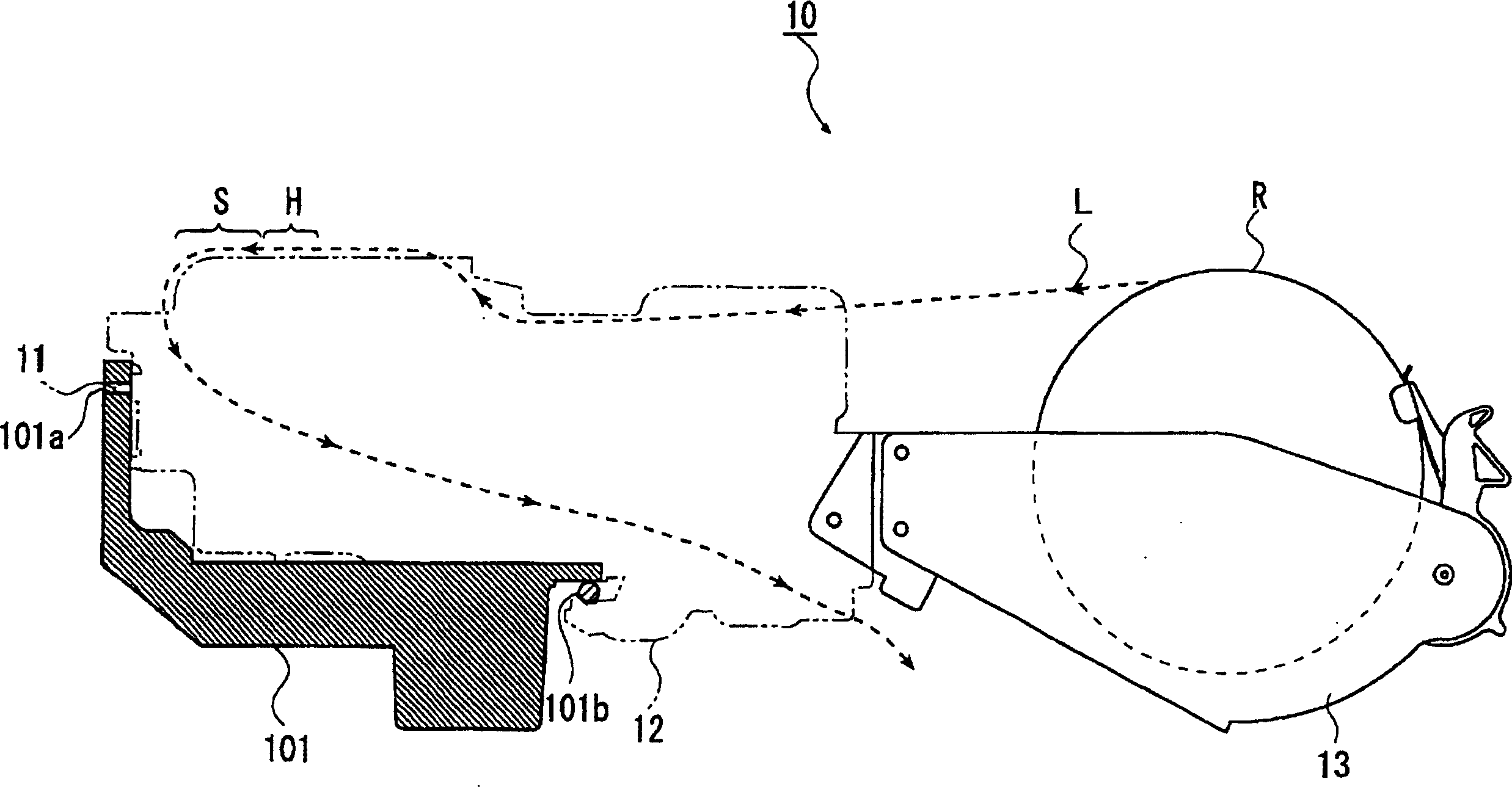

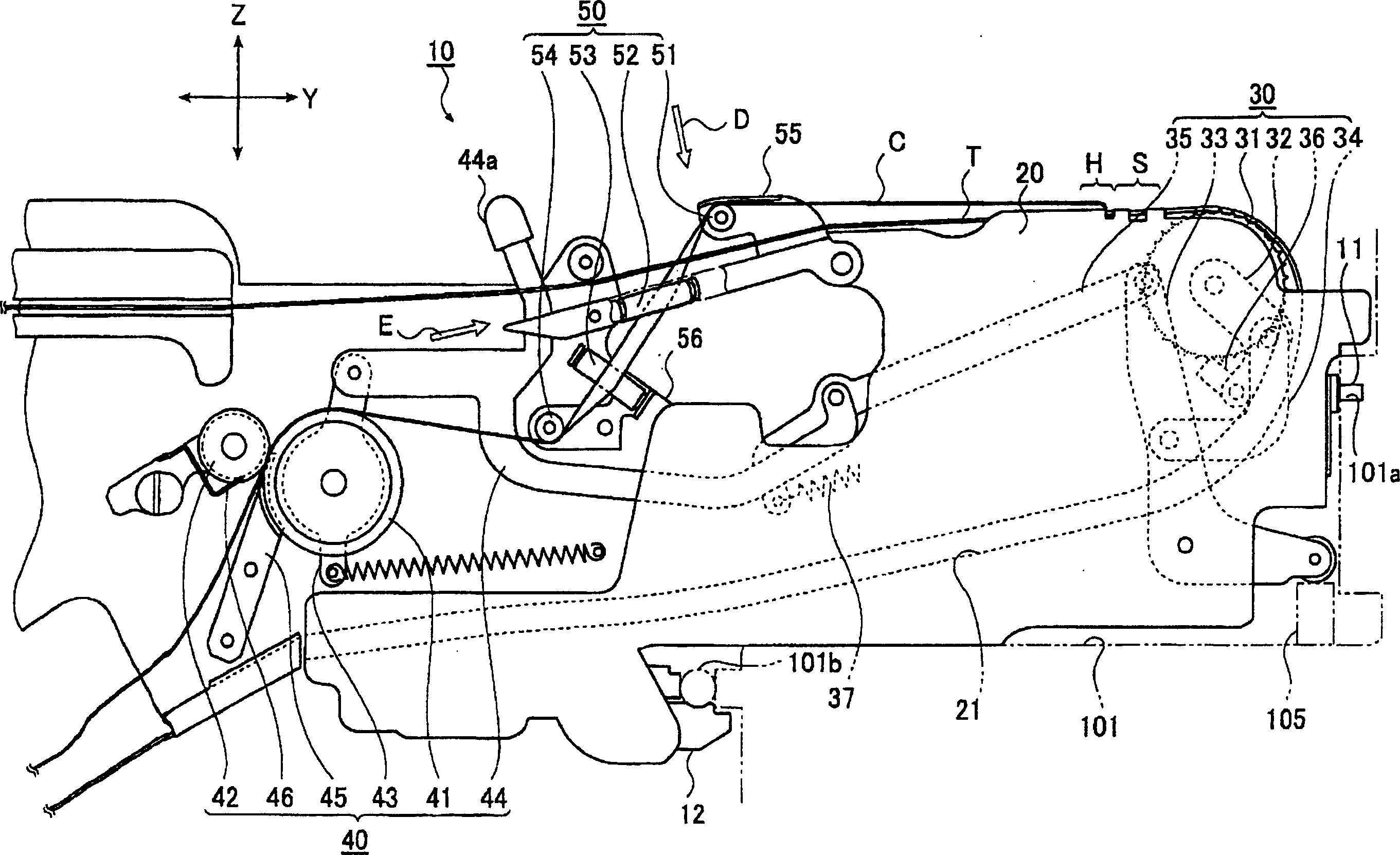

Electronic device supplier

InactiveCN1691886AStable and well handledSecure spaceElectrical componentsEngineeringElectronic component

An electronic component feeding apparatus 10 is loaded on an electronic component loading device 100 for feeding an electronic component. The electronic component feeding apparatus comprises a reel holder 13 for holding a reel R around which a carrier tape T is wound for holding the electronic component at a uniform interval in the lengthwise direction, a frame 20 including a carrier path 21 for guiding the carrier tape from the reel holder to at least an electronic component delivery position S to the electronic component loading device, and a cover sending mechanism 40 for feeding a cover tape C which is separated from the carrier tape guided on the carrier path to a predetermined discarding direction. The cover sending mechanism comprises a feeding roller 41 of which the outer periphery is comprised of an elastic body 41a, and a winding guide 42 for winding the cover tape around at least a portion of the outer periphery of the feeding roller.

Owner:JUKI CORP

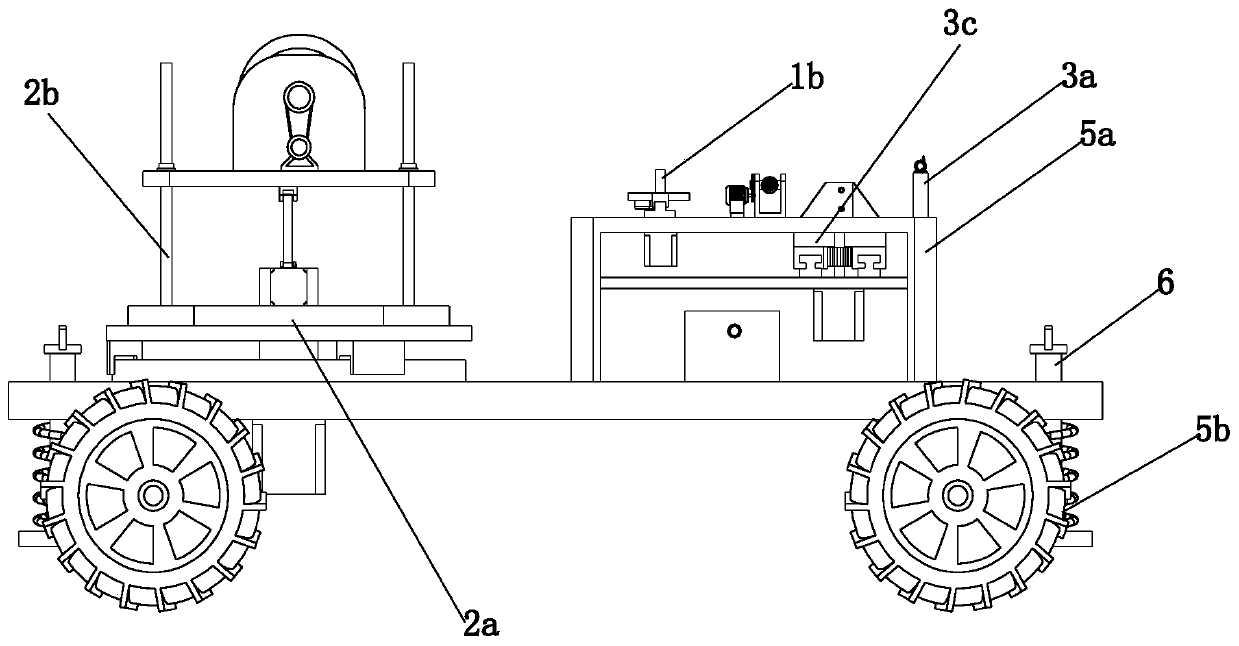

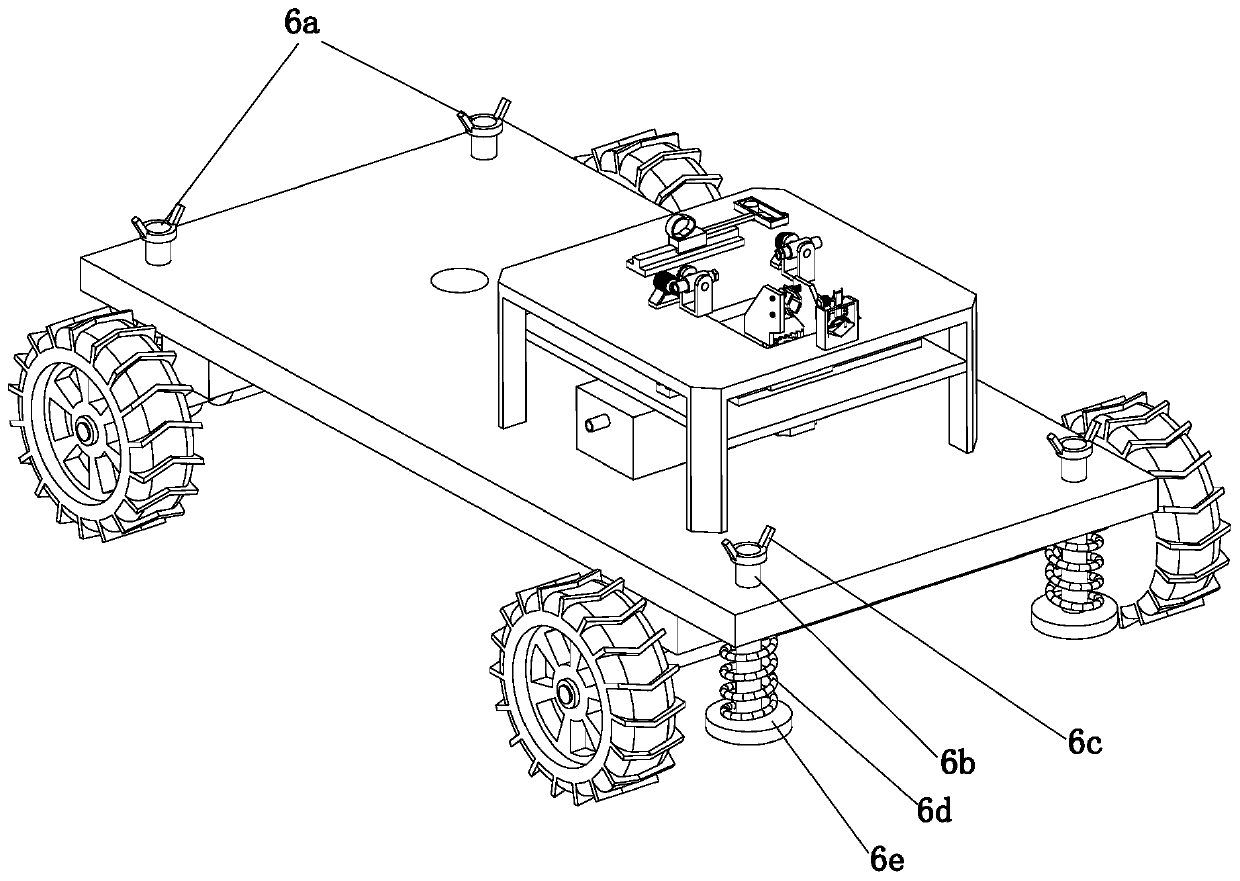

Cable winding control method for underground coal mine fully mechanized coal mining face

ActiveCN111099455AChange position automaticallyImprove winding efficiencyCleaning using toolsDrive wheelMining engineering

The invention discloses a cable winding control method for an underground coal mine fully mechanized coal mining face, and belongs to the technical field of underground coal mine fully mechanized coalmining face equipment. The control method is realized based on a cable winding device, wherein the cable winding device comprises a winding mechanism, a rotating mechanism, a guide mechanism, a waterstain blow-drying mechanism and a bottom plate; a bearing frame is arranged at the top of the bottom plate; four driving wheels which are distributed in a matrix mode are arranged at the bottom of the bottom plate; an anti-shaking assembly is arranged on the bottom plate; the winding mechanism comprises a winding assembly and an orderly winding assembly; and the guide mechanism comprises a positioning assembly and an abutting assembly which are arranged at intervals. According to the method, a cable can be guided through the guide mechanism, so that the cable which is knotted and clustered isprevented from being wound; the cable can be orderly wound on a winding drum through the orderly winding assembly, and a worker does not need to manually carry out winding operation; and the positionof the cable can be automatically changed through the rotating mechanism, so that the worker can conveniently recycle the cable on the winding drum.

Owner:浙江黎盛新材料科技有限公司

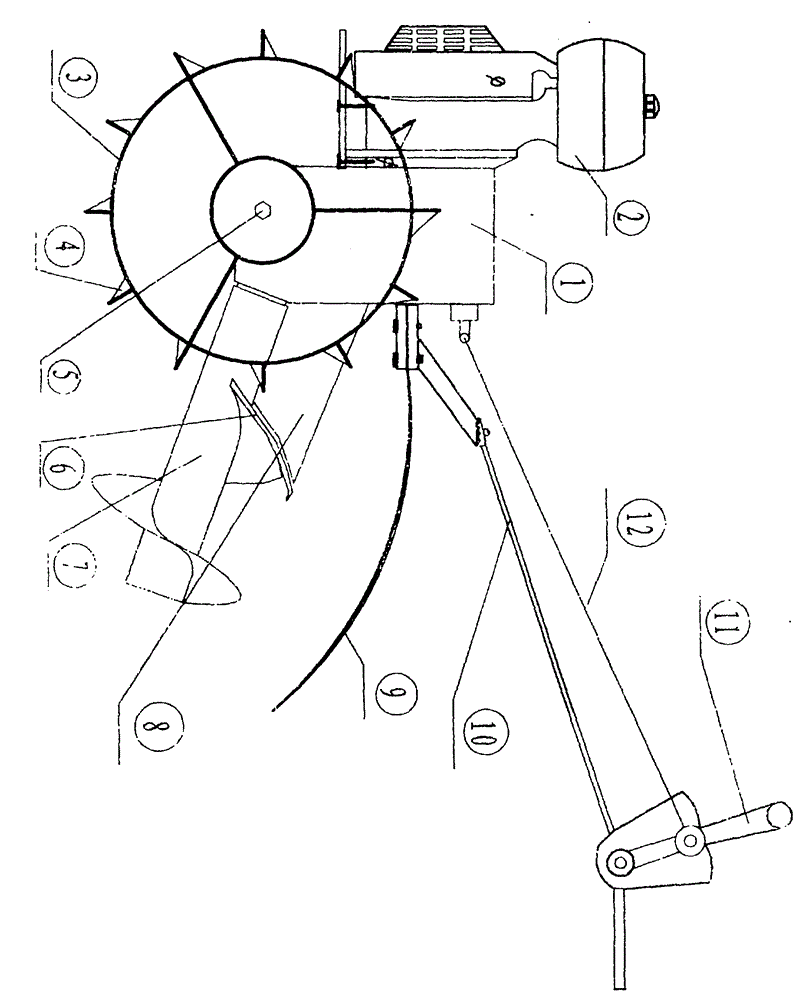

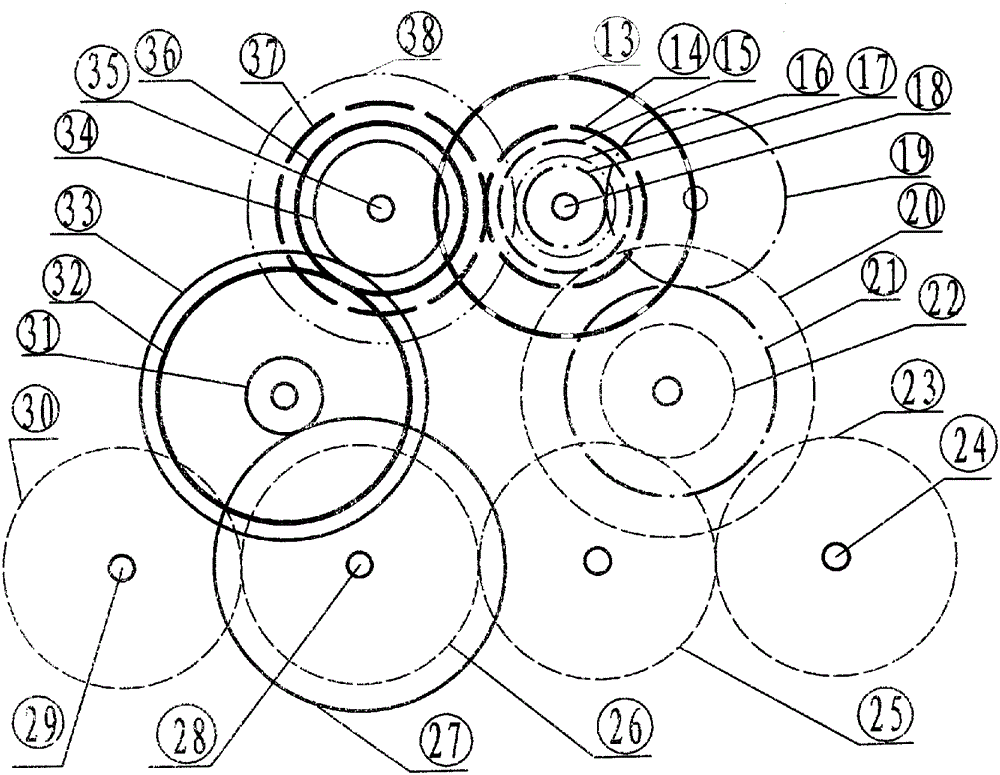

Tillage method for tilling firm ground, muddy land and weed land and multifunctional tillage machine thereof

InactiveCN105103695ALarge Tilling WidthImprove efficiencyPlantingMowersAgricultural engineeringTillage

The invention discloses a tillage method for tilling firm ground, muddy land and weed land and a multifunctional tillage machine corresponding to the tillage method, and relates to a land tillage method and a tillage machine used in the method. According to the tillage method, by means of a special tillage tool designed for the firm ground, the muddy land and the weed land, when the tool tills the firm ground in a milling mode, the machine does not vibrate, thrust force can be generated when the tool works in the muddy land, the tool is not deep-set, and the tool can be used for cutting, irrigation, hoeing and rotary tillage of the weed land. The multifunctional tillage machine corresponding to the tillage method comprises a handle frame (10), a main box (1), a power machine (2), a traction wheel (3) and multi-power shafts (24 and 29) downwards inclined and arranged below the rear portion of the main box (1). The multi-power shafts (24 and 29) is provided with a power shaft extension box (48) according to actual production requirements, more multi-power shaft modes which must be in an even number can be extended, or the tillage tool is directly installed. Multifunctional work of cutting, irrigation, hoeing, rotary tillage, ditching and pit digging can be achieved through the tillage machine under any condition of hilly and mountainous areas and plain areas.

Owner:陈世福

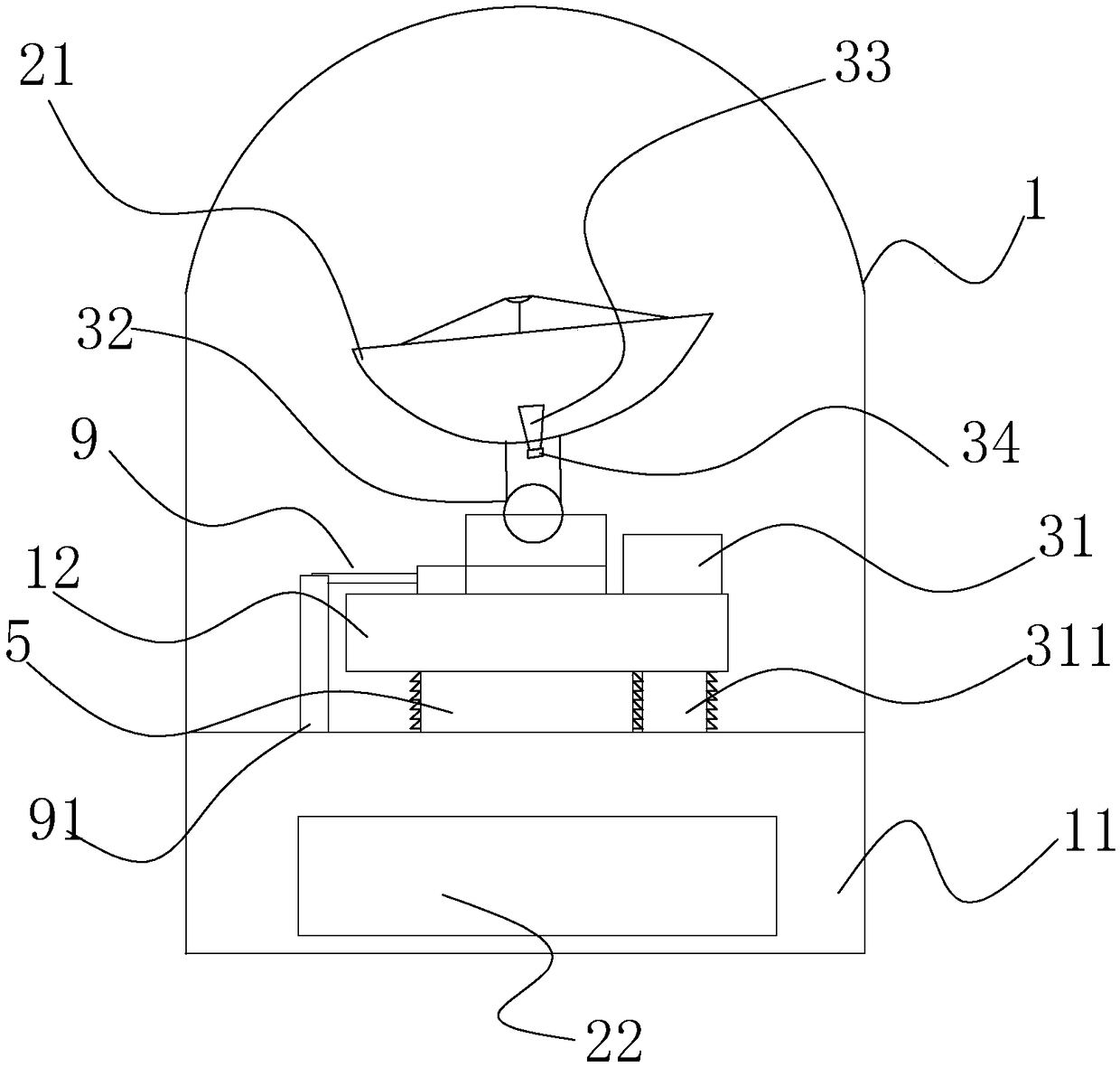

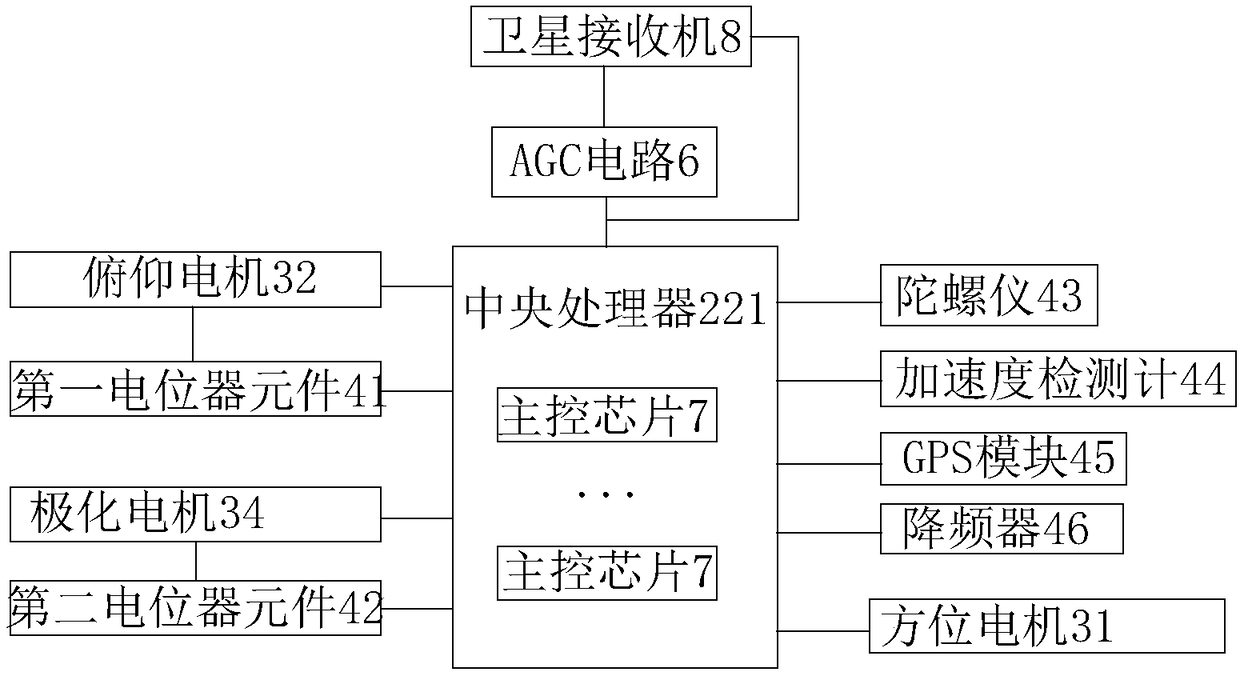

Marine satellite antenna

ActiveCN108281756AHigh strengthStrong weather resistanceAntenna adaptation in movable bodiesRadiating element housingsSatellite trackingClosed loop

The invention discloses a marine satellite antenna. The marine satellite antenna comprises an antenna outer cover with a base, and an antenna system positioned in the antenna outer cover; the marine satellite antenna is characterized in that the antenna system comprises a parabolic antenna arranged on the base and a control circuit arranged in the base; the parabolic antenna is mounted on the basethrough a mounting base; an azimuth-drive motor capable of controlling circumferential rotation of the mounting base is arranged on the mounting base; a pitching motor connected to the parabolic antenna and capable of controlling the parabolic antenna to perform pitching rotation is arranged on the mounting base; a feed source is arranged in the parabolic antenna; a polarized motor capable of controlling the feed source to rotate is arranged below the parabolic antenna; the azimuth-drive motor, the pitching motor and the polarized motor are all connected to the control circuit; and the control circuit comprises a central processing unit and a closed-loop control circuit connected to the central processing unit. The marine satellite antenna has the advantages of high response speed, in-time satellite tracking and the like.

Owner:宁波迪泰科技股份有限公司

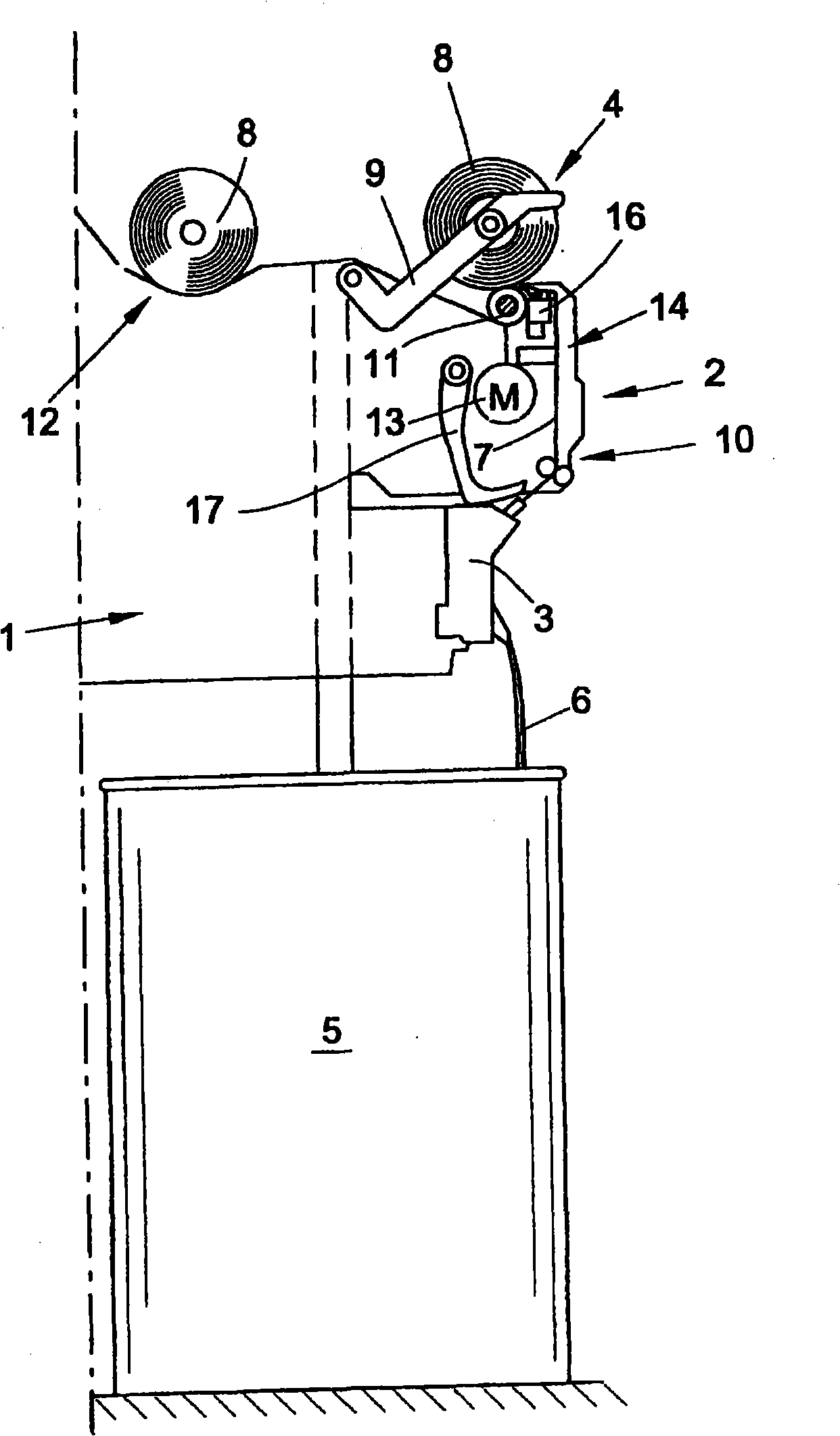

Yarn winding machine and yarn winding method

ActiveCN101804925AReduce the increase and decreaseCompact structureFilament handlingWinding machineYarn

The present invention provides a technique to prevent possible ribbon winding regardless of yarn type while inhibiting possible bulging. The winder 1 includes a contact roller 8 configured to come into contact with a package 4 during formation of the package 4, a traverse device 7 located upstream side of the contact roller 8 in the traveling direction of an elastic yarn 2, a free length varying means 9 for enabling the free length FL of the elastic yarn 2 located between the contact roller 8 and the traverse device 7 to be varied during formation of the package 4, and a control section 80 configured to control the free length varying means 9 in such a manner that the free length FL is increased during winding start of the package 4 and then reduced toward winding end.

Owner:TMT MACHINERY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com