Composite membrane having stable friction coefficient and capable of being spurted with codes and preparation method of composite membrane

A technology of friction coefficient and composite film, which is applied in the field of stable friction coefficient and printable composite film and its preparation. The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

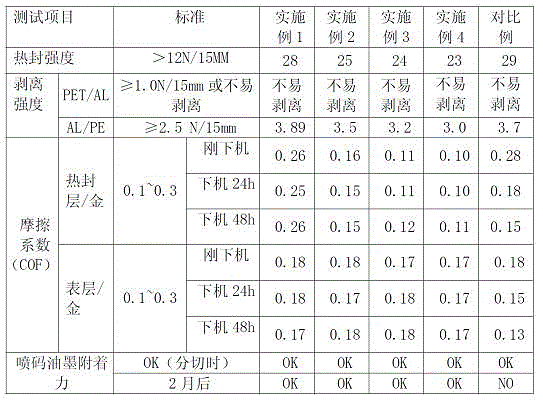

Embodiment 1

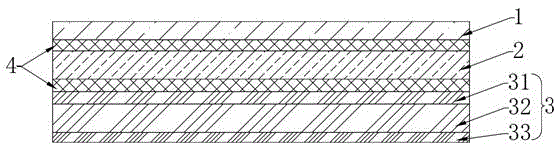

[0027] Such as figure 1 As shown, the friction coefficient of Example 1 is stable and the composite film that can be coded is composed of outer layer 1 (PET polyester film), polyurethane adhesive layer 4, barrier layer 2 (aluminum foil), polyurethane adhesive layer 4, Polyethylene co-extrusion film layer 3, polyethylene co-extrusion film layer 3 includes corona treatment layer 31, core layer 32, heat sealing layer 33 from outside to inside; corona treatment layer, core layer and heat sealing layer are blown film co-extruded. The thickness of the polyethylene co-extruded film layer is 50 μm; the thickness of the outer layer 1 PET polyester film is 12 μm, and the thickness of the barrier layer is 7 μm.

[0028] Embodiment 1 is not through printing, and preparation process is:

[0029] S1: Preparation of polyethylene co-extruded film layer, the components of each layer are configured according to the proportion, and the composition of the heat seal layer contains silicone slip ...

Embodiment 2

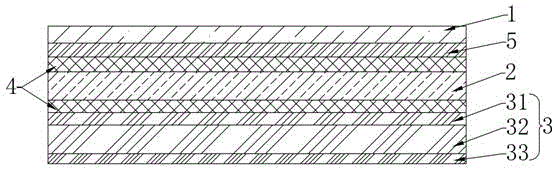

[0033] Such as figure 2As shown, the difference between Example 2 and Example 1 is that in the composition of the heat-sealing layer, the weight percentage of the slip agent is 4.5%, the weight percentage of the inorganic anti-blocking agent silicon dioxide is 0.5%, and the rest is linear low-density polystyrene. A blend of ethylene and low-density polyethylene, the weight percent of linear low-density polyethylene in the polyethylene resin is 34%, and the mixing ratio of linear low-density polyethylene and low-density polyethylene in the corona treatment layer and core layer is the same as that of the heat-sealing layer The outer layer is a PET polyester printing film, and the ink used is an alcohol-soluble ink. The PET polyester printing film includes a PET polyester film and an ink layer 5 from the outside to the inside.

[0034] The difference in preparation process is:

[0035] First, the printing process of PET polyester film, in the case of 50-60 ° C, use alcohol-solu...

Embodiment 3

[0038] The difference between Example 3 and Example 2 is: in the composition of the heat-sealing layer, the percentage by weight of the slippery agent is 10%, the percentage by weight of the inorganic anti-blocking agent silicon dioxide is 2%, and the linear low-density polyethylene in the polyethylene resin The weight percentage is 67%; the mixing ratio of linear low-density polyethylene and low-density polyethylene in the corona treatment layer and the core layer is the same as that of the heat-sealing layer.

[0039] The difference in preparation process is:

[0040] The coating amount of polyurethane two-component dry composite glue is 3.25gsm, the composite tension is controlled at 35%, the curing temperature of the composite film is 45°C, and the curing time is 48h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com