Patents

Literature

75results about How to "No migration will occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

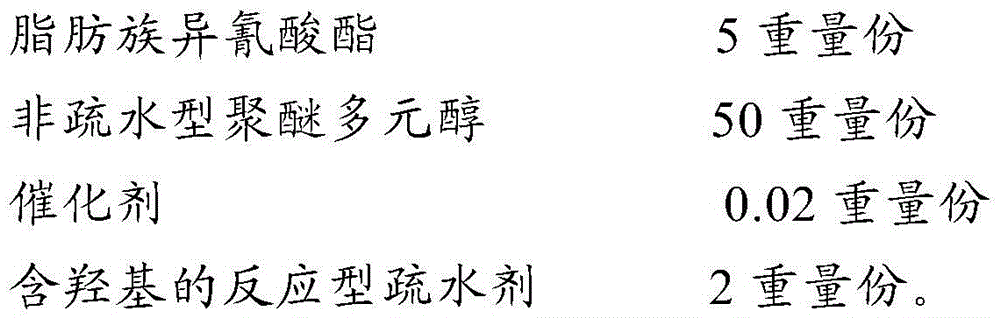

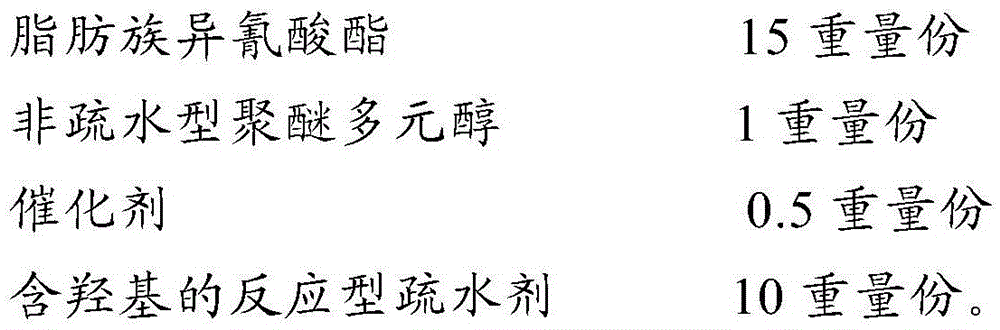

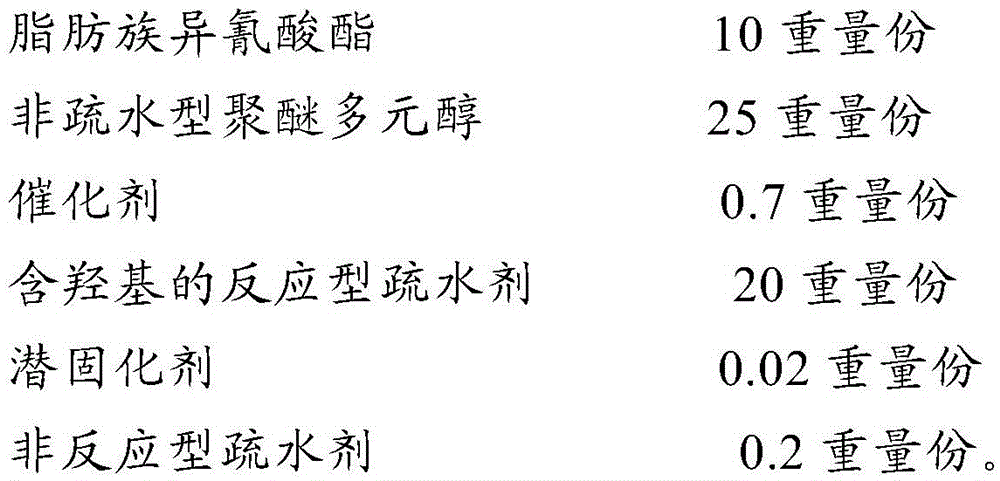

One-component polyurethane waterproof paint and preparation method thereof

ActiveCN105567072AGood weather resistanceColorfulPolyurea/polyurethane coatingsPolyolChemical reaction

The invention discloses one-component polyurethane waterproof paint and a preparation method thereof. The one-component polyurethane waterproof paint is prepared from aliphatic isocyanates, non-hydrophobic polyether polyol, catalysts, a hydroxyl containing reactive hydrophobic agent. The hydroxyl containing reactive hydrophobic agent in the one-component polyurethane waterproof paint is hydrophobic and highly compatible to other components, and accordingly compatibility of prepolymers generated by the hydroxyl containing reactive hydrophobic agent and the aliphatic isocyanates to other components of the one-component polyurethane waterproof paint is improved, and precipitation of the hydrophobic agent is avoided. Due to hydrophobility of the prepolymers, the one-component polyurethane waterproof paint is hydrophobic; since the hydroxyl containing reactive hydrophobic agent is combined into a molecular structure of polyurethane through chemical reactions, precipitation of the hydroxyl containing reactive hydrophobic agent is avoided permanently, hydrophobicity and hydrophobic stability of the one-component polyurethane waterproof paint are improved, and long-lasting hydrophobic effects are achieved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Photochromic double-shell microcapsule and preparation method and application thereof

InactiveCN102886233AHas thermosetting propertiesImprove processing resistanceTenebresent compositionsMicroballoon preparationIn situ polymerizationWear resistant

The invention relates to a photochromic double-shell microcapsule and a preparation method and application thereof. The microcapsule comprises a core, an internal shell and an external shell, wherein the core is manufactured by a photochromic material; the internal shell adopts vinyl monomer as polymerizing monomer, and wraps the core in an interfacial polymerization way; and the external shell adopts etherifying melamine resin prepolymer as polymerizing monomer, and wraps the internal shell in an in-situ polymerization way. The photochromic double-shell microcapsule provided by the invention is simple in preparation technology, and is non-toxic and innocuous; the wall of the microcapsule is high in toughness, is wear-resistant, heat-proof and water-proof, is good in processability, and is capable of permanently implementing a photochromic function; and the photochromic double-shell microcapsule can be applied to the field of textile and printing, and meets the demands on personalization and counterfeiting prevention.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

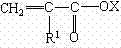

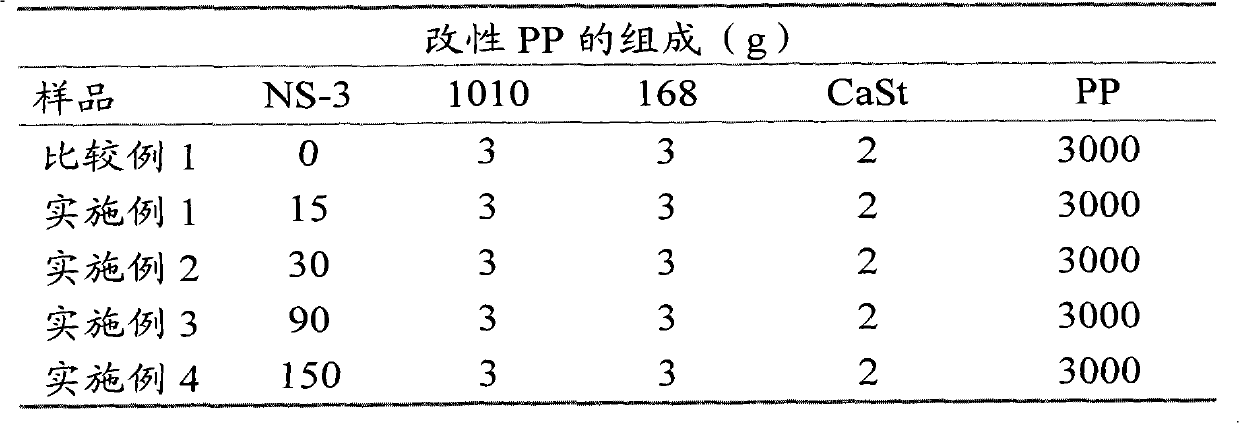

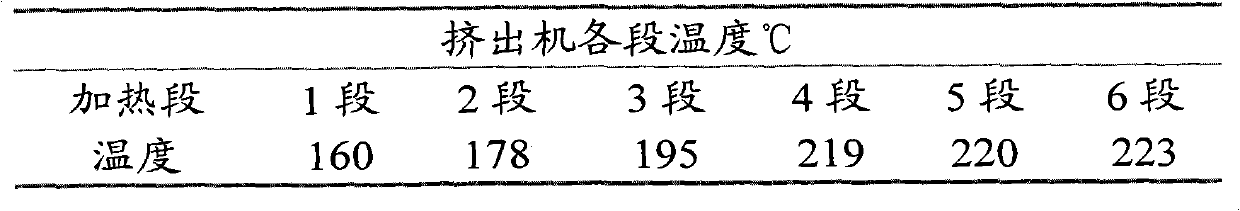

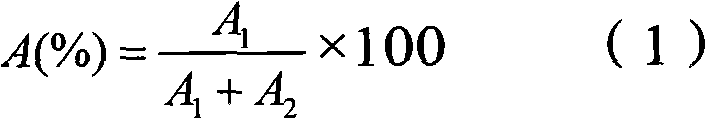

Nano-modified polypropylene soft packaging material

ActiveCN102020796AImprove mechanical propertiesImprove printing effectProcedure AgentsPolymer science

The invention provides a packaging polyolefin processing agent composition which is a mixture of nano silicon dioxide and ethylene-vinyl acetate copolymer, wherein the mass of the nano silicon dioxide accounts for 10-40% of the total mass of the processing agent composition, and the mass of the ethylene-vinyl acetate copolymer accounts for 60-90% of the total mass of the processing agent composition. The invention also provides packaging polyolefin modified by the processing agent composition. The modification of the nano silicon dioxide has greater influences on the mechanical property, the crystallization property, the polarity, the printing property, the composite property, the residue of organic solvent, and other indexes of the polypropylene. A result shows that after the polypropylene soft packaging material is subjected to nano modification, the toughness of the polypropylene soft packaging material is greatly enhanced; meanwhile, the polarity, the printing ink adhesive force and the peel strength of the material are improved; the adsorption of the modified polypropylene on toluene is greatly reduced. After nano modification, the using performance of the polypropylene used as the soft packaging material can be greatly improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Conductive paste for thick film circuit, thick film circuit board employing same and manufacturing method thereof

InactiveCN102760934AImprove conductivityWide variety of sourcesAntenna supports/mountingsSolid-state devicesSilver pasteConductive paste

A conductive paste for a thick film circuit, a thick film circuit board employing the same and a manufacturing method thereof relate to the field of thick film circuits. One of the purposes of the invention is to provide a conductive paste for a thick film circuit, which can replace a silver paste and low cost and high security. The conductive paste comprises the following components by mass percent: 72-77 percent of copper powder, 8-10 percent of inorganic adhesive, 4-6 percent of organic adhesive, 5-12 percent of organic solvent and 1-5 percent of additive. Another purpose of the invention is to provide a thick film circuit board employing the paste and adopting toughened glass as a baseplate. The third purpose of the invention is to provide a manufacturing method of the thick film circuit board. The manufacturing method comprises the steps of preparation of the conductive paste, a encapsulating paste and the baseplate, as well as the printing, encapsulating, sintering, performance test and packaging of a circuit diagram. The thick film circuit board has favorable sintering characteristic and aesthetic appearance, and can be widely used in the manufacturing field of electronic components.

Owner:SHENZHEN SENLONT ELECTRONICS

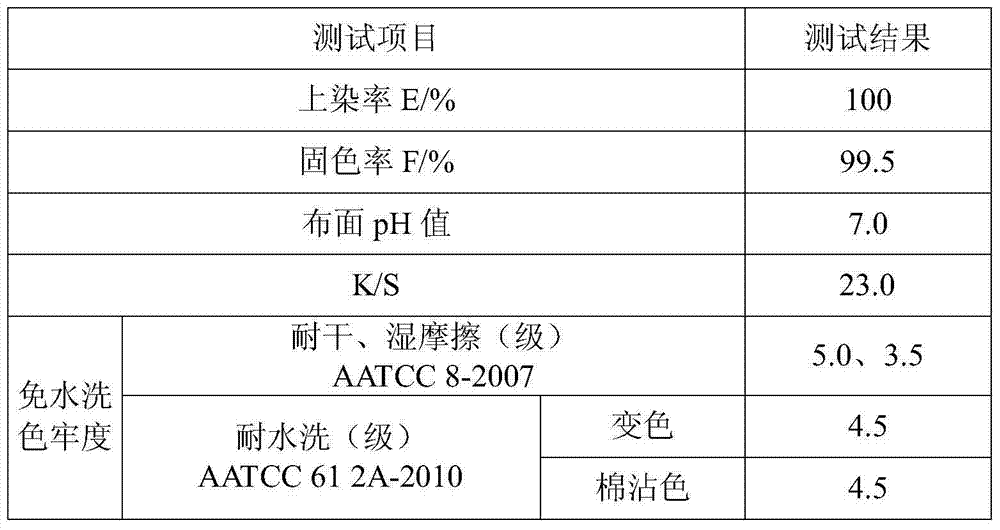

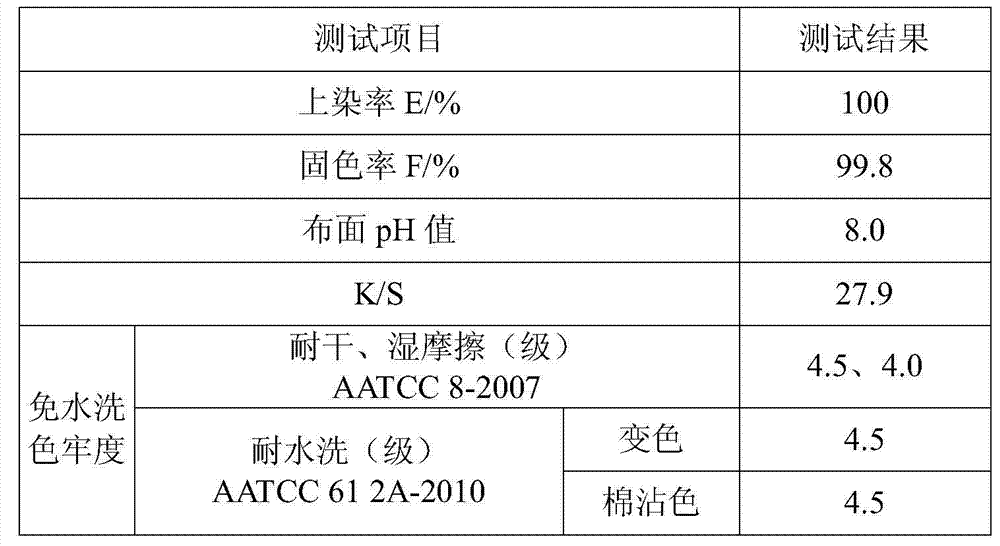

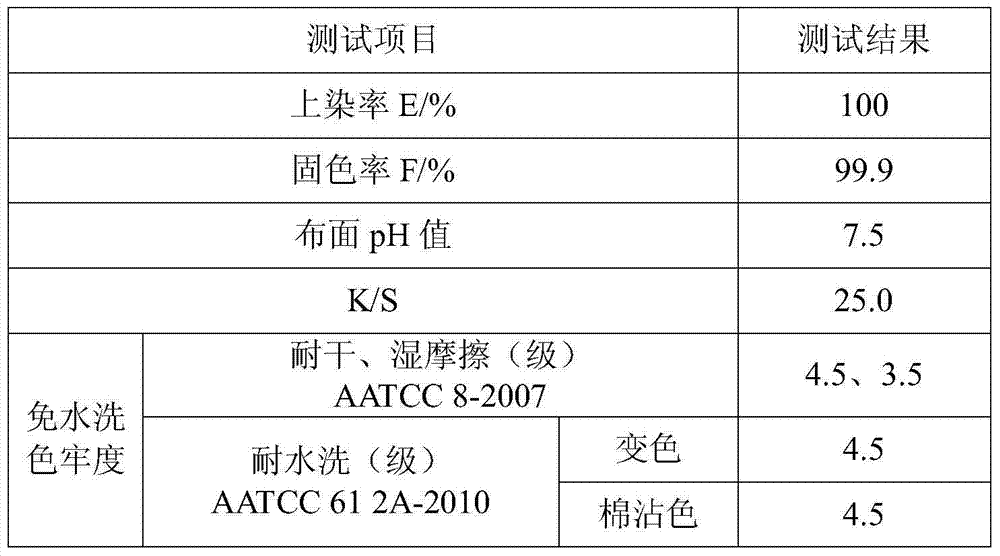

Non-aqueous solvent dyeing method of washing-free reactive dye

ActiveCN104746361AControl contentReduce coefficient of frictionDyeing processLiquid/gas/vapor fibres/slivers/rovings treatmentFiberYarn

The invention provides a non-aqueous solvent dyeing method of a washing-free reactive dye. The non-aqueous solvent dyeing method comprises the following steps: 1. carrying out full swelling on loose fibers, yarns, fabric or garments in a water solution of alkaline substances, controlling the take-up rate and drying; 2. mixing the dried loose fibers, yarns, fabric or garments with a reactive dye and a good solvent of the reactive dye to form a mixing system, heating the mixing system, adding a poor solvent of the reactive dye to the mixing system before heating or in the heating process, heating to dyeing temperature and then carrying out heat preservation; and 3. carrying out heat preservation on the loose fibers, yarns, fabric or garments treated in the step 2 in the non-polar or weak-polar poor solvent of the reactive dye containing a cation reagent, drying and thus finishing dyeing. According to the method, the loose fibers, yarns, fabric or garments can be completely dyed or subjected to fixation by the reactive dye, and do not need to be washed and neutralized after being dyed, so that the dyeing cycle is short and the energy consumption is low.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Composite latex for paints, water paint and preparation method of water paint

The invention relates to a composite nanometer oxide latex for paints, a water paint containing the latex and a preparation method of the water paint. The latex consists of a monomer mixture, an emulsifier, a film-forming additive, an initiator, sodium bicarbonate, a pH regulator, an antifoamer, deionized water and nanometer oxide slurry, wherein the nanometer oxide slurry is prepared by firstly dispersing a nanometer oxide, a surfactant and water in a dispersion machine and then sand grinding dispersion in sand grinder; the nanometer oxide is one or two or three of Al2O3, ZnO and TiO2; and the monomer mixture consists of methyl acrylate, methyl methacrylate, diacetone-acryloamide and butyl acrylate. In the synthesis process of the latex of the invention, the nanometer oxide slurry is added, so that nanometer particles can be uniformly and stably combined with synthesized macromolecules to show the functionality of a nanometer material and to realize the excellent hardness, wear resistance and soiling resistance of the water paint containing the composite nanometer oxide latex for paints.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

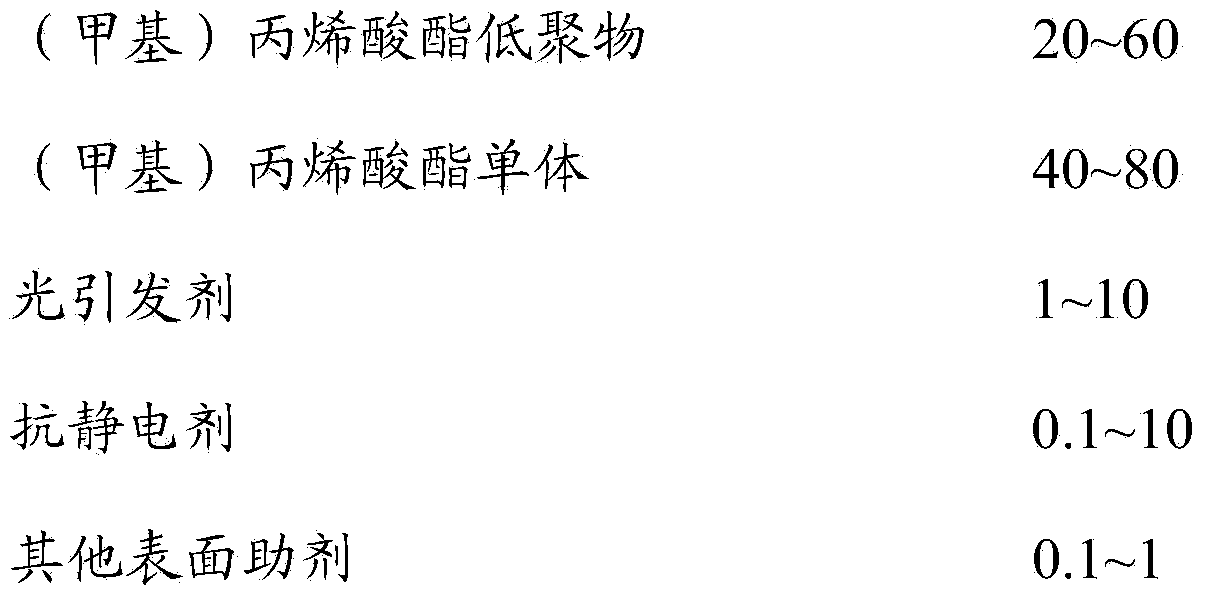

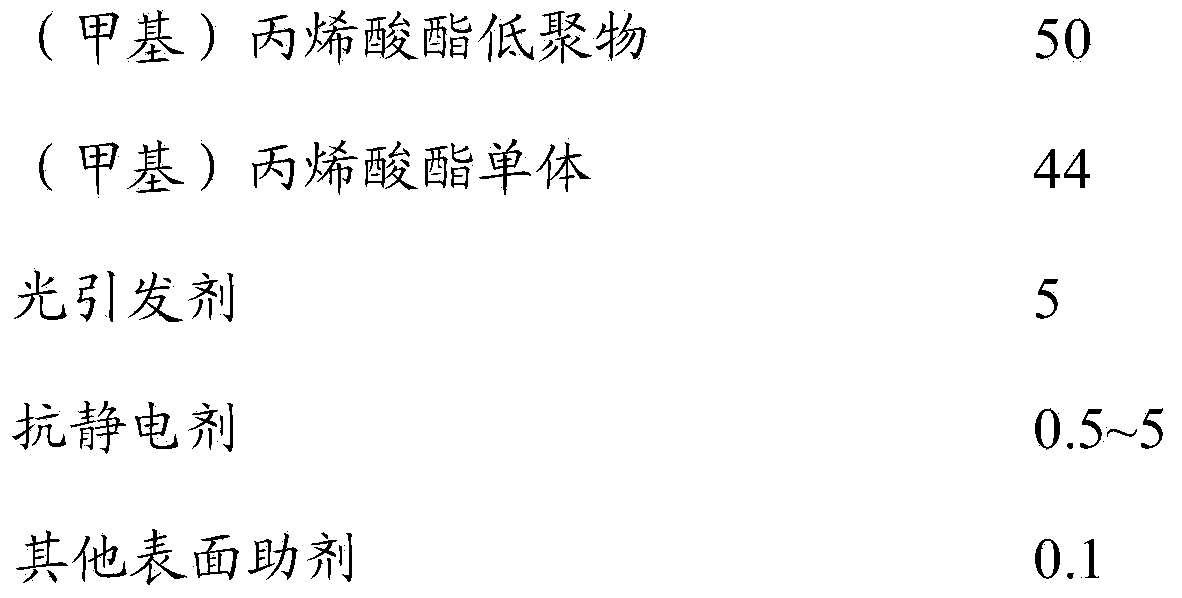

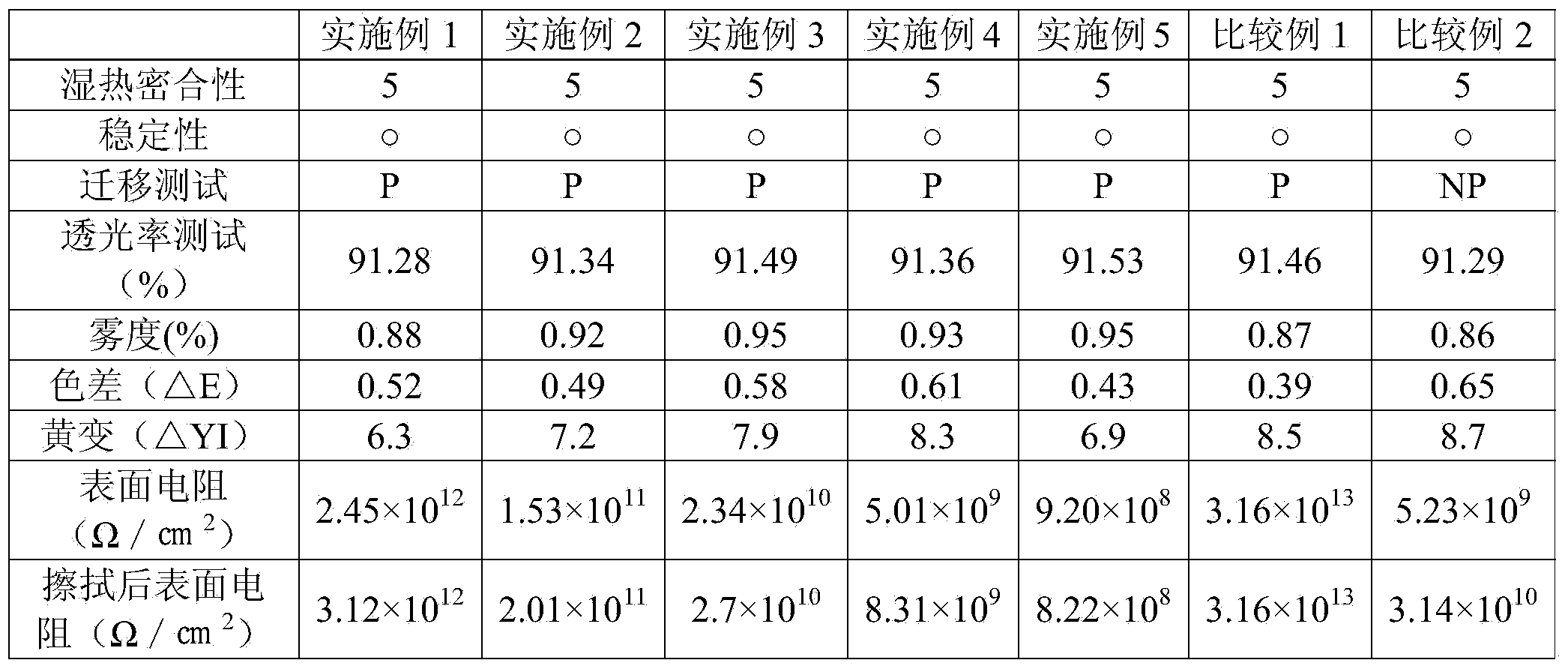

Ultraviolet-curable high-transparency permanent antistatic coating

ActiveCN103773093AIncreased durabilityEasy processing and constructionCoatingsPhotoinitiatorChemistry

The invention disclose an ultraviolet-curable high-transparency permanent antistatic coating which contains an oligomer of (methyl) acrylate, a monomer of (methyl) acrylate, a photoinitiator, an antistatic agent and other surface additives, wherein the antistatic agent is a reactive type alkyl nitrogen onium salt type organic matter or a mixture thereof; the antistatic coating is easy to process and apply, and the obtained coating layer is still capable of keeping excellent antistatic property under a low humidity condition; the additives do not affect the chroma and the transparency of the formed coating layer, separation, white-turning, yellowing and the like are prevented under mal-conditions such as a high temperature and a high humidity and the antistatic property of the coating layer is in the range from 108 to 1010 ohm / cm<2>; as a result, the ultraviolet-curable high-transparency permanent antistatic coating is capable of meeting general antistatic requirements, and applicable to treatment of surface antistatic coating layers of an optical thin film, a packaging thin film, high-grade carpentry, an automobile and the like which have high requirements for light transmission, color and luster, gloss, weather fastness and environmental protection.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Aquosity wood lacquer emulsions and wood lacquer of the same

InactiveCN101108886AEvenly distributedImprove stabilityLiquid surface applicatorsEmulsion paintsEmulsionLacquer

The invention provides a preparation method of waterborne woodenware finishes emulsion and the waterborne woodenware finishes emulsion prepared by the method. The method is that a nano TiO2 sizing agent is added during the synthetic process of the emulsion and comprises the following raw materials of the weight portion ratio: TiO2: 1.5 to 4; surfactant: 0.04 to 0.08; water: 3 to 6. The invention adopts the nano TiO2 sizing agent to participate in the polyreaction of the emulsion to make the nano TiO2 sizing agent distribute evenly in the emulsion and not move during drying the paint film, therefore, the waterborne woodenware finishes prepared by the emulsion not only has good stability, that is, precipitate will not happen even if stored over 6 months, but also has good resistance to temperature fluctuations, phototropy resistance and antibacterial property.

Owner:山东乐得仕软木发展有限公司

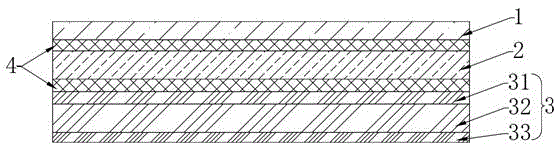

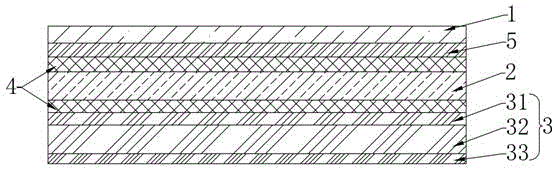

Composite membrane having stable friction coefficient and capable of being spurted with codes and preparation method of composite membrane

InactiveCN105667011AReduce coefficient of frictionImprove stabilityLamination ancillary operationsSynthetic resin layered productsSurface energySilicone resin

The invention discloses a composite film with a stable friction coefficient and which can be coded. It includes an outer layer, a barrier layer and a polyethylene co-extrusion film layer from the outside to the inside, and the polyethylene co-extrusion film layer includes a corona treatment layer from the outside to the inside. , a core layer and a heat-sealing layer. The material composition of the heat-sealing layer mainly includes polyethylene resin and a slip agent. The slip agent is a silicone slip agent masterbatch with polyethylene as a carrier. In the present invention, silicone slippery agent is added to the polyethylene co-extrusion film heat-sealing layer located inside the film, and it is extruded to the surface and evenly distributed during processing by utilizing its incompatibility with the main material to achieve The purpose of reducing the friction coefficient, and the molecular weight is large. Under the high temperature conditions during the film aging, storage and use, the silicone resin with low surface energy will not migrate and precipitate, and improve the stability of the friction coefficient of the inner surface of the film. Unwinding The speed meets the requirements of high-speed packaging machines. The invention discloses a method for preparing a composite film suitable for stable friction coefficient and capable of coding.

Owner:JIANGYIN SHENLONG PACKAGING MATERIALS CO LTD

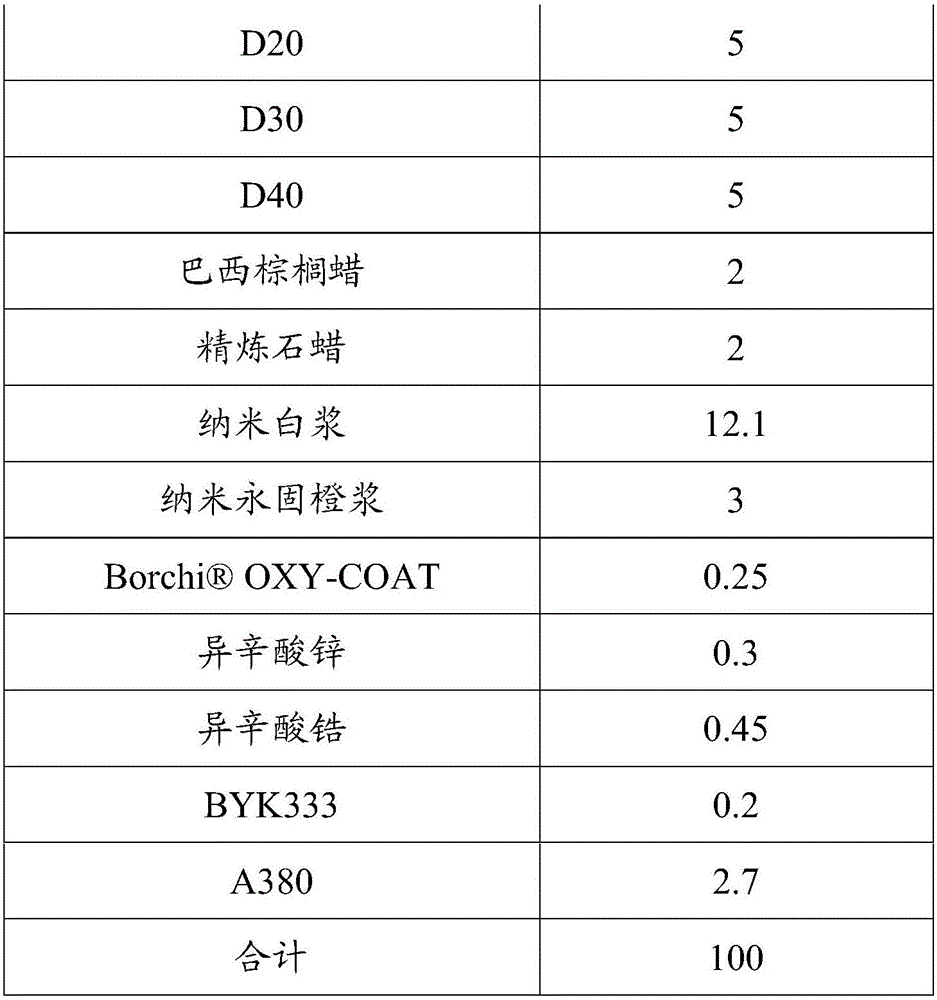

Flame-retardant natural fiber reinforced polylactic acid composite material and preparation method thereof

The invention belongs to the technical field of materials, and particularly relates to a flame-retardant natural fiber reinforced polylactic acid composite material and a preparation method of the flame-retardant natural fiber reinforced polylactic acid composite material, being used for the fields of electronics and the like. The preparation method comprises the specific steps of firstly, blending dried polylactic acid, an nanometer additive, an antioxidant and anti-dropping agent according to the proportion respectively, and extruding; mixing a fire retardant and natural fibers, and finally adding blending materials of natural fibers and polylactic acid subjected to fire retardant treatment into an extruder according to certain proportion, and blending and extruding to obtain the flame-retardant natural fiber reinforced polylactic acid composite material. The composite material has good flame retardant property and mechanical property, the preparation method is simple and effective, the process conditions are moderate, and the flame-retardant natural fiber reinforced polylactic acid composite material is suitable for batch production.

Owner:TONGJI UNIV +1

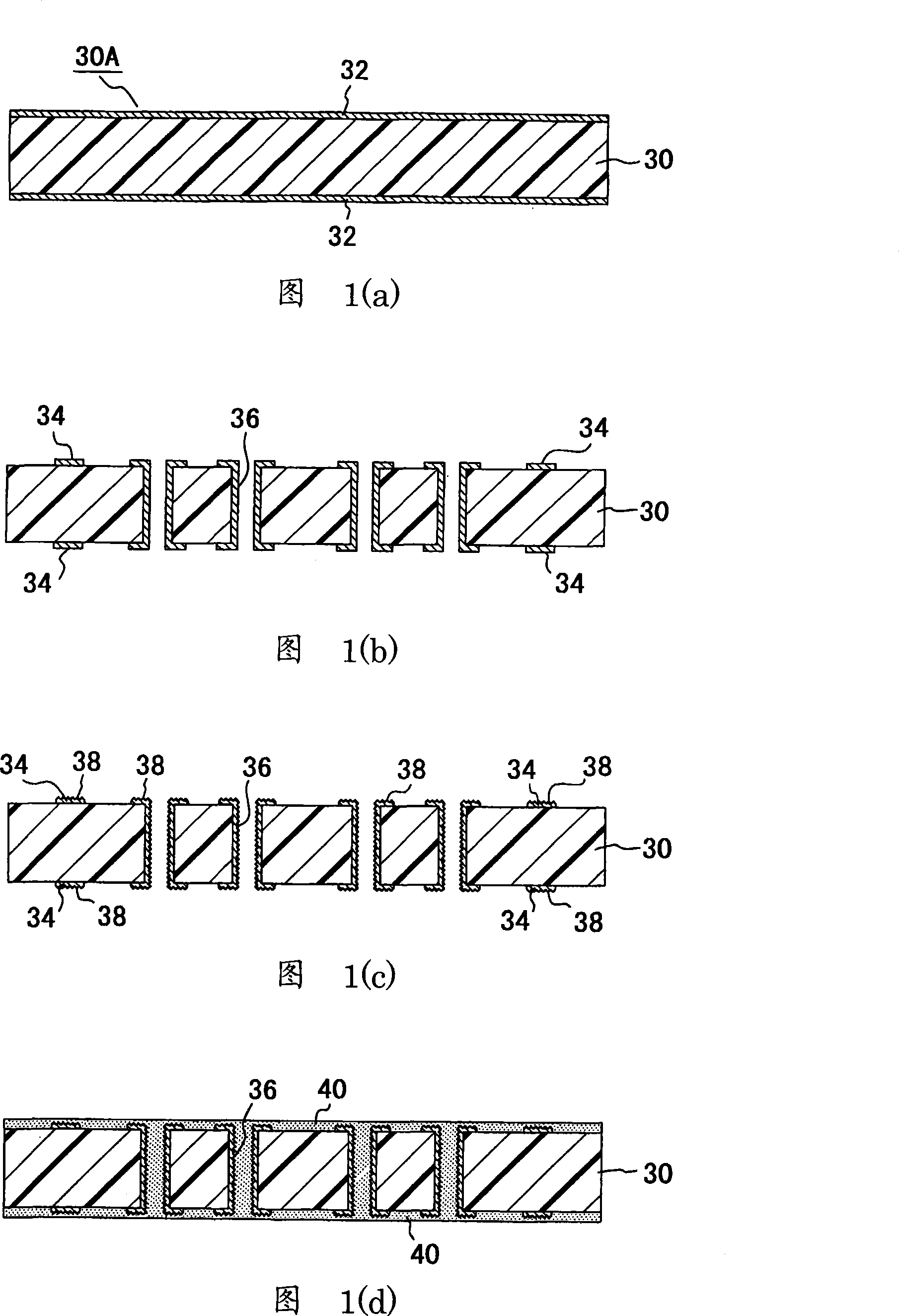

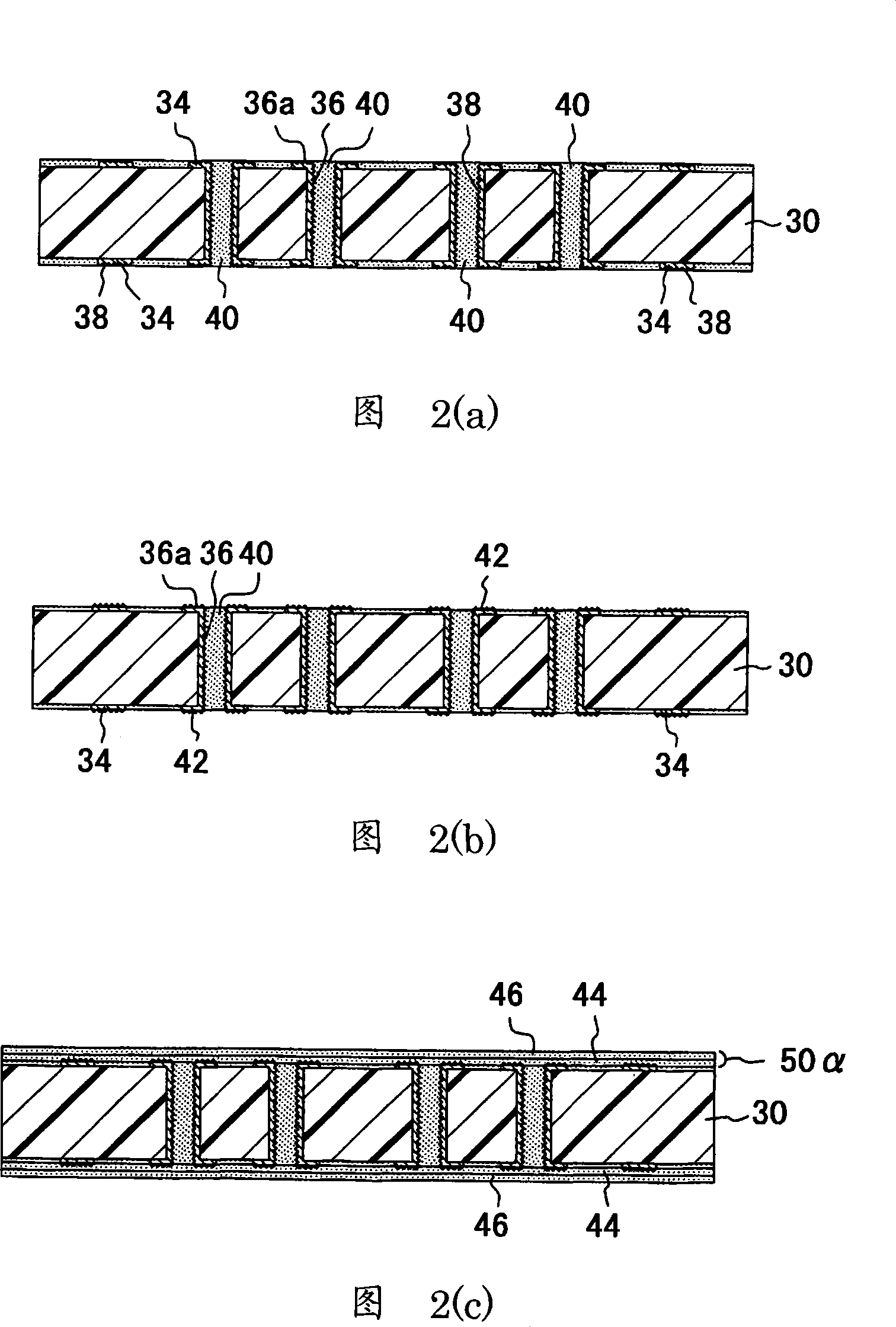

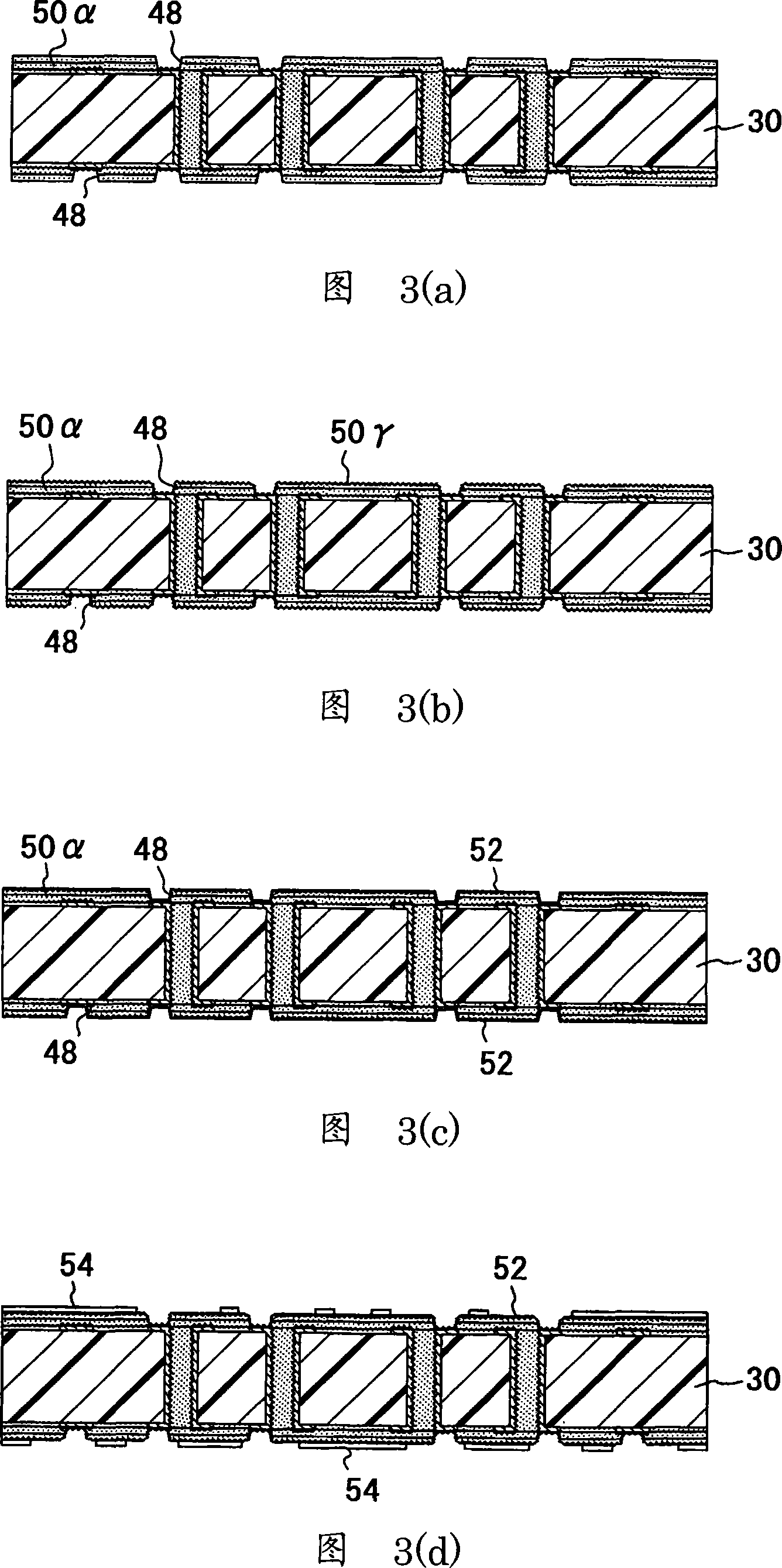

Printed wiring board

ActiveCN101180727AReduce distance deviationSmall movement speed deviationFinal product manufactureSemiconductor/solid-state device detailsResistElectrical conductor

Disclosed is a printed wiring board wherein a solder resist layer is formed on the surface of a wiring board which is provided with a conductor circuit, a part of the conductor circuit exposed from an opening formed in the solder resist layer is formed into a conductor pad, a solder bump is formed on the conductor pad, an electronic component is mounted on the board via the solder bump, and the electronic component is sealed with an underfill resin. In this printed wiring board, the surface of the solder resist layer is planarized at least in the electronic component mounting region or the planarized surface is further subjected to a roughening treatment. Also disclosed is a method for manufacturing such a printed wiring board

Owner:IBIDEN CO LTD

Multifunctional ecological soil conditioner

InactiveCN107129807AStrong ion exchange performanceFacilitated releaseAgriculture tools and machinesOther chemical processesEcological environmentMoisture

The invention discloses a multifunctional ecological soil conditioner. The soil conditioner comprises urea-formaldehyde foam containing organic matters, biochar, humic acid, wood vinegar, imidazole modified tapioca starch and azotobacter. The multifunctional ecological soil conditioner simultaneously has the multiple conditioning effects of stabilizing heavy metals, preserving moisture and fertility, realizing slow release and long-time action of nutrients, increasing the fertilizer utilization ratio, improving the soil structure and micro-ecological environment and the like, and can adapt to conditioning and restoration of various polluted soils.

Owner:HUNAN XISI ECOLOGY TECH

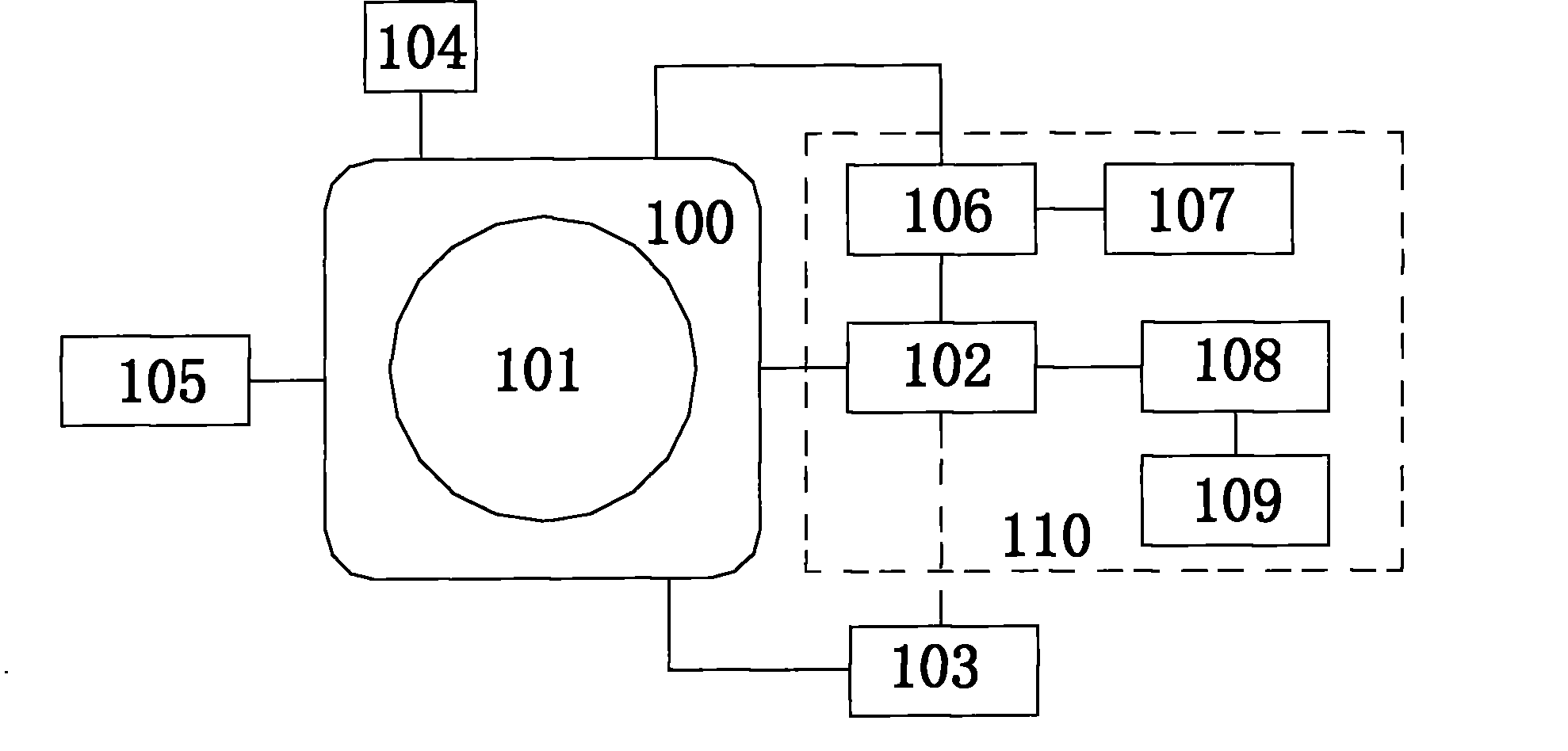

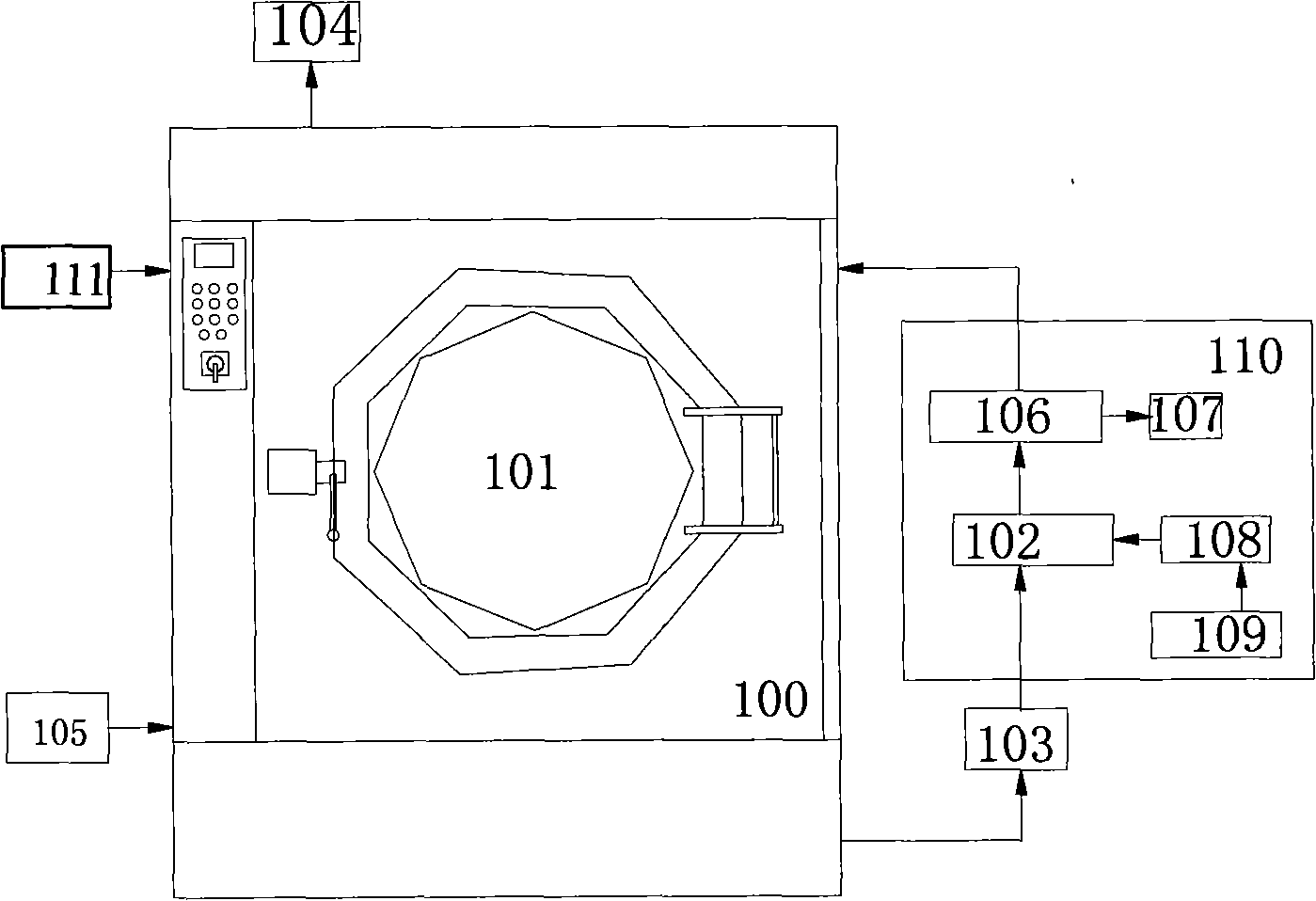

Device for carrying out oxidation discolourization treatment on fabric by utilizing high-concentration ozone water

InactiveCN101831774AConserve waterReduce energy consumptionTextile treatment machine arrangementsBleaching apparatusChemistryHigh concentration

The invention relates to a device for carrying out oxidation discolourization treatment on fabric by utilizing high-concentration ozone water, which comprises a wash-up device, a high-concentration ozone water generator, an ozone water concentration controller and an ozone absorber, wherein the wash-up device is provided with an inner cavity, and a roller is arranged in the inner cavity; the high-concentration ozone water generator is provided with a water absorbing pipe and a water discharging pipe which are respectively connected with the inner cavity; the ozone water concentration controller is connected with the high-concentration ozone water generator; the ozone water concentration controller is provided with an ozone water concentration probe which is arranged in the inner cavity; and the ozone absorber is connected with the inner cavity.

Owner:刘志国

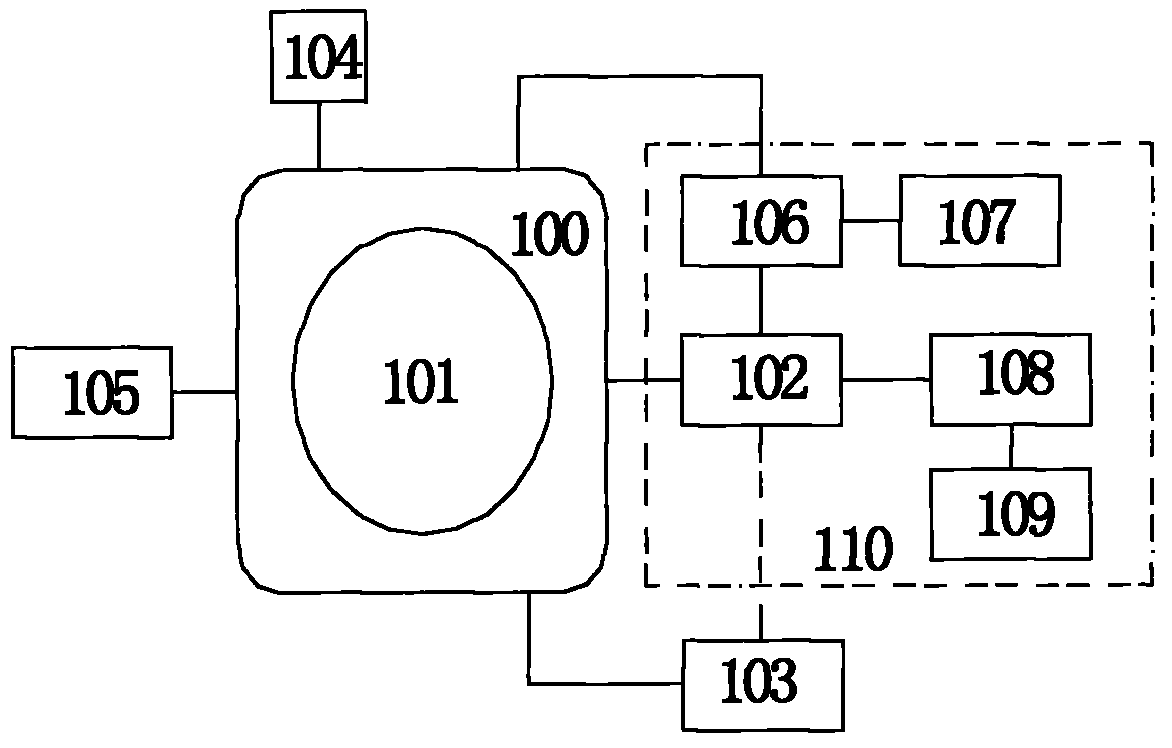

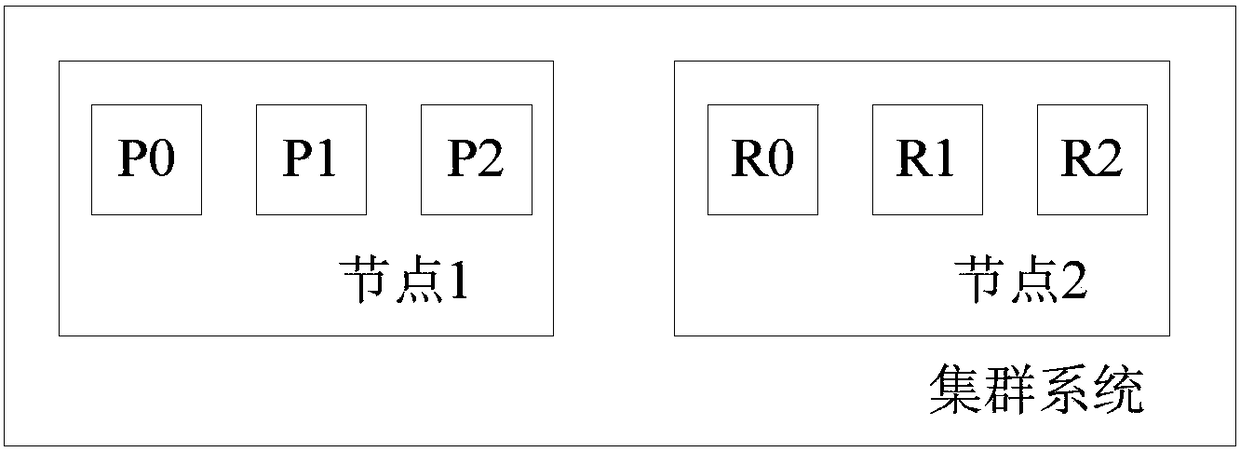

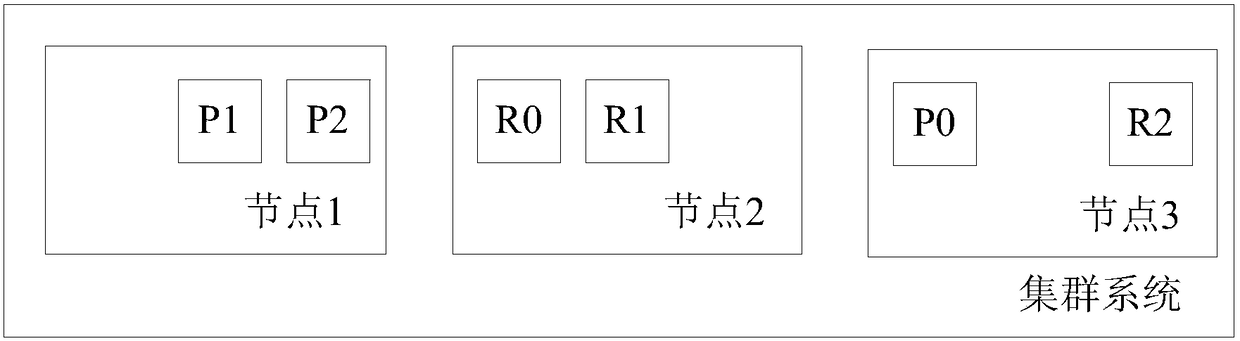

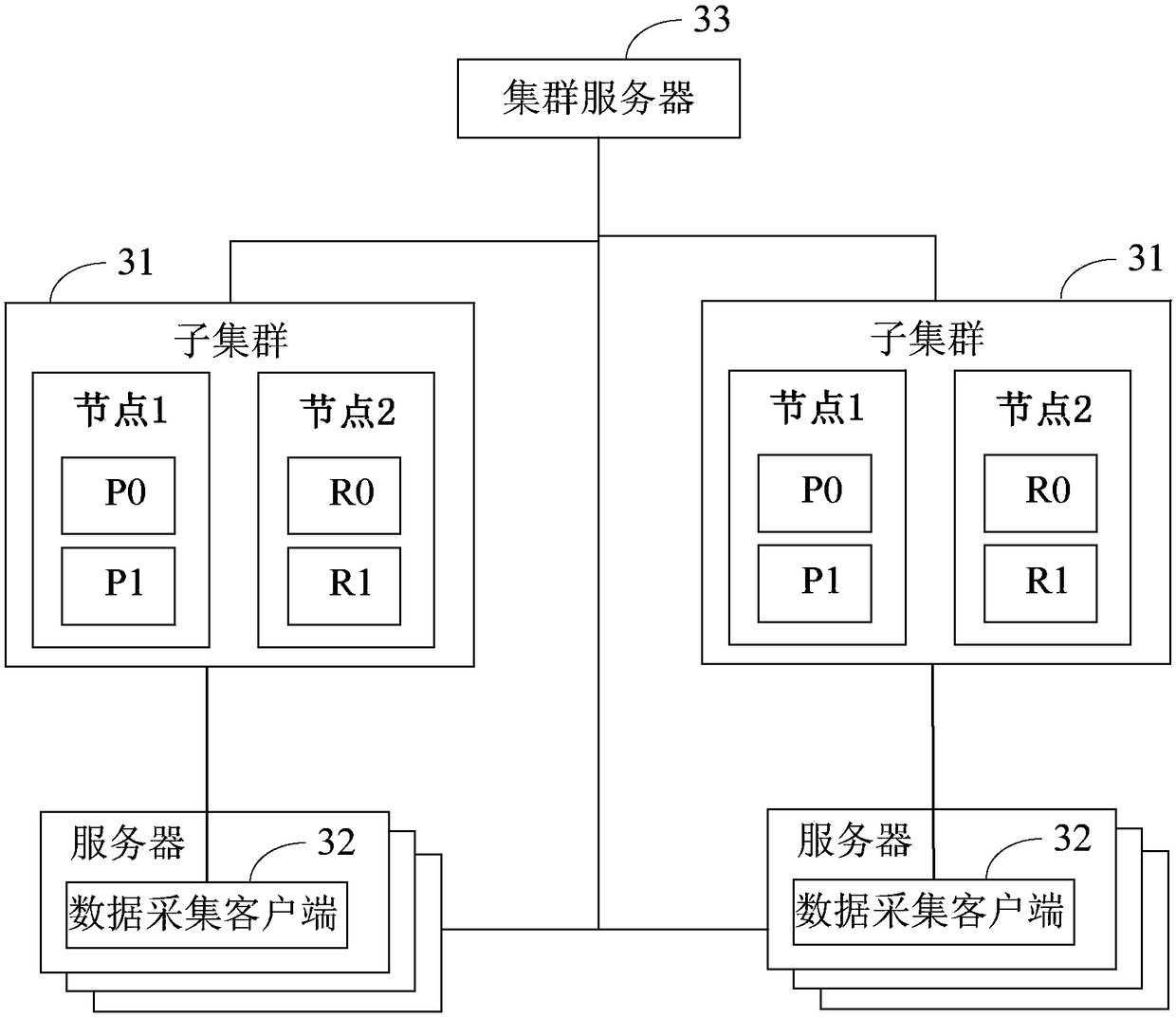

Cluster management method and cluster server

ActiveCN108089934AImprove reliabilityNo migration will occurInput/output to record carriersResource allocationApproaches of managementCluster systems

One embodiment of the invention provides a cluster management method and a cluster server. The method comprises following steps: determining whether new sub-cluster are added; if newly added sub-clusters are determined by a cluster server, then switching at least one data acquisition client terminal connected to the original sub-clusters to connect to the newly added sub-clusters; the method realizes that the data acquisition client end connected to the original sub-clusters are directly changed to be connected to the newly added sub-clusters by the cluster server during expansion by newly adding nodes in a cluster system. Because the data between sub-clusters does not communicate with each other, the sub-clusters working as a complete cluster can work independently. Therefore, after the capacity expansion, the data between the sub-clusters does not migrate, thereby improving the reliability of the cluster management method.

Owner:CHENGDU HUAWEI TECH

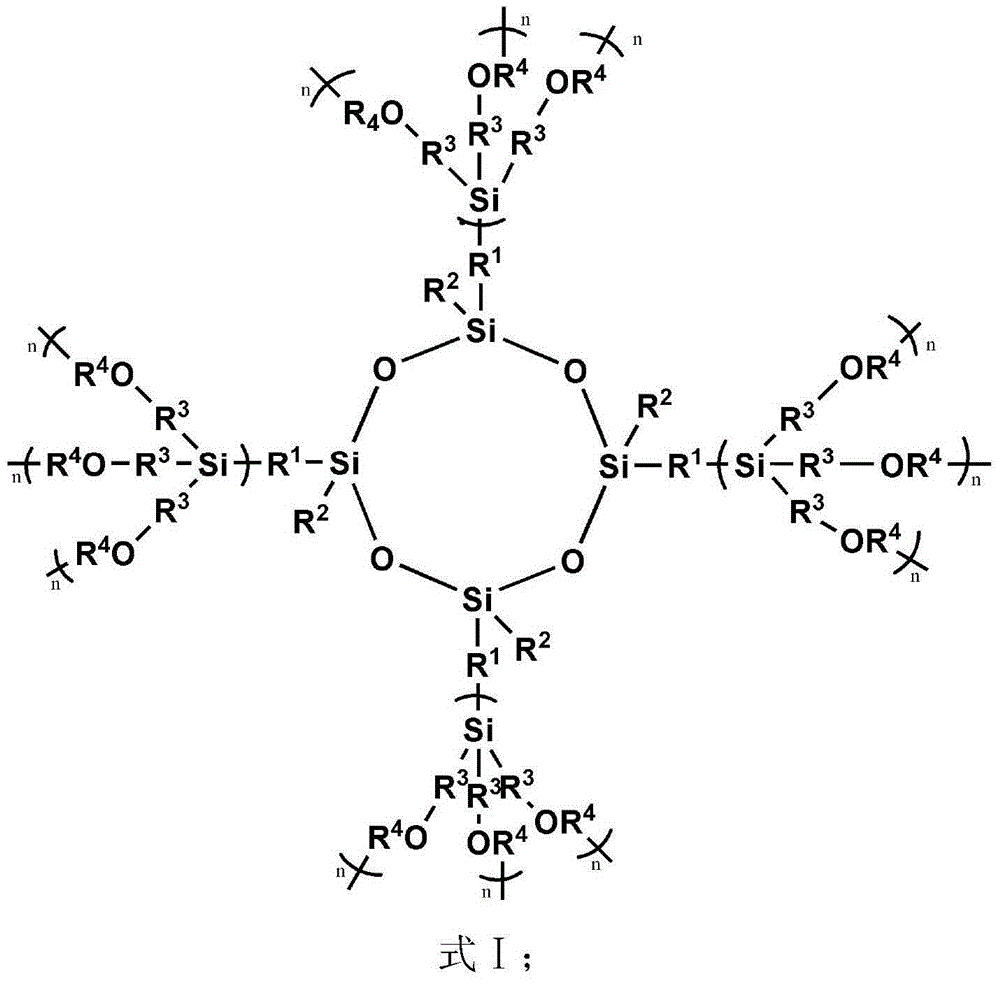

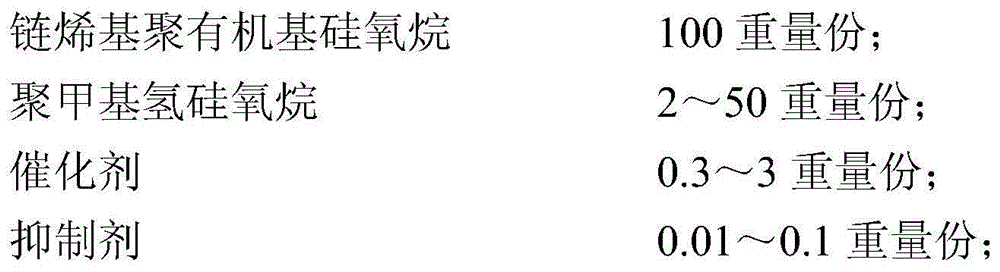

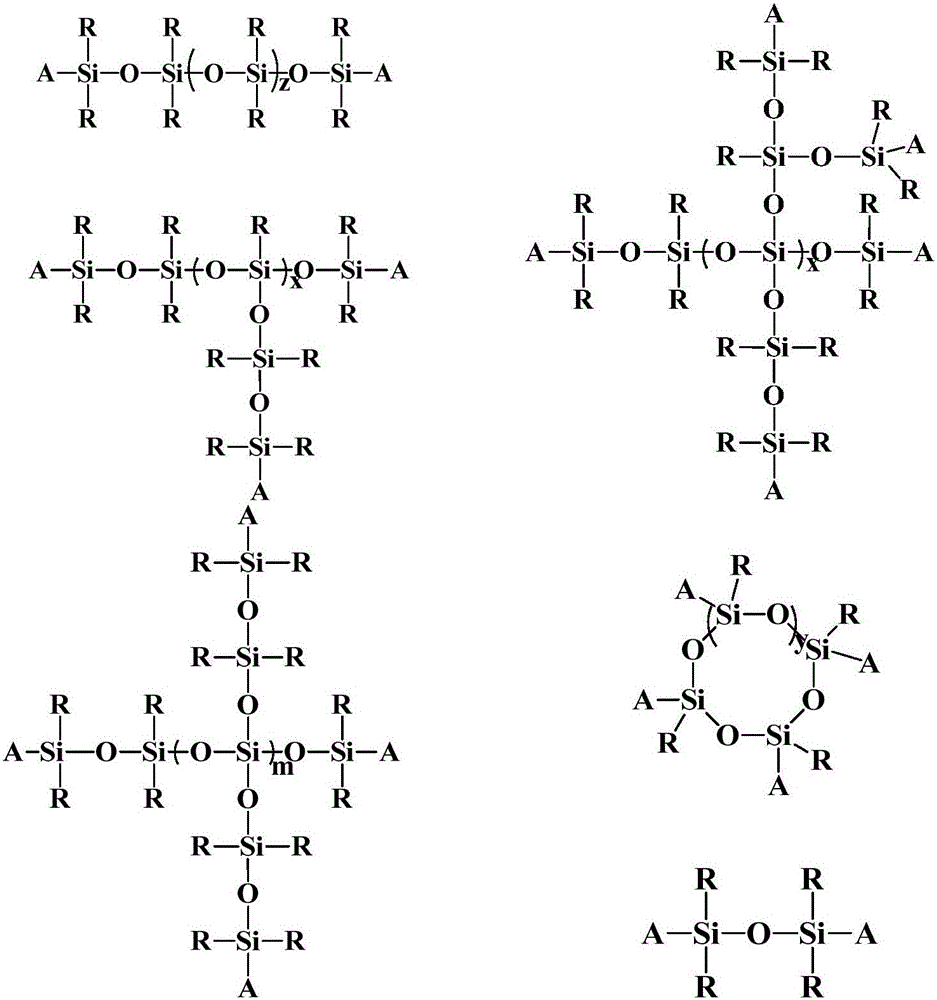

Spherical dendritic organic silicon macromolecule, preparation method thereof and application

The invention belongs to the field of chemical synthesis, and particularly relates to a spherical dendritic organic silicon macromolecule, a preparation method thereof and an application. The structural formula of the spherical dendritic organic silicon macromolecule is indicated in a formula I. The spherical dendritic organic silicon macromolecule is synthesized by a two-step circulation method, and then the synthesized spherical dendritic organic silicon macromolecule serves as a cross-linking compensation point and is applied to a solvent-free polysiloxane compound SL. The two-step circulation method includes hydrosilylation and nucleophilic substitution. Active sites capable of diverging are led into annular siloxane in the hydrosilylation. The nucleophilic substitution aims to lead in more cross-linking reaction sites and ensure that the solvent-free polysiloxane compound obtains a curing coating with a perfect cross-linking network structure when cured on a sheet substrate, so that stable performance of an anti-adhesion coating is ensured.

Owner:国科广化(南雄)新材料研究院有限公司 +2

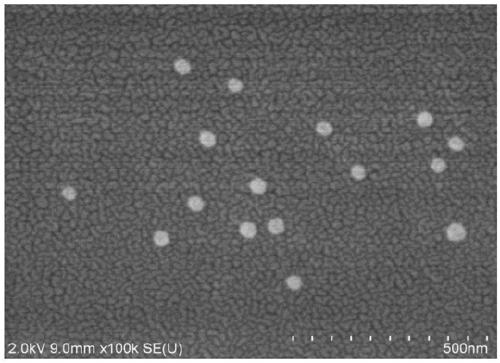

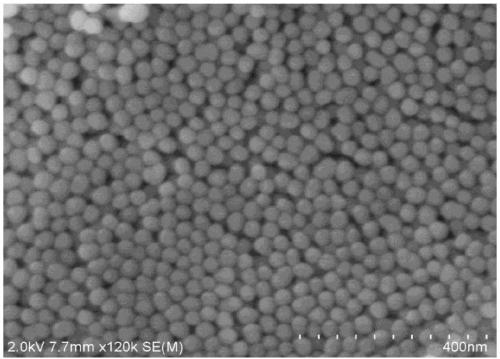

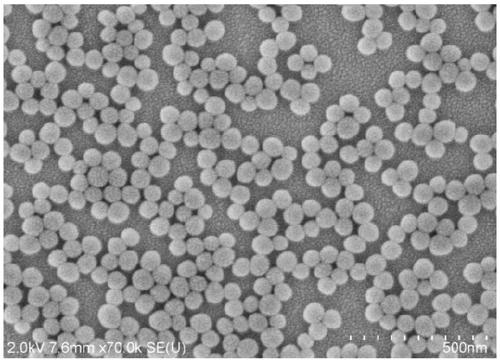

Preparation method of silicon dioxide antibacterial microsphere

ActiveCN110371988AEasy to prepareMild reaction conditionsMaterial nanotechnologySilicaChemistryAntimicrobial

The invention discloses a preparation method of a silicon dioxide antibacterial microsphere. A carrier, namely a silicon dioxide microsphere, and an antibacterial agent, namely a long-alkyl-chain silicon-containing quaternary ammonium salt are copolymerized, and the silicon-containing quaternary ammonium salt is directly bonded to the surface of the silicon dioxide microsphere, wherein the silicondioxide microsphere is prepared through a sol-gel method, and the volume ratio of a silicon source to the quaternary ammonium salt is 1:(0.1 to 1). According to the preparation method, a process is simple, reaction conditions are mild, the raw materials are easy to obtain, and the cost is low; and the obtained antibacterial microsphere is regular in sphere shape and uniform and controllable in particle size, antibacterial components on the microsphere do not migrate, the antibacterial property of the material is effectively improved, the contact-type antibacterial purpose is achieved, and thesilicon dioxide antibacterial microsphere is widely applied to the aspects of food packaging and clothing antibacterial coatings.

Owner:JIANGNAN UNIV

Nano-material-modified natural rubber cable material

InactiveCN104629103AImprove aging resistanceImprove mechanical propertiesRubber insulatorsPolymer scienceAlloy

The invention discloses a nano-material-modified natural rubber cable material which is prepared from natural rubber, liquid isoprene rubber, modified superfine lana powder, superfine acrylate rubber powder, stearic acid, zinc oxide, nano calcium carbonate, carbon black, nano alloy, sulfur, 1,4-bis-tert-butyl-peroxycumene, diallyl phthalate, castor oil, bis octadecanol ester, bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, an anti-aging agent and an accelerator. The nano-material-modified natural rubber cable material has the advantages of excellent mechanical properties and favorable aging resistance; and the cable prepared from the material has the advantages of favorable comprehensive properties and long service life.

Owner:无为县茂林电缆材料有限公司

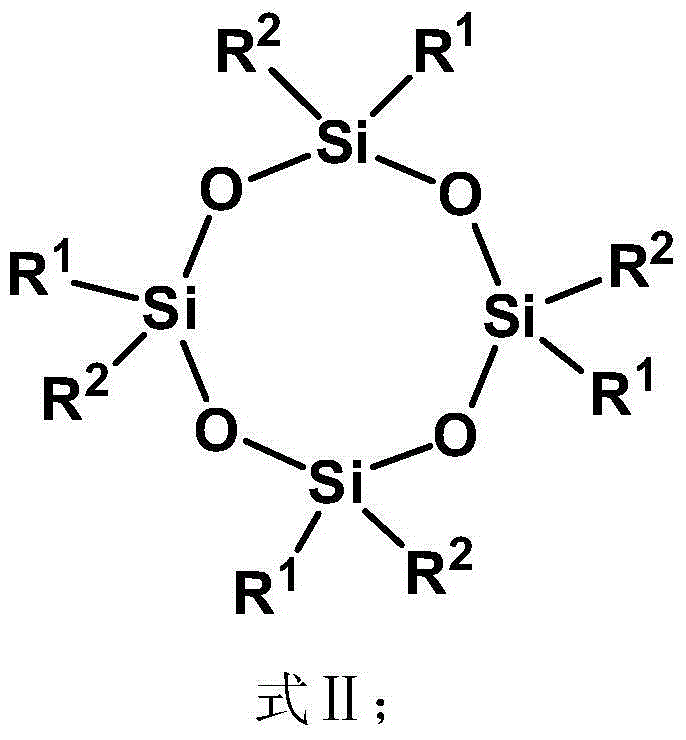

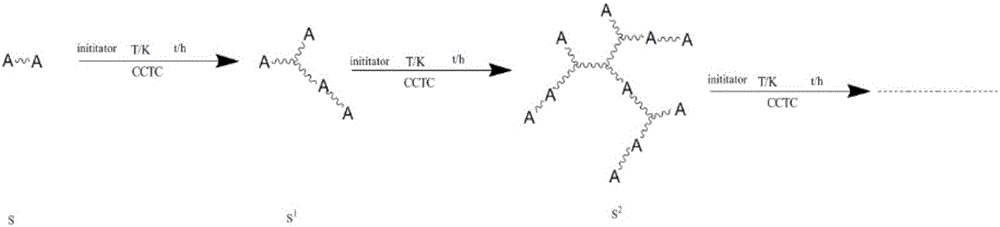

Reactive hyperbranched siloxane resin as well as preparation method and application thereof

The invention belongs to the field of chemical synthesis and discloses reactive hyperbranched siloxane resin as well as a preparation method and application thereof. The reactive hyperbranched siloxane resin is mainly prepared according to the following steps: adding a chain transfer catalyst, an initiating agent and a raw material monomer provided with an active group into a reaction vessel, reacting for 0.5-5 hours at the temperature of 50-100 DEG C, and purifying the obtained reaction product, so that the required reactive hyperbranched siloxane resin is obtained. The reactive hyperbranched siloxane resin obtained through chain transfer catalytic reaction has the advantages that structure surface active groups only contain double bond and influence of formation of hydroxyl groups in condensation reaction is avoided; the obtain reactive hyperbranched siloxane resin contains a large amount of double bond active groups which can participate in reaction of solvent-free polyorganic-based siloxane composite and change structure of a crosslinking system, so that a release layer with excellent performance is obtained.

Owner:国科广化(南雄)新材料研究院有限公司 +2

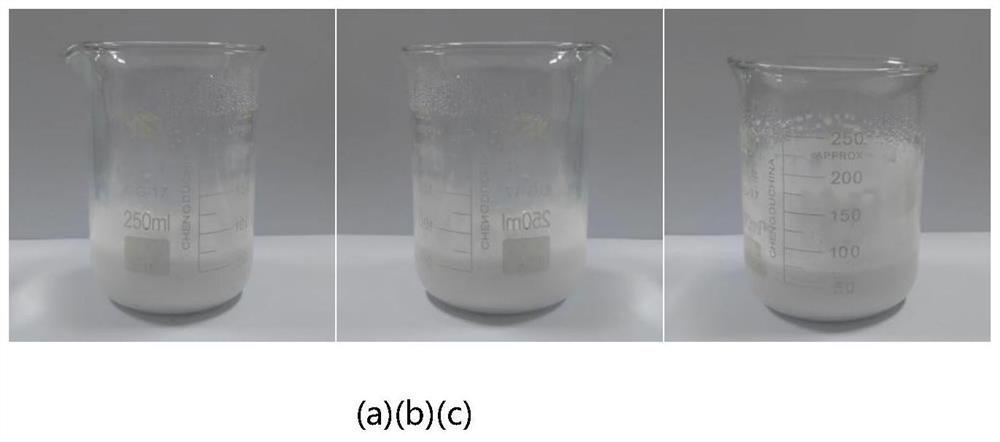

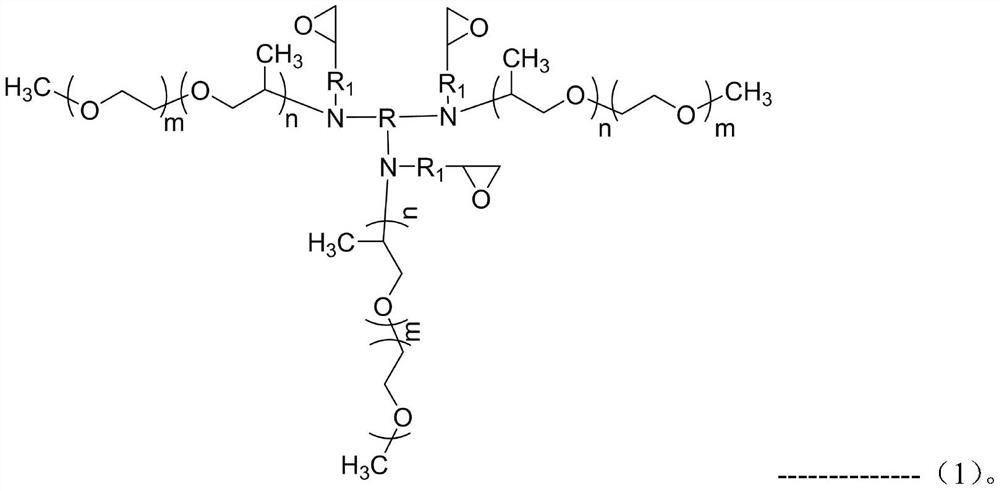

Emulsifier for branched chain reaction type epoxy resin and preparation method thereof

The invention discloses an emulsifier for branched chain reaction type epoxy resin and a preparation method thereof. The emulsifier contains the following molecular structures: N1 is monoamine polyether amine, P is a trifunctional epoxy monomer or a trifunctional acrylate monomer, and Q is a bifunctional epoxy monomer. The preparation method comprises the following steps: reacting a P monomer withmonoamine polyether amine N1 to obtain an intermediate product; and reacting the intermediate product with a Q bifunctional epoxy monomer to obtain the emulsifier. The structure of the prepared emulsifier contains an epoxy group, the emulsifier has good compatibility with epoxy resin, and the epoxy resin emulsion prepared from the emulsifier has good storage stability, centrifugal stability and freeze-thaw stability; meanwhile, the structure of the epoxy resin emulsion contains an epoxy group, so that the epoxy resin emulsion can participate in a curing reaction to enter a cured product network, and a cured coating has excellent medium resistance; the synthesis process is simple, the structure is clear, and no catalyst is needed.

Owner:NANCHANG HANGKONG UNIVERSITY

Poly-vinyl versatate-vinyl acetate-ethylene emulsion and emulsion polymerization preparation method

The invention discloses poly-vinyl versatate-vinyl acetate-ethylene emulsion and an emulsion polymerization preparation method. The poly-vinyl versatate-vinyl acetate-ethylene emulsion is copolymer emulsion with the solid content of 55.0-57.0 percent, which is prepared via free radical emulsion polymerization with vinyl versatate, vinyl acetate and ethylene as monomers, compound polyvinyl alcoholas protective colloid, octylphenol polyoxyethylene ether as an emulsifier and with the presence of redox initiators. The weight-average molecular weight of the terpolymer emulsion is 122,984-130,000,and the molecular weight distribution width is 5.295-6.000. The film prepared with the copolymer emulsion has good weathering resistance, alkali resistance, hydrolysis resistance, uniform particle size, appropriate molecular weight and distribution, low glass transition temperature (T is equal to below 2 DEG C), good film-forming performance, excellent performance and wide scope of application.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD +1

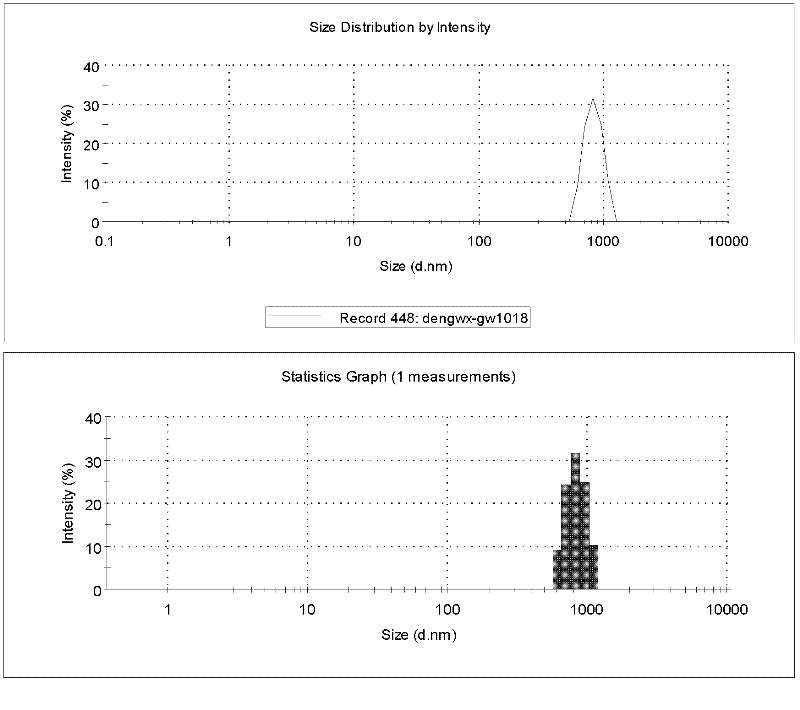

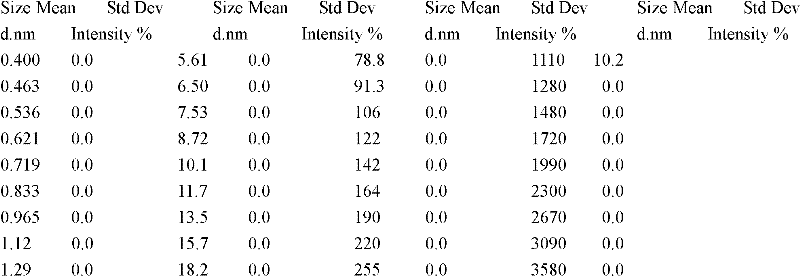

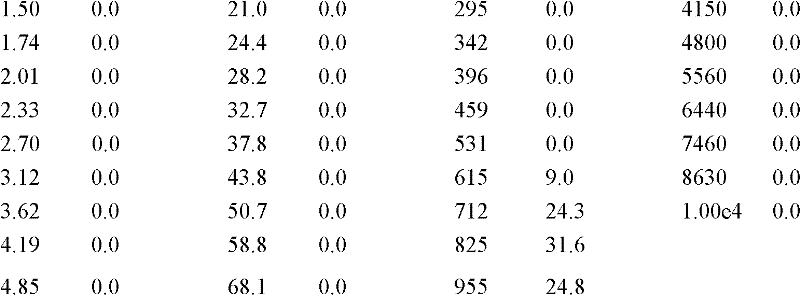

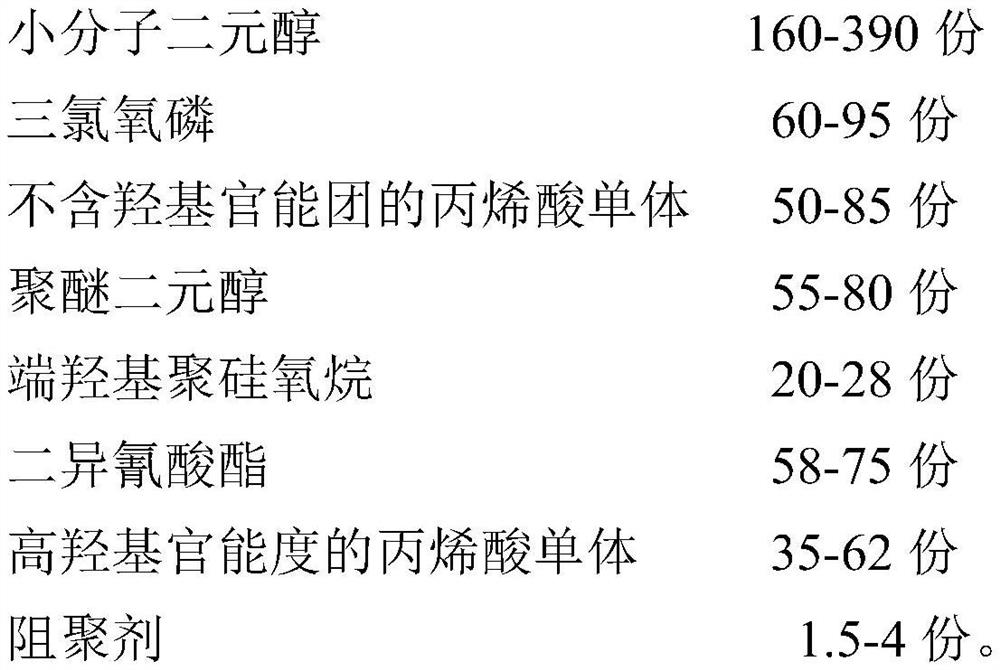

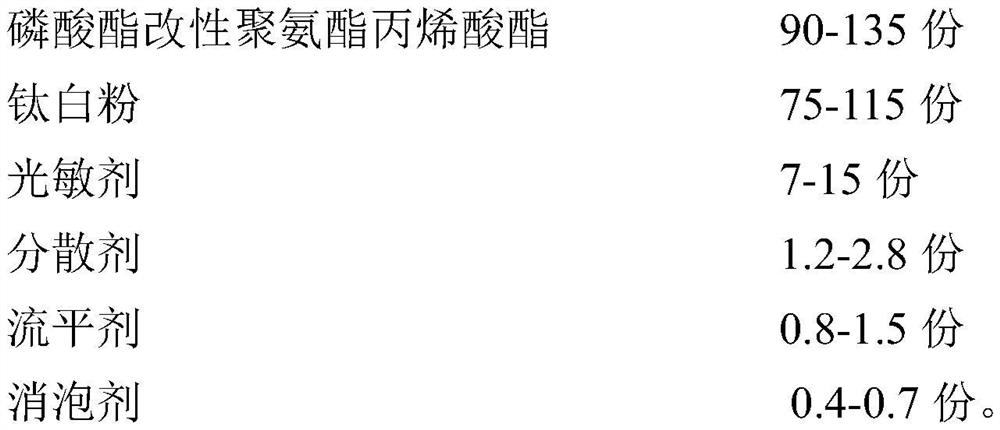

Ultraviolet-cured white butyl coating as well as preparation method and application thereof

ActiveCN112159622AImprove adhesionEasy to complexAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceUltraviolet

The invention provides an ultraviolet-cured white butyl coating as well as a preparation method and application thereof, and belongs to the field of coatings. The resin raw material used in the invention is urethane acrylate resin which has certain toughness and contains a phosphate structure; the polyurethane acrylate resin, titanium dioxide, a photosensitizer, a dispersing agent, a leveling agent and an antifoaming agent are synthesized into the ultraviolet-cured white butyl coating. The coating improves the adhesive force to tinplate in the true sense, and meanwhile, the siloxane resin component in the structure improves the temperature resistance, water resistance and other properties.

Owner:江阴广庆新材料科技有限公司

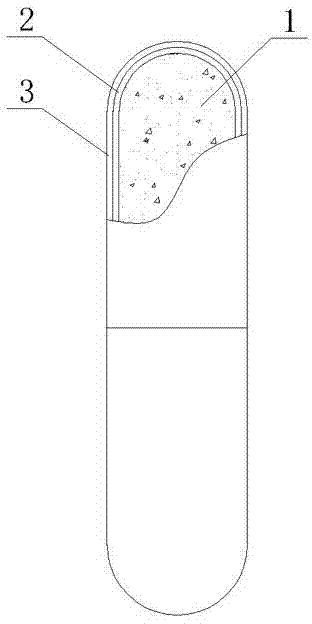

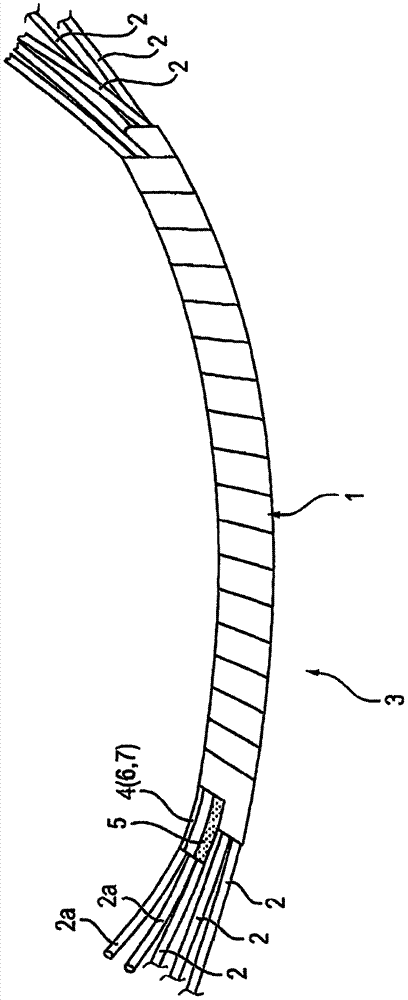

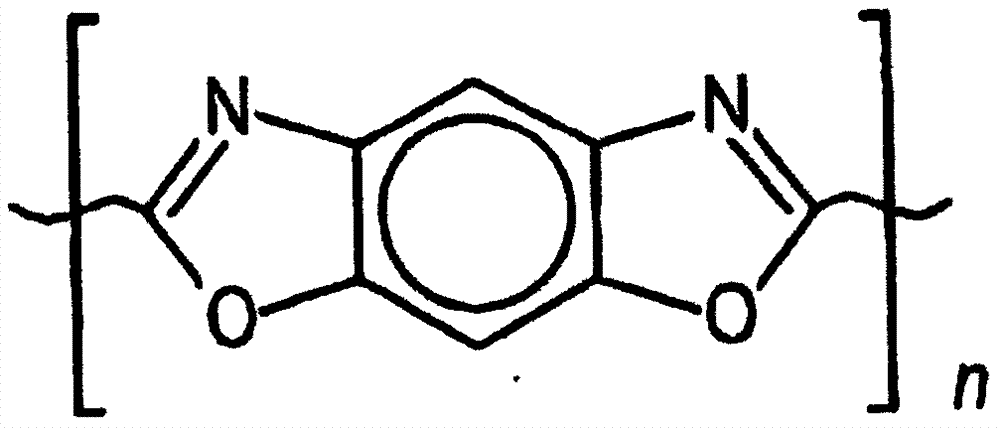

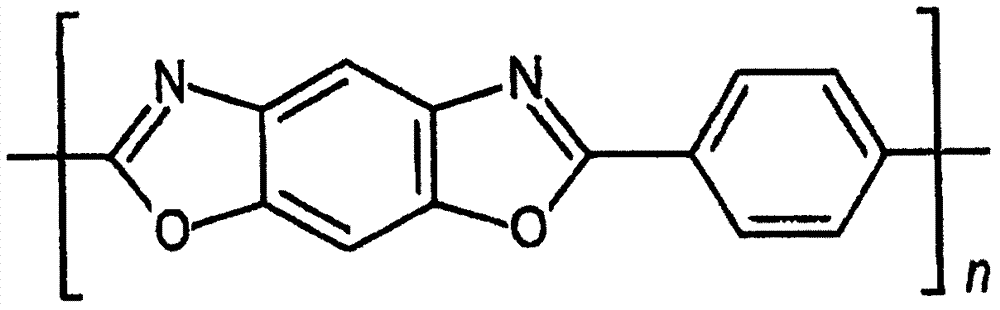

High-temperature and flame-resistant colored adhesive tape, use of a substrate for its manufacture, and cable harness including such an adhesive tape

ActiveCN106967371AReduced compatibilityNo migration will occurFilm/foil adhesivesInsulated cablesAdhesive beltPlastic materials

A colored adhesive tape (1), in particular a yellow, orange-colored, or black adhesive tape (1), preferably a cable wrapping tape, with a temperature class of at least T3 (LV 312), including a textile substrate with a polymer plastic substrate (4, 4a, 4b), on which an adhesive material (5, 5a, 5b) is applied. In order to improve the temperature stability of the tape, while maintaining advantageous properties, the color of at least a part of the substrate (4, 4a, 4b) is formed by the inherent color of the polymer plastic material. The tape is preferably substrate formed of a polymer plastic materials which are aromatic, nitrogen-containing polymers from the group of polyoxadiazoles (POD), polybenzobisoxazoles (PBO) or polybenzimidazoles (PBI) (4, 4a, 4b). The adhesive tape (1) may be used as a cable harness (3).

Owner:COROPLAST FRITZ MUELLER GMBH & CO KG

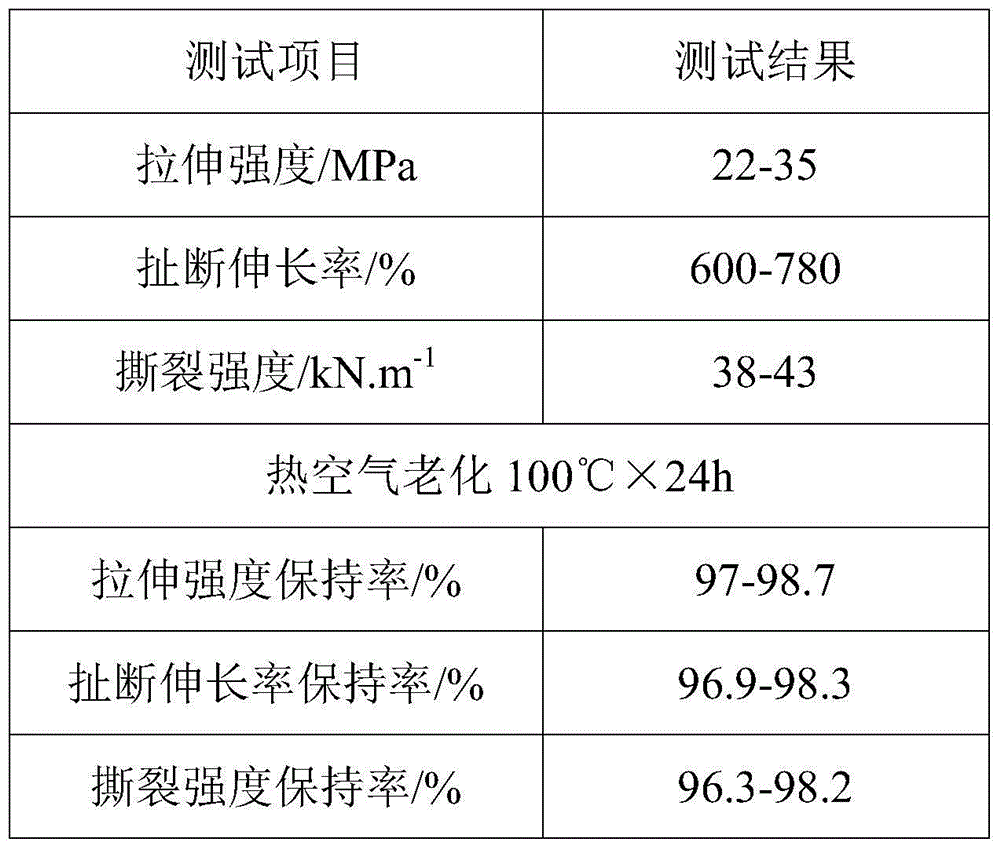

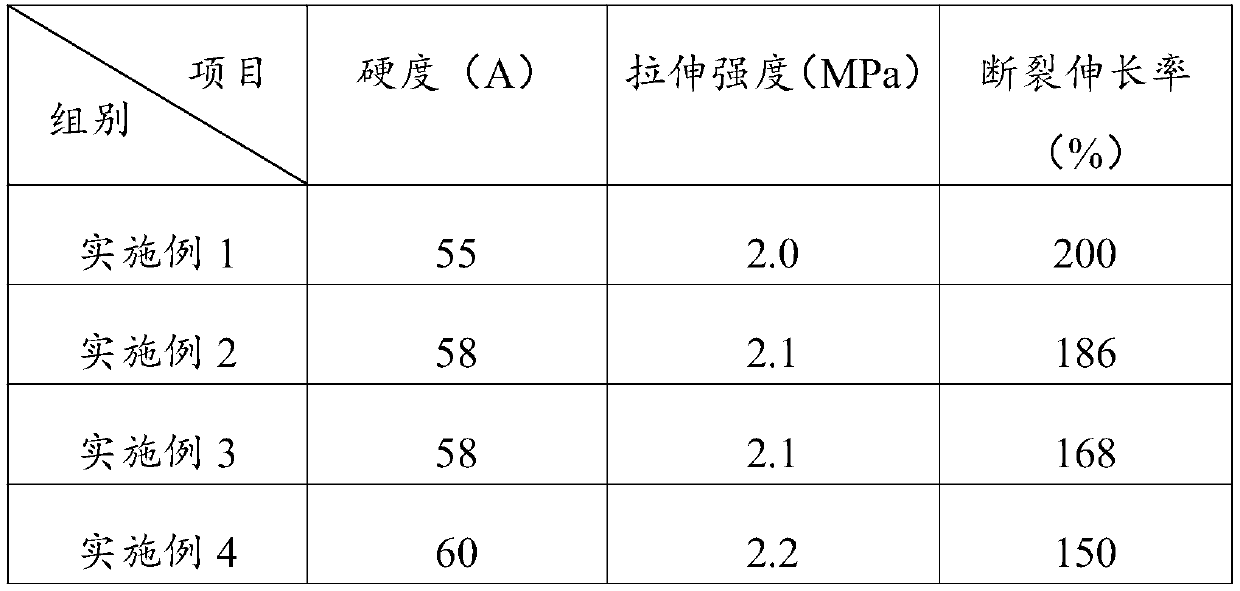

Manufacturing process of polyurethane prefabricated runway coiled material and obtained runway coiled material

The invention provides a manufacturing process of a polyurethane prefabricated runway coiled material. The manufacturing process comprises the following steps: firstly, paving a plastic film on a platform; then uniformly paving a polyurethane material on the plastic film; and carrying out high-temperature compounding on the two layers of materials to form the prefabricated runway coiled material.The manufacturing process is simple in process, short in production period and low in energy consumption. The manufacturing process is used for preparing polyurethane materials of the prefabricated runway coiled material. Polyether polyol and MDI are taken as main raw materials, the 3 ,3'-dichloro-4,4'-diaminodiphenylmethane is taken as a chain extender, and amino groups in the chain extender react with isocyanate end group prepolymer, so that the mechanical property of polyurethane is improved. By use of the white carbon black, the strength, the toughness, the heat resistance, the wear resistance and the aging resistance of the polyurethane can be improved. By use of the calcium carbonate, the mechanical property of the polyurethane is further enhanced. By use of the plasticizer, the processability of the polyurethane is improved. Pentaerythritol diphosphite distearyl ester is used as an antioxidant, so that the service life of polyurethane is prolonged. The prefabricated runway coiled material provided by the invention is high in safety performance and high in durability.

Owner:天津鼎兴橡塑有限公司

Aquosity wood lacquer emulsions, method of preparing the emulsions and aquosity wood lacquer of the same

InactiveCN101108888AEvenly distributedImprove stabilityLiquid surface applicatorsEmulsion paintsEmulsionLacquer

The invention provides a preparation method of the waterborne woodenware finishes emulsion. The method is that the composite nano sizing agent is added during the synthetic process of the emulsion and comprises the following raw materials of the weight portion ratio: Al2O3: 1 to 3; TiO2: 0.5 to 1; surfactant: 0.04 to 0.08; water: 3 to 6. The invention adopts the composite nano Al2O3 and TiO2 sizing agents to participate in the polyreaction of the emulasion to make the nano Al2O3 and TiO2 sizing agents distribute evenly in the emulsion and not move during drying the paint film, therefore, the waterborne woodenware finishes prepared by the emulsion not only has good stability, that is, precipitate will not happen even if stored over 6 months, but also has good rigidity, wear resistance, resistance to temperature fluctuations, phototropy resistance and antibacterial property.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for improving fire resistance and mechanical property of polyethylene/nylon 6 blend

The invention relates to a method for improving the fire resistance and mechanical property of a polyethylene / nylon6 blend. The method adopts the mode of two-step type step-by-step melt blending, controllable intumescent flame retardants are uniformly distributed in a nylon 6 phase domain in the polyethylene / nylon 6 blend, and then the fire resistance of the blend is greatly improved. Compared with a one-step processing method in the prior art, the limit oxygen index of the polyethylene / nylon 6 blend obtained through a step-by-step processing method can be increased by 15.6%-21.5%, the flame-retardant level of the blend can be increased to V-1 level or above from the phenomenon that the blend cannot be subjected to vertical combustion, and then the application value is greatly increased. The technical problem that in the prior art, for the polyethylene / nylon 6 blend, the fire resistance and the compatibilizing efficiency cannot be achieved simultaneously is solved.

Owner:HENAN UNIV OF SCI & TECH

Conductor paste for thick film circuit, thick film circuit board using same, and manufacturing method thereof

InactiveCN102760934BImprove conductivityWide variety of sourcesAntenna supports/mountingsSolid-state devicesConductive pasteSilver paste

A conductive paste for a thick film circuit, a thick film circuit board employing the same and a manufacturing method thereof relate to the field of thick film circuits. One of the purposes of the invention is to provide a conductive paste for a thick film circuit, which can replace a silver paste and low cost and high security. The conductive paste comprises the following components by mass percent: 72-77 percent of copper powder, 8-10 percent of inorganic adhesive, 4-6 percent of organic adhesive, 5-12 percent of organic solvent and 1-5 percent of additive. Another purpose of the invention is to provide a thick film circuit board employing the paste and adopting toughened glass as a baseplate. The third purpose of the invention is to provide a manufacturing method of the thick film circuit board. The manufacturing method comprises the steps of preparation of the conductive paste, a encapsulating paste and the baseplate, as well as the printing, encapsulating, sintering, performance test and packaging of a circuit diagram. The thick film circuit board has favorable sintering characteristic and aesthetic appearance, and can be widely used in the manufacturing field of electronic components.

Owner:SHENZHEN SENLONT ELECTRONICS

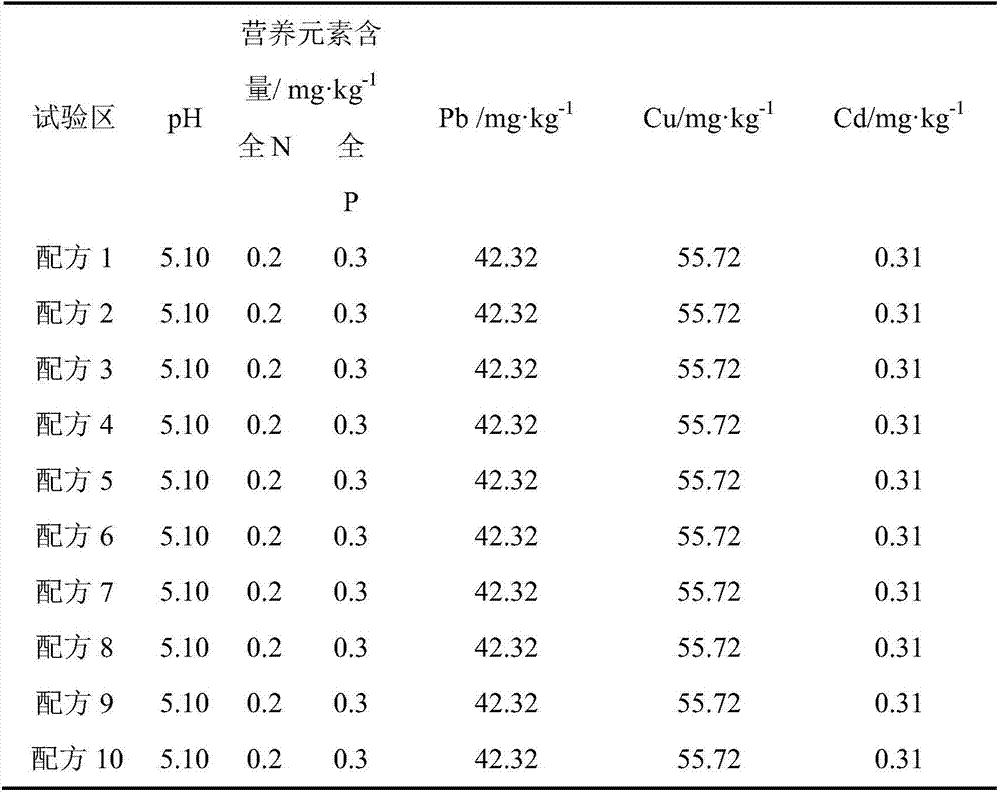

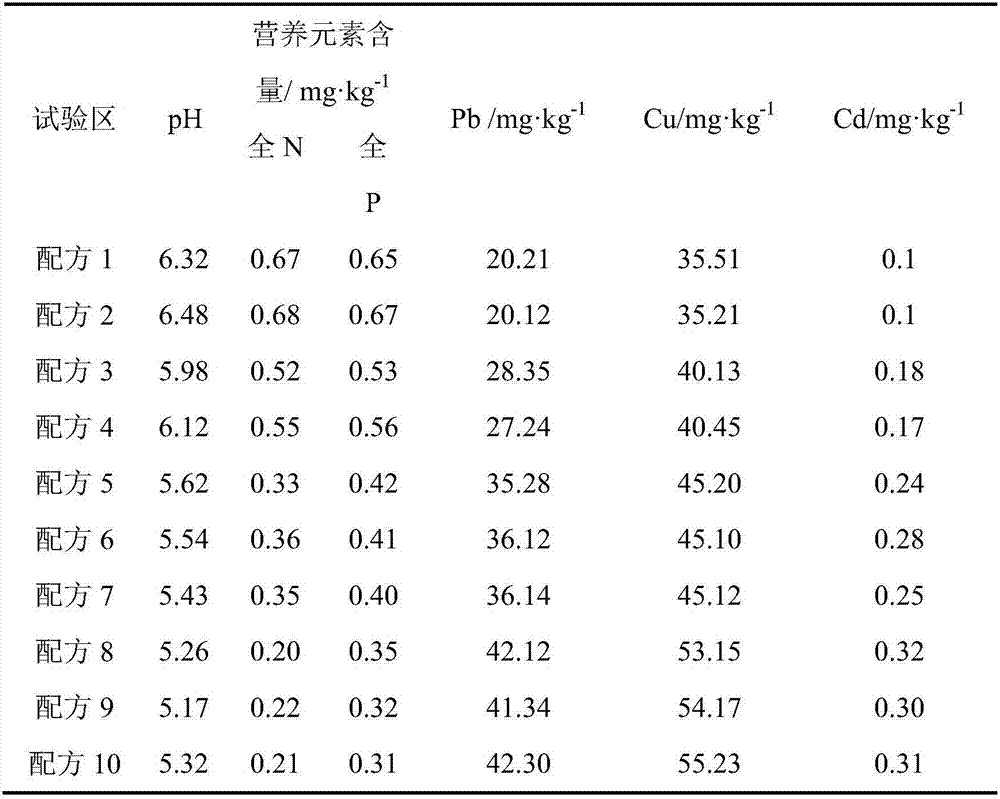

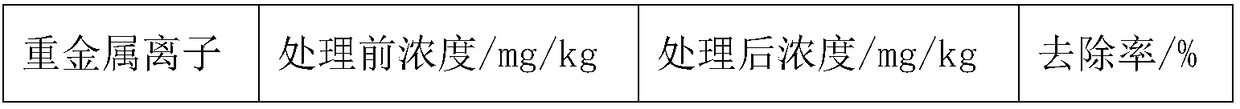

Heavy-metal-polluted soil treatment agent, and preparation method thereof

InactiveCN108998046AWide variety of sourcesEasy to useOrganic fertilisersSoil conditioning compositionsSoil treatmentGrape seed

The invention discloses a heavy-metal-polluted soil treatment agent, and a preparation method thereof. The heavy-metal-polluted soil treatment agent is prepared from raw materials with the following parts by weight: 1.6-2.8 parts of multivitamins, 3.8-6.5 parts of grape seeds, 43-48.6 parts of bauxite, 1.8-2.7 parts of citric acid, 4-7 parts of pinellia ternate, 3-5.2 parts of EDTA salt, 1.5-2.3 parts of ethyl acetate, 2.4-4.5 parts of dipotassium phosphate, and 8-11.7 parts of polyvinyl alcohol. The heavy-metal-polluted soil treatment agent and the preparation method thereof provided by the invention have the advantages that different preparation methods are adopted to obtain different products, and the different products react with one another and perform synergistic effects; and a finished product prepared through the method is easy to use, and can absorb, complex, flocculate and mineralize heavy metal ions in heavy-metal-polluted soil, so that the heavy metal ions cannot be migrated, heavy metals can be effectively removed, , and wide application prospects are achieved.

Owner:黄志优

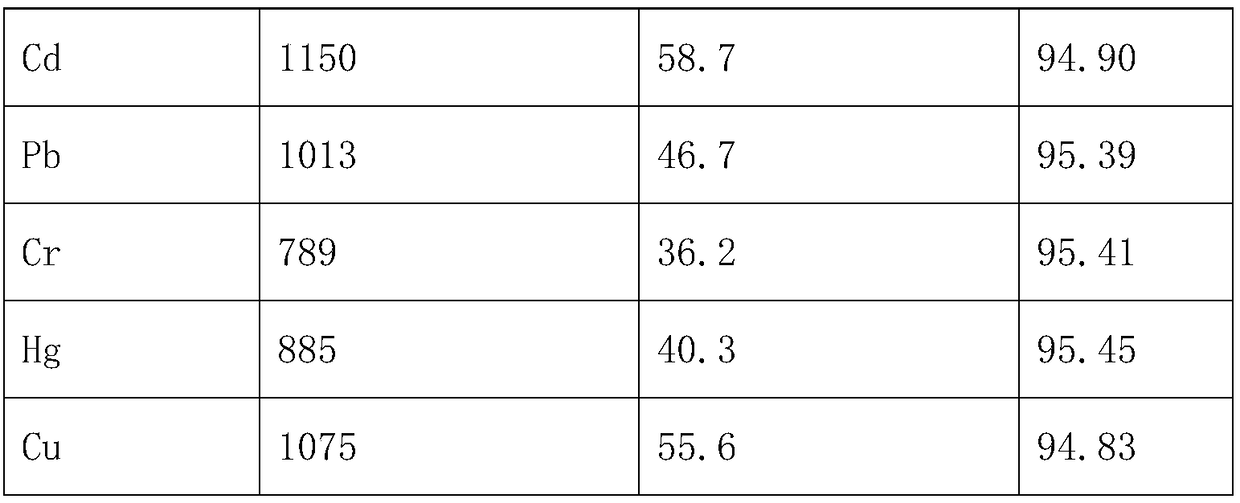

Stainless steel for medical instruments and preparation method thereof

The invention discloses stainless steel for medical instruments and a preparation method thereof. The stainless steel for the medical instruments comprises the following components of, in percentage by weight, 0.01%-0.07% of C, 0.02%-0.06% of Mn, 16%-18% of Cr, 6%-8% of Ni, 0.4%-0.8% of Mo, 0.03%-0.05% of V, 0.06%-0.1% of Nb, 0.8%-1.2% of Al, 0.01%-0.02% of B+S+F, 0.14%-0.36% of Ag, 0.14%-0.36% ofCu, the content of Sn is equal to the sum of the content of Cu and Ag, 0.01%-0.03% of silicones, 0.002%-0.004% of nanometer silicate fiber, and the balance of Fe. According to the stainless steel forthe medical instruments and the preparation method thereof, firstly, carrying out C, B and Fe alloying, S, C and Fe alloying, and Cu, Sn and Ag alloying on stainless steel for the medical instruments, and then obtaining the stainless steel through adding other components to carry out melt mechanical machining. The stainless steel for medical instruments and the preparation method thereof disclosed by the invention have the advantages that the hardness, the corrosion resistance and the high-temperature oxidation resistance of the medical instrument materials are improved.

Owner:长沙凯泽工程设计有限公司

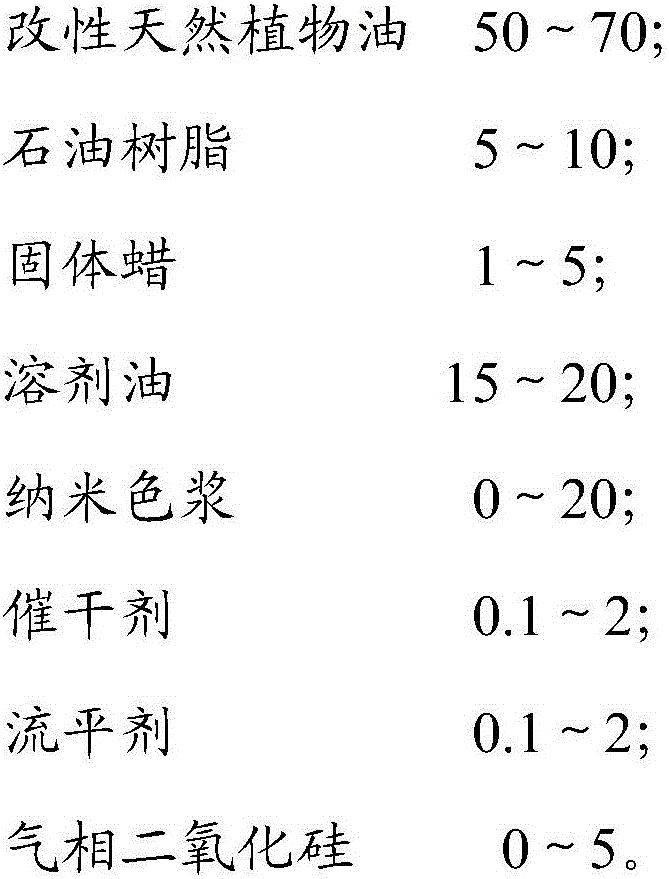

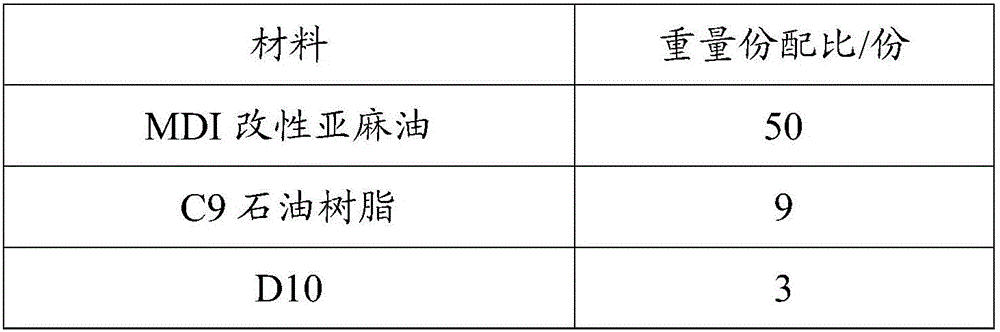

Aerosol paint and preparation method thereof

The invention discloses aerosol paint which comprises, by weight parts, 50-70 parts of modified natural plant oil, 5-10 parts of petroleum resin, 1-5 parts of solid wax, 15-20 parts of solvent oil, 0-20 parts of nanometer color paste, 0.1-2 parts of drier, 0.1-2 parts of flatting agent and 0-5 parts of fumed silica. By adoption of the technical scheme, the aerosol paint has the advantages that oxygen is completely insulated in an aerosol can, product thickening and oxidizing discoloration caused by the reaction with oxygen are avoided, product storage stability is greatly improved, the guarantee period of the product is prolonged, and the aerosol paint has the advantages of being flexible and convenient to construct and excellent in atomization performance. A high-activity iron complex is compounded with zinc isoocatanoate and zirconium 2-ethylhexanoate, MDI modified natural plant oil is optimal, and an oil film is environmentally friendly, quick in drying speed, high in hardness and good in waterproof performance. The aerosol paint is good in permeability, bright in color and good in weather resistance and does not migrate. The invention further discloses a method for preparing the aerosol paint.

Owner:AMRICAN SANVO HONG KONG CHEM TECH HLDG LTD

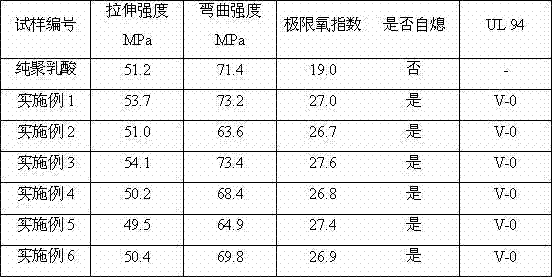

Flame-retardant natural fiber reinforced polylactic acid composite material and preparation method thereof

The invention belongs to the technical field of materials, and particularly relates to a flame-retardant natural fiber reinforced polylactic acid composite material and a preparation method of the flame-retardant natural fiber reinforced polylactic acid composite material, being used for the fields of electronics and the like. The preparation method comprises the specific steps of firstly, blending dried polylactic acid, an nanometer additive, an antioxidant and anti-dropping agent according to the proportion respectively, and extruding; mixing a fire retardant and natural fibers, and finally adding blending materials of natural fibers and polylactic acid subjected to fire retardant treatment into an extruder according to certain proportion, and blending and extruding to obtain the flame-retardant natural fiber reinforced polylactic acid composite material. The composite material has good flame retardant property and mechanical property, the preparation method is simple and effective, the process conditions are moderate, and the flame-retardant natural fiber reinforced polylactic acid composite material is suitable for batch production.

Owner:TONGJI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com