Stainless steel for medical instruments and preparation method thereof

A medical device and stainless steel technology, which is applied in the field of stainless steel for medical devices and its preparation, can solve the problems of unsatisfactory corrosion resistance and high temperature oxidation resistance of medical device materials, so as to avoid the decline of mechanical properties and enhance the corrosion resistance , the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

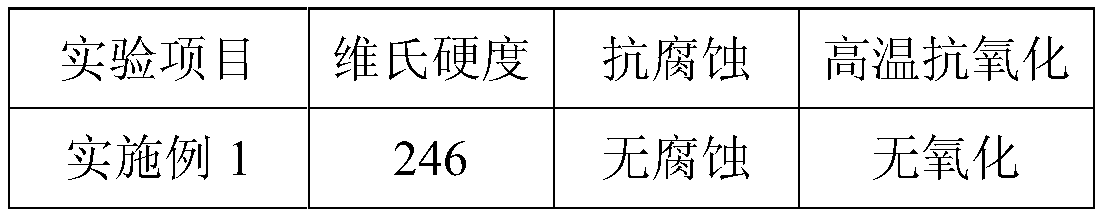

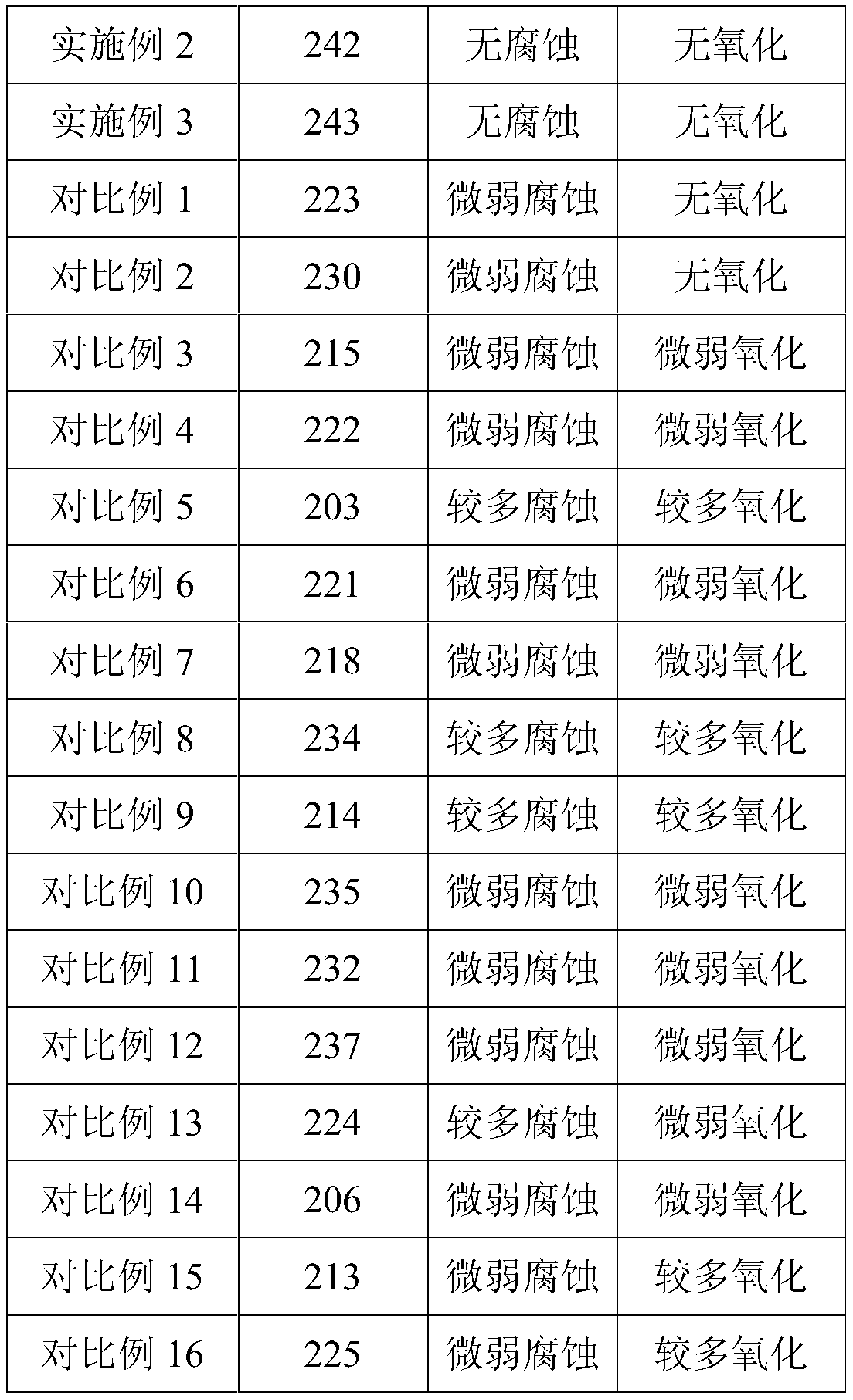

Examples

Embodiment 1

[0023] A stainless steel for medical devices, the stainless steel for medical devices comprises the following components by weight percentage: C: 0.04, Mn: 0.04, Cr: 17, Ni: 7, Mo: 0.6, V: 0.04, Nb: 0.08, Al: 1.0, B+S+F: 0.015, Ag: 0.25, Cu: 0.25, Sn content = sum of Cu and Ag content, polysilicone: 0.02, nano silicate fiber: 0.003, and the rest is Fe. The ratio of B, S and F is 1:1:1.

[0024]According to the above-mentioned preparation method of stainless steel for medical devices, the following steps are included: mixing 50% C, B, and 50% Fe, heating to 1200° C. to melt to obtain the first molten liquid, and mixing S, 50% C, and 50% Fe Heat to 1200°C to melt to obtain the second molten liquid, mix Cu, Sn, and Ag and heat to 1700°C to obtain the third molten liquid, mix the first molten liquid and the second molten liquid at 1200°C and cool down After reaching 800°C, add polysilicone and nano-silicate fiber, heat up to 1700°C, mix evenly, keep warm for 1 hour, add the third...

Embodiment 2

[0026] A stainless steel for medical devices, the stainless steel for medical devices comprises the following components by weight percentage: C: 0.01, Mn: 0.06, Cr: 16, Ni: 8, Mo: 0.4, V: 0.0.5, Nb: 0.06, Al: 1.2, B+S+F: 0.01, Ag: 0.36, Cu: 0.14, Sn content = sum of Cu and Ag content, polysilicone: 0.03, nano silicate fiber: 0.002, and the rest is Fe.

[0027] According to the above-mentioned preparation method of stainless steel for medical devices, the following steps are included: mixing 50% C, B, and 50% Fe, heating to 1200° C. to melt to obtain the first molten liquid, and mixing S, 50% C, and 50% Fe Heat to 1200°C to melt to obtain the second molten liquid, mix Cu, Sn, and Ag and heat to 1700°C to obtain the third molten liquid, mix the first molten liquid and the second molten liquid at 1200°C and cool down After reaching 800°C, add polysilicone and nano-silicate fiber, heat up to 1700°C, mix evenly, keep warm for 1 hour, add the third molten liquid, keep warm for 1 ho...

Embodiment 3

[0029] A stainless steel for medical devices, the stainless steel for medical devices includes the following components by weight percentage: C: 0.07, Mn: 0.02, Cr: 18, Ni: 6, Mo: 0.8, V: 0.03, Nb: 0.1, Al: 0.8, B+S+F: 0.02, Ag: 0.14, Cu: 0.36, Sn content = sum of Cu and Ag content, polysilicone: 0.01, nano silicate fiber: 0.004, and the rest is Fe.

[0030] According to the above-mentioned preparation method of stainless steel for medical devices, the following steps are included: mixing 50% C, B, and 50% Fe, heating to 1200° C. to melt to obtain the first molten liquid, and mixing S, 50% C, and 50% Fe Heat to 1200°C to melt to obtain the second molten liquid, mix Cu, Sn, and Ag and heat to 1700°C to obtain the third molten liquid, mix the first molten liquid and the second molten liquid at 1200°C and cool down After reaching 800°C, add polysilicone and nano-silicate fiber, heat up to 1700°C, mix evenly, keep warm for 1 hour, add the third molten liquid, keep warm for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com