Patents

Literature

334results about How to "Reduce gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

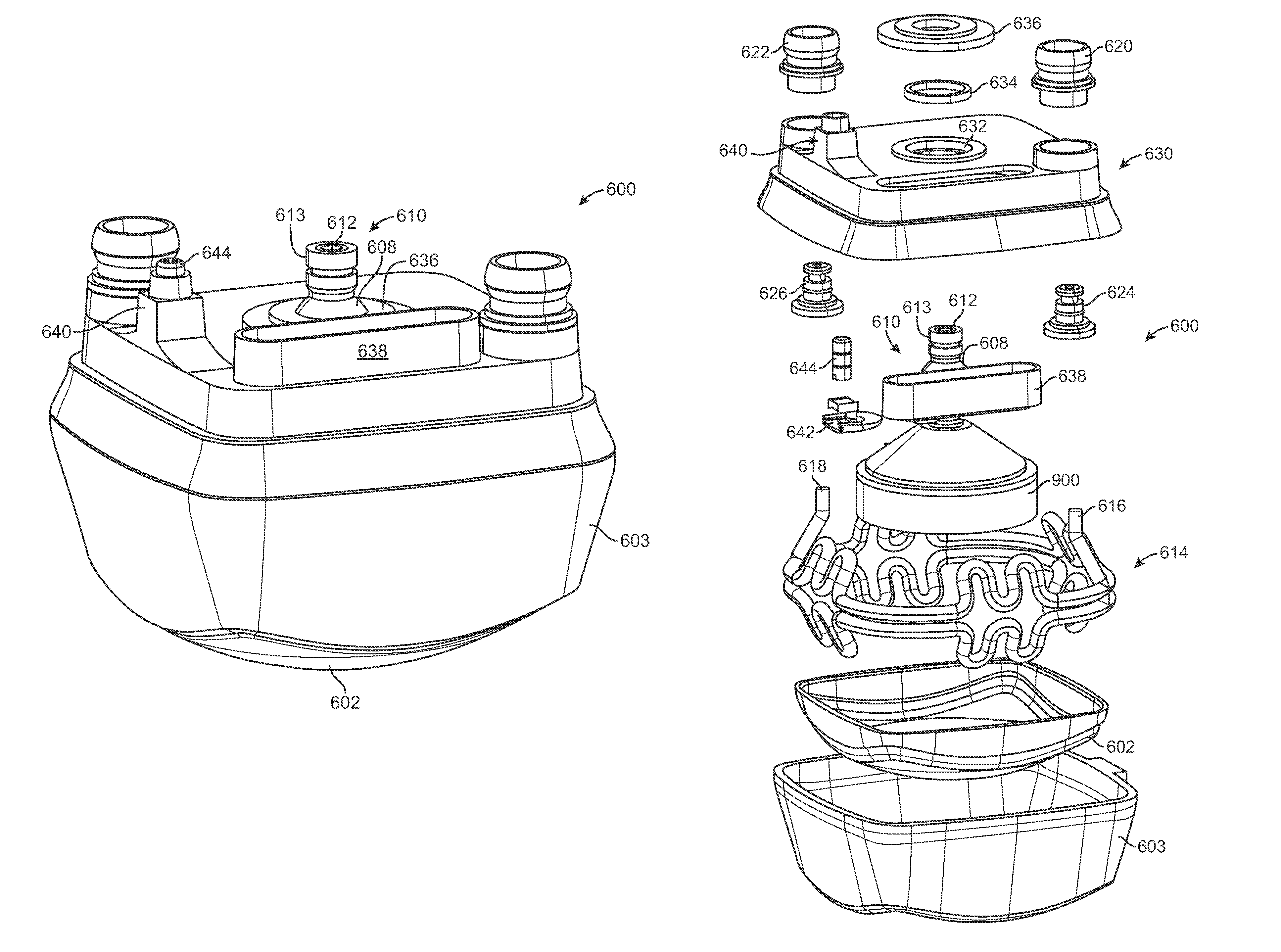

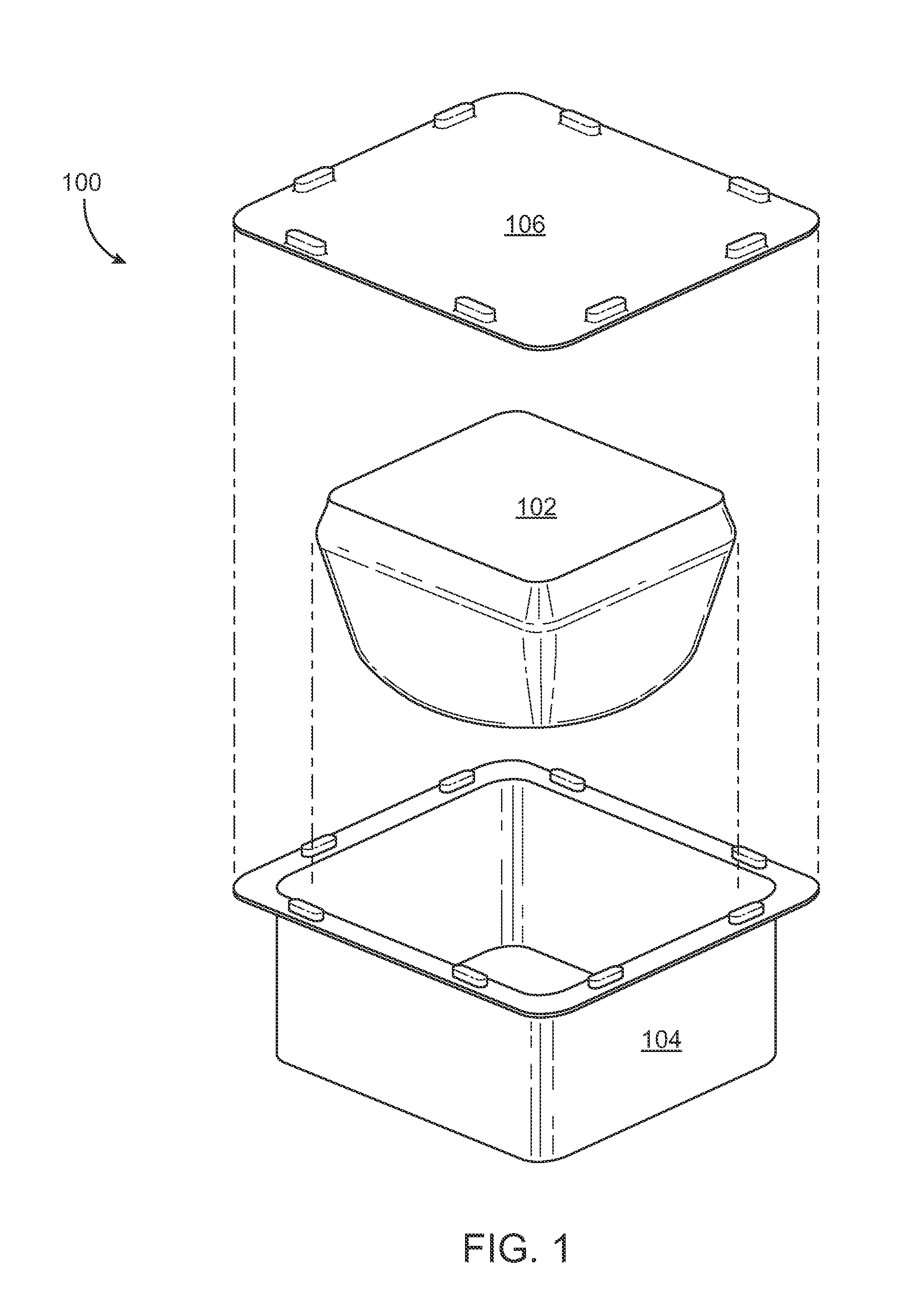

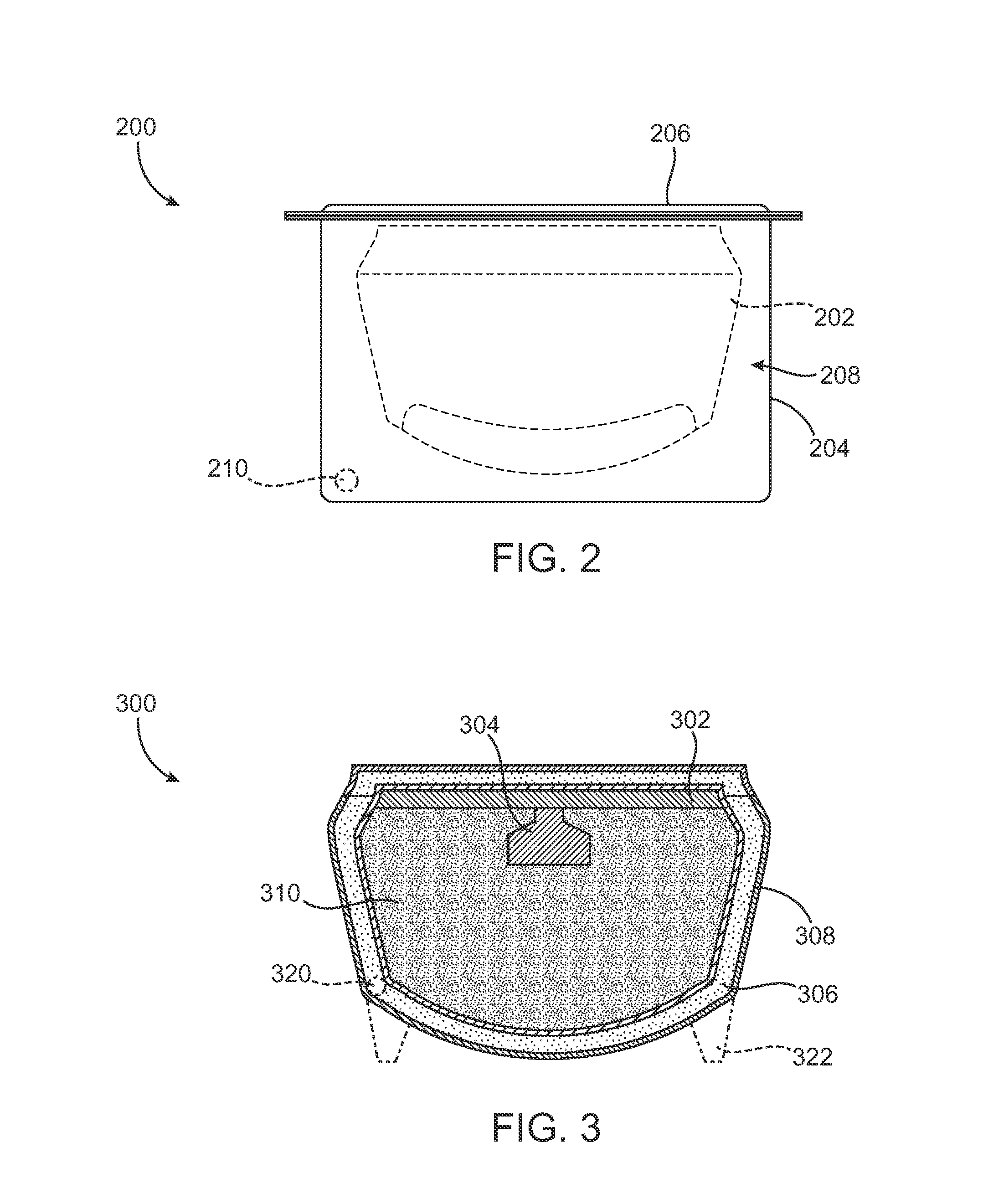

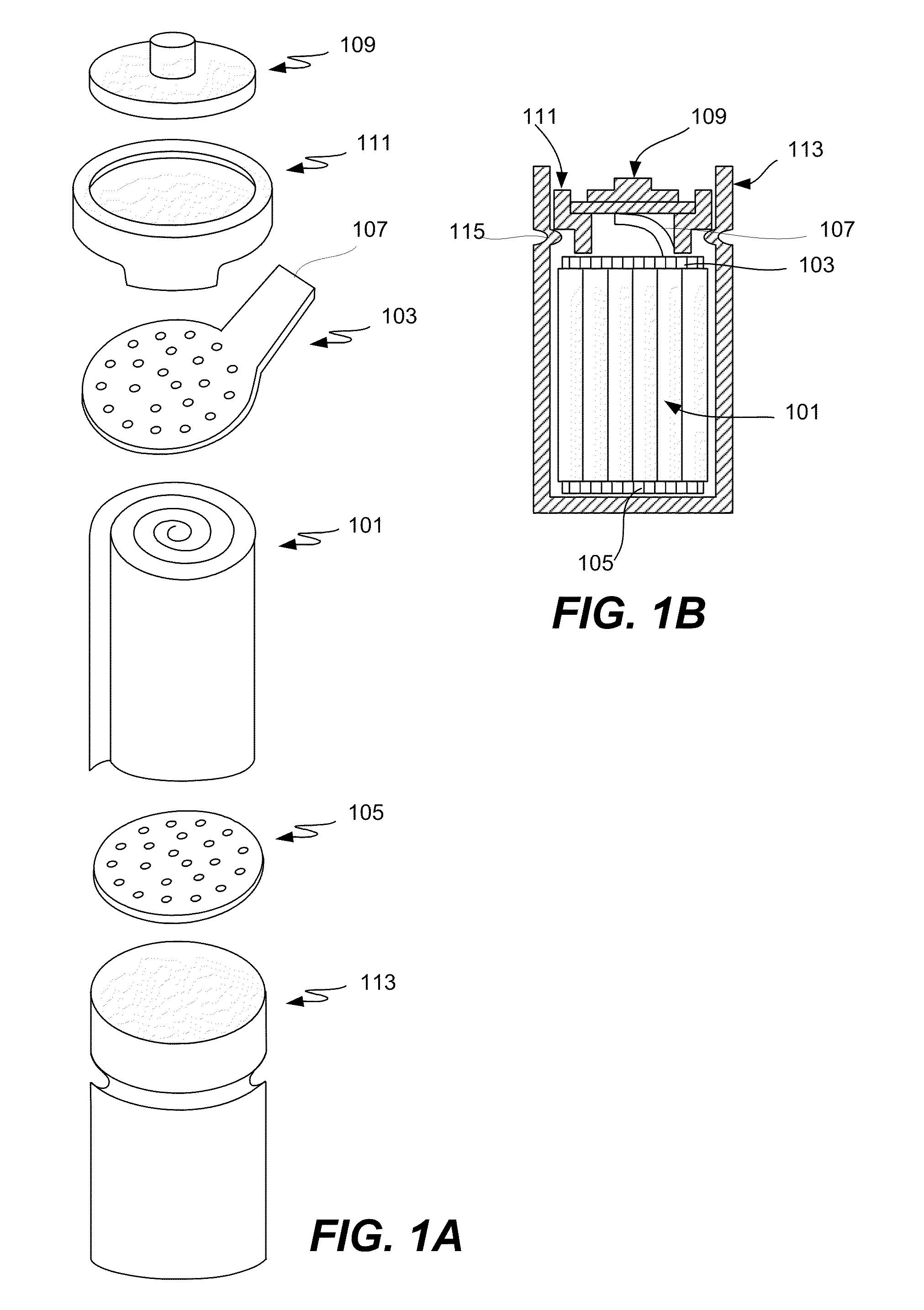

Modified atmosphere packaging for ultrasound transducer cartridge

ActiveUS8573392B2Extended shelf lifeReduce gasUltrasonic/sonic/infrasonic diagnosticsDispensing apparatusUltrasonic sensorTransducer

A modified atmosphere package for extending the shelf life of a replaceable transducer cartridge having a sealed volume and containing a fluid. The fluid may be fluid or a gas. If a fluid, such as water, then the modified atmosphere package may be configured to prevent the loss of fluid or the entry of gas into the transducer cartridge.

Owner:SOLTA MEDICAL

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

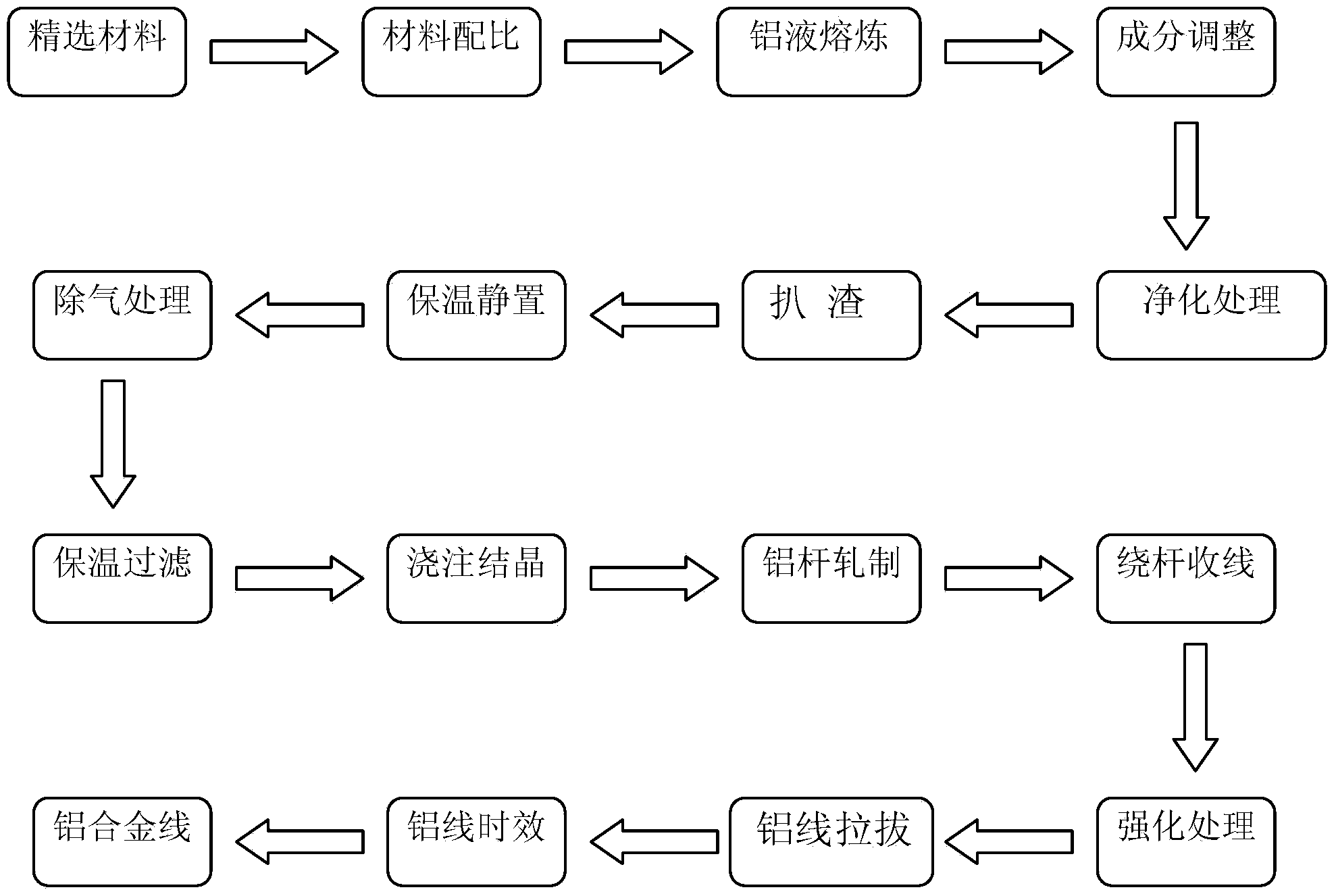

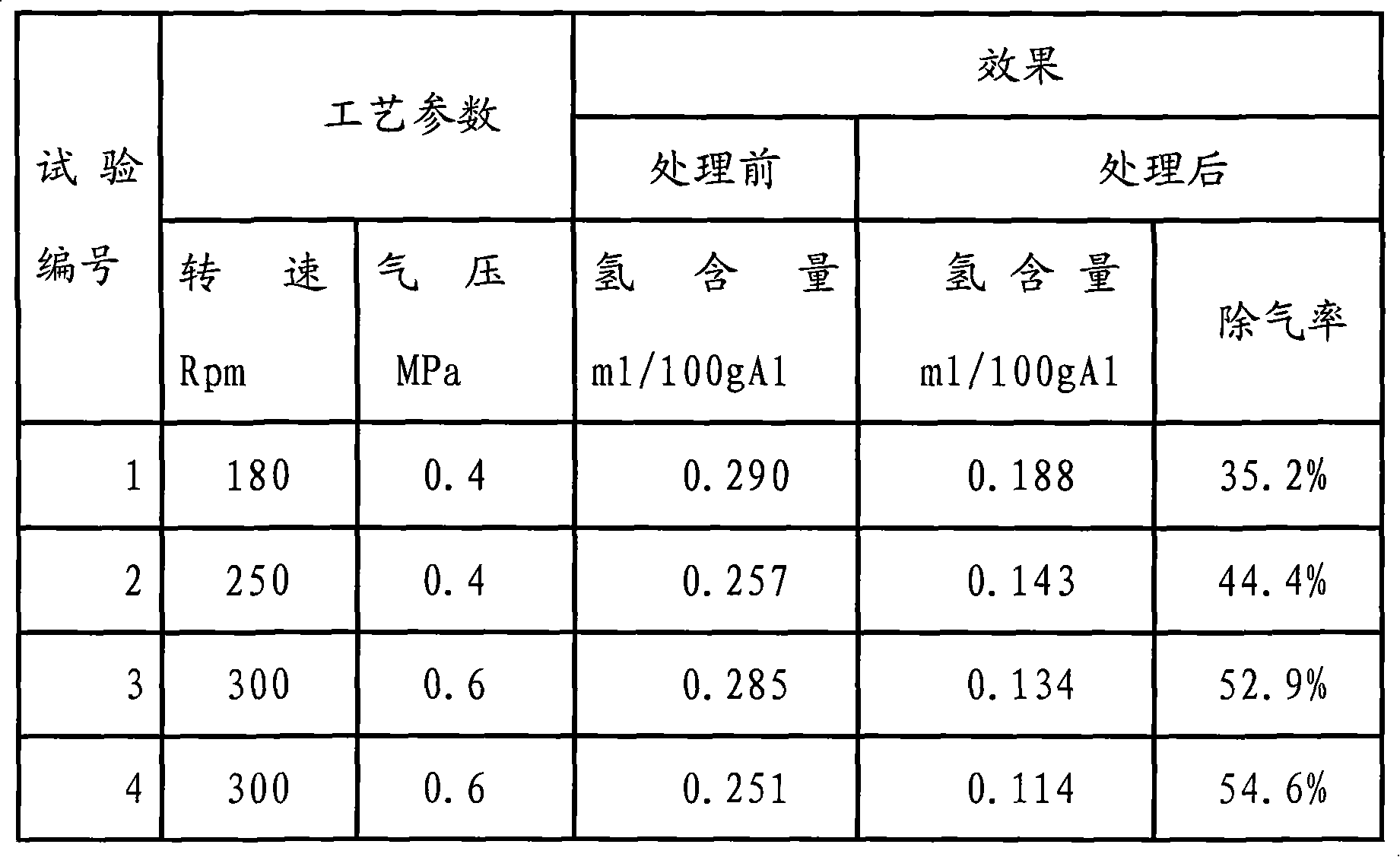

Medium strength aluminium alloy wire with conductivity of 60% IACS, and preparation method thereof

ActiveCN103820685AHigh strengthImprove conductivityMetal/alloy conductorsCable/conductor manufactureRare-earth elementManufacturing technology

The invention relates to a medium strength aluminium alloy wire with conductivity of 60% IACS, and a preparation method thereof, and belongs to the field of alloy manufacturing technology. The alloy elements comprise, by weight, 0.16%-0.22% of iron, 0.24%-0.30% of silicon, 0.40%-0.48% of magnesium, 0.01%-0.02% of boron and 0.08%-0.15% of a rare earth element, with the balance being aluminium. The medium strength aluminium alloy wire with a product conductivity higher than or equal to 60% IACS and tensile strength higher than or equal to 230 MPa is obtained by processes of selecting materials, smelting liquid aluminium, adjusting liquid aluminium ingredients, carrying out purifying treatment, deslagging, standing with heat preservation, degassing, filtering with heat preservation, casting and crystallizing, rolling an aluminum rod, drawing and aging. The wire and cable produced by using the aluminium alloy can be erected continuously by a conventional construction process. In a circuit operation process, circuit loss can be reduced; construction fee can be reduced; and the medium strength aluminium alloy has significant economic benefits and social benefits.

Owner:WUXI HUANENG ELECTRIC CABLE

Method for smelting nickel-based high temperature alloy in vacuum induction furnace

The invention relates to a method for smelting a nickel-based high temperature alloy in a vacuum induction furnace. The method sequentially comprises the following steps of: I, putting alloy raw materials into the furnace in a ratio; II, closing a furnace cover, vacuumizing, and performing power transmission to melt furnace burden; III, melting at the speed of less than or equal to 1 / 2 maximum furnace capacity / hour; IV, after the furnace burden is completely melted, starting performing bottom argon blowing, and refining for 20 to 25 minutes; V, stopping argon blowing, adding Al and Ti, and alloying; VI, after Al and Ti are completely melted, performing bottom argon blowing, and refining; VII, after refining is finished, closing a vacuum pump, and filling argon into the furnace and an ingot mold; VIII, alloying at the finishing point, namely adding B, Zr and a rare earth element, and adding a Ni-Mg alloy; and IX, performing electrified tapping after 3 to 4 minutes, and casting into an alloy ingot. By the method for smelting the nickel-based high temperature alloy in the vacuum induction furnace, refining time is 35 to 40 minutes, and the nickel-based high temperature alloy with very low carbon content can be obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Coating compositions having improved stability

ActiveUS20060047062A1Improve shelf lifeReduce gassing and gellationConductive materialNon-conductive material with dispersed conductive materialChemistryEmulsion

This invention relates to waterborne coating compositions having improved compatability with metal pigments, i.e., improved shelf life and reduced gassing and gellation. The compositions comprise at least one aqueous dispersion of (1) at least one emulsion copolymer polymerized from (a) at least one ethylenically unsaturated anionic monomer and (b) at least one other olefinically unsaturated monomer, said copolymer being made using at least one phosphate surfactant having at least one phosphorus acid group or salt thereof, said copolymer being crosslinked, and (2) at least one non-water soluble metal pigment. The compositions are useful in paints and other coatings.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Pasted zinc electrode for rechargeable nickel-zinc batteries

ActiveUS20100291439A1High viscositySimple working processFinal product manufacturePrimary cellsZinc metalSlurry

Active material for a negative electrode of a rechargeable zinc alkaline electrochemical cell is made with zinc metal particles coated with tin and / or lead. The zinc particles may be coated by adding lead and tin salts to a slurry containing zinc particles, a thickening agent and water. The remaining zinc electrode constituents such as zinc oxide (ZnO), bismuth oxide (Bi2O3), a dispersing agent, and a binding agent such as Teflon are then added. The resulting slurry / paste has a stable viscosity and is easy to work with during manufacture of the zinc electrode. Further, the zinc electrode is much less prone to gassing when cobalt is present in the electrolyte. Cells manufactured from electrodes produced in accordance with this invention exhibit much less hydrogen gassing, by as much as 60-80%, than conventional cells. The cycle life and shelf life of the cells is also enhanced, as the zinc conductive matrix remains intact and shelf discharge is reduced.

Owner:ZINCFIVE POWER INC

Electrolyte additive, high-voltage electrolyte and lithium ion battery containing electrolyte additive

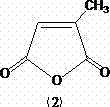

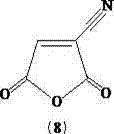

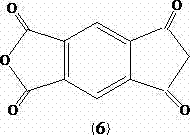

InactiveCN103094616AInhibit surface activityAvoid contactSecondary cellsAluminium-ion batteryOrganic solvent

The invention discloses an electrolyte additive, a high-voltage electrolyte and a lithium ion battery containing the electrolyte additive. The high-voltage electrolyte is prepared by adding the electrolyte additive into the conventional electrolyte; the conventional electrolyte comprises a non-aqueous organic solvent and lithium salt, wherein the content of the non-aqueous organic solvent is 80-85 percent of the total mass; the mass of the electrolyte additive is 0.01-10 percent of the total mass; and the electrolyte additive is maleic anhydride C4H2O3 or one of derivatives thereof and has the structure formula as shown in the abstract. According to the high-voltage electrolyte, a stable interfacial film can be formed on the surfaces of a positive electrode and a negative electrode, the reaction activity on the electrode surface is inhibited, oxidative decomposition of the electrolyte is reduced, and gas swelling is effectively inhibited, so that the safety performance and the cycle performance of the lithium ion battery under normal pressure and high voltage are improved and the service life of the lithium ion battery under normal pressure and high voltage is prolonged. The electrolyte is simple in preparation process and is suitable for industrial production.

Owner:JIANGXI YOULI NEW MATERIALS

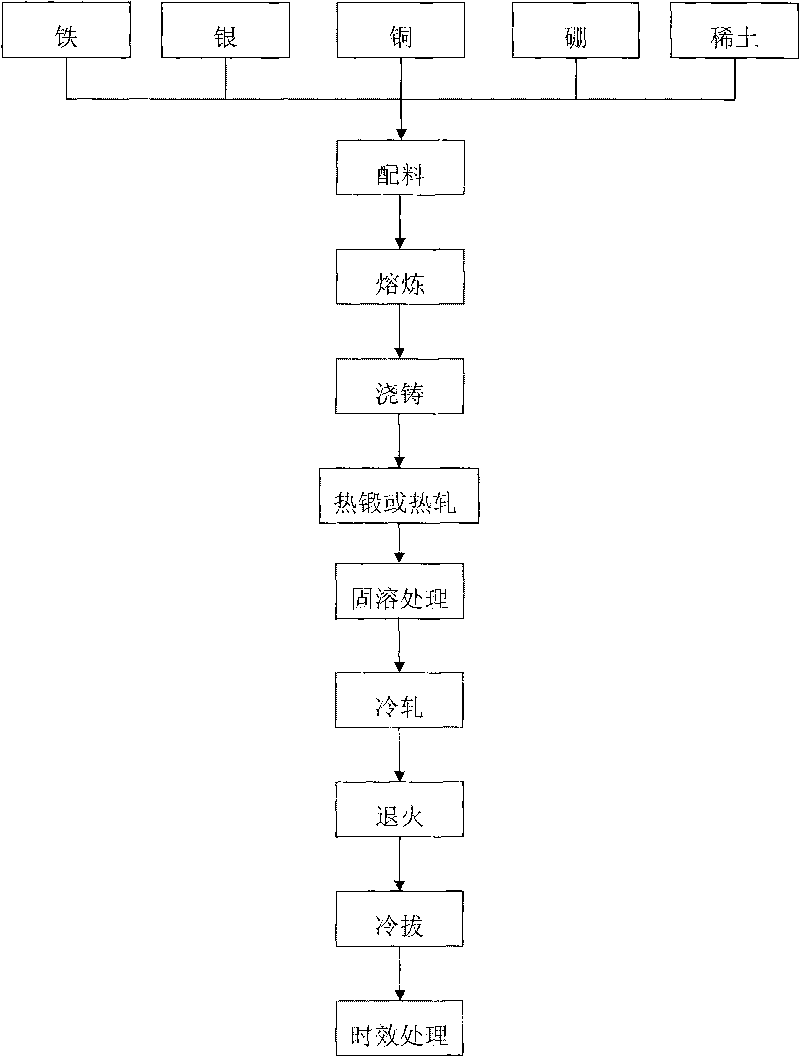

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Coating compositions having improved stability

ActiveUS7459496B2Improve compatibilityExtended shelf lifeConductive materialNon-conductive material with dispersed conductive materialPolymer scienceActive agent

This invention relates to waterbone coating compositions having improved compatability with metal pigments, i.e., improved shelf life and reduced gassing and gellation. The composition comprise at least one aqueous dispersion of (1) at least one emulsion copolymer polymerized from (a) at least one ethylenically unsaturated anionic monomer and (b) at least one other olefinically unsaturated monomer, said copolymer being made using at least one phosphate surfactant having at least one phosphorus acid group or salt thereof, said copolymer being crosslinked, and (2) at least one non-water soluble metal pigment. The compositions are useful in paints and other coatings.

Owner:LUBRIZOL ADVANCED MATERIALS INC

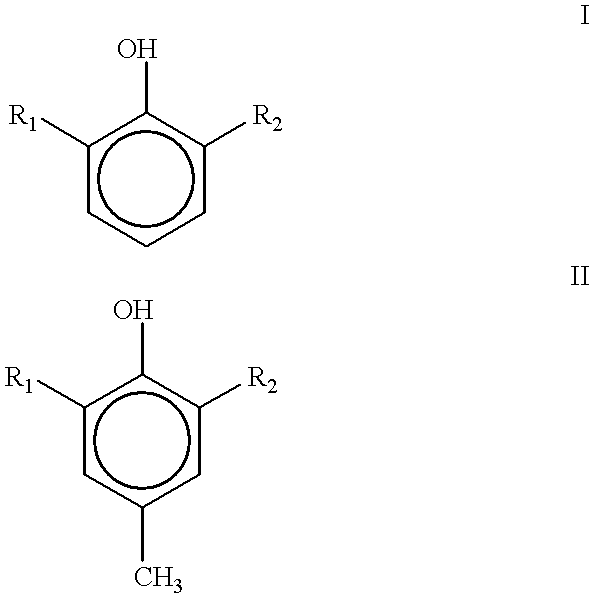

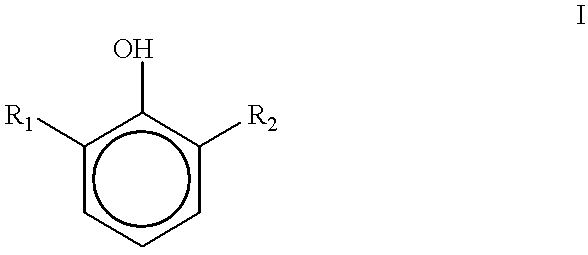

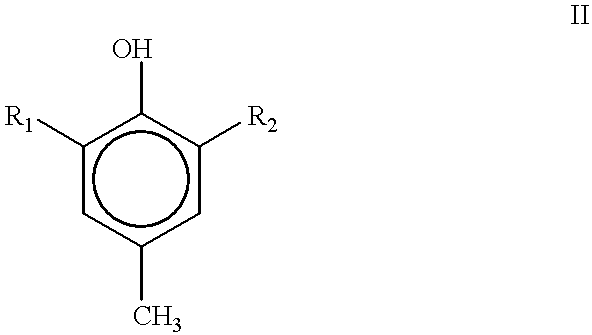

Electrical insulating oil with reduced gassing tendency

InactiveUS20020109127A1Reduce gasReduction tendencyLiquid organic insulatorsHydrocarbon distillationCyclic alkaneElectricity

An electrical oil having reduced gassing tendency includes a major amount of a paraffinic or naphthenic basestock and a blend of certain hindered phenols, especially a blend of 2,6-di-t-butyl phenol and 2,6-di-t-butyl cresol. A further enhanced gassing tendency can be provided to the electrical oil by including a tolyltriazole derivative.

Owner:EXXON RES & ENG CO

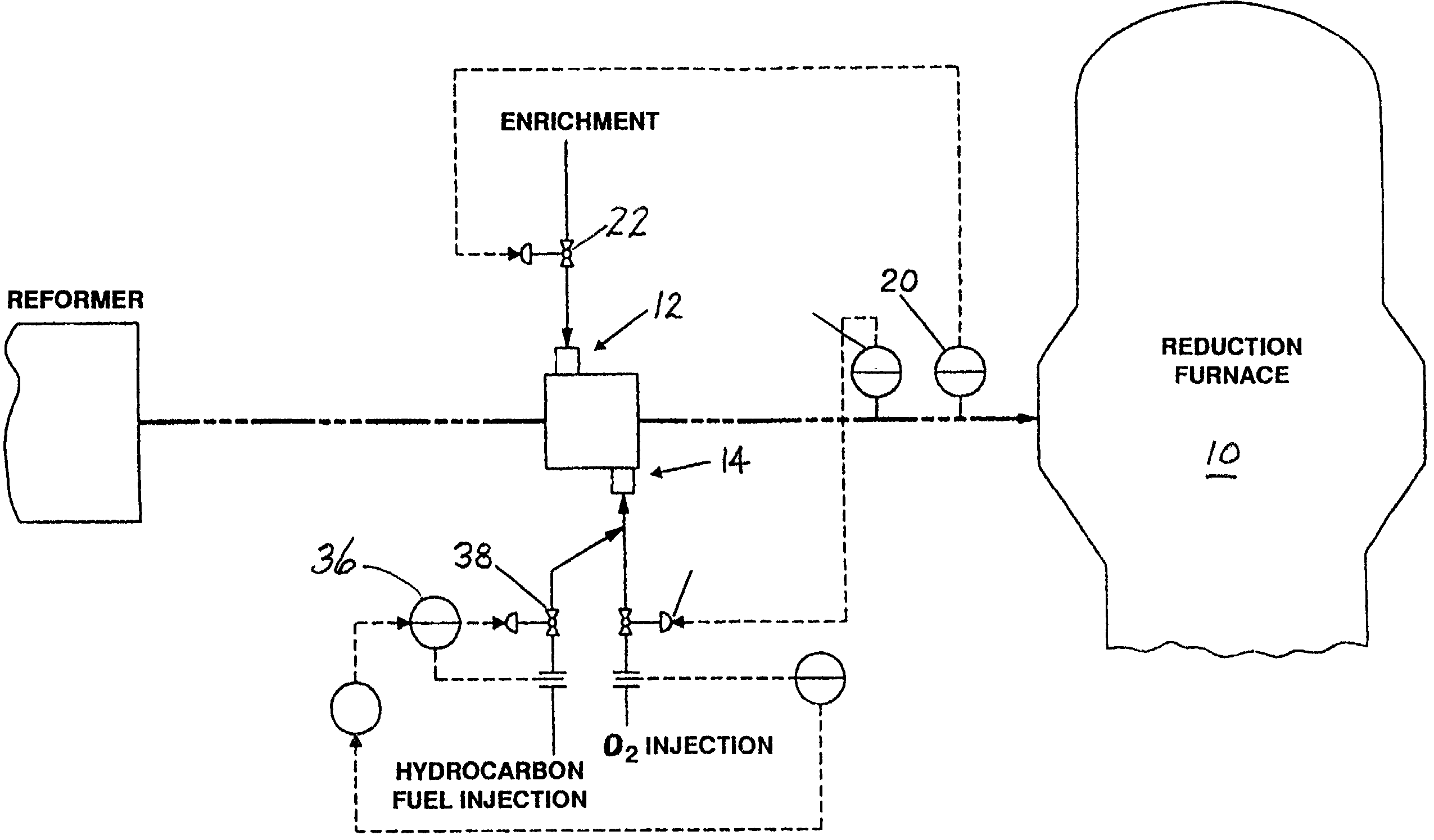

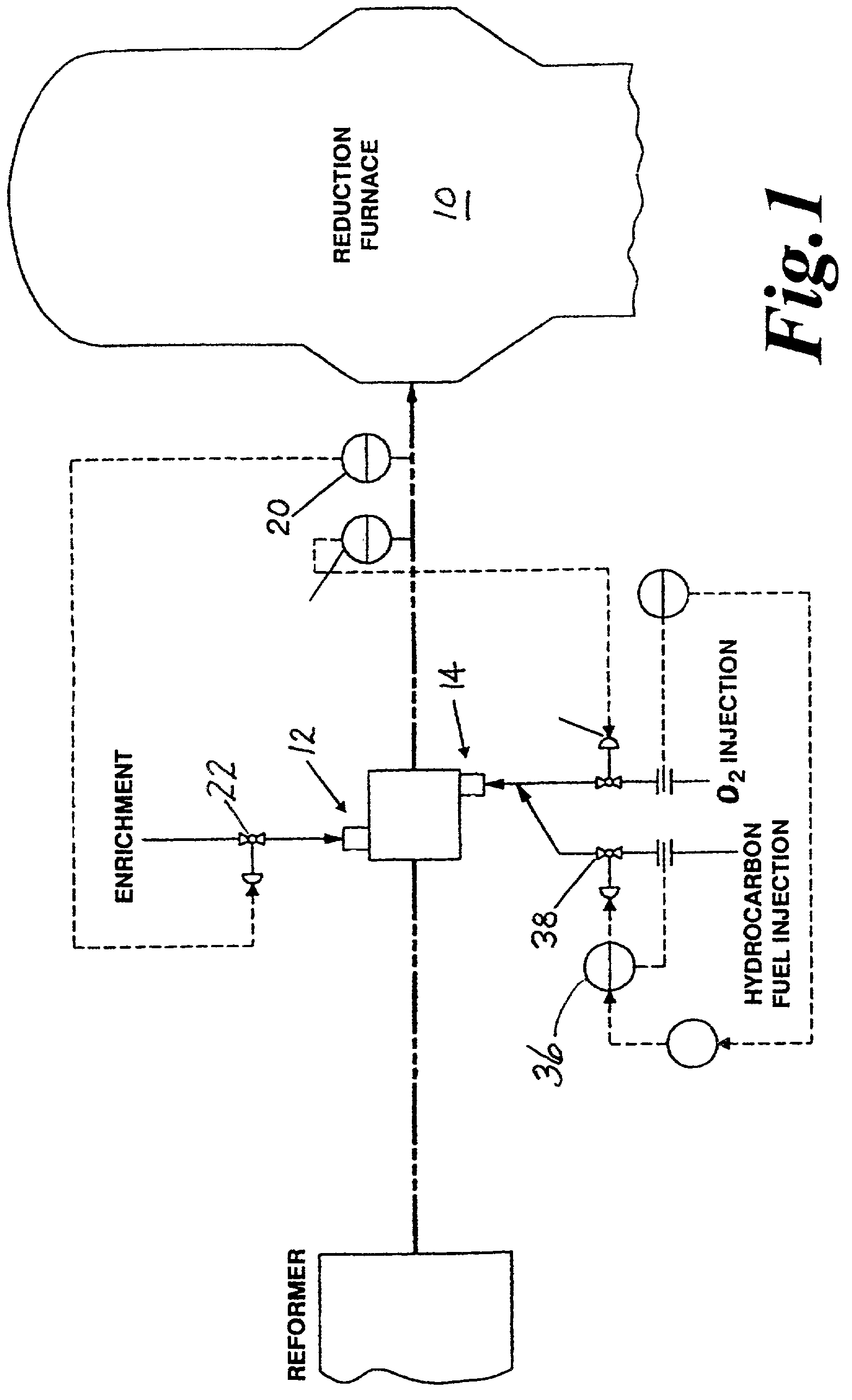

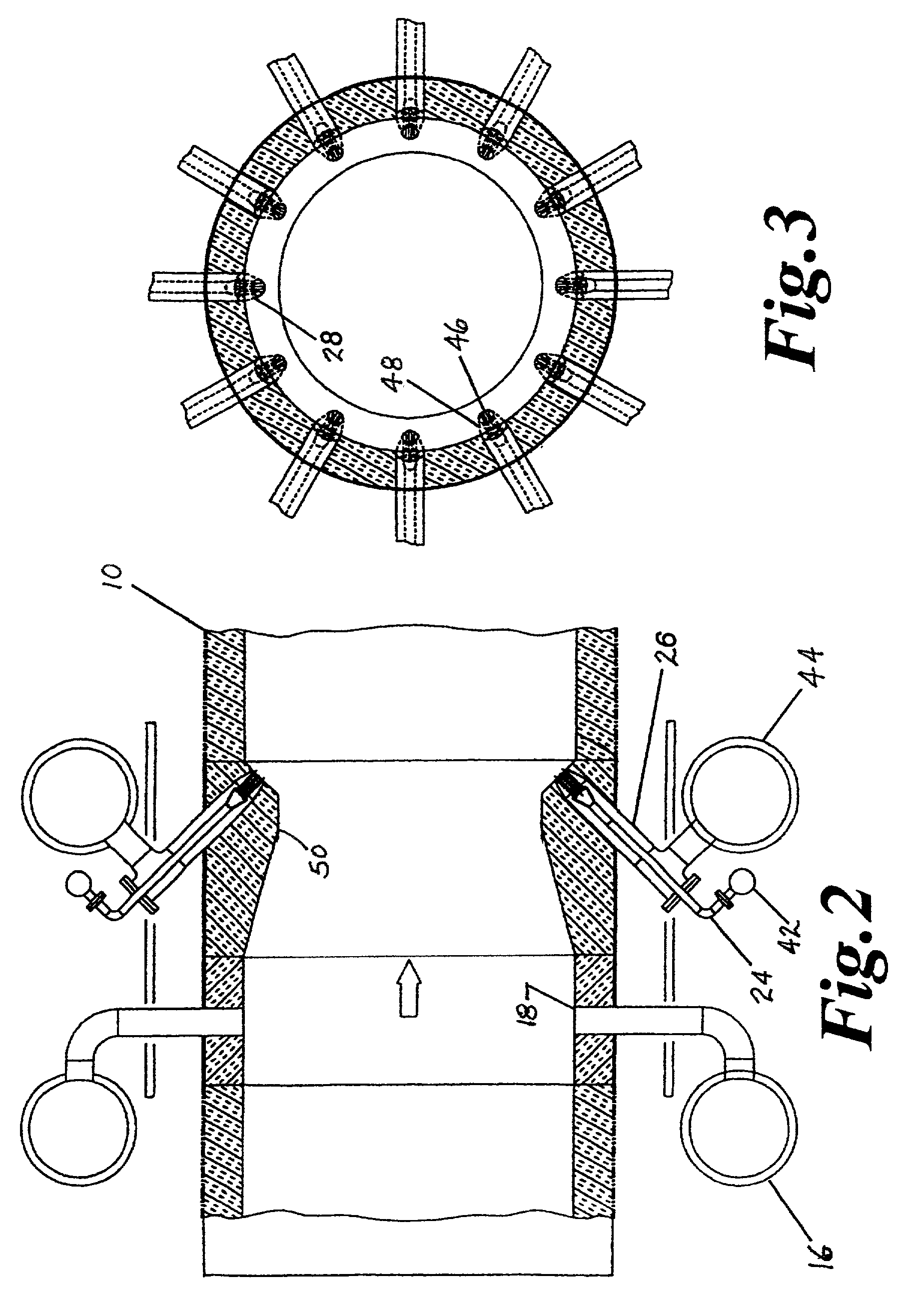

Apparatus and method for optimizing the use of oxygen in the direct reduction of iron

InactiveUS20020007699A1Increase volumeQuality improvementHydrogenChemical industryHydrogen contentProcess engineering

An apparatus and method for adjusting the parameters of a reducing gas stream prior to introduction into a direct reduction furnace, such parameters including temperature of the gas stream, and amount of hydrocarbon, carbon monoxide, and hydrogen contained in the reducing gas. The apparatus is placed in-line with the reducing gas recycle loop of a direct reduction furnace, which has an enrichment section which introduces hydrocarbon components to the main stream, and an oxygen / fuel injection system, located downstream from the enrichment section, which injects a shrouded stream of oxygen and hydrocarbon gas into the reducing gas stream. Temperature, carbon monoxide content, and hydrogen content of the reducing gas are adjusted by controlling the flow of oxygen and the ratio of hydrocarbon to oxygen injected in the oxygen / fuel injection system. Hydrocarbon content of the reducing gas is adjusted primarily by controlling the flow rate of the enrichment section.

Owner:MIDREX TECH INC

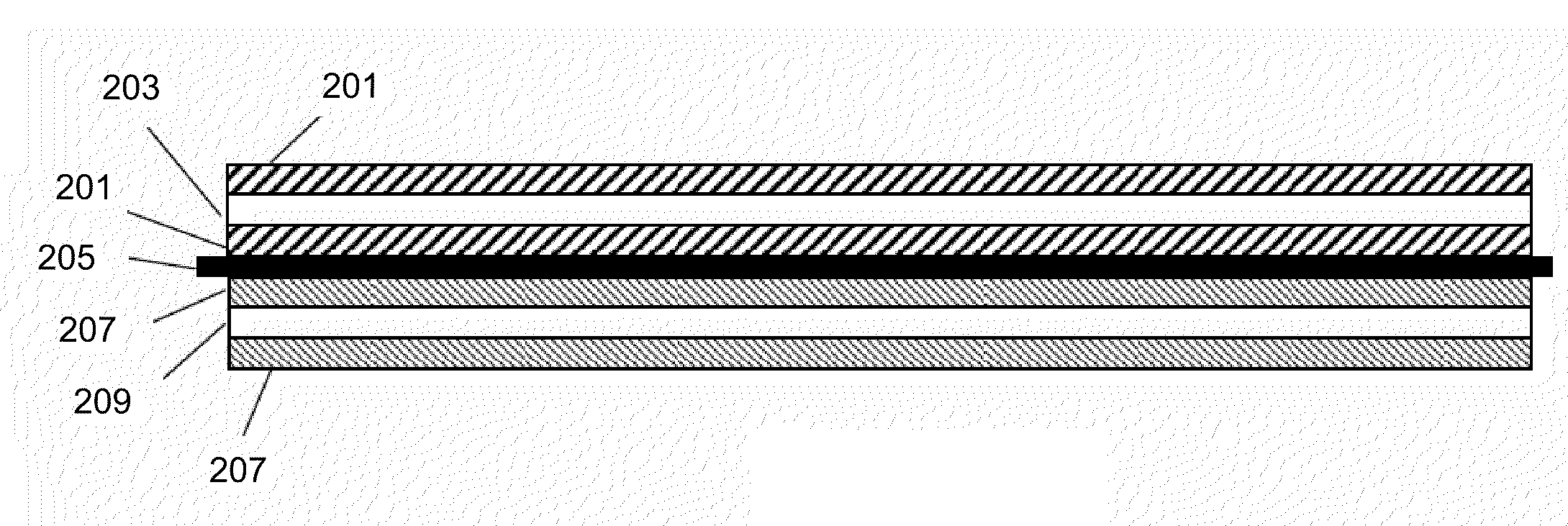

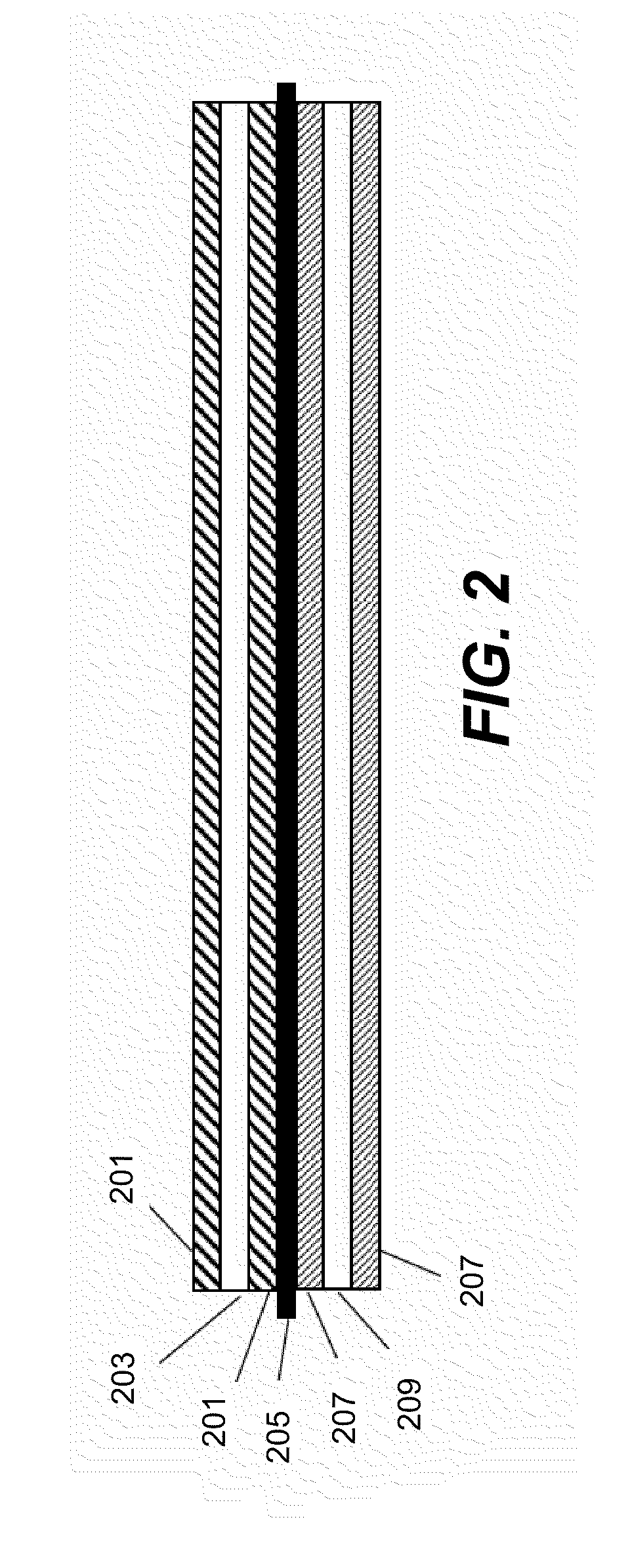

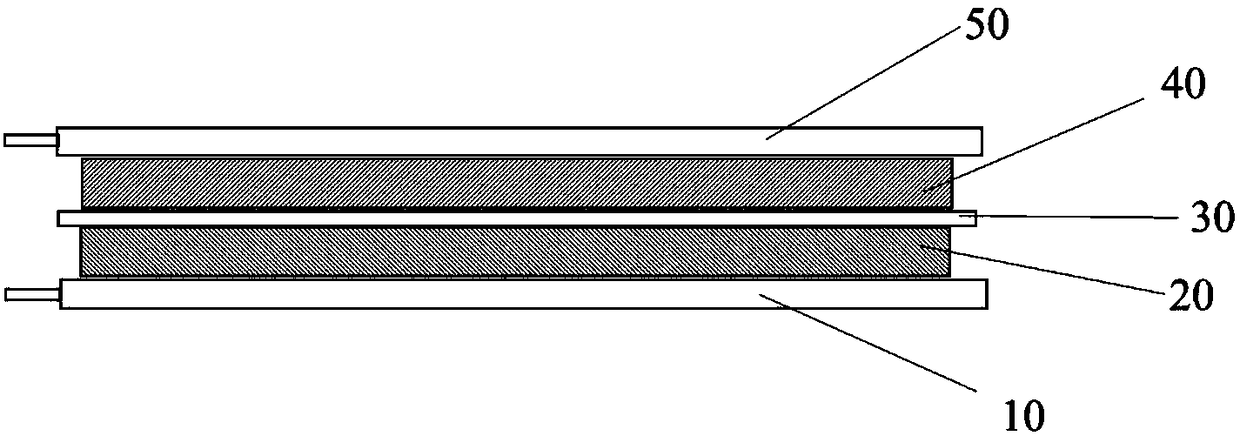

Full-solid-state battery and preparation method thereof

ActiveCN108493478ALower resistanceReduce lossSolid electrolytesCell electrodesSolid state electrolyteSolid-state battery

The invention relates to a full-solid-state battery, which comprises a positive electrode and solid-state electrolyte, wherein a positive electrode active material on the surface of the positive electrode is in contact with the solid-state electrolyte; the positive electrode active material and the solid-state electrolyte contain same substances. Preferably, the identical substance ingredients arefast ion conductors Li1+xAlxTi2+x(PO4)3 (the x is greater than 0 but smaller than or equal to 0.5). Therefore the composition ingredients of the solid-state electrolyte and the composition ingredients of the positive electrode active materials contain the identical substances, so that the homogenesis compatibility between the battery positive electrode and the solid-state electrolyte is improved;the interface resistance is reduced. The invention also relates to a preparation method of the full-solid-state battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

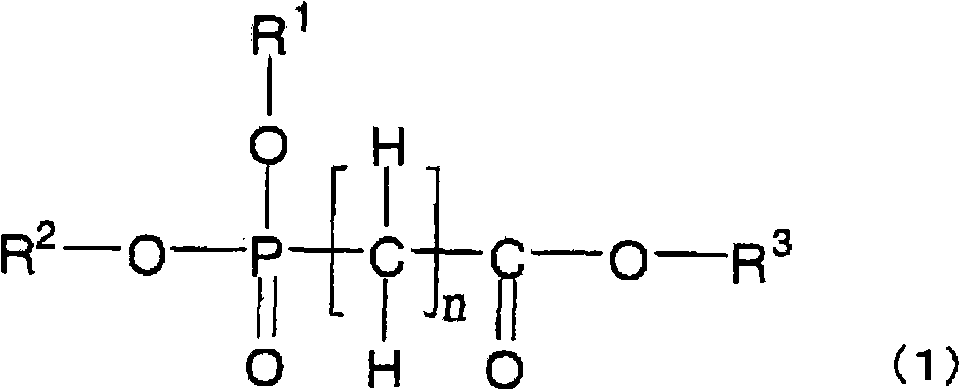

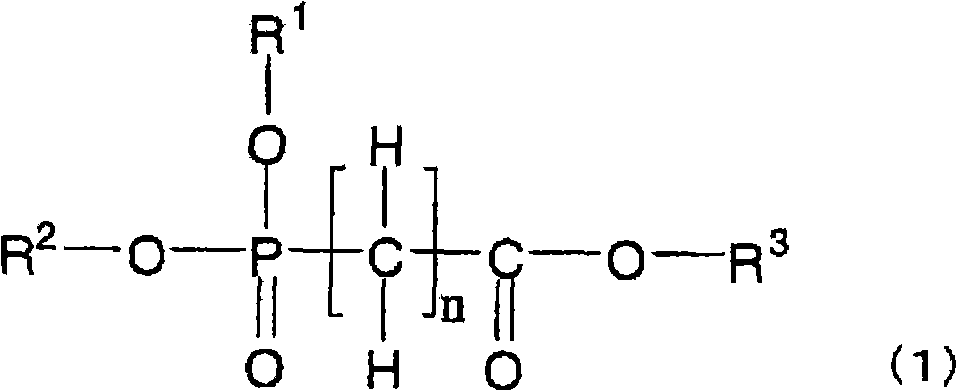

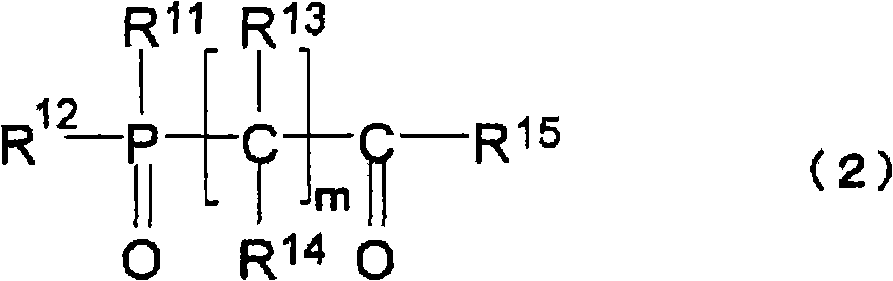

Nonaqueous electrolyte solution and nonaqueous electrolyte battery

Disclosed is a nonaqueous electrolyte solution which enables to obtain a battery with high capacity which generates only a small amount of gas, while being excellent in storage characteristics and cycle characteristics. This nonaqueous electrolyte solution contains an electrolyte and a nonaqueous solvent dissolving the electrolyte, and further contains a compound represented by the general formula (1) below in an amount of not less than 0.001% by volume but less than 1% by volume in the nonaqueous solvent. Alternatively, the nonaqueous electrolyte solution contains the compound represented by the general formula (1) below in an amount of not less than 0.001% by volume but less than 5% by volume in the nonaqueous solvent, and further contains at least one compound selected from the group consisting of cyclic carbonate compounds having a carbon-carbon unsaturated bond, cyclic carbonate compounds having a fluorine atom, monofluorophosphates and difluorophosphates. In the general formula (1), R<1>-R<3> independently represent an alkyl group having 1-12 carbon atoms which may be substituted by a halogen atom; and n represents an integer of 0-6.

Owner:MITSUBISHI CHEM CORP

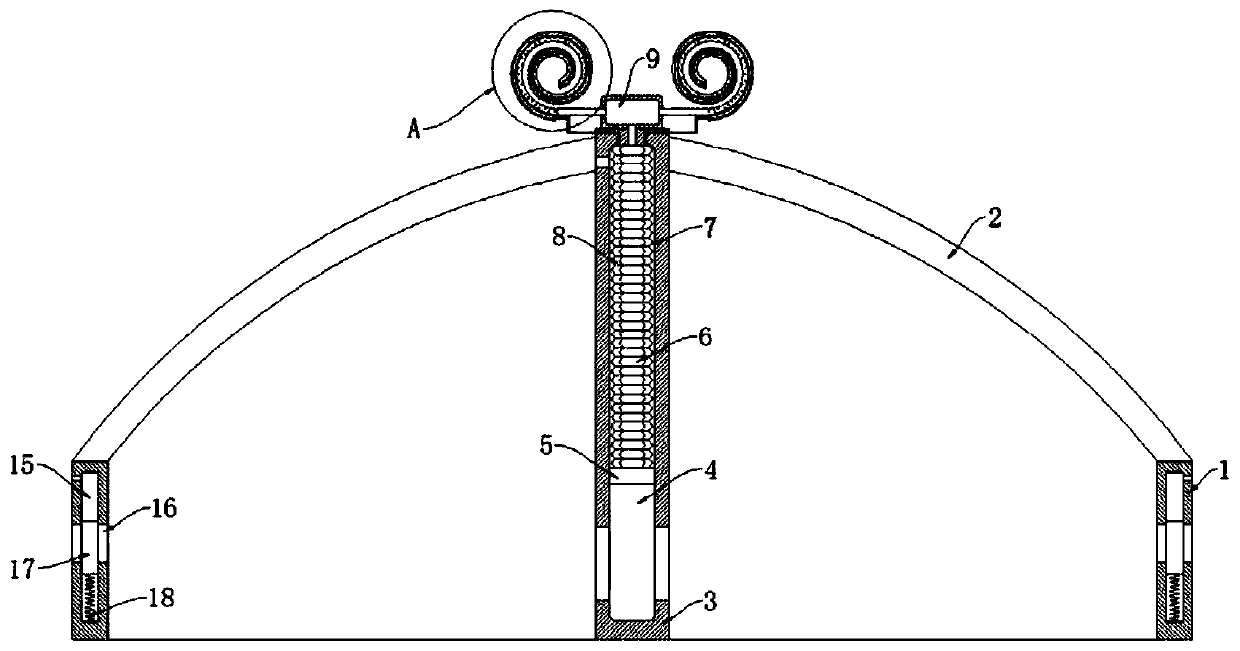

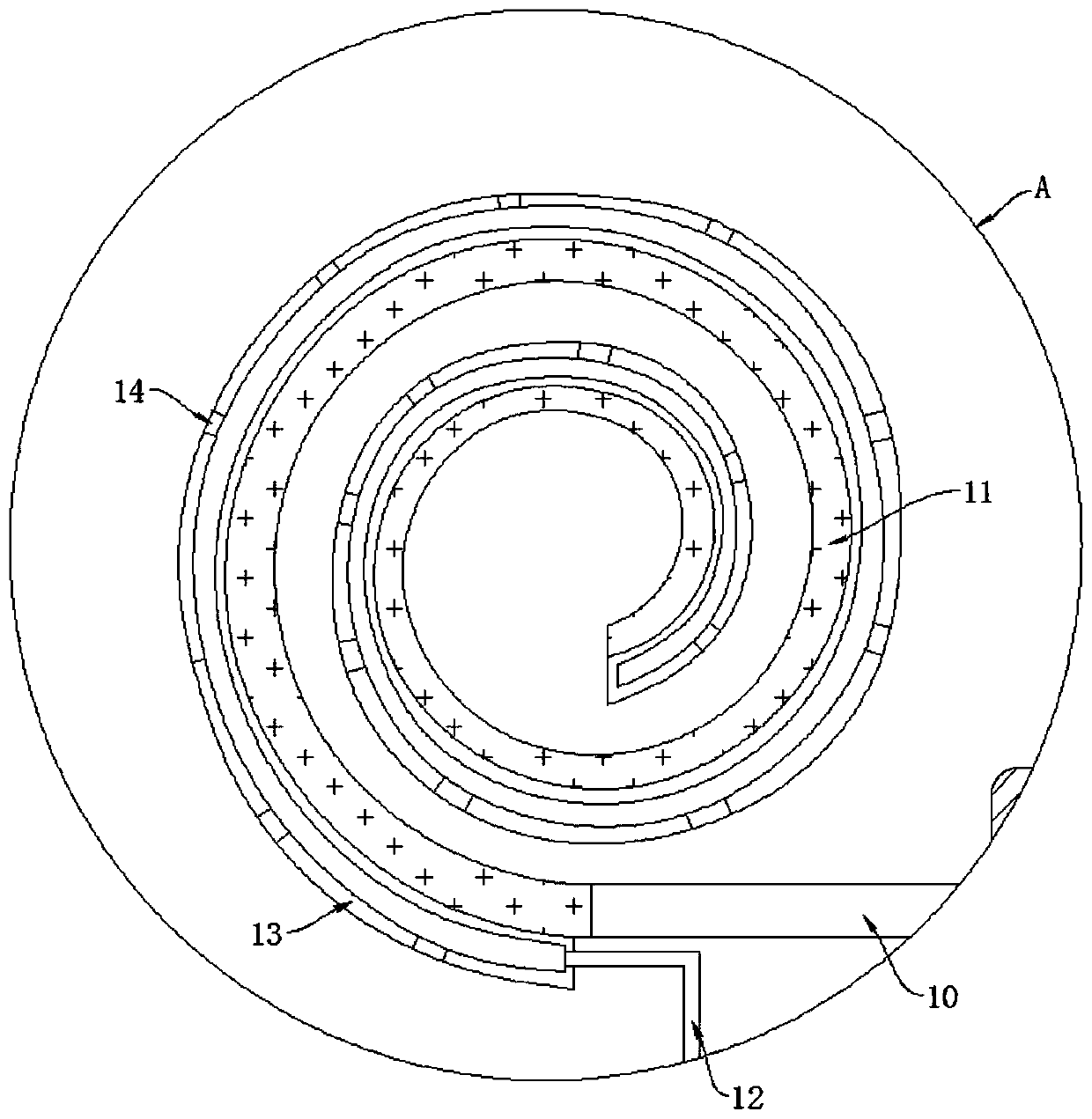

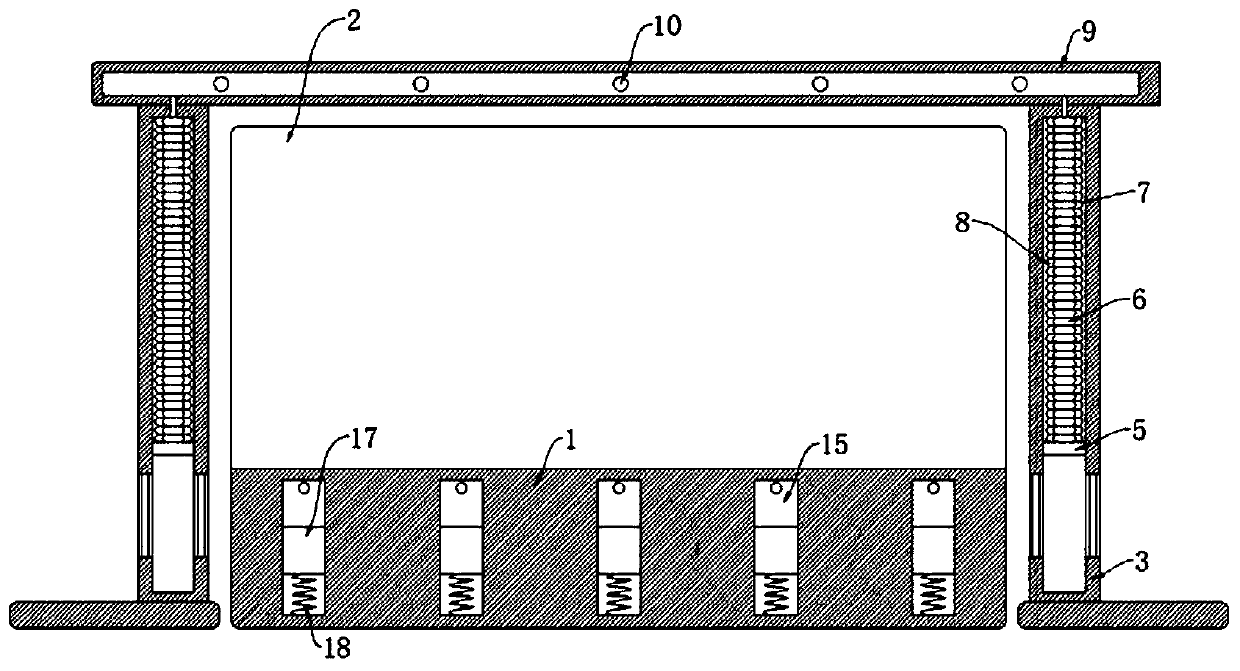

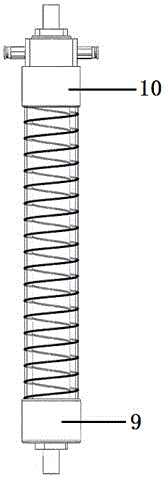

Agricultural planting greenhouse with automatic cooling function

InactiveCN110810077AReduce gasReduce direct sunlightClimate change adaptationGreenhouse cultivationThermal dilatationAgricultural science

The invention discloses an agricultural planting greenhouse with an automatic cooling function, which comprises a greenhouse body composed of support plates fixedly connected to a ground and a greenhouse framework; the two vertical plates are symmetrically and fixedly connected to the ground, a hollow plate is fixedly connected to the upper ends of the vertical plates, air guide plates are uniformly distributed on and communicated with opposite side walls of the hollow plate, and one end, far away from the side wall of the hollow plate, of each air guide plate is fixedly connected with a sun-shading plate that is of hollow structure. According to the invention, when external sunlight irradiation temperature rises in the noon, a thermal expansion liquid expands rapidly, so that air is introduced into the sun-shading plates that stretch to shield greenhouse protective film, the direct irradiation of sunlight to the greenhouse is reduced, the rise range of the temperature in the greenhouse is narrowed; when the external sunlight irradiation temperature falls, the thermal expansion liquid contracts so that the air in the sun-shading plates contracts less, manually laying and removing sunshade net is prevented, and the workload of people is reduced.

Owner:薛尧文

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

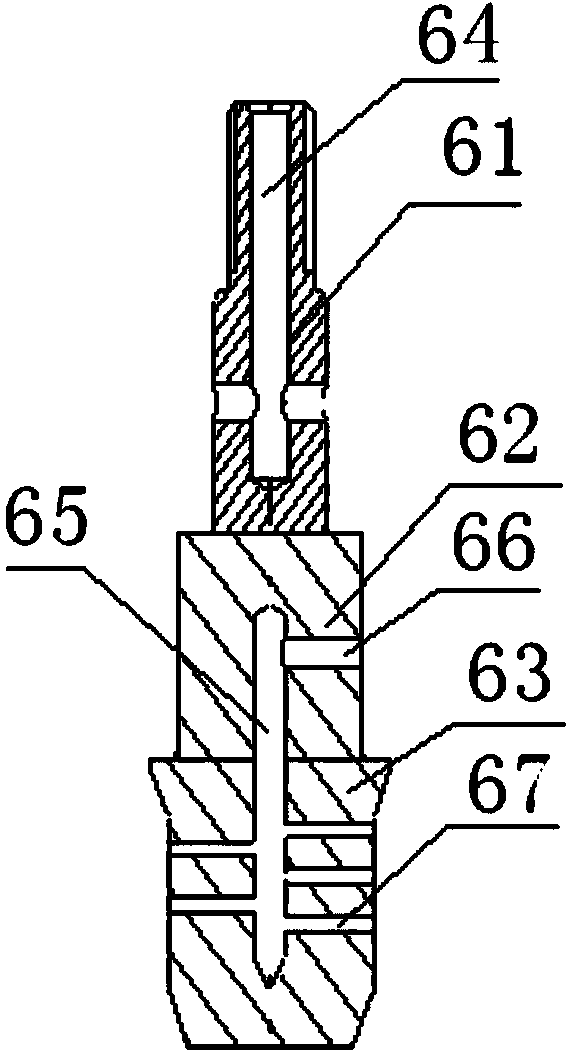

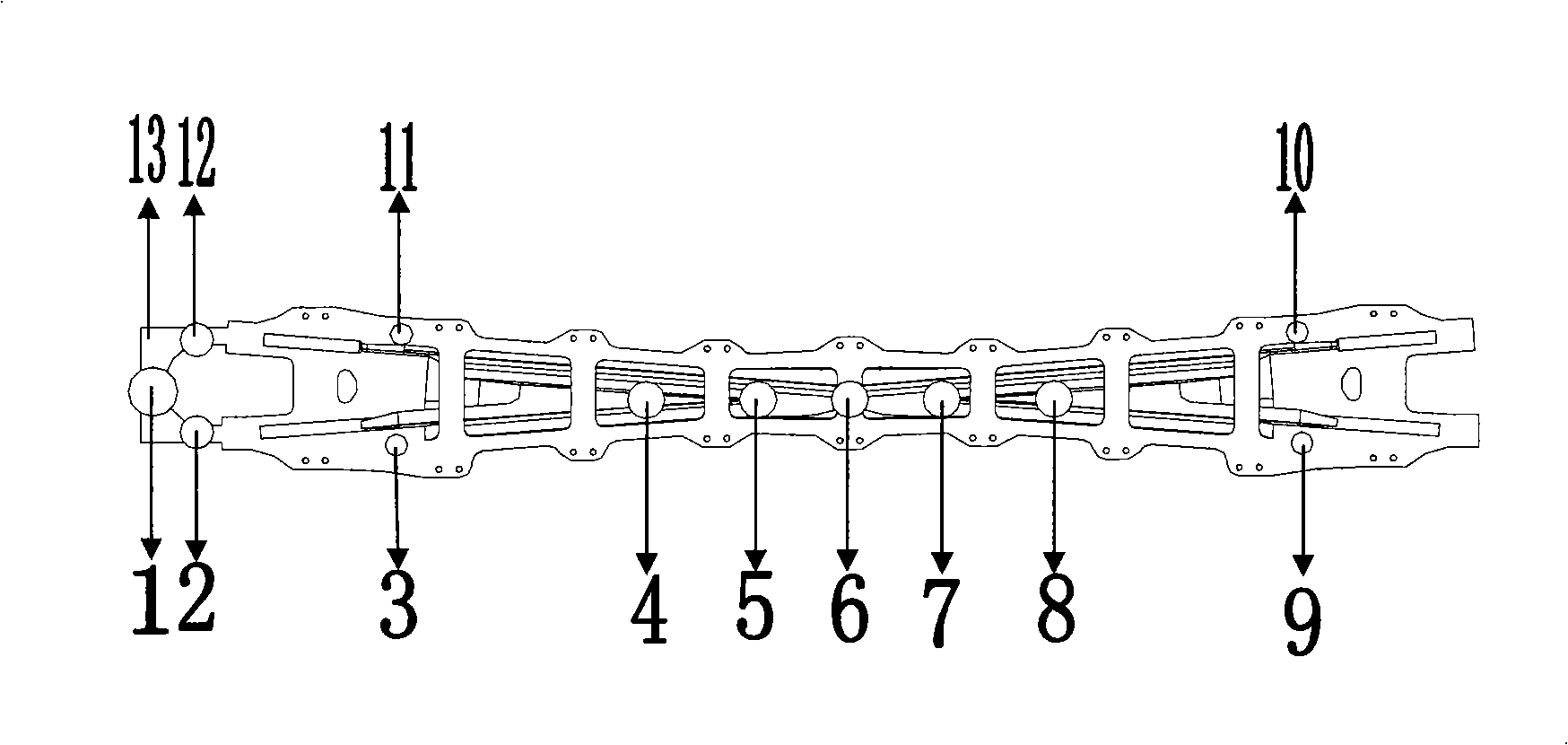

Double-tube sleeved type pneumatic artificial muscle

InactiveCN105666484AReduce frictionGuaranteed inflation and contractionProgramme-controlled manipulatorFiberDouble tube

The invention belongs to the pneumatic artificial technical field, and particularly relates to double-tube sleeved type pneumatic artificial muscle.The double-tube sleeved type pneumatic artificial muscle comprises an elastic outer tube, outer cellosilk, an elastic inner tube, inner cellosilk, a first air pipe connector, a second air pipe connector, a gap, an inner tube cavity, a first clamp, a second clamp, a gap vent and an inner tube cavity vent.By controlling the relationship of air pressure in the gap and air pressure in the inner tube cavity, active axial contraction and active axial rotation of the double-tube sleeved type pneumatic artificial muscle are achieved.Compared with pneumatic muscle of the same model in the market, the double-tube sleeved type pneumatic artificial muscle has the advantage that air consumption is lower, so that energy saving is better achieved.The performance of the pneumatic muscle is improved and enriched, functional innovation and expansion are achieved, and the double-tube sleeved type pneumatic artificial muscle is worth application.

Owner:CHINA JILIANG UNIV

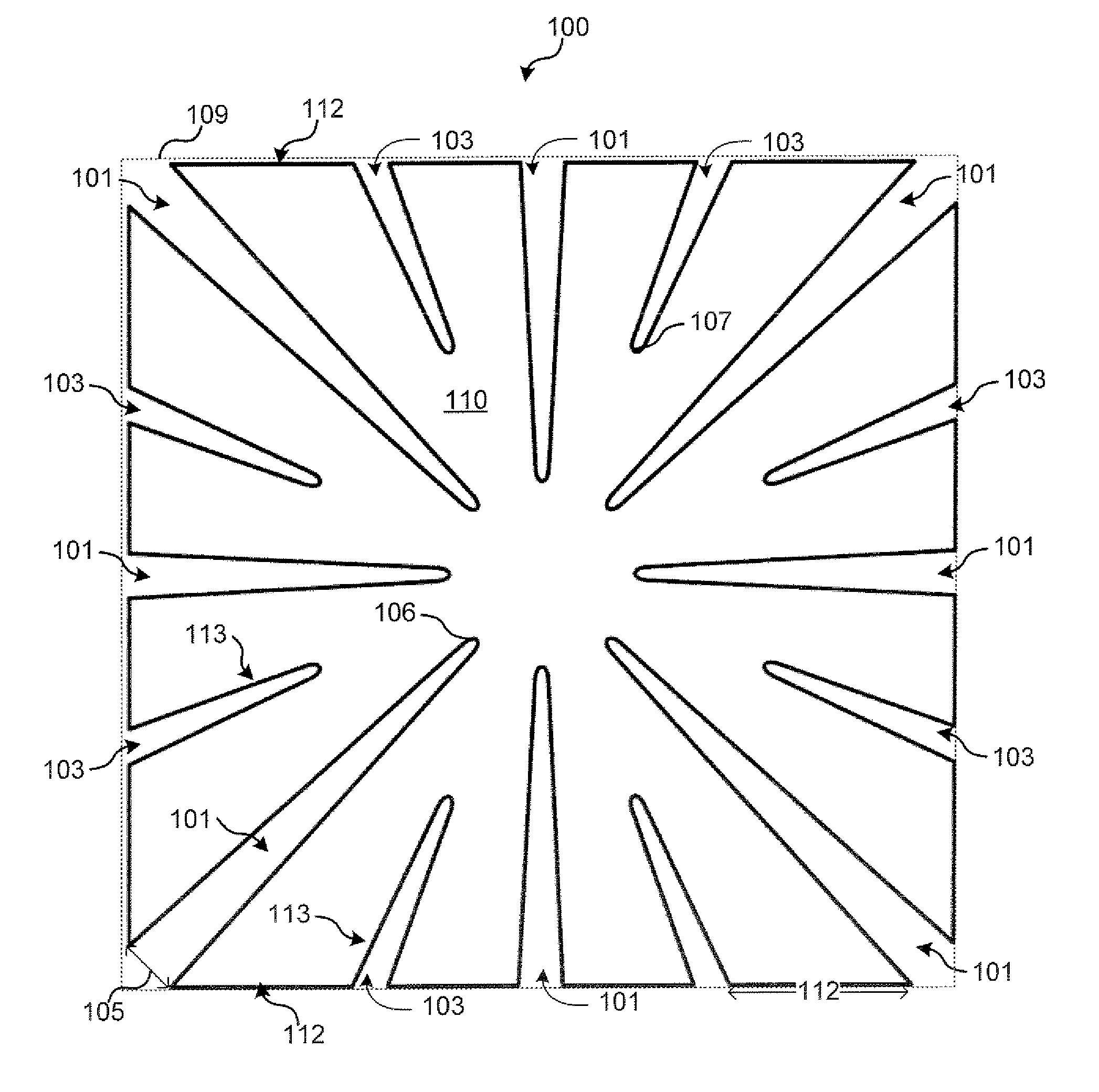

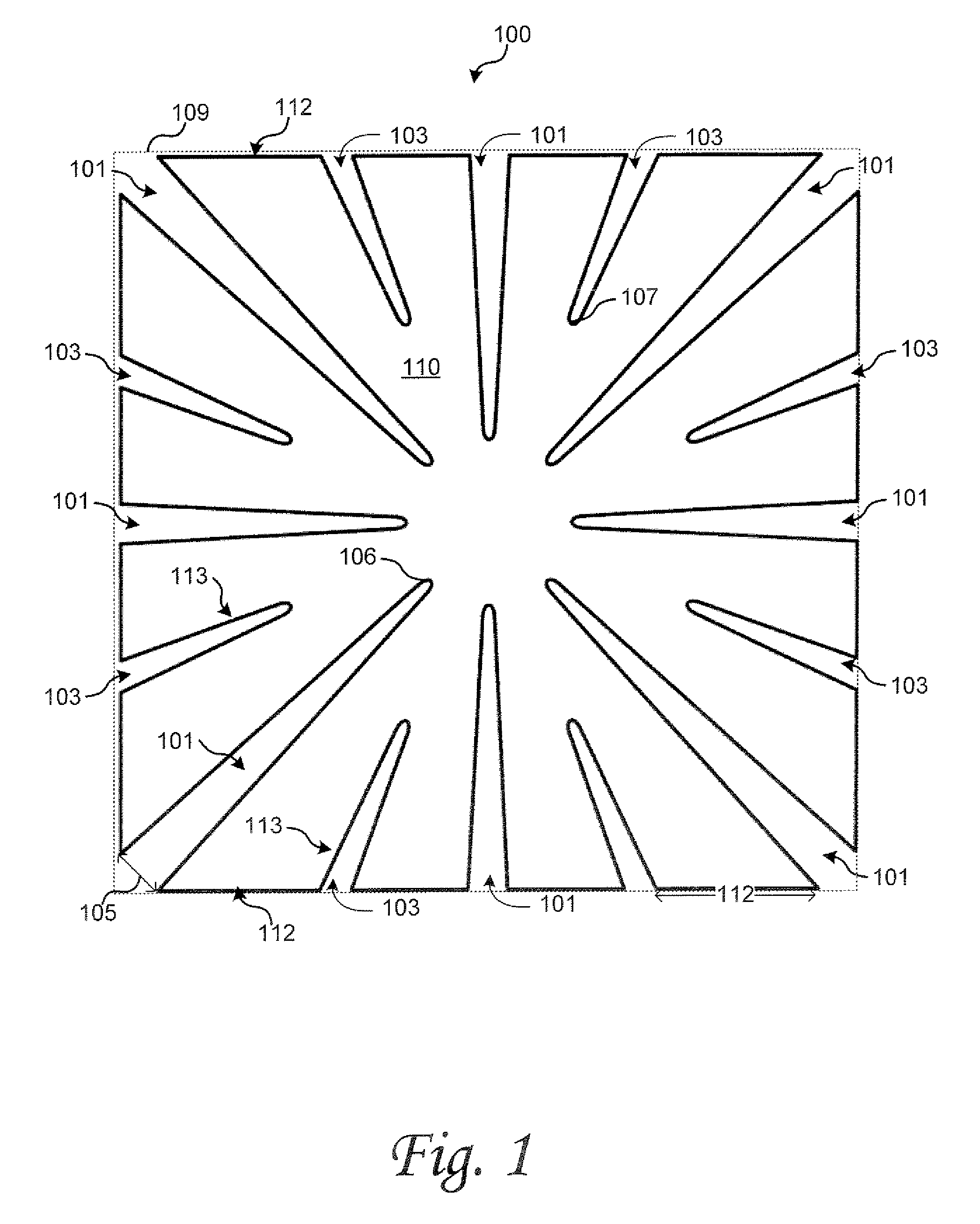

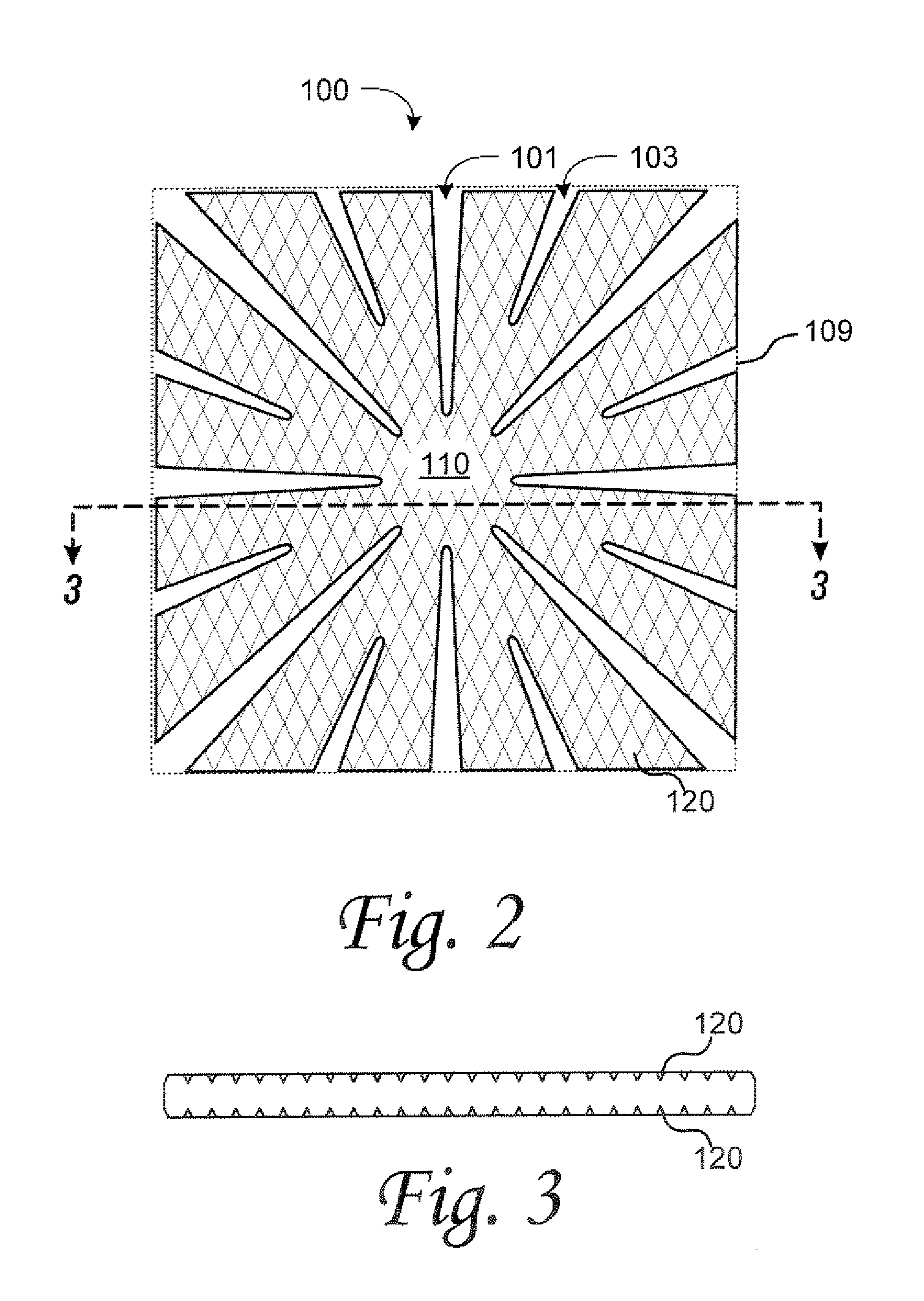

Solder preform

ActiveUS20110186617A1Improve efficiencyReduce gasWelding/cutting media/materialsSoldering mediaMetallurgyOxygen

A solder preform has gaps extending from the boundary of preform towards the preform center. During reflow soldering, the gaps close from the center towards the boundary. This allows flux and gasses to escape the interface between the solder and the substrate. Particularly, flux accumulates in the spaces formed by the gaps and is forced to the edge of the solder preform as the gap closes. In further embodiments, channels are formed on one or both surfaces of the solder preform. In addition to further assisting in the escape of gas and flux during reflow, the channels and gaps increase the effectiveness of oxygen purging using inert or reducing gasses in the reflow chamber. Additionally, the channels and gaps increase the effectiveness of vacuum solder.

Owner:INDIUM CORPORATION

A high-efficiency photovoltaic charging control method applied to an independent photovoltaic power generation system

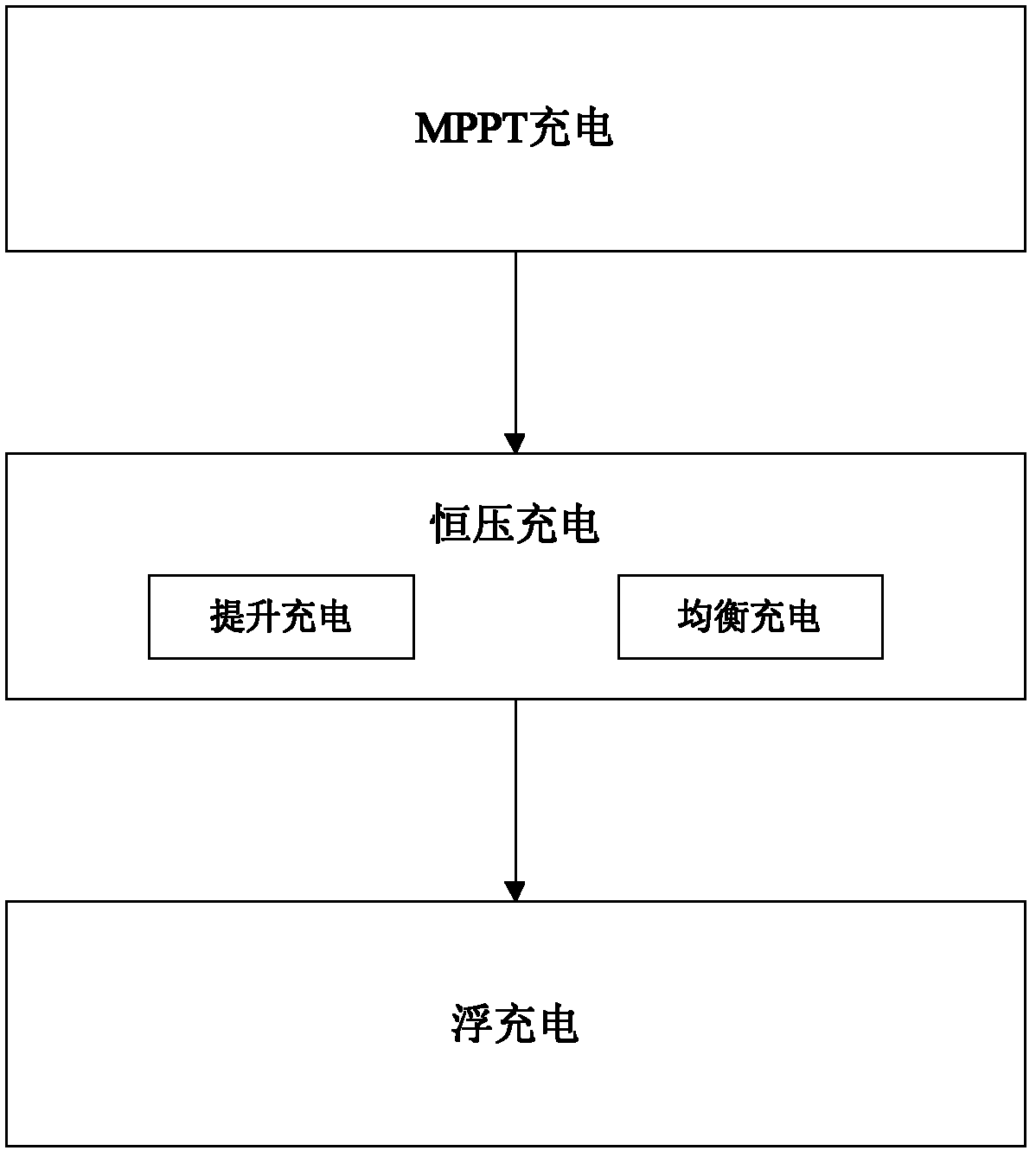

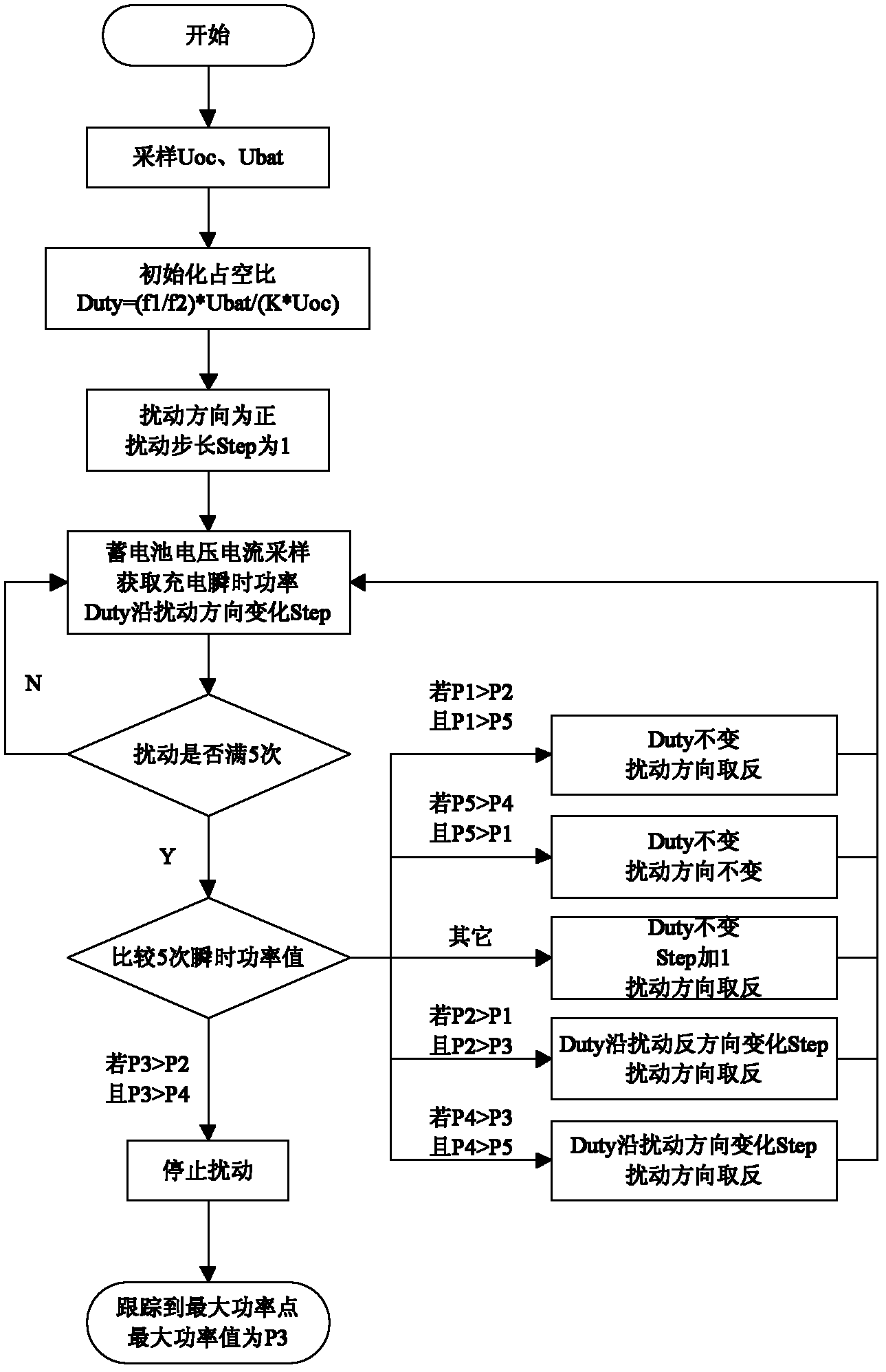

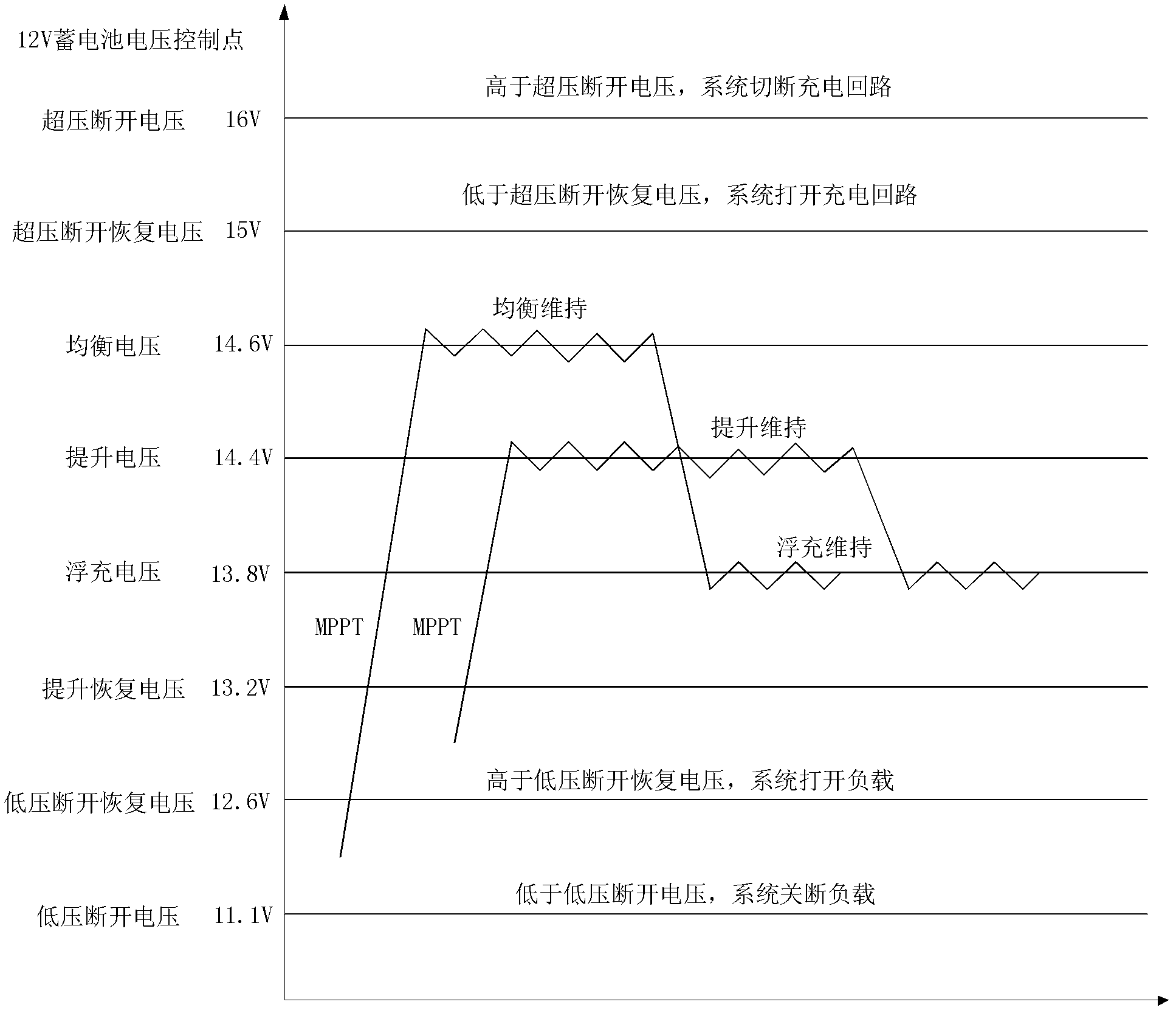

InactiveCN102290840AFix Tracking AccuracyFix tracking speedBatteries circuit arrangementsElectric powerFloating chargeThree stage

The invention discloses an efficient photovoltaic charge control method for an independent photovoltaic generating system, comprising the three stages of MPPT (maximum power point tracking) charge, constant-voltage charge and floating charge: stage one: using an MPPT method to quickly charge a storage battery, carrying out once power judgment every other continuous five disturbances, and realizing the exact power tracking under the condition of quick changes of environment conditions; stage two: using lifting charge and equalizing charge to supplement the electric energy of the storage battery in the normal and overcharging states respectively; and stage three: maintaining the full electric energy of the storage battery. In the method, the charge states are managed effectively, the chargeefficiency is improved, and the service life of the storage battery is prolonged.

Owner:BEIHANG UNIV

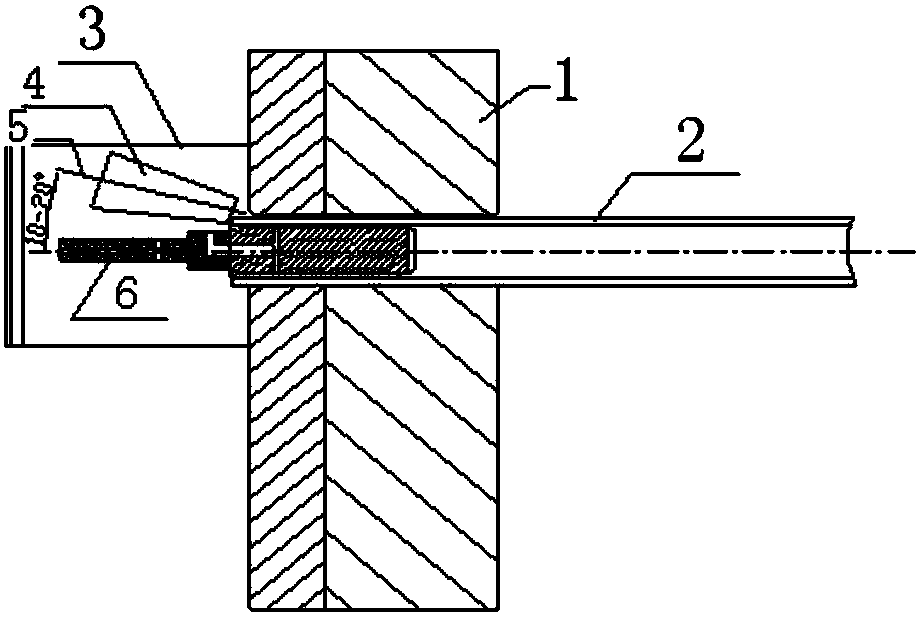

Welding method for titanium tube with ultra-thin wall

InactiveCN103817415AFusion wellReduce gasHeat exchange apparatusWelding/soldering/cutting articlesEngineeringTitanium

The invention belongs to the field of welding, and particularly relates to a welding method for a titanium tube with an ultra-thin wall. The welding method comprises the following steps: a hole is drilled in a tube plate, and a heat exchange tube and the tube plate are assembled after the ends of the heat exchange tube are cleaned, wherein it is guaranteed that the length of the portion, extending out of the tube plate, of the heat exchange tube ranges from 1mm to 2mm, and the distance between the outer wall of the heat exchange tube and the pore wall of the tube is not larger than 0.15mm; a tube plate automatic welding machine is adopted, and argon shields are formed on both the outer wall and the inner wall of the heat exchange tube; the purity of argon reaches 99.999 percent, so that the argon is high-purity argon, and a welding gun is closely attached to a workpiece to conduct all-position welding. According to the welding method for the titanium tube with the ultra-thin wall, gas shields are formed on both the outer wall and the inner wall of a tube in the welding process, so that welding gas is synchronous with gas inside the tube and gas outside the tube, the gas is saved, and oxidation does not occur easily in the welding process; by the adoption of the welding method, a heat exchange tube with the wall thickness being equal to or smaller than 0.8mm can be welded, the heat exchange tube and the tube plate are well fused after being welded, and a leakage does not easily occur in a striking and pressing process.

Owner:SMARTHEAT SHENYANG HEAT PUMP TECH

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

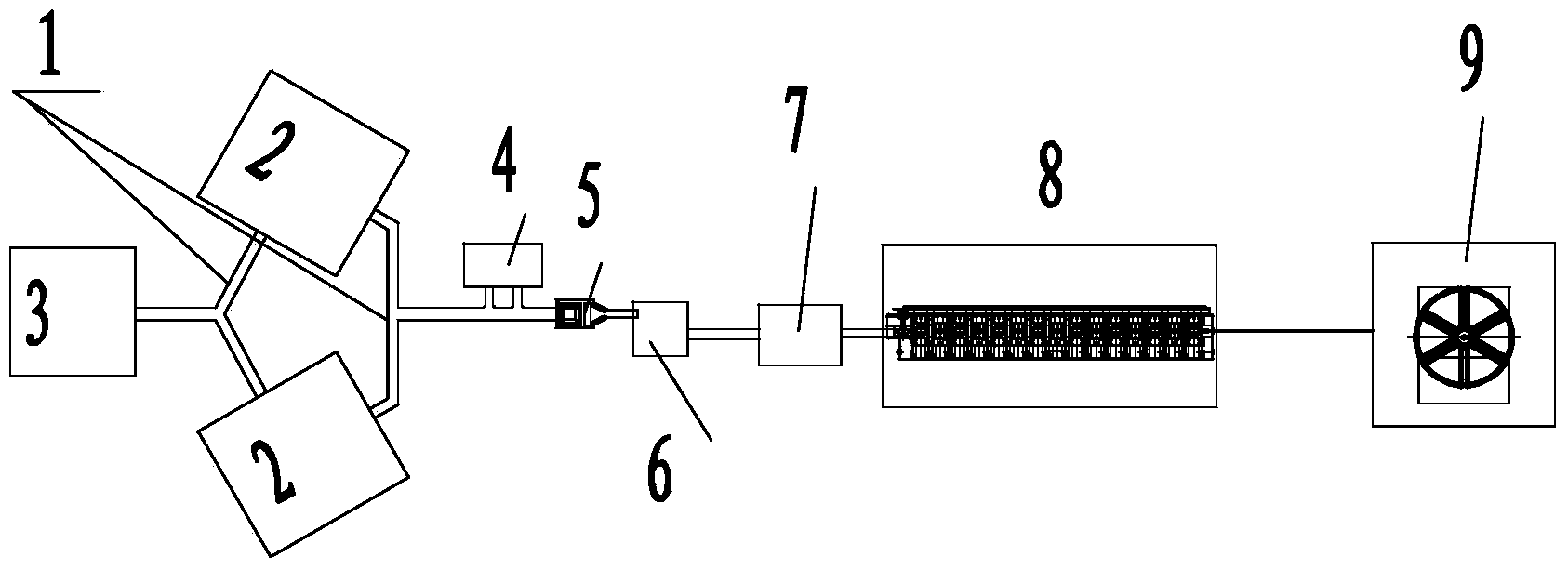

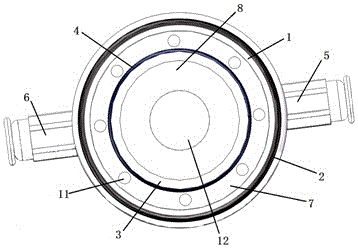

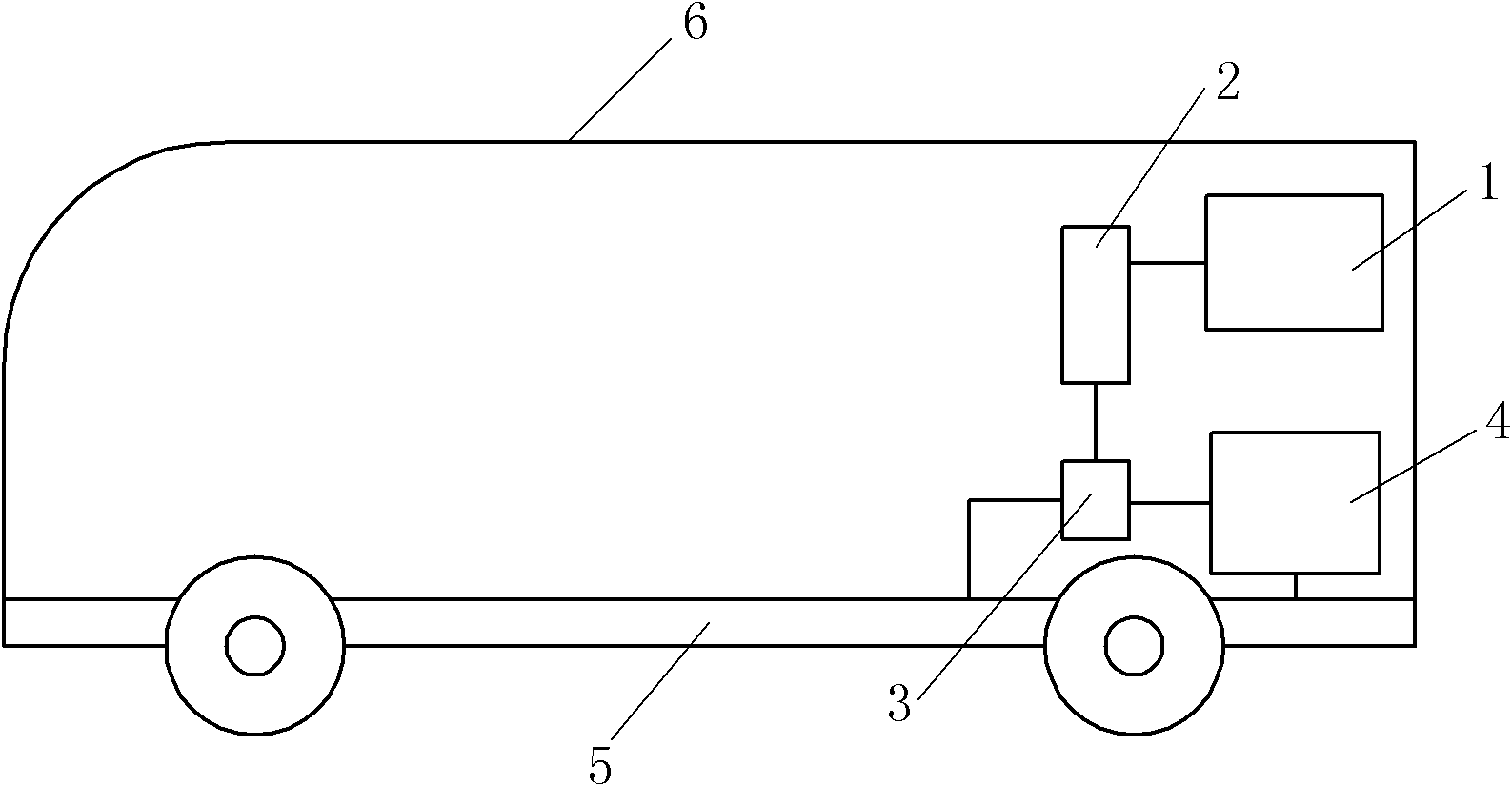

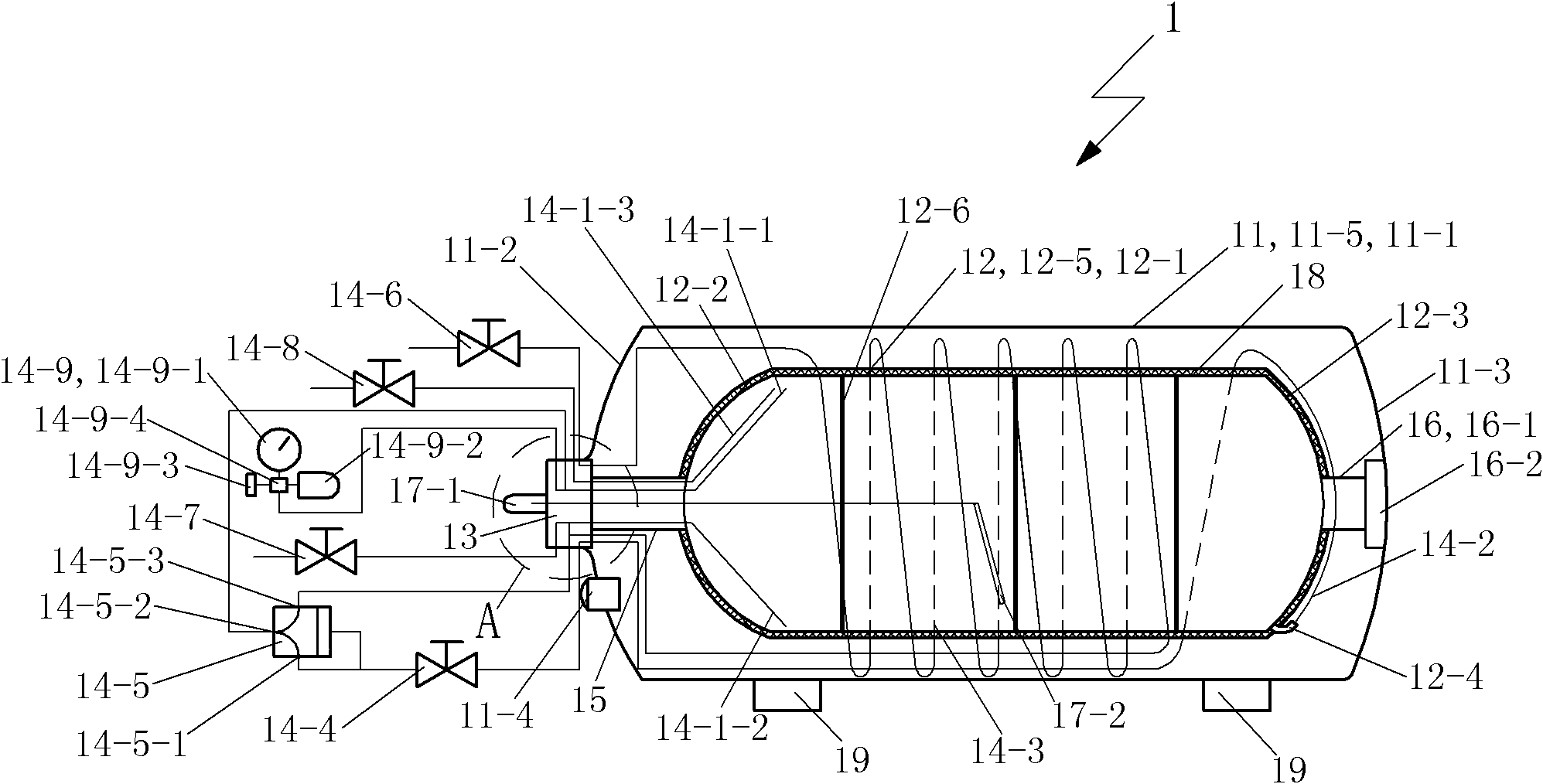

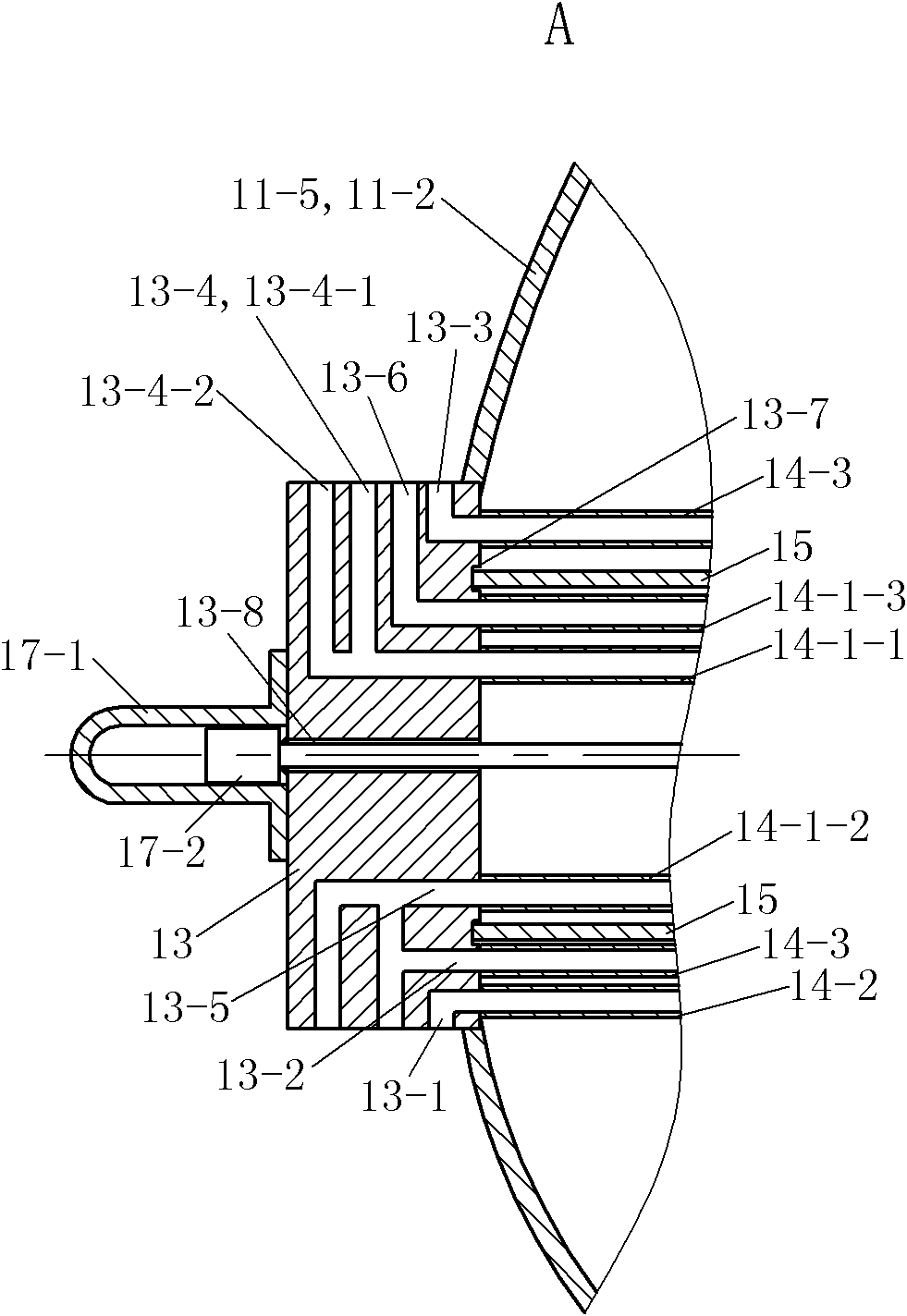

Horizontal low-temperature insulating air cylinder and vehicle power system taking gas as power source

InactiveCN102147049AGood insulation performanceIncrease storage capacityContainer filling methodsPressure vesselsTransmission systemEngineering

The invention relates to a horizontal low-temperature insulating air cylinder which comprises a casing, an internal cylinder, a distributor, a cylinder pipeline of a pipeline control system, a neck tube, a supporting piece and an insulating layer. The invention further relates to a vehicle power system taking gas as a power source, which comprises the horizontal low-temperature insulating air cylinder, a gasifier, a pressure regulating tank, an air engine, an operation and control mechanism, a power source control pedal, a chassis and a vehicle body; the power source control pedal is connected with a power input part of the operation and control mechanism; a power output part of the operation and control mechanism is connected with a control rod of a control valve of the pressure regulating tank; a gas outlet of the horizontal low-temperature insulating air cylinder is connected with a gas inlet of the gasifier through a connecting pipe; a gas outlet of the gasifier is connected with a gas inlet of the pressure regulating tank through a connecting pipe; a gas outlet of the pressure regulating tank is connected with a gas inlet of the air engine through a connecting pipe; a power output part of the air engine is connected with a power input part of a transmission system of the chassis; and the power source control pedal is connected with the control end of the control valve of the pressure regulating tank through the operation and control mechanism.

Owner:丁雨福

Method for preparing copper and chromium 50 electric contact material by utilizing vacuum arc remelting furnace

ActiveCN108441670ASmall particle sizeEvenly distributedTransportation and packagingMetal-working apparatusVacuum arc remeltingImpurity

The invention relates to a method for preparing a copper and chromium 50 electric contact material by utilizing a vacuum arc remelting furnace. Copper powder with particle diameter ranging from 0.01 micron to 1 micro, and chromium powder with particle diameter ranging from 0.01 micron to 1 micro are prepared with a new method, and are smaller in particle diameter compared with the copper powder and the chromium powder used in the prior art. The prepared copper powder and chromium powder are chosen to be mixed according to certain proportion, the mixer is pressed into material bars by using cold isostatic pressing, and the material bars carry out consumable electrode arc melting after being sintered to form alloy ingots. Under the action of a high-temperature electric arc, a consumable electrode carries out layered melting quickly and evenly and drops to the bottom of a water cooling crystallizer, and because of the large cooling rate on the periphery of the crystallizer furthermore, itis realized that Cu and Cr alloy ingots solidify, and then uniform and fine Cu and Cr alloy structures are obtained, wherein the content of Cr in Cu and Cr alloy ranges from 45% to 55%. According tothe method for preparing the copper chromium 50 electric contact material by utilizing the vacuum arc remelting furnace, a vacuum consumable electrode arc melting method is used for preparing a Cu andCr electric contact material with the content of Cr ranging from 45% to 55% (wt), the material is free of pores, loose, less in impurities, free of macro and micro defects such as Cu and Cr enrichment, and both the microstructure of Cu and the microstructure of Cr are smaller than 20 micrometers.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

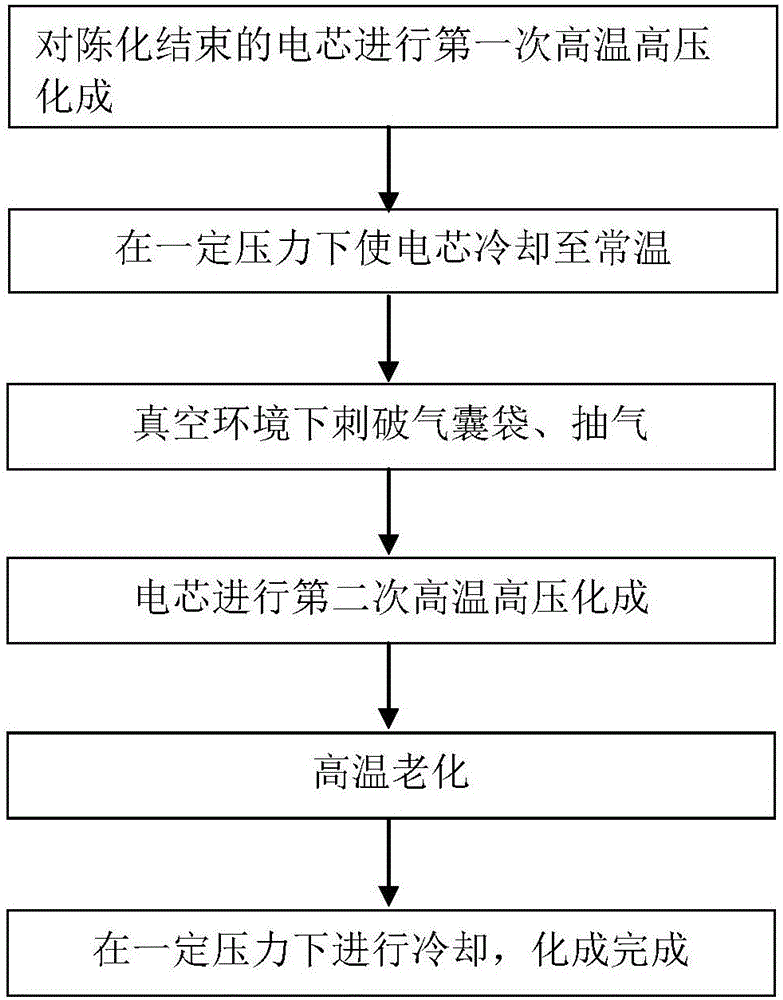

Formation method for lithium ion battery

InactiveCN106207293ALower internal resistanceHigh hardnessFinal product manufactureSecondary cells charging/dischargingThermal insulationRoom temperature

The invention discloses a formation method for a lithium ion battery. The formation method comprises the following steps of putting a cell which is fully aged into formation equipment to be subjected to high-temperature pressurizing formation, wherein the charging cut-off voltage is 3.5-3.8V; cooling the cell at a normal temperature and fixed pressure to reduce the temperature of the cell to the room temperature; putting the cooled cell into a vacuum environment, puncturing an airbag of the cell, and performing air exhausting and then sealing the opening; putting the cell which is subjected to complete air exhausting into the formation equipment to be subjected to high-temperature pressurizing formation, wherein the charging cut-off voltage is 3.9-4.5V; increasing the temperature and the pressure, and performing thermal insulation and pressure maintaining on the battery; and cooling the cell at a normal temperature and fixed pressure to reduce the temperature of the cell to the room temperature, and finishing the formation. According to the formation method, the steps of puncturing the airbag of the cell and air exhausting are added in the thermal pressure formation, so that the reaction gas can be discharged in time, and the performance of the lithium battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Casting technique of grain refined solid manganese steel frog of long life

The invention relates to a process for manufacturing a solid high manganese steel frog, in particular to a technique for casting the solid high manganese steel frog which has long service life and is subjected to grain refining. The technique is suitable for manufacturing various types and specifications of solid high manganese steel frogs with a weight of less than 2 tons. The technique comprises: 1) adopting a heat-insulated riser as a riser; 2) discharging molten steel at a high temperature, and performing argon gas blowing, feeding and refining in a refining ladle after discharging; 3) performing microalloying in the refining ladle, and adding molybdenum, niobium, vanadium and titanium; 4) filling argon gas into a die cavity before casting, and performing casting under the protection of the argon gas; and 5) adopting a hot shake-out process, thermally cutting the riser, and thermally sending the cut riser into a heat treatment kiln for homogenizing. The process reduces oxidation of molten metals through nitrogen protection, purifies the molten metals due to refining in the refining ladle, and solves the problems of large crystal grains, hole shrinkage, microcracks, short service life and the like of the solid high manganese steel frog due to grain microalloying and thinning and dispersed distribution of inclusion.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Smelting process of nitrogenous high alloy heat-resistant steel ZG3Cr24Ni7N

InactiveCN102618795AEasy to controlInto a stableProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a smelting process of nitrogenous high alloy heat-resistant steel ZG3Cr24Ni7N, which includes preparing a steel ladle, primary smelting in an electric arc furnace, refining the steel ladle and blowing nitrogen from the bottom of the ladle. The nitrogen which is rich in sources and low-price is used as material, the nitrogen is blown to molten steel for nitrogen alloying, and accordingly production cost of nitrogenous steel is lowered greatly. Alloy recovery efficiency is improved by reasonable processes, so that the problem that chemical components are difficult to control is solved, and the metallurgical quality of molten steel is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

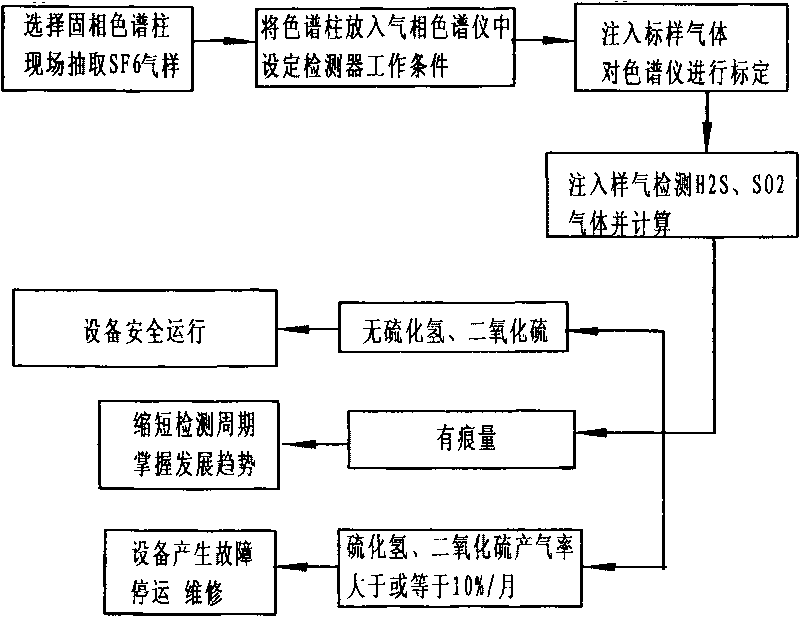

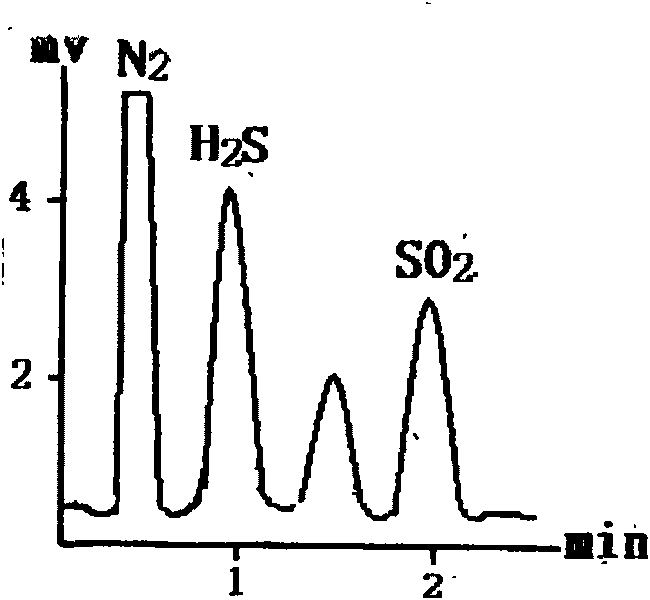

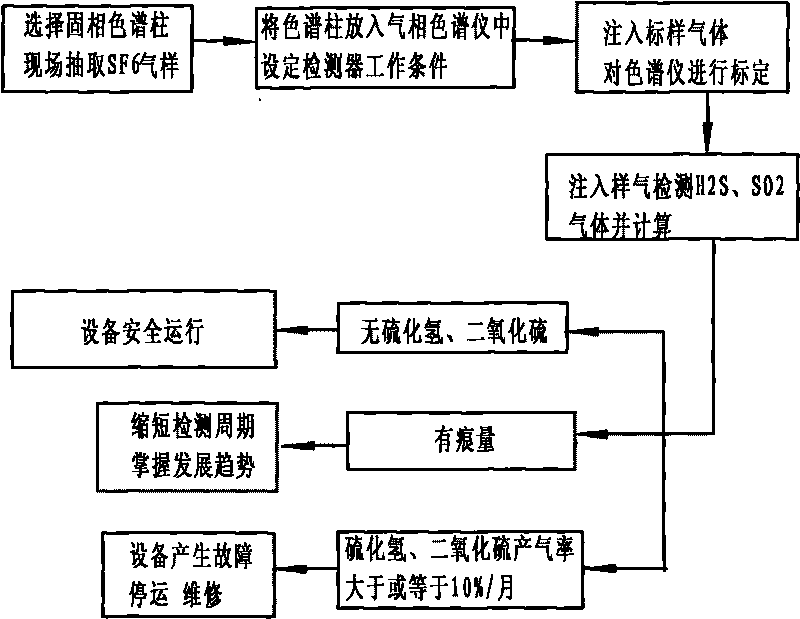

Method for detecting internal fault of SF6 electrical equipment by using gas chromatograph

InactiveCN101762655AReduce gasAvoid pollutionTesting dielectric strengthComponent separationGas solid chromatographyElectrical devices

The invention relates to a method for detecting internal fault of SF6 electrical equipment by using a gas chromatograph, comprising the following steps: a stainless steel tube filled with 60-80 meshes of GDX-301 stationary phase is firstly selected as a chromatographic column, then 50mL of SF6 gas sample is extracted from the SF6 electrical equipment in the field for later use; the chromatographic column is placed in the gas chromatograph, hydrogen is selected as carrier gas, and working conditions of a TCD (thermal conductivity detector) in the gas chromatograph is set; the chromatograph is demarcated; 0.5mL of gas sample is selected and the gas sample is injected into the chromatograph through an injection port of the chromatograph with the use of an injector, the computing mode of the chromatograph is selected, and then the gas sample is identified whether H2S or SO2 exists or not by the TCD after the gas sample is separated by the chromatograph and the contents of H2S and SO2 gases are automatically calculated; and the result is analyzed. The invention adopts gas-solid chromatography and has the advantages of good stability, less gas consumption, ready-for-detection and high accuracy, etc. The method is easy and feasible and has low detection cost. The invention provides simple and effective means for early detection of the internal fault of the SF6 electrical equipment and in-time elimination of hidden dangers.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

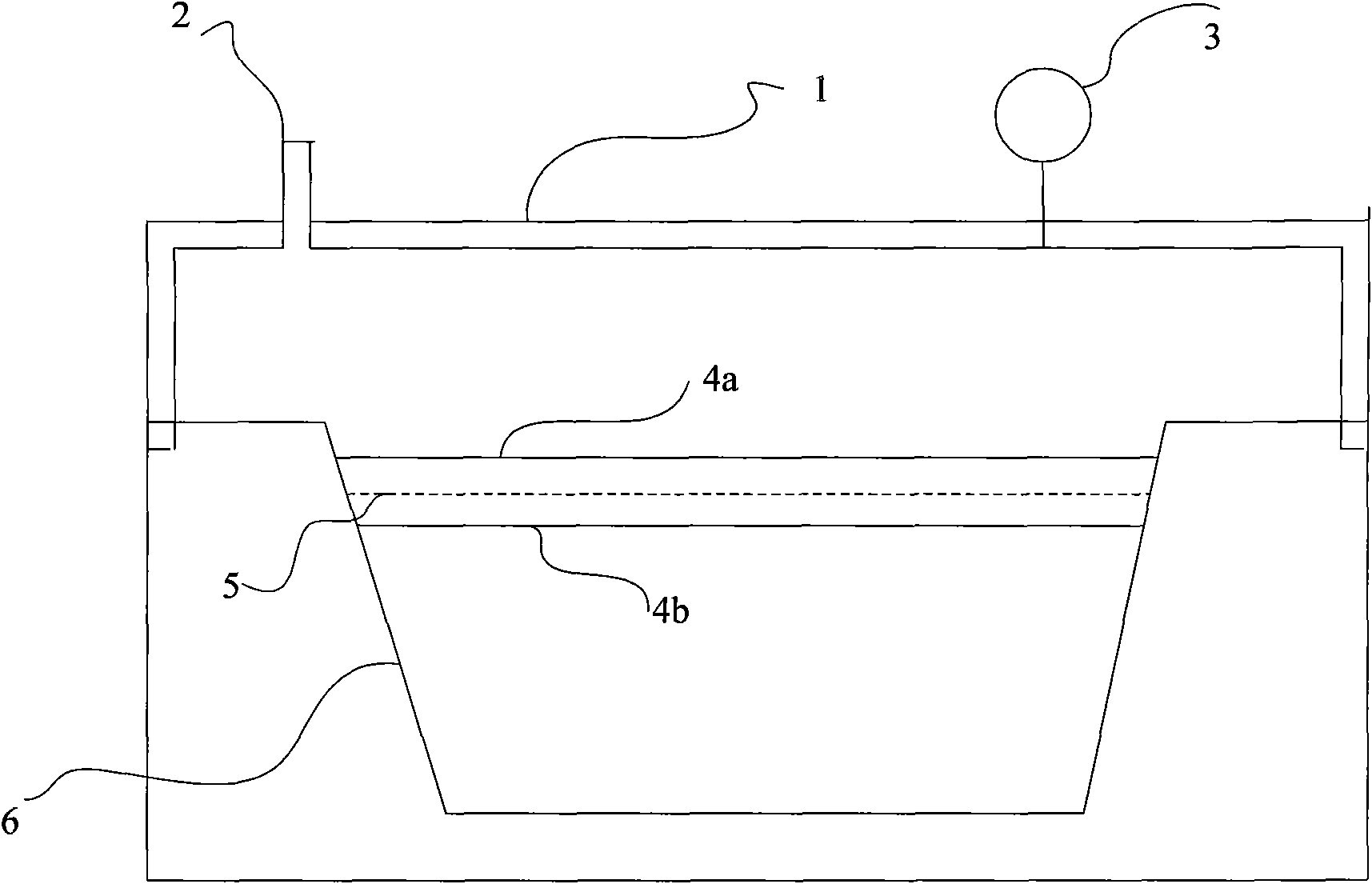

High-temperature alterant and method for purifying fusant by adopting same

The invention discloses a high-temperature alterant, which comprises the following components in percentage by weight: 15 to 20 percent of chloride, 40 to 45 percent of chloride, 25 to 30 percent of rare earth metal compound, 3 to 8 percent of titanium dioxide, and 2 to 6 percent of graphite. The invention also discloses a method for purifying a fusant, wherein the high-temperature alterant is added into a smelting furnace. The high-temperature alterant can reduce the sodium content in an electrolytic molten aluminum fusant and effectively control the grain size to achieve good grain refining effect. The method for purifying the fusant can effectively reduce gas and foreign impurities in the fusant, optimize the production process, ensure the quality of aluminum and aluminum alloy fusants, improve the ingot yield, save the energy consumption, and reduce the discharge of pollutants.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

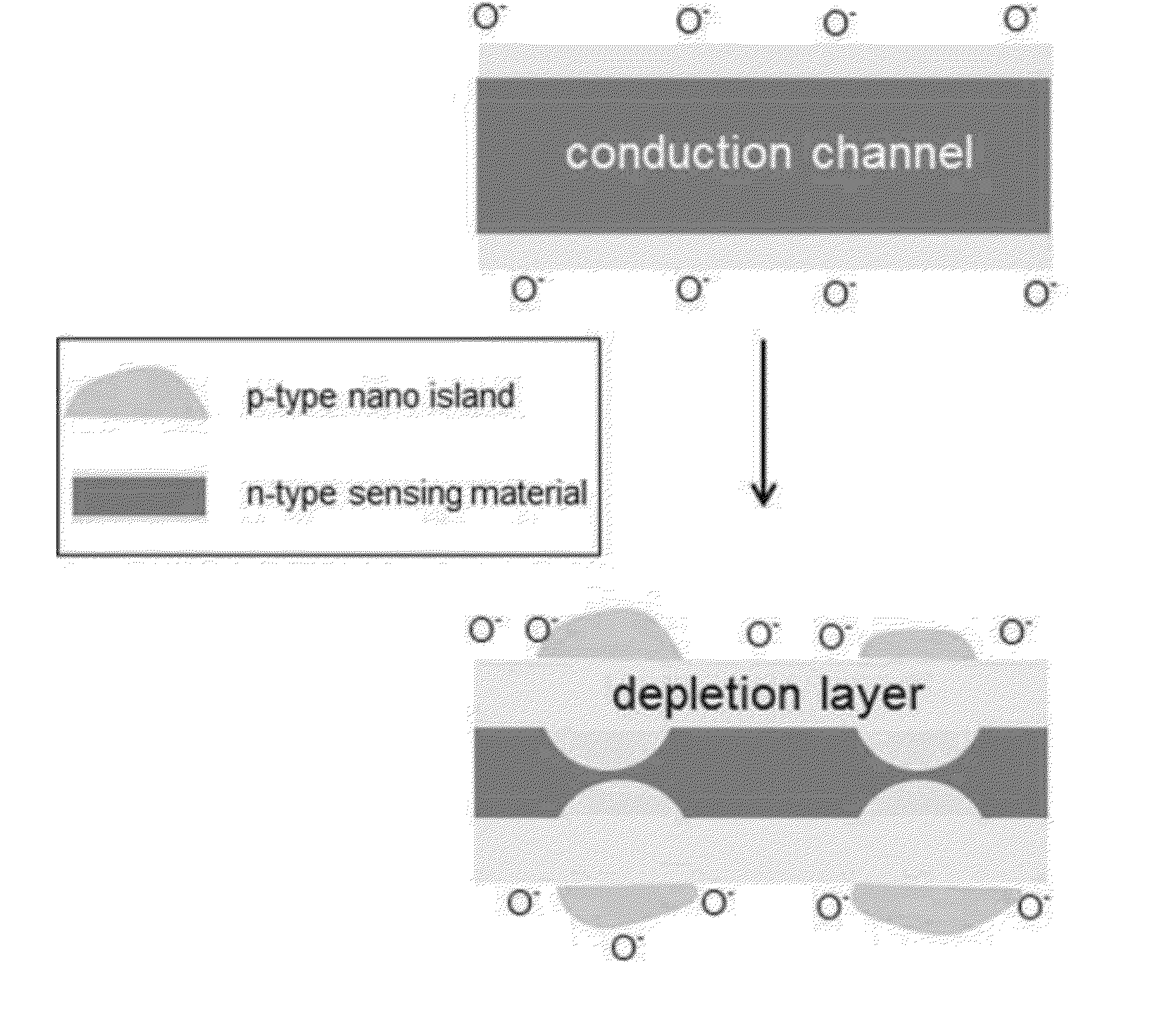

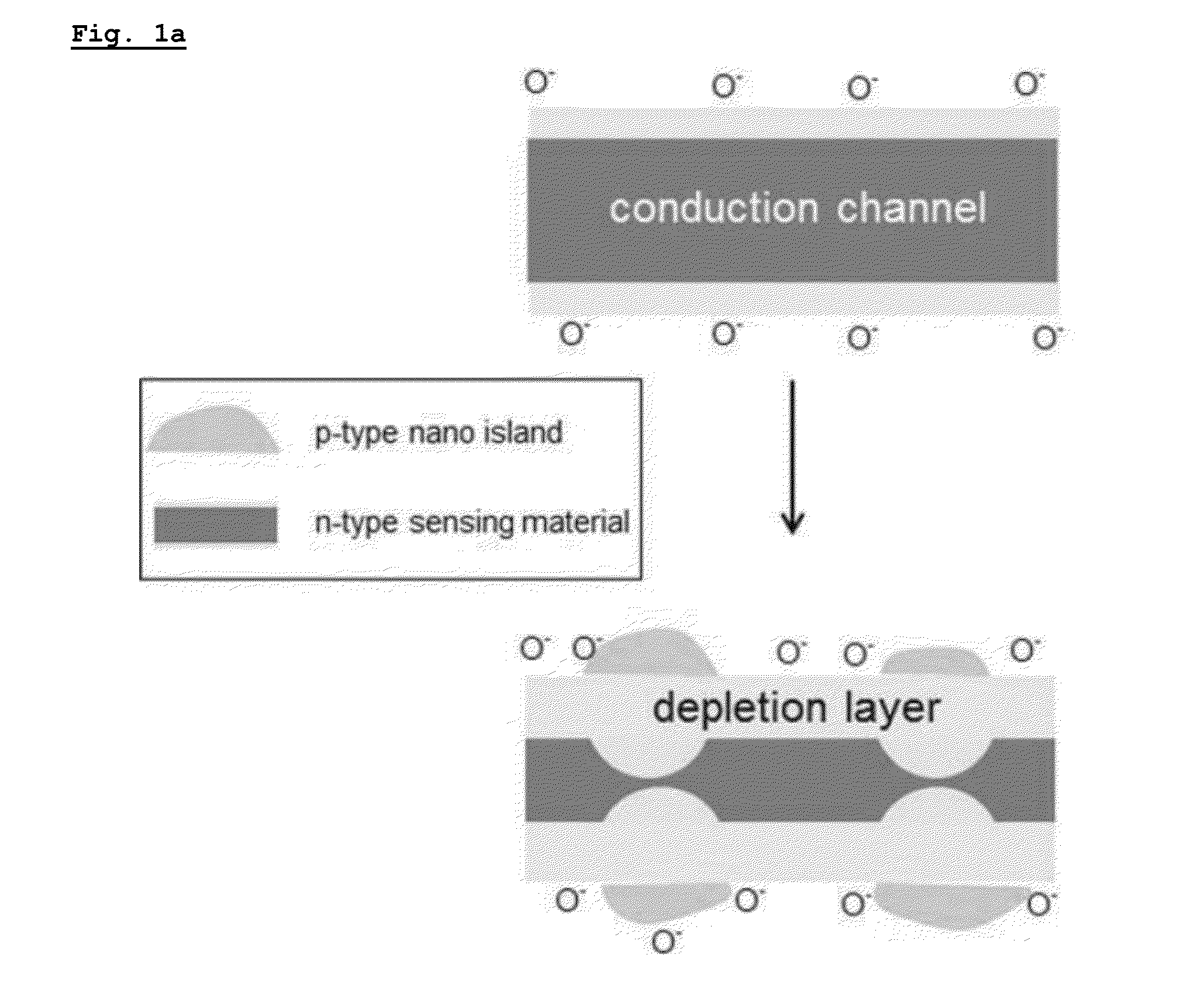

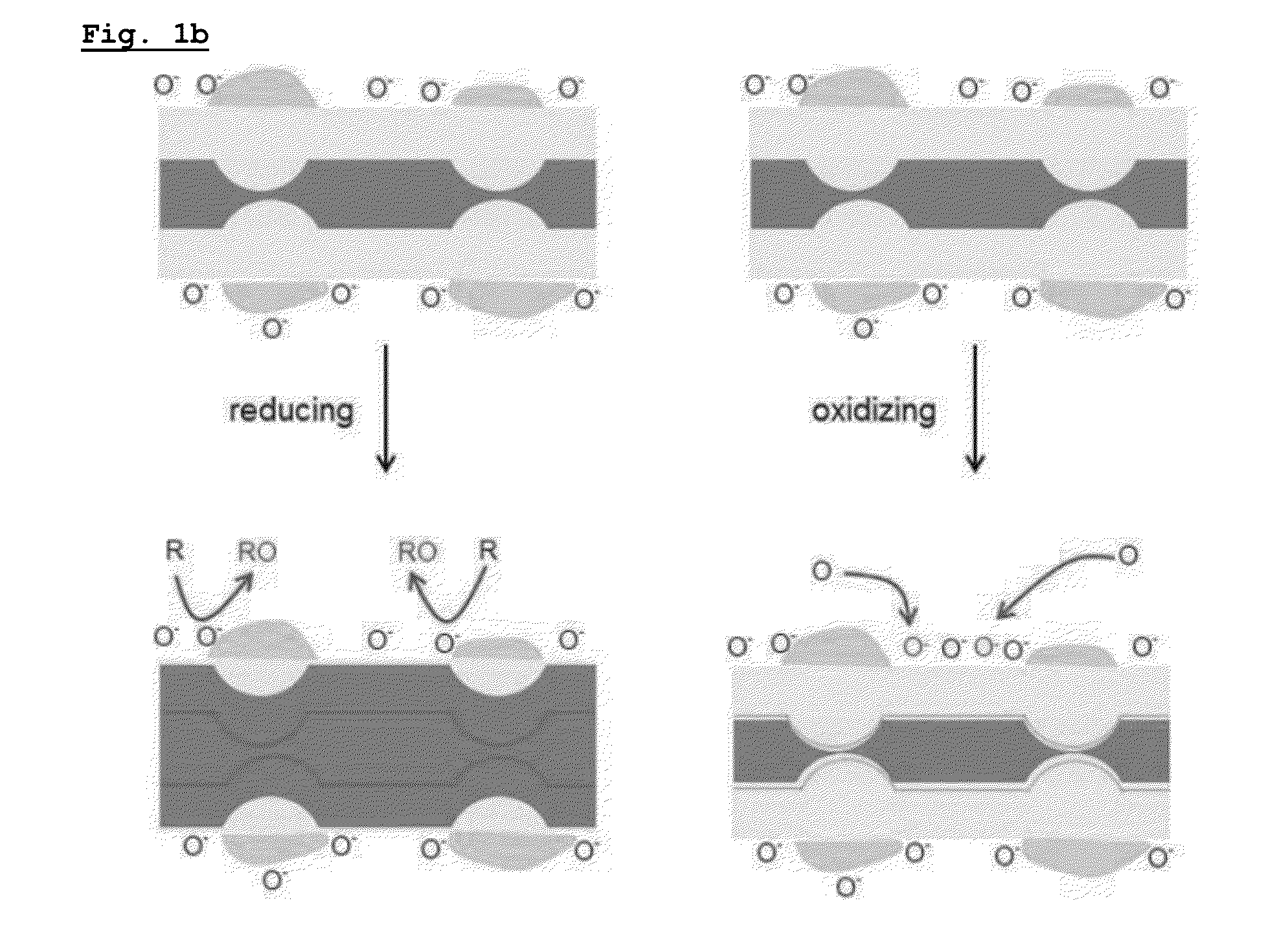

Sensor including core-shell nanostructure, and method for producing same

ActiveUS20150300980A1Maximize modulationHigh sensitivityMaterial analysis by electric/magnetic meansSemiconductor/solid-state device manufacturingMaterials scienceMetal

The present invention relates to a sensor including a core-shell nanostructure, and more particularly, to a sensor including: a base material; a sensing part including a core-shell nanostructure that has a core including a first metal oxide and a shell including a second metal oxide formed on the core; and two electrode layers spaced from each other on the sensing part.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

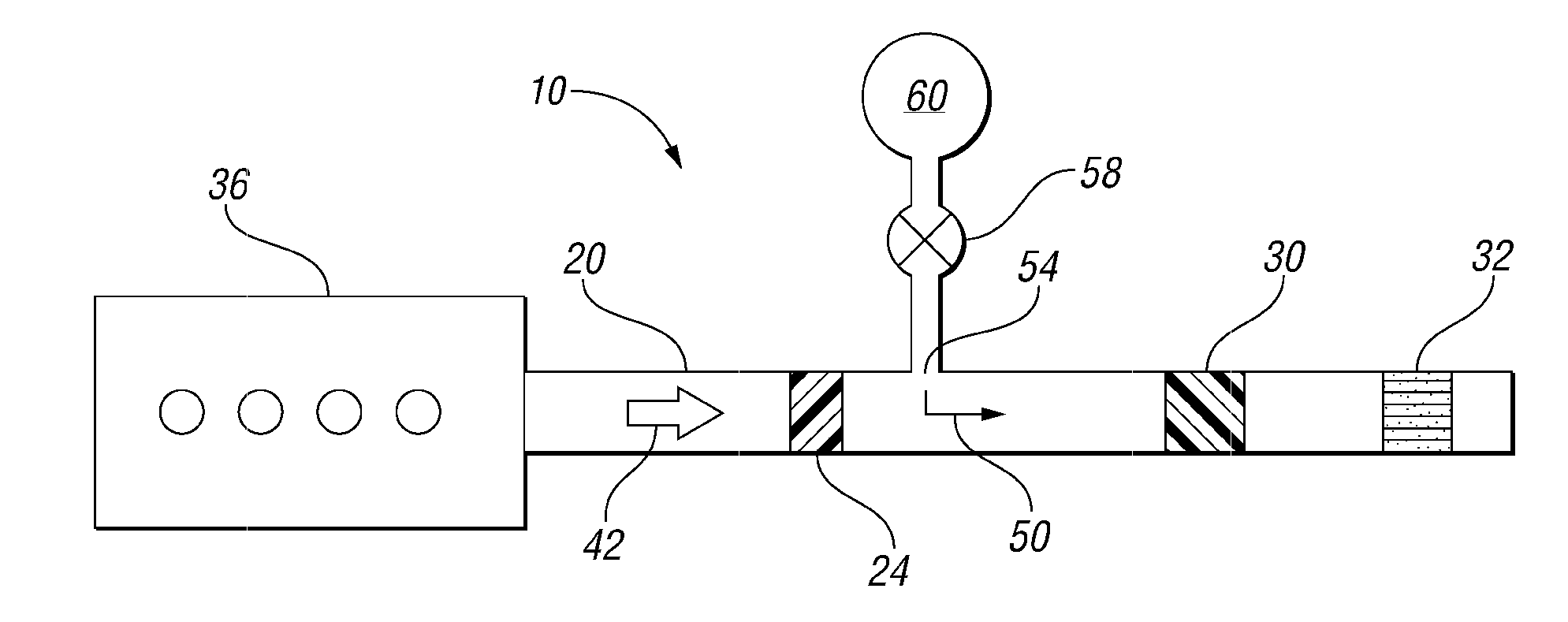

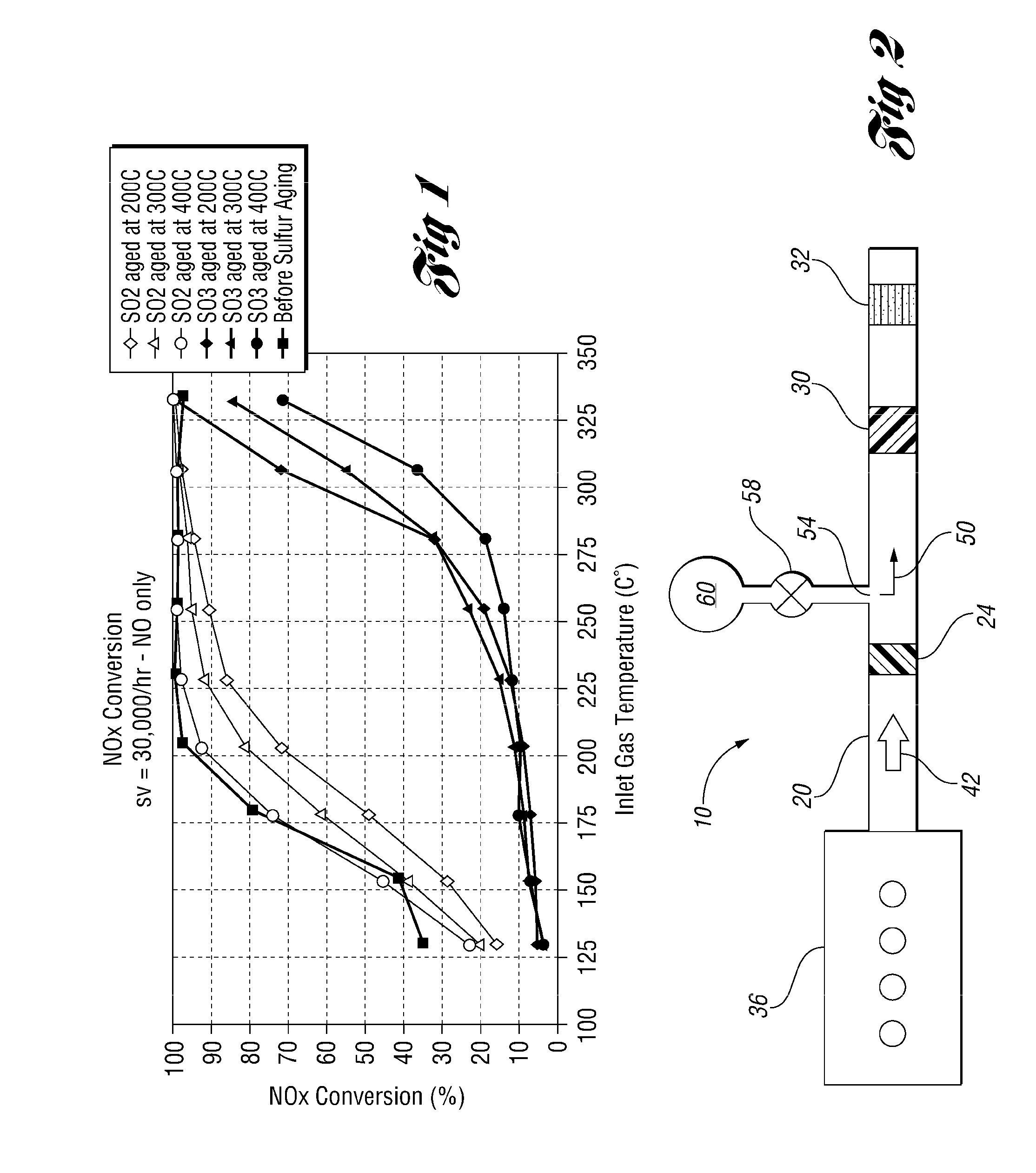

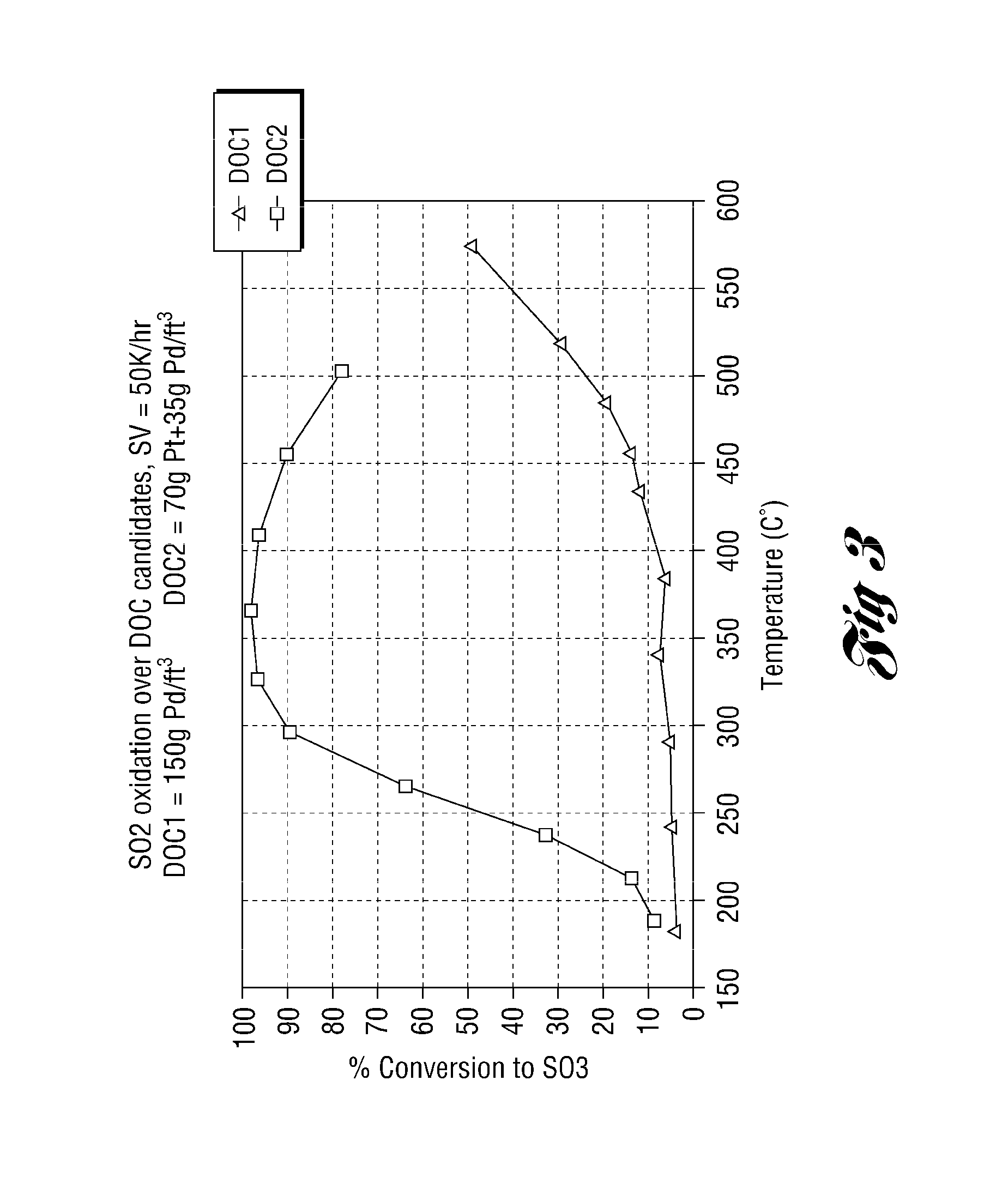

Emission scr NOX aftertreatment system having reduced so3 generation and improved durability

The present invention relates to an emission treatment system for reducing gases from the exhaust of an engine. In at least one embodiment, the emission treatment system includes an exhaust passage for transporting the exhaust from the engine, a selective catalytic reduction (SCR) catalyst disposed within the passage, and an oxidation catalyst disposed in the passage upstream of the SCR catalyst, with the oxidation catalyst having metal, with at least 90 wt. % of the metal comprising palladium (Pd).

Owner:FORD GLOBAL TECH LLC

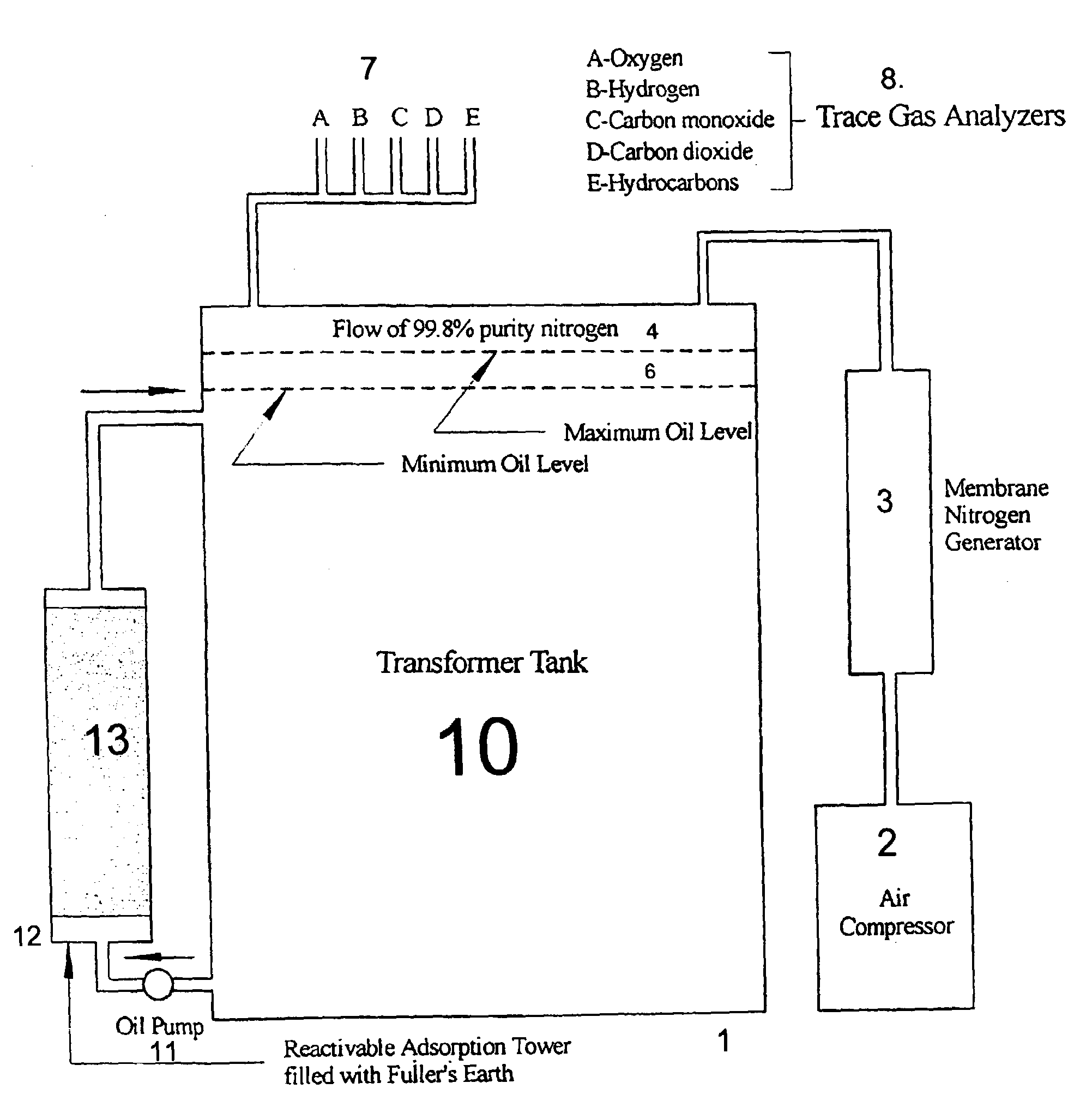

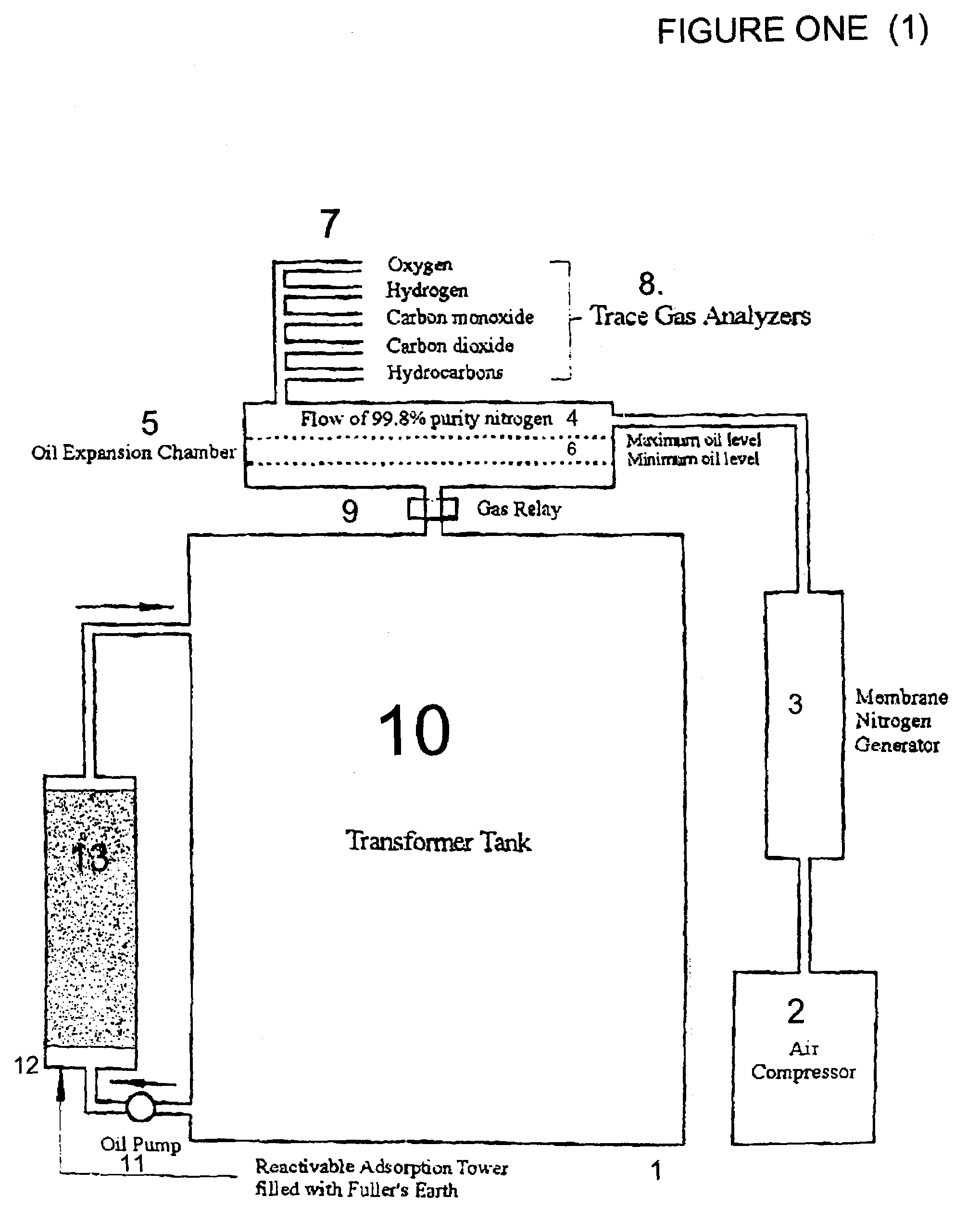

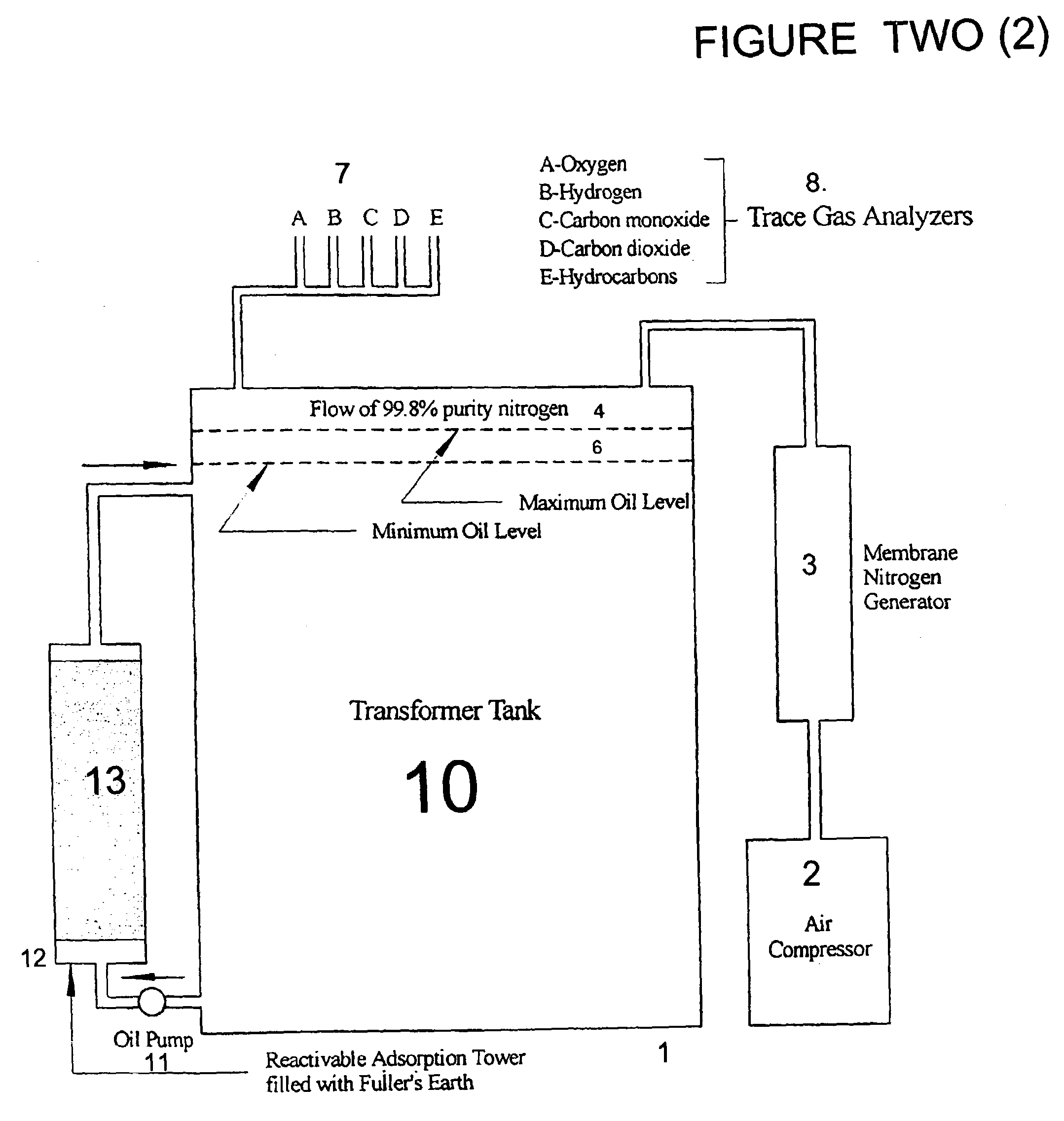

Method and apparatus for decreasing gassing and decay of insulating oil in transformers

InactiveUS7049922B2Delayed decayReduce gasTransformers/inductances coolingMaterial analysisTransformerOxygen

The invention deals with increasing the quality of insulating mineral oil in transformers, by providing an isolating layer of flowing nitrogen over the oil's surface to keep ambient air from combining or absorbing with or in the oil, also providing a kidney or filter to remove undesirable contaminants such as water, oxygen, free radicals and debris from the oil, and providing a means of sensing trace gases produced in the oil responsive to transformer conditions and mixed with nitrogen flow to diagnose transformer conditions of interest such as hot-spots, short circuits, insulation failure or similar indicators of failure or incipient failure or need for service, the trace gas analysis being capable of remote monitoring and interpretation. The invention has application in the field of transformers where it is useful to provide self-sufficient and environmentally equipment and methods to prolong service life and reliability between service or inspection of medium, high, and extra-high voltage power.

Owner:INSOIL CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com