Casting technique of grain refined solid manganese steel frog of long life

A casting process, high-manganese steel technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as micro-cracks, shrinkage cavities, coarse grains, etc., to reduce secondary oxidation, improve quality, and suppress The effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

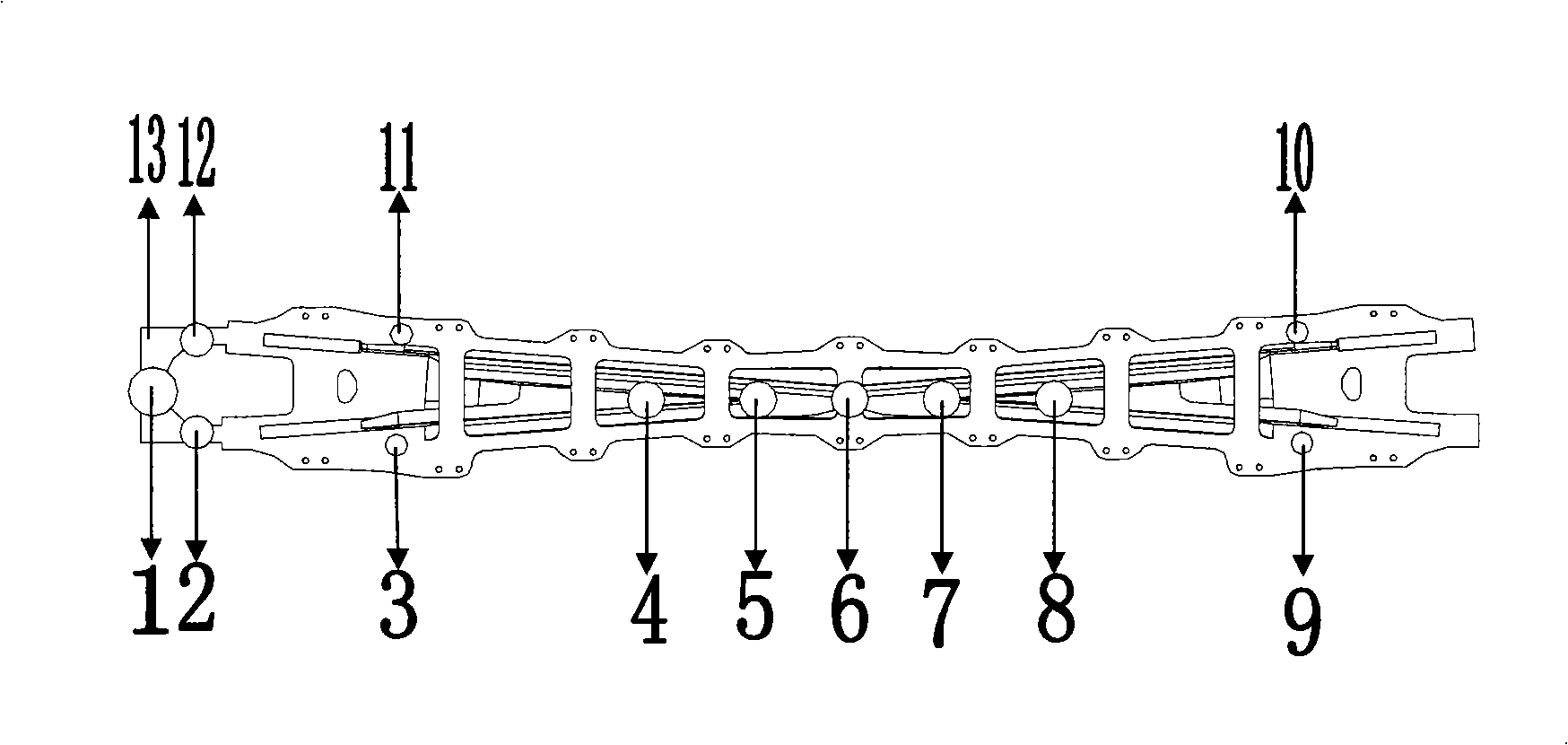

[0042] The temperature of the molten steel is 1590°C, the weight of the poured molten metal is 10.1 tons, and it is refined in the refining ladle. During the refining process, the argon pressure is 0.2MPa, the inner diameter of the pressure pipe is Φ10mm, the argon blowing time is 1 minute / ton of molten steel, and the wire feeding amount is 0.4% of the total weight of molten steel is poured, and the feeding wire is Si-Ca wire commonly used in refining. After removal of inclusions, microalloying is carried out at a temperature of 1550°C, and molybdenum, niobium, vanadium, and titanium are added, and the weight ratio of the added elements is 0.05% respectively. Pouring 5 frogs, the schematic diagram of frog casting process is as follows figure 1As shown, the gate 1 and the runner 13 connected with the gate 1 are located on one side of the casting, and the thermal insulation risers 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12. The pouring temperature is 1490°C, the cavity is filled with ...

Embodiment 2

[0047] The temperature of the molten steel is 1600°C, the weight of the poured molten metal is 10.3 tons, and it is refined in the refining ladle. During the refining process, the argon pressure is 0.3MPa, the inner diameter of the pressure pipe is Φ15mm, the argon blowing time is 0.6 minutes per ton of molten steel, and the wire feeding amount is 0.5% of the total weight of molten steel is poured, and the feeding wire is Si-Ca wire commonly used in refining. After removal of inclusions, microalloying is carried out at a temperature of 1560°C, and molybdenum, niobium, vanadium, and titanium are added, and the weight ratio of the added elements is 0.08% respectively. Pouring 5 frogs, the schematic diagram of frog casting process is as follows figure 1 shown. The pouring temperature is 1500°C, the cavity is filled with argon gas before pouring, and the pouring is carried out under the protection of argon gas. A heat preservation riser with a height-to-diameter ratio of 3:1 is u...

Embodiment 3

[0050] The temperature of the molten steel is 1610°C, the weight of the poured molten metal is 10.2 tons, and it is refined in the refining ladle. During the refining process, the argon pressure is 0.5MPa, the inner diameter of the pressure pipe is Φ20mm, the argon blowing time is 0.5 minutes / ton of molten steel, and the wire feeding amount is 1% of the total weight of molten steel is poured, and the feeding wire is Si-Ca wire commonly used in refining. After removal of inclusions, microalloying is carried out at a temperature of 1570°C, and molybdenum, niobium, vanadium, and titanium are added, and the weight ratio of the added elements is 0.1% respectively. Pouring 5 frogs, the schematic diagram of frog casting process is as follows figure 1 shown. The pouring temperature is 1480°C, the cavity is filled with argon gas before pouring, and the pouring is carried out under the protection of argon gas. A heat preservation riser with a height-to-diameter ratio of 3.5:1 is used. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com