High-temperature alterant and method for purifying fusant by adopting same

A technology of high-temperature metamorphism and melting, applied in the field of aluminum electrolysis, can solve problems such as poor castability, cold cracking, and high gas content, and achieve the effects of improving the yield of ingots, good grain refinement, and optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

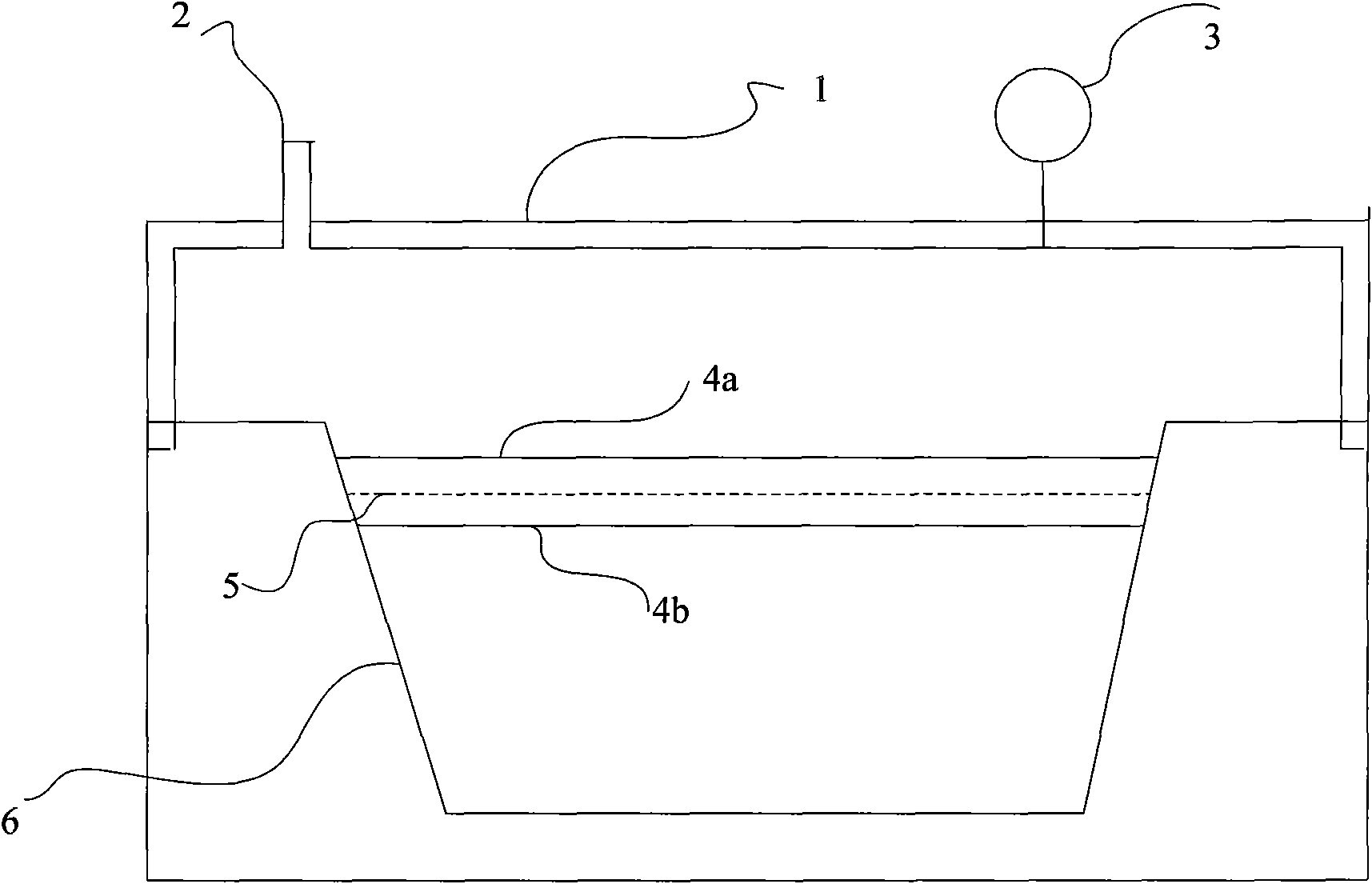

Method used

Image

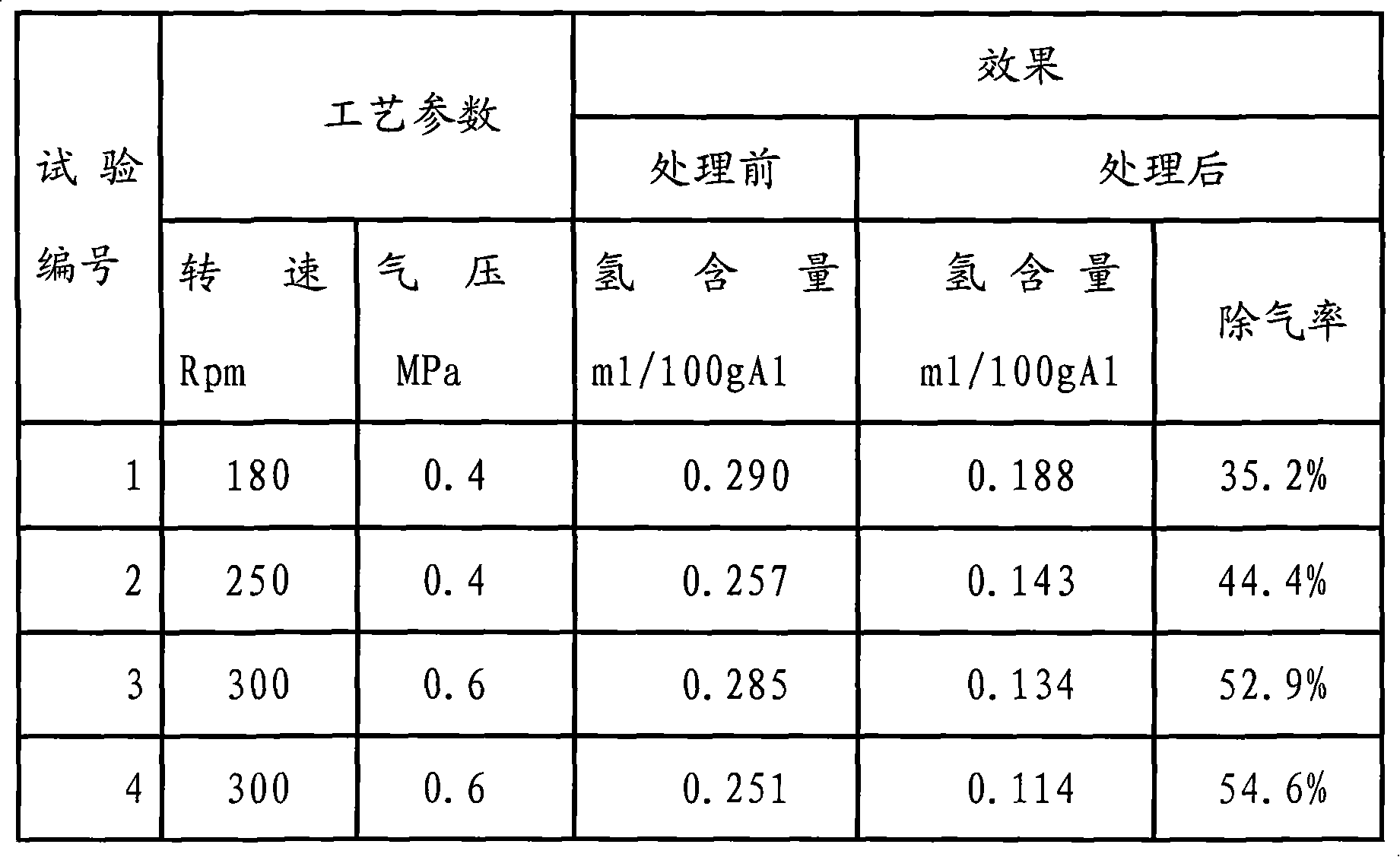

Examples

Embodiment 1

[0031] Mix 15% of fluorite, 45% of carnallite, 30% of cerium carbonate, 6% of titanium dioxide and 4% of graphite, and stir evenly to prepare a high-temperature modificator.

Embodiment 2

[0033] Mix 20% of potassium fluoride, 43% of carnallite, 27% of lanthanum fluoride, 8% of titanium dioxide and 2% of graphite, and stir evenly to prepare a high-temperature modifier.

Embodiment 3

[0035] Mix 18% of magnesium fluoride, 40% of carnallite, 25% of praseodymium chloride, 10% of titanium dioxide and 7% of graphite, and stir evenly to prepare the high-temperature modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com