Method for producing low-chromium ammonium polyvanadate

A technology of ammonium polyvanadate and ammonium sulfate, applied in the direction of improving process efficiency, etc., can solve problems such as not being able to meet special requirements, and achieve the effects of low chromium content, reduced consumption, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

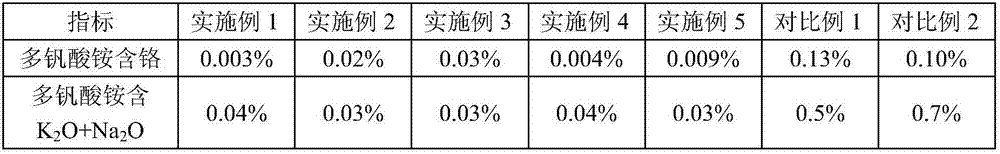

Examples

Embodiment 1

[0023] (1) Ammonium polyvanadate (containing chromium 0.08%, K 2 O+Na 2 O is 1.0%) was added in 30g / L sodium carbonate solution, the pH value was adjusted to 8.0, the heating temperature was controlled at 50°C, after ammonium polyvanadate and sodium carbonate reacted completely to form a solution, the volume and mass ratio of solution to polyacrylamide was 1L : 40mg, in solution, add cationic polyacrylamide, stand still clarification 2min, filter, obtain vanadium solution, containing vanadium concentration is 20g / L;

[0024] (2) Add sulfuric acid to the vanadium solution (concentration of vanadium-containing 20g / L) prepared in step (1) to adjust the pH to 1.5. According to the mass ratio of vanadium and ammonium sulfate in the vanadium solution is 1:0.6, add ammonium sulfate After being heated to boiling and reacting to generate ammonium polyvanadate, filter to obtain ammonium polyvanadate solid;

[0025] (3) the ammonium polyvanadate solid prepared by step (2) is washed amm...

Embodiment 2

[0027] (1) Ammonium polyvanadate (containing chromium 0.20%, K 2 O+Na 2 O is 0.63%) is added in 60g / L sodium carbonate solution, adjusts pH value to 9.5, and heating temperature is controlled at 80 ℃, after ammonium polyvanadate and sodium carbonate react completely to generate solution, by solution and polyacrylamide volume mass ratio is 1L: 80mg, add anionic polyacrylamide to the solution, stand still for clarification for 15min, and filter to obtain a vanadium solution with a vanadium-containing concentration of 50g / L;

[0028] (2) Dilute the vanadium solution prepared in step (1) with water to a vanadium-containing concentration of 25g / L, add sulfuric acid to adjust the pH value to 1.0, and add ammonium sulfate according to the mass ratio of vanadium and ammonium sulfate in the vanadium solution to 1:1.0 After being heated to boiling and reacting to generate ammonium polyvanadate, filter to obtain ammonium polyvanadate solid;

[0029] (3) the ammonium polyvanadate solid ...

Embodiment 3

[0031] (1) Ammonium polyvanadate (containing chromium 0.40%, K 2 O+Na 2 O is 0.59%) is added in 50g / L sodium carbonate solution, adjusts pH value to 9.0, and heating temperature is controlled at 65 ℃, after ammonium polyvanadate and sodium carbonate react completely to generate solution, by solution and polyacrylamide volume mass ratio is 1L: 70mg, add cationic polyacrylamide to the solution, stand still for clarification for 10min, filter to obtain a vanadium solution with a vanadium-containing concentration of 30g / L;

[0032] (2) Dilute the vanadium solution prepared in step (1) with water to a vanadium-containing concentration of 25g / L, add sulfuric acid to adjust the pH value to 1.0, and add sulfuric acid according to the mass ratio of vanadium and ammonium sulfate in the vanadium solution to 1:0.9 Ammonium, after heating to boiling and reacting to generate ammonium polyvanadate, filter to obtain ammonium polyvanadate solid;

[0033] (3) the ammonium polyvanadate solid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com