Device and method of preparing pure lithium chloride solution by precipitating sodium through evaporation of mixed aqueous solution of lithium chloride and sodium chloride

A technology of pure lithium chloride and lithium chloride, applied in the direction of lithium halide, alkali metal chloride, etc., can solve the problems of poor product quality, high operating cost, and low recovery rate of lithium chloride, and achieve easy cleaning and low operating cost The effect of low cost and easy operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

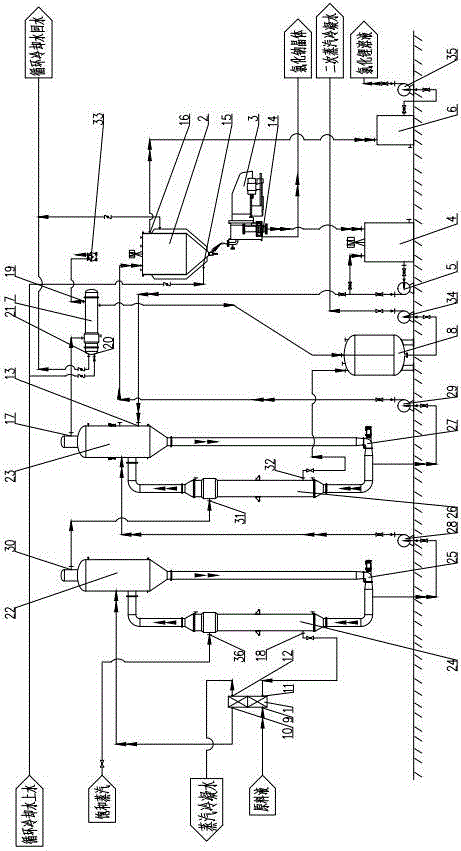

[0029] A device for producing pure lithium chloride solution by evaporating sodium chloride mixed aqueous solution of lithium chloride and sodium chloride, see figure 1 As shown, it includes a condensed water preheater 1, an evaporation crystallizer, a thickener 2, a centrifuge 3, a mother liquor tank 4, a mother liquor pump 5, a lithium chloride clear liquid tank 6, an indirect condenser 7 and a condensed water tank 8.

[0030] The evaporation crystallizer is a double-effect forced circulation evaporation crystallizer. The double-effect forced circulation evaporation crystallizer includes a first-effect evaporator, a first-effect crystallizer 22, a second-effect evaporator and a second-effect crystallizer 23. The first-effect evaporator includes a first-effect heating chamber 24 and a first-effect circulation pump 25, and the second-effect evaporator includes a second-effect heating chamber 26 and a second-effect circulation pump 27.

[0031]The condensed water preheater 1 is...

Embodiment 2

[0040] A device for producing pure lithium chloride solution by evaporating sodium chloride mixed aqueous solution of lithium chloride and sodium chloride, including condensate water preheater 1, evaporation crystallizer, thickener 2, centrifuge 3, mother liquor tank 4, mother liquor pump 5. Lithium chloride clear liquid tank 6, indirect condenser 7 and condensed water tank 8.

[0041] The condensed water preheater 1 is provided with a raw material inlet 9, a raw material outlet 10, a condensed water inlet 11 and a first condensed water outlet 12; the raw material outlet 10 of the condensed water preheater 1 is connected to the raw material inlet of the evaporation crystallizer through a pipeline , the raw material outlet of the evaporation crystallizer is connected with the feed port of the thickener 2 through a pipeline; the slurry outlet at the lower part of the thickener 2 is connected with the centrifuge 3, and the centrifuge mother liquor outlet of the centrifuge 3 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com