Horizontal low-temperature insulating air cylinder and vehicle power system taking gas as power source

A low-temperature insulation and gas cylinder technology, applied in the field of power systems, can solve problems such as the increase in the pressure of gas cylinder 1, the drop in supply pressure, and the inability of medium-sized vehicles to use low-temperature insulation gas cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (Example 1, horizontal cryogenic insulation gas cylinder)

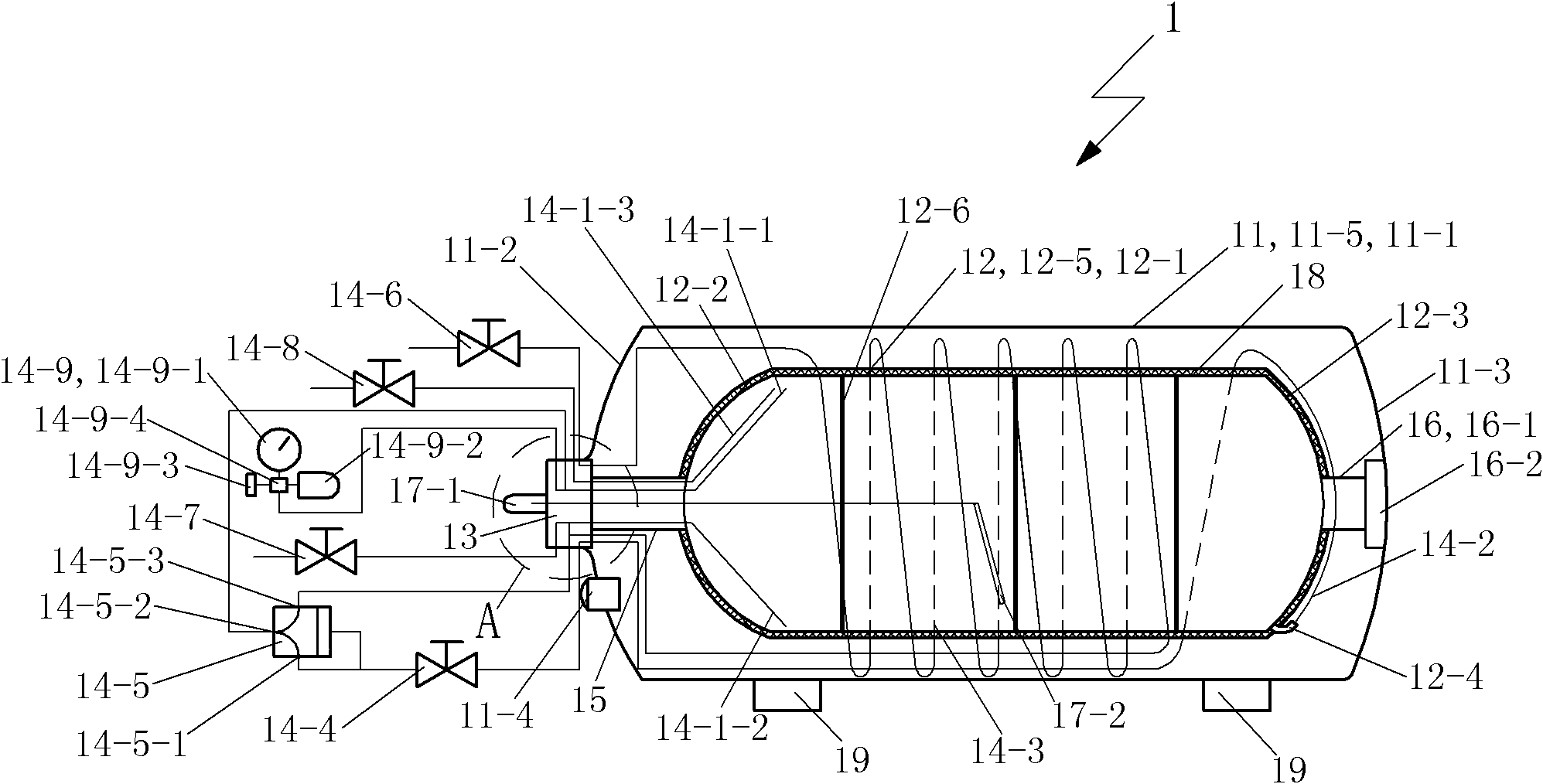

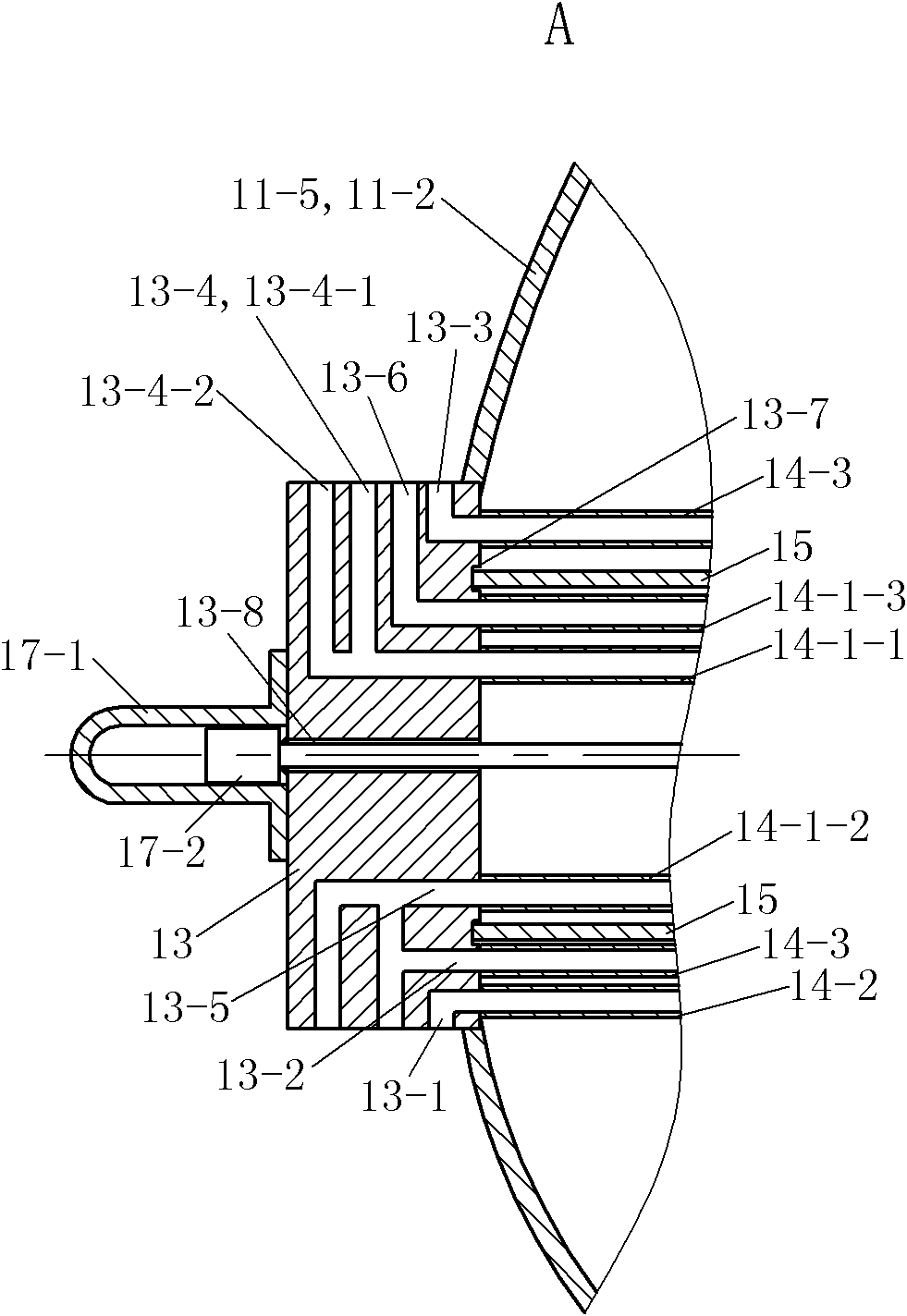

[0068] See figure 2 and image 3 , the capacity of the horizontal low-temperature insulated gas cylinder 1 of this embodiment is 200L, including an outer shell 11, an inner tank 12, a distributor 13, a pipeline control system 14, a neck tube 15, a support member 16, a liquid level assembly 17, and an insulating layer 18 and base 19.

[0069] See figure 2 , the housing 11 includes a housing 11-5 and a vacuum interface 11-4. The shell 11-5 includes a shell cylinder 11-1, a front shell 11-2 and a rear shell 11-3.

[0070] The casing cylinder 11-1 is in the shape of a cylinder, and is formed by bending a stainless steel plate and welding it through a longitudinal seam.

[0071] The front cover 11-2 of the housing is an arc-shaped curved panel with a rear opening and a central hole and a mounting hole. The central hole of the front cover 11-2 is also the central hole of the housing 11-5. The vacuum interface...

Embodiment 2

[0091] (Example 2, an automobile power system using gas as a power source)

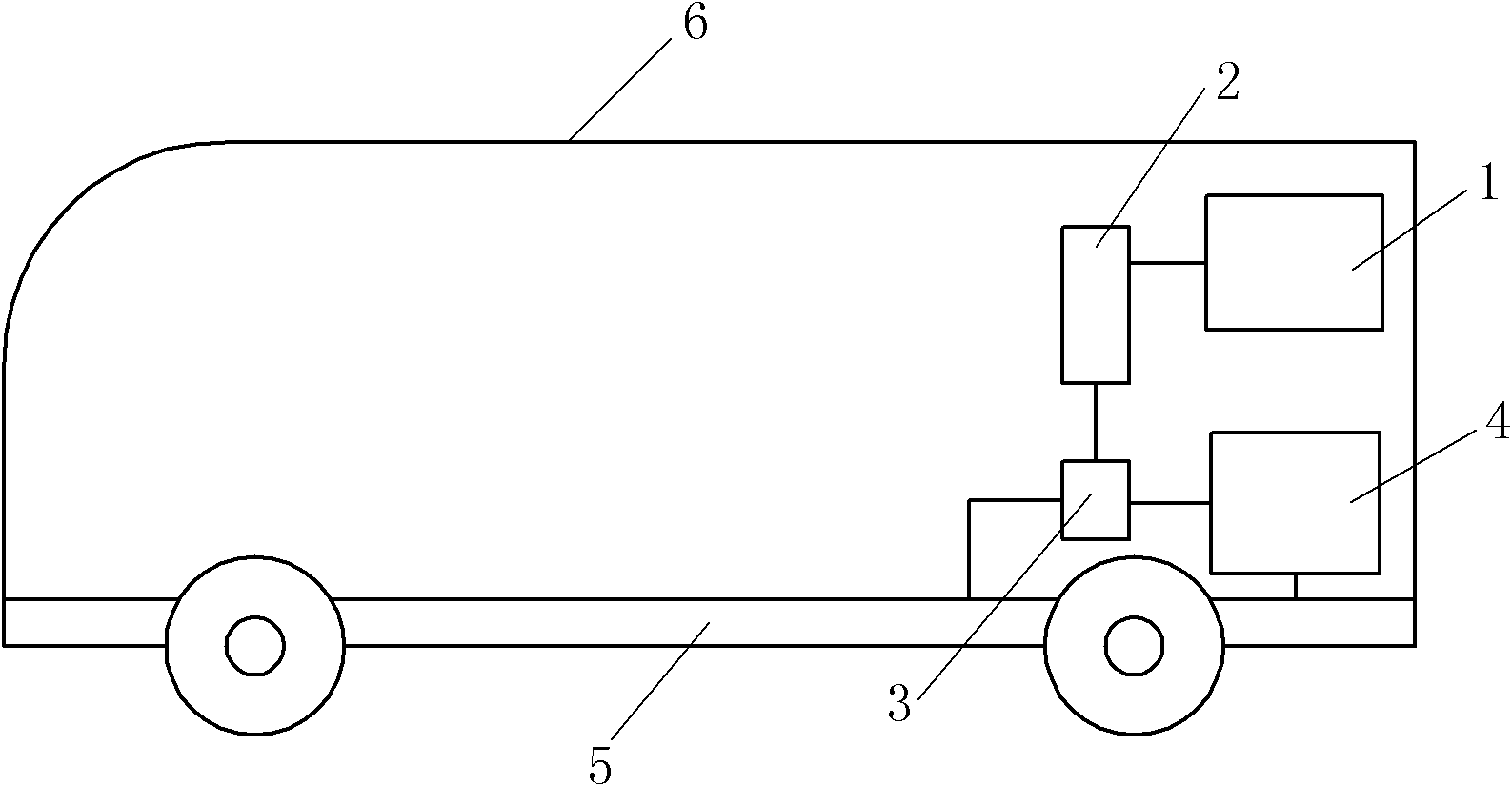

[0092] See figure 1 , the vehicle power system with gas as the power source of the present invention includes a horizontal cryogenic insulating gas cylinder 1, a carburetor 2, a surge tank 3, an air engine 4, a control mechanism, a power source control pedal, a chassis 5 and a vehicle body 6. The control mechanism adopts the carburetor control mechanism in the gasoline engine supply system in the automobile engine.

[0093] See figure 1 , the pressure regulating box 3 includes an air inlet, an air outlet and a control valve arranged at the air outlet. The control valve can control the gas outlet area flowing out of the pressure regulating box 3. Adjustable control rod, which can move up and down relative to the valve seat between the upper position and the lower position. When the control rod is in the upper position, the control valve is opened to the maximum. When the control rod is in the lower pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com