Formation method for lithium ion battery

A lithium ion battery and a formation method technology, applied in the field of formation of lithium ion batteries, can solve the problems of destroying the interface state of the battery cell, reducing the cycle performance of the lithium battery, and adversely affecting the performance of the lithium battery, so as to improve the performance of the lithium battery, improve the Hardness, gas reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above and other objectives, features, and advantages of the present invention more obvious, the following describes the embodiments of the present invention in conjunction with the accompanying drawings in detail.

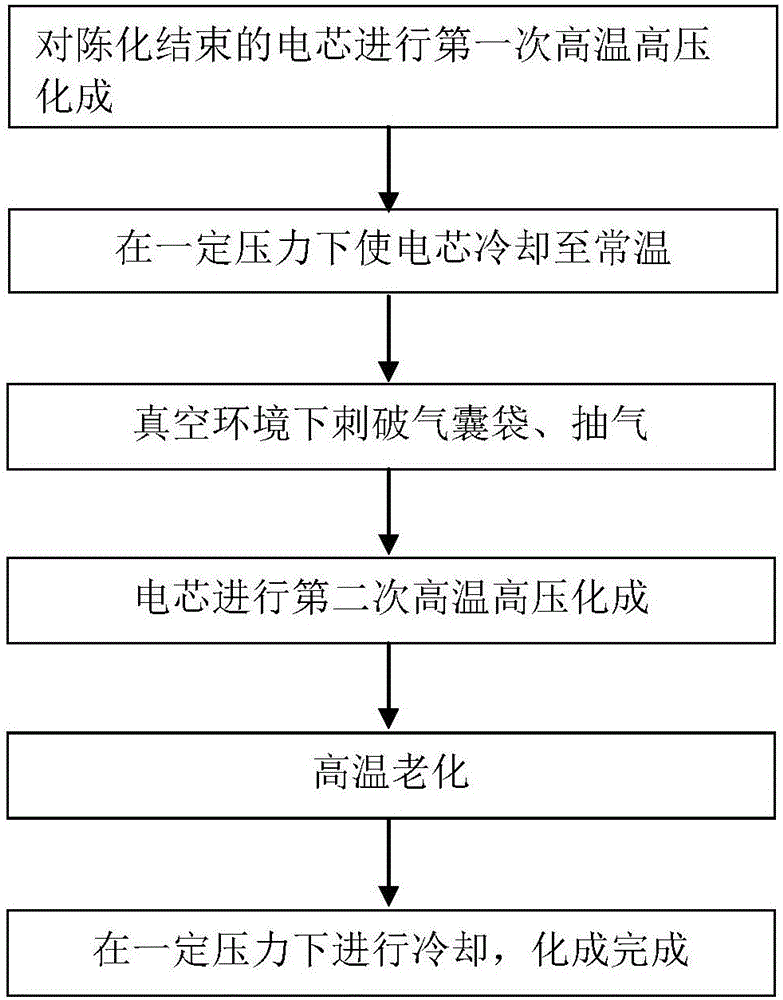

[0025] Such as figure 1 As shown, the steps of the formation method of the present invention are as follows:

[0026] Step A. Put the aged cells into the chemical conversion equipment for high-temperature pressurization. During chemical conversion, they are charged with a current of 0.05 ~ 0.5 CmA. The charge cut-off voltage is 3.5 ~ 3.8V, and the formation temperature is 30 ~ 100°C. The pressure is 0.01~10MPa;

[0027] Step B. Cool the battery cell at room temperature and a certain pressure to lower the battery cell temperature to room temperature, the pressure during cooling is 0.01-10MPa, the temperature is 5-30°C, and the cooling time is 30s-100min;

[0028] Step C. Place the cooled battery cell in a vacuum environment, puncture the air bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com