Patents

Literature

47results about How to "Good anti-HIC performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

X65 pipeline steel for use in acid condition and its making process

ActiveCN1811002AImprove the effect of controlled rollingImproved dynamic tear resistanceManufacturing convertersProcess efficiency improvementMetallurgyTear resistance

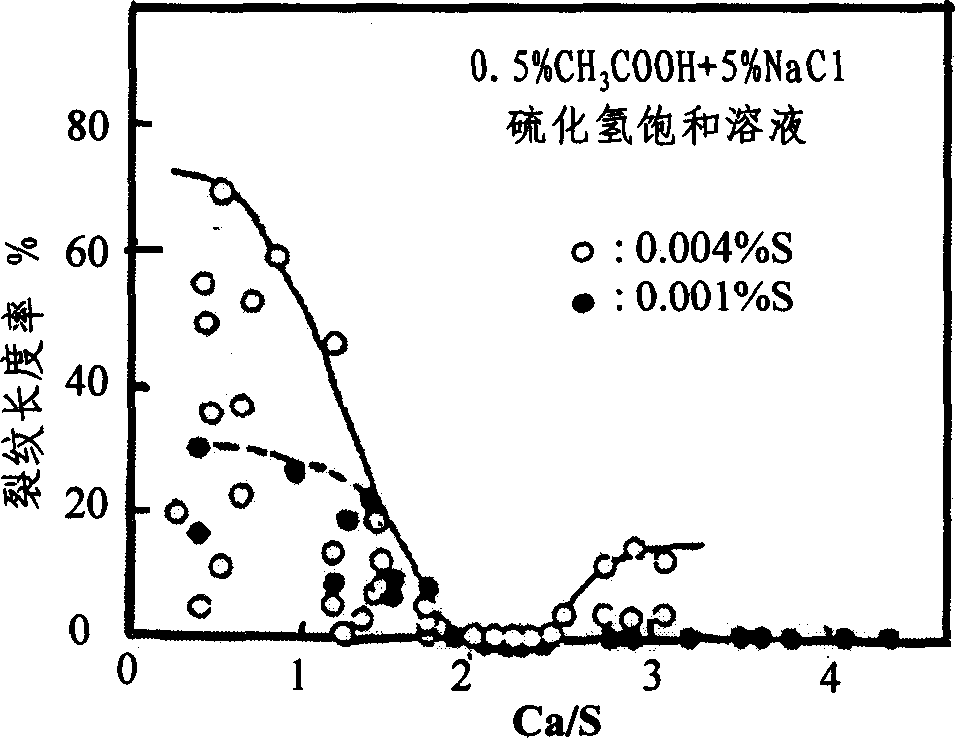

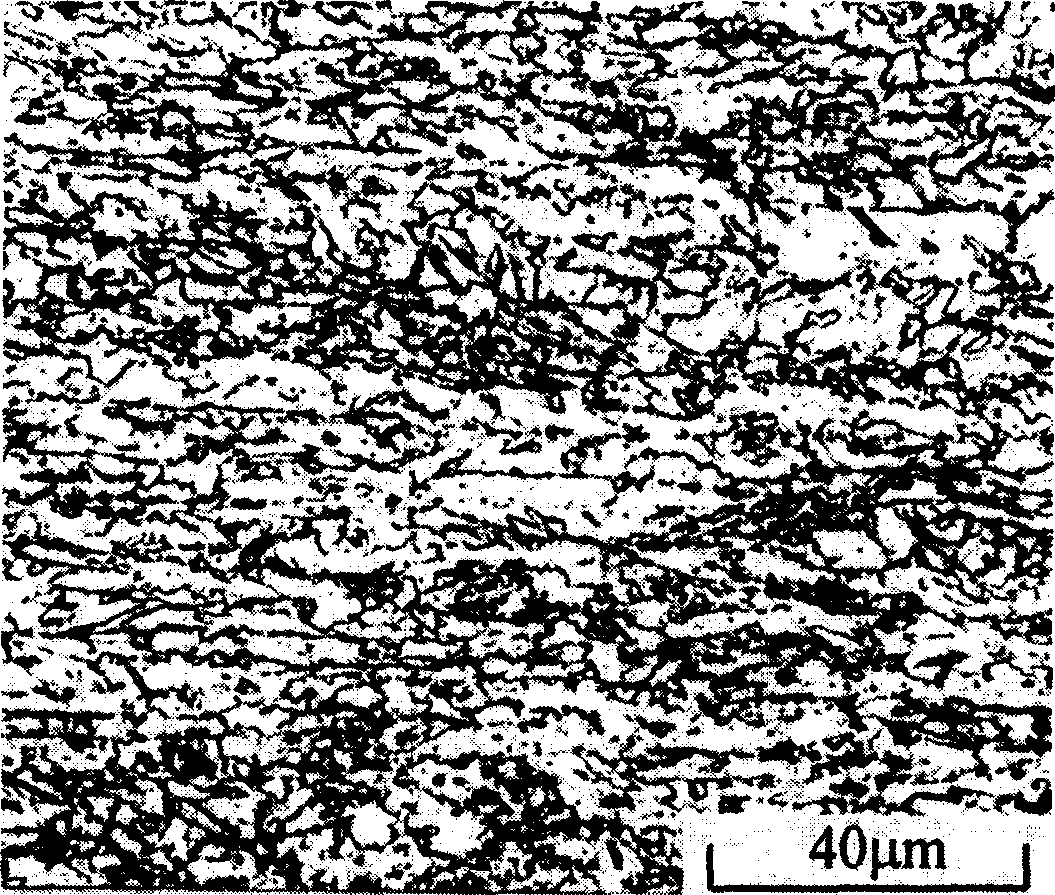

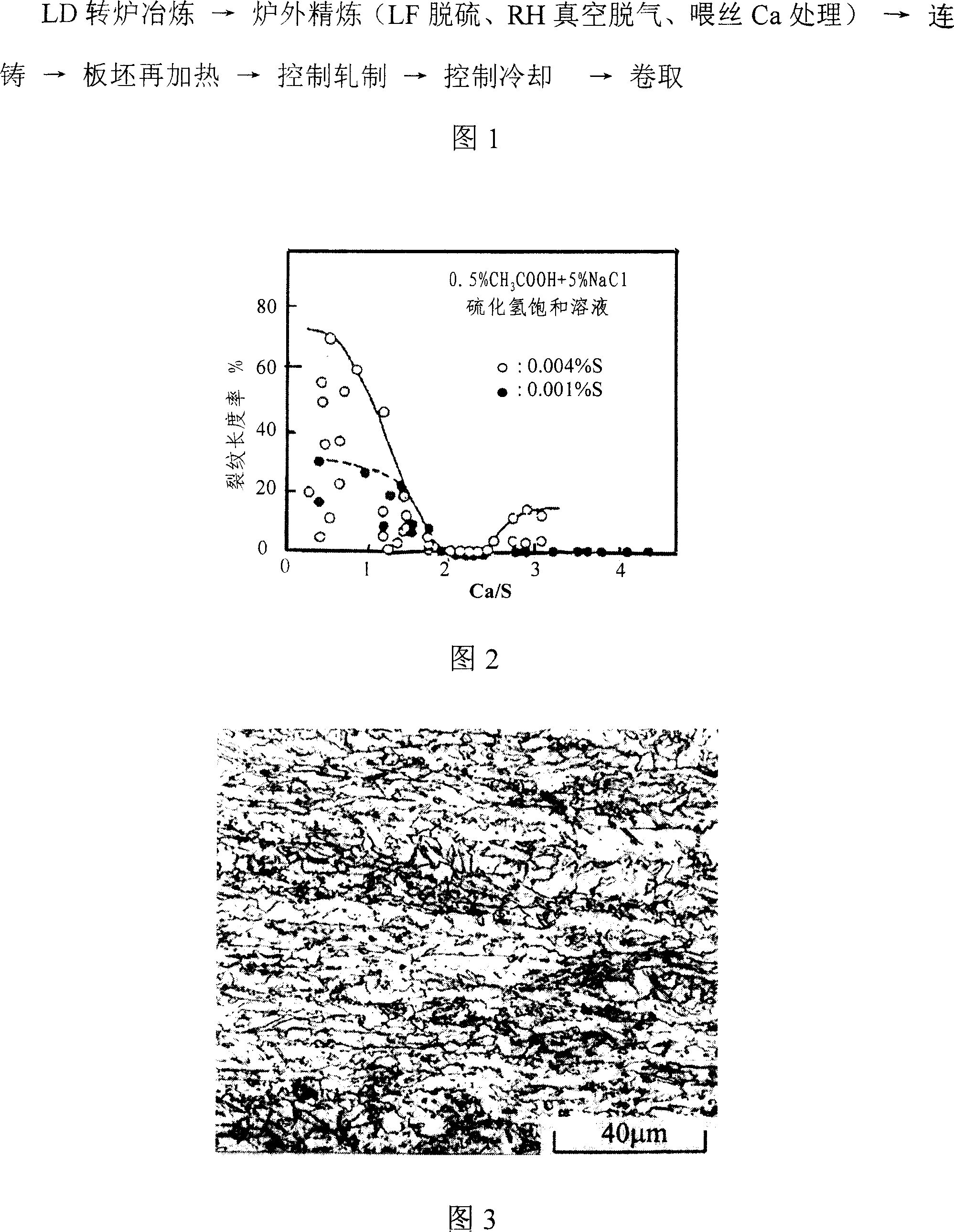

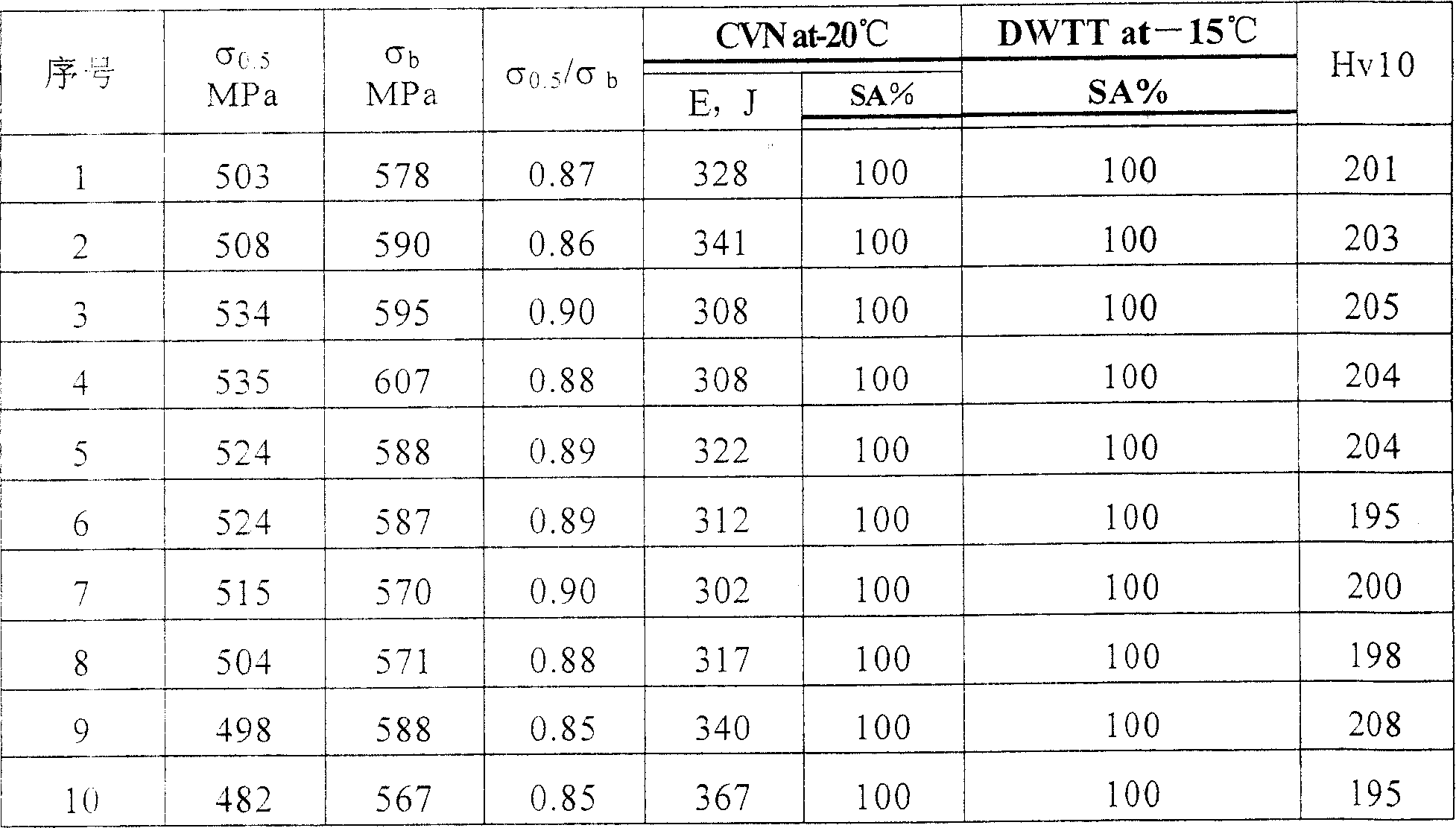

The X65 pipeline steel for use in acid condition consists of C 0.02-0.05 wt%, Mn 1.20-1.50 wt%, Si 0.10-0.50 wt%, S not more than 0.0020 wt%, P 0.004-0.012 wt%, Nb 0.05-0.07 wt%, Ti 0.005-0.025 wt%, Mo 0.050-0.195 wt%, Cu not more than 0.35 wt%, Ni not more than 0.35 wt%, N not more than 0.0080 wt%, Ca 0.0015-0.0045 wt% and Ca / S not less than 2.0 except Fe. Its making process includes the following steps: smelting in a converter or an electric furnace; secondary steel making including LF desulfurizing + RH vacuum deairing and Ca treatment; continuous casting; rolling with initial rolling termination temperature of 940-1020 deg.c and finish rolling termination temperature of 780-840 deg.c; and winding at 500-580 deg.c. The X65 pipeline steel has low manufacture cost, high HIC resistance, high dynamic tear resistance and high impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

Super-thick X70 pipeline steel and manufacturing method thereof

The invention discloses super-thick X70 pipeline steel and a manufacturing method thereof, wherein the pipeline steel is 30-32mm thick, and the pipeline steel comprises the following chemical ingredients in percentage by mass: 0.03-0.06% of C, 0.1-0.30% of Si, 1.30-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0050% of S, 0.030-0.050% of Nb, 0.008-0.020% of Ti, 0.10-0.30% of Ni, 0.l0-0.30% of Cr, 0.10-0.30% of Cu and the balance being Fe and inevitable impurity elements. smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining and RH vacuum degassing to obtain molten steel which is relatively high in purity, and then the pipeline steel, which is high in thickness, high in strength, narrow in strength interval, excellent in low-temperature toughness, and excellent in both low-temperature resistant aging performance and HIC resistance, is obtained through a controlled rolling and controlled cooling process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Non-copper and nickel acid resistant pipeline steel X52MS and production method of hot-rolled plate coil thereof

The invention relates to non-copper and nickel acid resistant pipeline steel X52MS. The non-copper and nickel acid resistant pipeline steel X52MS comprises the following components in percentage by weight: 0.02-0.06 wt% of C, 0.05-0.35 wt% of Si, 1.0-1.4 wt% of Mn, P not greater than 0.018 wt%, S not greater than 0.003 wt%, 0.10-0.50 wt% of Cr, 0.05-0.10 wt% of Ti, 0.005-0.10 wt% of Nb, 0-0.05 wt% of V, and the balance of Fe and inevitable trace impurities. The invention further provides a preparation method of a hot-rolled plate coil of the non-copper and nickel acid resistant pipeline steel X52MS. Part of all Cr is used for replacing original Ni / Cu elements, so that the material cost is largely reduced under the precondition of guaranteeing the material HIC resistance.

Owner:SHOUGANG CORPORATION

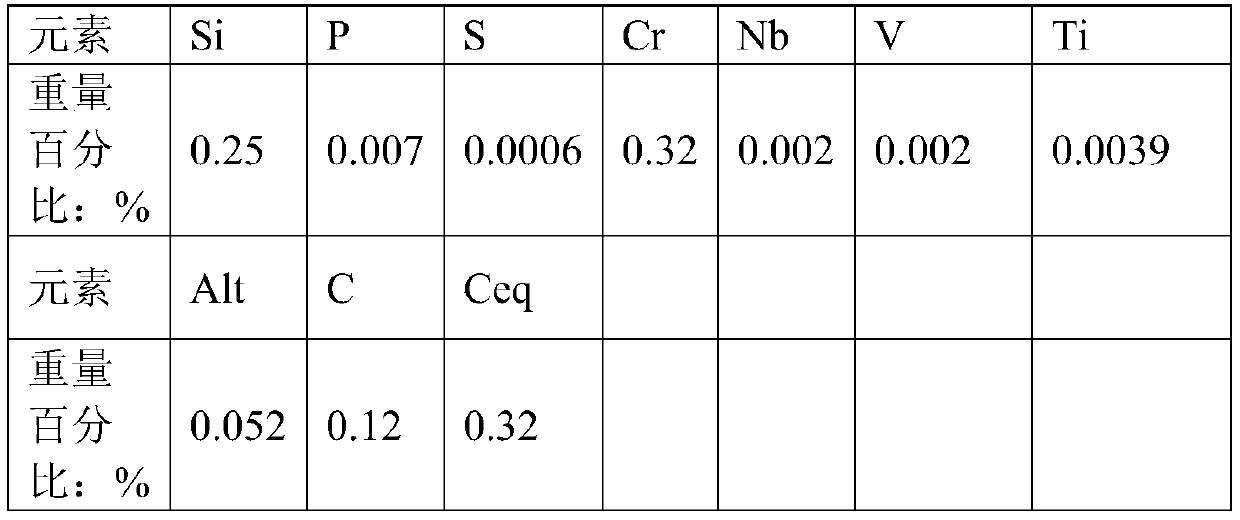

Pressure container steel plate resistant to hydrogen induced cracking and manufacturing method thereof

ActiveCN105886909AHigh strengthImprove low temperature impact toughnessFurnace typesHeat treatment furnacesNon-metallic inclusionsHardness

The invention relates to a pressure container steel plate resistant to hydrogen induced cracking. The steel plate comprises, by weight, 0.16%-0.20% of C, 0.15%-0.40% of Si, 1.05%-1.20% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, less than or equal to 0.01% of Nb, less than or equal to 0.01% of V, less than or equal to 0.01% of Ti, less than or equal to 0.0005% of B, and the balance Fe and inevitable impurity elements. The carbon equivalent Ceq is less than or equal to 0.42%, and a calculation formula for the carbon equivalent Ceq is Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The steel plate is high in strength and low-temperature impact toughness, low in hardness and good in HIC resistance. The steel plate has fine grains and low nonmetal inclusion content, and obvious banded structures do not exist. After long-time simulation of postweld heat treatment at a high temperature, the strength and the low-temperature impact toughness of the steel plate are not obviously weakened.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Economic HIC-resistant X90 pipeline steel plate and manufacturing method thereof

ActiveCN105803327AGood anti-HIC performanceImprove low temperature toughnessChemical compositionToughness

The invention discloses an economic HIC-resistant X90 pipeline steel plate. The steel plate comprises the following chemical components by mass percent: 0.02 to 0.06% of C, 1.7 to 1.90% of Mn, 0.15 to 0.35% of Si, 0.0005% of less of S, 0.010% of less of P, 0.04 to 0.07% of Nb, 0.008 to 0.03% of Ti, 0.10% or less of V, 0.06% of less of Al, 0.010% or less of N, 0.006% or less of O, 0.20% of less of Mo, 0.20% or less of Cu, 0.20% or less of Ni, 0.20% or less of Cr and 0.0005 to 0.0015% of Ca, and the balance being Fe and unavoidable impurity elements, wherein the ratio of the content of Ca to the content of S is 1.0 to 2.0. According to the economic HIC-resistant X90 pipeline steel plate, the improved technology of refining, continuous casting, high temperature reheating and TMCP is adopted according to the behavioral rule of hydrogen in structures, so that the steel has an excellent structure resisting HIC and has excellent low-temperature toughness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Pipeline steel plate for HIC (hydrogen induced cracking)-resistant X80 elbow pipes and manufacturing method thereof

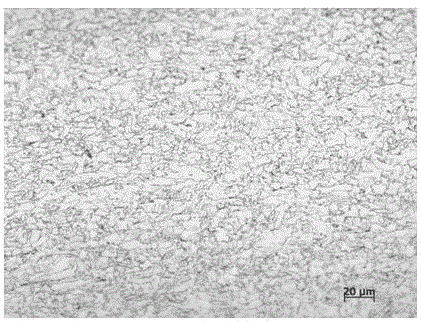

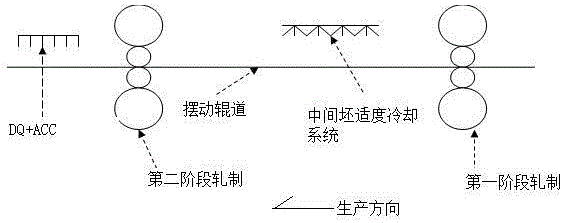

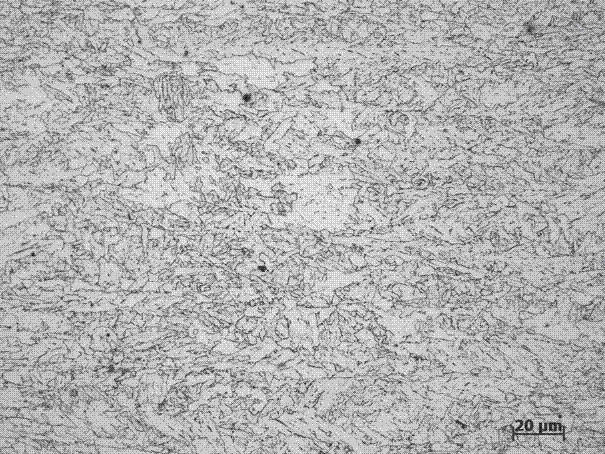

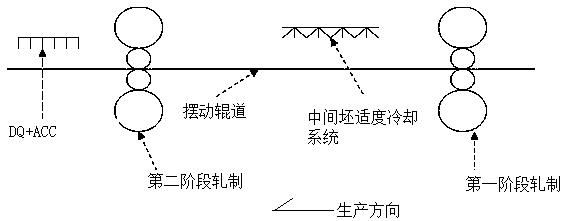

InactiveCN107099744ASolve the problem of anti-HIC performanceGood anti-HIC performanceHigh carbonNiobium

The invention discloses a pipeline steel plate for HIC (hydrogen induced cracking)-resistant X80 elbow pipes. A component design principle is characterized in that a proper amount of C (carbon) and Mn (manganese) is added, a trace amount of microalloying elements of Nb (niobium), V (vanadium), Ti (titanium) and the like is added, a small amount of Mo (molybdenum), Cu (copper), Ni (nickel) and the like is added, and a particular TMCP (thermo mechanical control process) technology is combined, so as to finally ensure the mechanical properties, especially HIC-resistant property at high carbon equivalent. The manufacturing process comprises the following steps of preparing materials according to a proportional ratio; sending into a converter or an electric furnace to smelt; refining outside the converter or the electric furnace; continuously casting; reheating a plate blank; performing TMCP technology and stack cooling after water cooling; straightening. The pipeline steel plate for the X80 elbow pipe has the advantages that the particular TMCP comprises two-phase rolling and intermediate blank cooling, so that the problem of HIC-resistant property at high carbon equivalent is solved; and the HIC-resistant property of pipeline steel plate for X80 elbow pipes is excellent.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

X65 pipeline steel for use in acid condition and its making process

ActiveCN100359035CImprove the effect of controlled rollingImproved dynamic tear resistanceManufacturing convertersProcess efficiency improvementMetallurgyTear resistance

Owner:BAOSHAN IRON & STEEL CO LTD

X52 seamless pipeline tube having HIC resistance and manufacturing method thereof

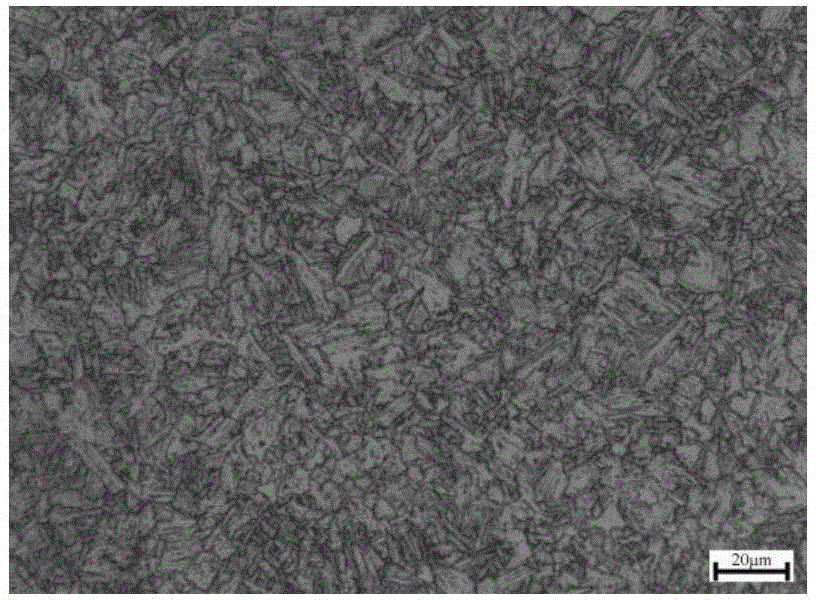

ActiveCN104419872AReduce manufacturing costGood anti-HIC performanceFurnace typesHeat treatment furnacesQuenchingGrain structure

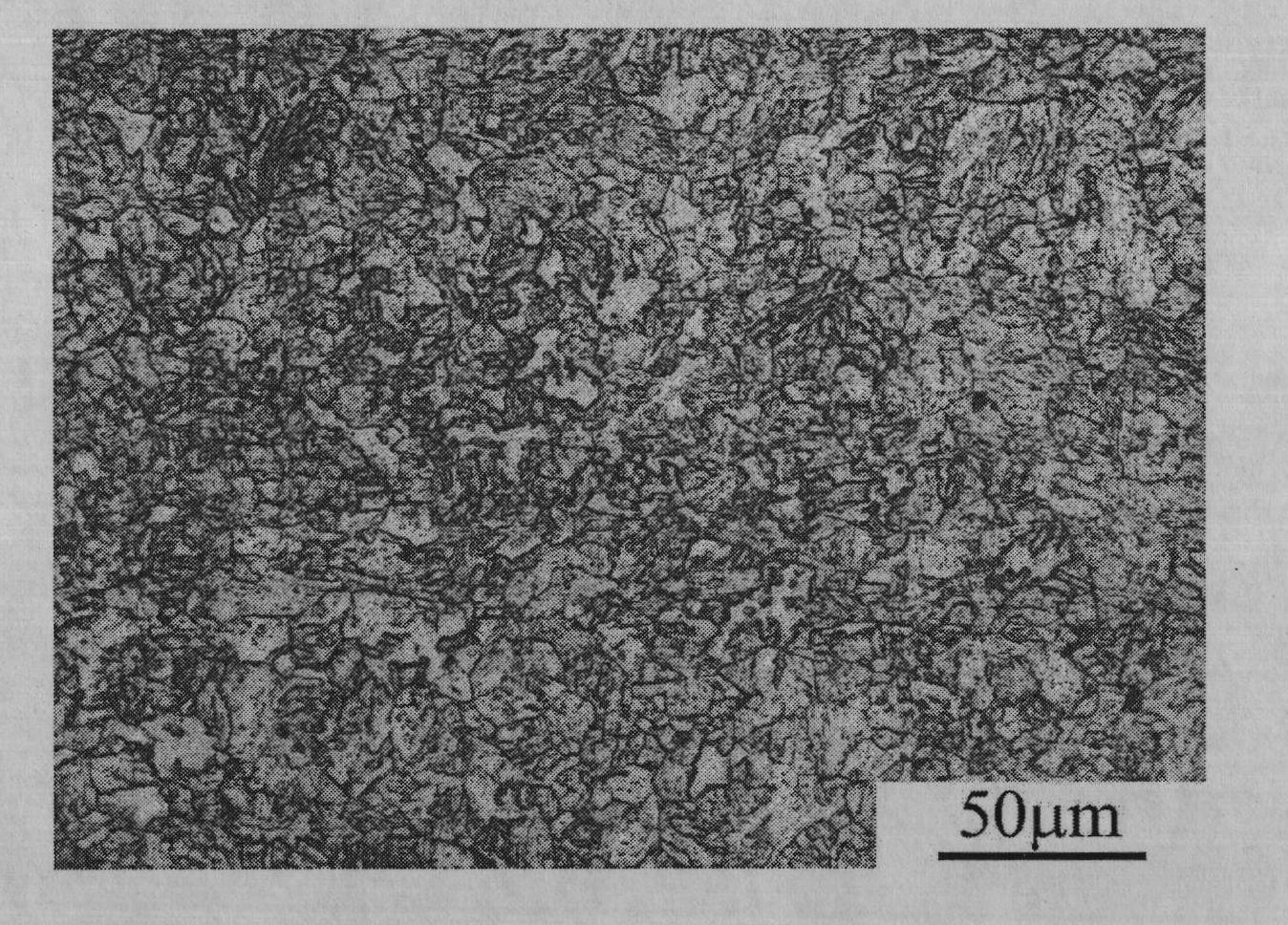

The invention provides an X52 seamless pipeline tube having HIC resistance and a manufacturing method thereof. The X52 seamless pipeline tube comprises the following components in percentage by weight: 0.08-0.16% of C, 0.2-0.4% of Si, 1.0-1.6% of Mn, 0.01-0.04% of Ti, 0.03-0.08% of V, 0.20-0.30% of Cu, 0.15-0.25% of Ni, less than or equal to 0.015% of P, less than or equal to 0.010% of S and the balance of iron and unavoidable impurities. The manufacturing method comprises the following steps: heating a tube billet obtained by hot rolling to 1200 DEG C-1300 DEG C by virtue of an annular furnace, carrying out continuous rolling method by virtue of an MPM, carrying out quenching and tempering heat treatment and carrying out strip temperature straightening at a temperature not less than 400 DEG C. By screening and matching alloying elements and carrying out heat treatment method of quenching and tempering, the HIC resistance of the tube is improved, the grain structure is uniform, good impact toughness is achieved and the manufacturing method is easily implemented.

Owner:ANGANG STEEL CO LTD

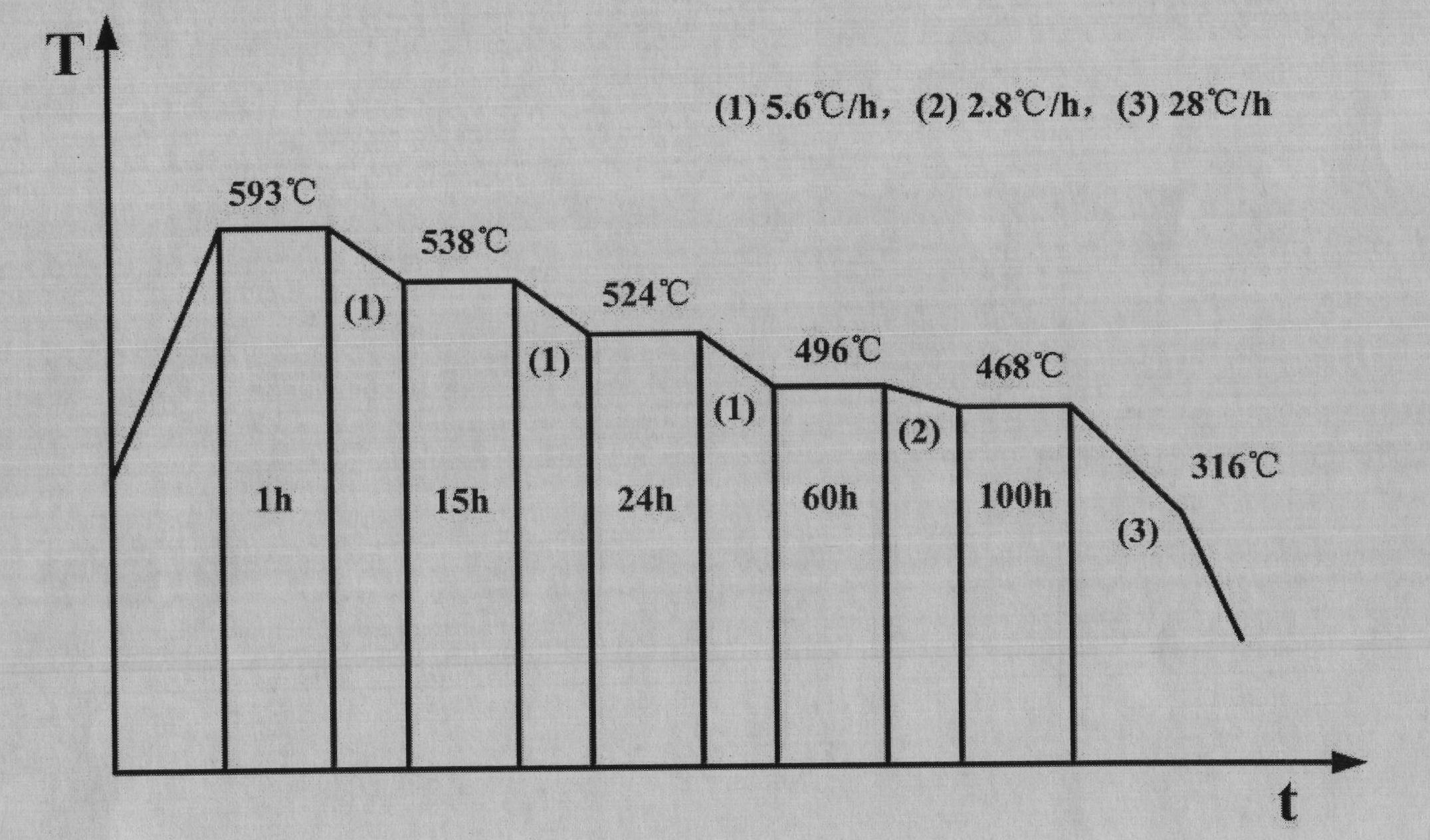

HIC-resistant heat resistant steel in iron element system and preparation process thereof

The invention relates to hydrogen induced cracking (HIC)-resistant heat resistant steel in an iron element system and a preparation process thereof. The steel comprises the following components in percentage by weight: 0.1 to 0.15 percent of C, 0.2 to 0.5 percent of Si, 0.3 to 0.6 percent of Mn, 2.0 to 2.5 percent of Cr, 0.9 to 1.1 percent of Mo, less than or equal to 0.003 percent of S, less than or equal to 0.010 percent of P and the balance of iron and impurities. The preparation process comprises a heating process, a hot rolling process and a heat treatment process sequentially, wherein the heat treatment process comprises a normalizing process and a tempering process. The steel has a high comprehensive mechanical property, a high low-temperature impact property, high HIC resistance and relatively low tempering tendering sensitivity; and the preparation process is simple, easy to operate, low in cost, high in yield and wide in thickness specification ranges, and a small number of alloys with a few varieties are added.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

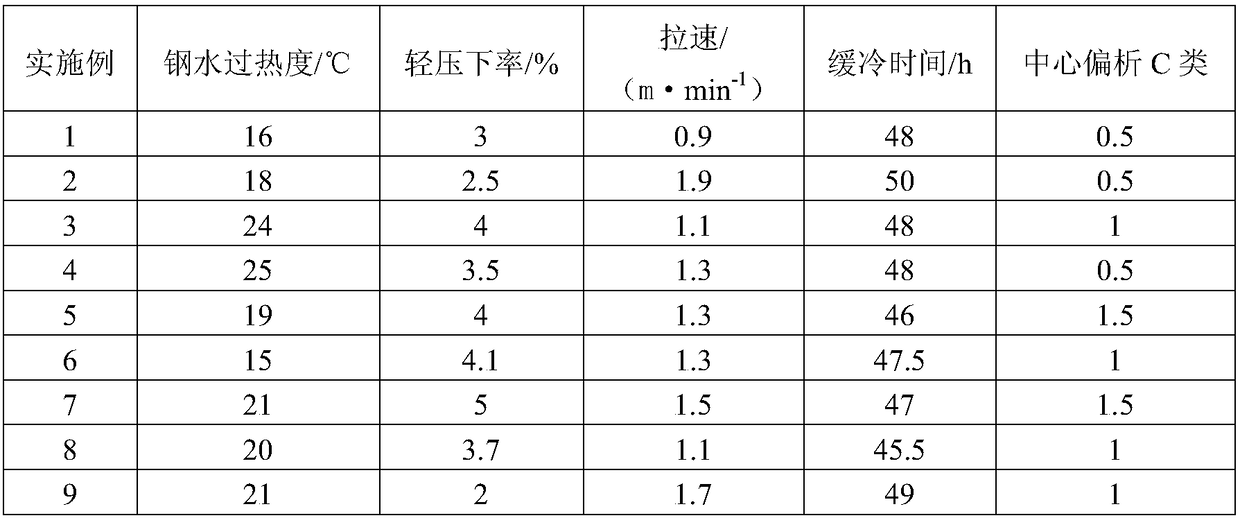

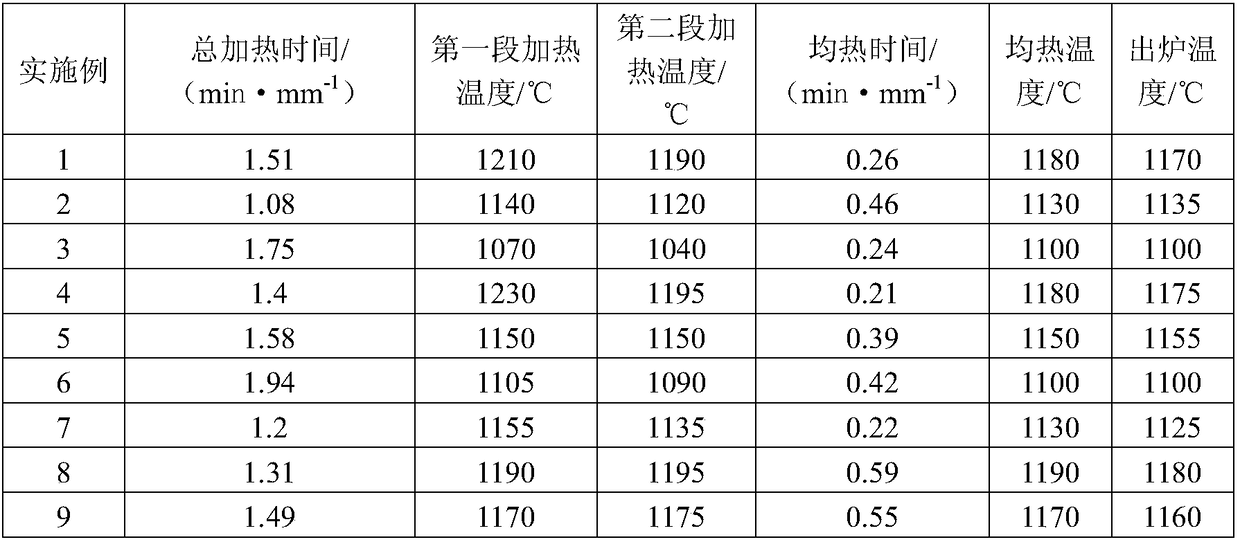

X80 pipeline steel plate for conveying coal-derived natural gas and manufacturing method thereof

The invention discloses an X80 pipeline steel plate for conveying coal-derived natural gas and a manufacturing method thereof. Steel comprises 0.019%-0.059% of C, 0.15%-0.45% of Si, 0.55%-1.85% of Mn,0-0.50% of Cu, 0-0.50% of Cr, 0-0.50% of Ni, 0.05%-0.35% of Mo, 0.03%-0.12% of Nb, 0.01%-0.04% of V, 0.008%-0.024% of Ti, 0.01%-0.04% of Al, 0-0.010% of P, 0-0.005% of S, and the balance Fe and unavoidable impurities, and S+P+O+N+H<=0.015%. The superheat degree of molten steel is 15-25 DEG C, the soft reduction rate is 2%-5%, and the drawing speed is 0.8-2.0 m / min. Two-section heating is adopted,rough rolling starting temperature is larger than or equal to 1000 DEG C, fine rolling starting temperature is 800-900 DEG C, fine rolling finish temperature is 750-850 DEG C, cooling starting temperature is 710-770 DEG C, cooling finish temperature is 460-600 DEG C, and the cooling speed is 5-20 DEG C / s. the steel plate has good strength, toughness and HIC resistance.

Owner:ANGANG STEEL CO LTD

VC nanoparticle-strengthened X90 steel plate for plastic pipe, and manufacturing method thereof

ActiveCN109023068AReduce manufacturing costGood anti-HIC performanceSteel platesMaterials preparation

The invention provides a VC nanoparticle-strengthened X90 steel plate for a plastic pipe, and a manufacturing method thereof. The steel plate comprises the following components in percentage by weight: 0.06%-0.12% of C, 0.10%-0.30% of Si, 0.60%-1.40% of Mn, 0.07%-0.15% of V, 0.001%-0.004% of N, 0.01%-0.04% of Ti, 0.025%-0.045% of Al, not greater than 0.010% of P, not greater than 0.005% of S, 0.10%-0.30% of Cu, 0.10%-0.30% of Mo, 0.10%-0.30% of Cr, 0.10%-0.30% of Ni and the balance Fe and inevitable impurity elements. The manufacturing method comprises the following steps: material preparation, converter or electric furnace smelting, external refining, casting, plate blank reheating, controlled rolling and controlled cooling. The steel plate produced by the manufacturing method meets the various mechanical property requirements of the X90 steel plate for the plastic pipe, and is especially high in low-temperature toughness and anti-HIC property.

Owner:ANGANG STEEL CO LTD

Solid gas protection welding wire used for welding crude oil carrier cargo oil tank boat deck

ActiveCN103862191AImprove anti-HIC performanceImprove toughnessWelding/cutting media/materialsSoldering mediaChemical elementImpurity

The invention discloses a solid gas protection welding wire used for welding a crude oil carrier cargo oil tank boat deck. The mass percentage ratios of the chemical elements are as follows: 0.02-0.10% of C, 0.30-0.60% of Si, 0.80-1.00% of Mn, 0.02-0.10% of Ti, 0-0.50% of Mo, 0.20-0.50% of Cr, 0.01-0.10% of Al, 0.10-0.80% of Cu, 0.10-0.80% of Ni, and the balance of Fe and other unavoidable impurities. The tensile strength of the solid gas protection welding wire used for welding the crude oil carrier cargo oil tank boat deck provided by the invention is greater than 440 MPa, and the impact work of a weld metal at 20 DEG C below zero is greater than 47 J, so that the solid gas protection welding wire has good corrosion resistance. Besides, the solid gas protection welding wire used for welding the crude oil carrier cargo oil tank boat deck and a mother board for welding have the consistent corrosion resistance and pitting resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing ultra-low-temperature high-core-impact-value acid-resistant container steel by using casting blank

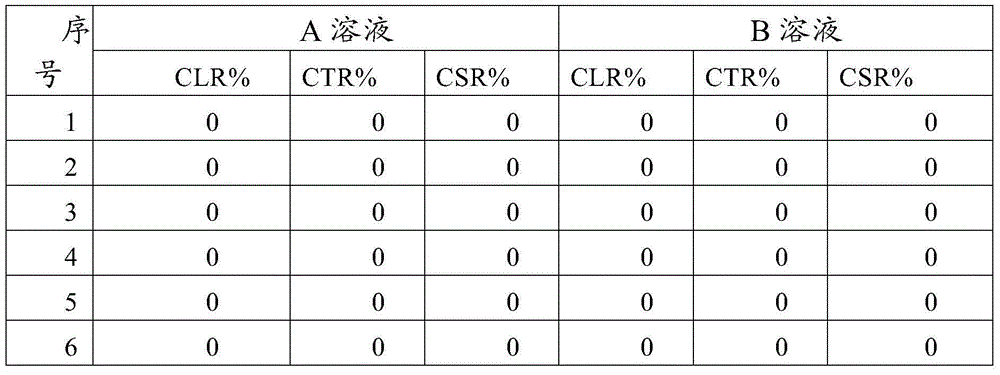

The invention discloses a method for producing an ultra-low-temperature high-core-impact-value acid-resistant container steel by using a casting blank. The method comprises the following steps of determining the steelmaking components; carrying out a heating process; carrying out a tapping and rolling process; and carrying out a heat treatment process. According to the method, the ultra-low-temperature high-core-impact-value acid-resistant container steel is produced through the design of being low in carbon and small in chromium alloy component amount in combination with the reasonable rolling control and cooling control, quenching and tempering and heat treatment processes, so that the mechanical property reaches the technical standard requirements, and the acid resistance meets the requirements of NACE-TM2084-2016, the actual level of the mechanical property reaches the following standards that the yield strength is greater than or equal to 340 MPa, the tensile strength is greater than or equal to 480 MPa, the elongation is greater than or equal to 35%, the transverse Akv at the core of a steel plate and at 60 DEG C below zero is greater than or equal to 240 J, the HIC resistance reaches the standards that CLR is equal to 0%, CTR is equal to 0%, and the CSR is equal to 0%, and therefore, the problems of unstable low-temperature impact property, poor HIC resistance, unstableweldability and the like of the production of the ultra-low-temperature high-core-impact-value by using a casting blank in the prior art are solved.

Owner:NANJING IRON & STEEL CO LTD

A kind of extra-thick specification x70 pipeline steel and its manufacturing method

ActiveCN104264069BImprove low temperature toughnessImprove corrosion resistanceChemical compositionHigh intensity

The invention discloses an extra-thick specification X70 pipeline steel and a manufacturing method thereof. The thickness of the pipeline steel is 30-32 mm, and its chemical components are C: 0.03-0.06%, Si: 0.1-0.30%, Mn in terms of mass percentage. : 1.30~1.60%, P: ≤0.010%, S: ≤0.0050%, Nb: 0.030~0.050%, Ti: 0.008~0.020%, Ni: 0.10~0.30%, Cr: 0.10~0.30%, Cu: 0.10~ 0.30%, the balance is Fe and inevitable impurity elements. The smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain molten steel with high purity. Pipeline steel with excellent toughness, low temperature aging resistance and HIC resistance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Production method of acid-resistant pipeline steel

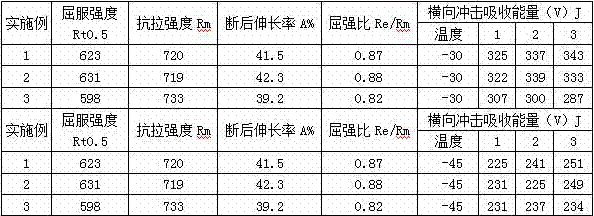

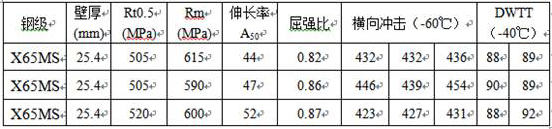

The invention relates to a production method of acid-resistant pipeline steel. The steel comprises the following chemical components in percentage by mass: 0.02-0.04%of C, 0.15-0.35% of Si, 1.10-1.25%of Mn, less than or equal to 0.010% of P, less than or equal to 0.0015% of S, 0.020-0.045% of Alt, 0.015-0.045% of Nb, 0.010-0.020% of Ti, 0.08-0.15% of Mo, 0.08-0.15% of Ni, 0.08-0.20% of Cu, less than or equal to 0.0005% of B, 0.12-0.14% of Pcm and the balance Fe and inevitable impurities. By adopting an online quenching and tempering process, a steel plate with thickness of 8-26.4 mm * 65MS isproduced, and the steel plate has high strength and ultra-strong low-temperature toughness, wherein the yield strength is 480-530 MPa, the tensile strength is 570-630 MPa, the elongation A50 is 35%-55%, the yield ratio is smaller than or equal to 0.88, the impact at 60 DEG C below zero is 300-400 J, and the drop hammer at 40 DEG C below zero is 85%-100%.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Manufacturing method of corrosion-resistant steel tubes for natural gas conveying pipelines

The invention discloses a manufacturing method of corrosion-resistant steel tubes for natural gas conveying pipelines. Steel is composed by the following components: by weight percentage, 0.10-0.14 of C, 0.5-0.8 of Si, 1.30-1.50 of Mn, <=0.008 of P, <=0.003 of S, 1.3-1.5 of Cr, 0.3-0.7 of Ni, 0.25-0.45 of Nb, 0.005-0.01 of B, <=0.15 of Cu, 0.020-0.050 if Al, 0.030-0.10 of N, 0.05-0.10 of V and the balance Fe and inevitable impurities. The manufacturing method includes the following steps: 1 steel smelting; 2 tube molding; 3 heat treatment and straightening; and 4 aftertreatment. Mechanical properties and corrosion resistance of the steel manufacture by the method fully meet requirements of the natural gas conveying pipelines.

Owner:NANTONG BEICHENG SCI & TECH ENTREPRENEURIAL MANAGEMENT

Nbc nano-particle reinforced steel plate for X90 plastic pipes and manufacturing method of steel plate

The invention provides an Nbc nano-particle reinforced steel plate for X90 plastic pipes and a manufacturing method of the steel plate. The steel plate comprises, by weight, 0.06-0.12% of C, 0.10-0.30% of Si, 0.60-1.40% of Mn, 0.07-0.15% of Nb, 0.01-0.004% of N, 0.01-0.04% of Ti, 0.025-0.045% of Al, not greater than 0.010% of P, not greater than 0.005% of S, 0.10-0.30% of Cu, 0.10-0.30% of MO, 010-0.30% of Cr, 0.10-0.30% of Ni and the balance being Fe and other inevitable impurity elements. The manufacturing method includes the steps of preparing of materials, smelting in converter or electric furnace, external refining, casting, reheating of plates, controlled rolling and controlled cooling. The steel plate produced by the method has good plastic deformation capacity, and can guarantee safety of oil and gas transmission pipelines laid in zones with complex geological conditions.

Owner:ANGANG STEEL CO LTD

Production method for X80 grade pipeline steel resistant to hydrogen-induced cracking (HIC)

The invention discloses a production method for X80 grade pipeline steel resistant to hydrogen-induced cracking (HIC), and belongs to the technical field of metal materials. The production method forthe X80 grade pipeline steel resistant to HIC includes the technical processes of converter smelting, vacuum Si-Ca processing, casting into ingot blanks, ingot blank heating, rough rolling, precisionrolling, cooling and curling. The components of the ingot blanks include, by mass percentage, 0.02-0.04% of C, 0.20-0.23% of Si, 0.60-0.80% of Mn, 0.20-0.30% of Cu, 0.30-0.45% of Cr, 0.20-0.25% of Mo,0.03-0.05% of Nb, 0.02-0.03% of V, 0.01-0.02% of Ti, 0.005% or less of P, 0.002% or less of S, and the balance Fe and unavoidable impurities. The ingot blank heating temperature, rough rolling temperature, precision rolling temperature and cooling mode are controlled, and the X80 grade pipeline steel with low cost and good HIC resistance is prepared.

Owner:武汉钢铁有限公司

An economical HIC-resistant x90 pipeline steel plate and its manufacturing method

ActiveCN105803327BGood anti-HIC performanceImprove low temperature toughnessToughnessContinuous casting

Disclosed is an economical HIC-resistant X90 pipeline steel plate, the chemical components by mass percent of the steel plate are: C: 0.02%-0.06%, Mn: 1.7%-1.90%, Si: 0.15%-0.35%, S: ≤0.0005%, P: ≤0.010%, Nb: 0.04%-0.07%, Ti: 0.008%-0.03%, V: ≤0.10%, Al: ≤0.06%, N: ≤0.010%, O: ≤0.006%, Mo: ≤0.20%, Cu: ≤0.20%, Ni: ≤0.20%, Cr: ≤0.20%, Ca: 0.0005%-0.0015%, wherein the content ratio of Ca / S is 1.0-2.0, and the balance being Fe and inevitable impurity elements. According to the behaviour rule of hydrogen in the structure, the steel has a structure with an excellent HIC-resistant performance and excellent low-temperature toughness through an improved refining-continuous casting-high temperature reheating-TMCP process.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

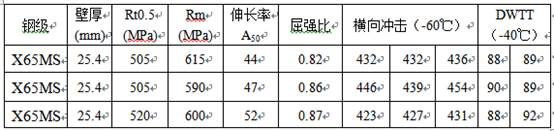

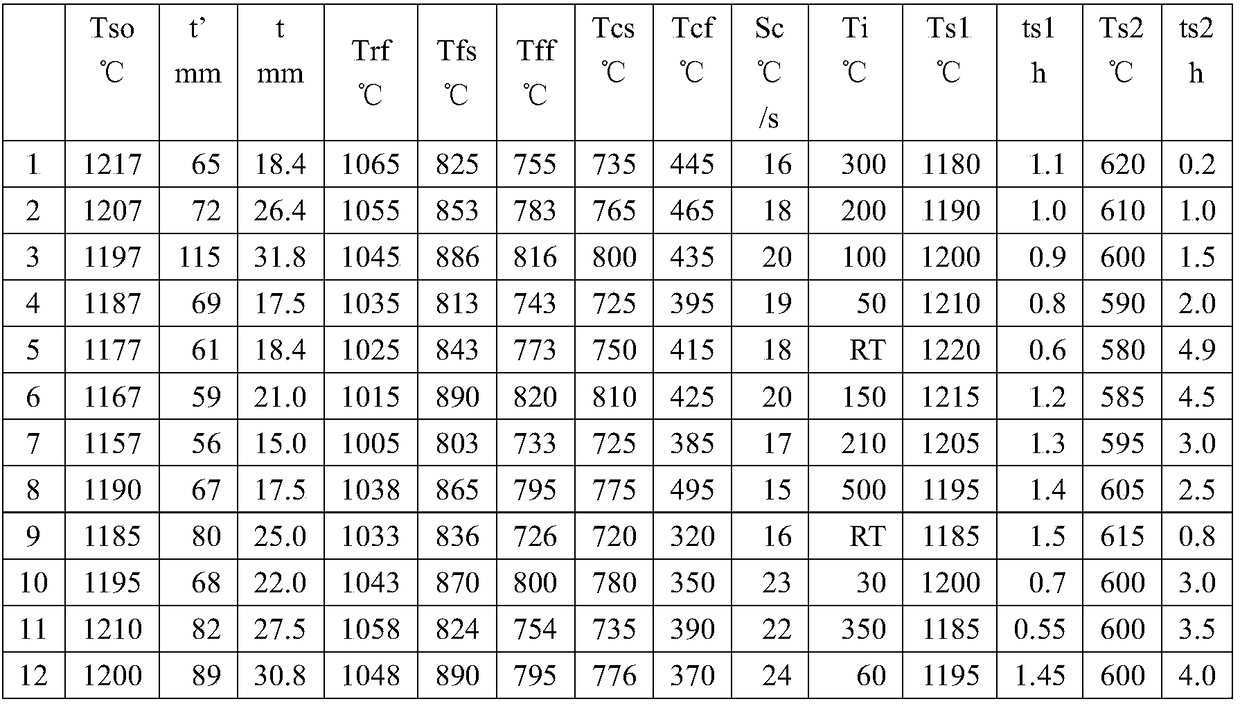

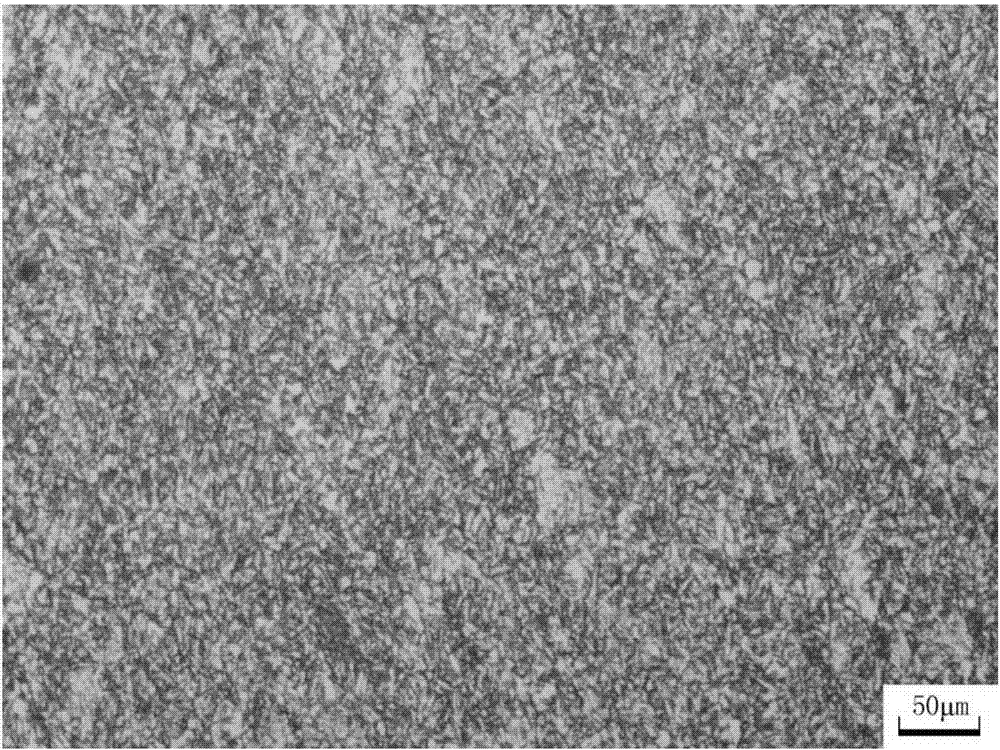

TMCP delivery economical HIC-resistance pipeline steel plate X65MS and manufacturing method thereof

ActiveCN109047694AImprove economyAvoid performance degradation against HICTemperature control deviceManufacturing convertersSheet steelHigh pressure water

The invention discloses a TMCP delivery economical HIC-resistance pipeline steel plate X65MS and a manufacturing method thereof. The TMCP delivery economical HIC-resistance pipeline steel plate X65MScomprises chemical components including 0.06-0.10% of C, 0.3-0.4% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.08% of Nb+Ti+V, 0.1-0.3% of Cr, less than or equal to 0.008% of P, less than or equal to 0.0008% of S, less than or equal to 0.002% of [N], less than or equal to 0.0010% of [O], less than or equal to 0.0001% of [H], and the balance Fe and inevitable impurities. A uniform polygonal ferritic structure is obtained. The preparation method comprises the technological steps of KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing, continuous casting, continuous casting billet covering slow-cooling, continuous casting billet inspection and cleaning, casting billet heating, high-pressure water descaling, controlled rolling and controlled cooling, straightening and steel plate pile slow-cooling. Through the preparation method, production of the HIC-resistance pipeline steel plate X65MS with the economical components and HIC resistance isrealized.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Corrosion resistant low chromium oil casing tube used in CO2 and H2S coexistence environment

The invention relates to the technical field of petroleum pipes, in particular to a corrosion resistant low-chromium oil bushing used in an environment in which CO2 and H2S coexist. Aiming at overcoming the problem of relatively high cost of pipes in solving the problem that the oil bushing is liable to be corroded with increasing coexistence environments of CO2 and H2S in the prior art. The technical proposal provided by the invention is that the oil bushing comprises the following compositions: C: 0.18-0.24%, Si: 0.25-0.50%, Mn: 0.45-0.55%, P: 0.01-0.015%, S: 0.003-0.005%, Cr: 2.95-3.10%, Mo: 0.40-0.75%, Cu: 0.10-0.25%, Ni: 0.009-0.05%, Al: 0.015-0.055%, Ti: 0.010-0.035%, B: 0.0018-0.0024%, Nb: 0.03-0.06% and V: 0.05-0.10%; controlled compositions (wt%) are as follows: ratio of As, Sn, Sb, N, Ca / S is 1.5 and the balance is Fe. Compared with the prior art, the invention has the advantages of superior effect and on increase in cost.

Owner:XIAN MAURER PETROLEUM ENG LAB

Natural gas pipe with corrosion resisting inner layer and machining process thereof

InactiveCN106591705AImprove toughnessGood anti-HIC performanceAnti-corrosive paintsEpoxy resin coatingsRare-earth elementHeat-affected zone

The invention discloses a natural gas pipe with a corrosion resisting inner layer. The pipe comprises a steel pipe body and a corrosion resisting layer arranged on the inner wall of the steel pipe body; and the steel pipe body comprises the following chemical components in percentage by mass: 0.041-0.045% of C, 8.65-8.85% of Cr, 0.12-0.13% of Si, 1.26-1.47% of Mn, 0.22-0.31% of Co, 0.031-0.033% of V, 0.31-0.35% of Re, 0.17-0.18% of Al, 0.021-0.023% of Ti, 0.31-0.42% of Zr, 0.004-0.006% of Ca, 0.21-0.22% of Ni, 0.15-0.21% of Mo, P not more than 0.020%, S not more than 0.015%, 0.23-0.26% of rare earth element, and the balance of Fe and inevitable impurities. Dispersed and compounded fine oxide particles are formed in steel through reasonable low-carbon no-niobium component design and through a smelting process based on an oxide metallurgy technology; and the high-temperature thermostable fine dispersed inclusion particles are used for pinning austenitic grain boundary of a welding heat affected zone under high heat input conditions to refine austenitic grains.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

A kind of X70 pipeline steel with high HIC performance and its preparation method

Owner:WUHAN UNIV OF SCI & TECH

X70QS seamless line pipe with HIC (Hydrogen Induced Cracking) resistance

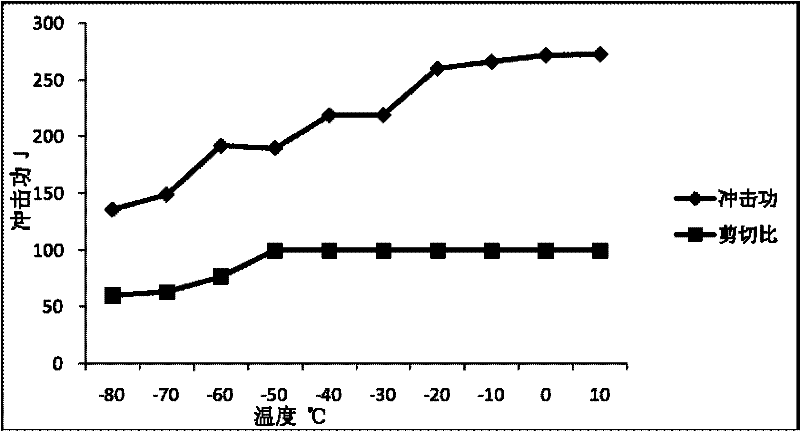

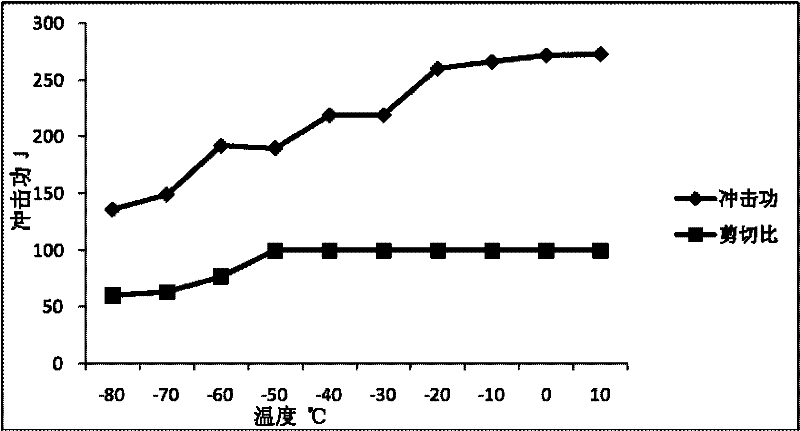

The invention provides an X70QS seamless line pipe with HIC (Hydrogen Induced Cracking) resistance, comprising the following components in weight by percentage: 0.06%-0.14% of C, 0.20%-0.45% of Si, 1.00%-1.30% of Mn, P not more than 0.015%, S not more than 0.003%, 0.05%-0.30% of Cr, 0.05%-0.30% of Mo, 0.015%-0.060% of Al, 0.003%-0.010% of N, 0.030%-0.050% of Nb, 0.05%-0.09% of V, not more than 0.10% of Ni, not more than 0.20% of Cu and the balance of Fe and impurities, wherein Ni and Cu which have limited content are residual element in the steel, the carbon equivalent CEpcm is not more than 0.22%, and CEIIW is not more than 0.39%. The X70QS seamless line pipe has the advantages of high strength and excellent impact performance and can ensure the impact power to be greater than 150J at -40 DEG C, which is much higher than the impact power standard values of the API (American Petroleum Institute) and the ISO (International Standards Organization); by controlling the CE and the PCM (Pulse-Code Modulation), the X70QS seamless line pipe qualitatively ensures better welding performance; the X70QS seamless line pipe has the advantages of high ductility, low yield ratio and high elongation; and the X70QS seamless line pipe has favorable HIC resistance, thereby ensuring that when the yield strength is greater than 485 MPa, the crack-sensitive rate CSR is not greater than 2%, the crack-length rate is not greater than 10%, and the crack-thickness rate CTR is not greater than 3%.

Owner:TIANJIN STEEL PIPE MFG CO LTD

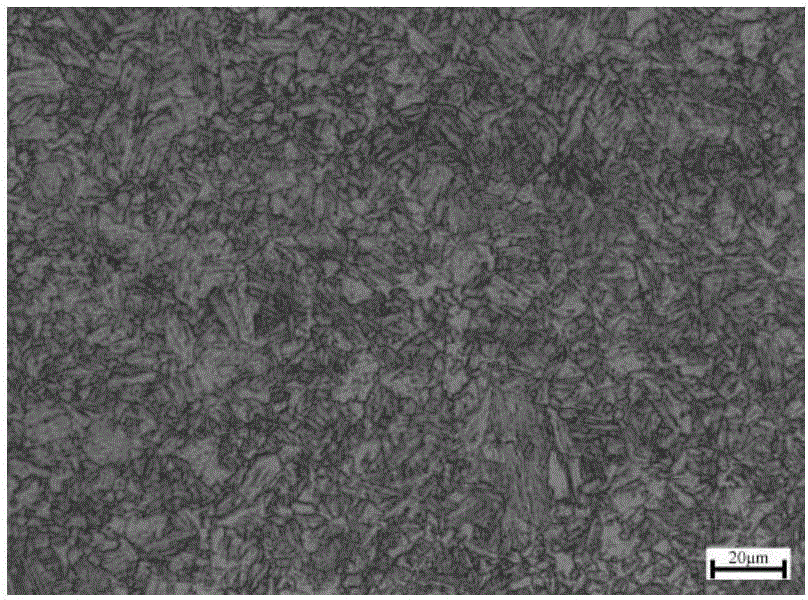

Submarine X70-grade pipeline steel resistant to hydrogen sulfide corrosion and production method thereof

PendingCN111607747APrevents segregation from formingPrevent infiltrationHeat treatment process controlLaminar coolingSubmarine

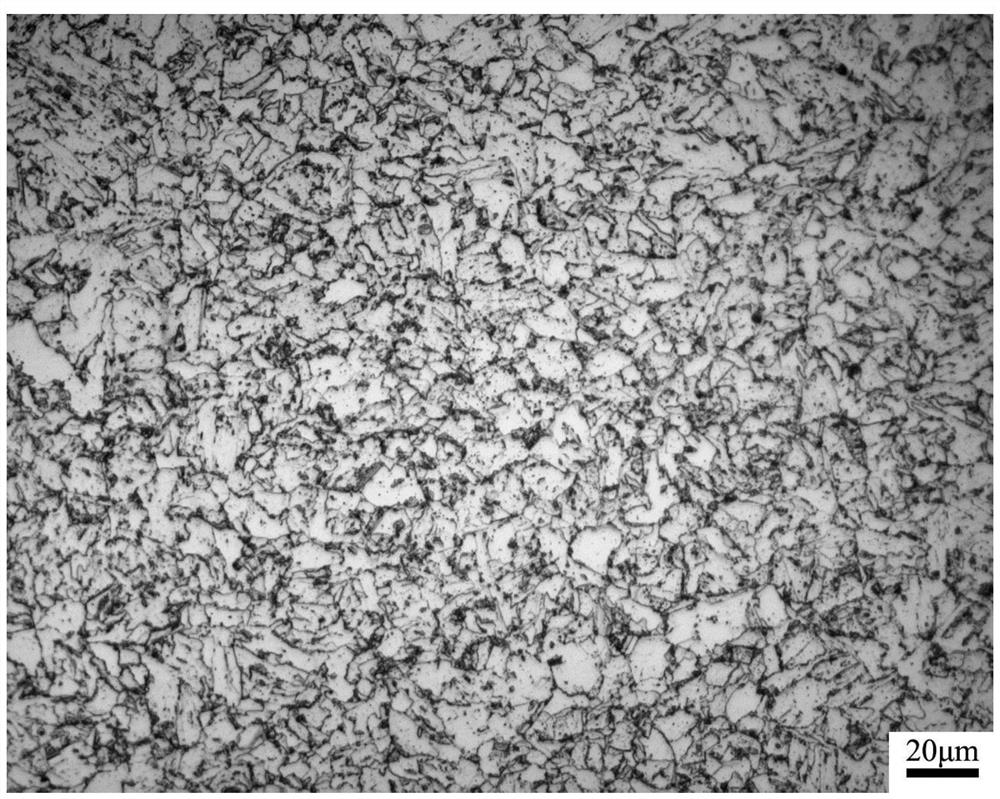

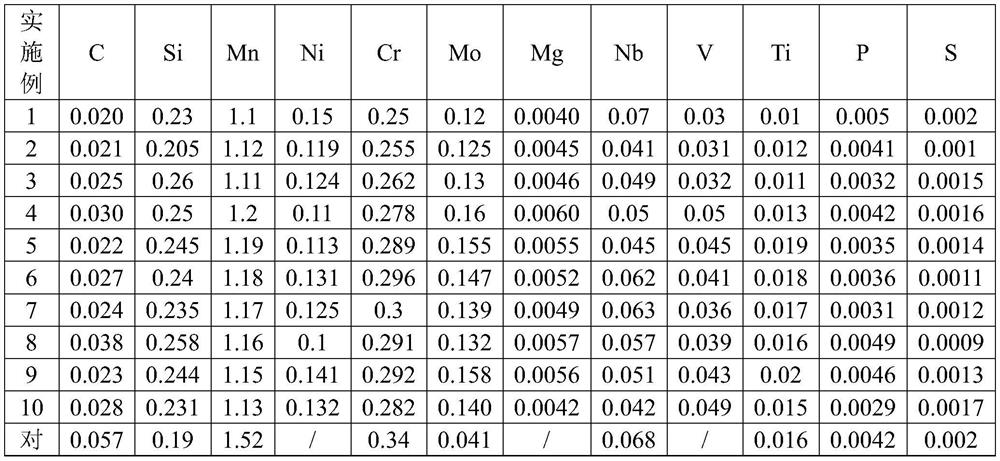

The invention discloses submarine X70-grade pipeline steel resistant to hydrogen sulfide corrosion. The submarine X70-grade pipeline steel resistant to the hydrogen sulfide corrosion comprises the following components of, in percentage by weight, 0.02%-0.03% of C, 0.23%-0.26% of Si, 1.10%-1.20% of Mn, 0.10%-0.15% of Ni, 0.25%-0.30% of Cr, 0.12%-0.16% of Mo, 0.004%-0.006% of Mg, 0.04%-0.07% of Nb,0.03%-0.05% of V, 0.01%-0.02% of Ti, not more than 0.005% of P, not more than 0.002% of S and the balance Fe and inevitable impurities. A production method of the submarine X70-grade pipeline steel resistant to the hydrogen sulfide corrosion comprises the following steps that 1) smelting is carried out in a converter, Mg treatment is carried out in conventional vacuum, and casting and blank forming are carried out; 2) a cast blank is heated, and the heating temperature of the cast blank is controlled to be 1220-1250 DEG C; 3) the starting temperature of rough rolling is 1030-1080 DEG C, the ending temperature of rough rolling is 970-990 DEG C, and the total reduction rate is 65%-75%; (4) the starting temperature of finish rolling is 870-910 DEG C, the ending temperature of finish rolling is 840-870 DEG C, the cumulative reduction rate of finish rolling is not lower than 65%, and a steel plate with the thickness of 12 mm is formed through seven passes of rolling; and (5) laminar coolingis carried out, and the steel plate is cooled to 450-510 DEG C at the cooling speed of 40-60 DEG C / s, and curled for later use. Compared with the prior art, the submarine X70-grade pipeline steel resistant to the hydrogen sulfide corrosion has the advantages of being high in strength, high in toughness and high in hydrogen sulfide corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

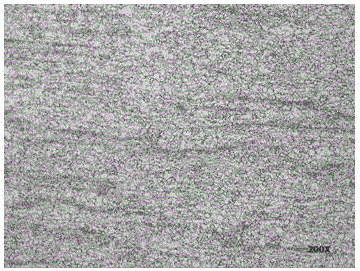

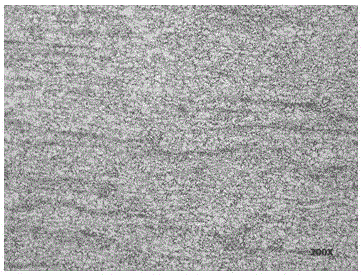

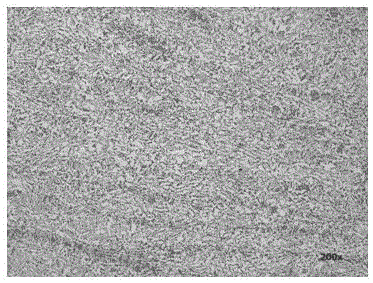

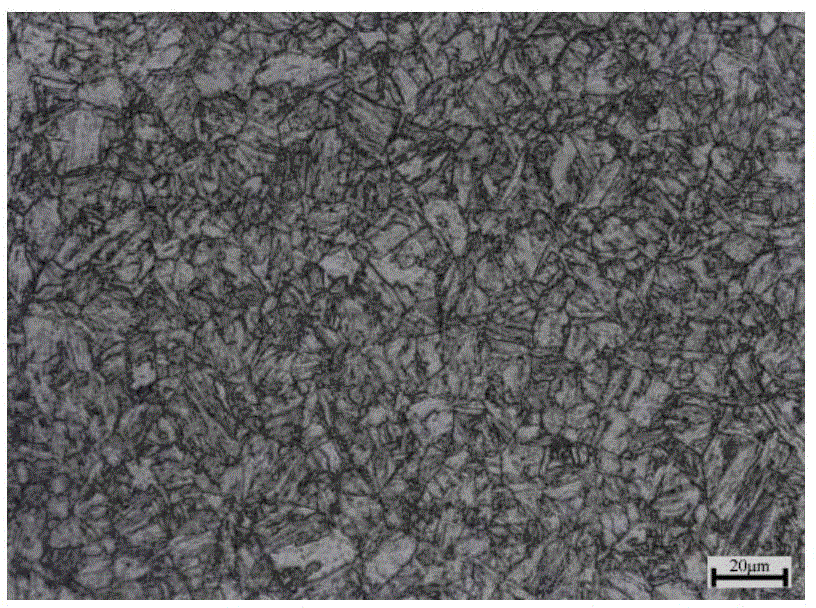

X70-grade pipeline steel with high HIC (hydrogen induced cracking) resistance as well as preparation method thereof

The invention relates to X70-grade pipeline steel with high HIC (hydrogen induced cracking) resistance as well as a preparation method thereof. The chemical components of the pipeline steel are as follows: 0.04 to 0.05 weight percent of C, 0.2 to 0.3 weight percent of Si, 1.1 to 1.2 weight percent of Mn, 0.006 to 0.008 weight percent of P, 0.0008 to 0.0015 weight percent of S, 0.08 to 0.10 weightpercent of Cu, 0.2 to 0.25 weight percent of Cr, 0.09 to 0.10 weight percent of Ni, 0.1 to 0.12 weight percent of Mo, 0.03 to 0.04 weight percent of Nb, 0.02 to 0.03 weight percent of V, 0.002 to 0.005 weight percent of Ti, 0.002 to 0.005 weight percent of Mg and the balance of Fe and unavoidable impurities. The rolling temperature of the pipeline steel is as follows: the temperature of rough-rolling finishing rolling is 950 to 1050 DEG C; the temperature of precision-rolling open rolling is 920 to 950 DEG C; the temperature of precision-rolling finishing rolling is 860 to 890 DEG C; the temperature of relaxation terminating is 730 to 740 DEG C; and the temperature of plate blank re-reddening is 400 to 430 DEG C. The process is simple; and the prepared product has high HIC resistance.

Owner:WUHAN UNIV OF SCI & TECH

Corrosion-resistant steel for natural gas transmission pipelines

The invention discloses corrosion-resistant steel for natural gas transmission pipelines, which comprises the following components by weight percent: 0.10 to 0.14 percent of C; 0.5 to 0.8 percent of Si; 1.30 to 1.50 percent of Mn; 0 to 0.008 percent of P; 0 to 0.003 percent of S; 1.3 to 1.5 percent of Cr; 0.3 to 0.7 percent of Ni; 0.25 to 0.45 percent of Nb; 0.005 to 0.01 percent of B; 0 to 0.15 percent of Cu; 0.020 to 0.050 percent of Al; 0.030 to 0.10 percent of N; 0.05 to 0.10 percent of V; and Fe and unavoidable impurities in balancing amount.

Owner:NANTONG WEALTH MASCH TECH CO LTD

A pipeline steel with HIC resistance and large deformation resistance and its manufacturing method

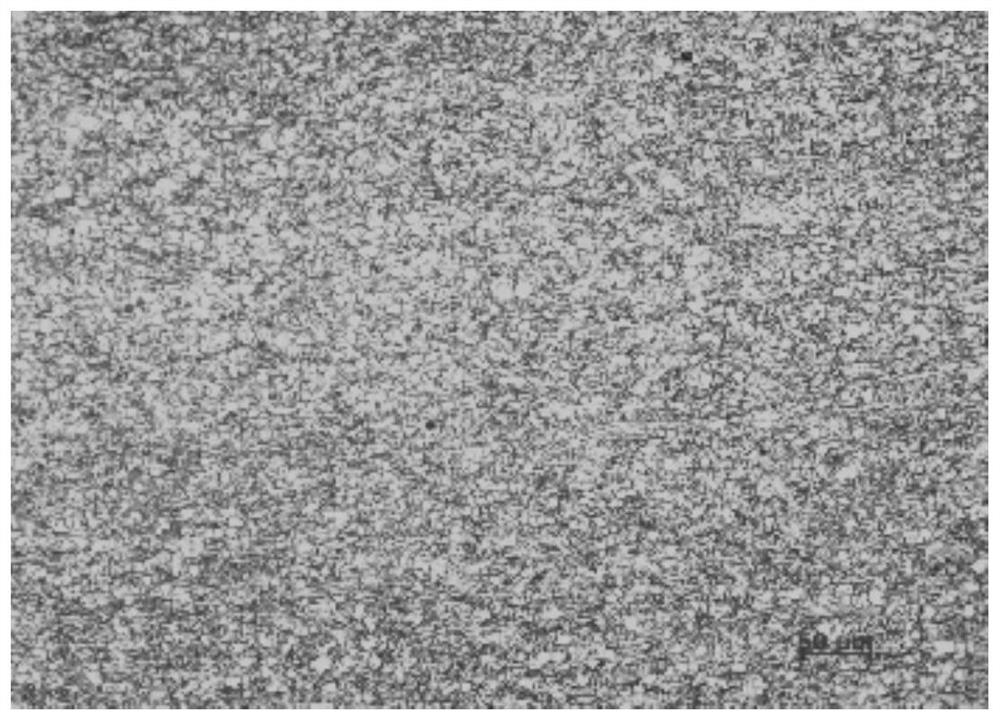

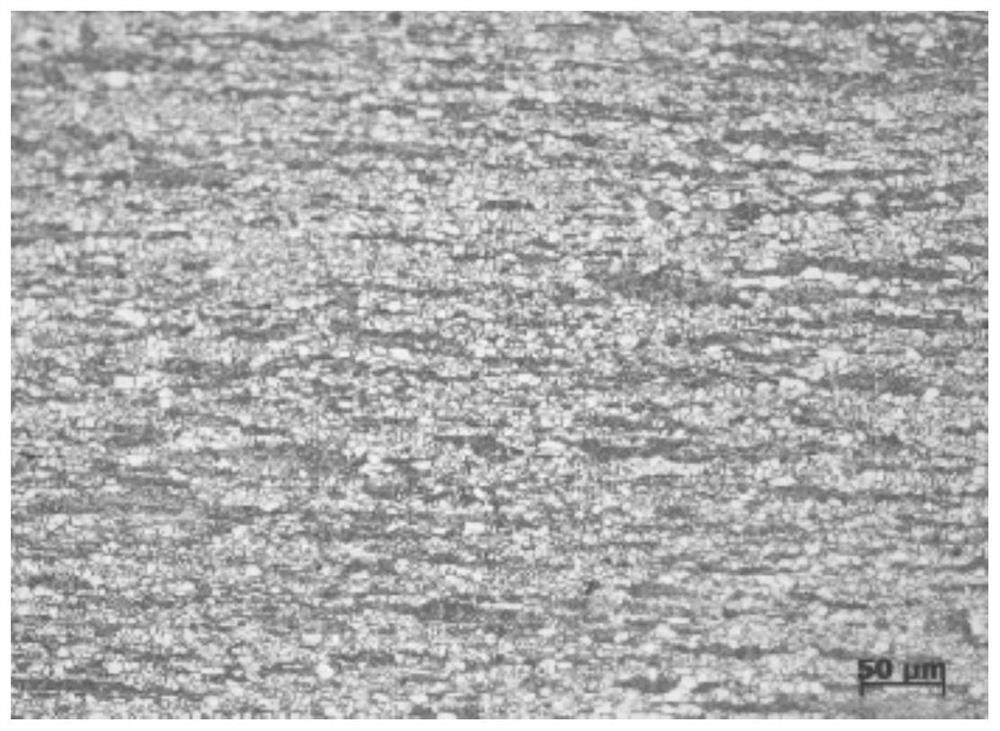

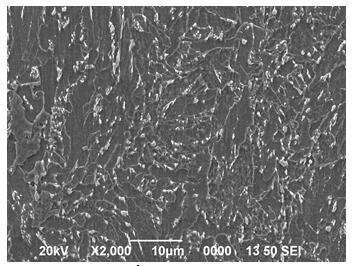

ActiveCN110964991BGood anti-HIC performanceGood co-deformation effectFurnace typesQuenching agentsCrazingLine tubing

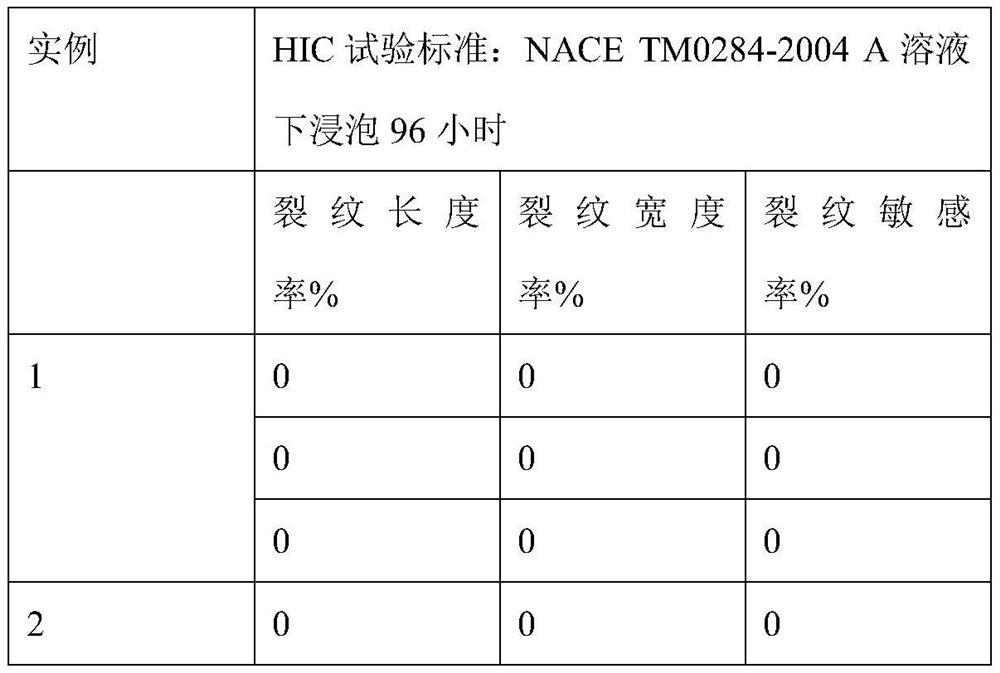

The invention relates to a pipeline steel with HIC resistance and large deformation resistance. The alloy composition is C: 0.03-0.039%, Si: 0.15-0.35%, Mn: 1.6-1.9%, S: ≤0.002% , P: ≤0.012%, Al: 0.02~0.045%, Cr: 0.15~0.35%, 0.05≤Nb+V+Ti≤0.1%, Nb, V, Ti are not 0, Ni: 0.15~0.50%, Cu : 0.01~0.25%, Ca: ≤0.002%, N: ≤0.0046%, Mo: 0.01~0.20%, the balance is Fe and unavoidable impurity elements, with bainite single-phase structure, and bainite crystal The particle size is above 11.5 grade. The transverse yield strength ratio of the product is Rt0.5 / Rm≤0.78, Charpy impact energy at -20°C is greater than or equal to 350J, and the drop hammer shear area SA% at -20°C is greater than or equal to 90%; Ratio≤0.77; Longitudinal stress ratio Rt1.5 / Rt0.5≥1.18, Rt2.0 / Rt1.0≥1.1; HIC resistance: Soak in NACE TM0284‑2004A solution for 96 hours, crack length rate%: 0, crack Width ratio %: 0, crack sensitivity ratio %: 0.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A kind of production method of acid-resistant pipeline steel

A production method of acid-resistant pipeline steel, the chemical composition of the steel is C=0.02%-0.04%, Si=0.15%-0.35%, Mn=1.10%-1.25%, P≤0.010%, S≤ 0.0015%, Alt=0.020%~0.045%, Nb=0.015%~0.045%, Ti=0.010%~0.020%, Mo=0.08%~0.15%, Ni=0.08%~0.15%, Cu=0.08%~0.20% , B≤0.0005%, Pcm=0.12%~0.14%, the balance is Fe and inevitable impurities. Using online quenching + tempering process, the production thickness is 8~26.4mmX65MS, the steel plate has high strength and super low temperature toughness, yield strength 480~530MPa, tensile strength 570~630MPa, elongation A 50 =35%~55%, yield ratio≤0.88, impact at ‑60℃=300~400J, drop weight at ‑40℃ is 85%~100%.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com