A pipeline steel with HIC resistance and large deformation resistance and its manufacturing method

A technology of anti-large deformation and pipeline steel, applied in the field of pipeline steel, can solve the problems of unsatisfactory anti-HIC performance, multiple HIC cracks, etc., and achieve the effect of good anti-HIC performance, not easy to aggregate, and excellent anti-large deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

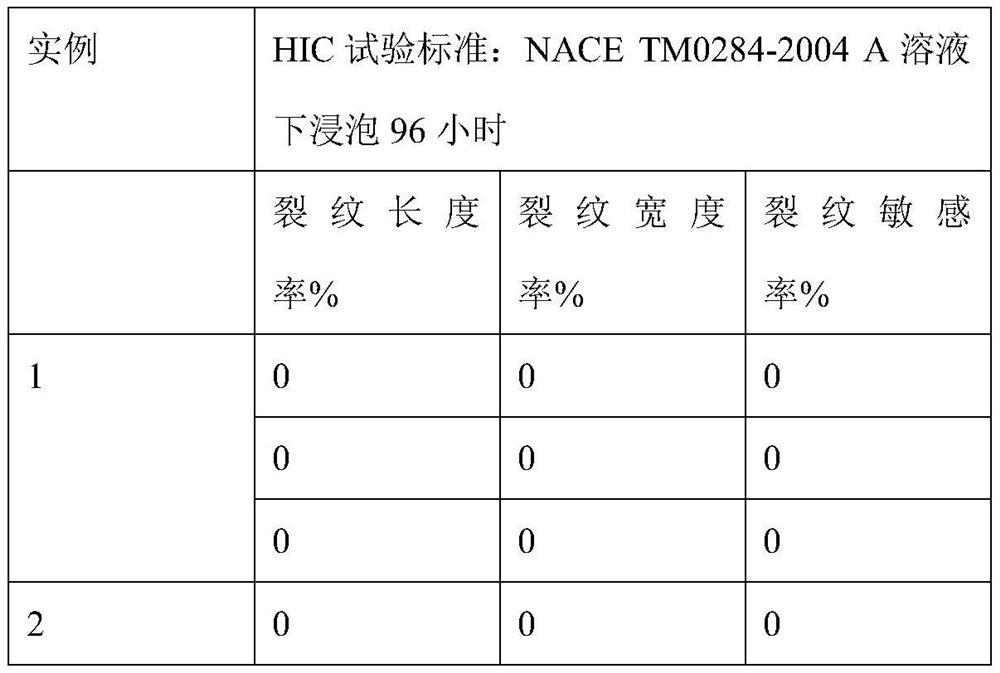

Examples

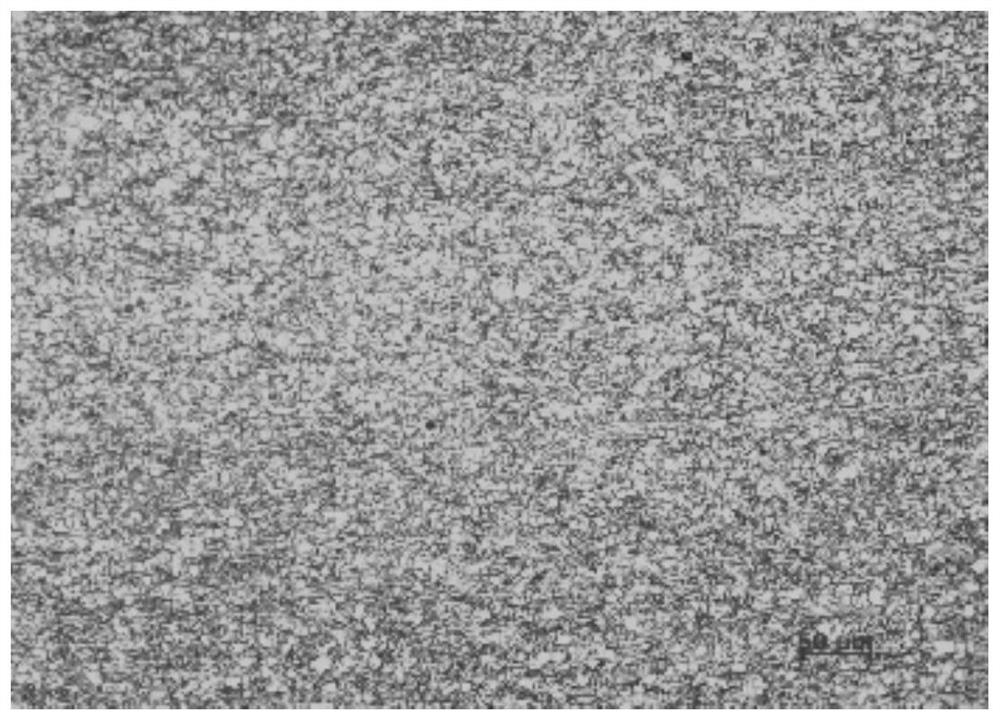

Embodiment 1

[0032] Continuously cast the molten steel with the same chemical composition as the pipeline steel plate to be continuously cast into a continuous casting slab with a thickness not greater than 370mm, and the chemical composition of the obtained continuous casting slab includes: C: 0.03%, Si: 0.30% , Mn: 1.6%, S≤0.002%, P≤0.012%, Al: 0.03%, Cr: 0.25%, Nb+V+Ti: 0.06%, Ni: 0.25%, Cu: 0.15%, Ca: ≤0.002% , N: ≤0.0046%, Mo: 0.13%, and the balance is Fe and unavoidable impurity elements.

[0033] Heat the continuous casting slab to 1150°C, keep it warm for 3.5 hours, take it out of the furnace, and carry out two-stage rolling after descaling with 20MPa high-pressure water: the first stage is rolling in the recrystallization zone, the rolling temperature is 1150°C, and rolling is divided into 7 passes , wherein the deformation rate of the two-pass rolling is ≥19%, the final rolling temperature is 1050°C, and the thickness of the intermediate billet obtained after rolling in the recryst...

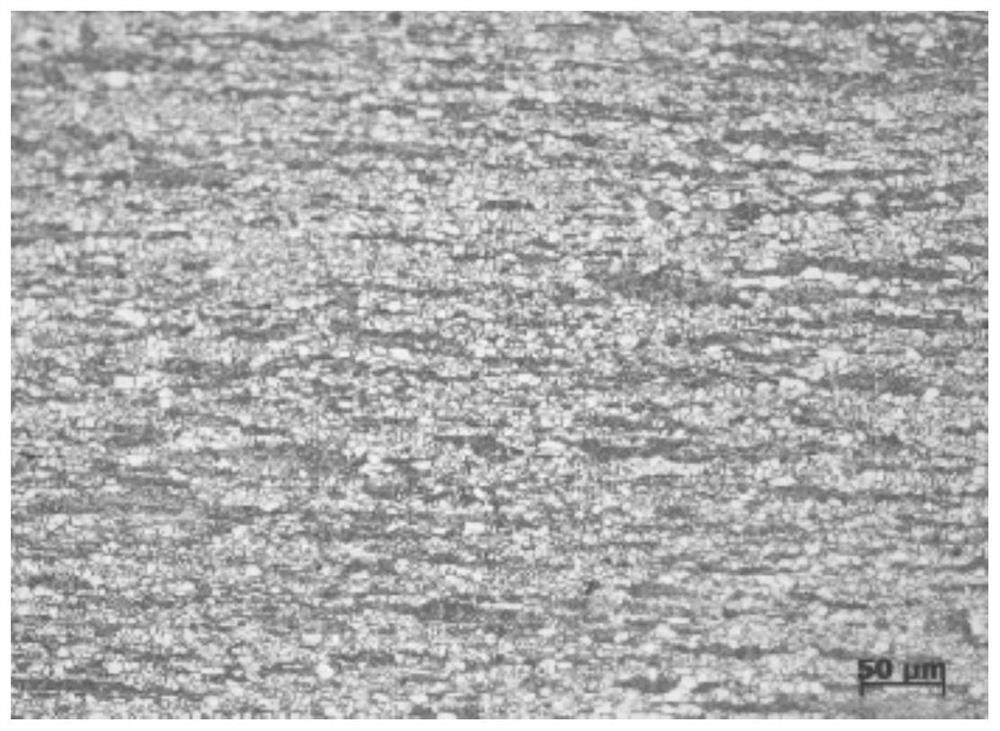

Embodiment 2

[0035] The molten steel with the same chemical composition as the pipeline steel plate is continuously cast into a continuous casting slab with a thickness of about 370mm through a continuous casting machine. The chemical composition of the obtained continuous casting slab includes: C: 0.033%, Si: 0.25%, Mn : 1.8%, S≤0.002%, P≤0.012%, Al: 0.03%, Cr: 0.25%, Nb+V+Ti: 0.08%, Ni: 0.3%, Cu: 0.12%, Ca: ≤0.002%, N: ≤0.0046%, Mo: 0.20%, and the balance is Fe and unavoidable impurity elements.

[0036] Heat the continuous casting slab to 1150°C, keep it warm for 3.0 hours, take it out of the furnace, and carry out two-stage rolling after descaling with 20MPa high-pressure water: the first stage is rolling in the recrystallization zone, the rolling temperature is 1150°C, and rolling is divided into 5 passes , wherein the deformation rate of the two-pass rolling is ≥17%, the final rolling temperature is 1030°C, and the thickness of the intermediate billet obtained after rolling in the re...

Embodiment 3

[0038] The molten steel with the same chemical composition as the pipeline steel plate to be produced is continuously cast through a continuous casting machine into a continuous casting slab with a thickness not greater than 370mm, and the chemical composition of the obtained continuous casting slab includes: C: 0.039%, Si: 0.25% , Mn: 1.85%, S≤0.002%, P≤0.012%, Al: 0.03%, Cr: 0.25%, Nb+V+Ti: 0.10%, Ni: 0.45%, Cu: 0.25%, Ca: ≤0.002 %, N: ≤0.0046%, Mo: 0.20%, and the balance is Fe and unavoidable impurity elements.

[0039] Heat the continuous casting slab to 1160°C, keep it warm for 4 hours, take it out of the furnace, and carry out two-stage rolling after descaling with 20MPa high-pressure water: the first stage is rolling in the recrystallization zone, the rolling temperature is 1140°C, and rolling is divided into 5 passes , wherein the deformation rate of the two-pass rolling is ≥17%, the final rolling temperature is 1050°C, and the thickness of the intermediate billet obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com