X80 pipeline steel plate for conveying coal-derived natural gas and manufacturing method thereof

A coal-to-natural gas and manufacturing method technology, applied in the field of X80 pipeline steel plates for coal-to-natural gas transportation and its manufacturing, can solve problems such as complex procedures, increased manufacturing costs, and reduced productivity, so as to reduce production costs, realize safe use, The effect of excellent anti-acid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with specific embodiment the present invention is further described:

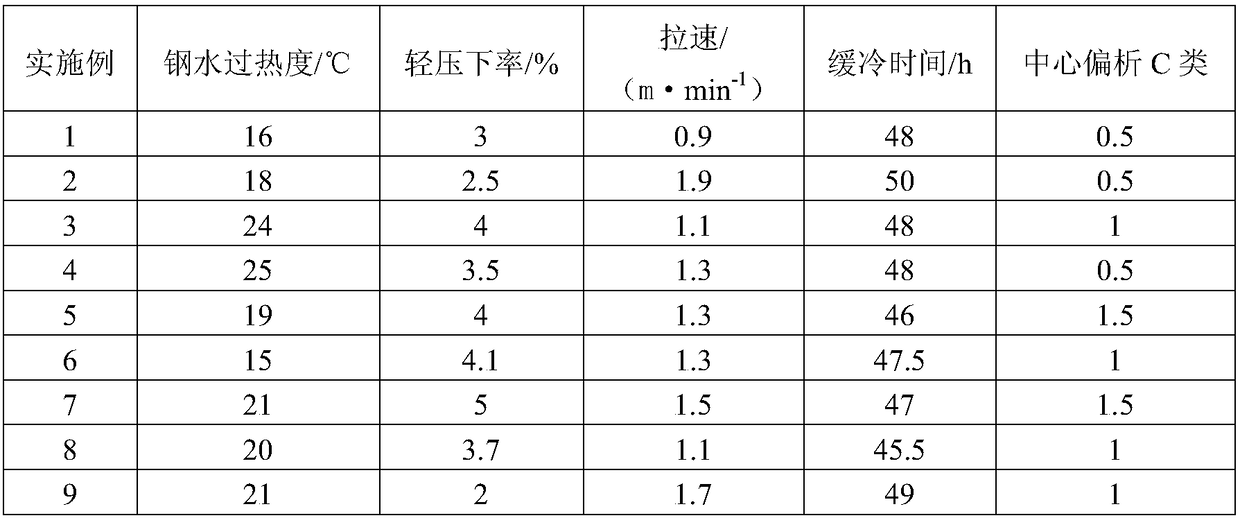

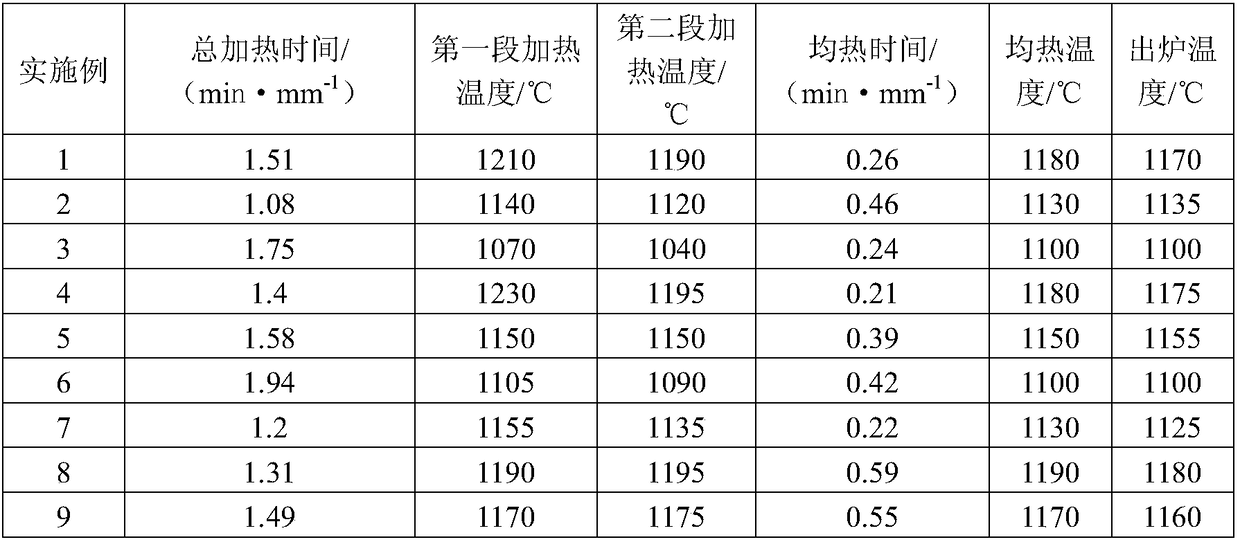

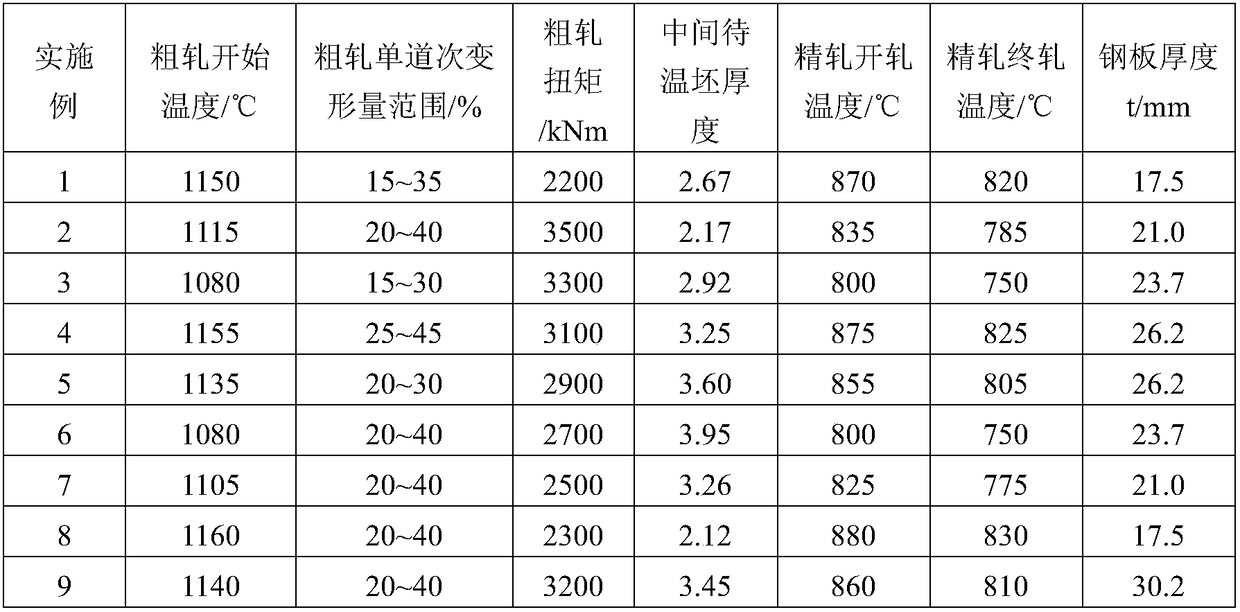

[0043] The technical problems involved in the present invention are solved by the following technical solutions: X80 pipeline steel plate for transporting coal to natural gas and its manufacturing method, its chemical composition mass percentage is: C0.019%~0.059%, Si 0.15%~0.45%, Mn0. 55%~1.85%, Cu≤0.50%, Cr≤0.50%, Ni≤0.50%, Mo 0.05%~0.35%, Nb 0.03%~0.12%, V0.01%~0.04%, Ti 0.008%~0.024%, Al 0.01%~0.04%, P≤0.010%, S≤0.005%, and S+P+O+N+H≤0.015%, the rest is Fe and unavoidable impurities. Before continuous casting, add Si-Ca line treatment to RH. During continuous casting, control the superheat of molten steel at 15-25°C, control the light reduction rate between 2%-5%, and the casting speed at 0.8-2.0m / min ; After continuous casting, the continuous casting slab is slowly cooled for 45 to 50 hours, and the central segregation of the casting slab is low-magnification rating C class...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com