Patents

Literature

95results about How to "Effective pinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

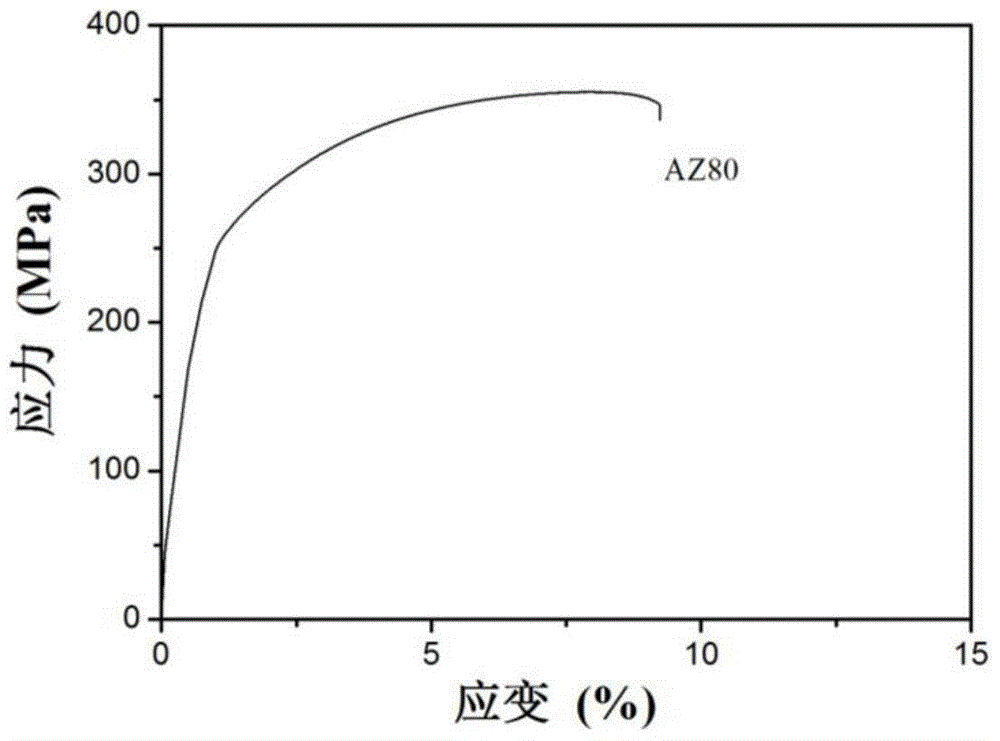

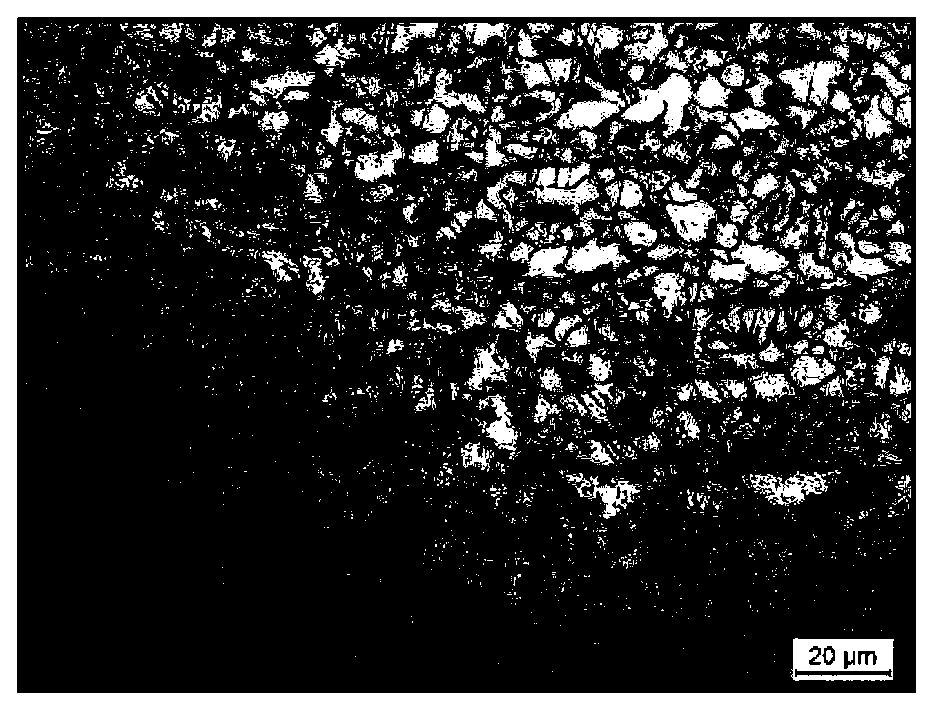

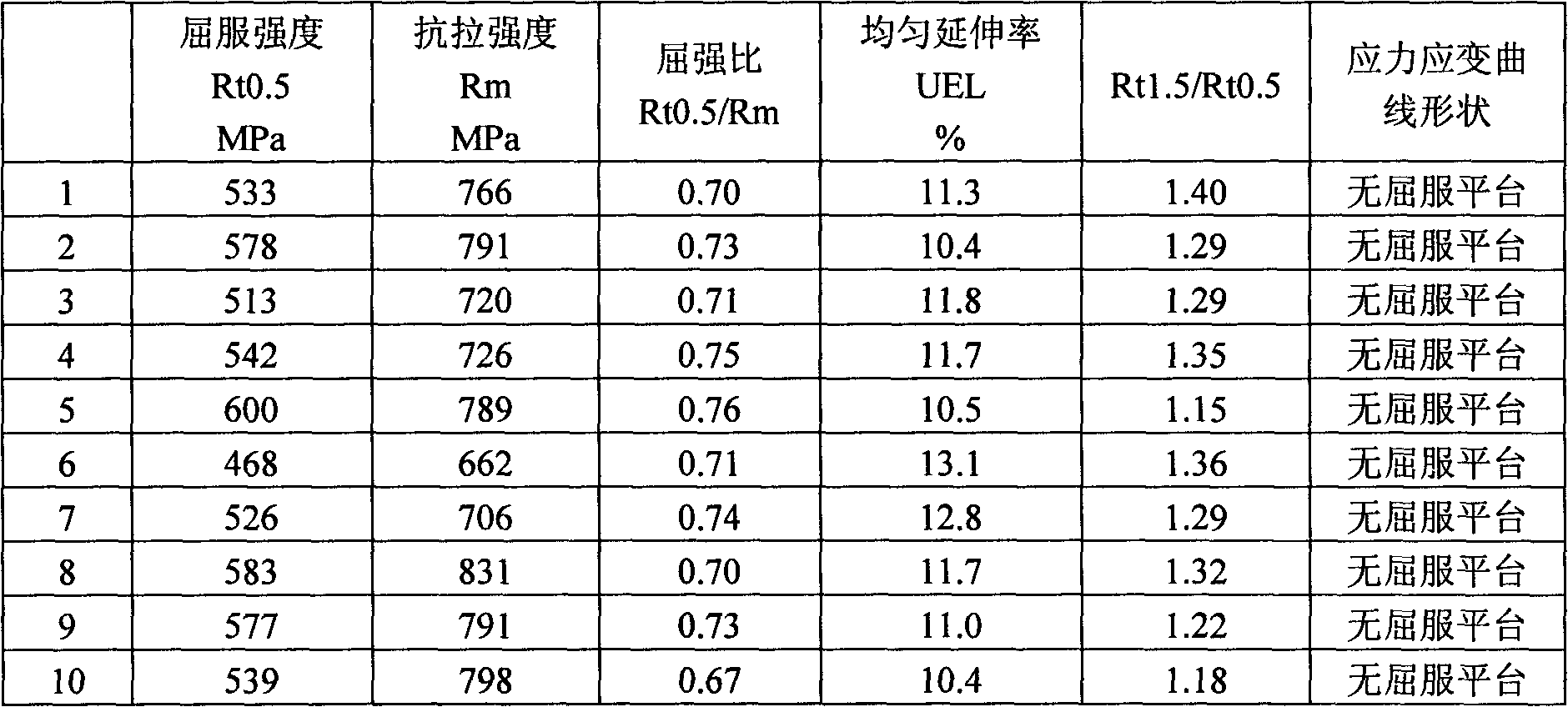

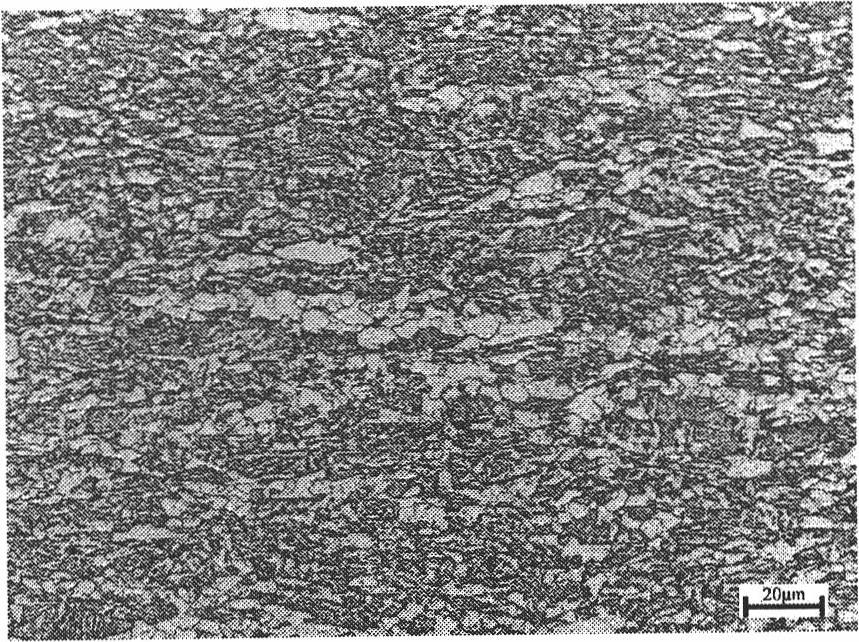

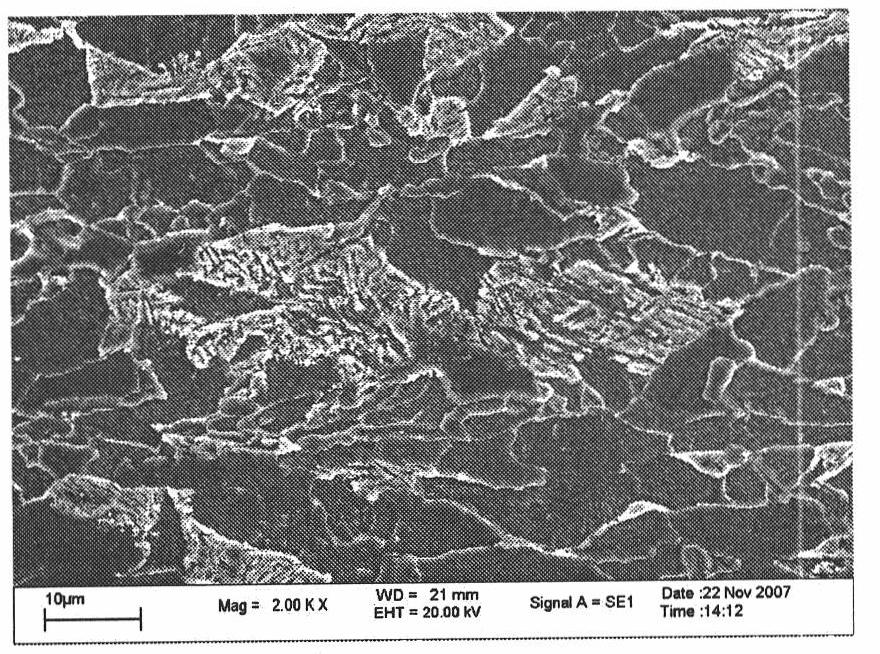

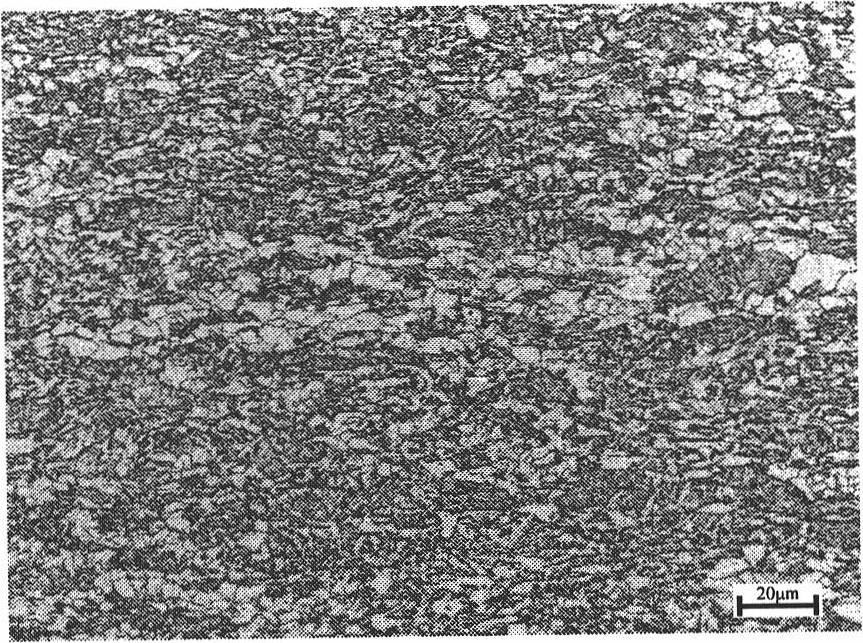

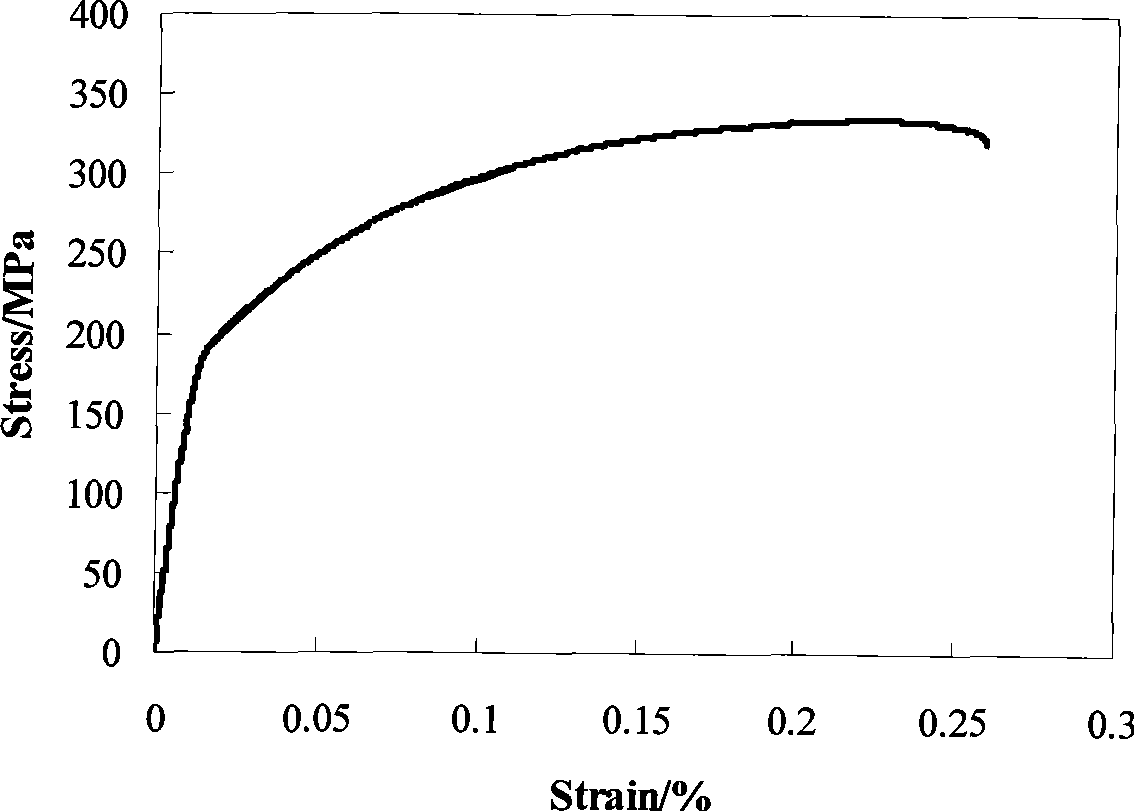

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

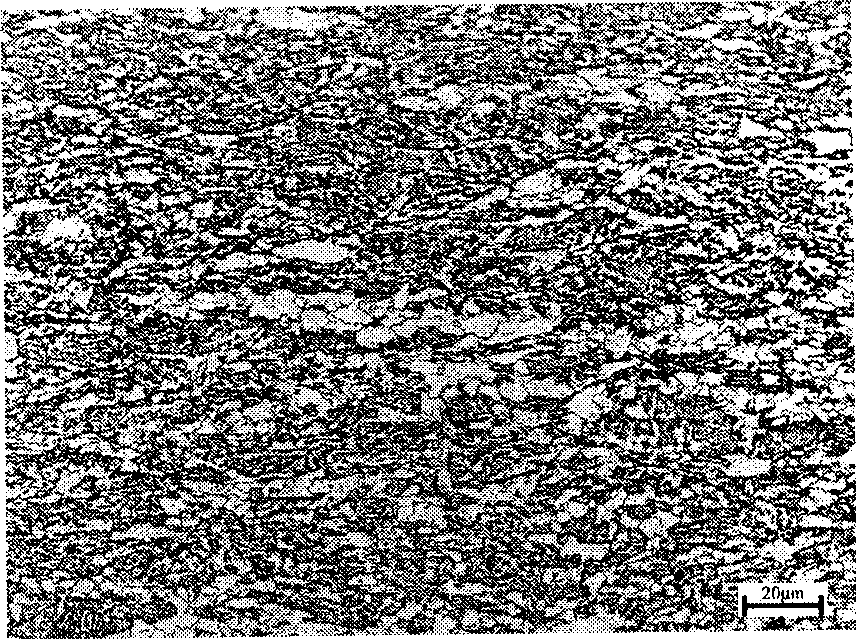

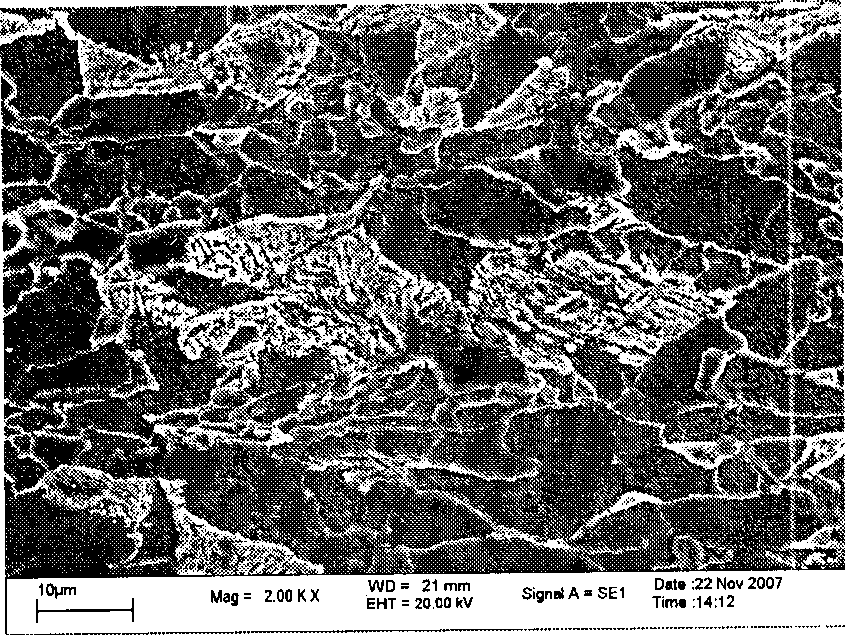

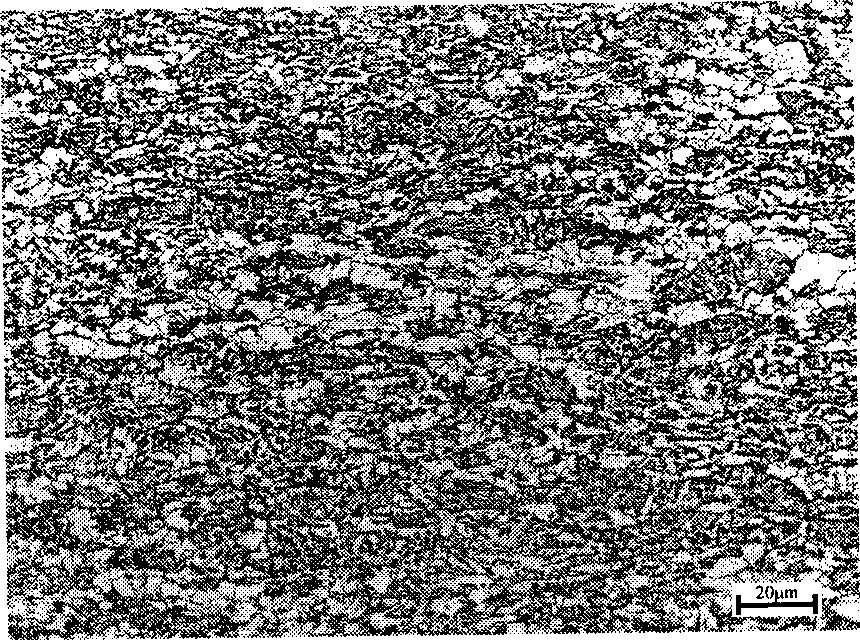

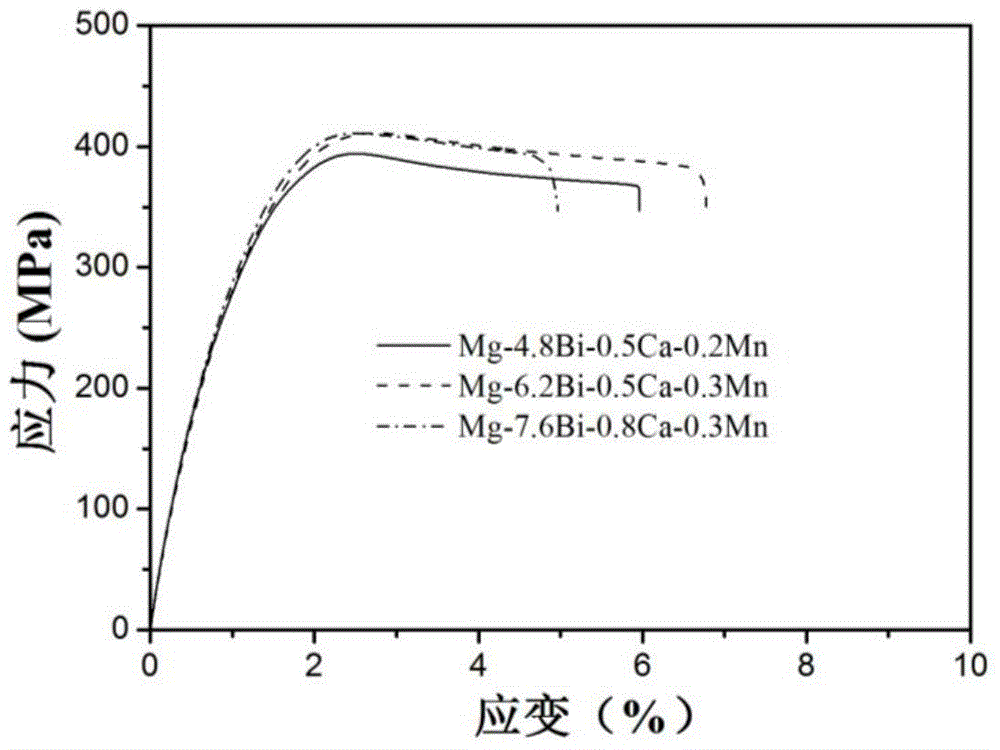

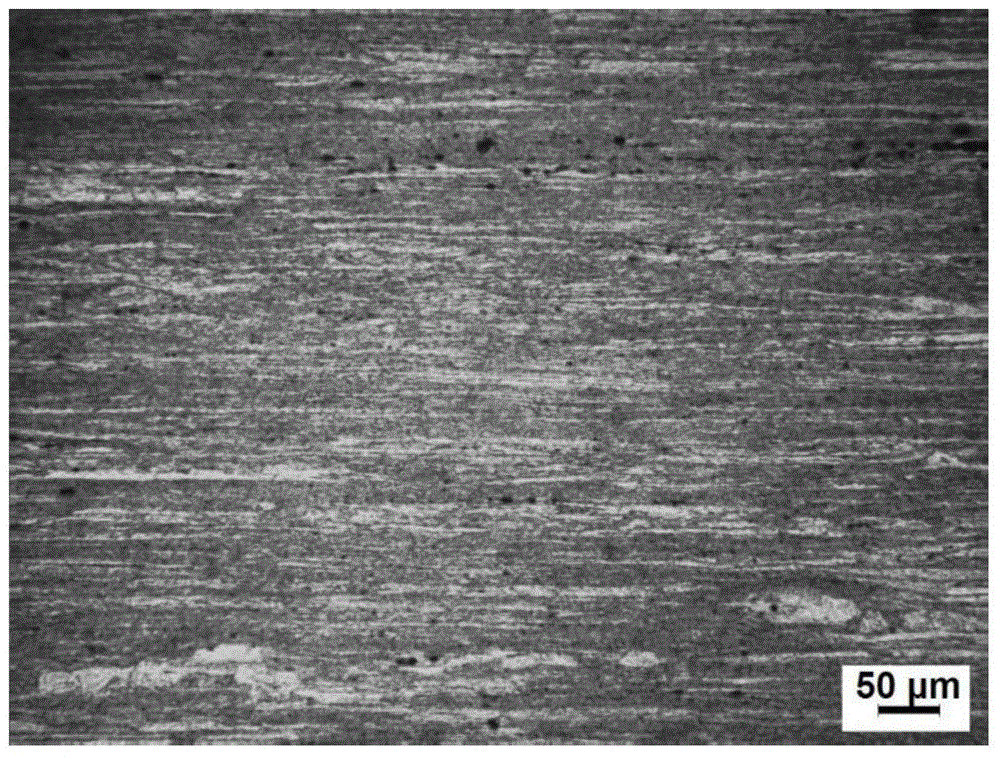

Low-cost non-rare-earth type high-strength magnesium alloy and preparing method thereof

The invention relates to low-cost non-rare-earth type high-strength magnesium alloy and a preparing method thereof. The alloy is Mg-Bi-Ca-Mn magnesium alloy, and is prepared from, by mass, 2-10% of Bi, 0.1-1.5% of Ca, 0.1-1.0% of Mn and the balance magnesium. The novel magnesium alloy is based on a Mg-Bi binary metal series, the element Bi serves as the main alloy element, and the Mg3Bi2 phase with high melting point is contained in the magnesium alloy. Furthermore, the magnesium alloy is evenly dispersed and distributed on a matrix through a simple alloying means, the metamorphism to a second phase by the element Ca and the element Mn and the combination of a plastic deformation processing means so that crystal boundary migration can be effectively pinned in the deformation process to hinder dislocated movement, grains are obviously refined, the strength of the alloy is greatly improved, and thus the ultra-high-strength magnesium alloy is developed in the alloy series.

Owner:HEBEI UNIV OF TECH

Cerium lanthanum containing high-strength anti-corrosion die-casting magnesium alloy

The invention relates to cerium lanthanum high-strength corrosion resistant die casting magnesium alloy and is characterized in that the components and the weight percentage of the alloy are provided as follows: 8.5 to 9.5 percent of Al, 0.4 to 0.9 percent of Zn, 0.2 to 0.6 percent of Mn, 0.01 to 1.5 percent of rare earth Ce, 0.01 to 1.5 percent of La, and impure elements of less than or equal to 0.02 percent of Fe, less than or equal to 0.002 percent of Cu, less than or equal to 0.01 percent of Si, less than or equal to 0.001percent of Ni and the allowance is magnesium. The used alloying materials are cerium lanthanum rare earths which are left after separating Nd and Pr from ordinary cerium-rich mischmetals; at present, the rare earth materials are in a position of cheapness and large overstock in the market. The cerium lanthanum high-strength corrosion resistant die casting magnesium alloy avoids the waste of the rare earth resources; the mechanical properties and plasticity of the alloy are both better than AZ91 alloy and the corrosion resistance can be improved by a plurality of times or dozens of times.

Owner:白山市天安金属镁矿业有限公司

390 MPa class low-temperature hull steel having excellent toughness and manufacturing method thereof

ActiveCN103882297ALow elemental contentReduce contentTemperature control deviceReduction rateNiobium

The invention discloses 390 MPa class low-temperature hull steel having excellent toughness and a manufacturing method thereof. The hull steel comprises, by weight, 0.05-0.12% of carbon, 0.08-0.30% of silicon, 1.0-1.40% of manganese, not more than 0.01% of phosphorus, not more than 0.01% of sulphur, 0.01-0.05% of aluminum, 0.02-0.04% of niobium, 0.005-0.020% of titanium with the balance being ferrum and unavoidable impurities. A first stage rolling temperature is 1050-1100 DEG C, a total reduction rate is not less than 60% and a finish rolling temperature is 900-940 DEG C; a second stage rolling temperature is 850-900 DEG C, the total reduction rate is not less than 60% and the finish rolling temperature is 790-880 DEG C. The steel is the steel is subjected to ultra-rapid cooling at a cooling speed of larger than 30 DEG C per second and is cooled at a cooling speed of larger than 10 DEG C per second in a manner of laminar flow; a self-tempering temperature of the steel ranges from 580-640 DEG C and the final cooling temperature of the steel ranges from 500-630 DEG C; and the steel is air cooled to the room temperature.

Owner:ANGANG STEEL CO LTD

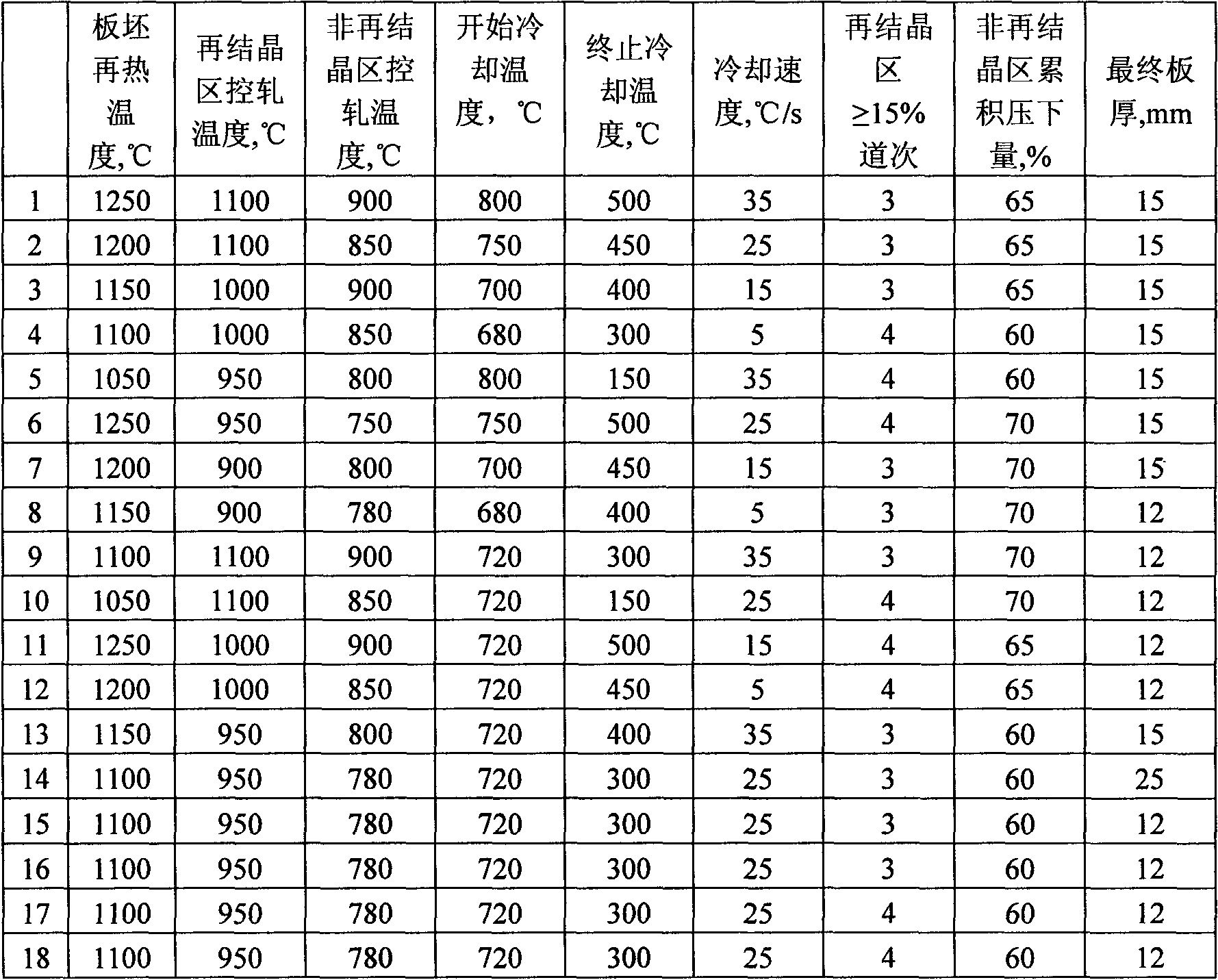

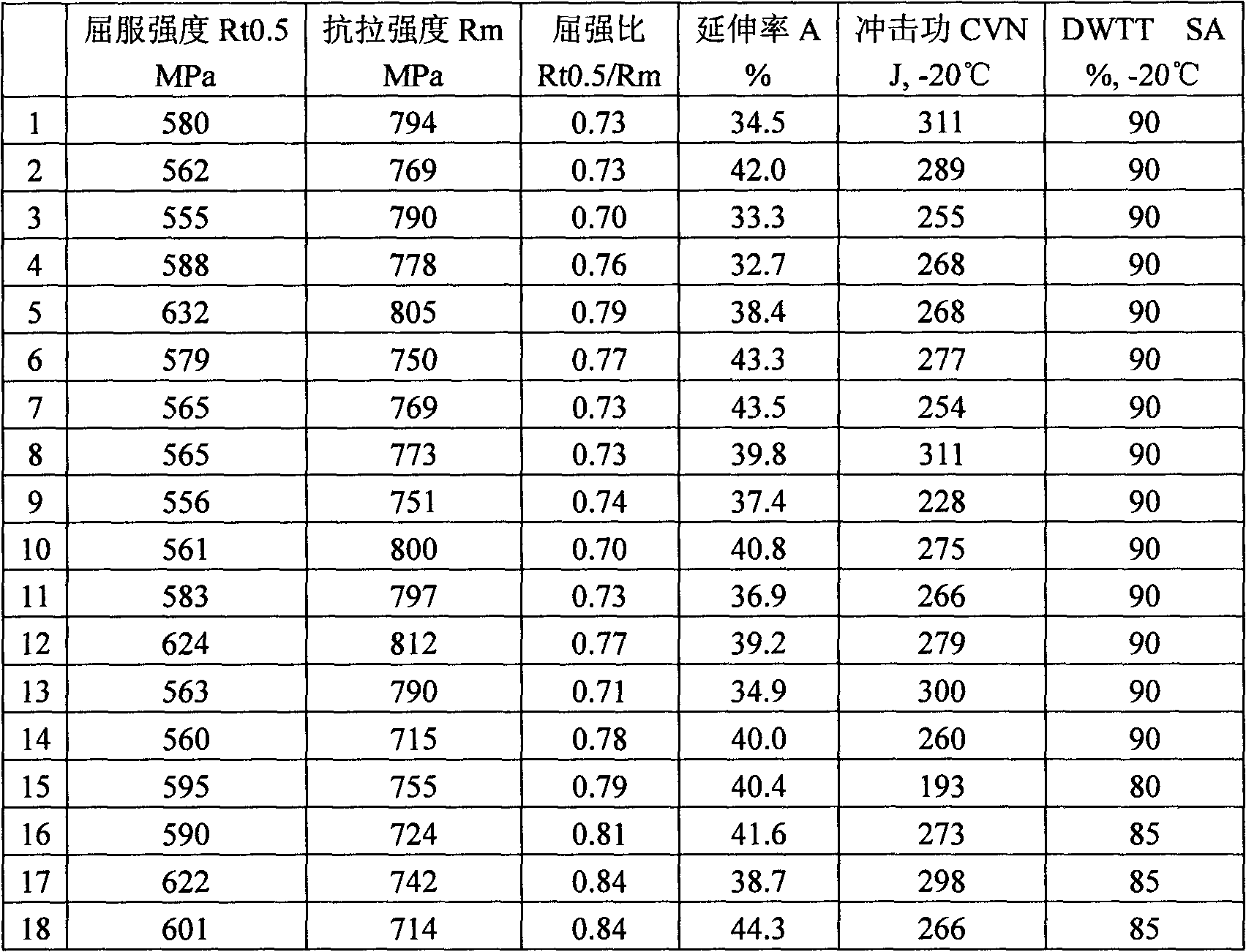

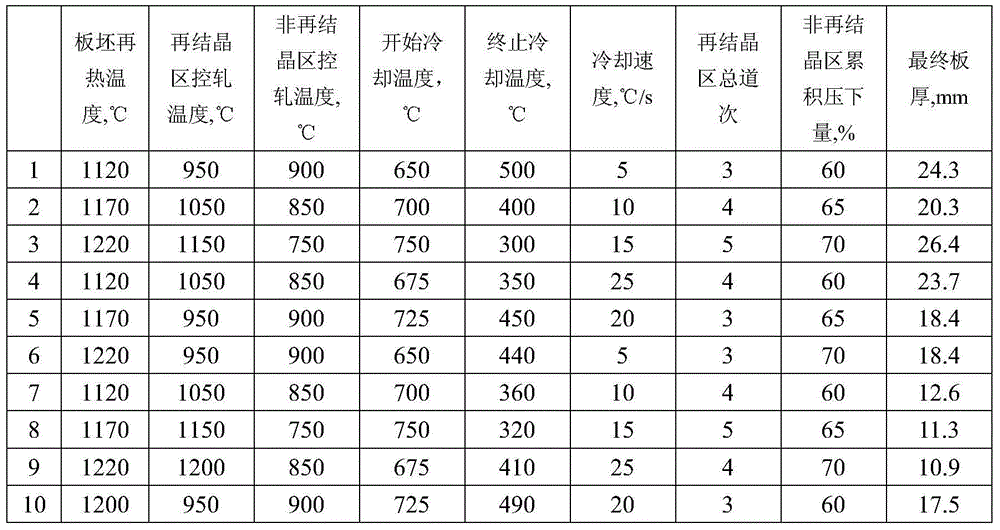

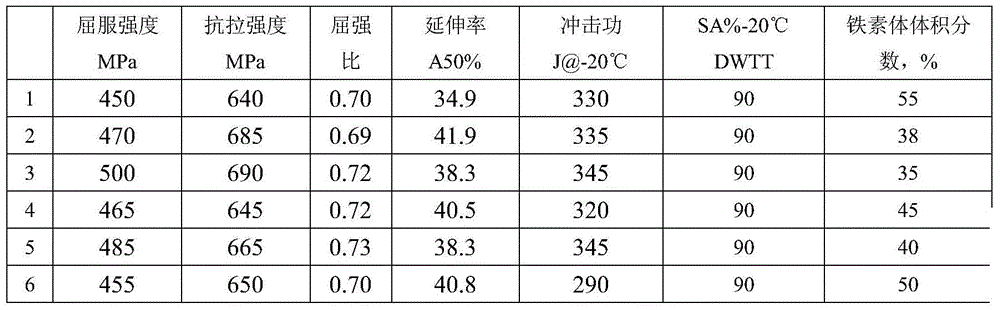

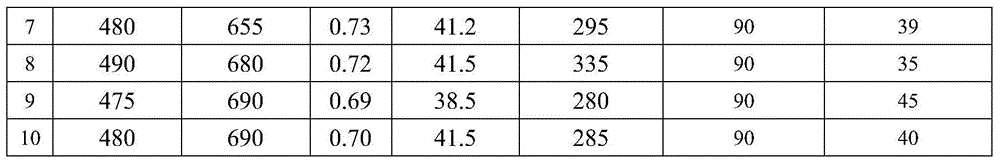

Strain design based economical pipe line steel and its manufacturing method

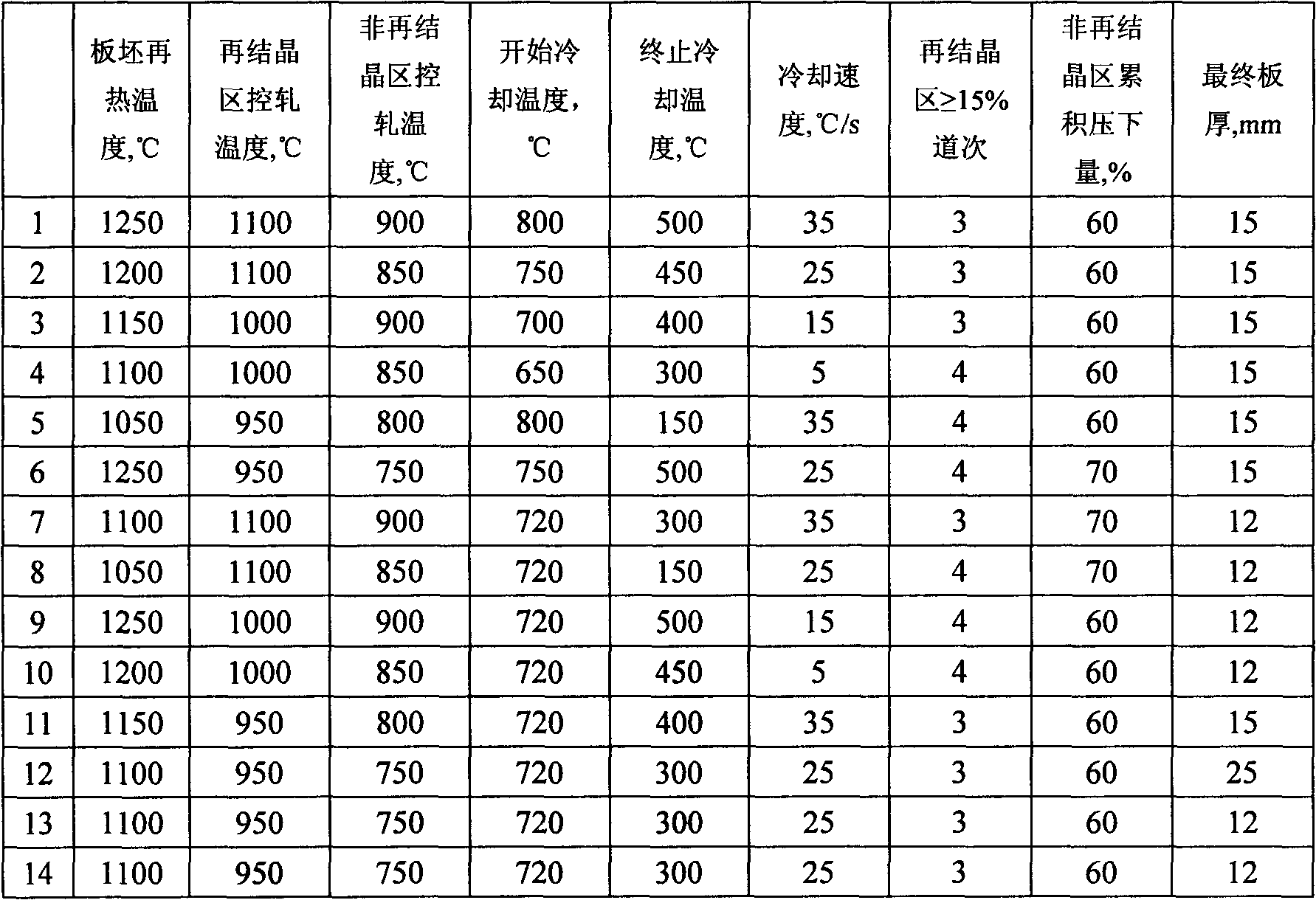

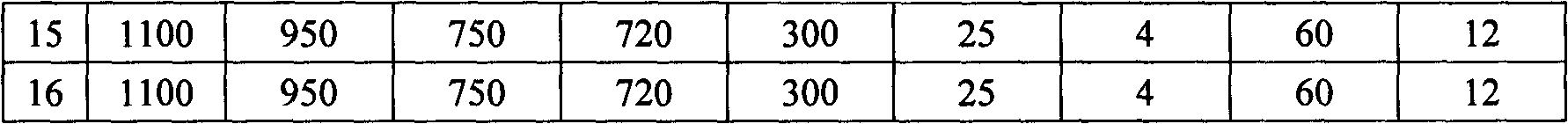

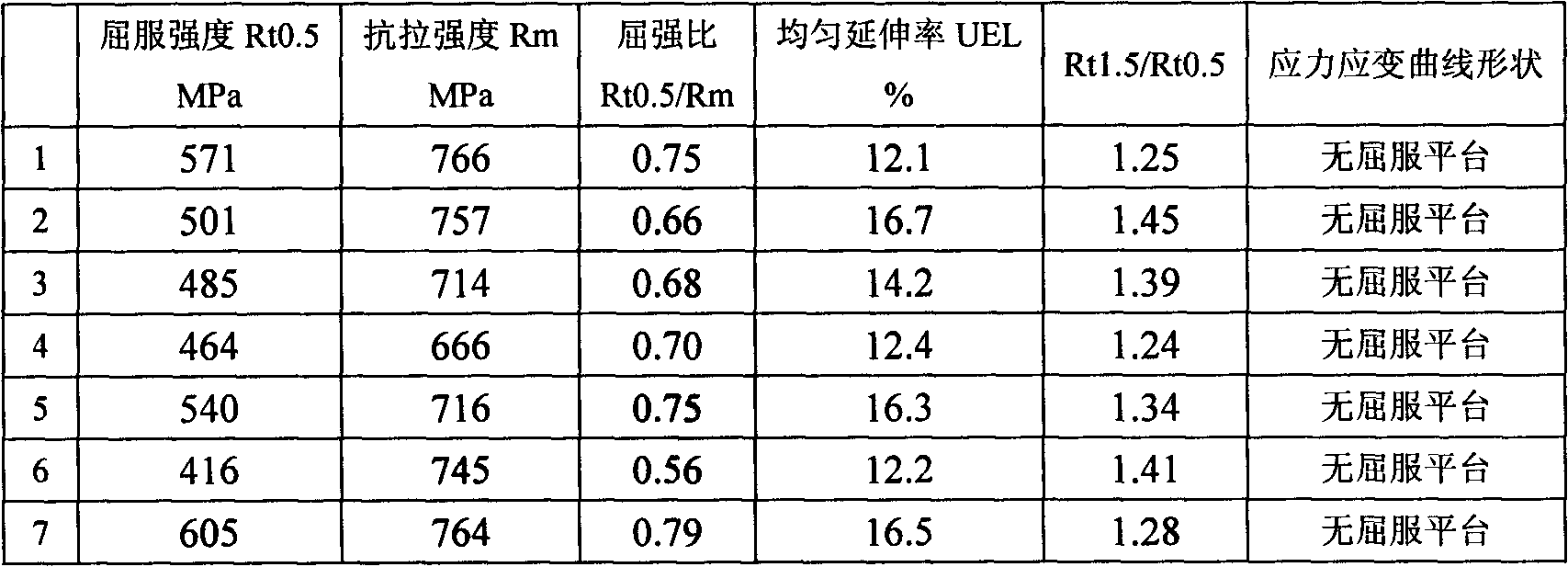

ActiveCN102828120AReduce manufacturing costShorten the relaxation timeTemperature control deviceSheet steelHeating temperature

The invention provides strain design based economical pipe line steel and its manufacturing method. The steel comprises the following ingredients of: by weight, 0.06-0.10% of C, 0.1-0.6% of Si, 1.0-2.0% of Mn, P being less than or equal to 0.015%, S being less than or equal to 0.003%, 0.1-0.3% of Cr, 0.01-0.10% of Nb, 0.005-0.03% of Ti, 0.01-0.06% of Al, N being less than or equal to 0.012%, 0-0.5% of Cu, 0-0.5% of Ni and the balance being Fe. The method provided by the invention comprises steps of smelting, secondary refining, casting and hot rolling, and is characterized in that slab heating temperature is 1050-1280 DEG C; controlled rolling temperature in a recrystallization zone is 900-1250 DEG C; controlled rolling temperature in a non-recrystallization zone is 750-950 DEG C; initial cooling temperature is 680-800 DEG C; finish cooling temperature is 100-500 DEG C; and cooling rate is 5-35 DEG C / s. According to the invention, elements of Mo, V, B and the like are not added, and the total amount of Cu, Cr and Ni is low. In addition, subsequent heat treatment is not required, the process is simple and requires low cost, and production efficiency is high. The steel plate not only has high strength but also has low yield ratio and high uniform extension features. By the adoption of the steel, safety of pipeline operation and economy of pipeline construction can be greatly raised.

Owner:ANGANG STEEL CO LTD

Strain design based pipe line steel X70 and its manufacturing method

ActiveCN102828125AExtend evenlyProper extensionTemperature control deviceImpurityHeating temperature

The invention discloses strain design based pipe line steel X70 and its manufacturing method. the steel comprises the following ingredients of: by weight, 0.06-0.10% of C, 0.1-0.6% of Si, 1.0-2.5% of Mn, P being less than or equal to 0.015%, S being less than or equal to 0.003%, Cr being less than 0.1%, 0.05-0.35% of Mo, 0.01-0.15% of Nb, 0.005-0.03% of Ti, 0.01-0.06% of Al, one or two components selected from 0-0.5% of Cu and 0-0.5% of Ni, and the balance Fe and unavoidable microscale impurities. The manufacturing method is characterized in that slab heating temperature is 1050-1280 DEG C by a controlled rolling and controlled cooling method; the temperature for controlled rolling in a recrystallization zone is controlled within the range of 900-1250 DEG C; the temperature for controlled rolling in a non-recrystallization zone is controlled within the range of 700-950 DEG C; initial cooling temperature is 650-800 DEG C; finish cooling temperature is 100-500 DEG C; and cooling rate is 5-35 DEG C / s. According to the invention, elements of V, B and the like are not added, and the total amount of Mo, Cu, Cr and Ni is low. In addition, subsequent heat treatment is not required, the process is simple and requires low cost, and production efficiency is high.

Owner:ANGANG STEEL CO LTD

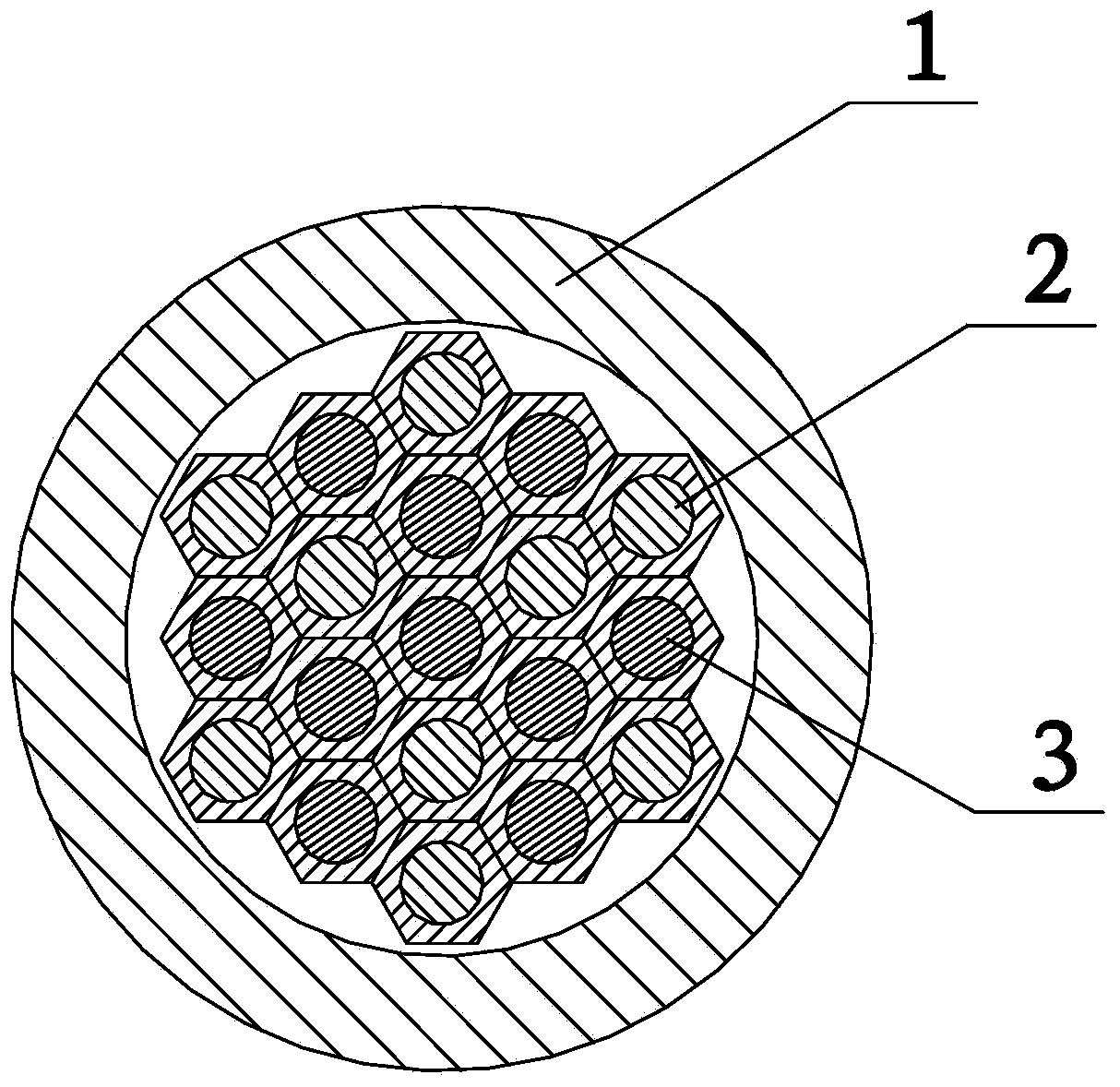

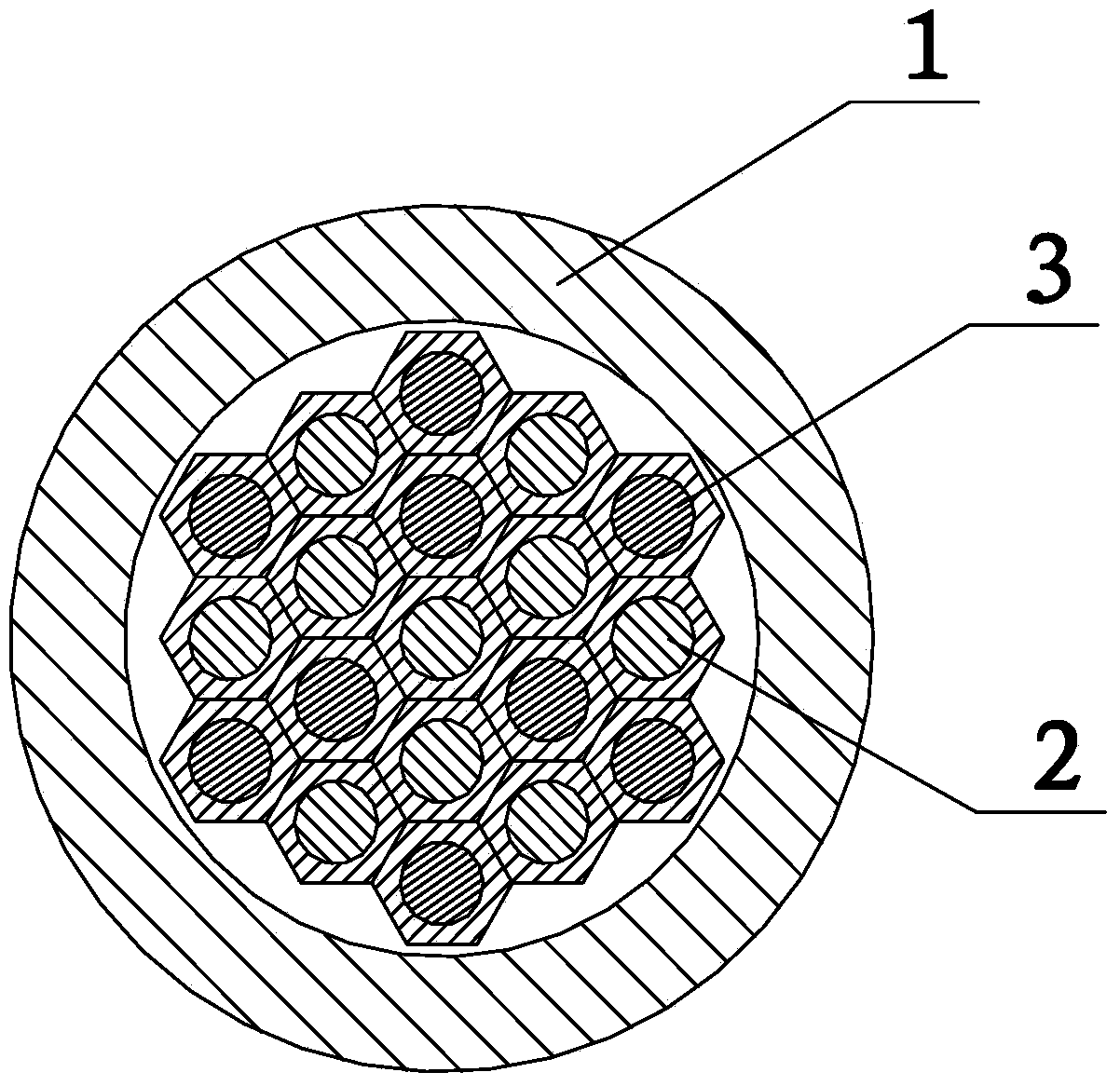

Preparation method of rectangular multicore composite superconductive strip

ActiveCN103440931AEvenly distributedNo reunionSuperconductors/hyperconductorsSuperconductor devicesAlloySlurry

The invention discloses a preparation method of a rectangular multicore composite superconductive strip. The preparation method comprises the following steps of step one. preparing mixed slurry by using amorphous boron powder, magnesium powder and a malic acid ethanol solution; step two. preparing tubing precursor powder; step three. tubing, carrying out rotary swaging, and drawing, thus obtaining a Cu-Nb-MgB2 single-core rod; step four. placing the Cu-Nb-MgB2 single-core rod and a Cu-NbTi single-core rod in a Cu-Ni alloy tube for secondary packaging, thus obtaining a secondary complex; five. processing the secondary complex into a wire rod, then carrying out rotary swaging and drawing so as to obtain a rectangular multicore composite strip; step six. winding a high-silica glass fiber to form a disk, and clamping the two ends of the disk to be flat; and step seven. carrying out thermal treatment so as to obtain the rectangular multicore composite superconductive strip. Compared with a single MgB2 and NbTi superconducting material, the composite superconductive strip prepared by the method is relatively wide in temperature using range and has relatively high using magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

Wrought magnesium alloys in high intensity, high plasticity, and preparation method

This invention discloses a method for preparing Mg alloy with high strength and high plastic deformation. The compositions of the Mg alloy are: Zn 4.5-5.5 wt.%, Ce 0.5-2.5 wt.%, Ti 0.01-0.20 wt.%, Si less than or equal to 0.08 wt.%, Fe less than or equal to 0.01 wt.%, Cu less than or equal to 0.01 wt.%, Ni less than or equal to 0.002 wt.%, impurities less than or equal to 0.05 wt.%, and Mg as balance. The method adds rare earth element Ce to Mg-Zn-Zr alloy, and replaces Zr with Ti, thus can refine the alloy grains. Besides, Mg forms a dispersed reinforcing phase, which can effectively improve the comprehensive properties of the Mg alloy. The surface quality of the extruded product of the Mg alloy is obviously improved when compared with ZK series deformed Mg alloys. The average tensile strength, yield strength and elongation at breakage of the Mg alloy at room temperature are 360 MPa, 245 MPa and 7%, respectively. The average tensile strength and elongation at breakage of the Mg alloy at 150 deg.C are 250 MPa and 11%, respectively.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

High strength and toughness rare earth magnesium alloy

The invention belongs to the magnesium alloy material field and particularly relates to a high strength and toughness rare earth magnesium alloy. The invention solves the defects of low strength and plasticity of the Mg-Al base alloy which is widely used now. The alloy comprises the following elemental compositions by weight percent: 3-9% of Al, 0.2-0.6% of Zn, 0.1-0.5% of Mn, 0.05-1.0% of Ce, 0.05-1.0% of La, 0.1-3.0% of Y, 0.1-2.0% of Er, 0.1-2.0% of Ho, 0.004% or less of impurity element Fe, 0.002% or less of impurity element Cu, 0.02% or less of impurity element Si, 0.001% or less of impurity element Ni and the balance Mg. Through combined action of the elements and proper homogenizing treatment, the comprehensive performance of the alloy is significantly improved.

Owner:TAIYUAN HUA YIN TAI ALLOY

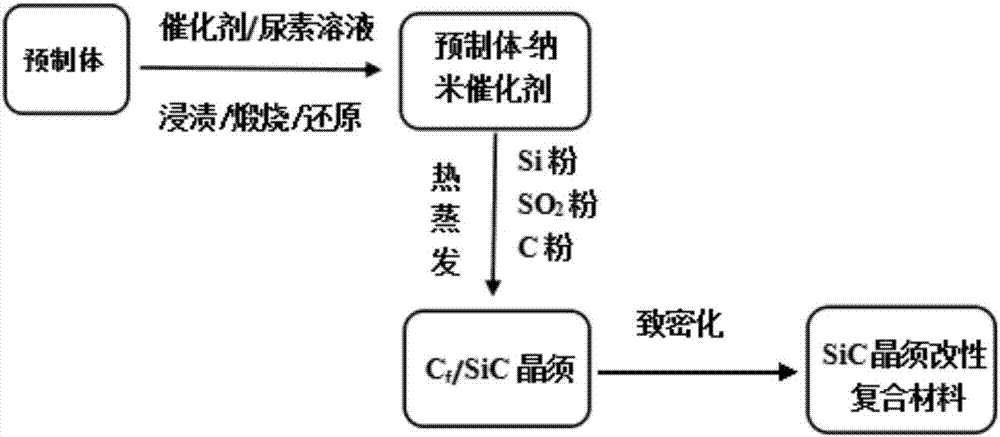

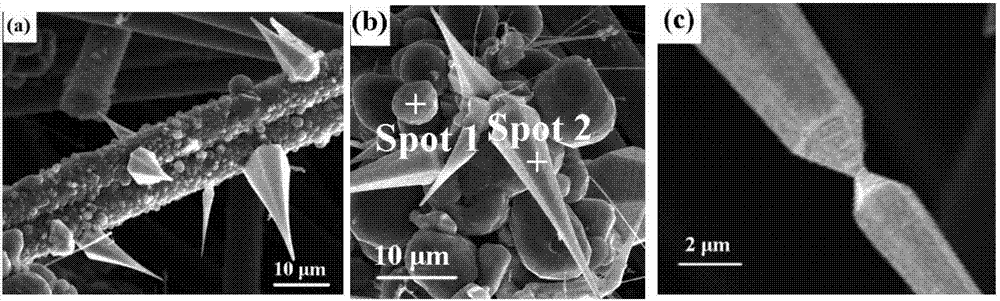

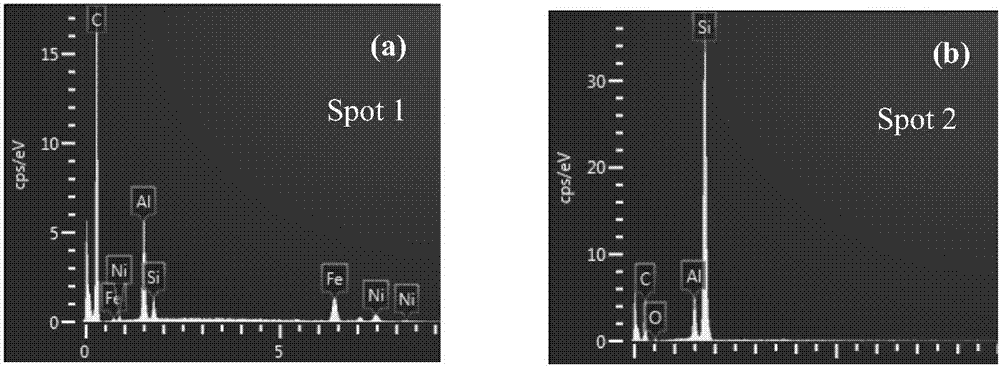

Preparation method for in-situ synthesizing of conical SiC crystal whisker through coprecipitation and thermal evaporation technology

ActiveCN107059129AImprove oxidation resistanceImprove fracture toughnessPolycrystalline material growthSingle crystal growth detailsNano catalystFiber

The invention relates to a preparation method for in-situ synthesizing of conical SiC crystal whisker through a coprecipitation and thermal evaporation technology. The preparation method comprises the steps of depositing a layer of carbon on a carbon fiber prefabricated body through a CVI method, filling defects on the surface of the prefabricated body and providing sufficient reaction raw materials; then putting the prefabricated body into a urea solution containing a catalyst to be dipped, calcining and reducing to obtain a nano catalyst; then suspending a sample containing the nano catalyst at the position of the top end in a graphite mold where silicon powder and carbon powder are loaded and evenly mixed and then obtaining the conical SiC crystal whisker through thermal treatment in certain temperature. The preparation method disclosed by the invention is simple, free of pollution, safe and stable, can effectively improve oxidation resistance, breaking tenacity and creep resistance of a composite material and combination strength between a base body and an enhanced body, can be applied to carbon / carbon, carbon / ceramic, magnesium-based and aluminum-based composite materials and has very good economical and social benefits.

Owner:无锡博智复合材料有限公司

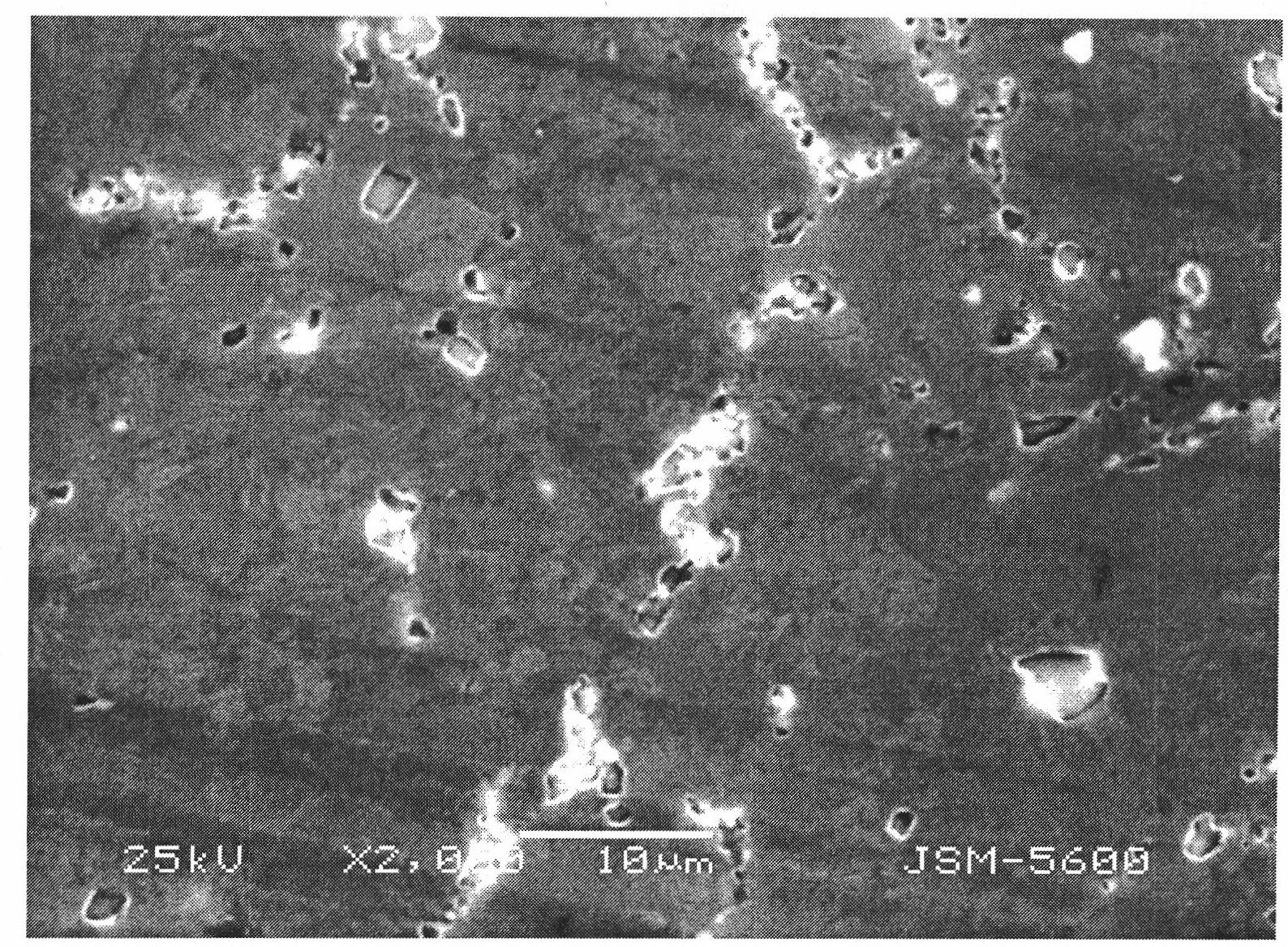

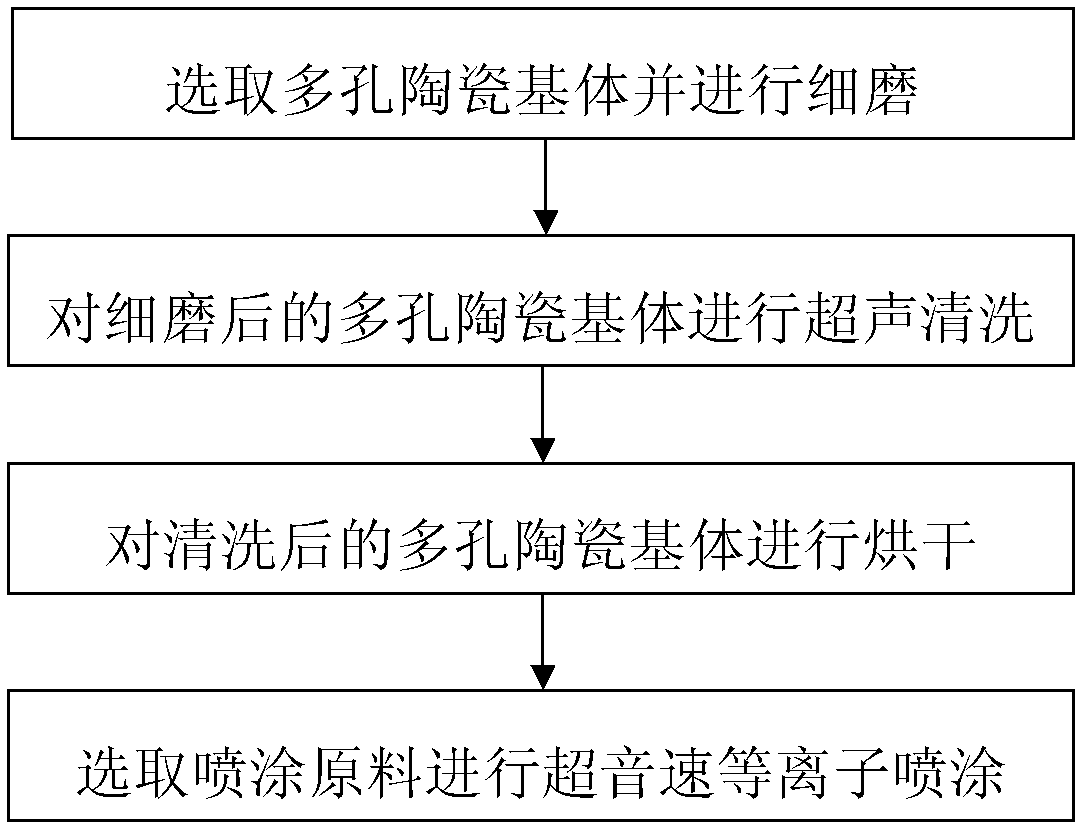

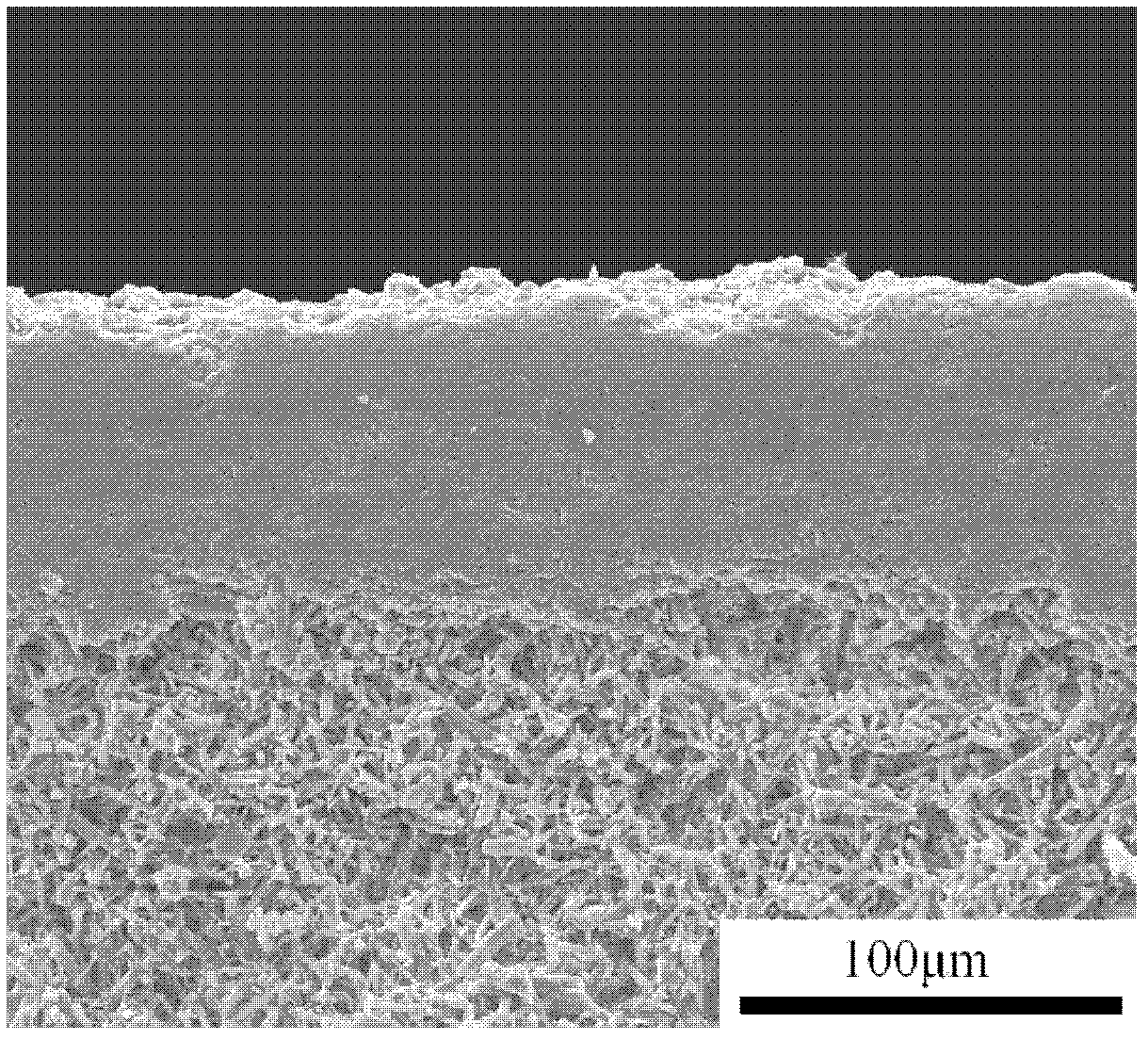

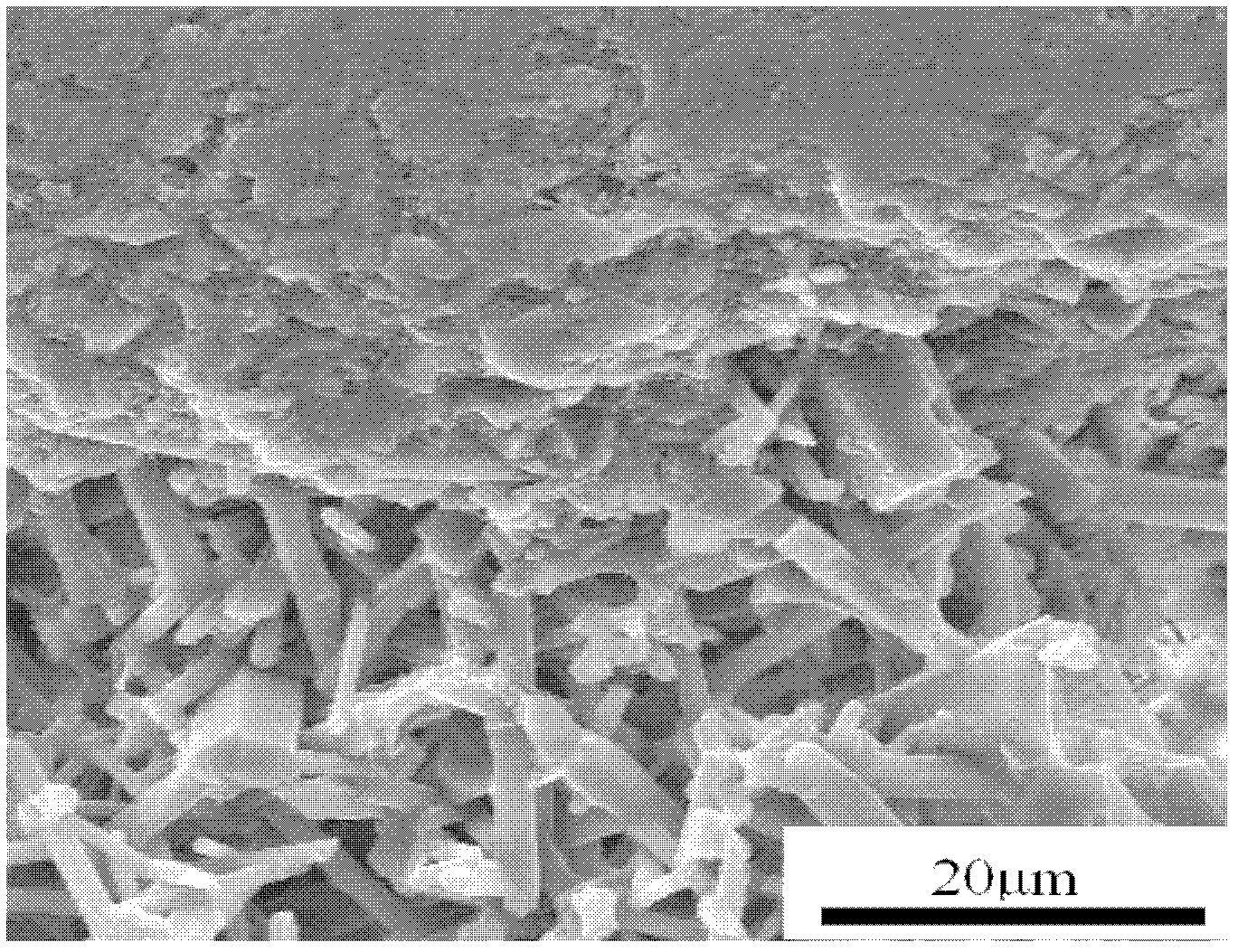

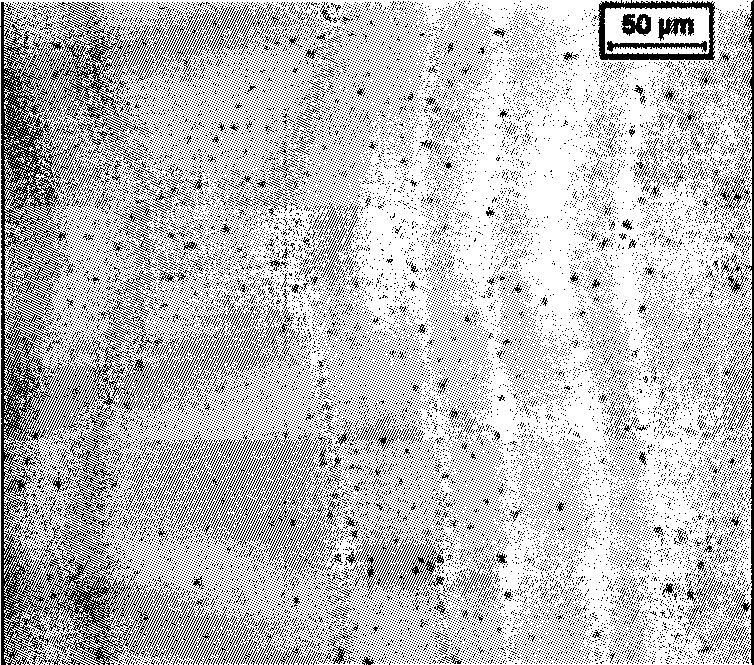

Method for preparing ceramic coating on surface of porous ceramic substrate

The invention discloses a method for preparing a ceramic coating on the surface of a porous ceramic substrate, which includes: firstly, selecting a porous ceramic substrate and fine grinding; secondly, ultrasonically cleaning the porous ceramic substrate after fine grinding; thirdly, drying the cleaned porous ceramic substrate; and fourthly, selecting spraying materials for supersonic plasma spraying. The method can be used for preparing ceramic coatings on the surfaces of porous ceramic substrates, particles in the coating can be effectively and completely pinned in the substrate, the coatings and the substrates are firm in bonding, and preparation of a bottom layer or a transitional layer is not needed. Further, the method has the advantages of simplicity, flexibility, high efficiency and easiness in industrial application.

Owner:XI AN JIAOTONG UNIV

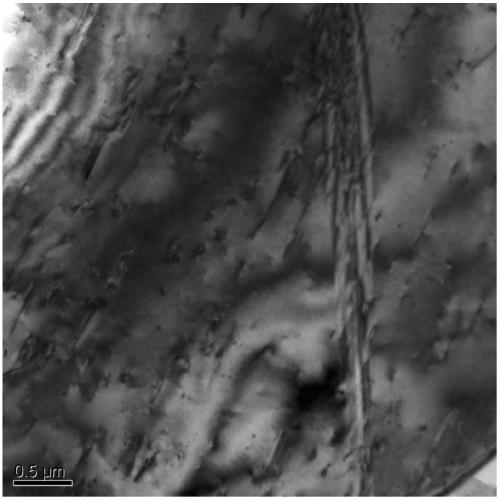

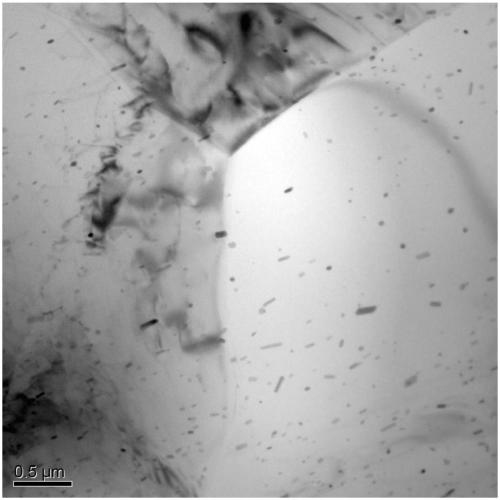

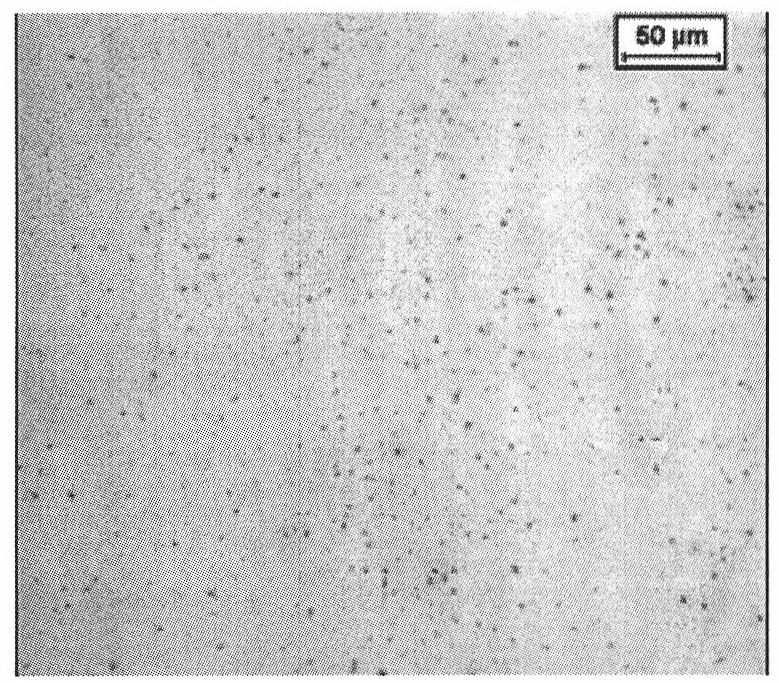

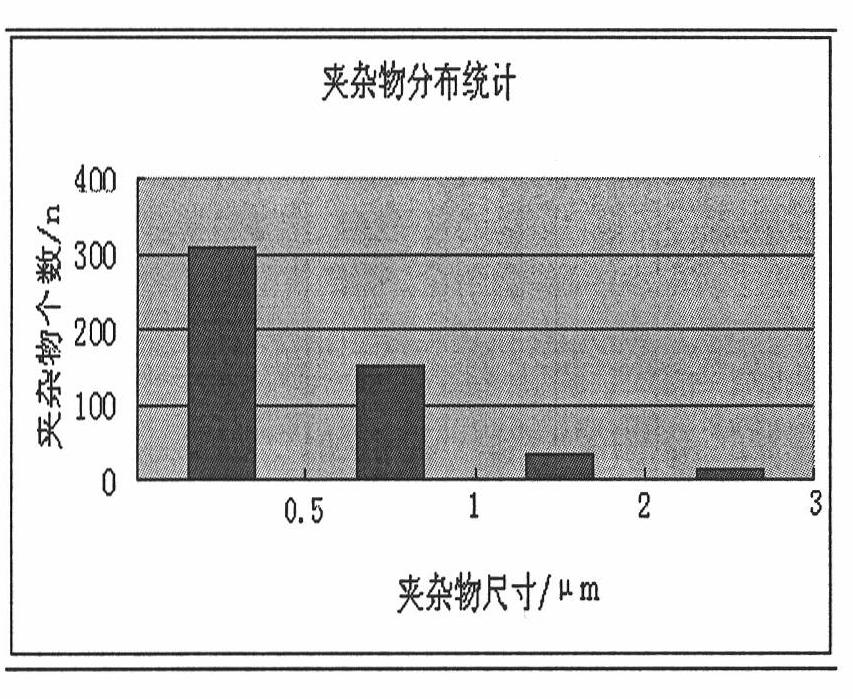

Method for improving steel plate heat-affected zone toughness of steel plate under high input energy welding condition

The invention pertaining to the technical field of high-strength steel plates for welding provides a method of improving the heat-affected zone toughness of a steel plate under a large heat input welding condition.CGHAZ toughness of a steel plate under a large heat input welding condition is improved on the basis of a CaO-MnS mechanism.HAZ toughness can be improved effectively by adding Ca into C-Mn steel, wherein, the Ca performs deoxidization through a gas-liquid interface for generating reactions of [Ca]+[O]=(CaO) and [Ca]+[S]=(CaS); fine dispersed nano-scale mass points of CaO and CaS are formed, MnS adheres to the mass points go grow to form a rotundity shape, and when the Ca content achieves to 50-60ppm, the HAZ toughness can be improved effectively.The invention has advantages of effective austenite grain boundary forming by nails, grains being fined and the CGHAZ toughness being improved.

Owner:SHOUGANG CORPORATION

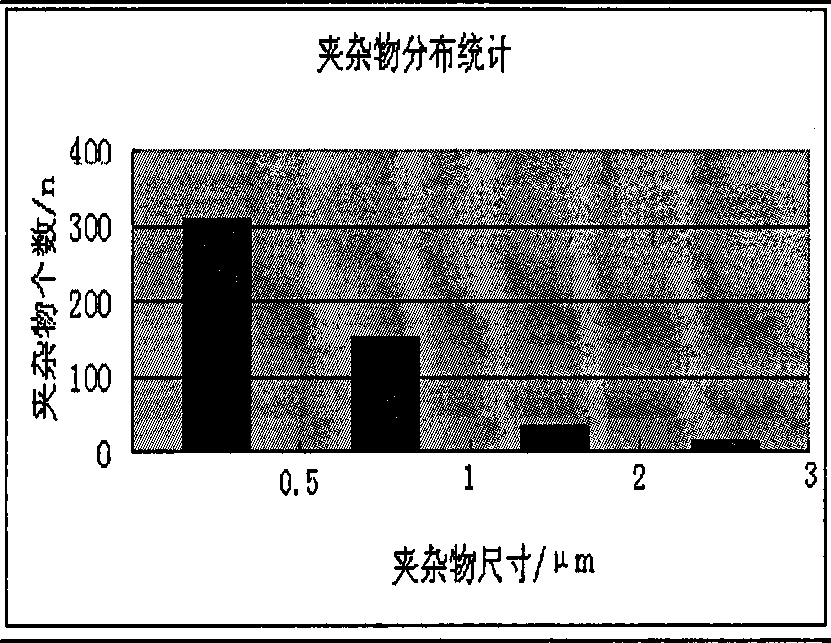

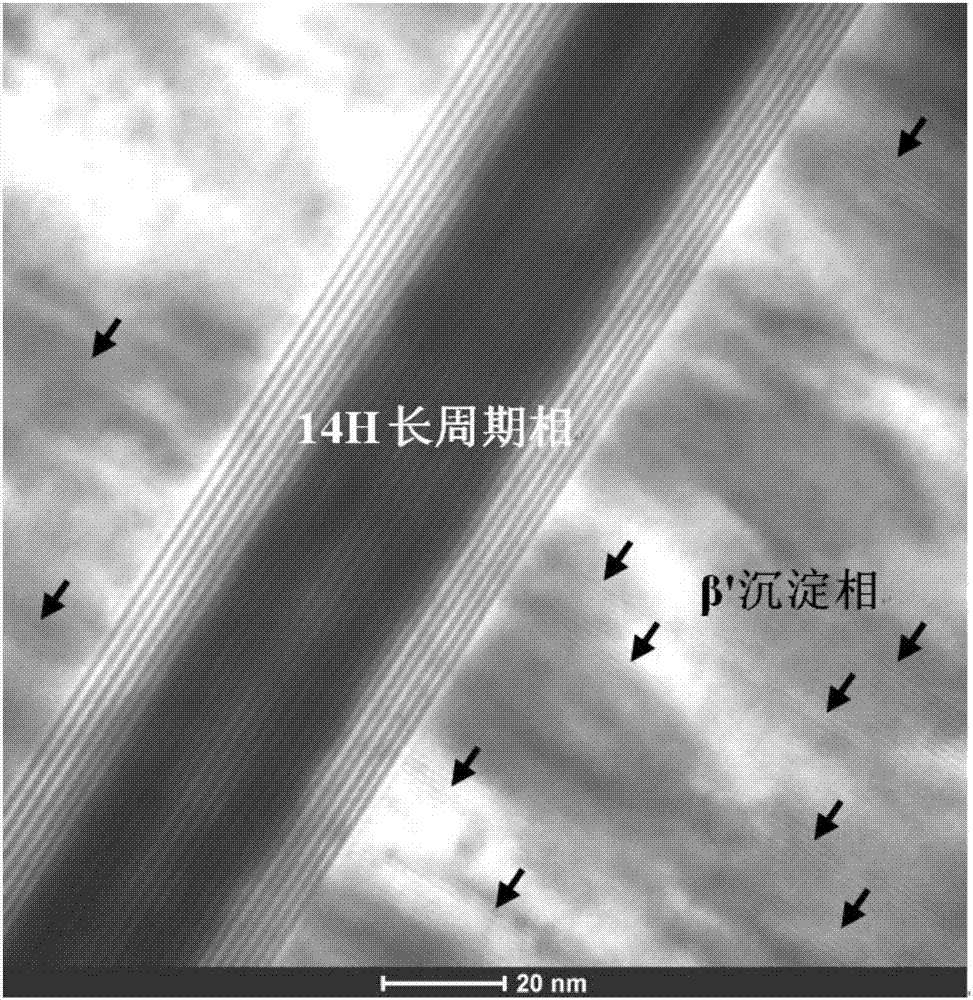

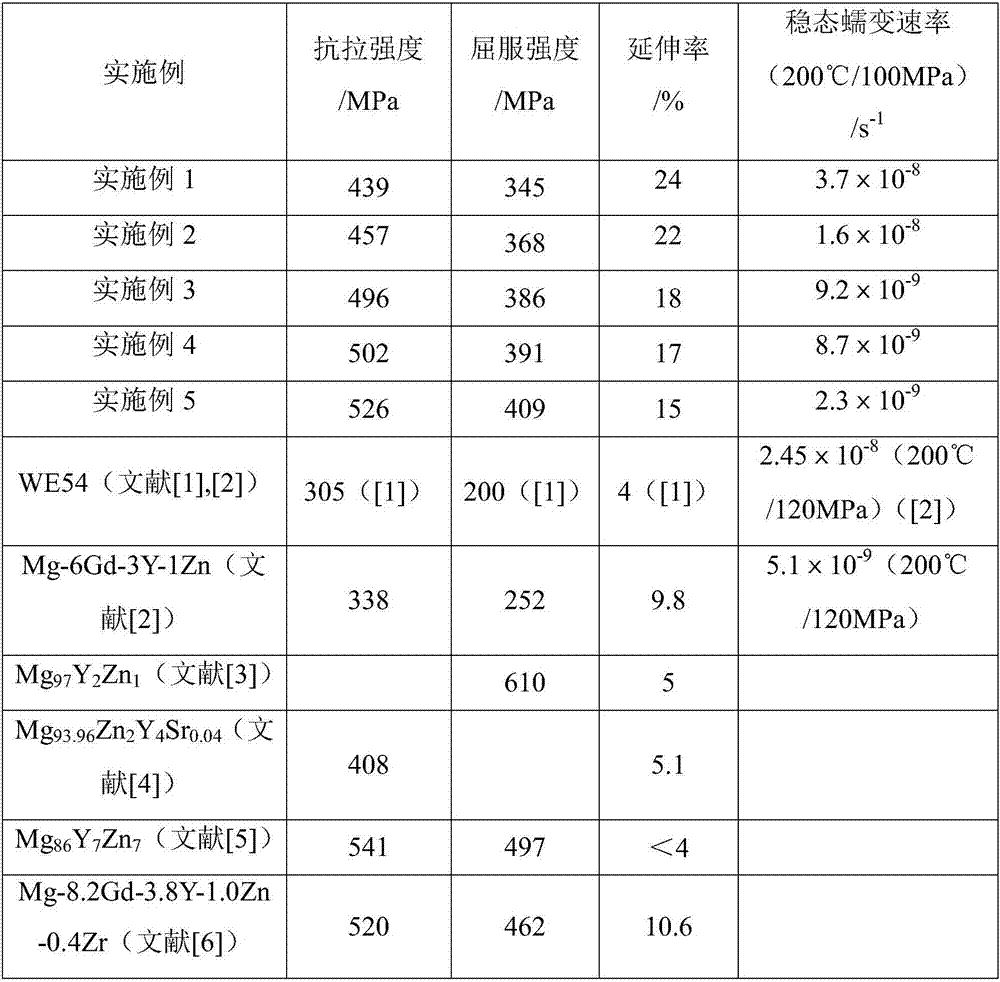

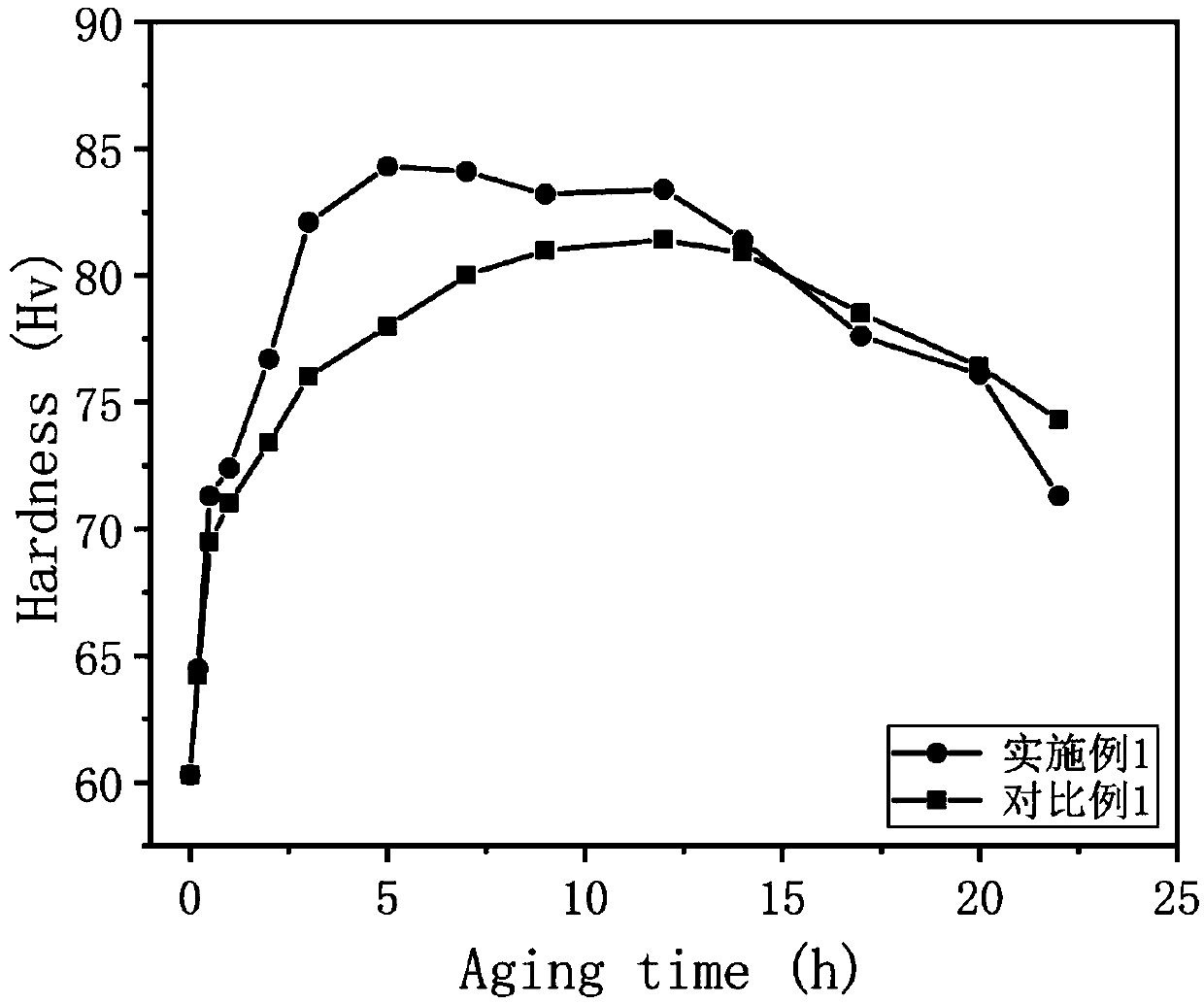

High-strength and high-plasticity heat-resistant magnesium alloy with adjustable LPSO structure and nanometer precipitated phase and preparing method thereof

The invention discloses a preparing method of a high-strength and high-plasticity heat-resistant magnesium alloy with an adjustable LPSO structure and a nanometer precipitated phase. The preparing method comprises the following steps: A, cutting a Mg-Y-Zn alloy ingot, placing the alloy ingot in an equal-channel angular pressing (ECAP) die, carrying out thermal insulation at 280-330DEG C, and then carrying out ECAP treatment on the ingot so as to obtain an ultra-fine crystal bulk; and B, placing the ultra-fine crystal bulk in a thermal treatment furnace, carrying out thermal insulation at 350-400DEG C for 2-8 hours, carrying out quenching, then placing the ultra-fine crystal bulk in a vacuum oven, carrying out thermal insulation at 200-225DEG C for 22-30 hours, and carrying out quenching so as to obtain ultra-fine crystal magnesium alloy containing an LPSO structure and a nanometer precipitated phase. The high-plasticity ultra-fine crystal rare-earth magnesium alloy containing the LPSO structure is obtained through ECAP processing. Besides, by using double heat treatment to adjust the LPSO structure in the alloy, introducing the nanometer precipitated phase and utilizing the organic combination and unification of three enhancing factors, such as fine-crystal enhancement, LPSO phase enhancement and nanometer precipitated phase enhancement, the heat-resistant magnesium alloy with high strength, high plasticity and high creep resistance is obtained.

Owner:南通河海大学海洋与近海工程研究院 +1

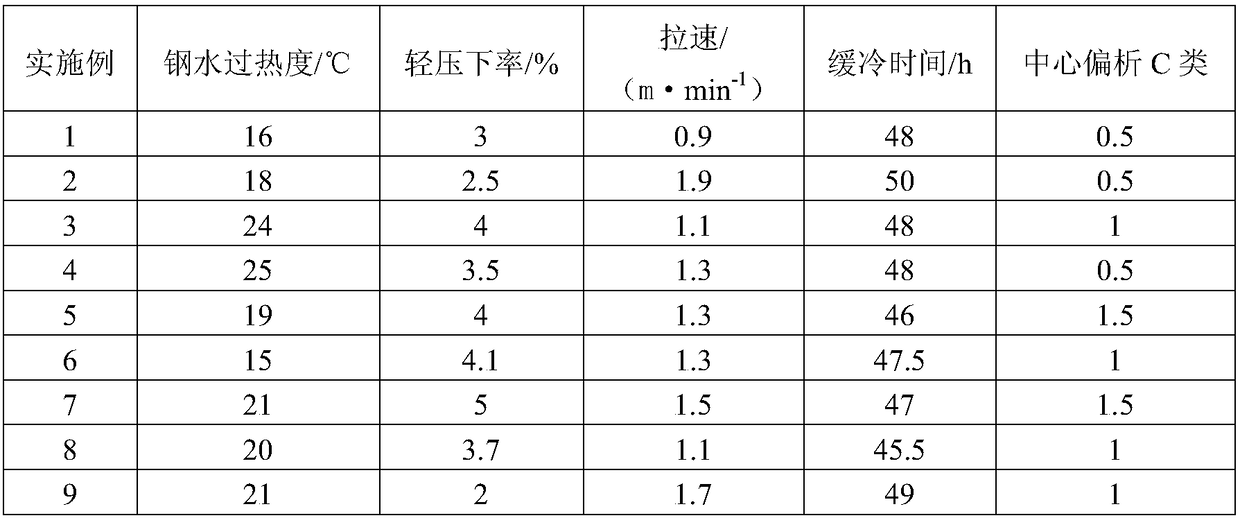

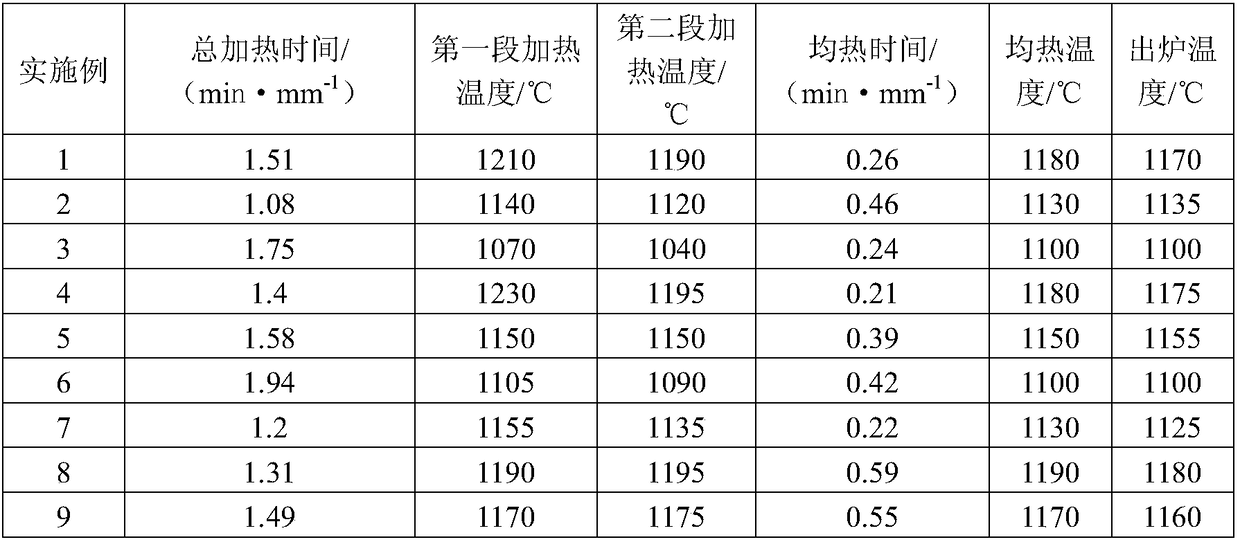

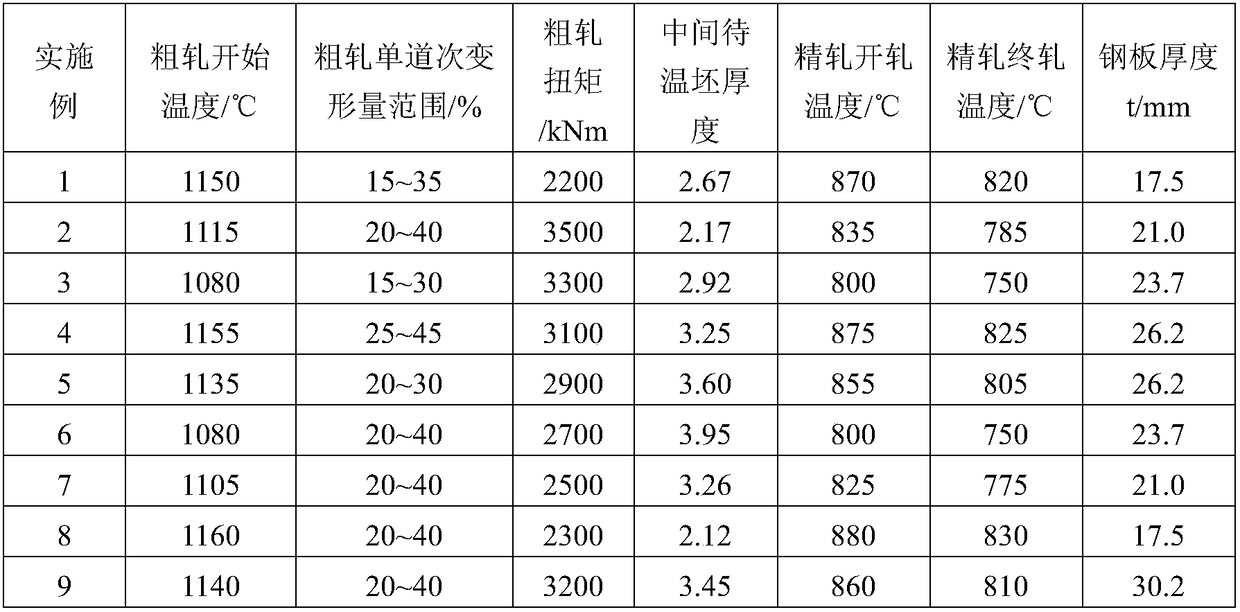

X80 pipeline steel plate for conveying coal-derived natural gas and manufacturing method thereof

The invention discloses an X80 pipeline steel plate for conveying coal-derived natural gas and a manufacturing method thereof. Steel comprises 0.019%-0.059% of C, 0.15%-0.45% of Si, 0.55%-1.85% of Mn,0-0.50% of Cu, 0-0.50% of Cr, 0-0.50% of Ni, 0.05%-0.35% of Mo, 0.03%-0.12% of Nb, 0.01%-0.04% of V, 0.008%-0.024% of Ti, 0.01%-0.04% of Al, 0-0.010% of P, 0-0.005% of S, and the balance Fe and unavoidable impurities, and S+P+O+N+H<=0.015%. The superheat degree of molten steel is 15-25 DEG C, the soft reduction rate is 2%-5%, and the drawing speed is 0.8-2.0 m / min. Two-section heating is adopted,rough rolling starting temperature is larger than or equal to 1000 DEG C, fine rolling starting temperature is 800-900 DEG C, fine rolling finish temperature is 750-850 DEG C, cooling starting temperature is 710-770 DEG C, cooling finish temperature is 460-600 DEG C, and the cooling speed is 5-20 DEG C / s. the steel plate has good strength, toughness and HIC resistance.

Owner:ANGANG STEEL CO LTD

High performance deformed magnesium alloy

The high performance deformable magnesium alloy has the components including Mn 1.3-2.3 %, Ce 0.4- 1.2 %, Sr 0.1-0.5 %, Si not more than 0.05 %, Fe not more than 0.004 %, Cu not more than 0.025 %, Ni not more than 0.001 %, and Mg for the rest. The magnesium alloy with increased RE elements Ce and Sr amount has high mechanical performance and is suitable for intruding production.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

Method for preparing compound MgB2 superconductor

The invention discloses a method for preparing compound MgB2 superconductor, and belongs to the technical field of MgB2 superconductor preparation. The method comprises the following steps: taking magnesium powder, boron powder and white phosphorus, milling with anhydrous ethanol, freezing into blocks with liquid nitrogen, conducting pulverization and sieving, then conducting stirring and preheating, adding an ignited magnesium rod, then heating, keeping heat and stirring, filtering to obtain a filtered matter, washing with a hydrochloric acid solution and distilled water, drying, mixing and grinding with graphene, conducting cold drawing to obtain a compound superconductor wire rod, and keeping heat in the xenon condition so as to prepare the compound MgB2 superconductor. The method has the benefits that the preparation steps are simple, the effective pinning center of the superconductor is effectively improved, the critical current density is increased by 12-16%, and the purity is increased by 25.6% or above; the fragility of the obtained product is less, the MgB2 core wire has no crack in the production process, and the material performance is good.

Owner:陈建峰

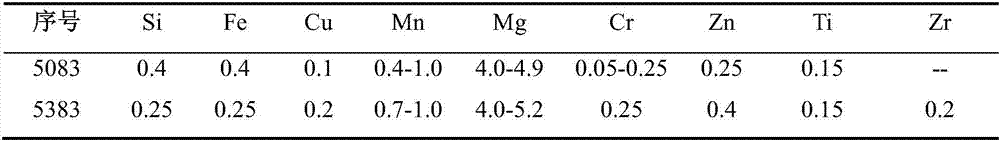

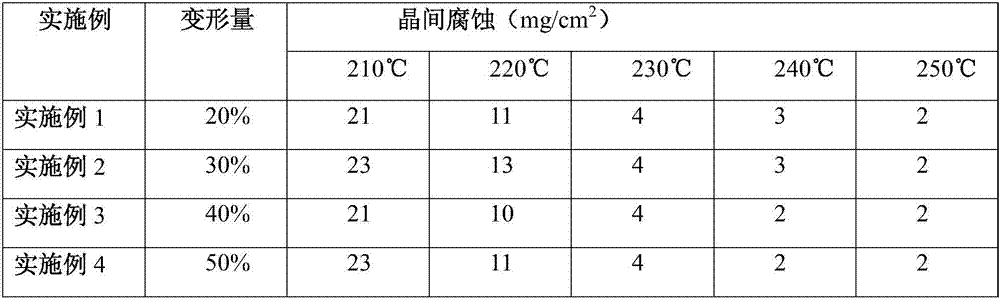

Stabilization technology for 5383 aluminum alloy

InactiveCN107475648AHigh strengthRaise the recrystallization temperatureUltimate tensile strengthDislocation

The invention belongs to the technical field of aluminum alloys, and relates to a stabilization technology for a 5383 aluminum alloy. On the basis of components of a 5083 alloy, the Zr element is added and can be combined with the Al element to form an Al3Zr phase, the dislocation, subboundary and grain boundary in the 5383 aluminum alloy can be effectively pinned through the Al3Zr phase, and accordingly the strength and the recrystallization temperature of the 5383 aluminum alloy are obviously increased. 5383 aluminum alloy panels with the thickness being 6 mm are subjected to cold rolling, cold rolling is conducted to 4.8 mm, 4.2 mm, 3.6 mm and 3.0 mm, the deformations of the 5383 aluminum alloy panels are 20%, 30%, 40% and 50%, the deformed 5383 aluminum alloy panels are annealed for 2 hours at the temperatures of 210 DEG C, 220 DEG C, 230 DEG C, 240 DEG C and 250 DEG C, then, the mechanical performance and corrosion resistance of the aluminum alloy panels with different deformations and at different annealing temperatures are tested, and the technology in which the cold rolling deformation ranges from 30% to 50% and the annealing temperature ranges from 230 DEG C to 250 DEG C is selected as the optimal stabilization technology.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

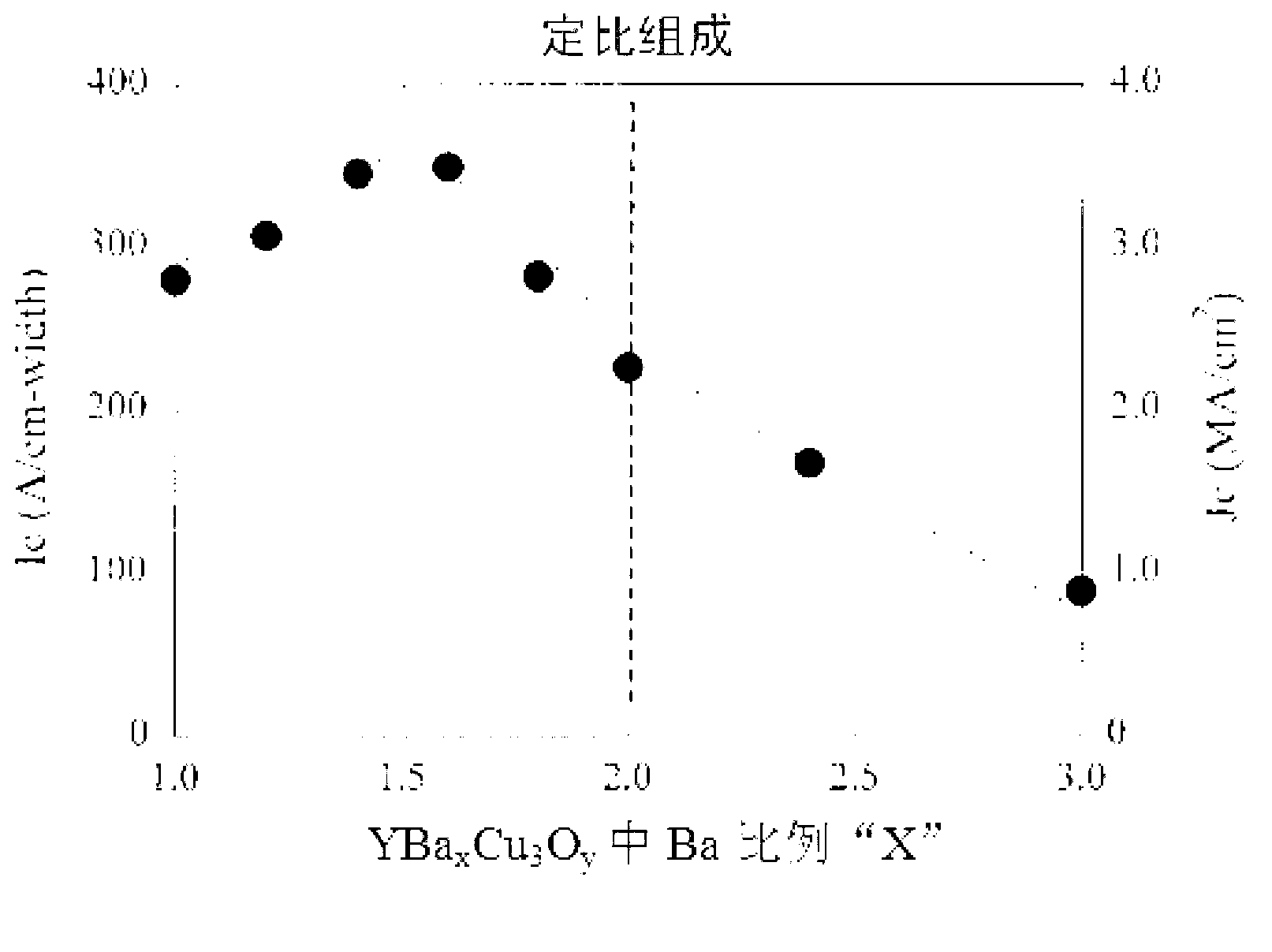

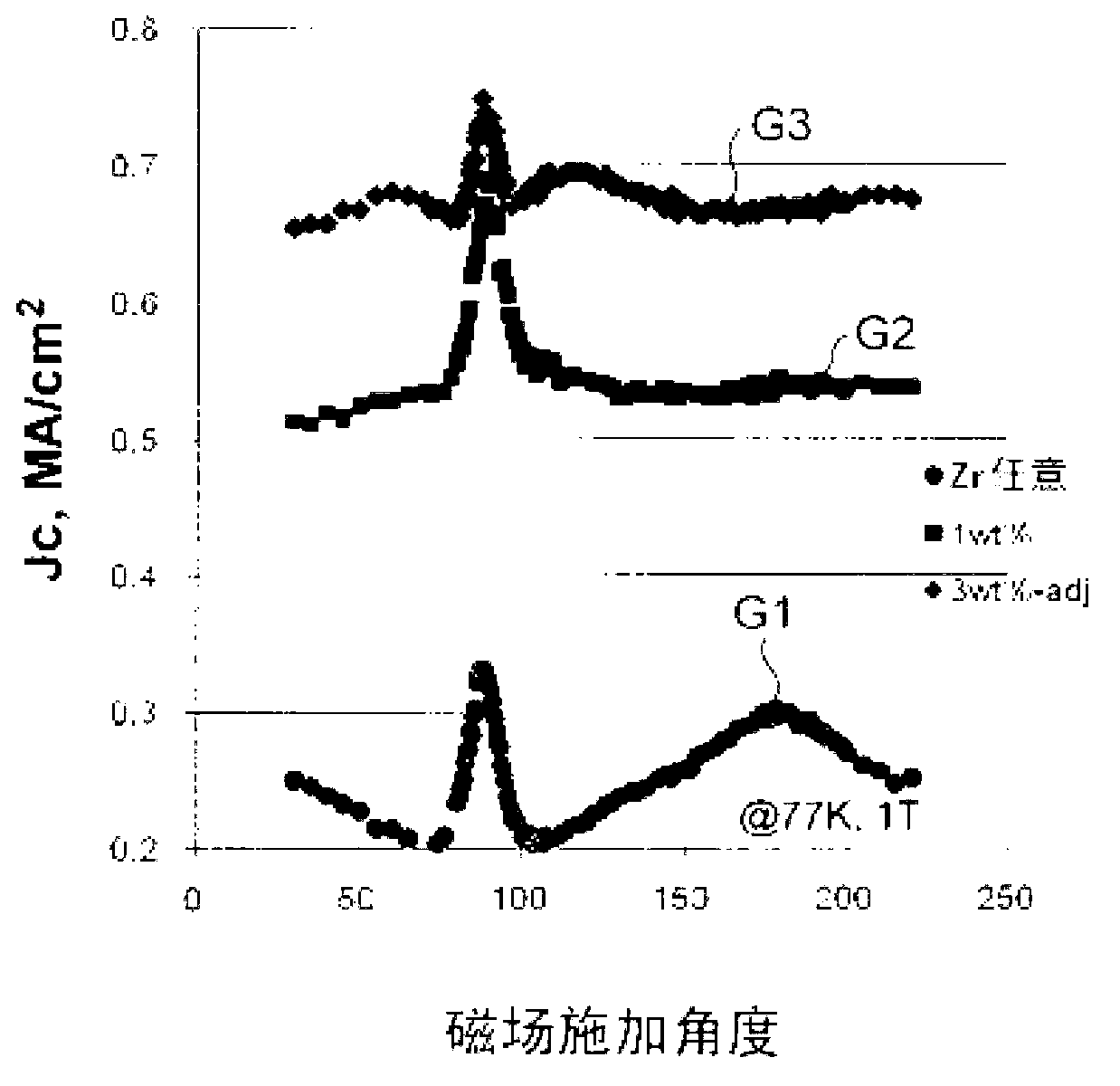

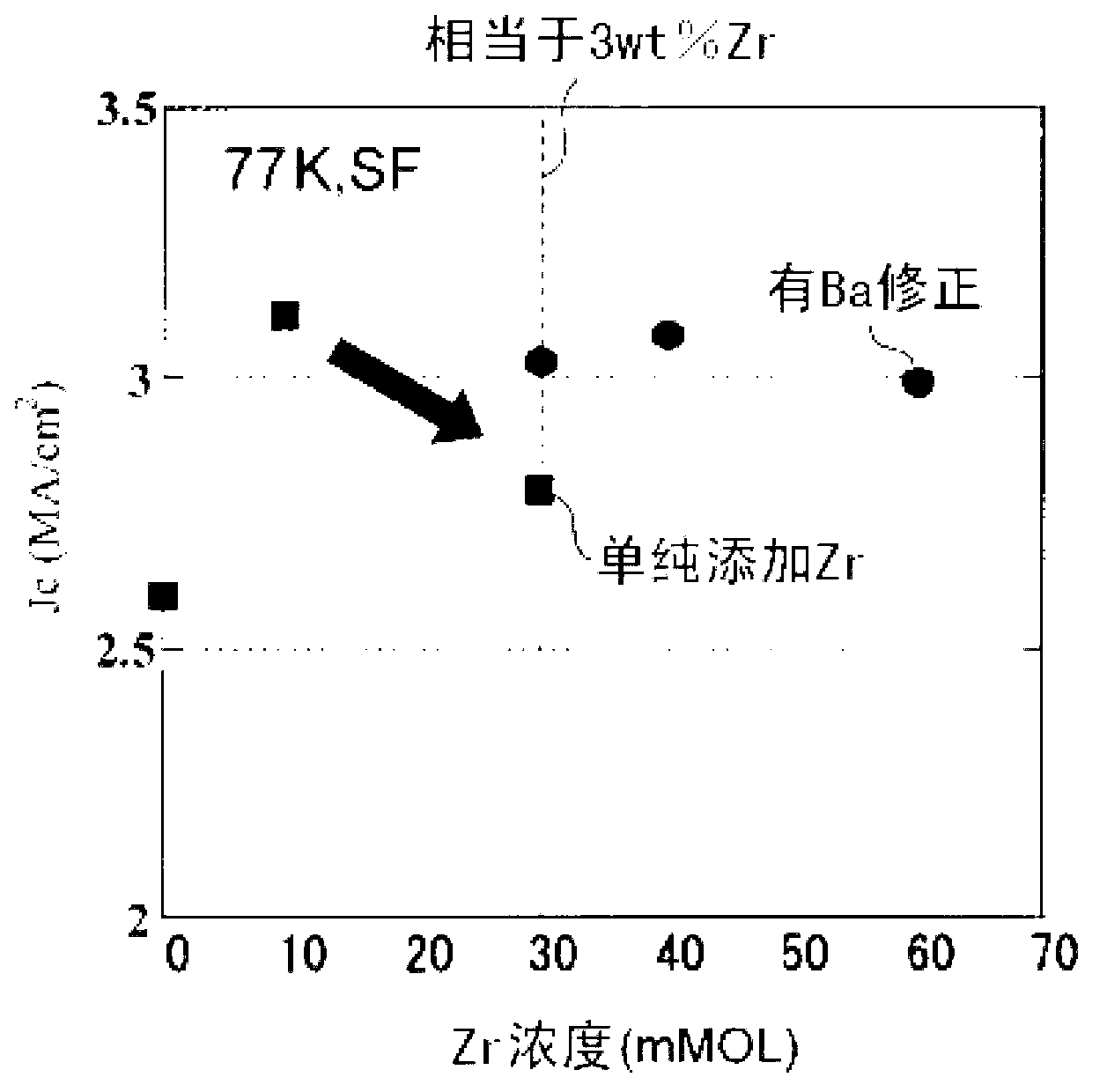

Oxide superconductivity wire material and method of manufacturing thereof

InactiveCN103189934AEffective pinningImproved superconductivitySuperconductors/hyperconductorsSuperconductor devicesMagnetic fluxMetal substrate

Provided is an oxide superconducting wire material, wherein pinning of magnetic flux, under an environment in which magnetic field is applied, can be conducted efficiently towards any magnetic-field applying angle direction, to secure a high superconductive property. The oxide superconducting wire material (100) is provided with a metal substrate (110), an intermediate layer (120) formed upon the metal substrate (110), and a REBaCuO-system superconductive layer (140) formed upon the intermediate layer (120). RE comprises one or more elements selected from Y, Nd, Sm, Eu, Gd, and Ho. Oxide particles including Zr are distributed within the superconductive layer (140) as magnetic-flux pinning points (145), and the mole ratio (y) of Ba included within the superconductive layer (140) is, when the mole ratio of Zr is assumed to be x, within a range of (1.2+ax)@y@(1.8+ax), wherein 0.5@a@2.

Owner:SWCC SHOWA CABLE SYST CO LTD +1

Low-cost X80 straight seam welded pipe and manufacturing method thereof

ActiveCN105779904AWork hardening effect is obviousReduce manufacturing costLaminar coolingLower grade

The invention discloses a low-cost X80 straight seam welded pipe and a manufacturing method thereof. Chemical components of the low-cost X80 straight seam welded pipe include, by weight percent, 0.039%-0.079% of C, 0.16%-0.26% of Si, 1.33%-1.83% of Mn, smaller than or equal to 0.017% of P, smaller than or equal to 0.0046% of S, 0.14%-0.24% of Cr, 0.019%-0.059% of Nb, 0.019%-0.039% of V, 0.0051-0.028% of Ti, 0.011%-0.057% of Al, 0.13%-0.28% of Ni and the balance Fe and a trace of inevitable impurities. According to technological characteristics, the soaking temperature ranges from 1120 DEG C to 1220 DEG C, two-stage control rolling is adopted, and the rolling temperature in a recrystallization area ranges from 950 DEG C to 1200 DEG C; second-stage rolling is conducted in a non-recrystallization area, and the air cooling ending temperature ranges from 650 DEG C to 750 DEG C; and the laminar cooling speed ranges from 5 DEG C / s to 25 DEG C / s, JCO or UO is adopted for pipe manufacturing, the expanding rage e is larger than or equal to t / D, and the maximum value of the expanding rate is 2.5%. The low-cost X80 straight seam welded pipe and the manufacturing method thereof have the beneficial effects that a low-grade steel plate is used for manufacturing the high-grade X80 straight seam submerged arc welding pipe, strength and plasticity indexes are good, and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

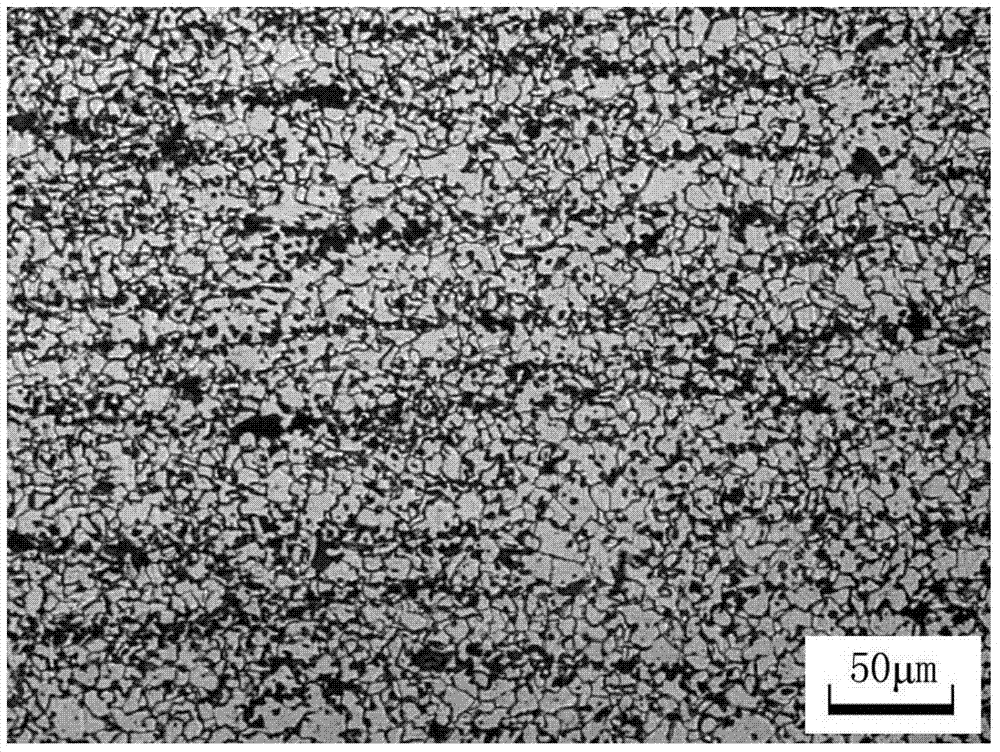

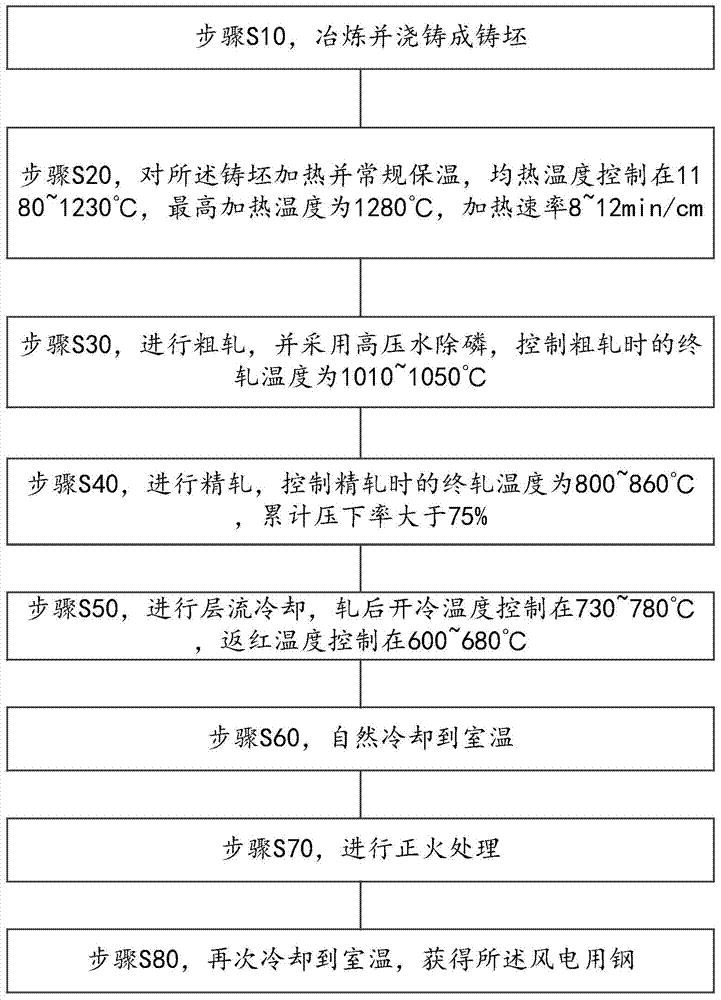

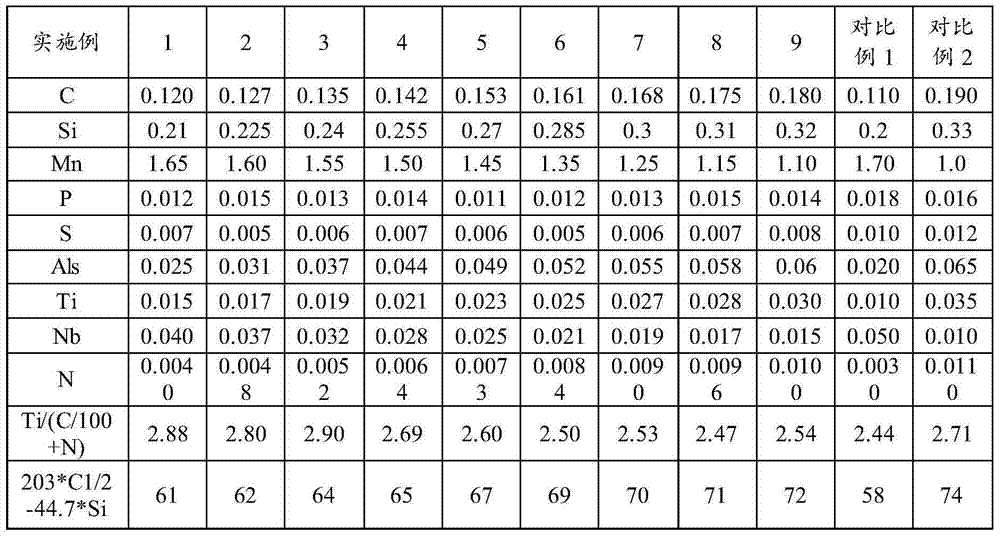

Normalized steel plate for wind power, and production method thereof

The invention discloses a normalized steel plate for wind power, and a production method thereof. The yield strength, the tensile strength, the elongation percentage A, the -40DEG C impact energy and the -60DEG C impact energy of the normalized steel plate for wind power are not lower than 370MPa, 500-650MPa, not lower than 30%, not lower than 250J and not lower than 200J respectively. The steel plate comprises, by mass, 0.12-0.18% of C, 0.21-0.32% of Si, 1.10-1.65% of Mn, 0.015% or less of P, 0.008% or less of S, 0.015-0.040% of Nb, 0.015-0.03% of Ti, 0.025-0.06% of Als, 0.004-0.010% of N, and the balance of Fe and inevitable impurities; and 203*C<1 / 2>-44.7*Si is not lower than 61 and not greater than 72, and Ti / (C / 100+N) is in a range of 2.47-2.69 or 2.88-2.90. Nb and Ti alloy is used in the steel plate, so alloy cost of the steel plate is reduced, the low temperature performances of the steel plate are enhanced, the yield strength is high, and the technical problems of high alloy cost, poor low temperature performances and small normalized yield strength of steel plates for wind power in the prior art are solved.

Owner:武汉钢铁有限公司

Composite cored wire composed of solid calcium metal, silicon iron and titanium-silicon nitride alloy containing rare earth, barium and molybdenum

The invention relates to an alloy cored wire, in particular to a composite cored wire composed of solid calcium metal, silicon iron and titanium-silicon nitride alloy containing rare earth, barium and molybdenum. The cored wire comprises a core layer and a steel sheet layer wrapping the core layer. A meshed supporting layer made of steel or iron is arranged between the core layer and the steel sheet layer. The core layer comprises a silicon iron and titanium-silicon nitride alloy powder layer, a middle protecting layer and a solid calcium metal wire, wherein the solid calcium metal wire is wrapped with the middle protecting layer; the silicon iron and titanium-silicon nitride alloy powder layer wraps the middle protecting layer and is composed of silicon iron powder and titanium-silicon nitride alloy powder containing rare earth, barium and molybdenum; the particle size of the silicon iron powder and the particle size of the titanium-silicon nitride alloy powder are both below 3 mm; and the mass ratio of the solid calcium metal wire to the silicon iron powder to the titanium-silicon nitride alloy powder containing rare earth, barium and molybdenum is 1:(1-2):(2-5). Compared with a conventional calcium metal wire, the composite cored wire has the advantages of being higher in yield, longer in preservation time and more stable in yield, and also has significant economic benefits.

Owner:浙江宝信炉料股份有限公司

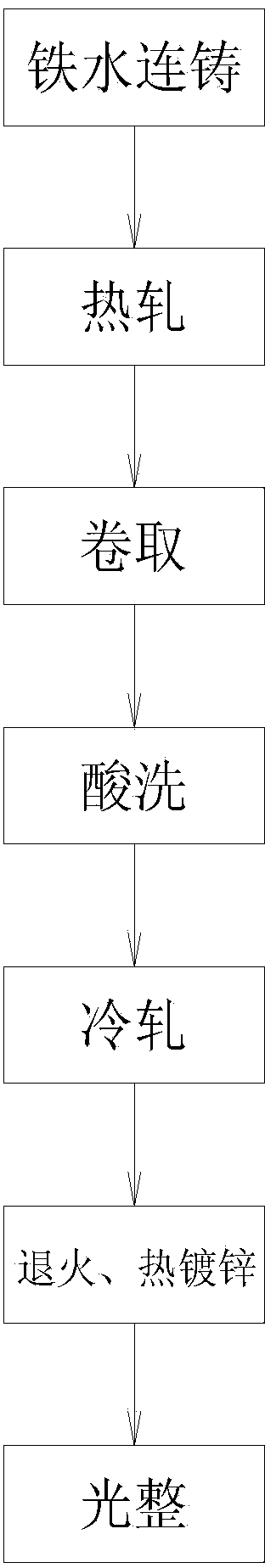

High-yield-ratio hot-galvanized micro-carbo/aluminum killed steel plate and production method thereof

InactiveCN104046890AEffective pinningHigh yield strengthHot-dipping/immersion processesSheet steelContinuous annealing

The invention relates to a high-yield-ratio hot-galvanized micro-carbo / aluminum killed steel plate and a production method thereof. The method comprises the following steps: carrying out desulphurization, bessemerizing, RH vacuum refining and continuous casting on molten iron so as to obtain a continuous casting sheet billet; carrying out hot rolling on the continuous casting sheet billet so as to obtain a hot rolled sheet billet; rolling the hot rolled sheet billet so as to obtain hot-rolled steel coil; carrying out uncoiling and acid pickling on the hot-rolled steel coil; carrying out cold rolling on the hot-rolled steel coil subjected to acid pickling so as to obtain a cold-rolled steel plate; carrying out annealing and hot galvanizing on the cold-rolled steel plate in a continuous annealing furnace; and carrying out finishing processing on the annealed cold-rolled steel plate. The high-yield-ratio hot-galvanized micro-carbo / aluminum killed steel plate produced according to the method has good forming properties and mechanical properties, and can satisfy the requirements of cargo trucks on the stamping formability of steel plates.

Owner:SHOUGANG CORPORATION

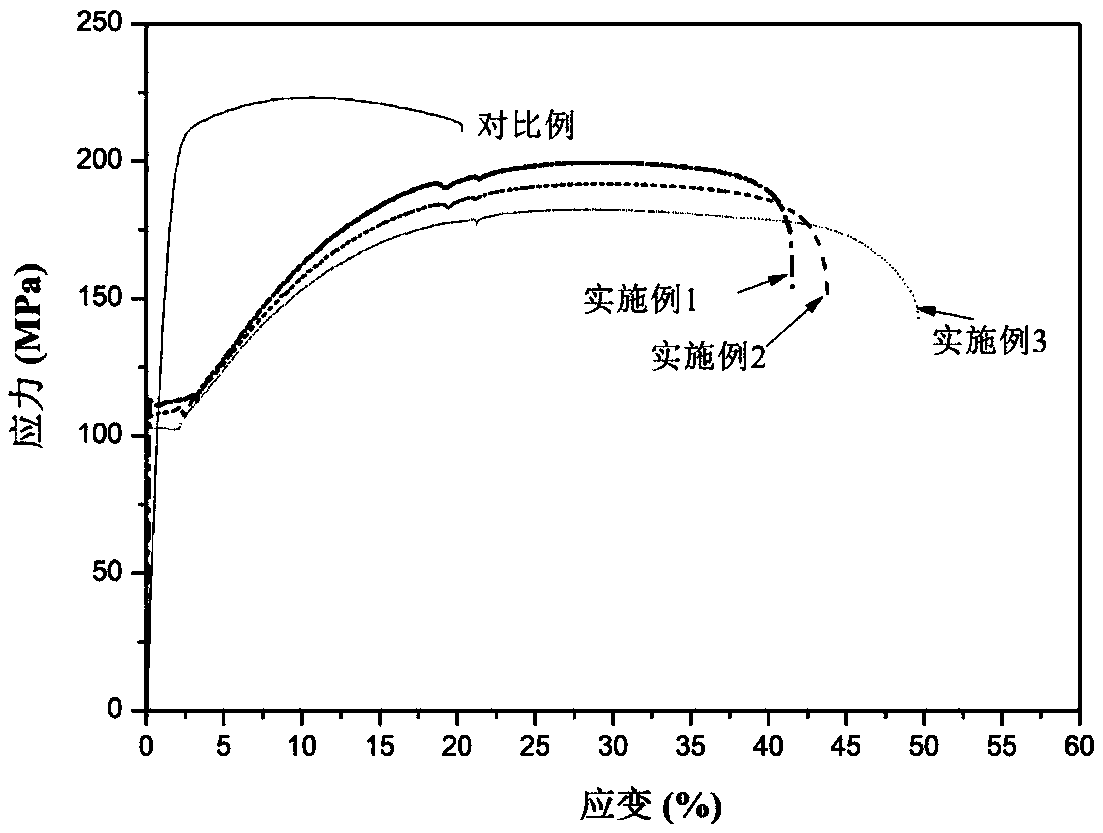

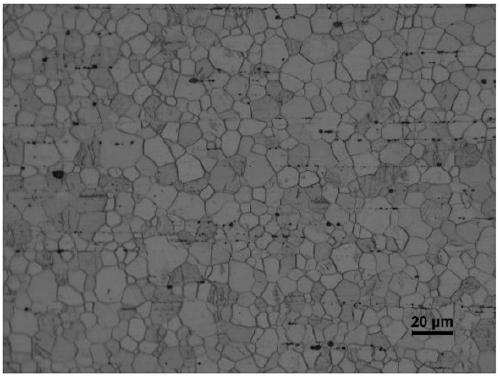

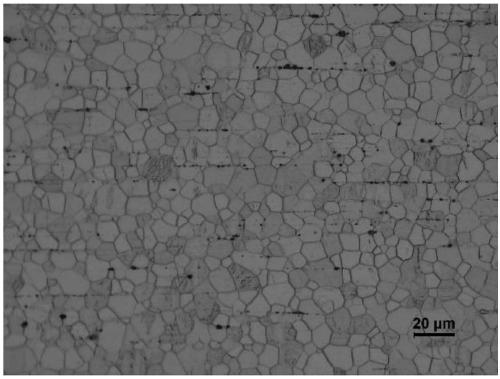

High-plasticity magnesium alloy and preparation method thereof

ActiveCN109402429AImprove flame retardant performanceGood plasticity at room temperatureChemical compositionRoom temperature

The invention relates to high-plasticity magnesium alloy and a preparation method thereof. The alloy is Mg-Bi-Nd-Mn magnesium alloy, and comprises the following chemical components in percentages by mass: 2-8 wt% of Bi, 1.5-4 wt% of Nd, 0.05-0.15 wt% of Mn, and the balance of Mg and inevitable impurities, and moreover, the mass ratio of Bi to Nd equals to 1.3-2: 1. The process is simple, the plasticity of deformed magnesium alloy at the room temperature is excellent, the ductility at the room temperature reaches 43% or above, and meanwhile, the flame retardant property is good.

Owner:HEBEI UNIV OF TECH

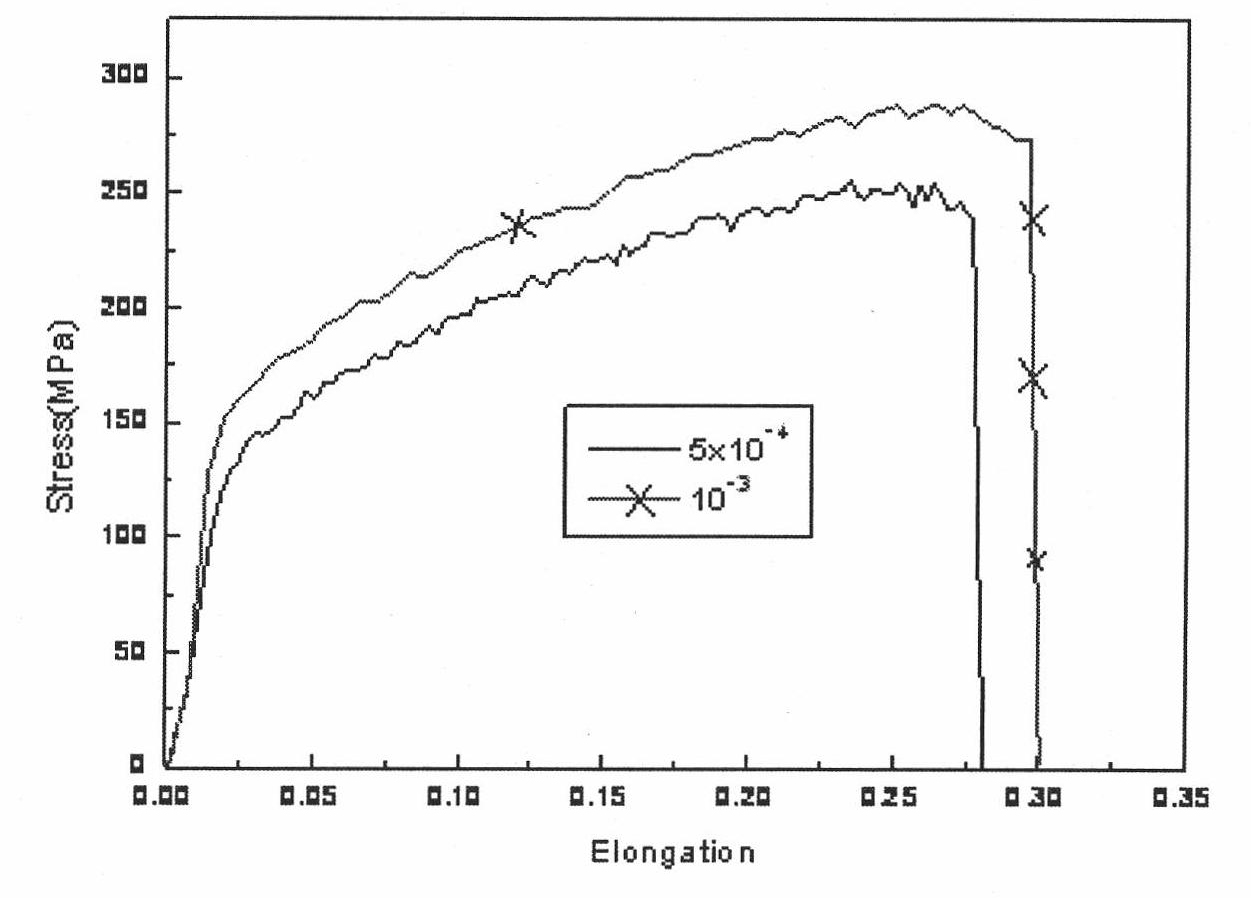

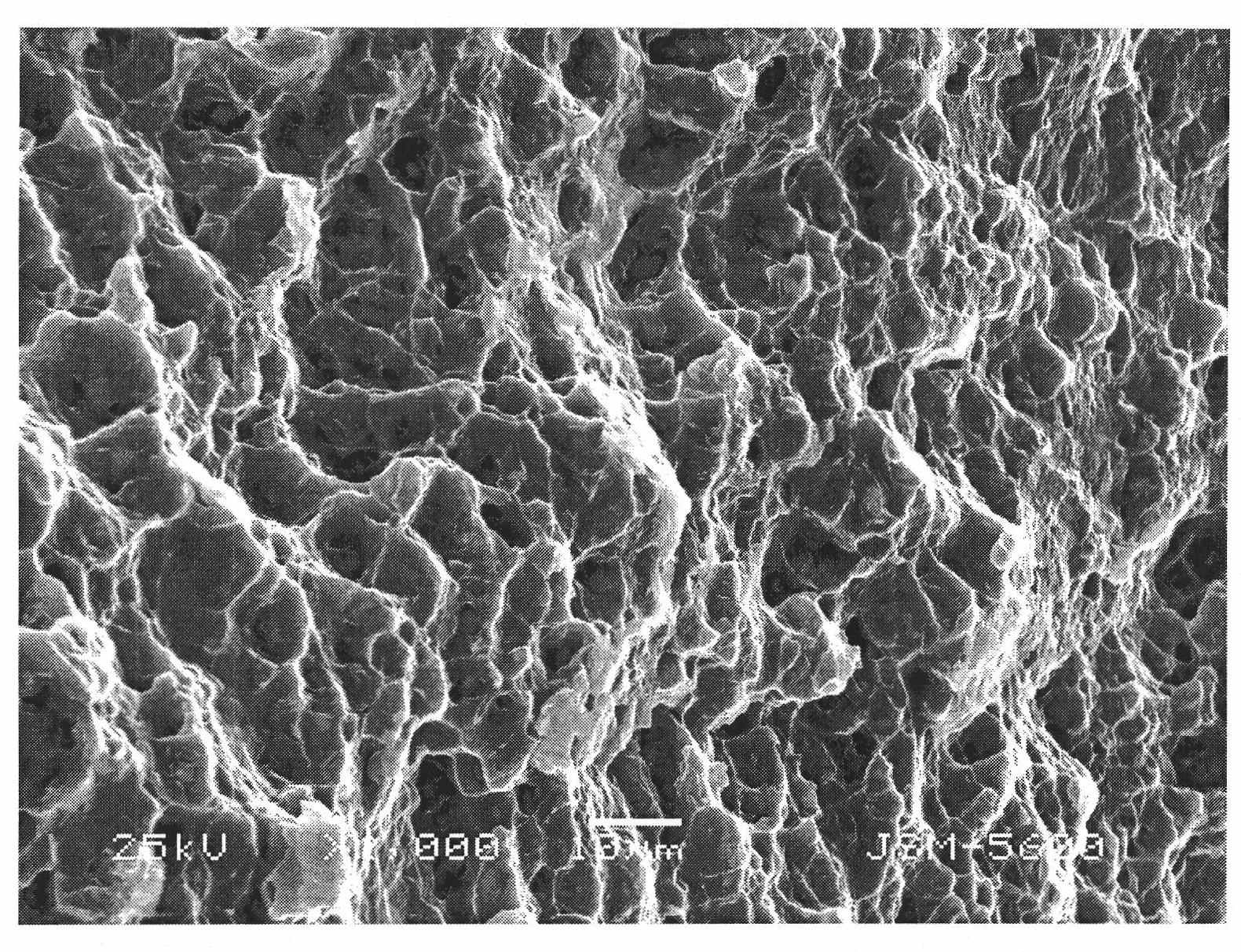

Production method of heavy plate of X80 level large-deformation resistance pipe line steel

InactiveCN101456034BReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

Adjusting and controlling method for orientation of precipitation phase in magnesium alloy

The invention belongs to the field of metal processing reinforcement, and relates to an adjusting and controlling method for orientation of precipitation phase in magnesium alloy. The adjusting and controlling method comprises the main process steps of 1, the solid-soluble treatment of magnesium alloy ingots; 2, magnesium alloy hot extrusion into rod; 3, stress aging extending rod preparing and stress relief annealing conducting; and 4, stress aging treatment. By means of the adjusting and controlling method, the pull stress along the c axis of a crystal or the pressure stress perpendicular tothe c axis of the crystal is applied in the aging process, the size of stress is 60-80% of the yield strength at the corresponding aging temperature, the solute atom forms a cylinder precipitate phase during precipitation, the misalignment of the substrate is pinned more effectively, and the mechanical properties of the magnesium alloy is improved; and the adjusting and controlling method is simple in operating step, significant in effect and more suitable for large-scale industrial production.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

High-strength, high-conductivity, heat-resistant aluminum alloy wire with large rare earth content and preparation method thereof

ActiveCN108220693BEffective pinningInhibit recrystallization softeningConductive materialMetal/alloy conductorsHeat resistanceRare earth

The invention provides a high-rare-earth-content high-intensity heat-resistance aluminum alloy conducting wire and a preparation method thereof. The conducting wire is prepared from the following elements in percentage by weight: 0.1 to 2 percent of Zr, 2 to 5 percent of La, 2 to 6 percent of Ce, 2 to 6 percent of Y, 0.05 to 0.20 percent of Fe, 0.05 to 0.10 percent of Si, smaller than or equal to0.10 percent of other impurity elements and the balance of aluminum. The invention also provides the preparation method of the conducting wire. The tensile intensity of the heat-resistance aluminum alloy conducting wire reaches 320 MPa; the conductivity can reach 60-percent IACS; the long-time operation temperature can reach 300 DEG C; the conducting wire can withstand the 1h heating checking operation at 280 DEG C; the intensity ascends instead of descending. After the 1h heating checking operation at 400 DEG C, the intensity residue rate reaches higher than 97 percent.

Owner:SHANGHAI JIAOTONG UNIV +1

Method for improving steel plate heat-affected zone toughness of steel plate under high input energy welding condition

The invention pertaining to the technical field of high-strength steel plates for welding provides a method of improving the heat-affected zone toughness of a steel plate under a large heat input welding condition.CGHAZ toughness of a steel plate under a large heat input welding condition is improved on the basis of a CaO-MnS mechanism.HAZ toughness can be improved effectively by adding Ca into C-Mn steel, wherein, the Ca performs deoxidization through a gas-liquid interface for generating reactions of [Ca]+[O]=(CaO) and [Ca]+[S]=(CaS); fine dispersed nano-scale mass points of CaO and CaS areformed, MnS adheres to the mass points go grow to form a rotundity shape, and when the Ca content achieves to 50-60ppm, the HAZ toughness can be improved effectively.The invention has advantages of effective austenite grain boundary forming by nails, grains being fined and the CGHAZ toughness being improved.

Owner:SHOUGANG CORPORATION

Fine grain, high strength and deformed magnesium alloy material

The present invention provides a high-strength deformation magnesium alloy material having a stable fine-grained structure. The alloy comprises the following components by weight: zincium of 8.5%-9.5%, zirconium of 0.4%-0.8%, rare earth erbium of 0.4%-4.0% and magnesium and ineluctable foreign matters of the rest.Without applying especial processes such as equidistant channel extrusion pressing, fast cooling and the like, stable fine grain tissue of a size of 2-10mum can be obtained through a deformation process by a deformation apparatus of extrusion pressing, rolling, smithing and the like in the common industry, mechanical performances guidelines of materials such as strength, plastic property, work hardening index and the like can be adjusted effectively to satisfy the requirements of use characteristic and processability of finished products or half-finished products.

Owner:CHONGQING UNIV

Solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn

The invention relates to alloy core spun yarn, in particular to solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn. The solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn comprises a core layer and a sheet steel layer wrapping the outside of the core layer; a netlike supporting layer made of steel or iron is arranged between the core layer and the sheet steel layer; the core layer comprises a ferrosilicon and titanium-silicon nitride alloy powder layer, a middle protection layer and a solid calcium metal line; the solid calcium metal line is wrapped with the middle protection layer; the ferrosilicon and titanium-silicon nitride alloy powder layer wraps the middle protection layer and is composed of ferrosilicon powder and titanium-silicon nitride alloy powder of which the particle sizes are 3 mm or smaller; and the mass ratio of the solid calcium metal line to the ferrosilicon power to the titanium-silicon nitride alloy powder is 1:(1-2):(2-5). Compared with common solid calcium metal lines, the solid calcium metal, ferrosilicon and titanium-silicon nitride alloy powder composite core spun yarn has the advantages that the yield is higher, the preservation time is longer, the yield is more stable, and remarkable economic benefits are achieved.

Owner:浙江宝信炉料股份有限公司

Titanium-silicon nitride alloy cored wire

The invention relates to an alloy cored wire and particularly relates to a titanium-silicon nitride alloy cored wire comprises a core layer and a steel sheet layer wrapped outside the core layer, wherein the core layer is made of titanium-silicon nitride alloy powder with particle size being smaller than 3mm; a net-shaped support layer made of steel or iron is arranged between the core layer and the steel sheet layer; the titanium-silicon nitride alloy powder is prepared from elements in percentage by mass. According to the titanium-silicon nitride alloy cored wire, the alloy powder is added into micro-alloyed steel by a method using the cored wire, so that the problem of low recovery rate can be solved; consumption of ferrosilicon and ferromanganese can also be reduced; the application of titanium-silicon nitride and cored wire alloys thereof can be developed; the titanium-silicon nitride alloy cored wire has remarkable economic benefit.

Owner:浙江宝信炉料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com