Strain design based pipe line steel X70 and its manufacturing method

A technology of pipeline steel and manufacturing method, applied in the direction of temperature control, can solve problems such as 0.85 or more, some even reach 0.92, not suitable for cost-effective pipeline steel, unable to meet material selection standards, etc., and achieve good toughness and high strain. Hardening index, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with specific embodiment the present invention is further described:

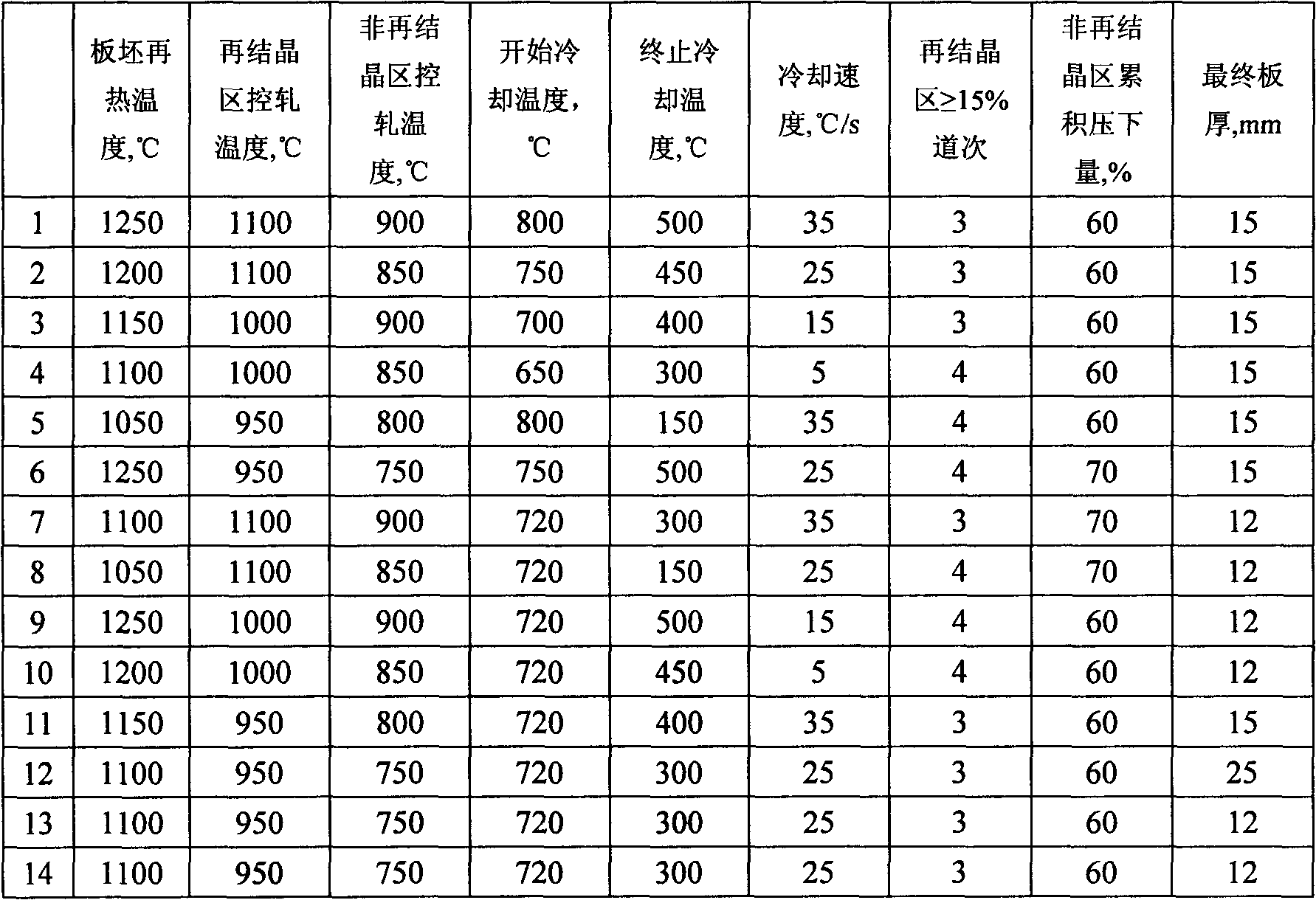

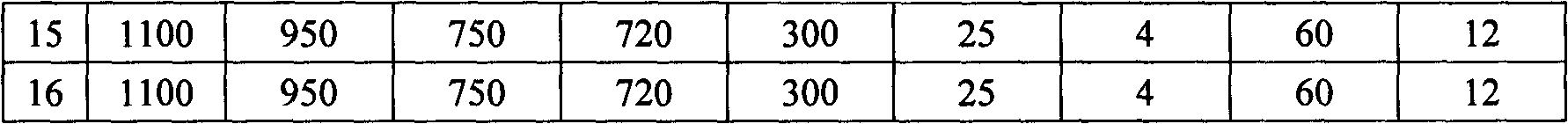

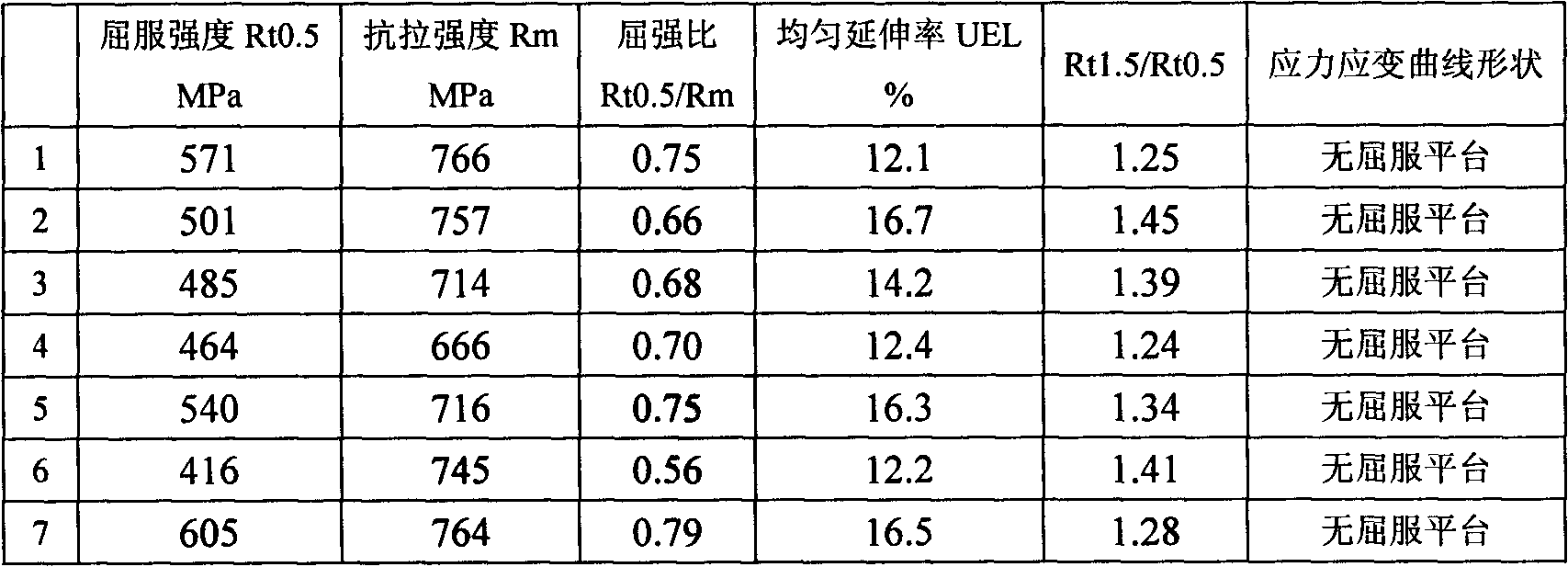

[0044] The chemical composition, process parameters and performance results of Examples 1-12 and Comparative Examples 13-16 are shown in Table 1-4.

[0045] 1. Chemical composition

[0046] The chemical compositions (wt%) of Examples 1-12 and Comparative Examples 13-16 are shown in Table 1.

[0047] Table 1 chemical composition (wt%)

[0048]

C

Si

mn

P

S

Ti

Nb

Cu

Ni

Cr

Mo

Al

1

0.06

0.33

1.68

0.01

0.003

0.017

0.03

0.24

0.23

0.09

0.05

0.04

2

0.06

0.26

1.64

0.01

0.003

0.012

0.04

0.15

0.15

0.09

0.09

0.03

3

0.07

0.42

1.55

0.01

0.003

0.015

0.03

0

0.45

0.05

0.05

0.03

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com