Patents

Literature

252results about How to "Reduce plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

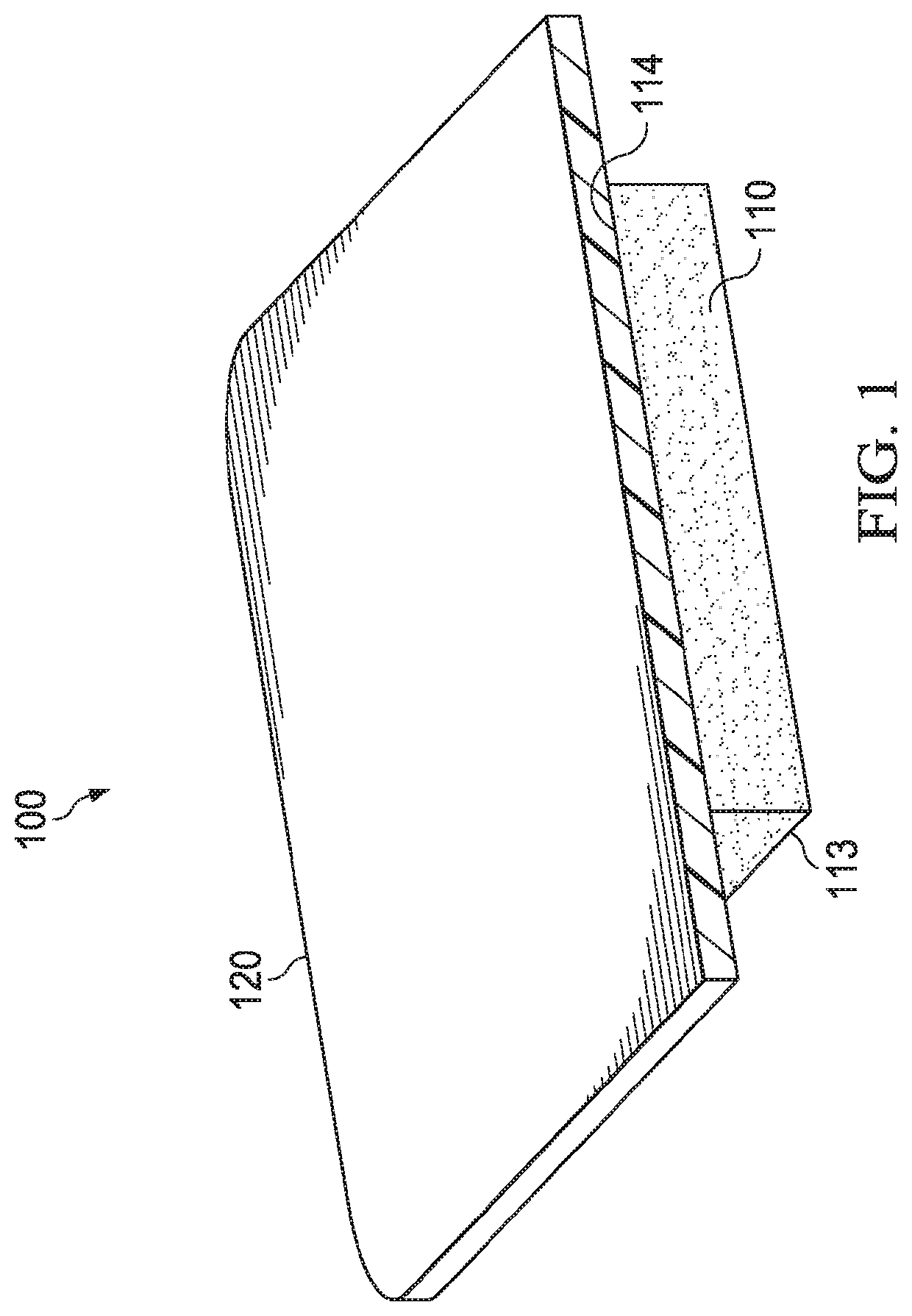

Magnetic recording medium and method of manufacturing the same

ActiveUS20130260179A1Excellent characteristicsImprove running stabilityRecord information storageCoating by liquid dispersionNon magneticMaterials science

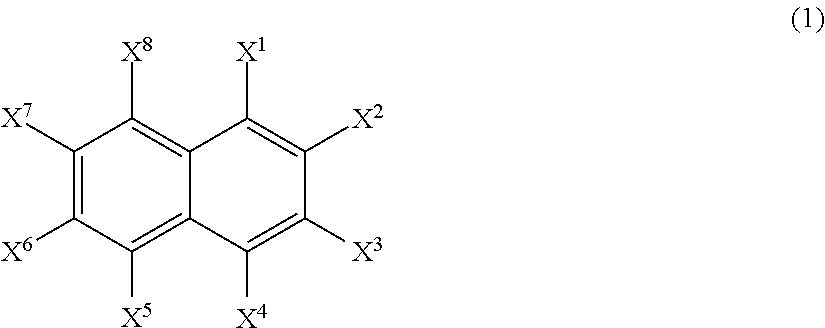

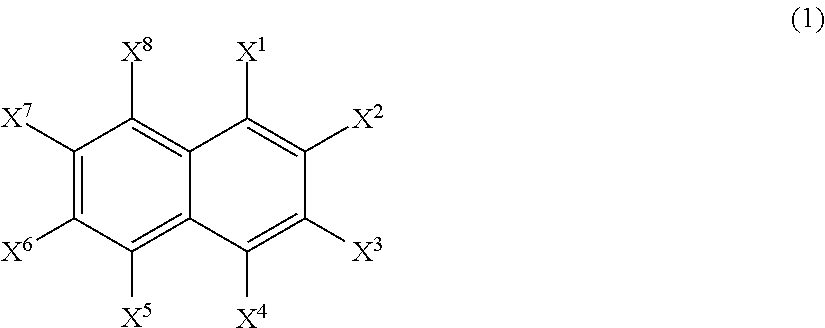

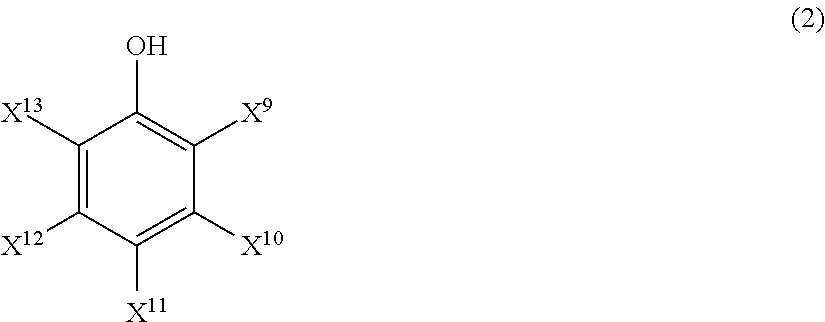

An aspect of the present invention relates to a magnetic recording medium, which comprises a nonmagnetic layer containing a nonmagnetic powder and a binder and a magnetic layer containing a ferromagnetic powder and a binder in this order on a nonmagnetic support, wherein the nonmagnetic layer has a thickness of equal to or less than 300 nm; a composite elastic modulus as measured on a surface of the magnetic layer ranges from 6.0 to 8.0 GPa; the magnetic layer comprises an abrasive with a specific surface area by BET method ranging from 14 m2 / g to 40 m2 / g; and a surface abrasive occupancy on a surface of the magnetic layer ranges from 0.2% to 2%.

Owner:FUJIFILM CORP

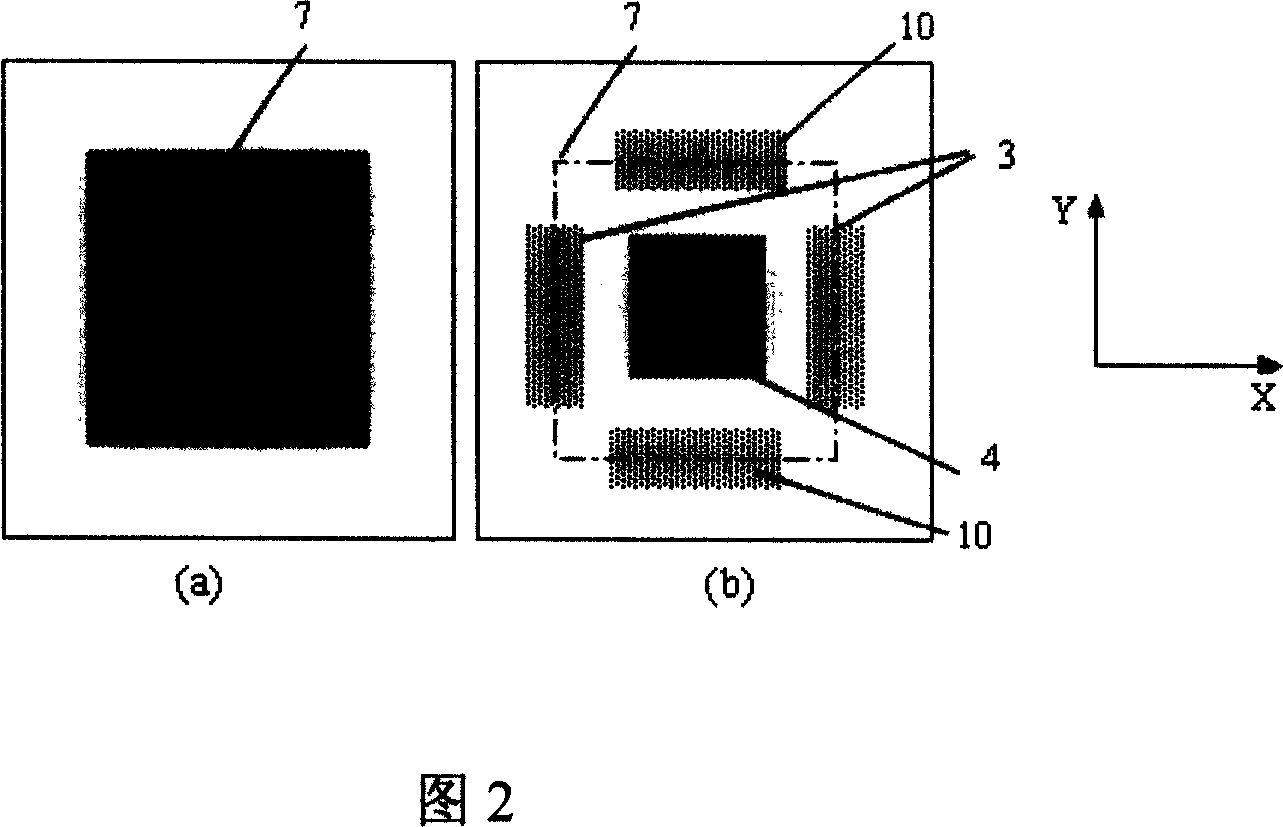

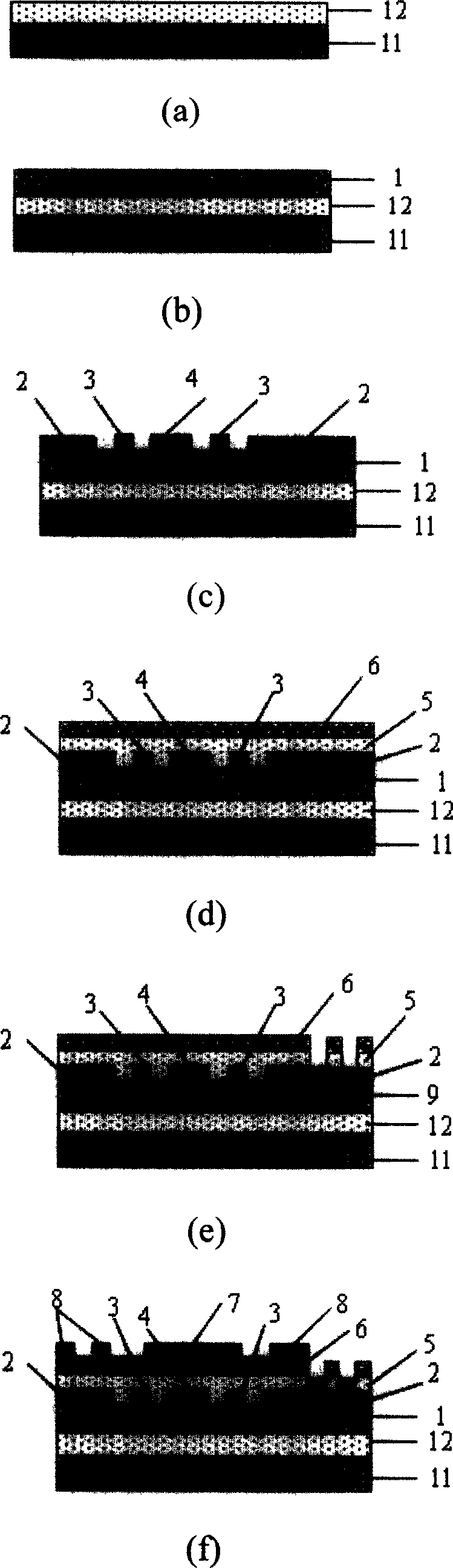

Flexible capacitance type touch sensor production method

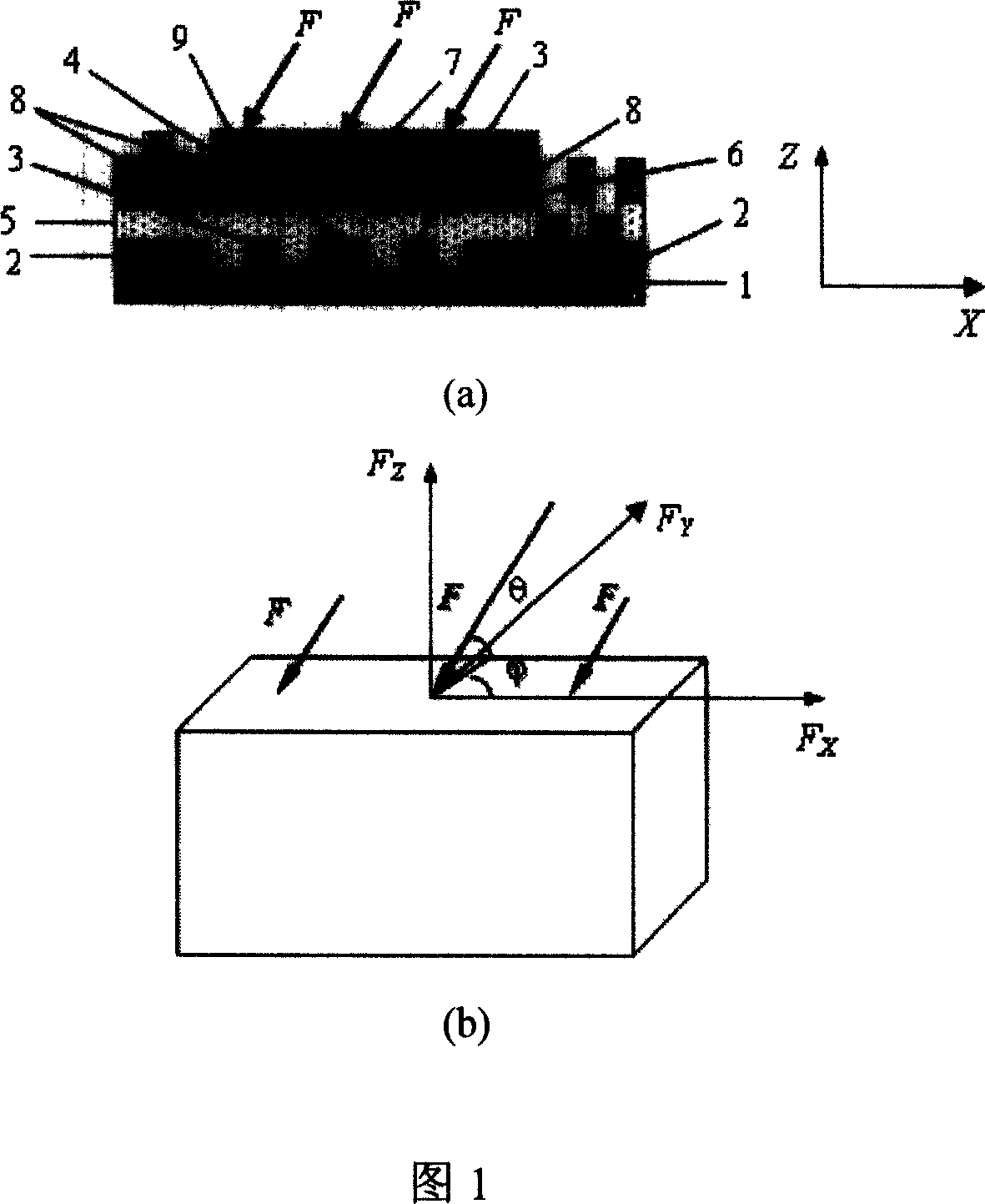

InactiveCN101059380ALow costImprove yieldSemi-permeable membranesForce measurementElectricitySensor array

The invention relates to a method for producing flexible capacitor touch sensor, characterized in composed of middle layer preparation of PDMS, preparation of flexible PI substrate, graph metal sensitive electrode and relative electric connection, preparation of a first high-elasticity dielectric layer PDMS and a second flexible dielectric layer PI, graph metal drive electrode and relative electric connection, graph a top flexible insulation protective layer PI, separation of the flexible capacitor touch sensor. The invention optimizes and combines techniques, to realize the compatibility of organic flexible material PDMS, PI and traditional MEMS technique. And the capacitor touch sensor has compact structure, high mechanical strength, and high flexibility, while the product can contact the surface with any curvature to sense the volumes of normal force and tangent force, and be applied for the production of flexile capacitor touch sensor array.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

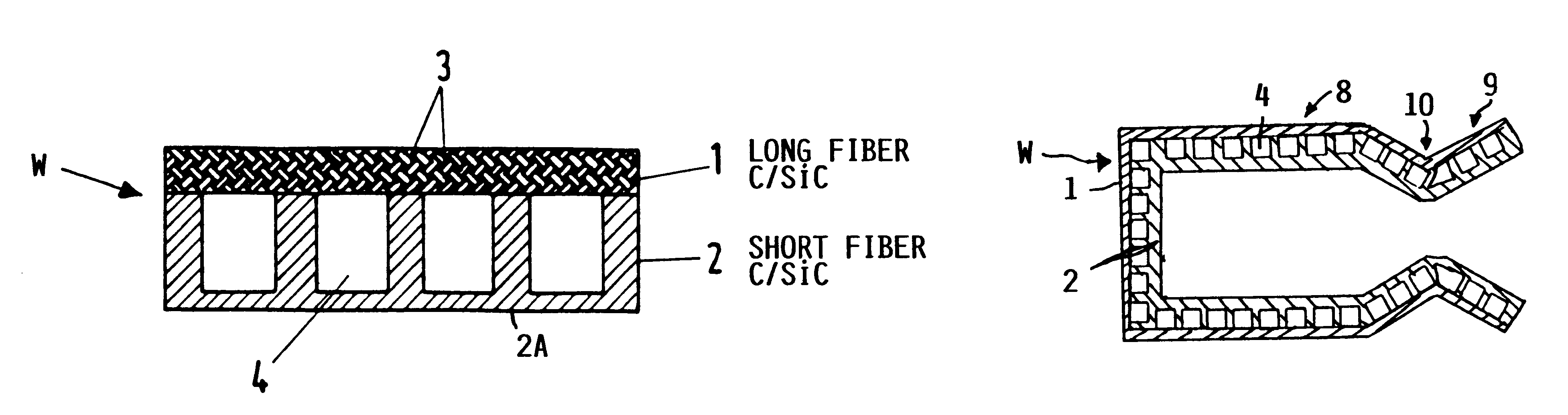

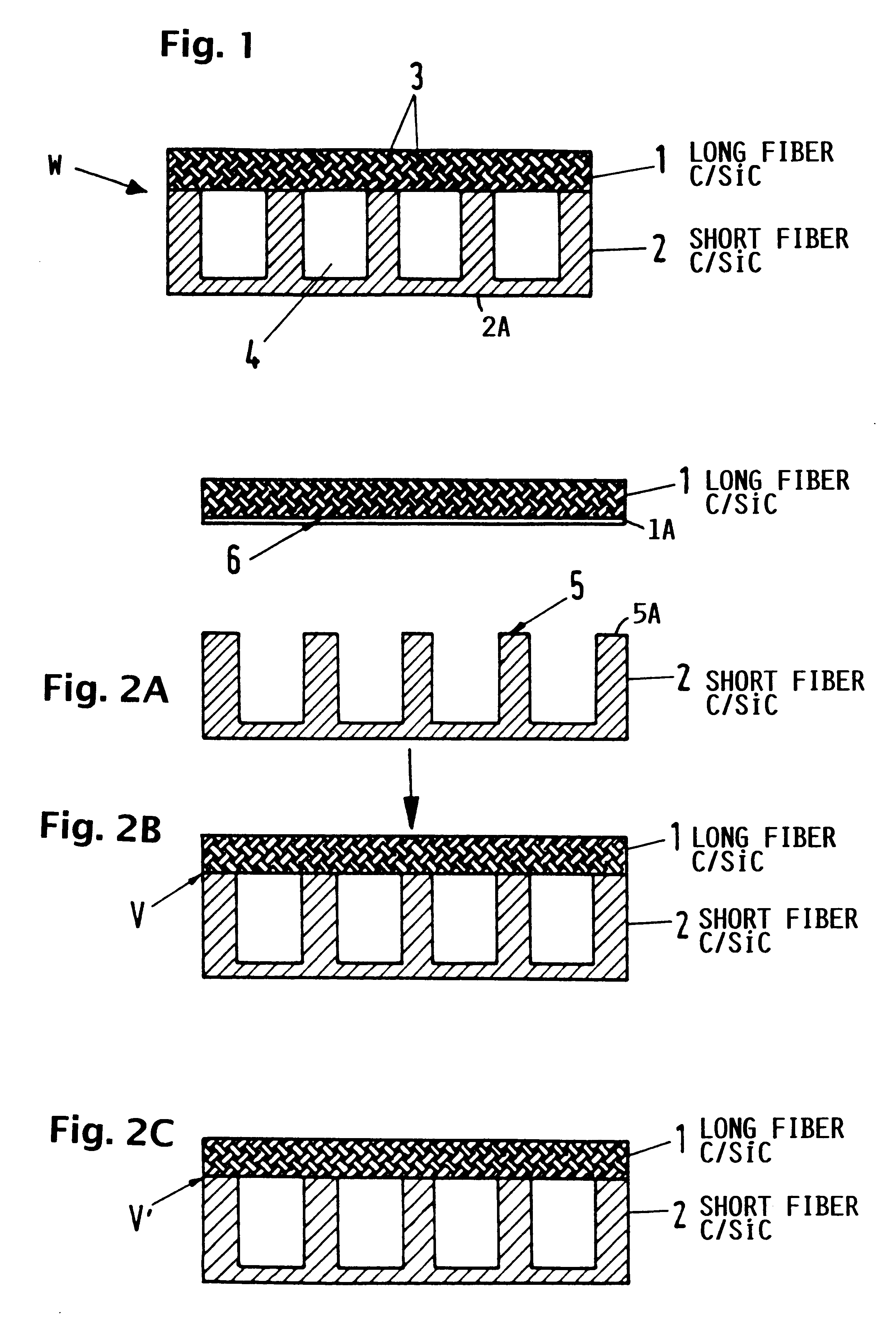

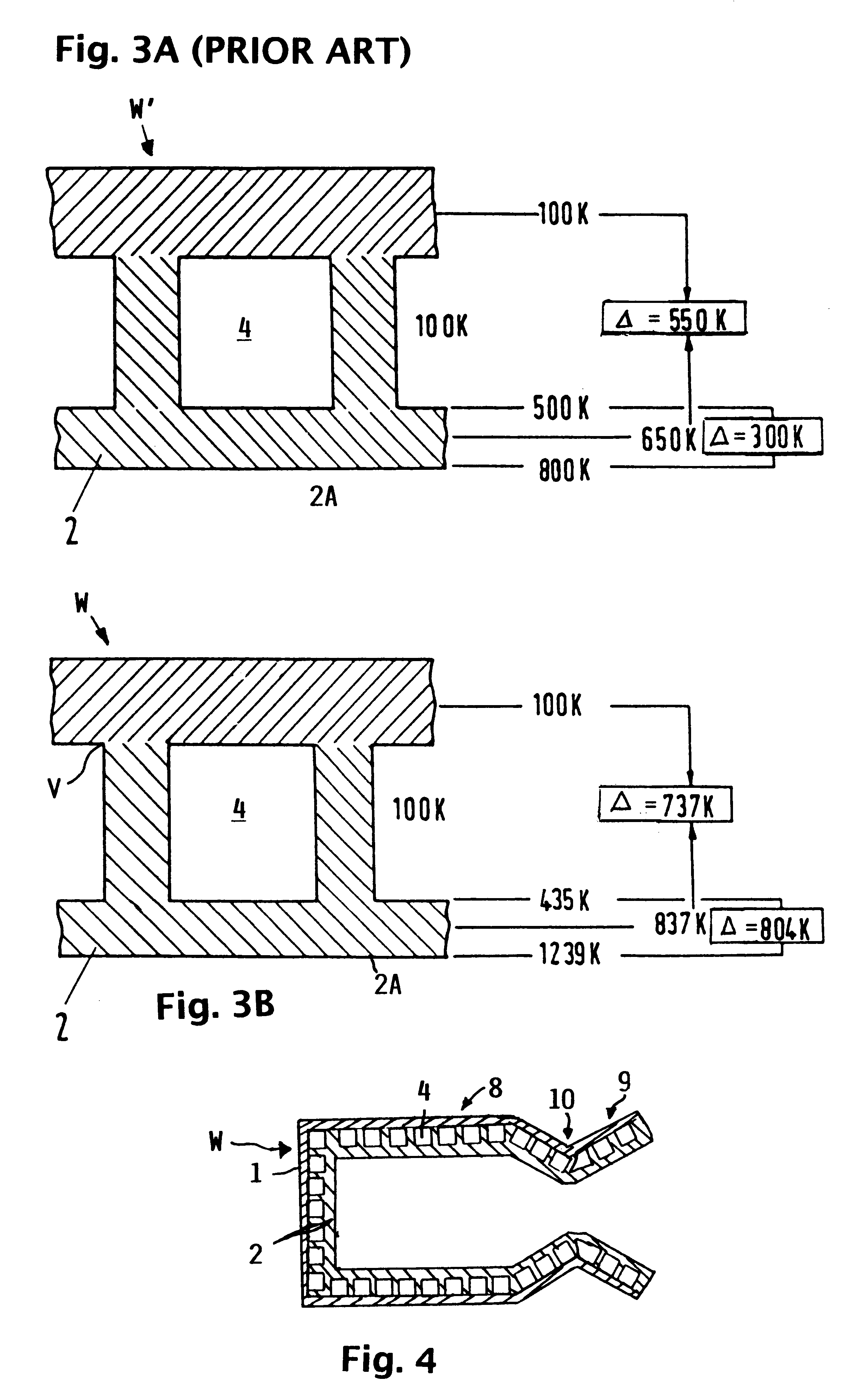

Combustion chamber wall construction for high power engines and thrust nozzles

InactiveUS6182442B1Long lastingReduce quality problemsContinuous combustion chamberPower plant exhaust arrangementsFiberCombustion chamber

A wall construction for a combustion chamber or thrust nozzle of a high power engine of a flying body includes an inner wall body that is subjected to the hot gases within the combustion chamber, and an outer jacket that surrounds the inner wall body and carries the mechanical loads. The inner wall body has a plurality of cooling channels through which a cooling medium may flow. The outer jacket is made of a long-fiber C / SiC composite material, while the inner wall member is made of a short fiber C / SiC composite material. The reduced thermal expansion coefficient of this ceramic composite material in comparison to metal alloys leads to a reduced straining and reduced deformation of the wall construction and therewith an increased operating life.

Owner:DAIMLER AG

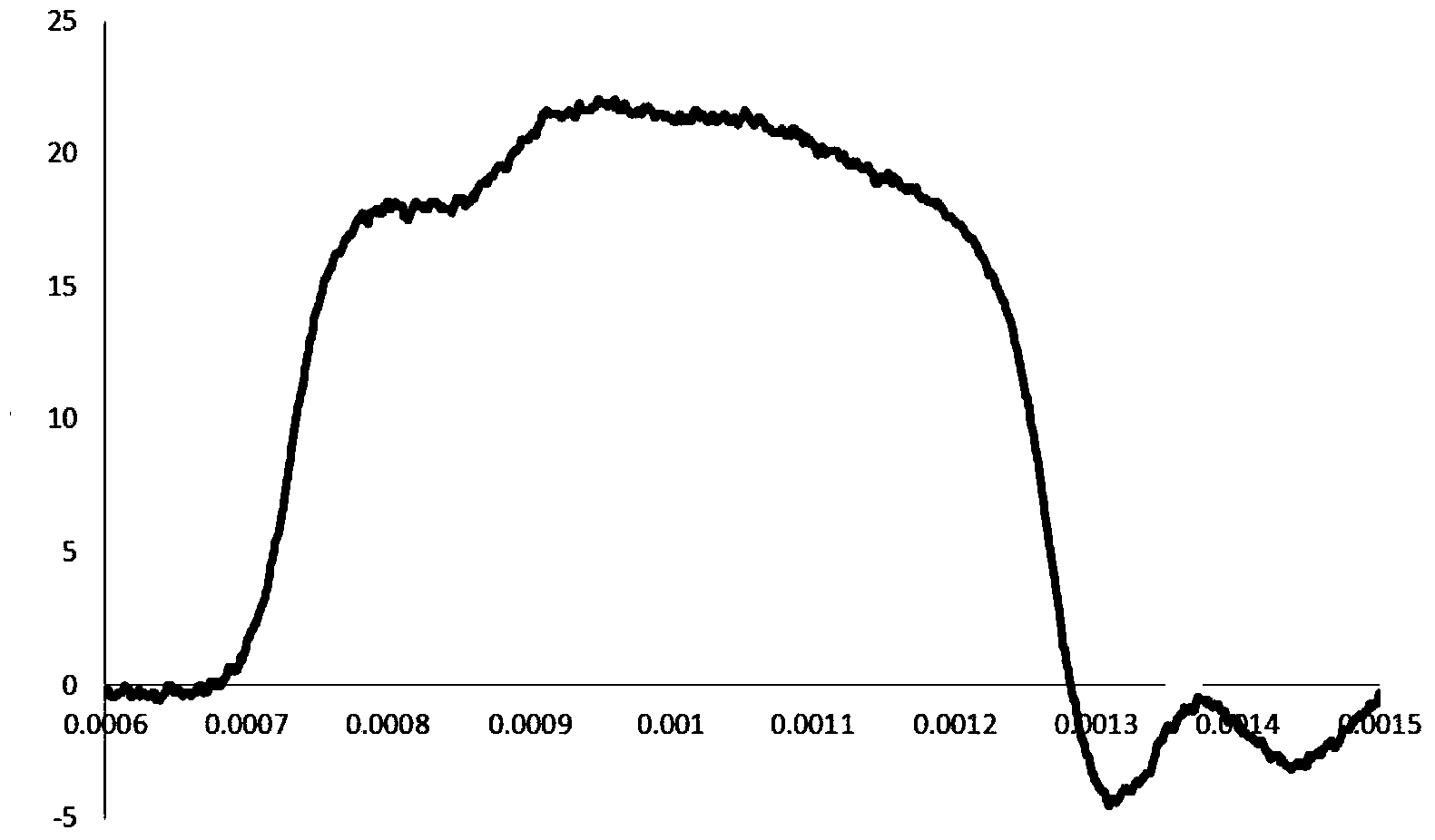

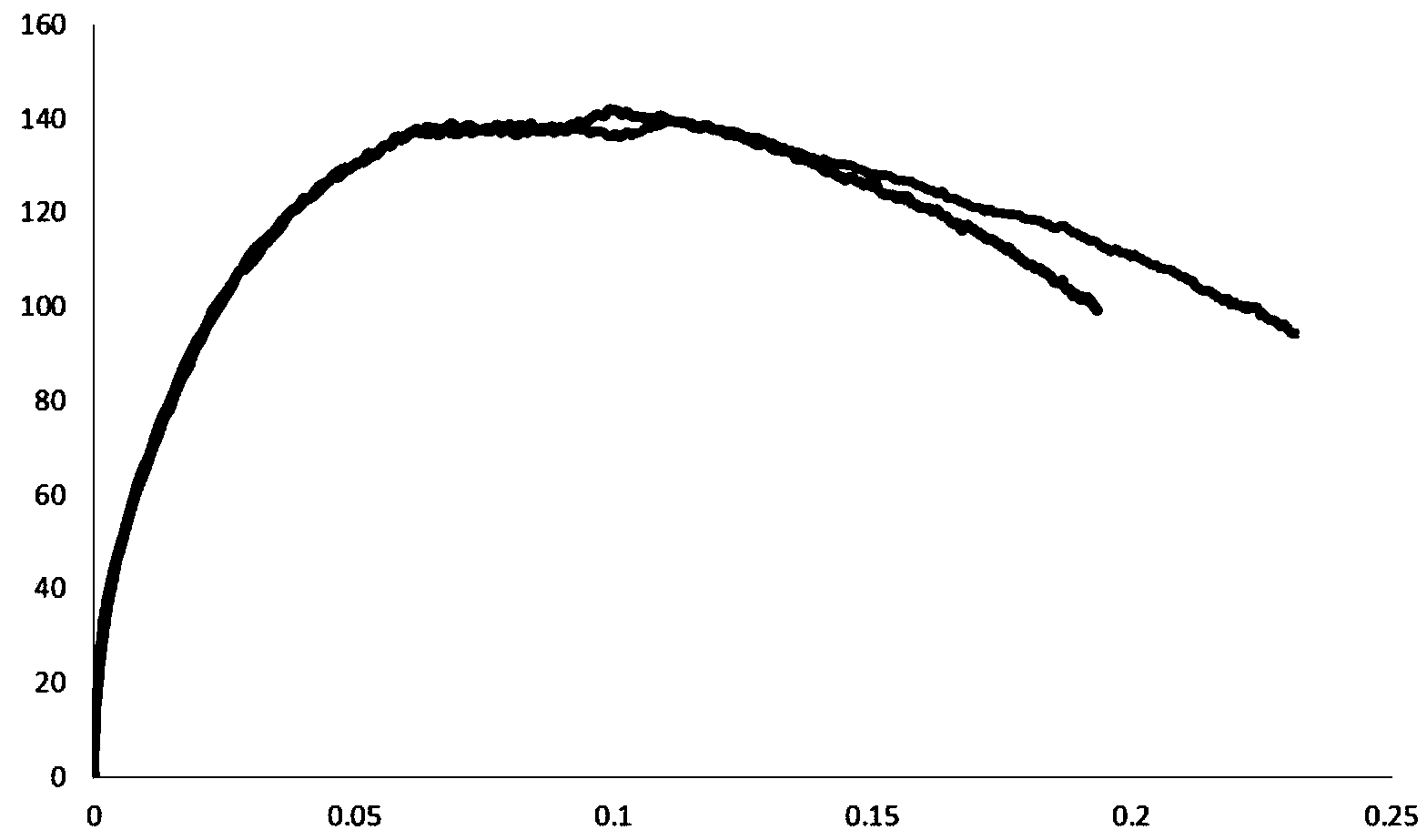

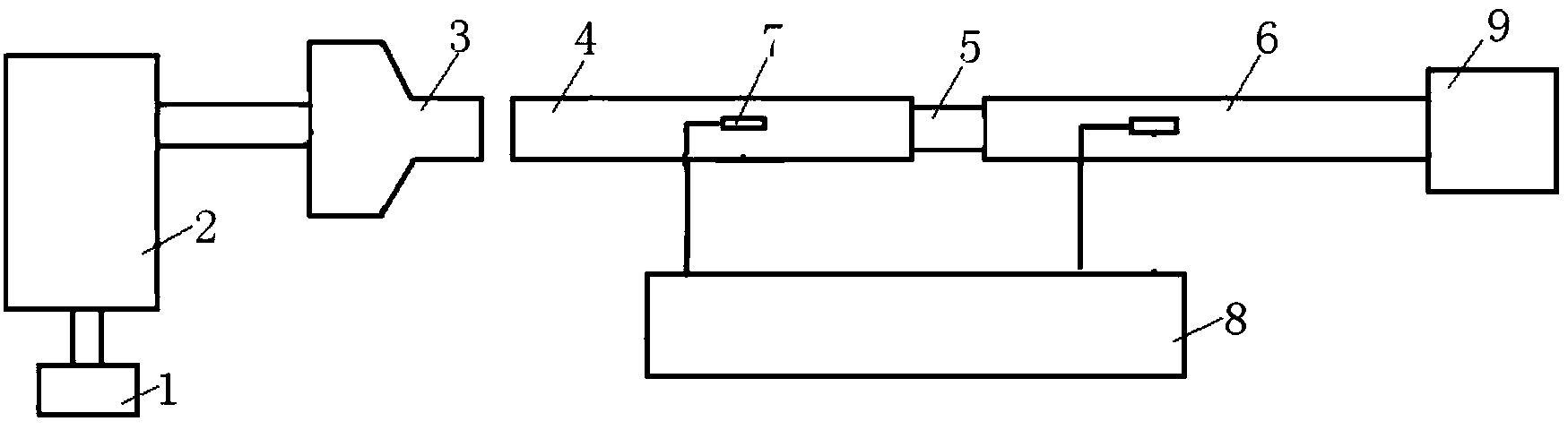

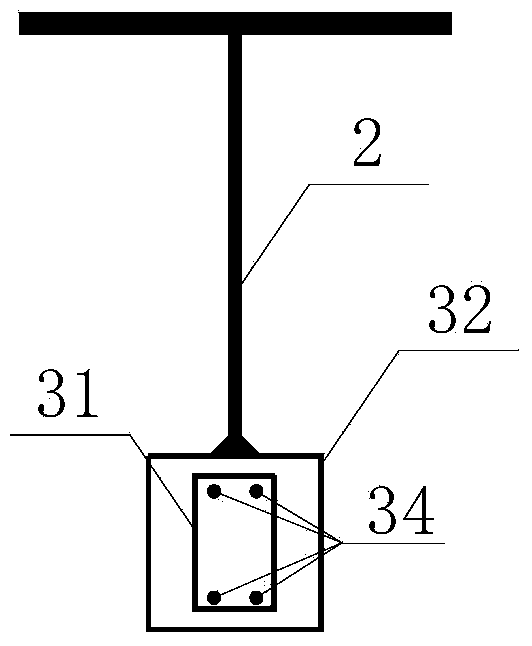

Experimental device of split hopkinson pressure bar based on electromagnetic force load

ActiveCN103913382AGood repeatabilityEasy to operateMaterial strength using tensile/compressive forcesElectromagnetic shieldingEngineering

The invention discloses an experimental device of a split hopkinson pressure bar based on electromagnetic force load. The experimental device comprises an electromagnetic riveting device and a split hopkinson pressure bar experiment device, wherein the electromagnetic riveting device is arranged at one end of an incident bar of the split hopkinson pressure bar experiment device; the end face of an electromagnetic riveting gun on the electromagnetic riveting device is in full contact with the end face of the end of the incident bar, so that the electromagnetic riveting device can generate stress pulse which is directly input into the incident bar and generated pulse signals can be accurately controlled. By adopting the experimental device, the split hopkinson pressure bar is not greatly improved; the electromagnetic riveting device is only used for replacing an air gun in a conventional split hopkinson pressure bar system; accurate control of stress wave is achieved in an electromagnetic way; meanwhile, the width of the stress wave generated by the electromagnetic load is not limited by the length of an impacting bar, so that the width of the stress wave generated by the experimental device is large enough at a high strain rate, thereby achieving the normalization of experimental technologies of the split hopkinson pressure bar.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

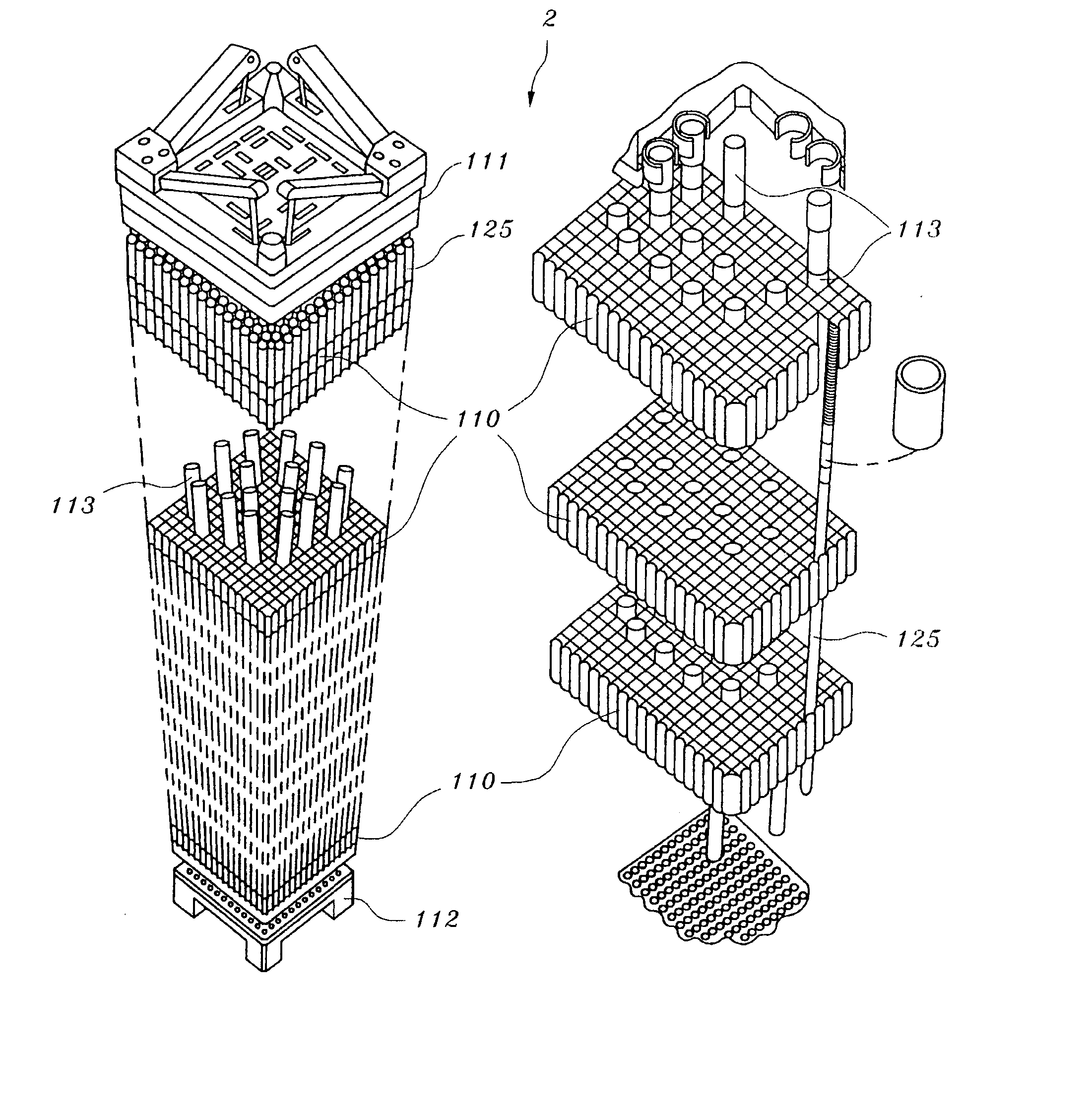

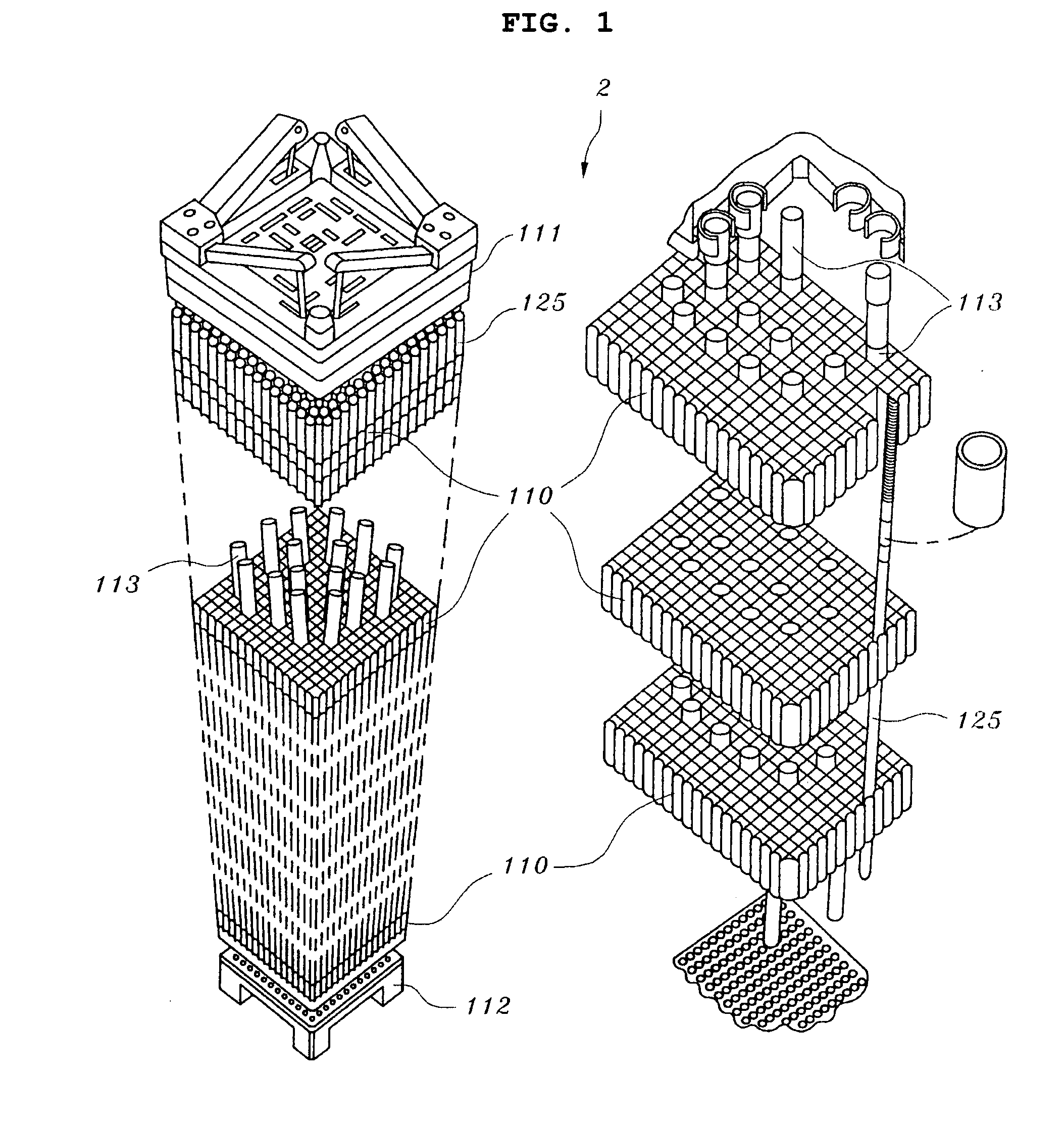

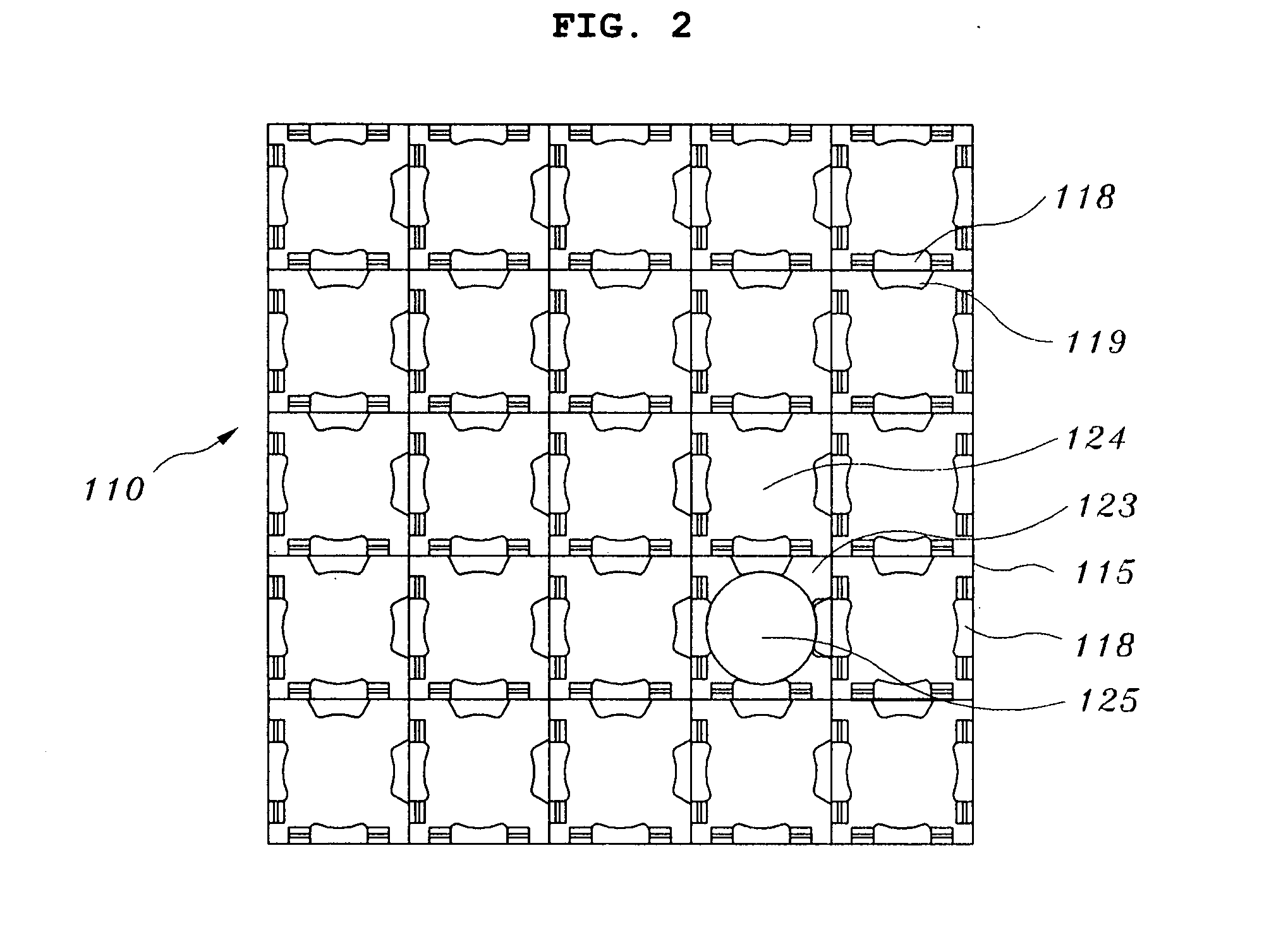

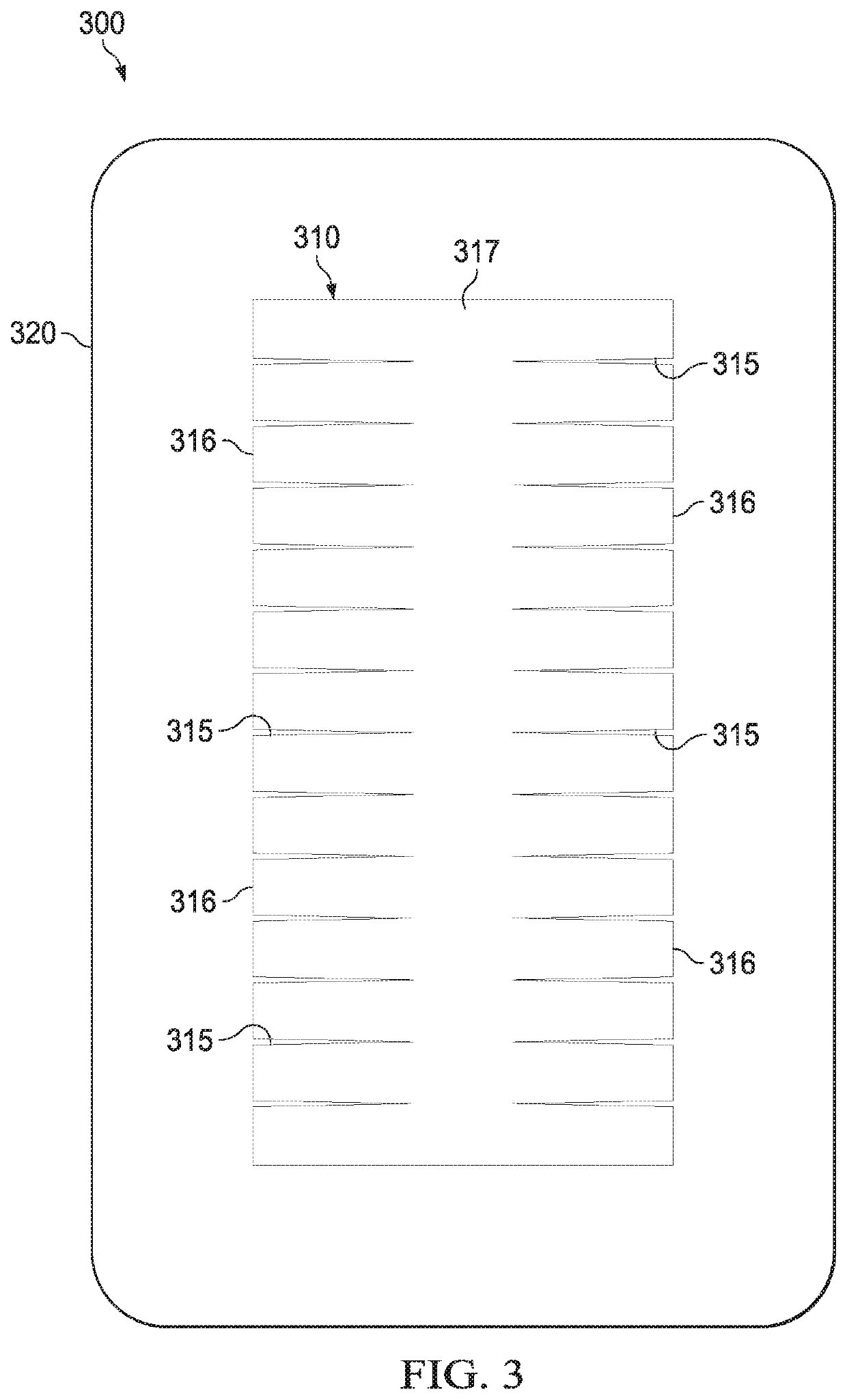

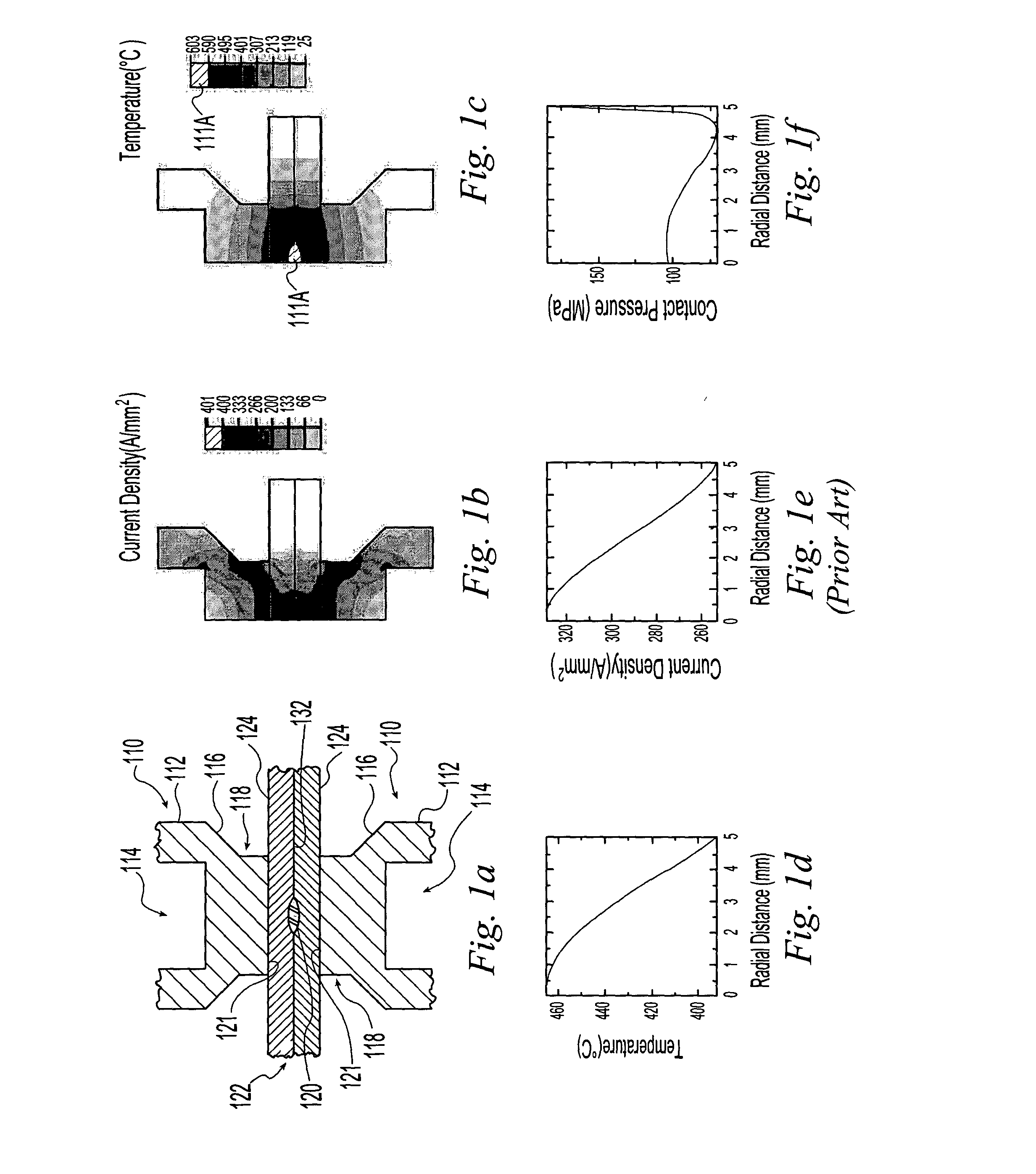

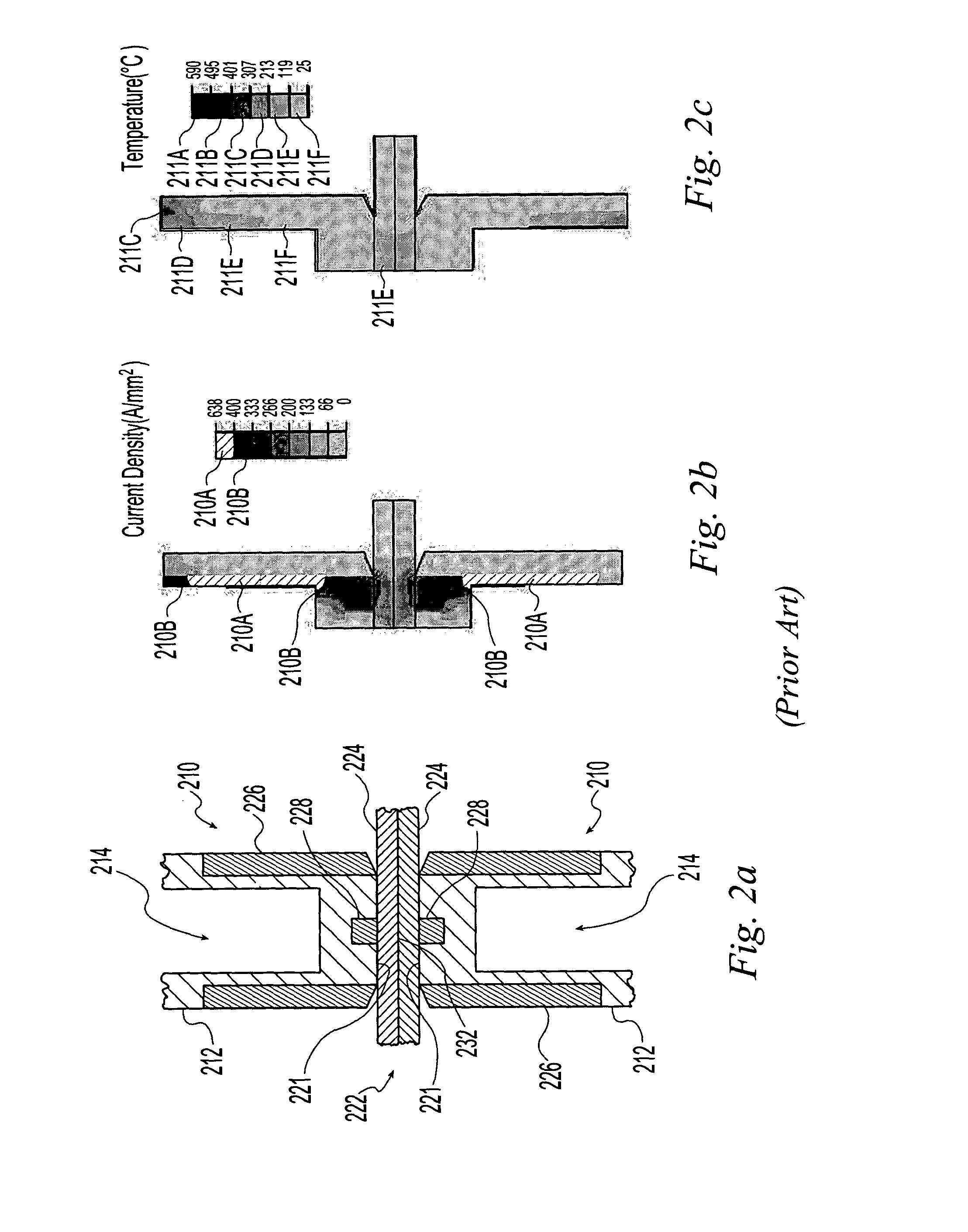

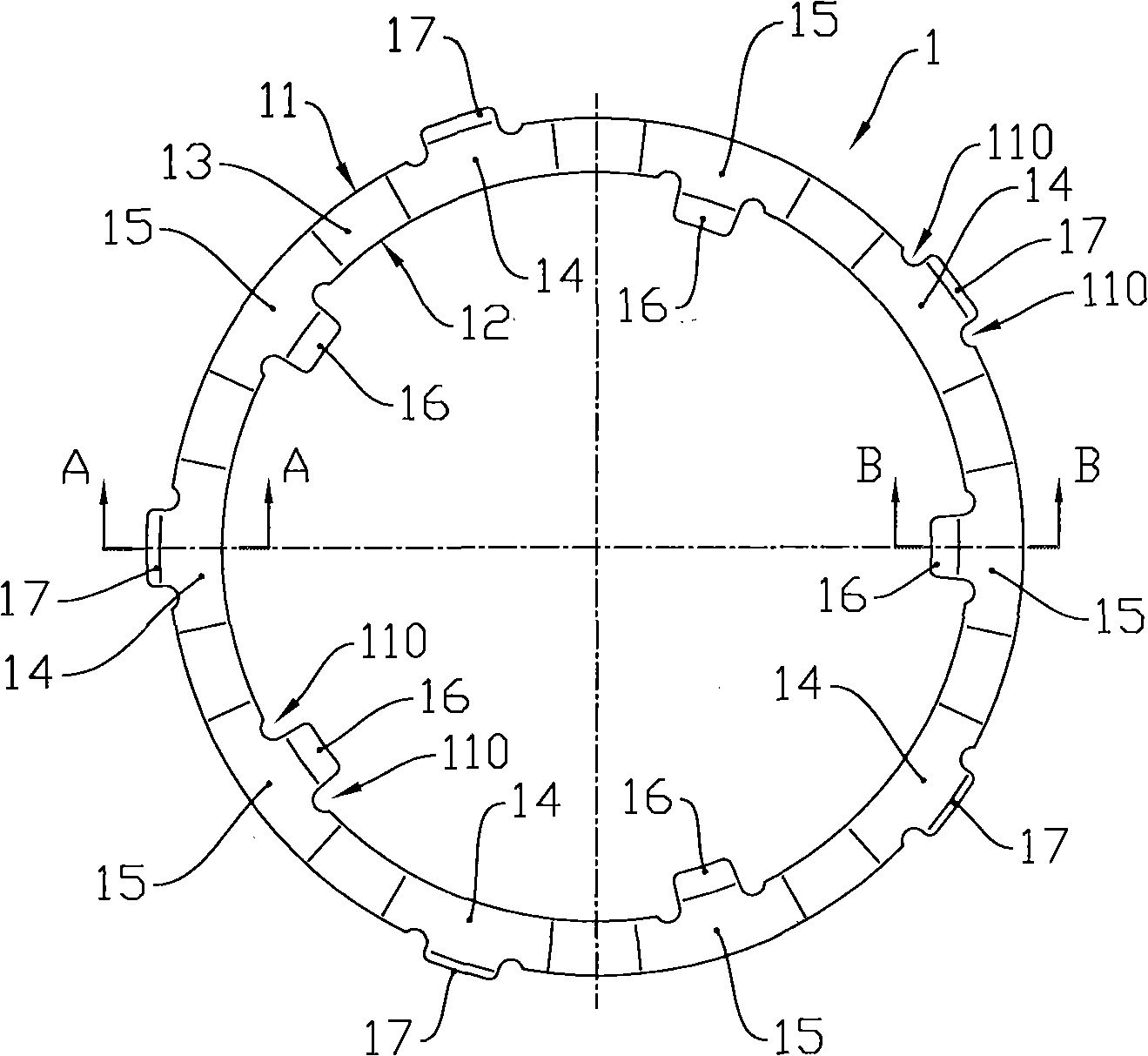

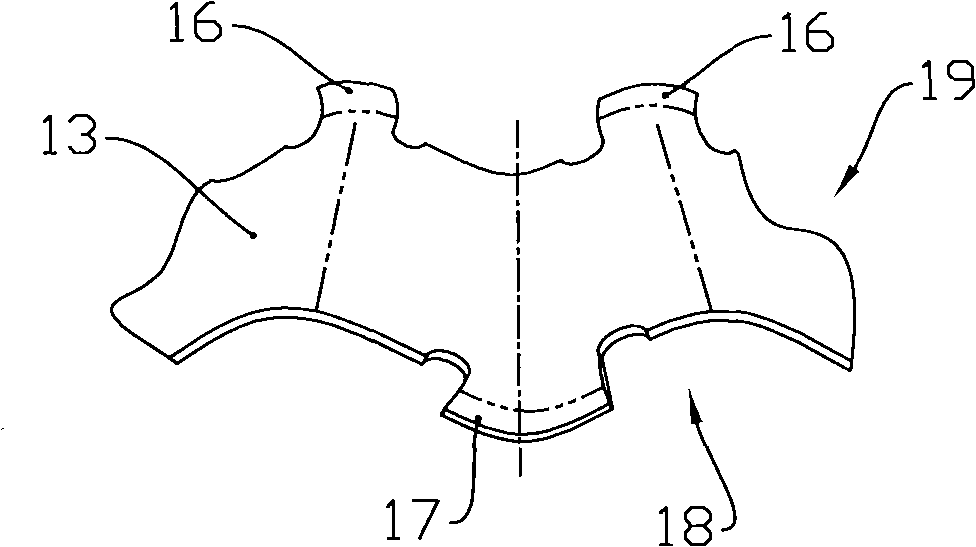

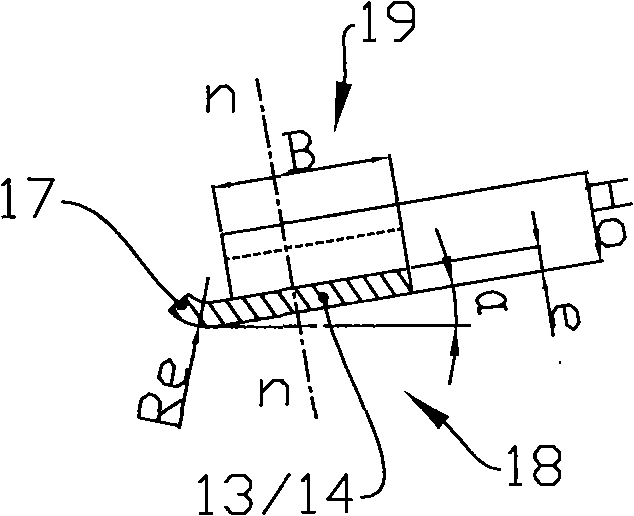

Spacer grid spring for increasing the conformal contact area with fuel rod

ActiveUS20070242793A1Increase elasticityEnlarge regionNuclear energy generationFuel element assembliesSupport conditionPlastic property

A grid strap includes a spacer grid spring that increases the conformal contact area with a fuel rod of a nuclear fuel rod assembly. The shape of the spacer grid spring of the grid strap which is in contact with the fuel rod is optimized, thereby the elasticity of the spacer grid spring contacting the fuel rod is increased, the conformal contact area with a contact portion of the spacer grid spring contacting the fuel rod when the fuel rod is inserted into each cell of a spacer grid is expanded to obtain uniform stress distribution, and excessive plastic deformation of the spacer grid spring can be reduced. Further, magnitude and distribution of contact pressure between the fuel rod and the spacer grid spring are improved, thereby reducing the possibility of fretting wear caused by contact between the fuel rod and the spacer grid spring. The elastic behavior region of the spacer grid spring is expanded, so that the fuel rod can be reliably supported until the lifetime of the fuel rod expires despite changes in the supporting conditions of the fuel rod.

Owner:KOREA ATOMIC ENERGY RES INST +1

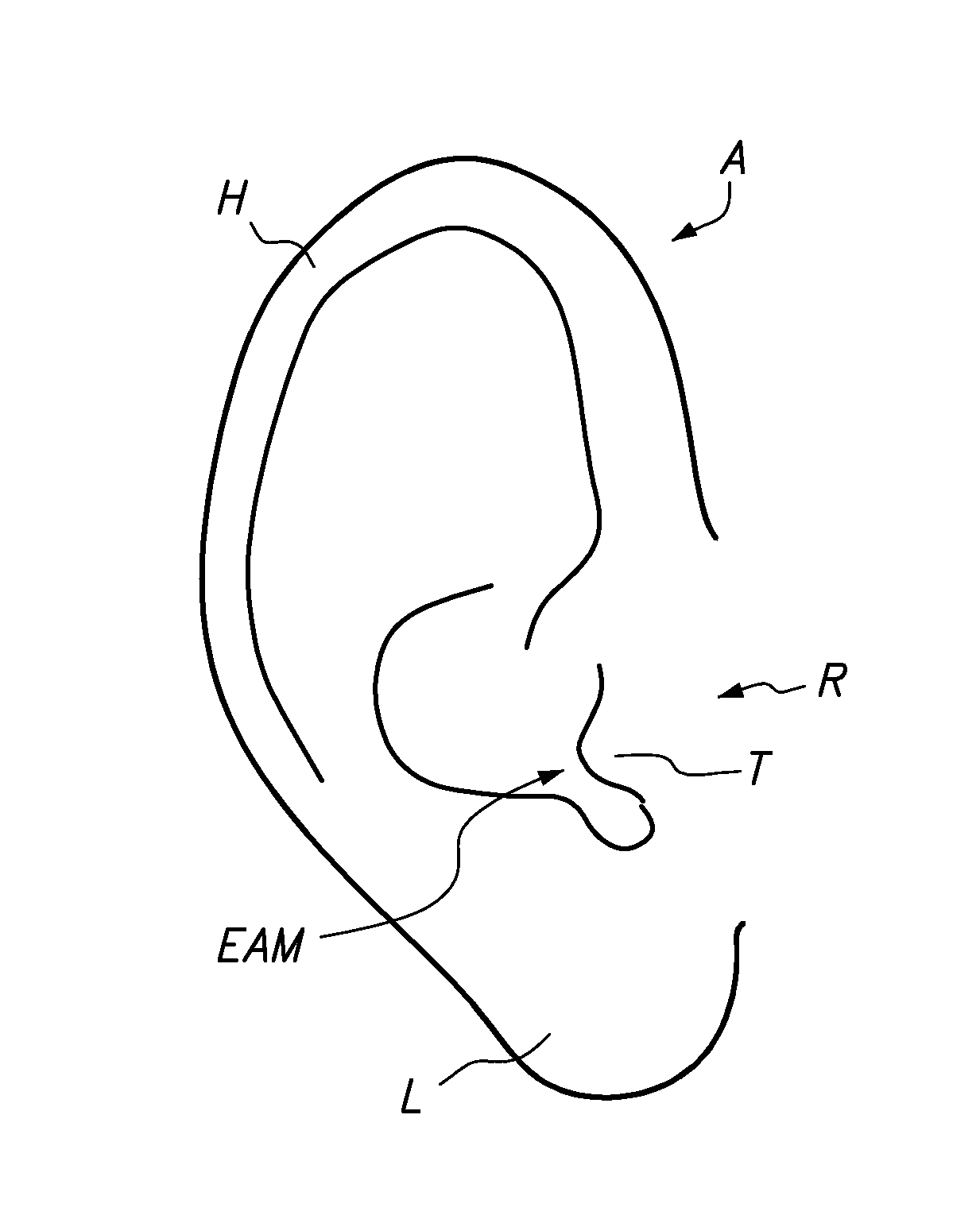

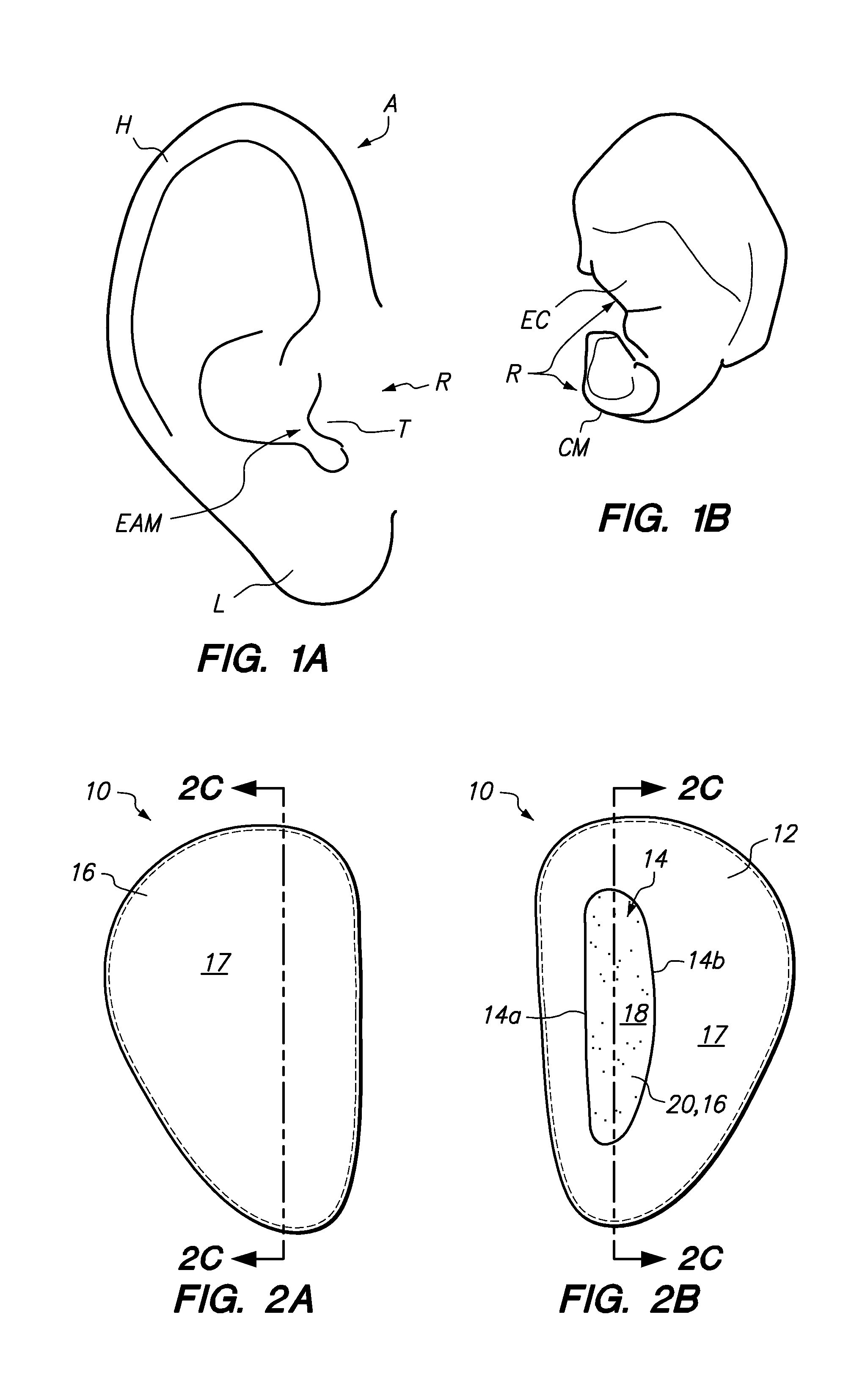

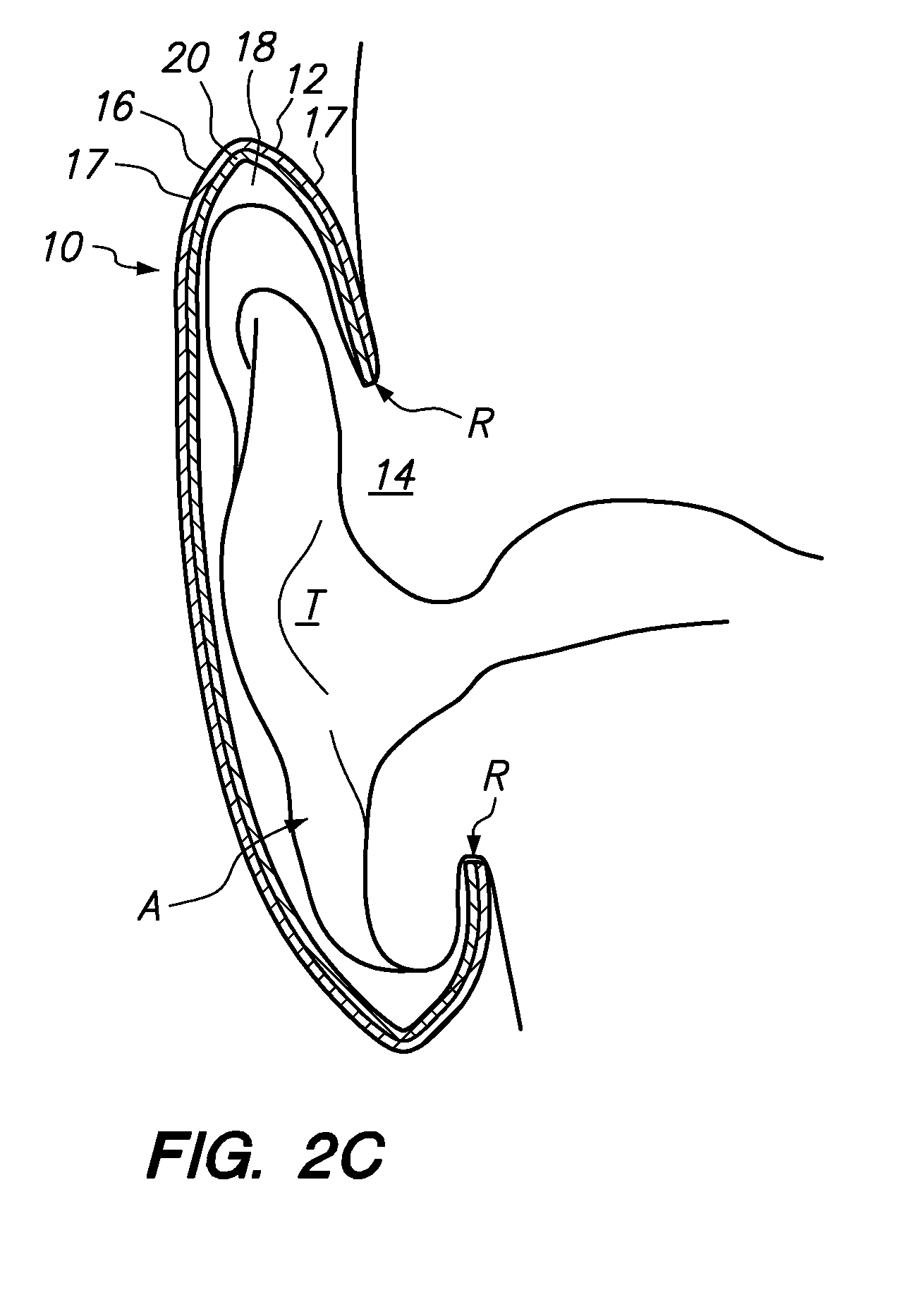

Methods and apparatus for ear protection

Methods and apparatus are provided for protecting the external ear from the elements, heat, cold, wind, rain and / or snow. In some embodiments, an ear protector comprises a conforming anchor with an opening through which the external ear may be passed. The ear protector further comprises an insulating outer covering that, in combination with the anchor, forms the ear protector with a chamber positioned between the outer covering and the anchor. During use, the chamber is configured to receive the external ear, with the anchor's opening conformably positioned in proximity to at least a portion of the ear's root. The perimeter of the conforming anchor's opening resiliently deforms during passage of the external ear through the opening and into the chamber, and then conforms to the geometry of at least a portion of the ear root in order to securely and comfortably maintain the ear protector in position over the external ear without additional external support. The conforming anchor preferably is fabricated from a closed cell foamed elastomer.

Owner:MICHLITSCH KENNETH J +1

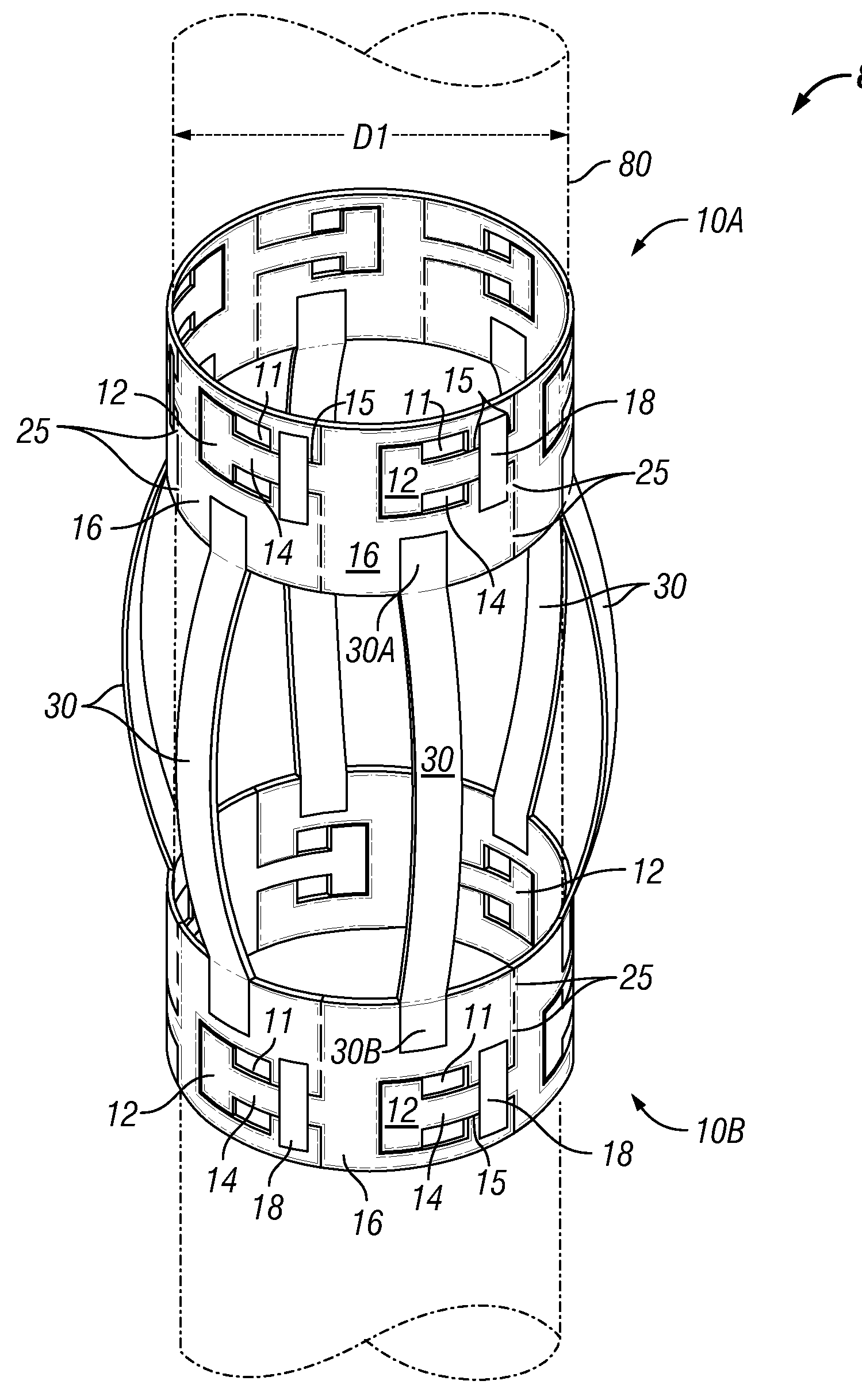

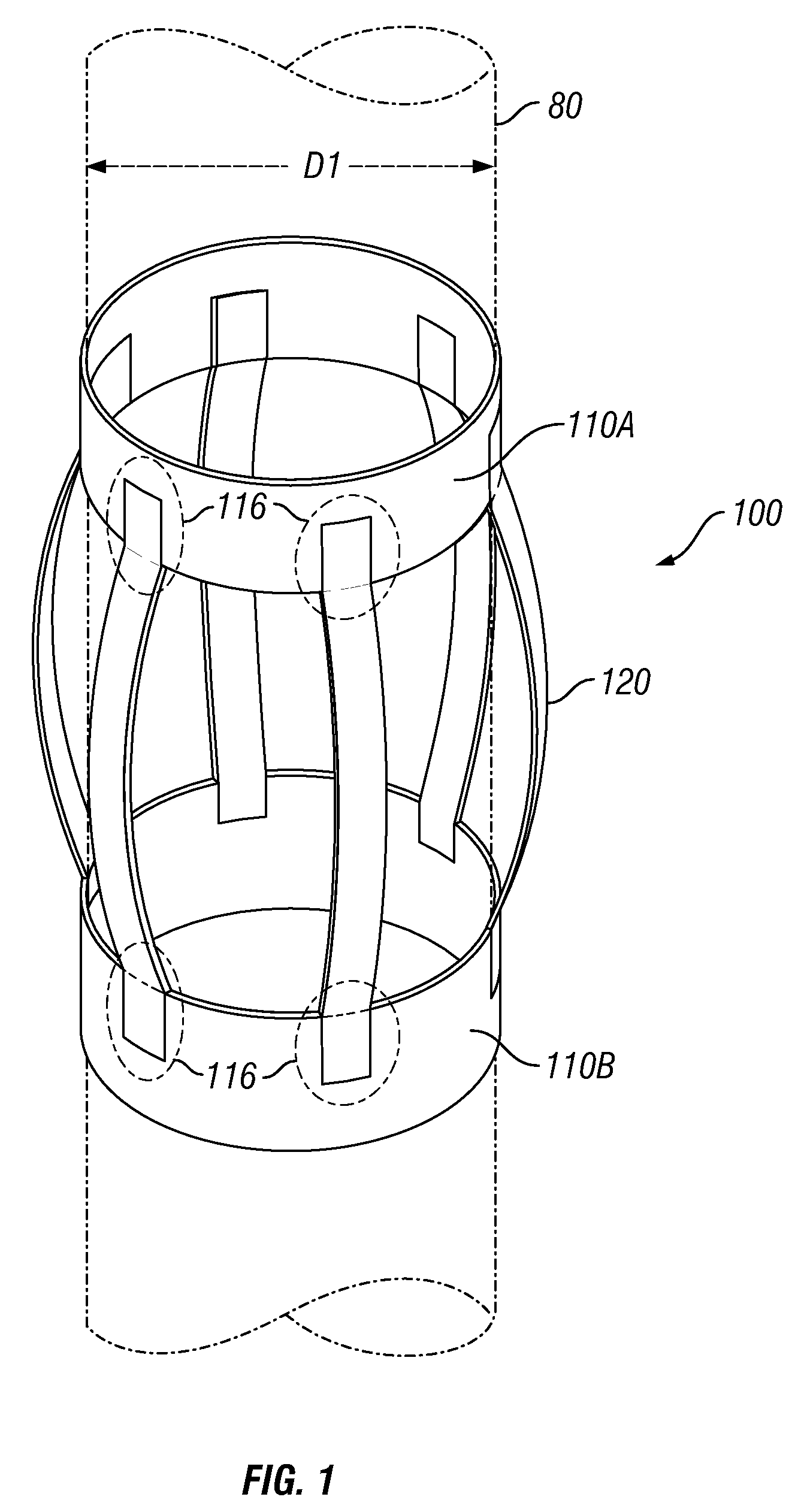

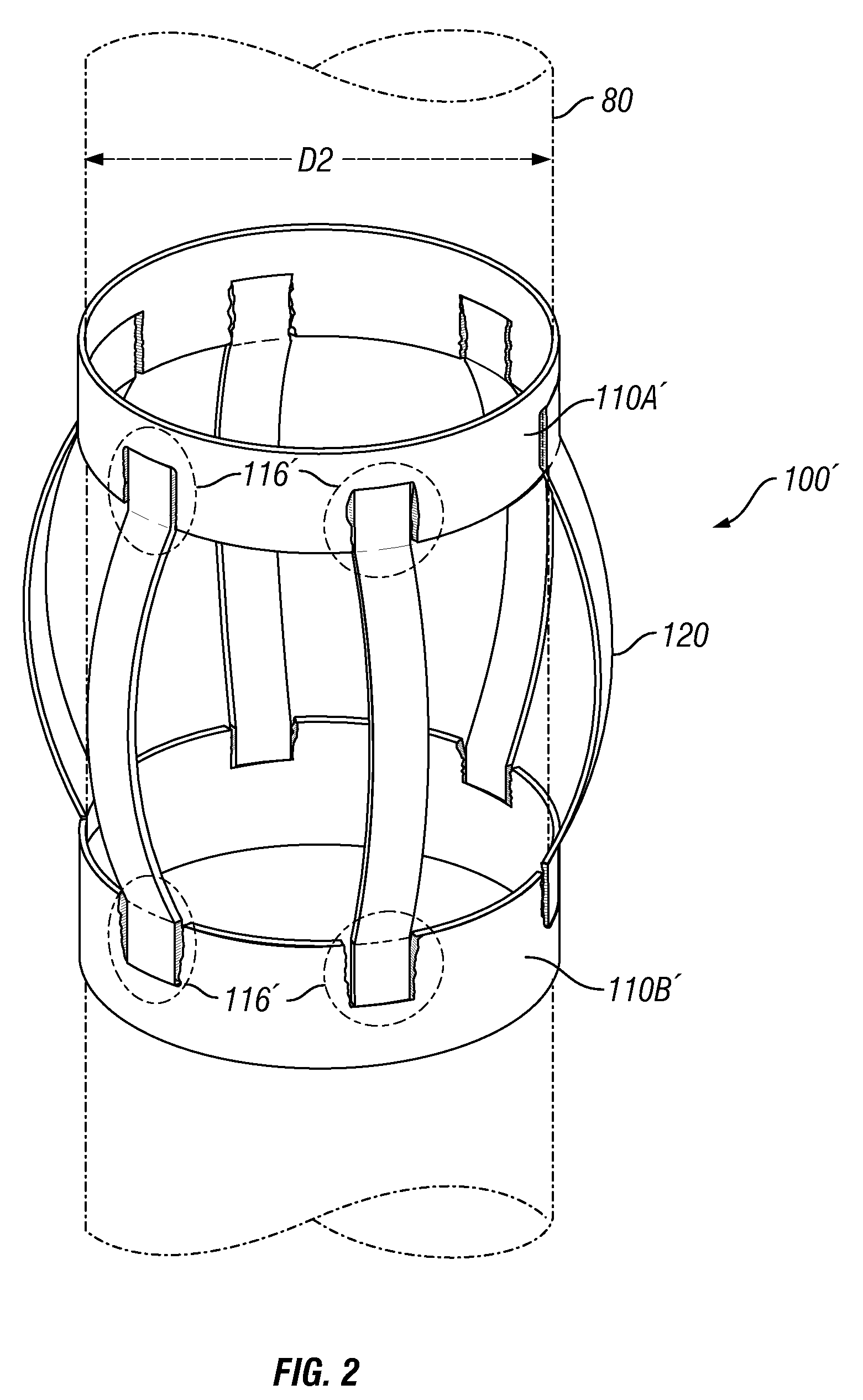

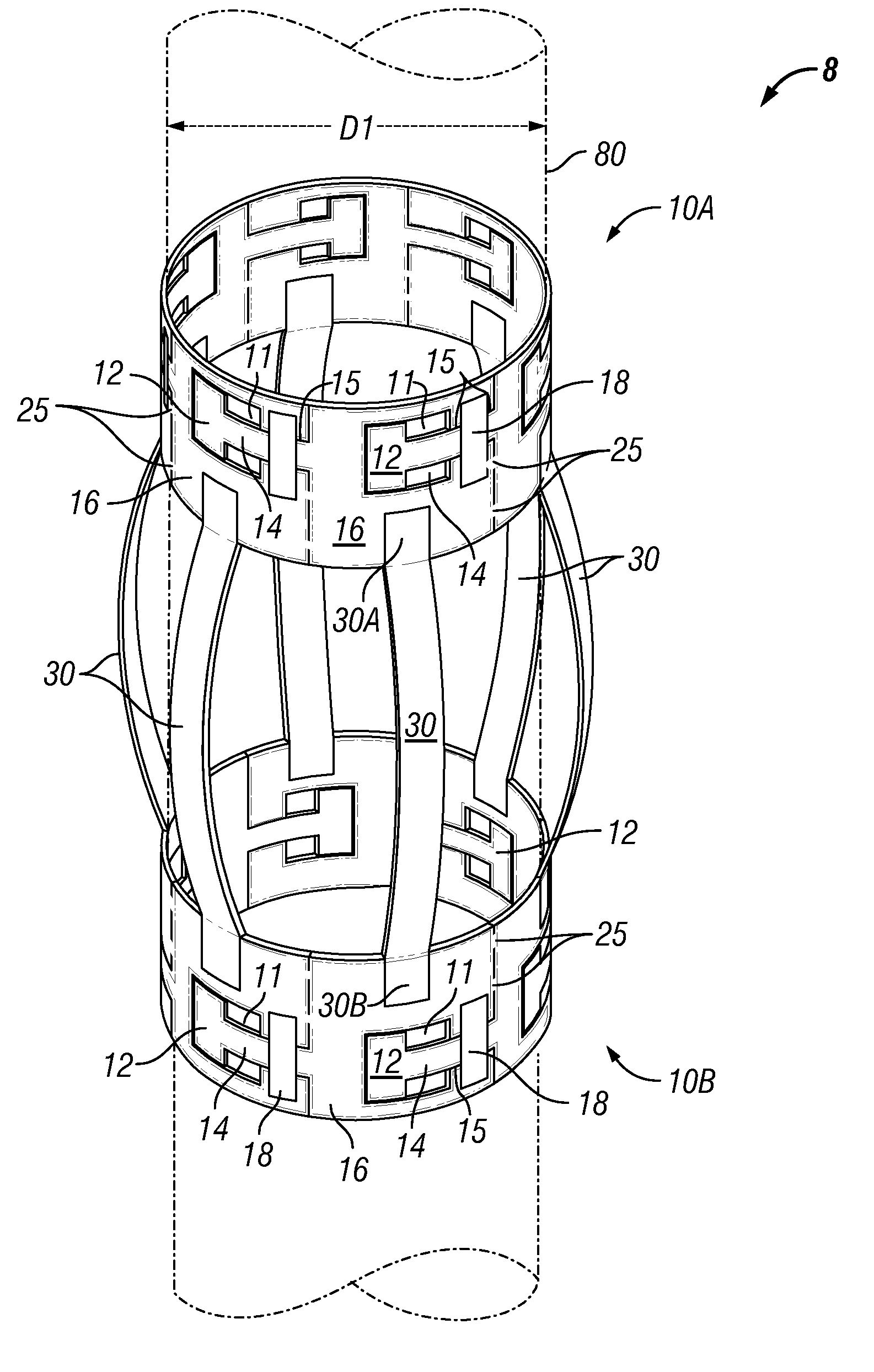

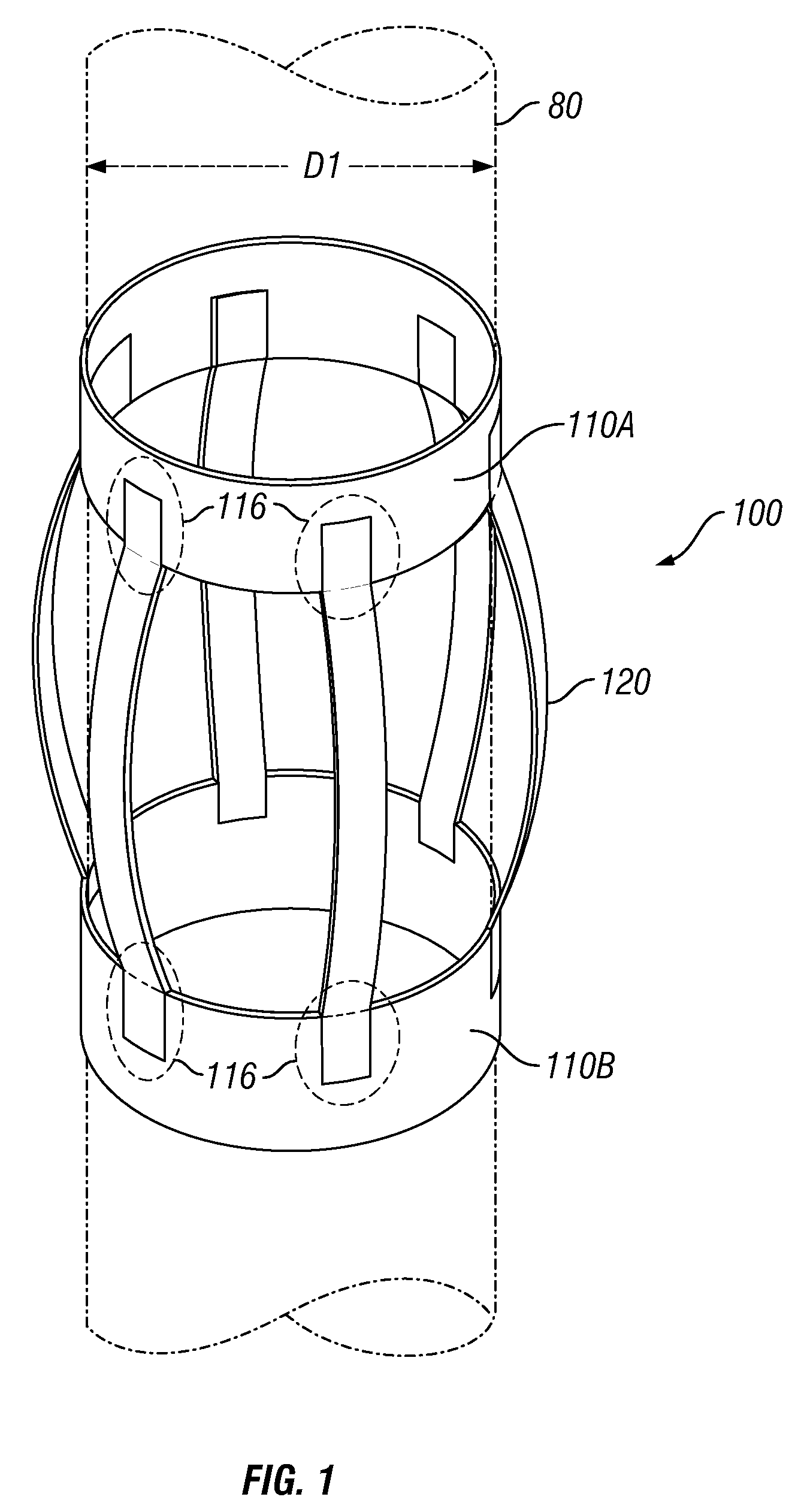

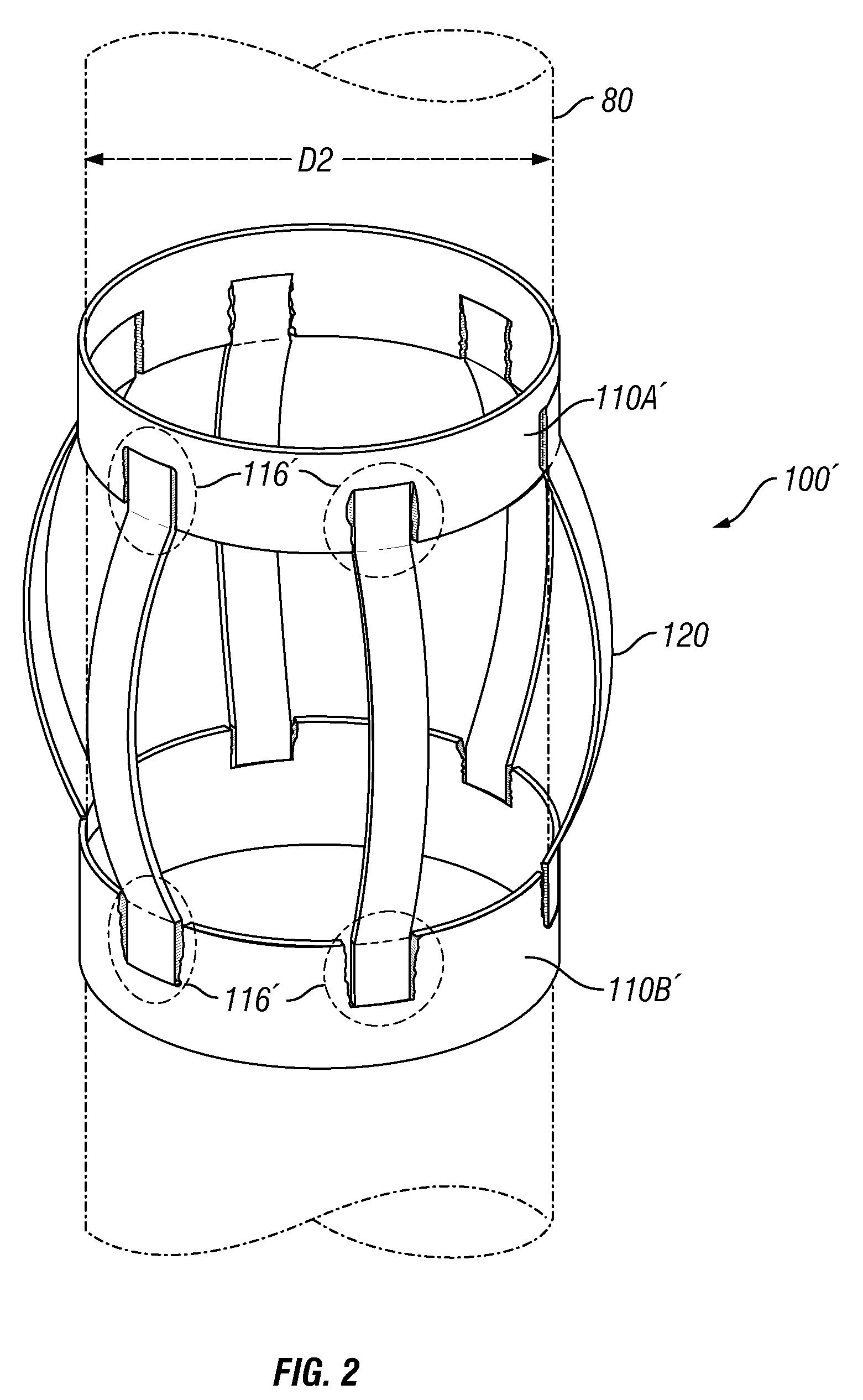

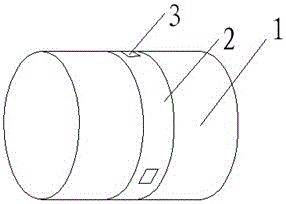

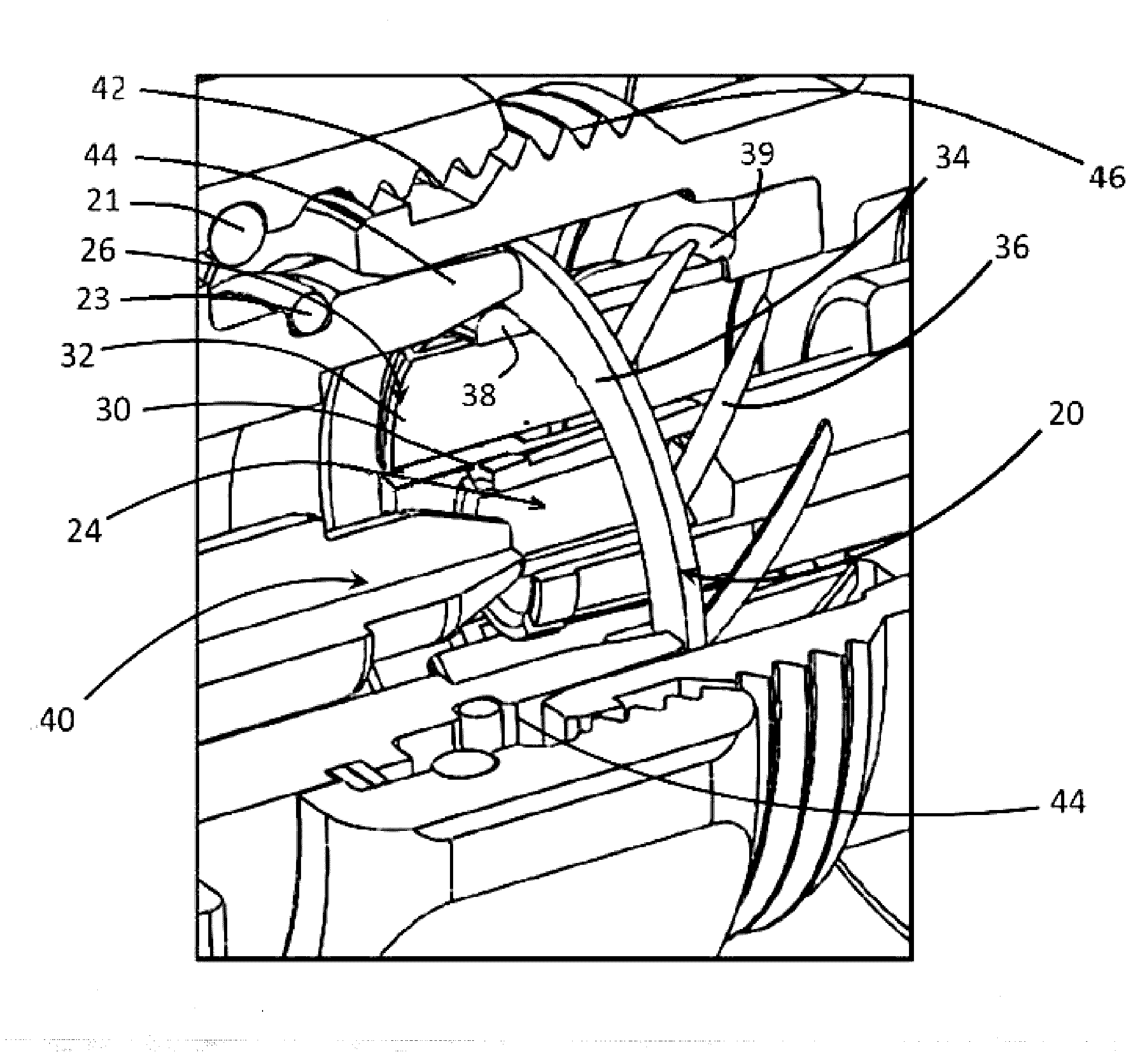

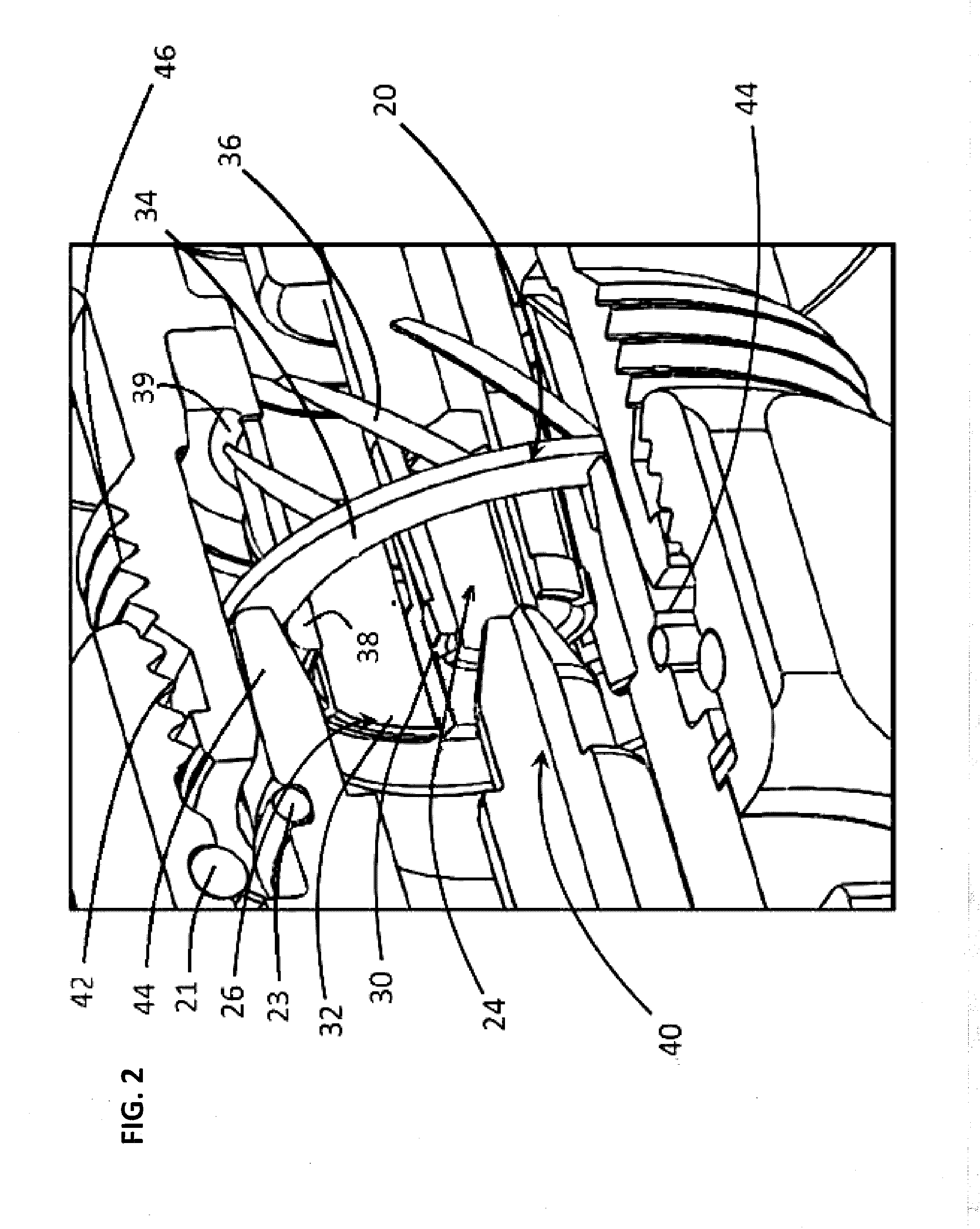

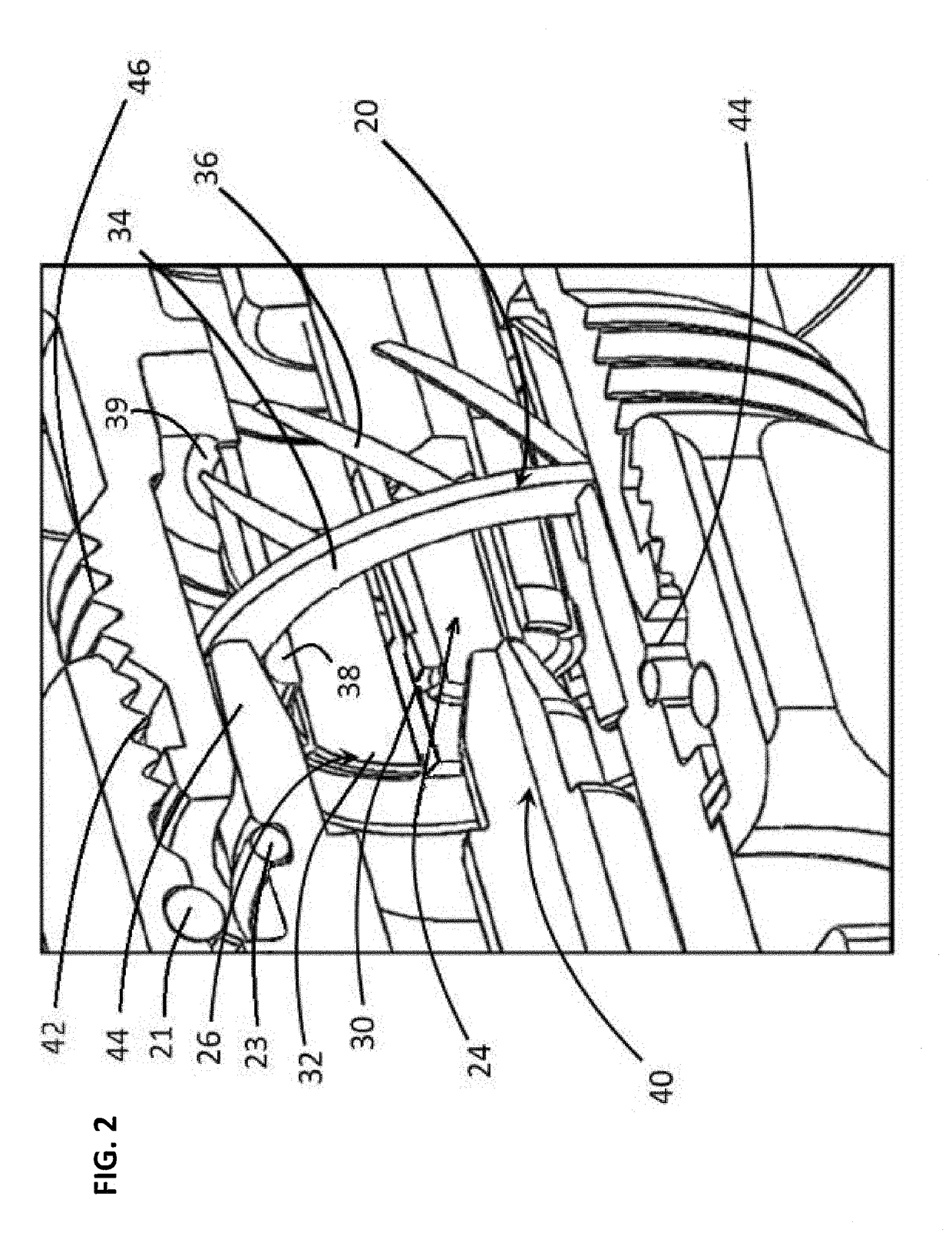

Expandable Centralizer For Expandable Pipe String

ActiveUS20080283253A1Eliminate needIncrease the diameterDrilling rodsFluid removalEngineeringBiomedical engineering

A close-tolerance expandable bow spring centralizer 8 having a first expandable collar 10A coupled to and spaced apart from a second expandable collar 10B through a plurality of bow springs 30 wherein expandable collars 10A, 10B comprise a plurality of slidably coupled links 16 that separate to expand the diameter of the collars 10A, 10B, e.g., upon expansion of an expandable pipe string 80 on which the centralizer 8 is received. Expandable bow spring centralizer 8 may grip the expandable pipe string 80 when in the collapsed configuration to eliminate the need for a stop collar. Additionally or alternatively, a fin 32 may be connected to each bow spring 30, and then connected to one or more adjacent fins 32 upon collapse of the bow springs 30 to form a restraining band 39 that may be ruptured, e.g., upon expansion of the expandable pipe string 80.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Magnet Core and Method for Its Production

InactiveUS20090206975A1Minimal hysteresis lossLow iron lossesMaterial nanotechnologyInorganic material magnetismMetallurgyMagnet

Magnet cores pressed using a powder of nanocrystalline or amorphous particles and a pressing additive should be characterised by minimal iron losses. These particles have first surfaces represented by the original strip surfaces and second surfaces represented by surfaces produced in a pulverisation process, the overwhelming majority of these second particle surfaces being smooth cut or fracture surfaces without any plastic deformation, the proportion T of areas of plastic deformation of the second particle surfaces being 0≦T≦0.5.

Owner:VACUUMSCHMELZE GMBH & CO KG

Expandable centralizer for expandable pipe string

ActiveUS7878241B2Eliminate needIncrease the diameterDrilling rodsFluid removalEngineeringBiomedical engineering

A close-tolerance expandable bow spring centralizer 8 having a first expandable collar 10A coupled to and spaced apart from a second expandable collar 10B through a plurality of bow springs 30 wherein expandable collars 10A, 10B comprise a plurality of slidably coupled links 16 that separate to expand the diameter of the collars 10A, 10B, e.g., upon expansion of an expandable pipe string 80 on which the centralizer 8 is received. Expandable bow spring centralizer 8 may grip the expandable pipe string 80 when in the collapsed configuration to eliminate the need for a stop collar. Additionally or alternatively, a fin 32 may be connected to each bow spring 30, and then connected to one or more adjacent fins 32 upon collapse of the bow springs 30 to form a restraining band 39 that may be ruptured, e.g., upon expansion of the expandable pipe string 80.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Electric arc preheating repair welding method for stir friction plug

InactiveCN101966621AFull plastic flowSufficient plastic flow, the stirring needle is not easy to breakNon-electric welding apparatusFriction weldingPore diameter

The invention discloses an electric arc preheating repair welding method for a stir friction plug, relates to a repair welding method for the stir friction plug and aims to solve the problem of poor continuous flowability of a material because a stirring needle is broken before complete plastic deformation and flow under the action of strong resisting force of a material at a repair welding position of the stir friction plug. The method comprises the following steps of: 1, performing electric arc preheating on a key hole left by friction stir welding or secondary friction stir welding repairing, namely, putting a circular ring at a key hole position until the center of the circular ring is coincided with that of the key hole, performing electric arc heating on the circular ring by using a tungsten electrode argon arc welding machine at the temperature of between 180 and 200 DEG C and transferring heat to a region needing repair welding after the circular ring is heated so as to preheat the key hole in the region needing repair welding, wherein the central pore diameter of the circular ring is greater than that of the key hole; and 2, performing repair welding on the key hole, namely, during repair welding, moving a welding tool towards a welding direction by 1 to 5 millimeters and allowing the stirring needle to undergo plastic deformation and flow so as to fill the key hole. The method is used for performing repair welding on the weld defects of the stir friction welding and the key hole.

Owner:HARBIN INST OF TECH

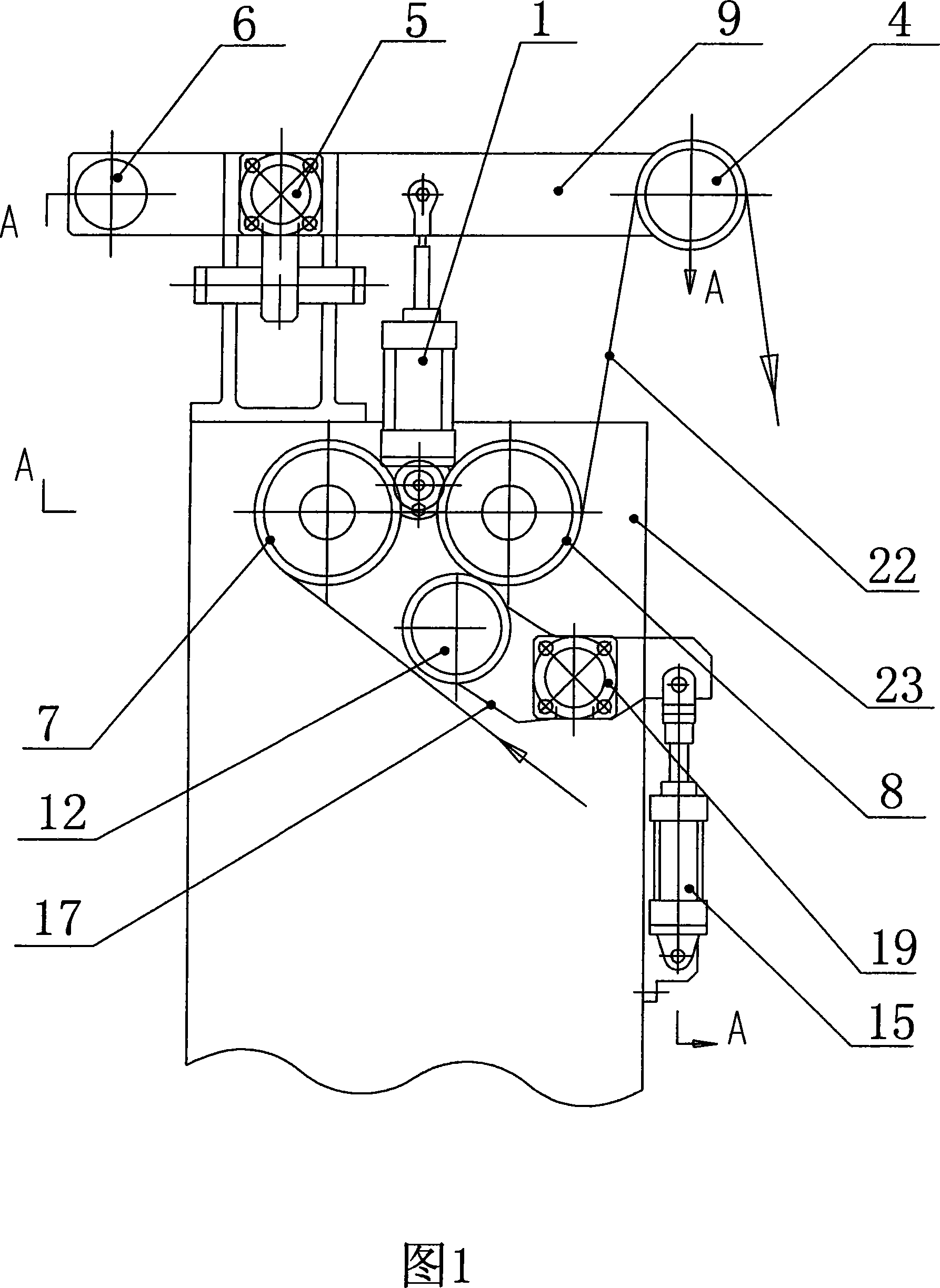

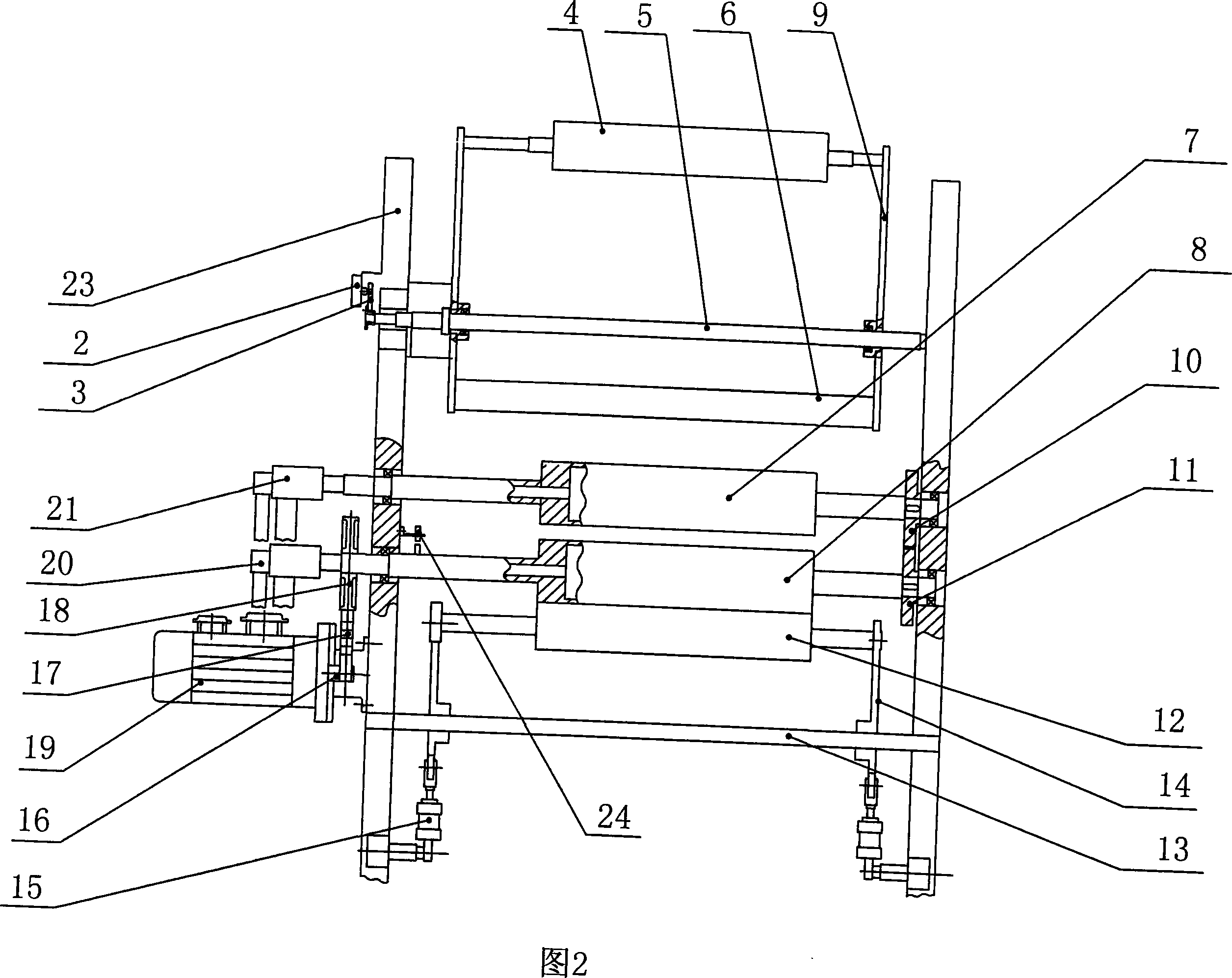

Printing machine introducing and preprocessing device for easy-to-stretch coiling block material

InactiveCN101214752AHigh precision flatnessReduce plastic deformationRotary pressesWebs handlingFrequency conversionPrinting press

The invention discloses an inletting and pretreatment device used for a tensile spool material printing press, which comprises a tension detection and control mechanism and a pretreatment mechanism. The tension detection and control mechanism comprises a super low friction air cylinder (1), a tension detection floating roll (4), a zero tension control counterweight shaft (6), a high precision rotating potentiometer and a vector frequency conversion motor (19) and so on. The pretreatment mechanism comprises a press roll (12), a cooling pull roll (8), a preheat roll (7) and so on. Cooling medium is fed in the cooling pull roll (8); and heating agent is fed in the preheat roll (7). The invention completes the inletting of spool material with higher tension control precision, and facilitates control of low tension and even zero tension with higher tension control precision. The invention is not only applicable for pretreatment and inletting during printing of tensile materials, such as thin-film material, paper and so on, without affecting the inletting of common spool materials at all.

Owner:NINGBO XINDA PRINTING MACHINERY +1

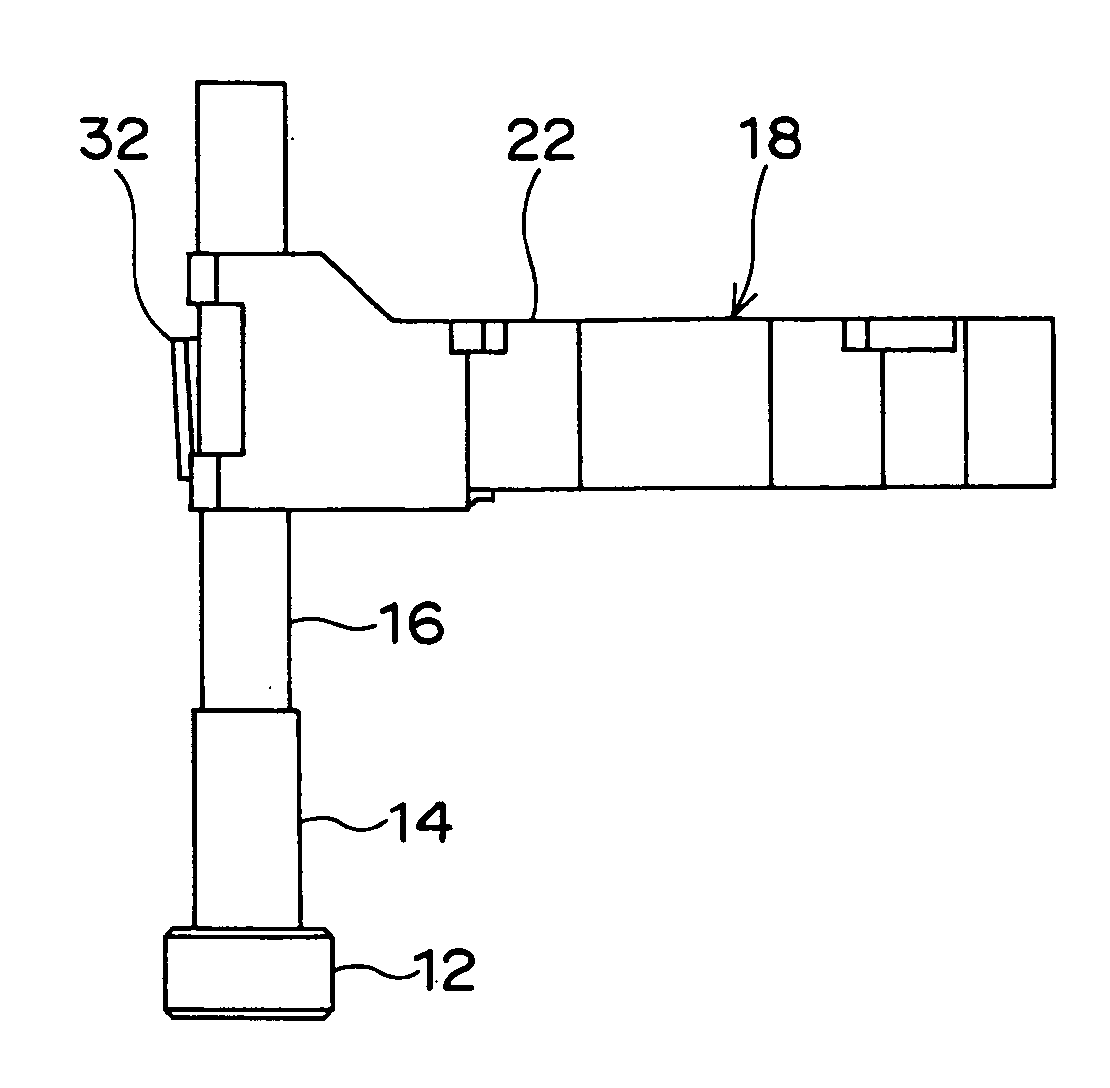

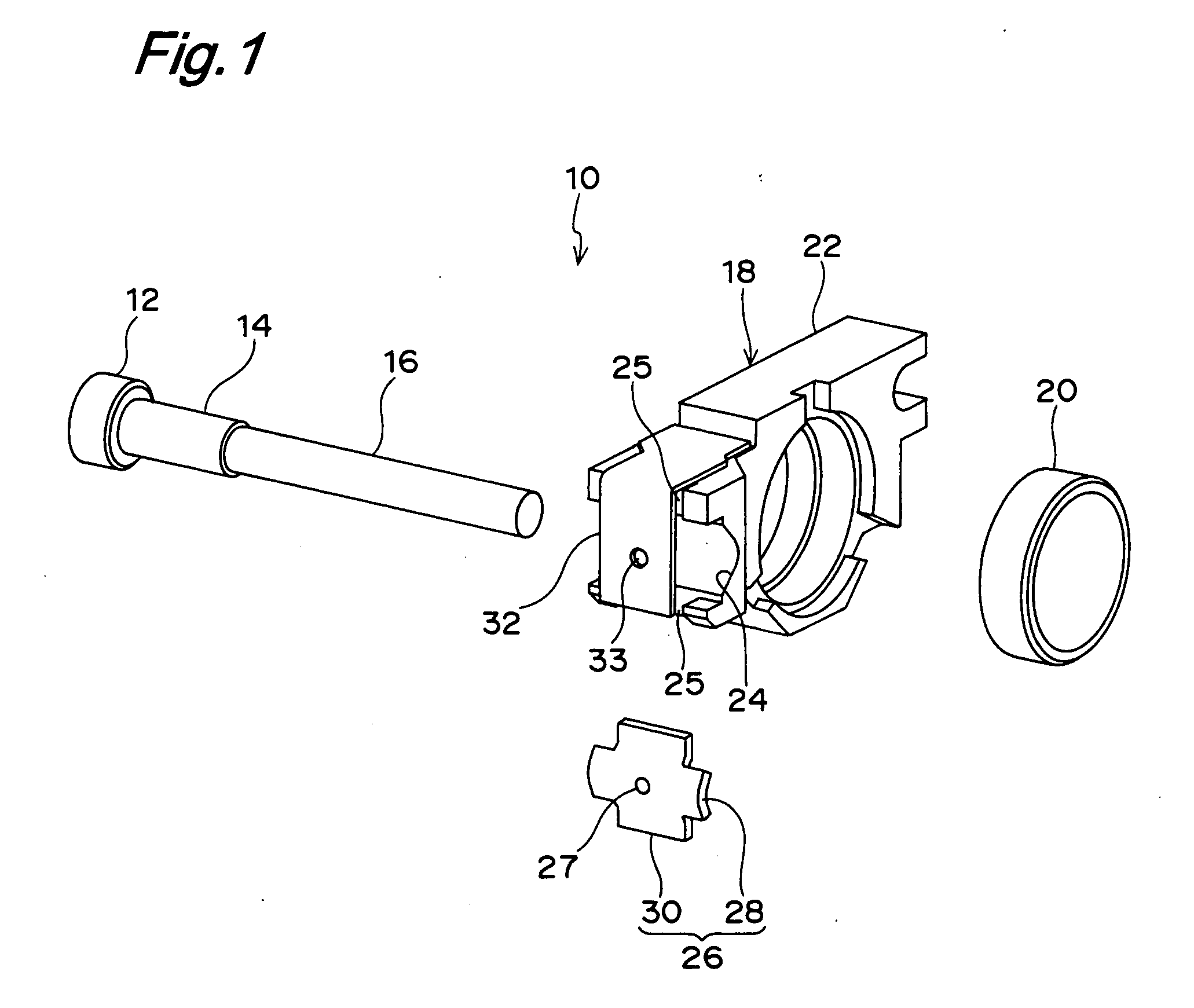

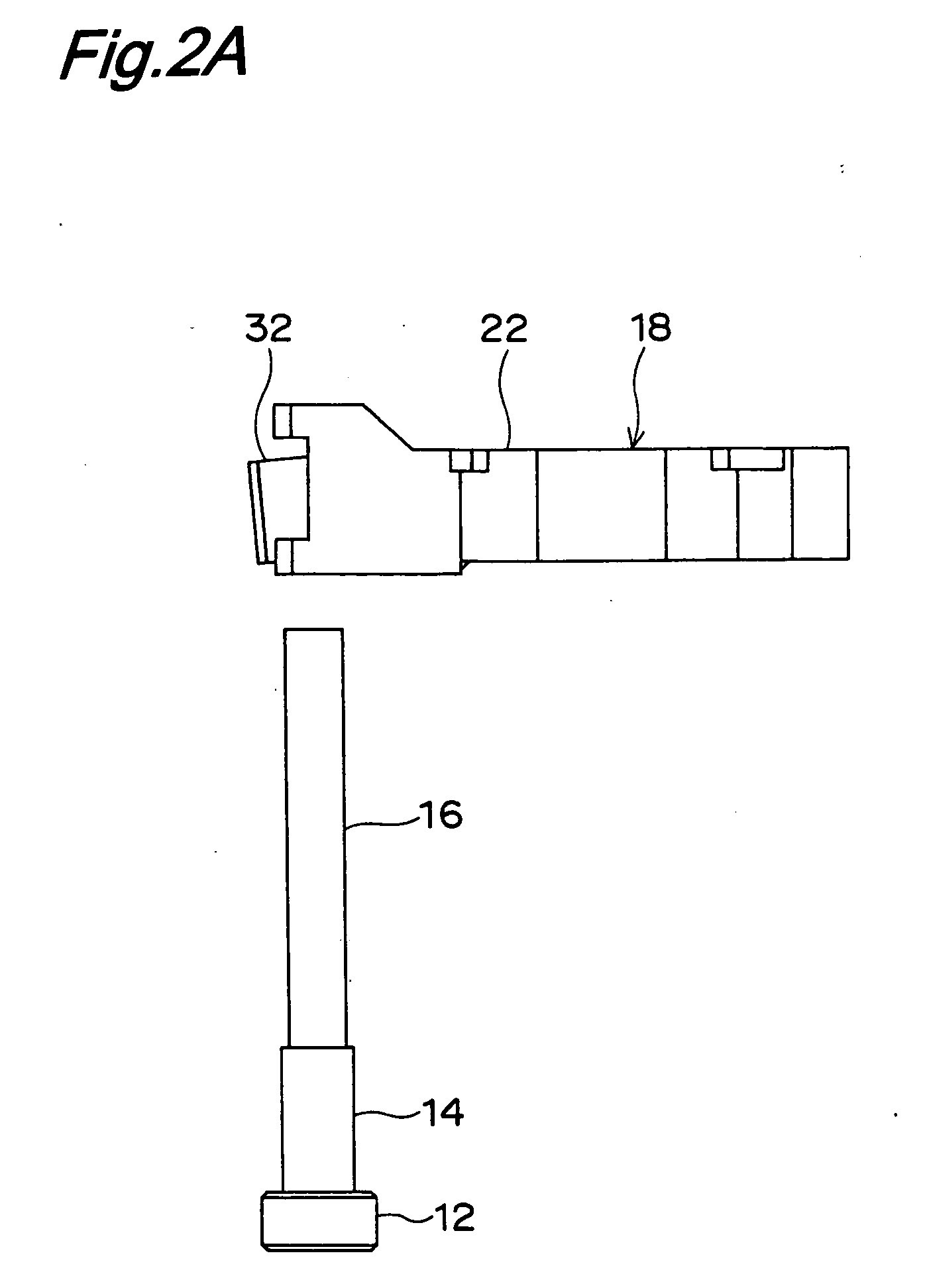

Drive unit

InactiveUS20070096601A1Low costEasy to carryPiezoelectric/electrostriction/magnetostriction machinesMountingsLeaf springEngineering

A drive unit of the present invention includes a piezoelectric element, a drive friction member fixed to one end of the piezoelectric element, and a movable member frictionally fitted to the drive friction member. By making the piezoelectric element expanded and contracted, the movable member is moved relative to the drive friction member. The leaf spring for pressing the movable member against the drive friction member is provided integrally with the movable member.

Owner:KONICA MINOLTA OPTO

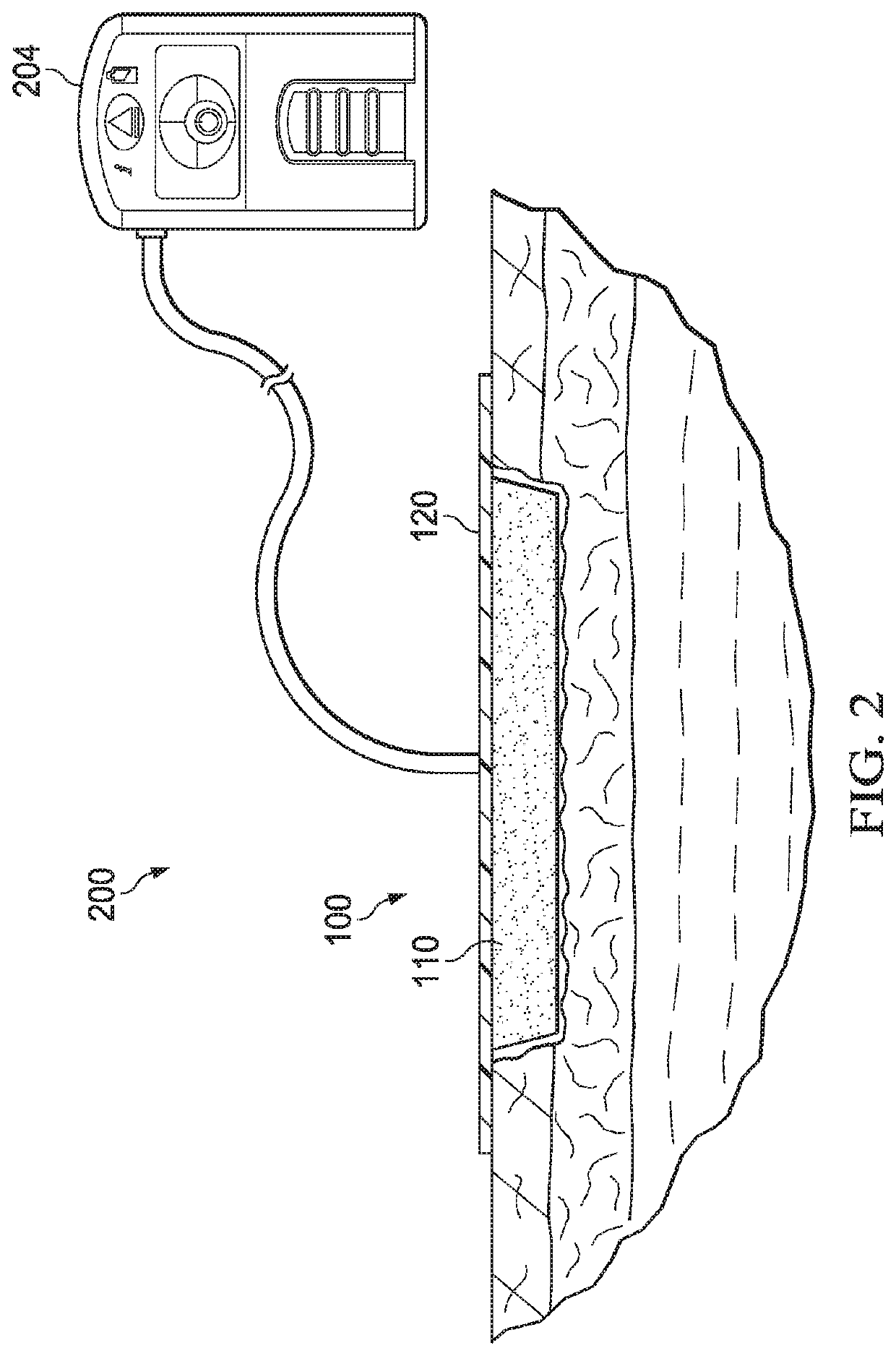

Post-operative surgical wound dressing

InactiveUS20200197227A1Eliminating and minimizing and reducing edemaReduce plastic deformationPlastersAdhesive dressingsWound dressingReoperative surgery

Described herein is a wound dressing comprising: a composite island configured to collectively exhibit substantially elastic recovery under wound treatment conditions and comprising a foam layer and an absorbent layer coupled to the foam layer, the foam layer exhibiting substantially elastic recovery under wound treatment conditions and the absorbent layer not exhibiting substantially elastic recovery under wound treatment conditions; a backing layer having a margin that extends beyond the composite island; and an adherent layer disposed on at least the margin of the backing layer. In addition, described herein is a method of eliminating, minimizing, or reducing edema for a wound surrounded by tissue, by positioning the wound dressing over the wound, optionally such that at least a portion of the adherent layer contacts the tissue.

Owner:KCI USA +2

Resistance spot welding electrode

InactiveUS20050029234A1Easy to weldLong electrode lifeOhmic-resistance electrodesWelding/cutting media/materialsElectrical resistance and conductanceEngineering

A composite resistance spot welding electrode is disclosed which comprises a co-axial annular neck ring, a co-axial insert, a co-axial annular sleeve, or combinations there of. The electrode provides improved nugget formation and longer electrode life.

Owner:BATTELLE MEMORIAL INST

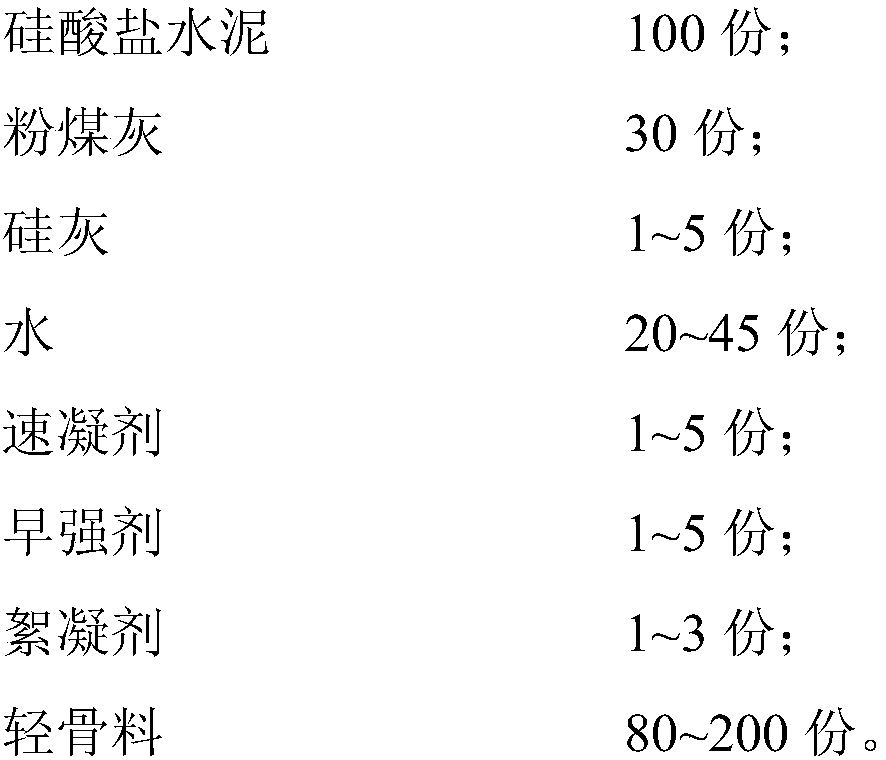

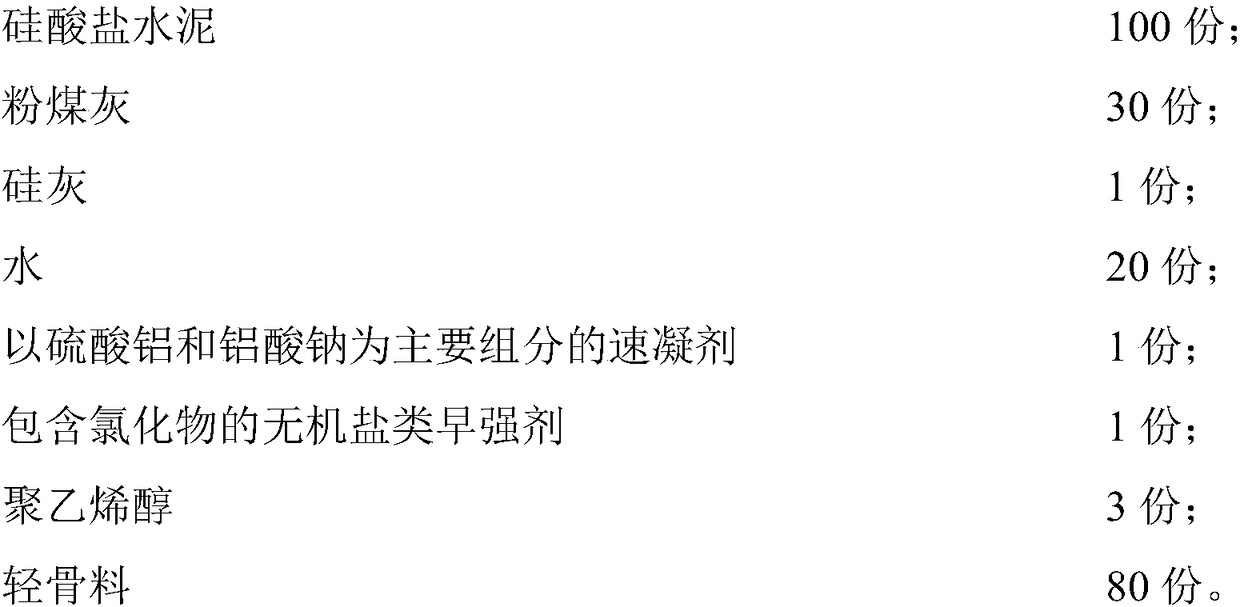

Lightweight aggregate concrete used for 3D printing and preparation method and application thereof

InactiveCN108164215ARelieve pressureReduce plastic deformationCeramic shaping apparatusSelf weightPlastic property

The invention relates to a lightweight aggregate concrete used for 3D printing and a preparation method and an application thereof. The concrete comprises the following components in parts by weight:100 parts of Portland cement, 30 parts of fly ash, 1-5 parts of silicon ash, 20-45 parts of water, 1-5 parts of an accelerator, 1-5 parts of an early strength agent, 1-3 parts of a flocculating agent,and 80-200 parts of a light aggregate. The preparation method comprises the following steps: mixing ceramsite to obtain the light aggregate, then mixing Portland cement, fly ash, silicon ash, the accelerator, and the early strength agent to obtain mixed powder, and uniformly mixing the light aggregate and the mixed powder to obtain a coagulation material, which can be used as the raw material ofa 3D printer construction concrete structure. Compared with the prior art, self weight of the lightweight aggregate concrete is light, pressure of the concrete at middle and upper layers on the concrete at a lower layer during a printing process can be greatly reduced, plastic deformation of the concrete at bottom is reduced, collapse possibility is reduced, and the concrete provides the heat insulation function for the concrete material.

Owner:TONGJI UNIV

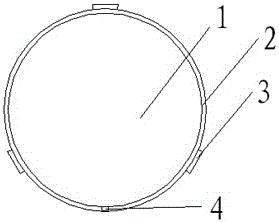

Endoscope robot control method and device based on pressure sensor information

ActiveCN105796043AControl contact forceSmall elastic deformationSurgeryEndoscopesControl systemSimulation

The invention discloses an endoscope robot control method and device based on pressure sensor information. An operator actively controls a robot to bend in the intestine according to intestinal interior information fed back by a camera at the front end of an S-shaped body of the colonoscope robot; a robot control system collects contact force information of the robot and the intestine in real time by means of a pressure sensor of the bent body part, and the relation between the robot motion distance r and contact force F is obtained by analyzing the colon tissue biomechanical characteristics, so that the joint posture of the robot is adjusted to ensure that the contact force is within the safety threshold value range; the control system corrects the whole posture of all joints of the robot by means of the motion coupling relation of all the joints, the contact force coming from all the joints of the robot can be effectively detected, and when the robot touches the intestine, the colonoscope robot control system can control the robot gently to enable the contact force between the robot and the intestine to be within the safety threshold value range, so that safety of the intestine of the human body during examination is ensured.

Owner:SUZHOU UNIV

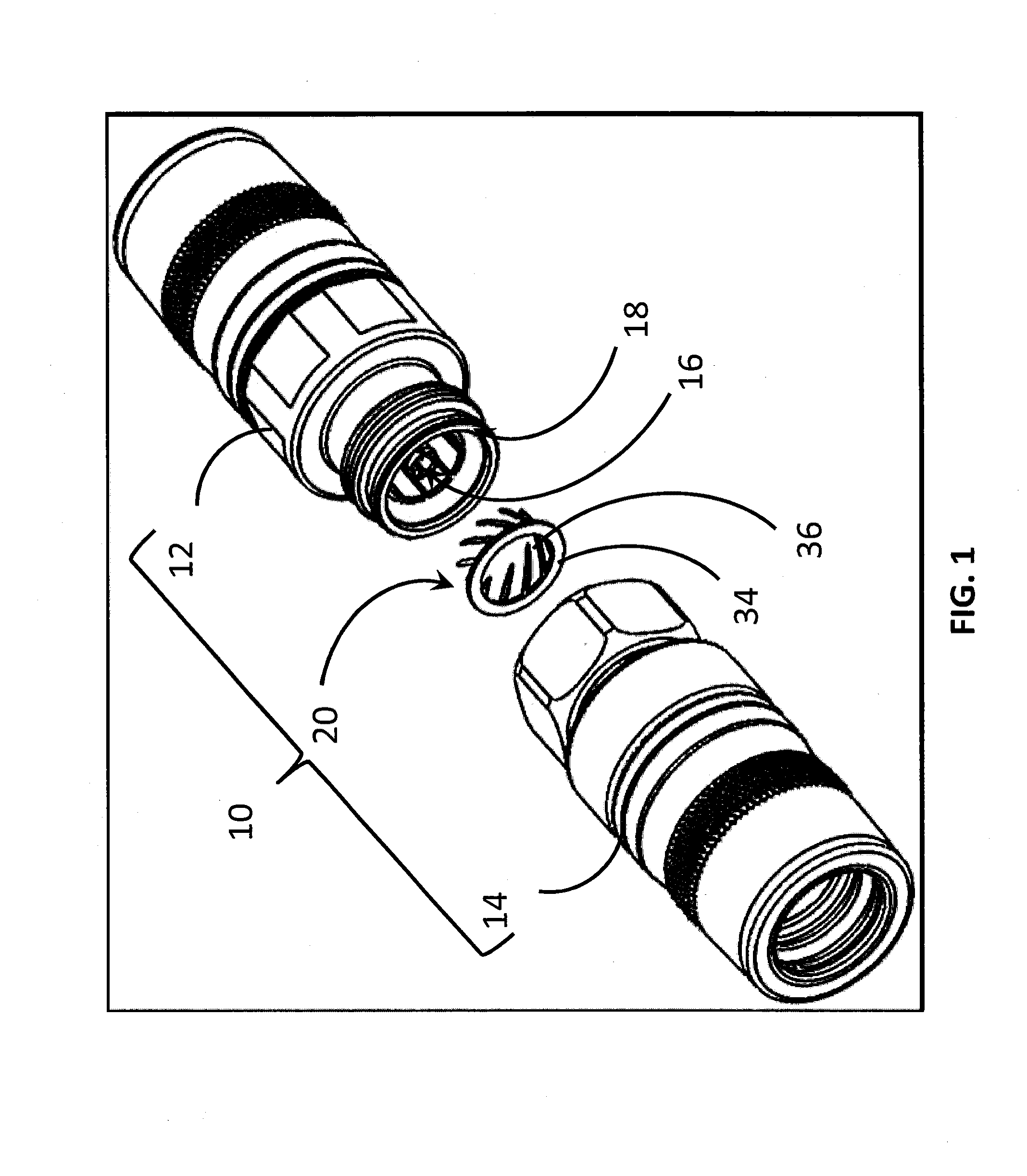

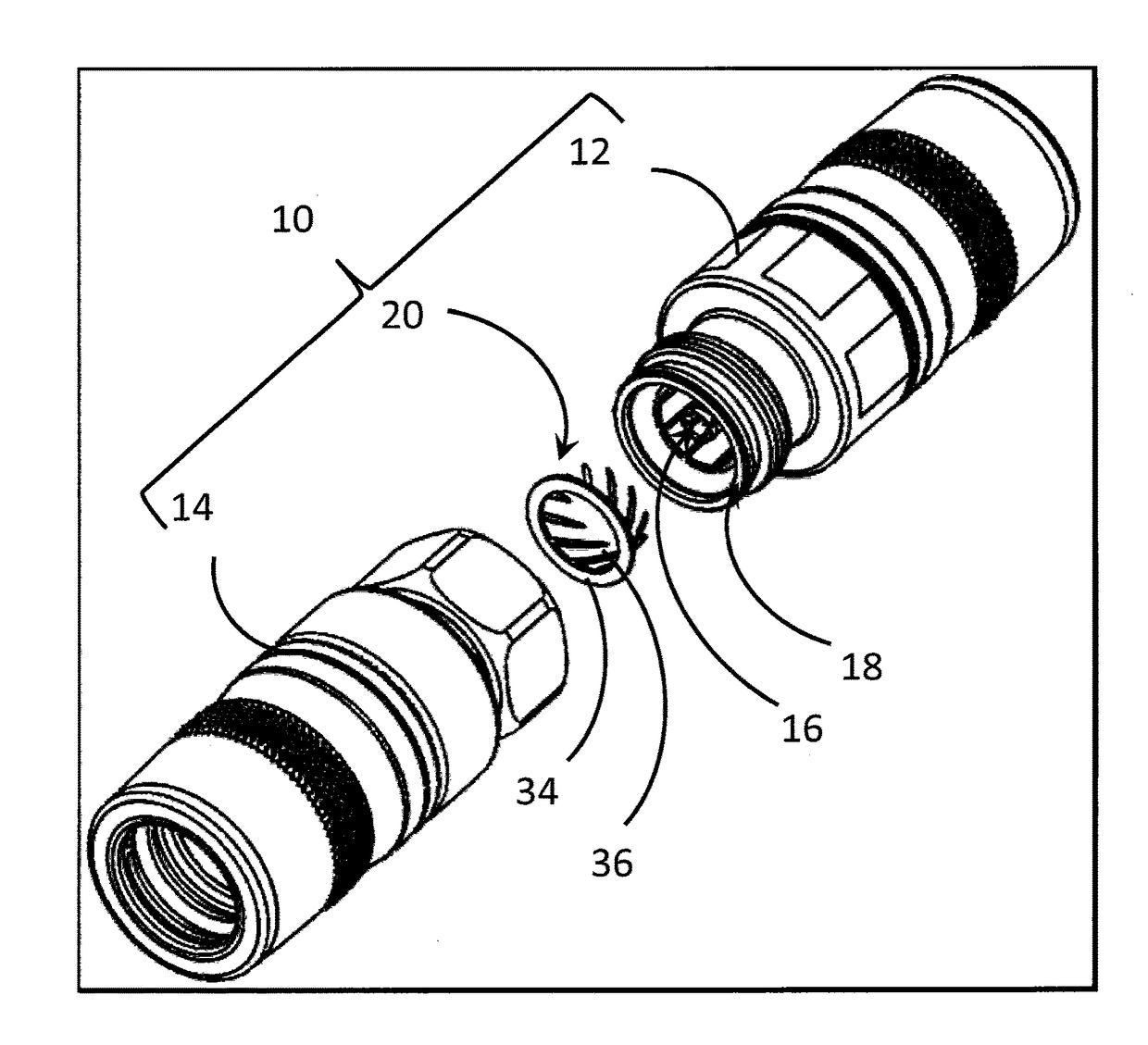

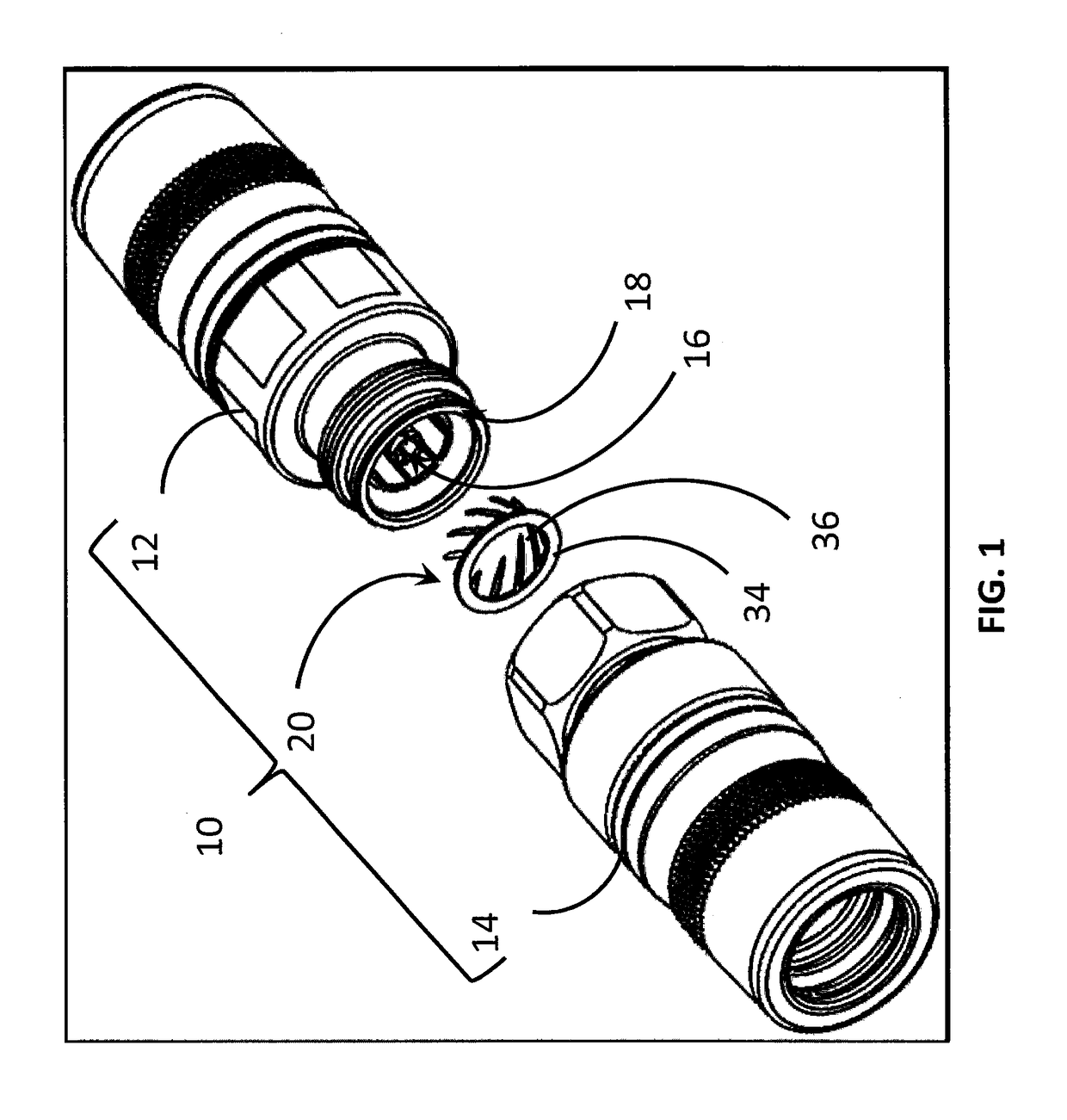

Device and method for protecting spring-biased conductor elements

ActiveUS20160336676A1Avoid damageReduce plastic deformationAntenna connectorsTwo-part coupling devicesElectrical conductorEngineering

A connector is provided including first and second connector portions each comprising electrically-connecting inner and outer conductors. A insert interposes the spring-biased fingers of an outer conductor basket of one of the connectors to prevent damage to the fingers in an unassembled condition / state, thereby ensuring electrical connectivity of the fingers in an assembled condition / state.

Owner:JOHN MEZZALINGUA ASSOC LLC

Special disk spring gasket and clutch release bearing assembly

ActiveCN101493111AReduce plastic deformationIncrease the amount of axial dimension deformationMechanical actuated clutchesWashersMobile vehicleDistortion

The invention relates to a special disk spring washer of a clutch release bearing of a motor vehicle. The washer of the prior art is short of enough elastic deformation amount in a stated elastic force range to cause that the plastic deformation or over-error elasticity of the spring washer easily comes about in assembly. A ring-shaped wave main part of the special disk spring washer forms a taper angle shape with the diametral plane, and the inner edge and the outer edge of the ring-shaped wave main part are respectively provided with an inner edge radula and an outer radula to increase the axis size distortion deflection of the ring-shaped wave main body, thus broadening the allowable deformation range of the mounting dimensions of the spring washer in the necessary elastic range, increasing the percent of pass of products, and reducing the plastic deformation caused by the limit axial direction deformation mount of the spring washer when in mounting.

Owner:陈炳顺

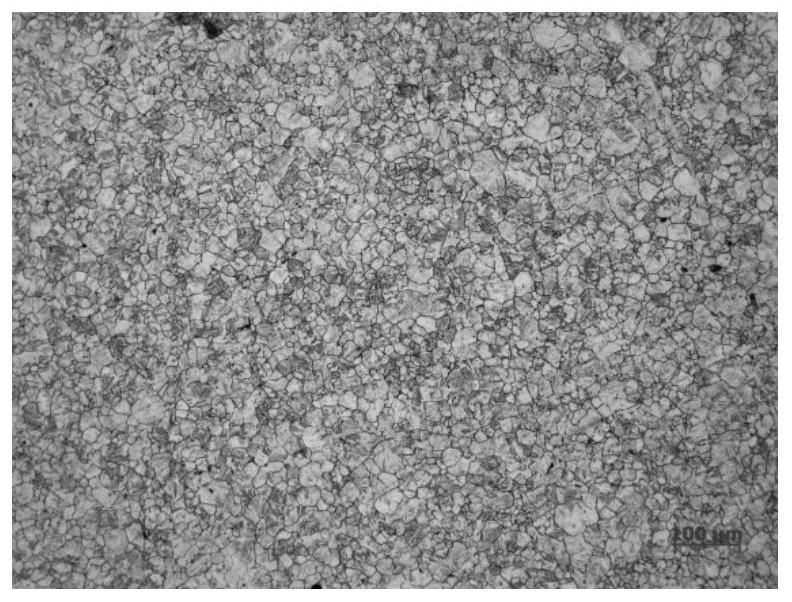

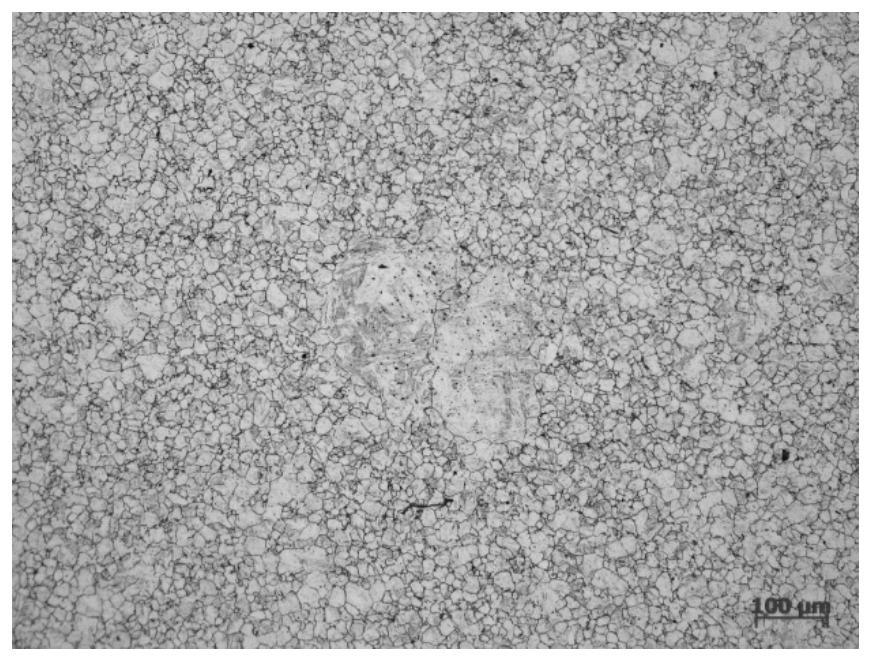

Manufacturing method of steel for speed reducer gear of electric automobile

PendingCN112981271AHigh strengthUniform plastic deformationProcess efficiency improvementScrapElectric furnaces

The invention relates to a manufacturing method of steel for a speed reducer gear of an electric automobile, belongs to the technical field of iron-based alloys, and particularly relates to steel for gears. According to the element composition design related, the steel comprises, by mass, 0.20%-0.35% of C, 0.05%-0.35% of Si, 1.20%-1.60% of Mn, 1.10%-1.50% of Cr, 0.20%-0.50% of Mo, smaller than or equal to 0.035% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.20% of Ni, 0.010%-0.080% of Al, 0.0060%-0.0260% of N and the balance Fe and inevitable impurities, wherein Al / N is equal to 1.5 to 3.9. The smelting technological process comprises the following steps of pre-treated molten iron and optimized scrap steel, primary smelting in an electric furnace, refining in an LF furnace, vacuum degassing in a VD furnace, continuous casting of square billets, shot blasting of the continuously-cast square billets, heating in a walking beam furnace, descaling with high-pressure water, rolling of the continuous casting billets, surface flaw detection and internal ultrasonic flaw detection of hot-rolled round steel, quality inspection and warehousing. The element components are matched with the smelting process, and the steel meets the requirements of high strength and long fatigue life of the steel for an electric automobile speed reducer. And remarkable advantages are obtained on the aspects of hardenability and grain uniformity.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for preparing nitrogen-yttrium-zirconium hard coating with nano structure on surface of hard alloy substrate

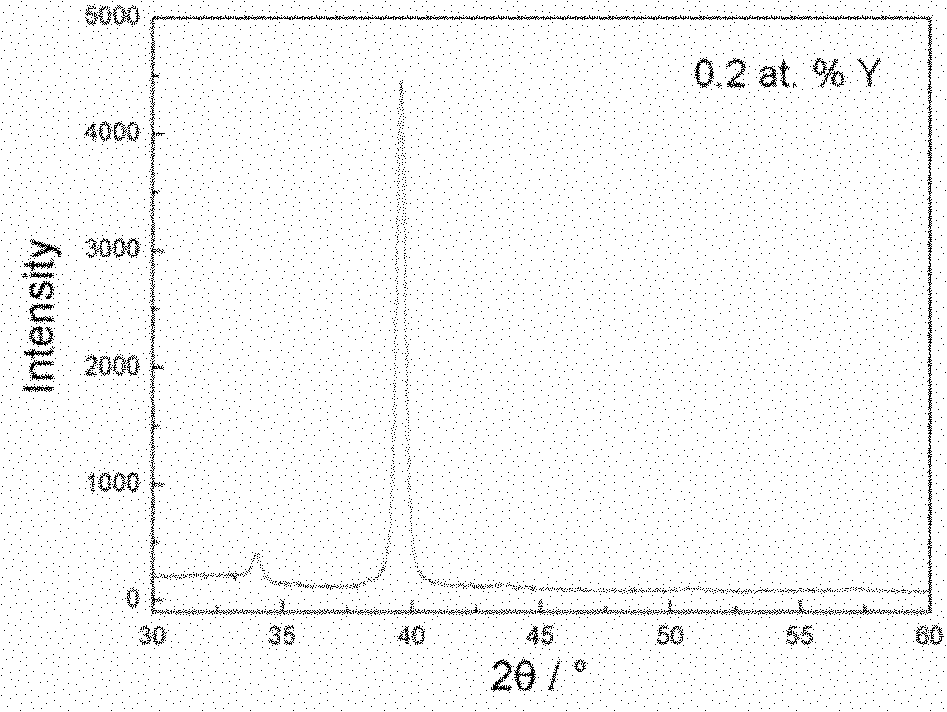

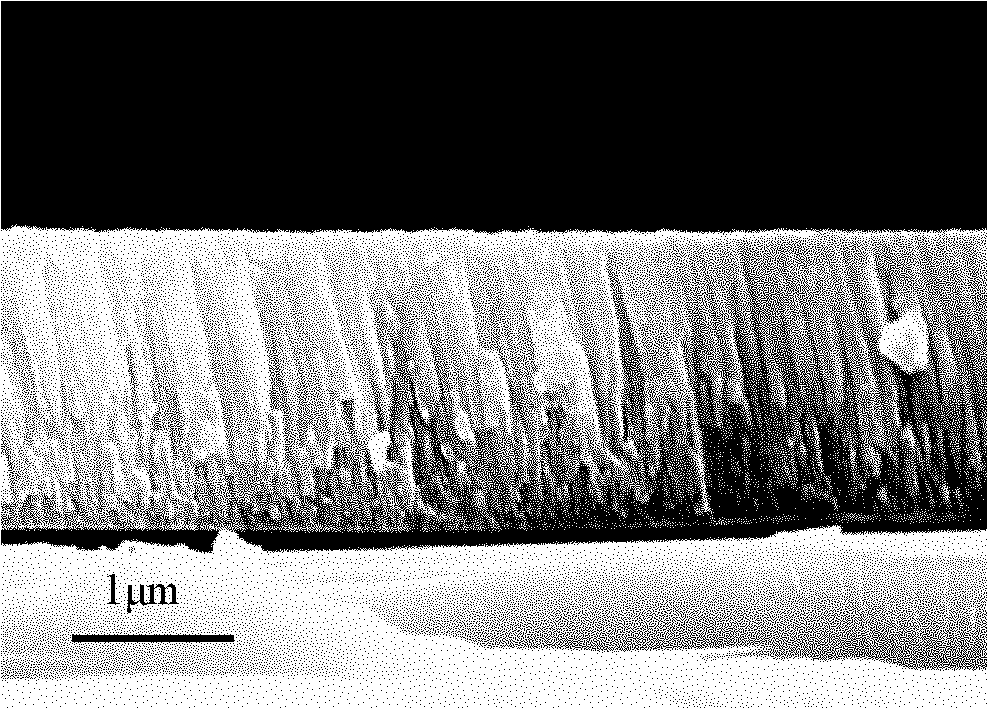

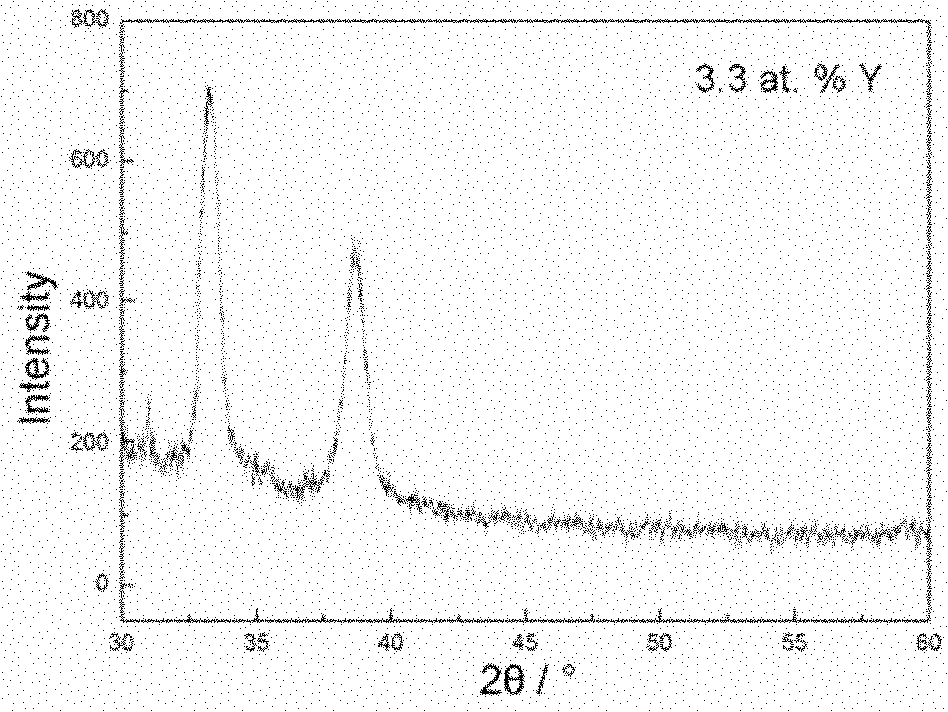

InactiveCN101928916AY content decreasedPromote growthVacuum evaporation coatingSputtering coatingNano structuringAlloy substrate

The invention discloses a method for preparing a nitrogen-yttrium-zirconium hard coating with a nano structure on the surface of a hard alloy substrate, which relates to a hard alloy, in particular to a method for preparing the nitrogen-yttrium-zirconium hard coating with the nano structure on the surface of the hard alloy substrate by using a magnetron sputtering process. In the method, the nitrogen-yttrium-zirconium hard coating with a nano composite structure and high hardness is formed by sputtering and deposition on the surface of the hard alloy substrate which is polished mechanically, washed ultrasonically and washed by an ion source, wherein the sputtering and deposition are direct-current and radio-frequency reactive co-sputtering and deposition, the control total pressure is 0.3 to 0.5Pa, the nitrogen flow rate is 15 to 20 percent, the Zr target direct current power is 250 W, the radio frequency power supply power of a Y target is 50 to 200W, the temperature of the substrate is 300 DEG C, and the deposition time is 90 minutes.

Owner:XIAMEN UNIV

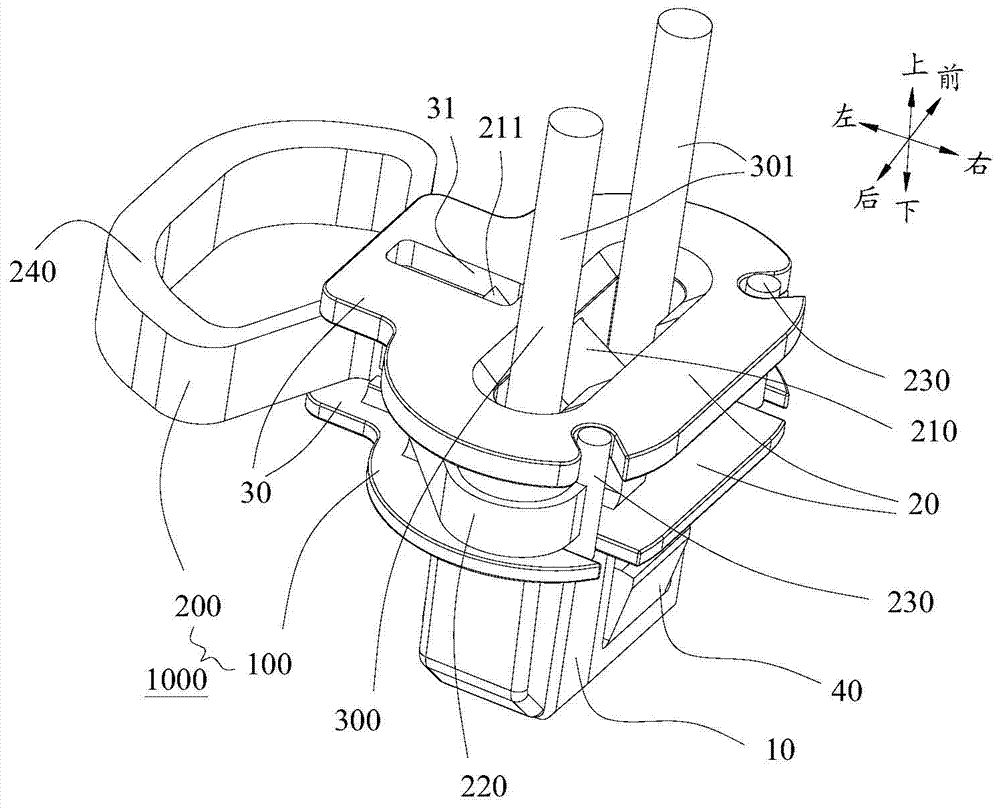

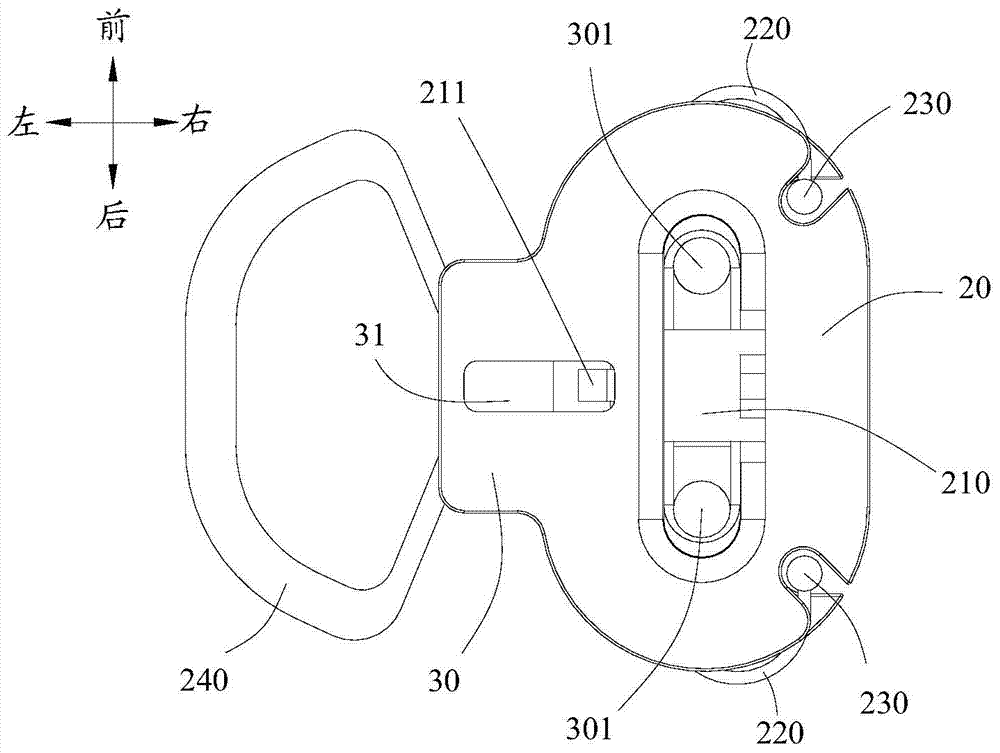

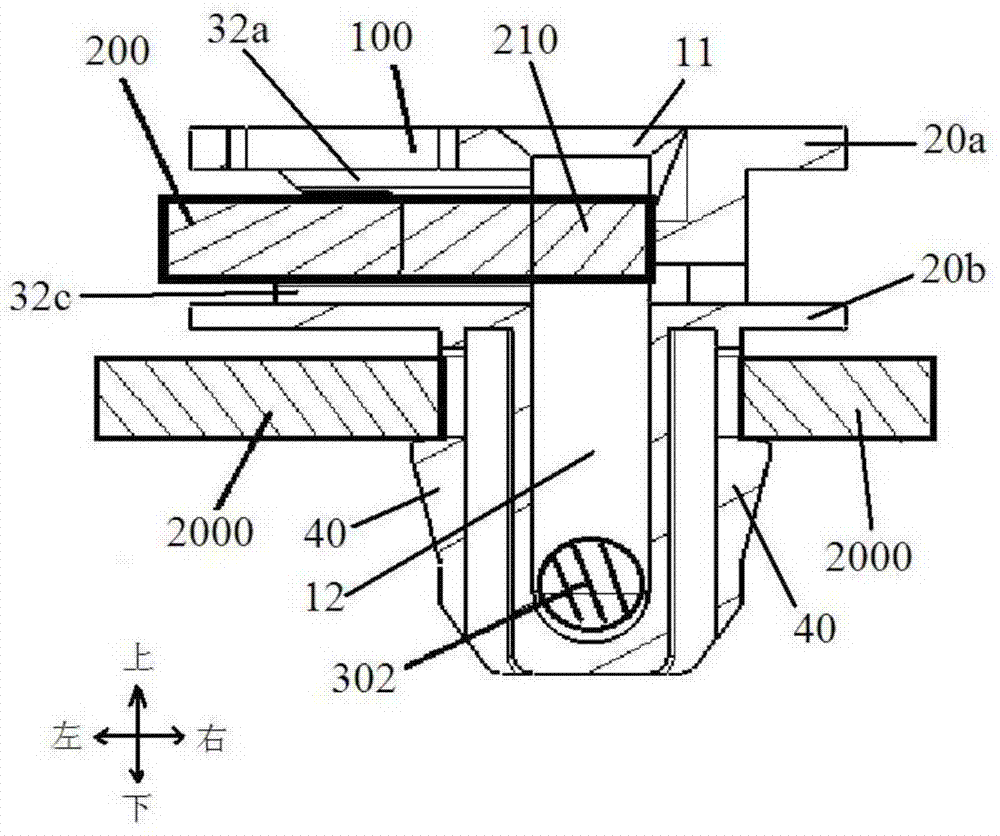

Cushion locking device and vehicle with cushion locking device

ActiveCN104512280AReasonable structureEasy to operateVehicle seatsRopes and cables for vehicles/pulleyInterference fitCushion

The invention discloses a cushion locking device and a vehicle with the cushion locking device, wherein the cushion locking device comprises a deck and a fastener; the deck is internally provided with an accommodation cavity with a slot in the top; a pin hole communicated with the accommodation cavity is formed in the side wall of the deck. The fastener comprises a pin and two grabs which are arranged on the opposite side walls of the pin and are symmetrical relative to the pin; one end of the pin is inserted into the accommodation cavity through the pin hole; the two grabs are arranged on the peripheral wall of the deck in a matching manner, so that the fastener is enabled to be arranged on the deck. According to the cushion locking device, by arranging the fastener on the deck, the cushion locking device is reasonable in structure, and convenient to operate, and a cushion and a car body can be connected firmly and reliably. Meanwhile, the cushion locking device does not adopt a steel wire, so that interference fit between the steel wire and the deck is avoided, the friction damage and the plastic deformation of the deck are decreased, and the deck can also be used even after the cushion is disassembled and assembled for multiple times, so that the use cost is lowered.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

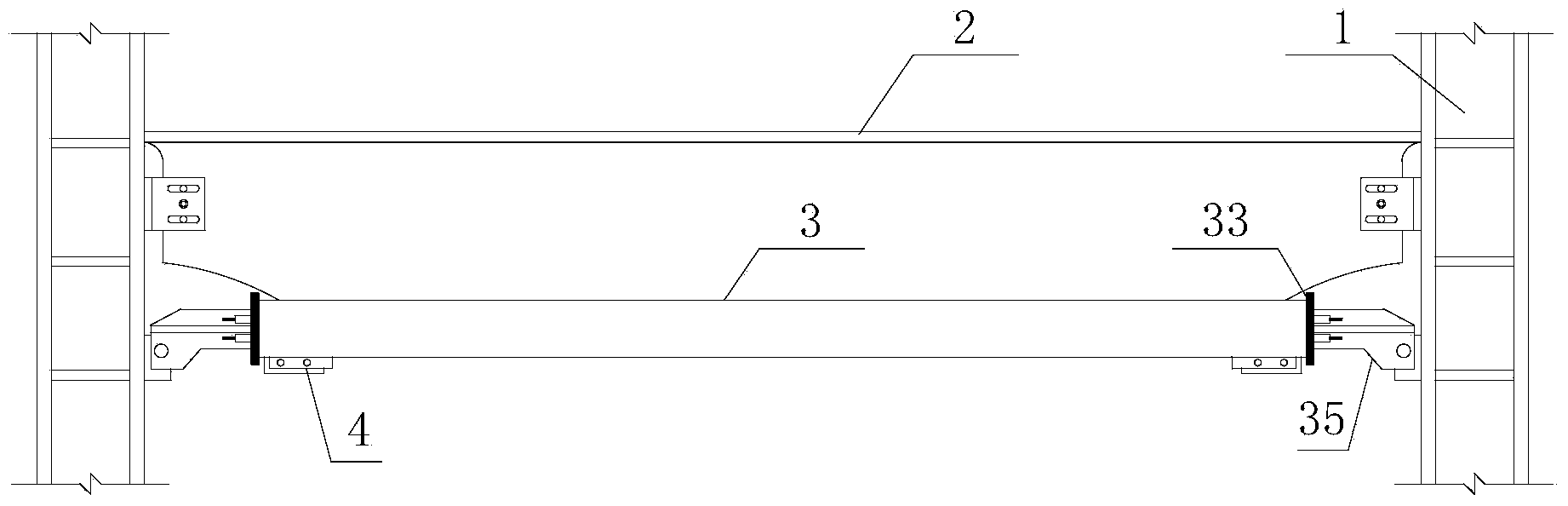

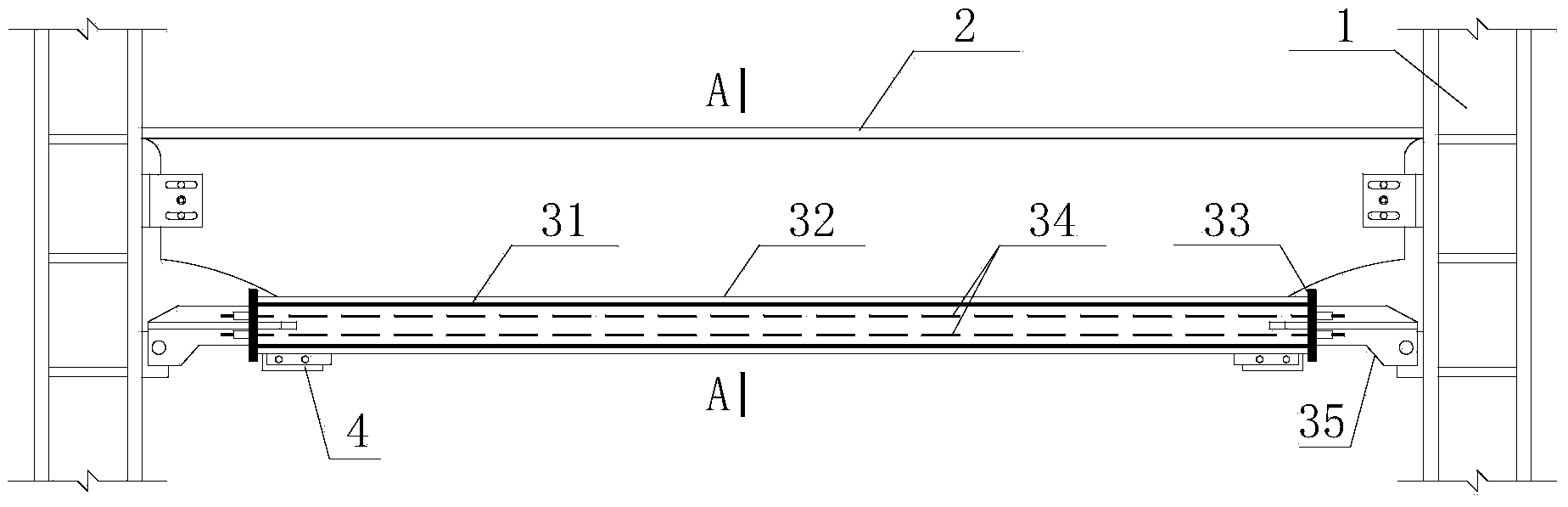

Post-tensioning prestress type self-centering steel frame structure

The invention discloses a post-tensioning prestress type self-centering steel frame structure. The post-tensioning prestress type self-centering steel frame structure comprises at least one structural unit. Each structural unit comprises two steel frame columns, a T-shaped steel beam, a self-centering connecting piece and friction energy consumption parts, wherein the T-shaped steel beam is used for connecting the upper ends of the steel frame columns, the self-centering connecting piece is located on the lower side of the T-shaped steel beam and used for connecting the steel frame columns, and the friction energy consumption parts are located on the lower portion of the self-centering connecting piece. Each self-centering connecting piece comprises an inner sleeve, an outer sleeve, end plates, pretensioning rods and connectors, wherein the inner sleeve is sleeved with the outer sleeve, the end plates are located at the two ends of the sleeves, the pretensioning rods are arranged in the inner sleeve and anchored on the end plates, and the connectors are connected with the ends of the inner sleeve. Each friction energy consumption part comprises an inner friction plate, an outer friction plate and a friction gasket, wherein the inner friction plate is connected with the inner sleeve, the outer friction plate is connected with the lower side face of the outer sleeve, the friction gasket is arranged between the inner friction plate and the outer friction plate, and the sliding direction of the inner friction plate and the sliding direction of the outer friction plate are arranged in the axial direction of the outer sleeve. Column space is kept unchanged when the columns are laterally deformed, and the strength, the rigidity and the ductility of the structure can be flexibly and independently adjusted and controlled in the design process.

Owner:SOUTHEAST UNIV

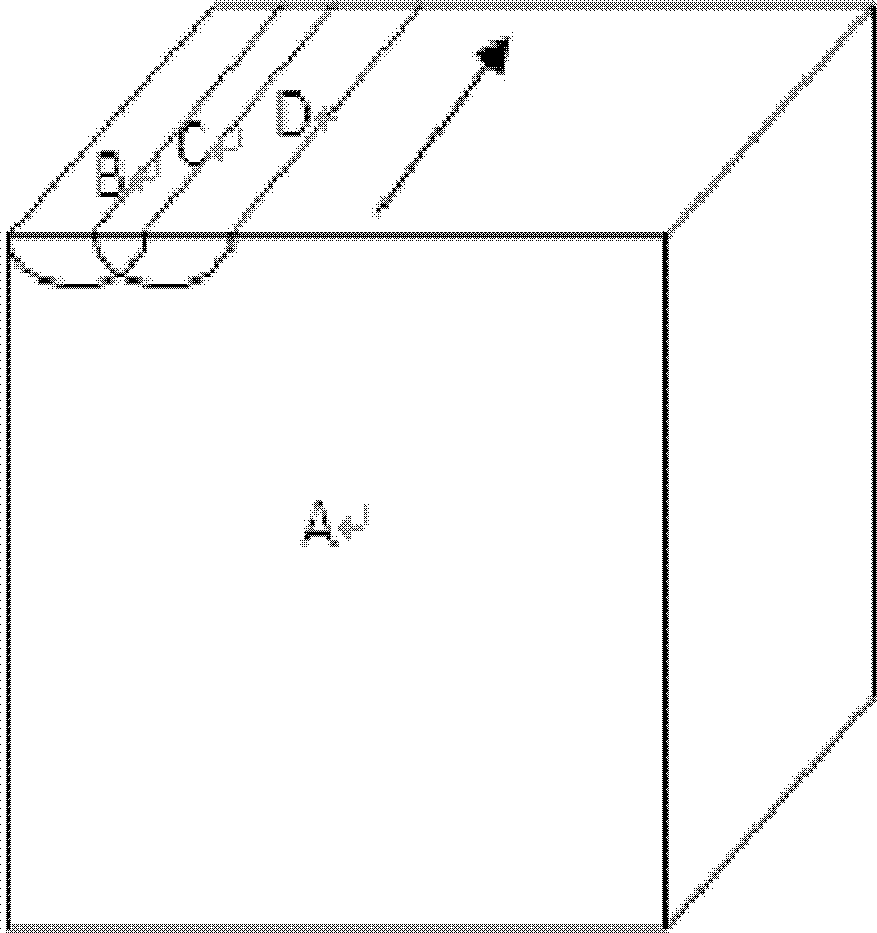

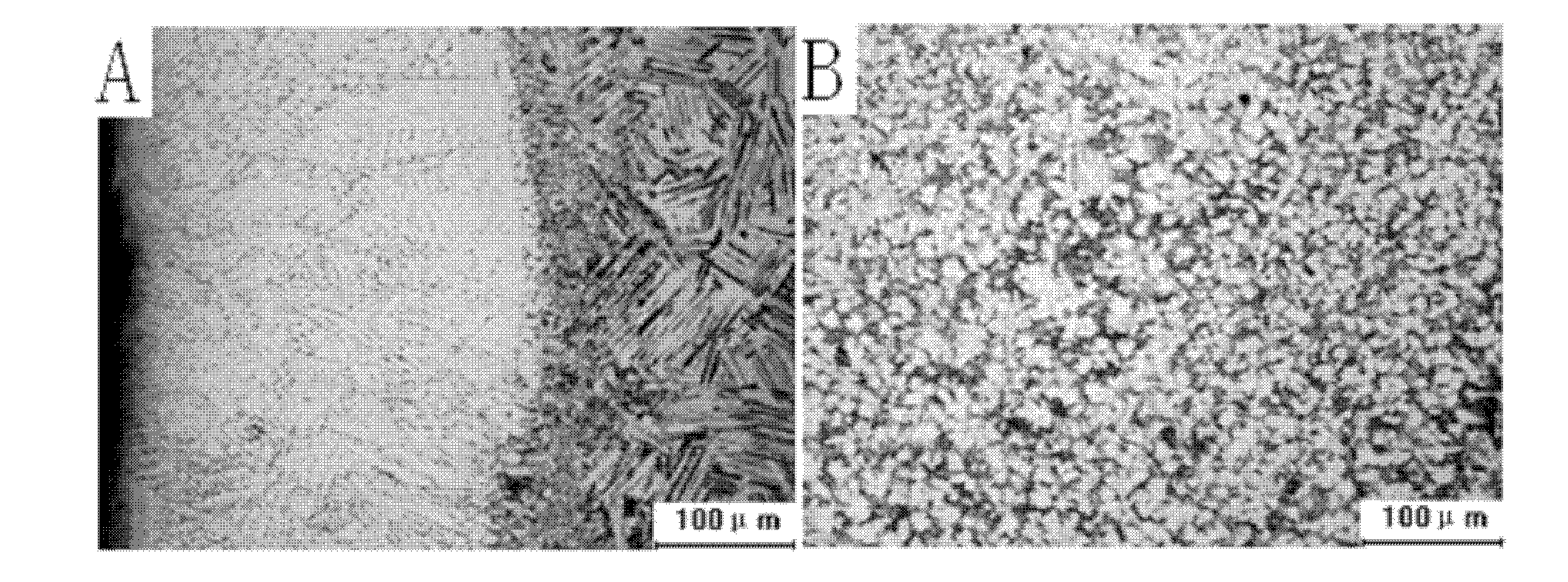

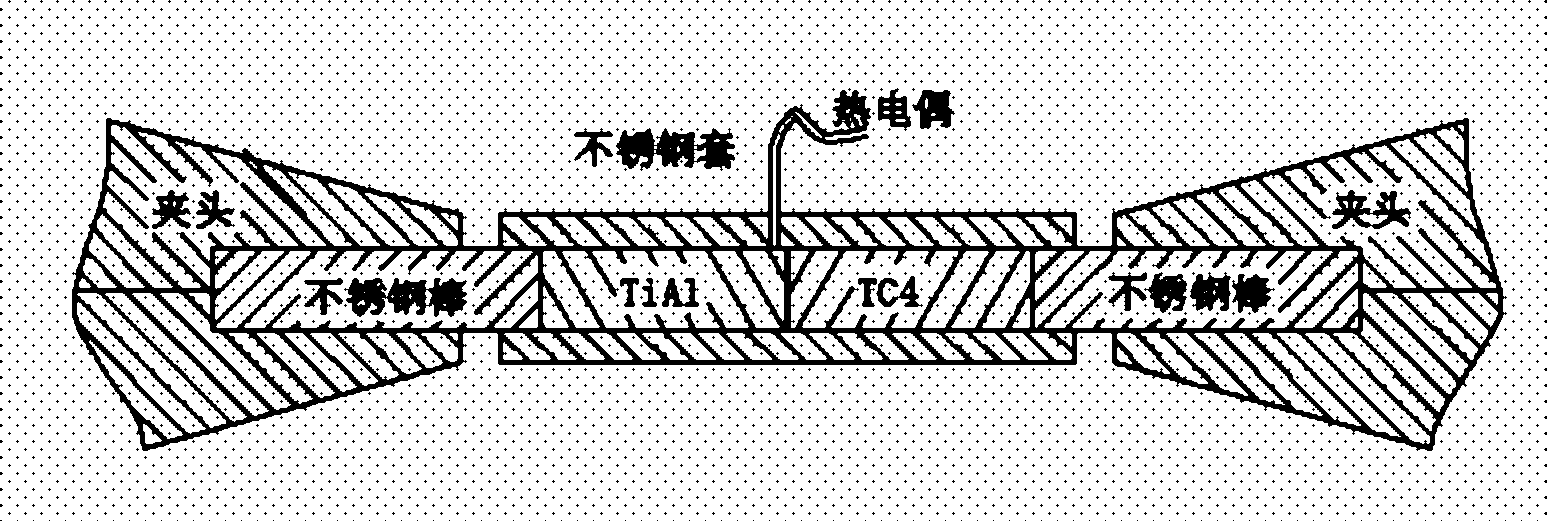

Method for performing diffusion welding of aluminum base alloy and titanium alloy after laser melting

InactiveCN102554457AProcess stabilityReduce plastic deformationWelding/soldering/cutting articlesNon-electric welding apparatusTitanium alloyMetal

The invention discloses a method for performing diffusion welding of aluminum base alloy and titanium alloy after laser melting, which belongs to the field of welding technology. The method comprises the following steps: clearing the surface of welding parent metal; performing laser melting on cleared aluminum base alloy and titanium alloy to be welded; putting the aluminum base alloy and the titanium alloy to be welded in a protective sleeve after the laser melting; and performing the diffusion welding for the aluminum base alloy and the titanium alloy at a temperature range of 900-930 DEG C and a pressure range of 60-90MPa. According to the invention, the tensile strength of an obtained joint is at a range of 320-380MPa under normal temperature, up to 70-87% of the tensile strength of titanium alloy parent metal; and under the temperature of 400 degree, the tensile strength is at the range of 330-400MPa, up to 70-83% of the tensile strength of titanium alloy parent metal.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

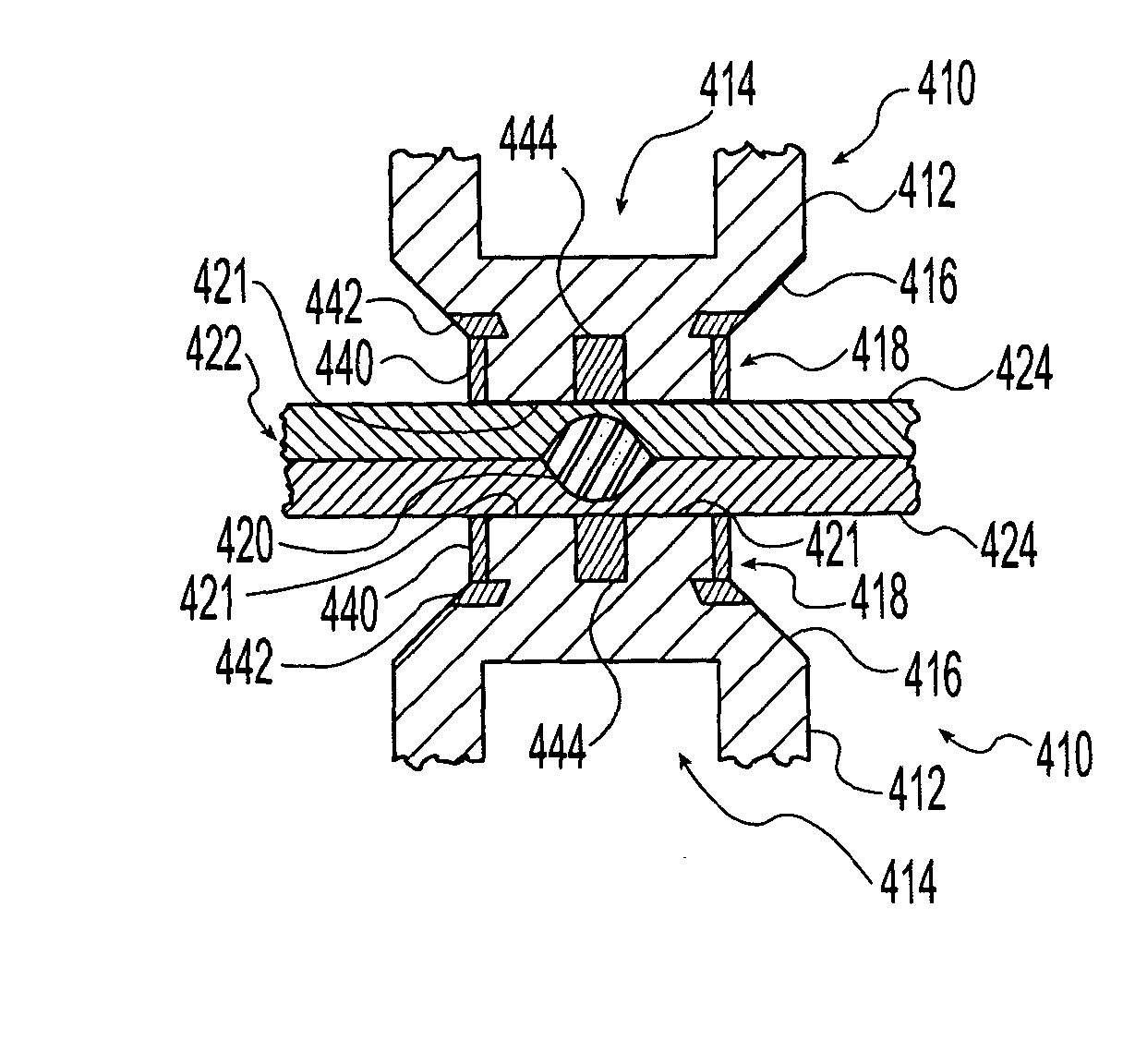

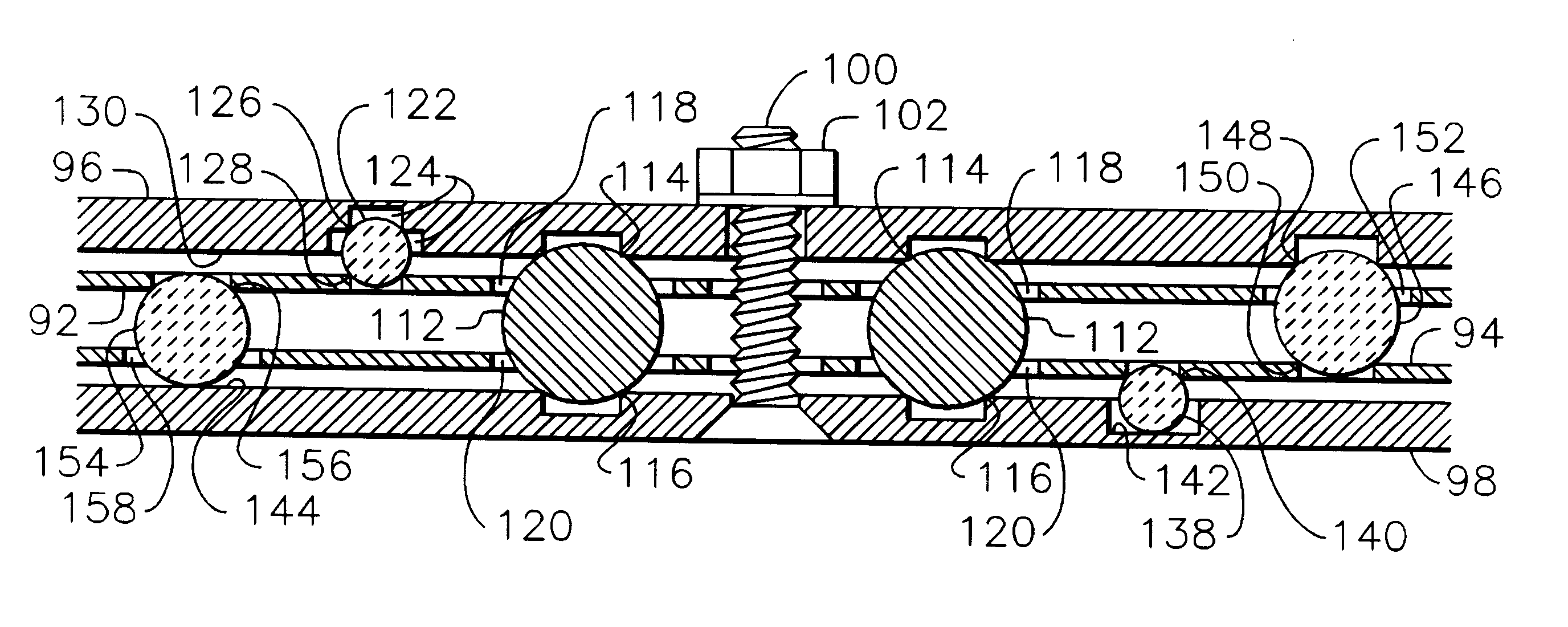

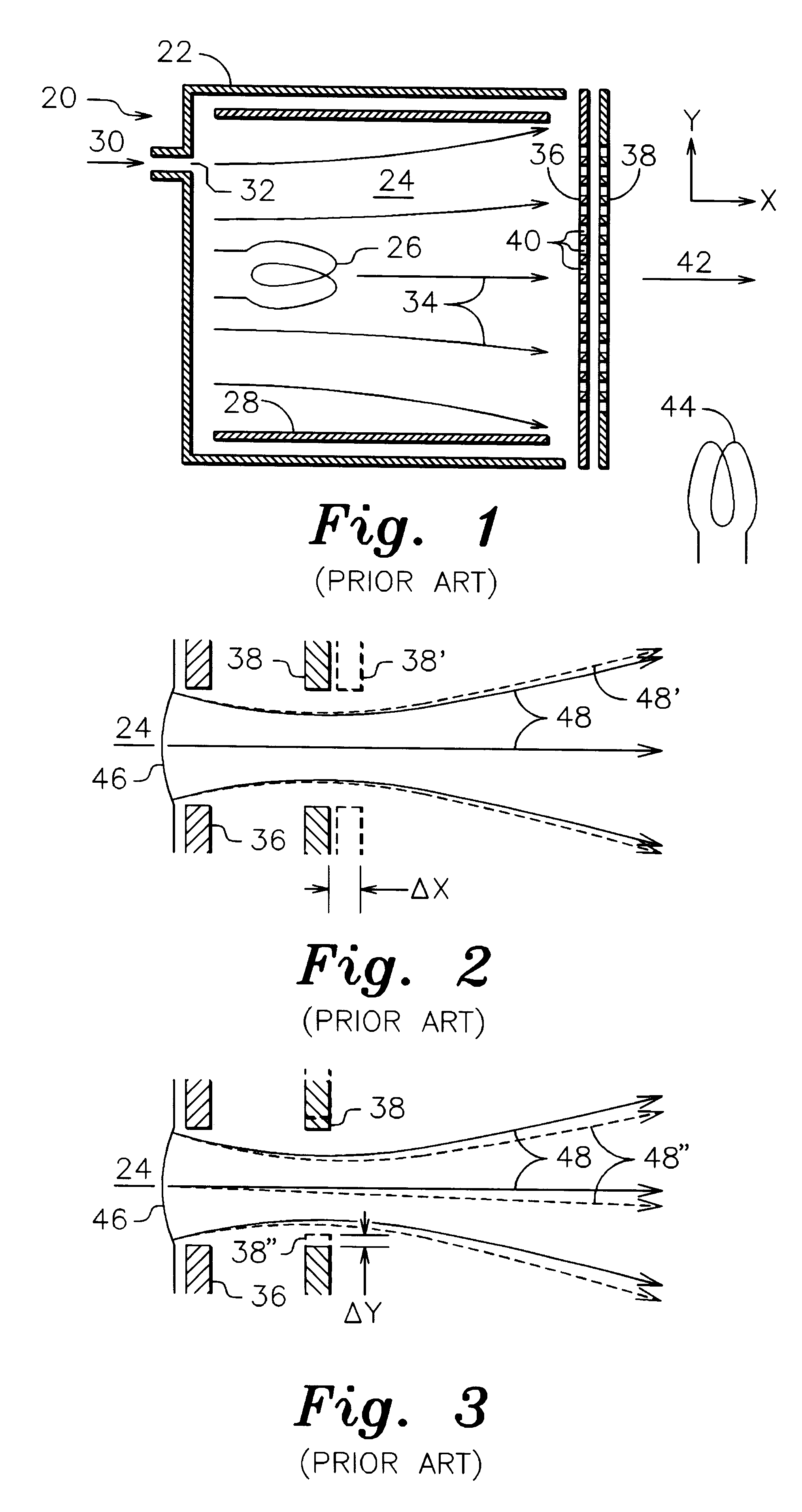

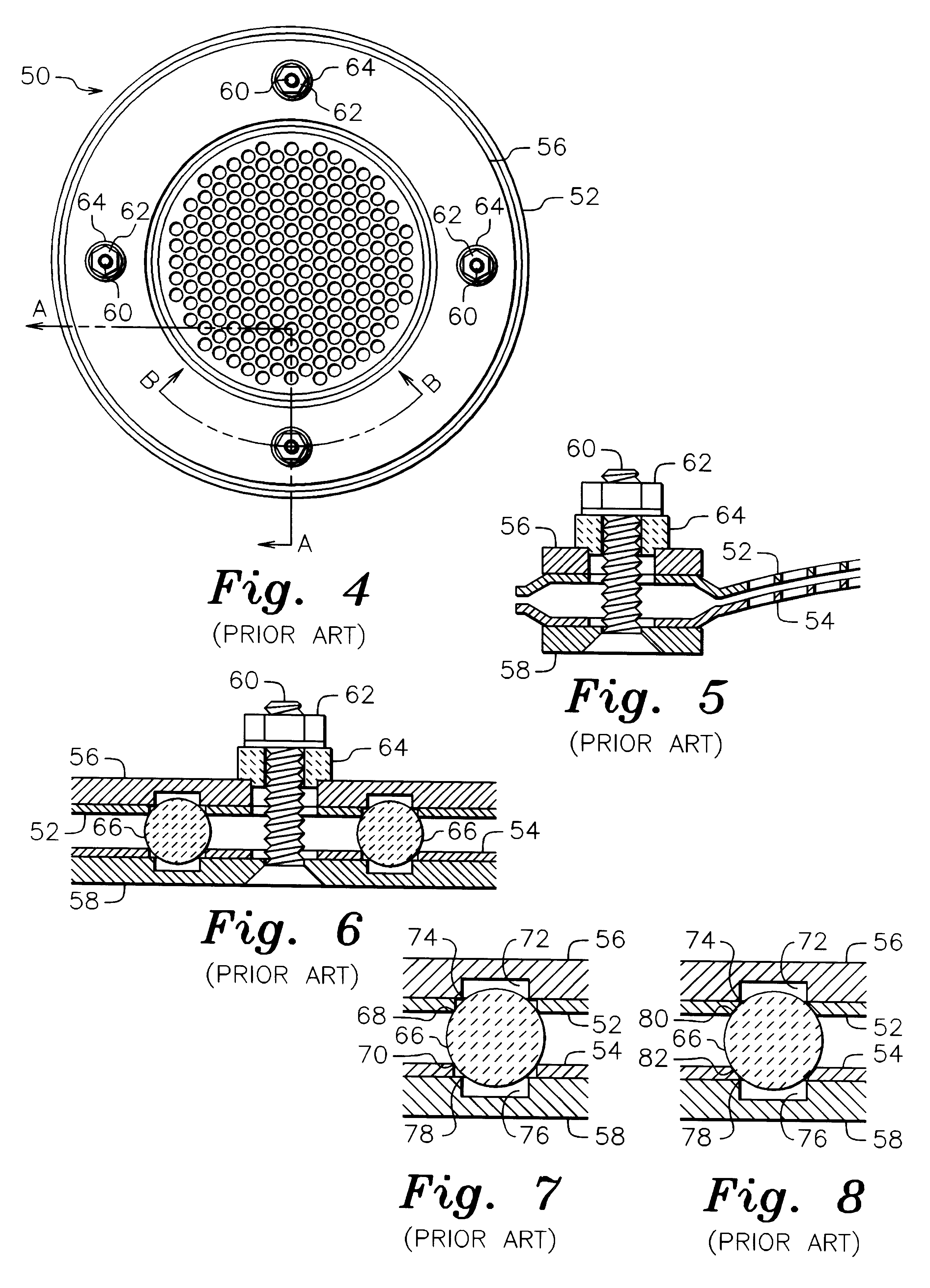

Ion optics

InactiveUS6246162B1Reduce forceReduces plastic deformationElectrode assembly support/mounting/spacing/insulationIon beam tubesPhysicsElectrically conductive

In one embodiment of the present invention, the ion optics for use with an ion source have first and second electrically conductive grids having mutually aligned respective pluralities of apertures through which ions may be accelerated and wherein each has an integral peripheral portion. There is also a support member. There are first and second series of seats around the respective peripheral portions of the first and second grids. A plurality of first spherical insulators are distributed between seats of the first and second series, thereby establishing a predetermined distance between the grids while still enabling radial movement between their peripheral portions. There are third and fourth series of seats around the support member and the peripheral portion of the second grid, respectively, with seats of the fourth series displaced from those of the second series in the same grid. A plurality of second spherical insulators are distributed between seats of the third and fourth series, thereby establishing a predetermined distance between the support member and the second grid while still enabling motion in at least the radial direction between the support member and the peripheral portion of the second grid. A clamping force between the support member and the peripheral portion of the first grid maintains contact between the insulators and their seats.

Owner:KAUFMAN & ROBINSON

Device and method for protecting spring-biased conductor elements

ActiveUS10122131B2Avoid damageReduce plastic deformationAntenna connectorsTwo-part coupling devicesMating connectionElectrical conductor

A connector including first and second connector portions each comprising electrically-connecting inner and outer conductors and an inhibitor interposing the inner and outer conductors configured to inhibit the inadvertent insertion of a non-mating connector between the inner and outer conductors. In one embodiment an insert is disposed over a plurality of spring-biased fingers of the outer conductor to prevent deformation of the fingers in an unassembled condition / state by insertion of the non-mating connector. In another embodiment, the insert includes a plurality of radial members disposed between a central hub and an outer ring to prevent insertion of the non-mating connector.

Owner:JOHN MEZZALINGUA ASSOC LLC

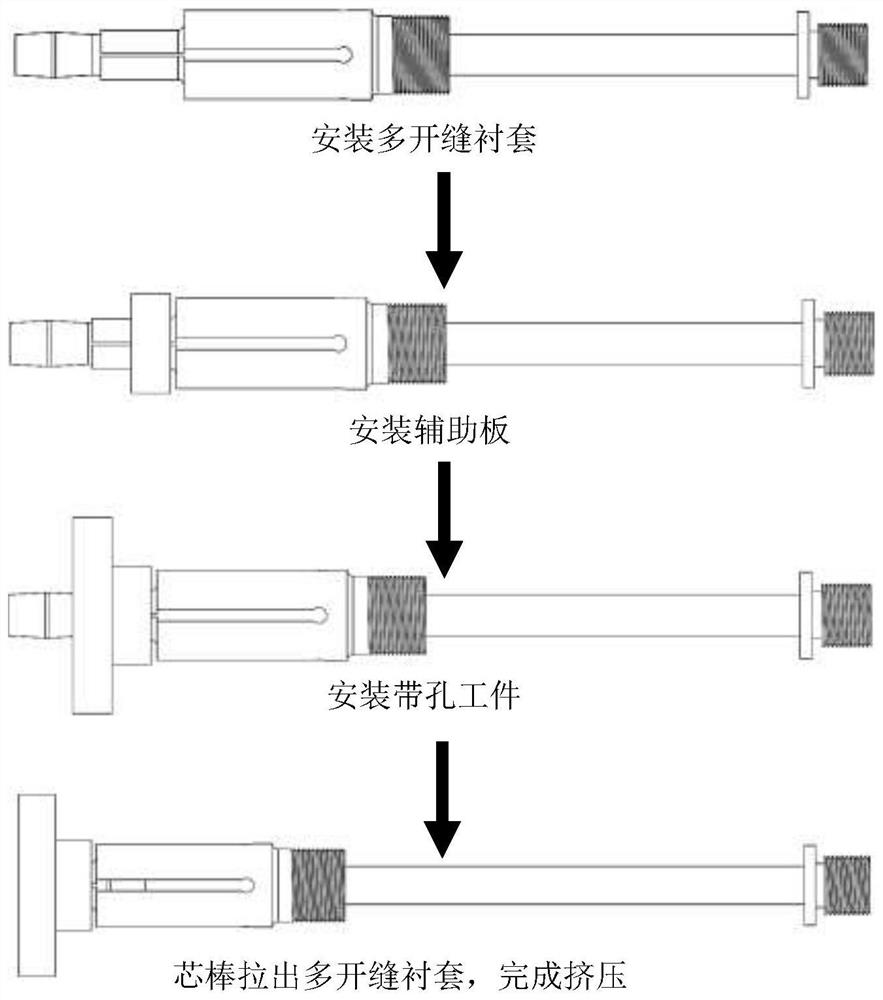

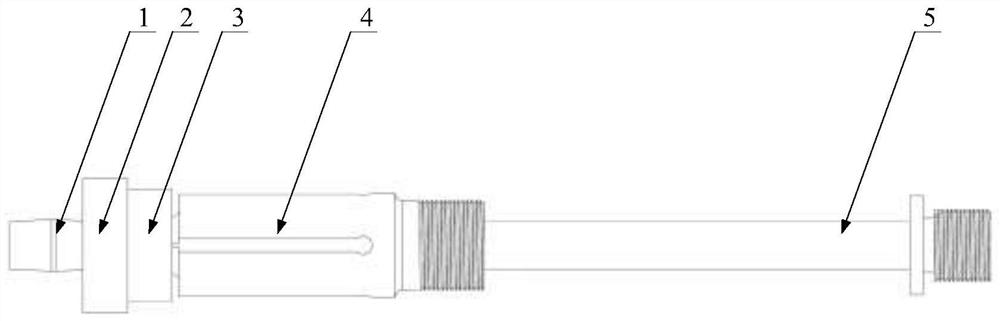

Process for strengthening assembly hole through cold extrusion of slotted bushing

The invention provides a process for strengthening an assembly hole through cold extrusion of a slotted bushing. The process comprises the following steps: (1) the slotted bushing (4) penetrates through one end of an extrusion core rod (5) to be arranged on a guide section (6) and is fixed on a clamp through a thread (8) at the tail part, and the extrusion core rod (5) and the slotted bushing (4) penetrate through a workpiece (2) with a hole to finish installation; (2) when the extrusion core rod (5) is pulled out of the assembly hole of the workpiece with the hole at a constant speed, a working ring of the extrusion core rod extrudes the slotted bushing, the slotted lining elastically expands under the action of extrusion force to extrude the hole wall of the assembly hole of the workpiece with the hole, and the hole wall of the assembly hole is plastically deformed, so that the strengthening effect is achieved; and one or more slots are symmetrically formed in the slotted bushing. The structure is simple, the slotted bushing can be repeatedly used, and therefore the cost of the hole extrusion strengthening process is reduced. A uniform residual stress field is formed on the wall of the assembly hole of the workpiece with the hole, and the fatigue life of the workpiece with the hole is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

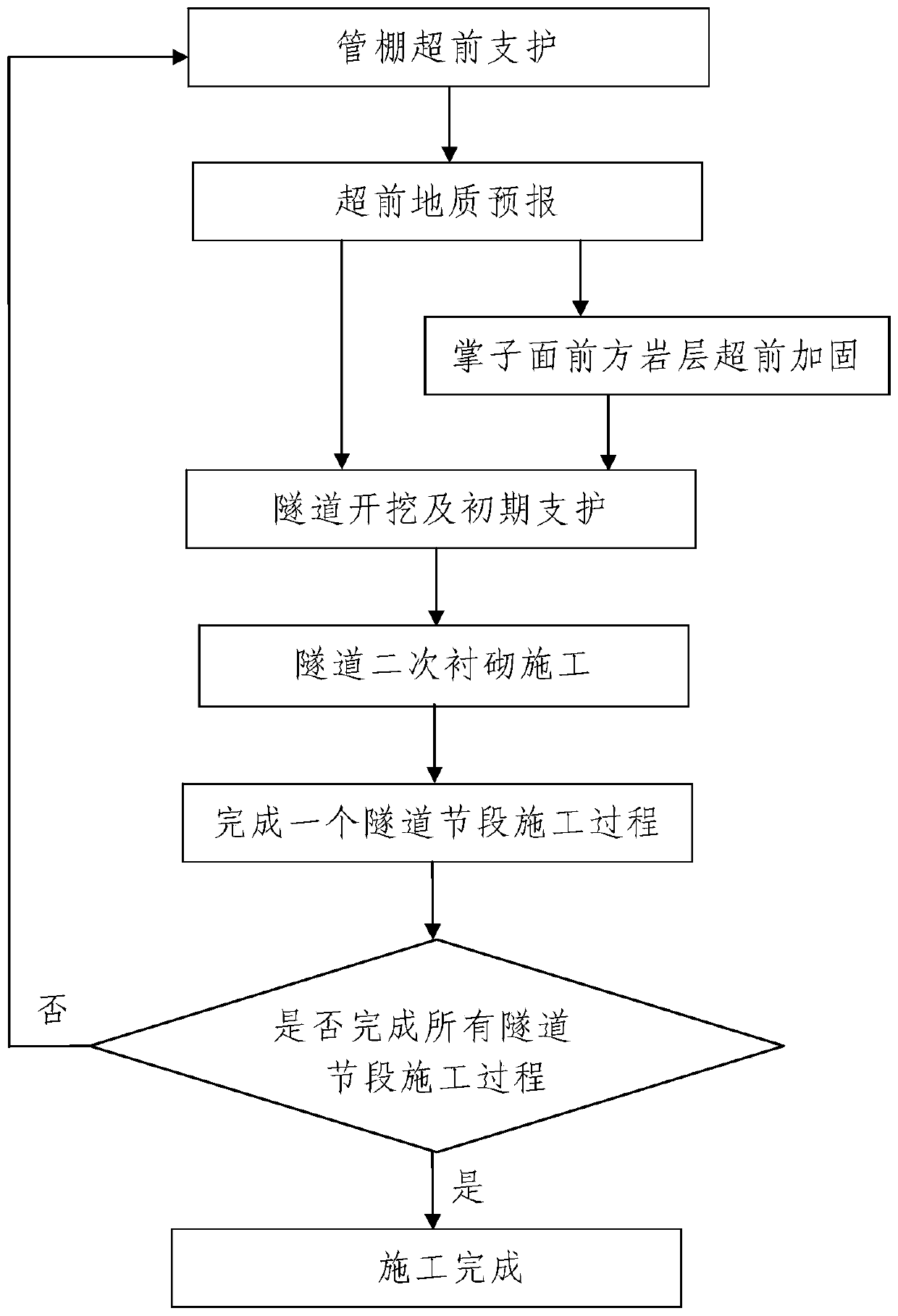

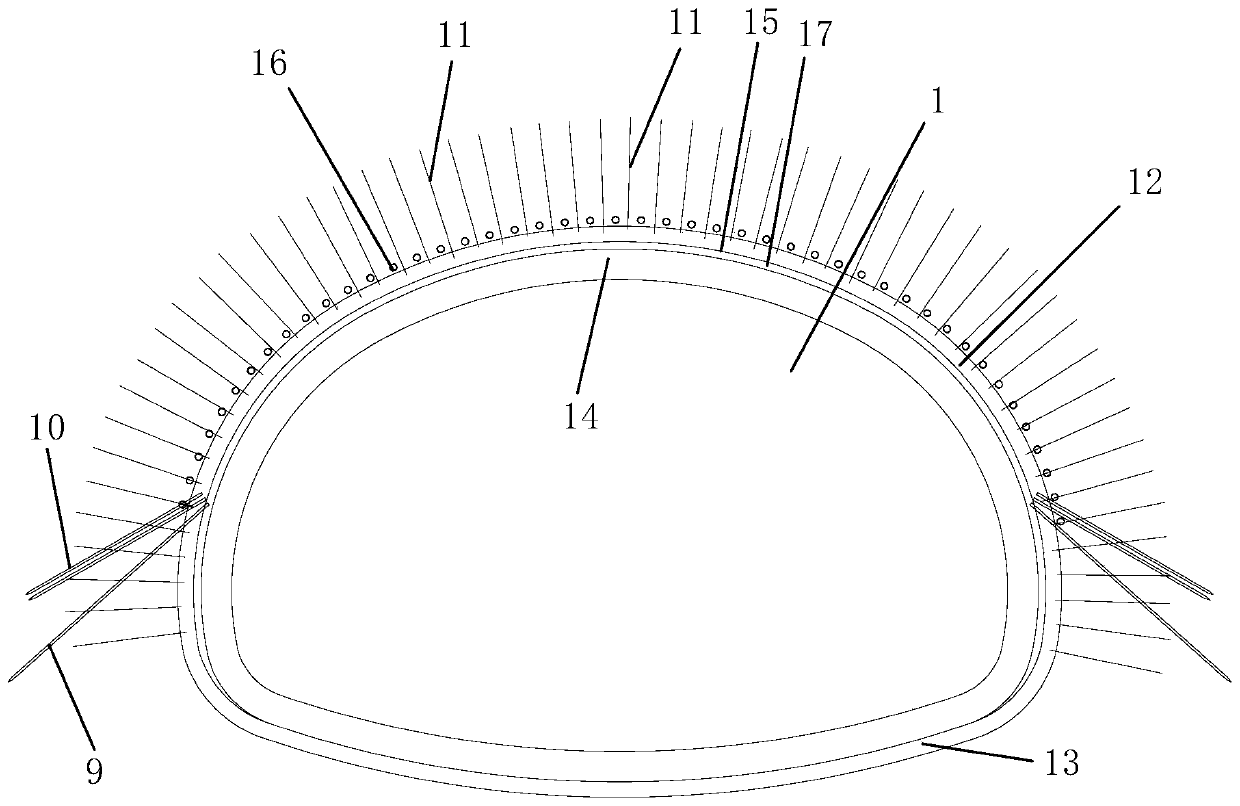

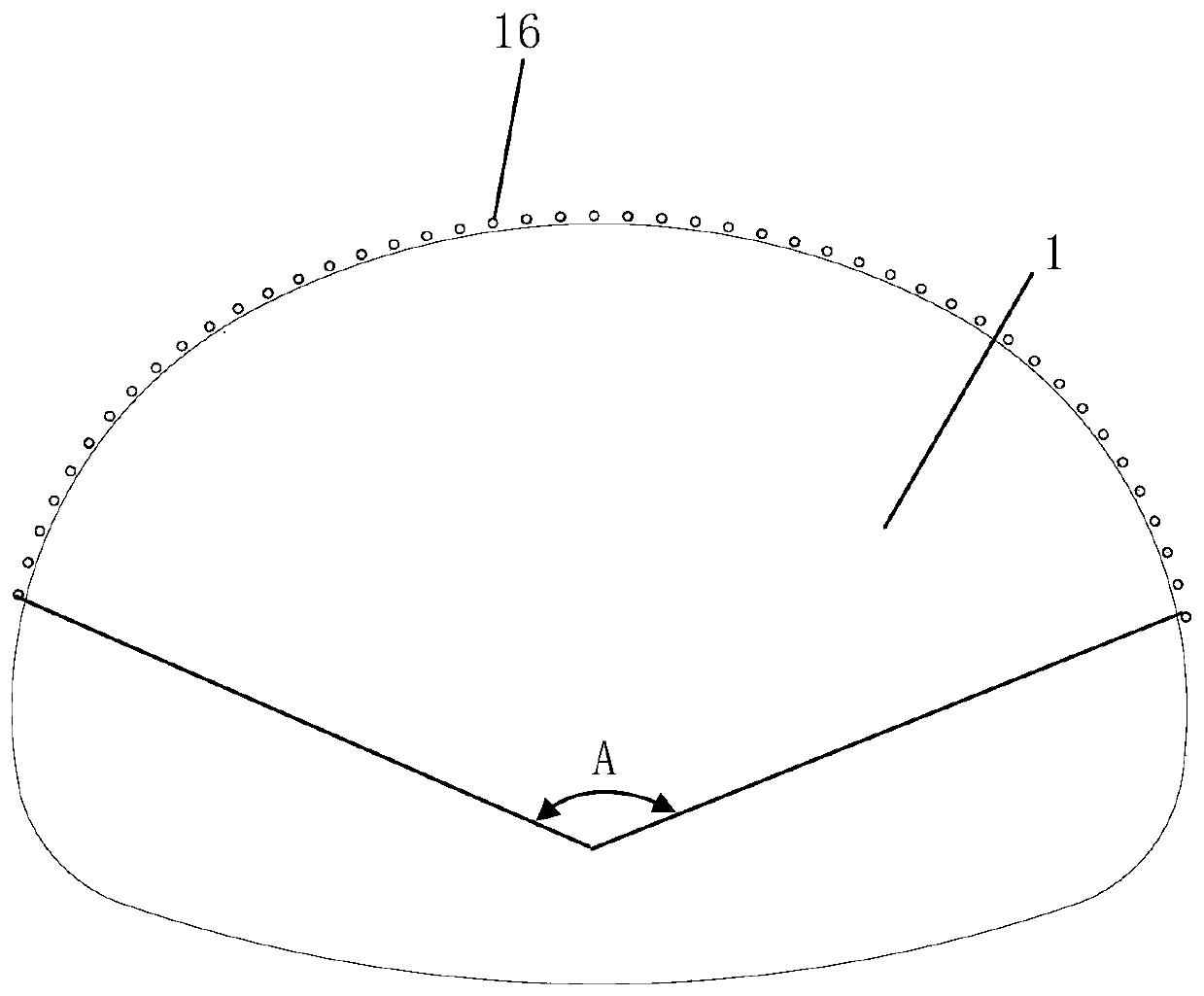

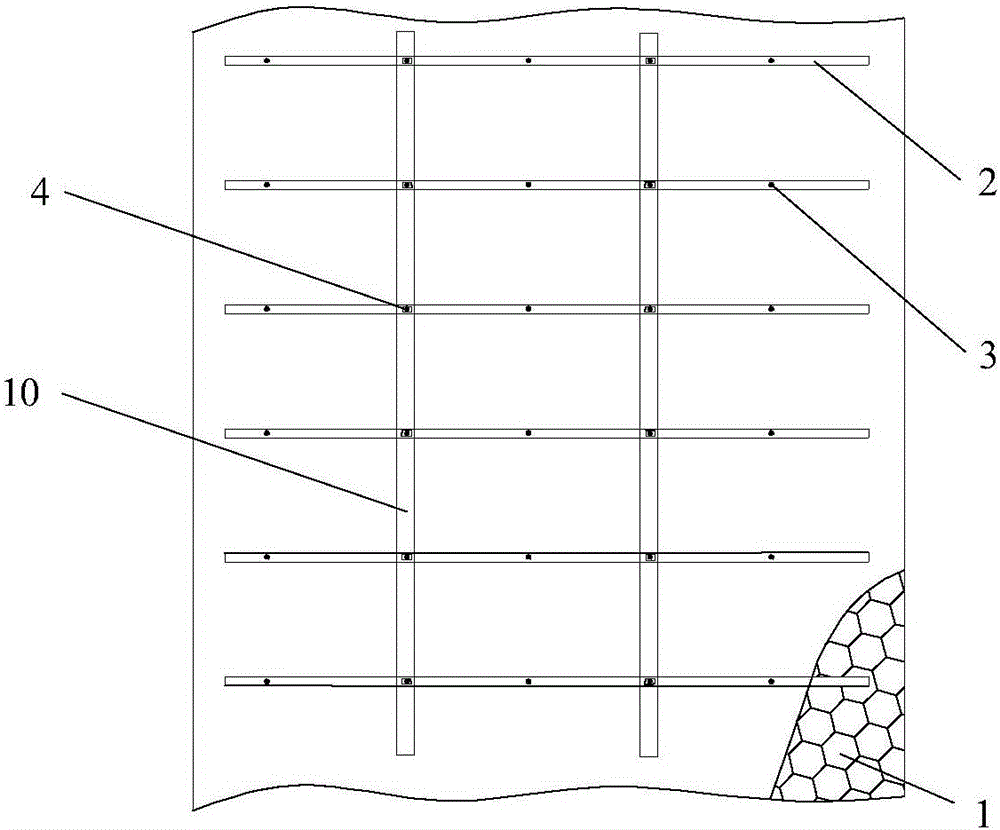

Stability control construction method of water-enriched soft rock tunnel passing through fault crushed zone

ActiveCN110905530AThe method steps are simpleReasonable designUnderground chambersDrainageSupporting systemArchitectural engineering

The invention discloses a stability control construction method of a water-enriched soft rock tunnel passing through a fault crushed zone. A plurality of tunnel segments in a construction tunnel are constructed respectively from back to front. During construction of any one of the tunnel segments, the method comprises the following steps: 1, performing pipe shed forepoling; 2, performing tunnel excavation and preliminary bracing: performing upper peripheral side cavity excavation and preliminary bracing, performing a reserved core soil area cavity excavation and preliminary bracing, excavatingthe cavity which is excavated firstly and performing preliminary bracing as well as excavating the cavity which is excavated secondly and performing preliminary bracing; and 3, performing tunnel secondary lining construction. The method is reasonable in design, simple and convenient in construction and good in use effect; before excavation, the upper cavity is subjected to forepoling by a self-drilling pipe shed and is excavated by a two-step method, so that the excavation efficiency is effectively improved; and meanwhile, an integral supporting system with a stable structure, which is formedby connecting a surrounding rock integral reinforced structure outside the cavity and a tunnel preliminary bracing structure and tunnel secondary lining, can effectively improve the stability of thetunnel structure and guarantee the later safety of the tunnel structure.

Owner:中铁二十局集团第二工程有限公司

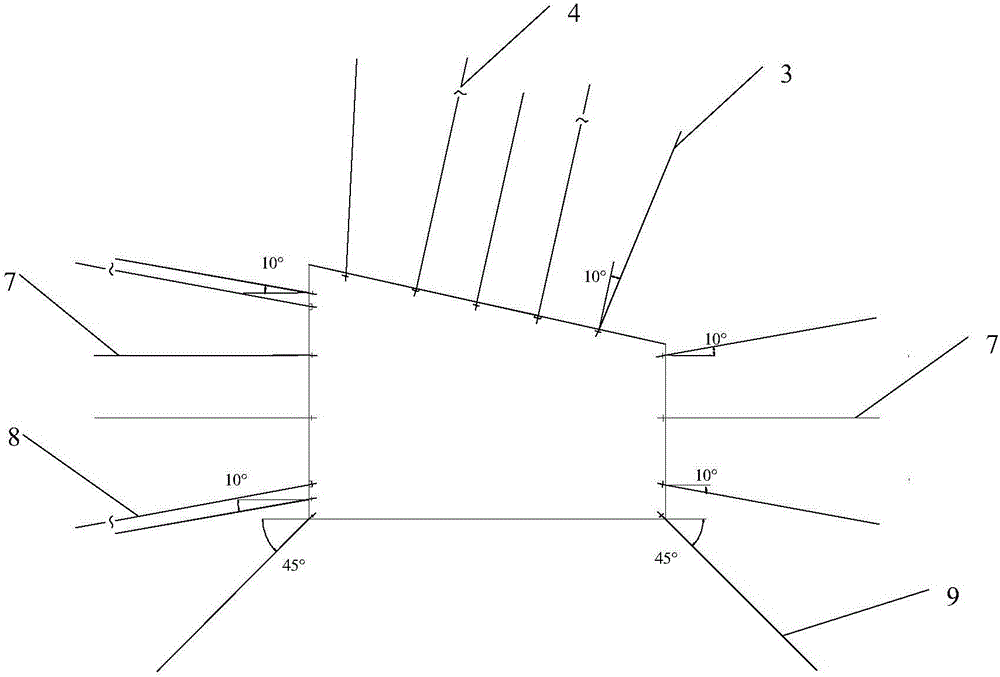

Deep three-soft coal seam asymmetric tunnel supporting structure

ActiveCN105909289AReduce displacementIncrease anchoring forceAnchoring boltsNon symmetricStressed state

The invention discloses a deep three-soft coal seam asymmetric tunnel supporting structure comprising a tunnel top support, a roadside support, and a tunnel bottom support; the tunnel top support comprises a metal net used for supporting the tunnel top, and top steel bar ladder beams, top anchor poles and top anchor cables used for reinforcing the tunnel top,; the roadside support comprises a high side support and a low side support, each of which comprises an electric welding plain net used for supporting the roadside, and side steel bar ladder beams and side anchor poles used for reinforcing the tunnel roadside; the high side support also comprises side cables; the tunnel bottom support comprises base angle anchor poles vertically and symmetrically arranged along the tunnel, wherein the base angle anchor poles are arranged on two side base angles formed by the tunnel bottom and the roadside, and the angle of depression is 45 degrees. The anchor-beam-net-cable combined support mode is employed; the anchor poles, anchor cables and steel bar ladder beams of the tunnel top and roadside can improve tunnel surrounding rocks stress states; the side cables are arranged so as to reinforce tunnel high side local support; the base angle anchor poles are arranged so as to effectively control the tunnel bottom heaves.

Owner:CHINA UNIV OF MINING & TECH

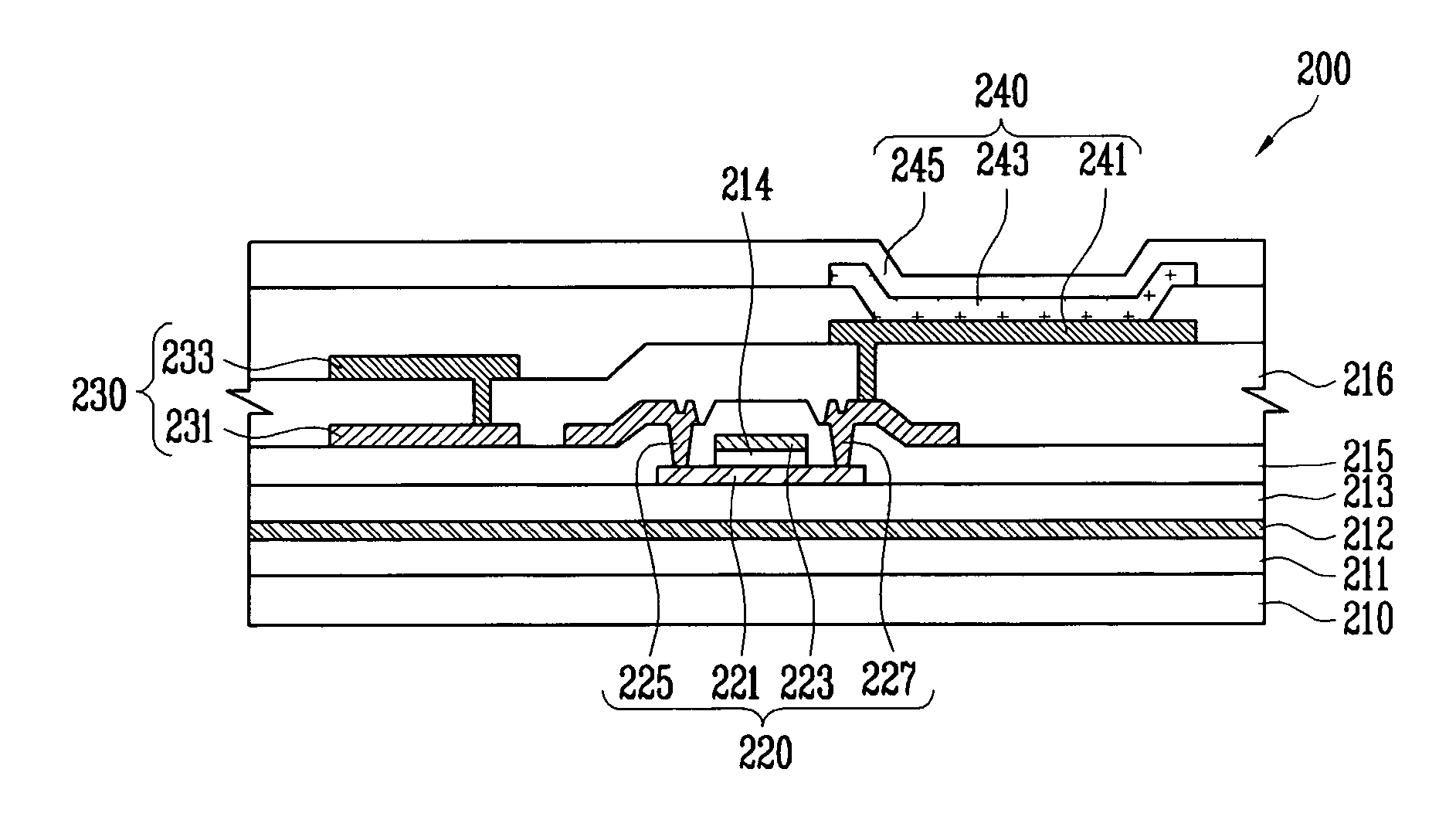

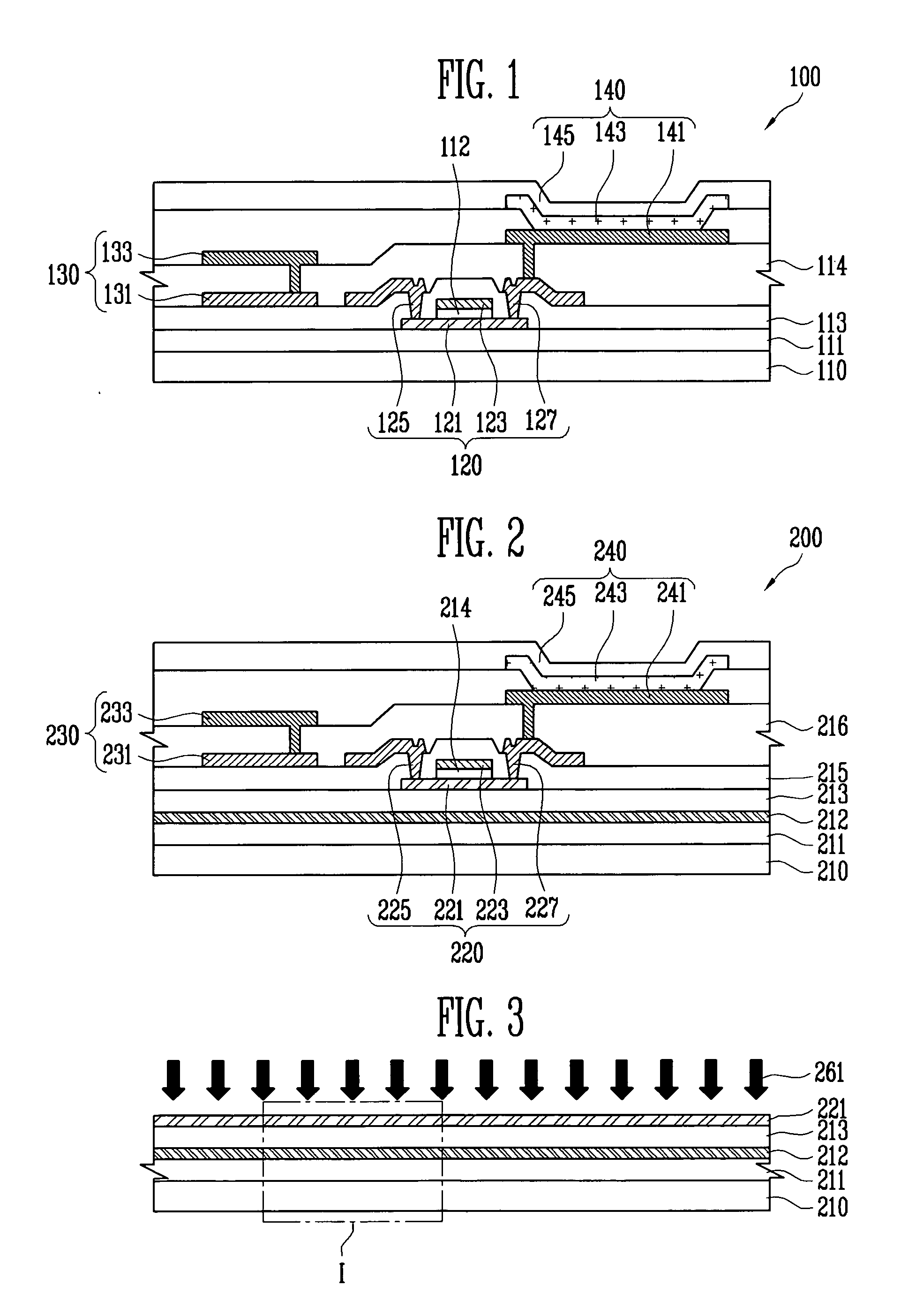

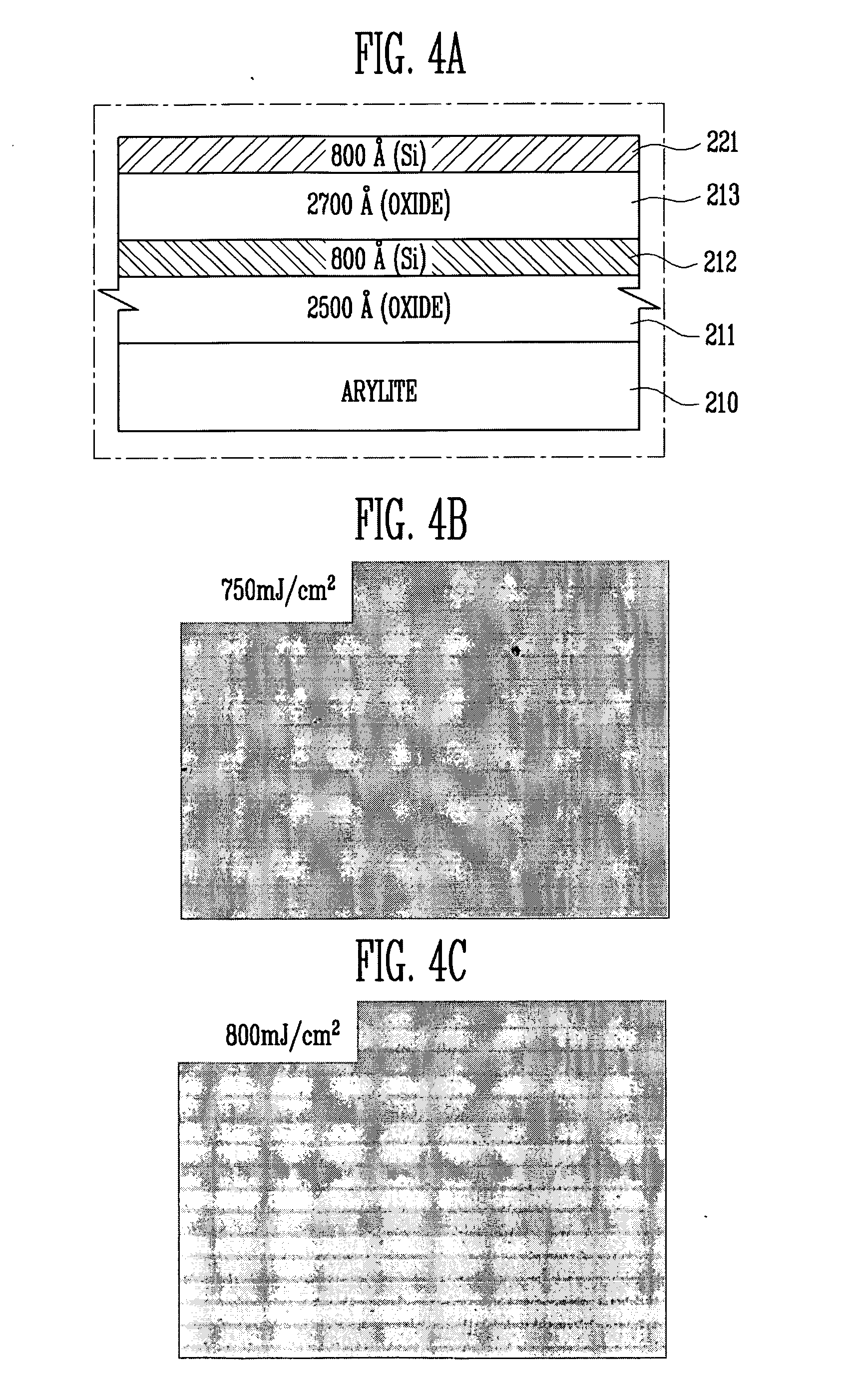

Active matrix driving display device and method of manufacturing the same

InactiveUS20070085090A1Reduce plastic deformationImprove securitySolid-state devicesNon-linear opticsActive matrixDisplay device

Provided are an active matrix driving display device and a method of manufacturing the same. The active matrix driving display device includes: a first buffer layer formed on a plastic substrate; a laser-absorbing layer formed on the first buffer layer; a second buffer layer formed on the laser-absorbing layer; and an active layer formed on the second buffer layer, whereby it is possible to prevent deformation of the plastic substrate even when light or heat is used during the formation of the active layer.

Owner:ELECTRONICS & TELECOMM RES INST

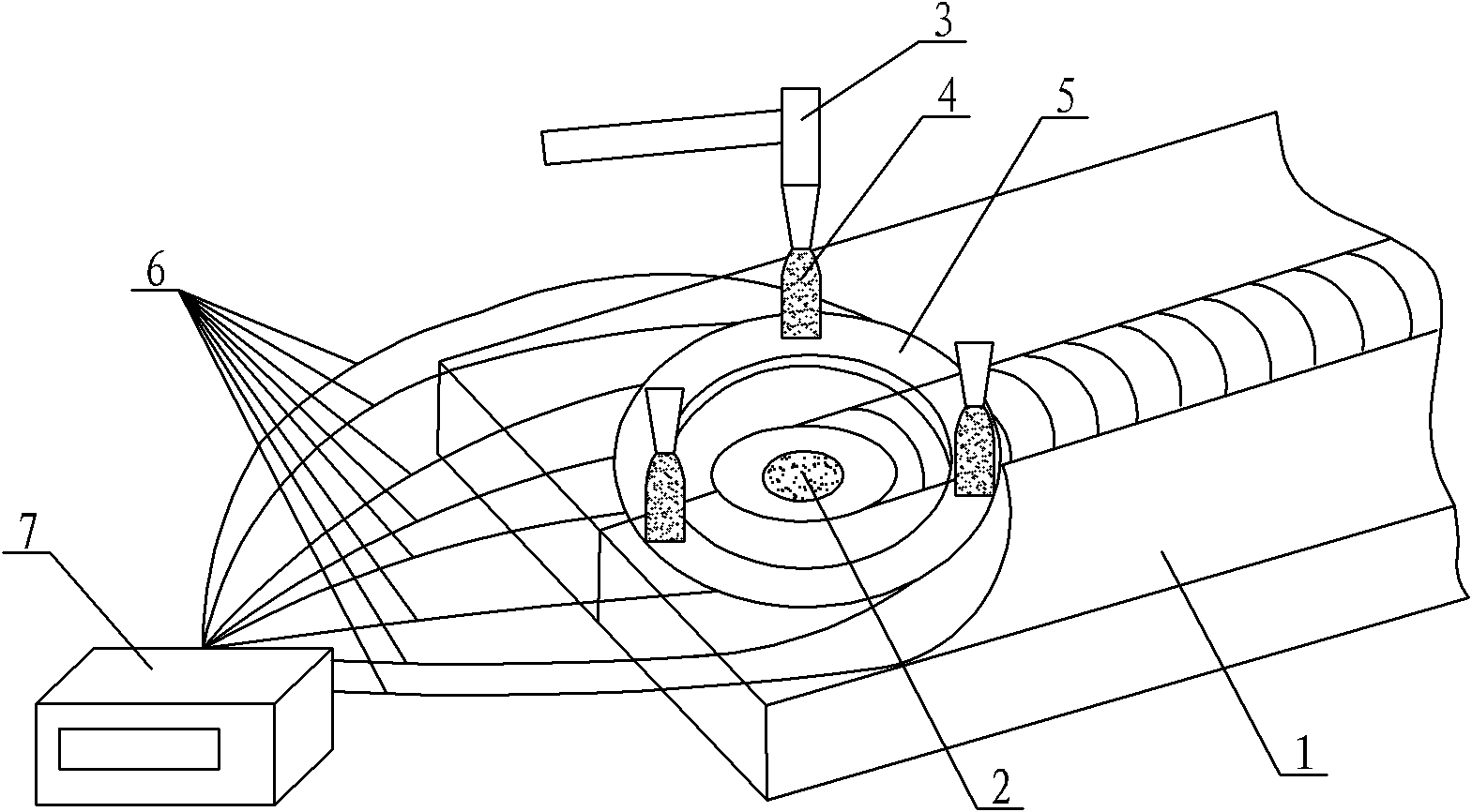

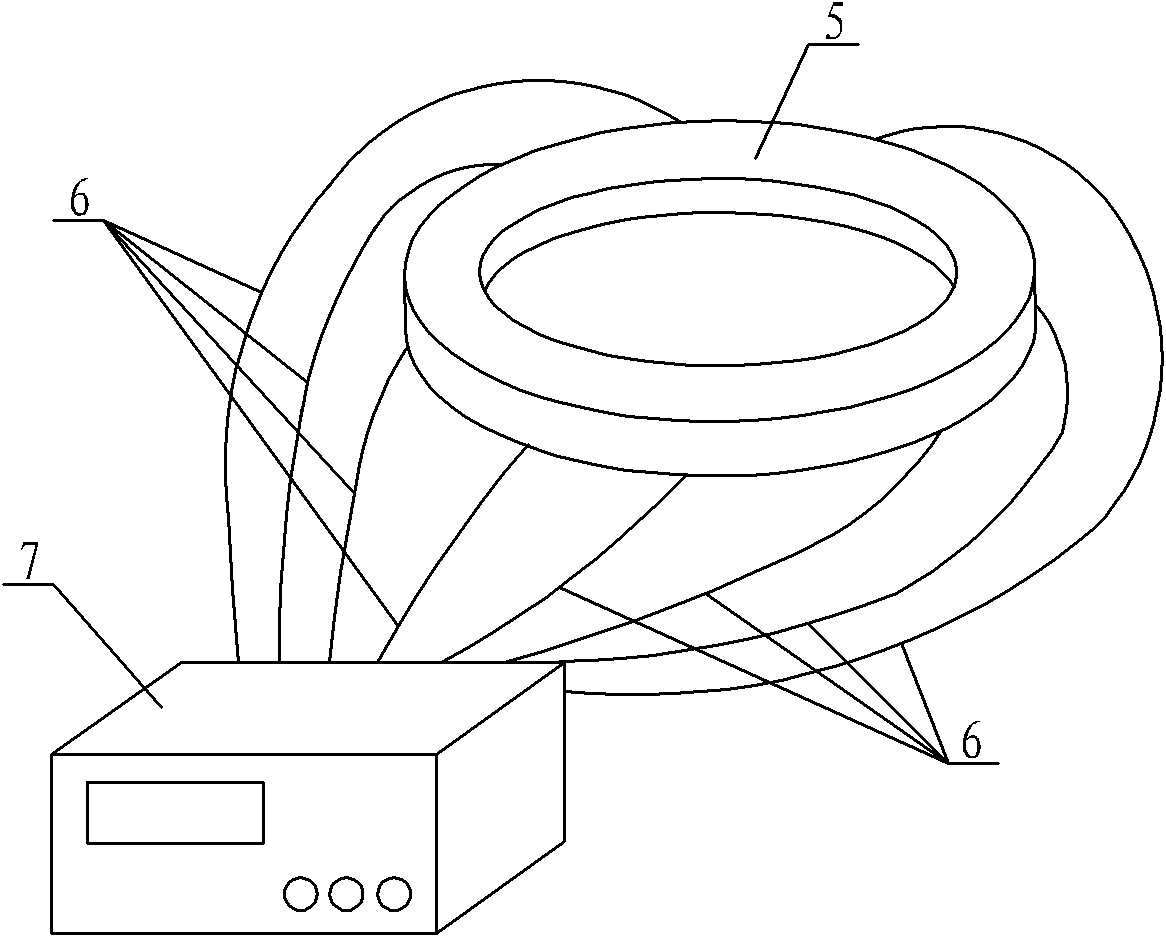

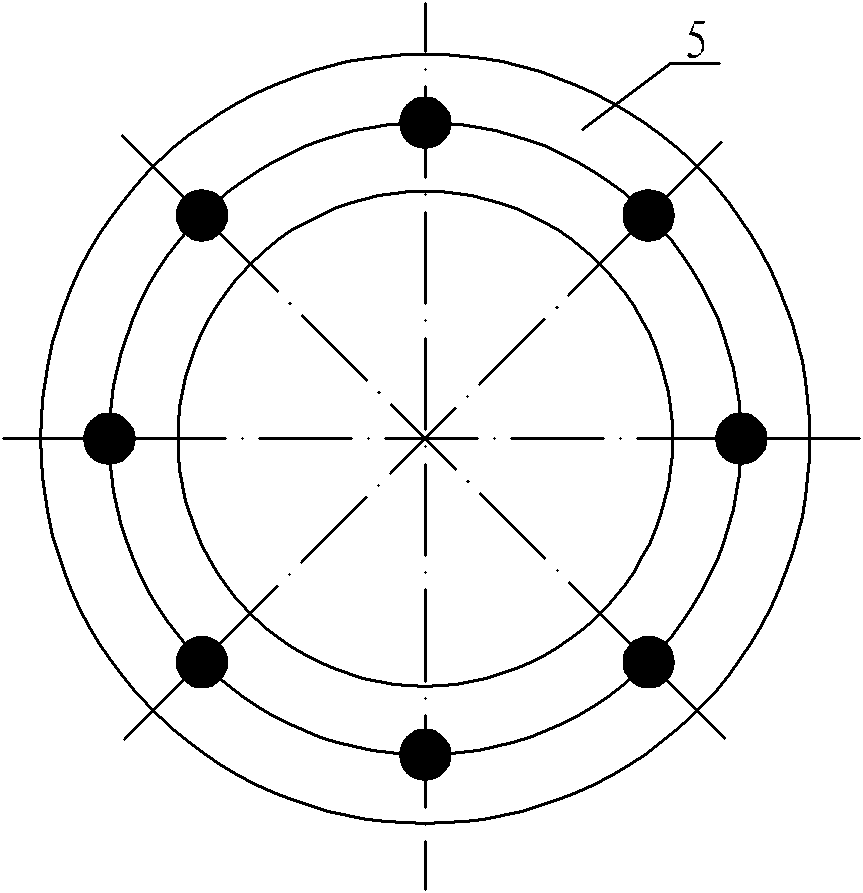

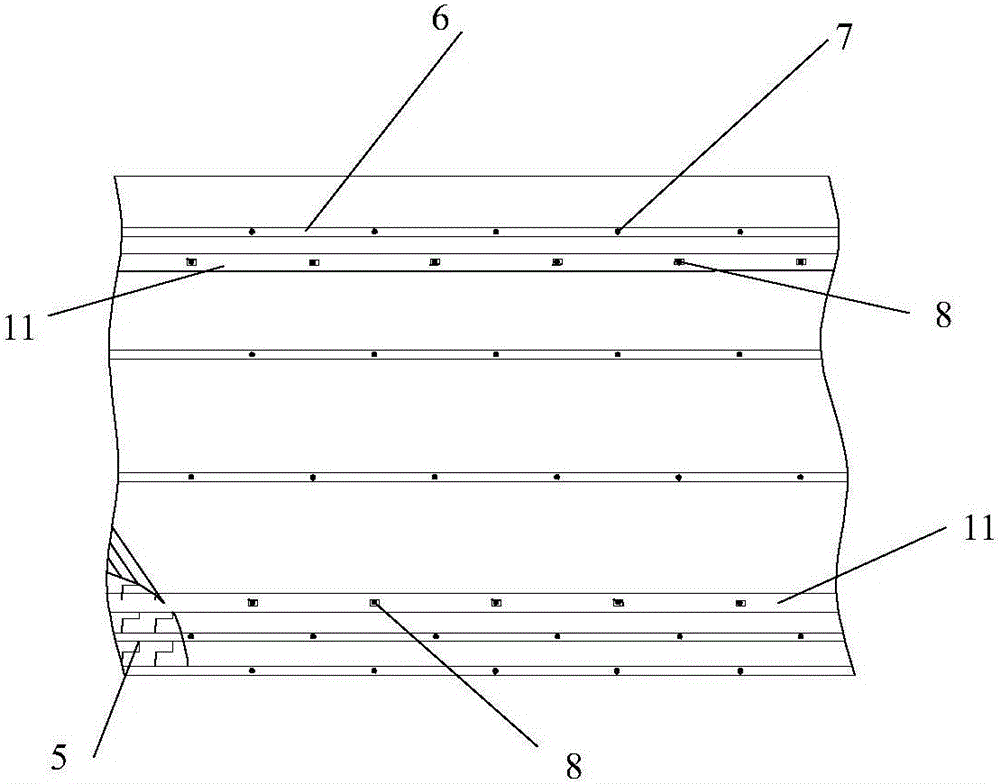

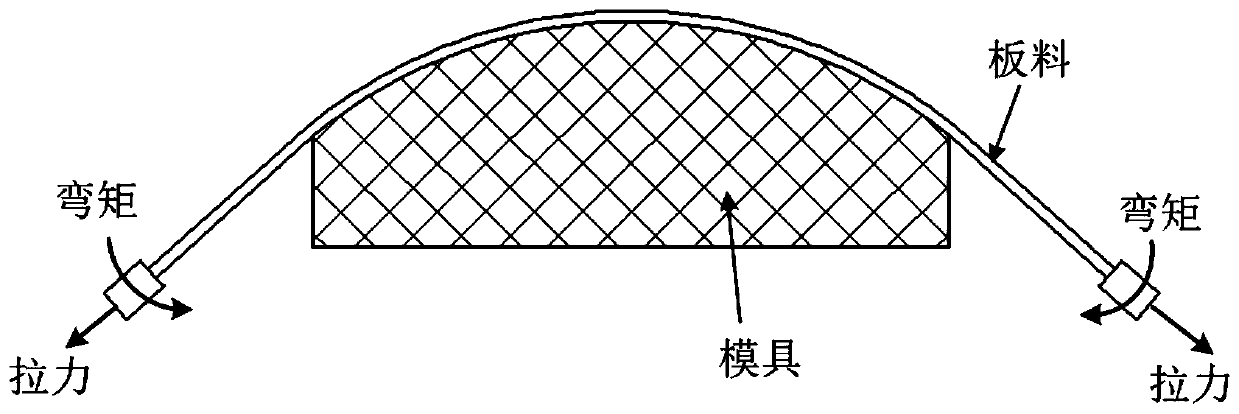

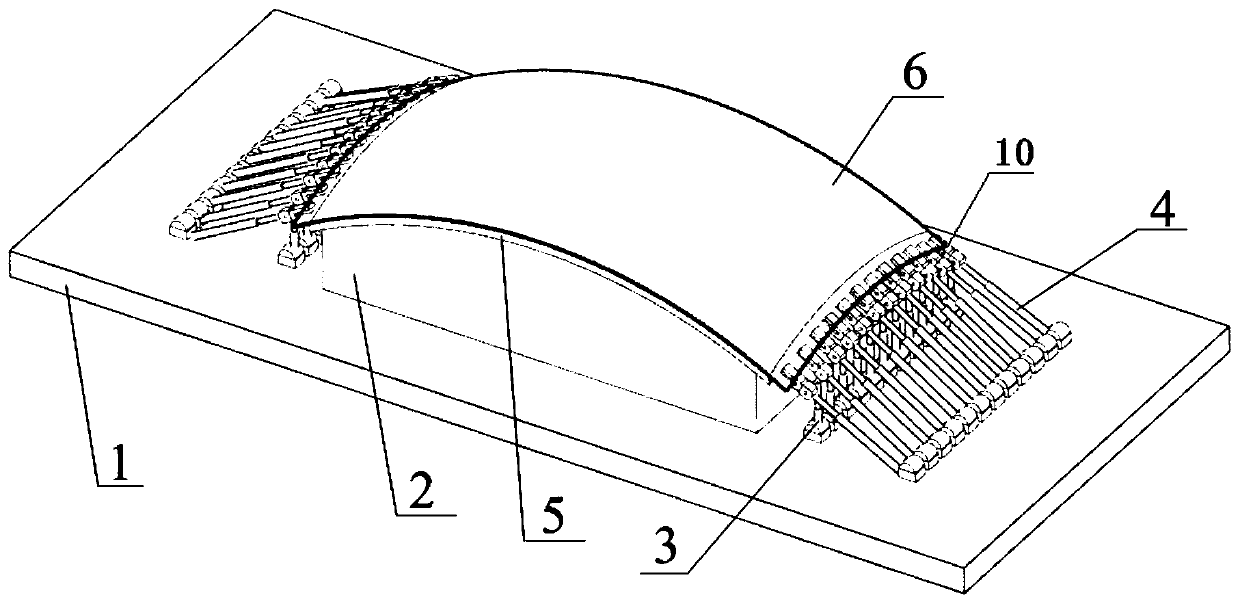

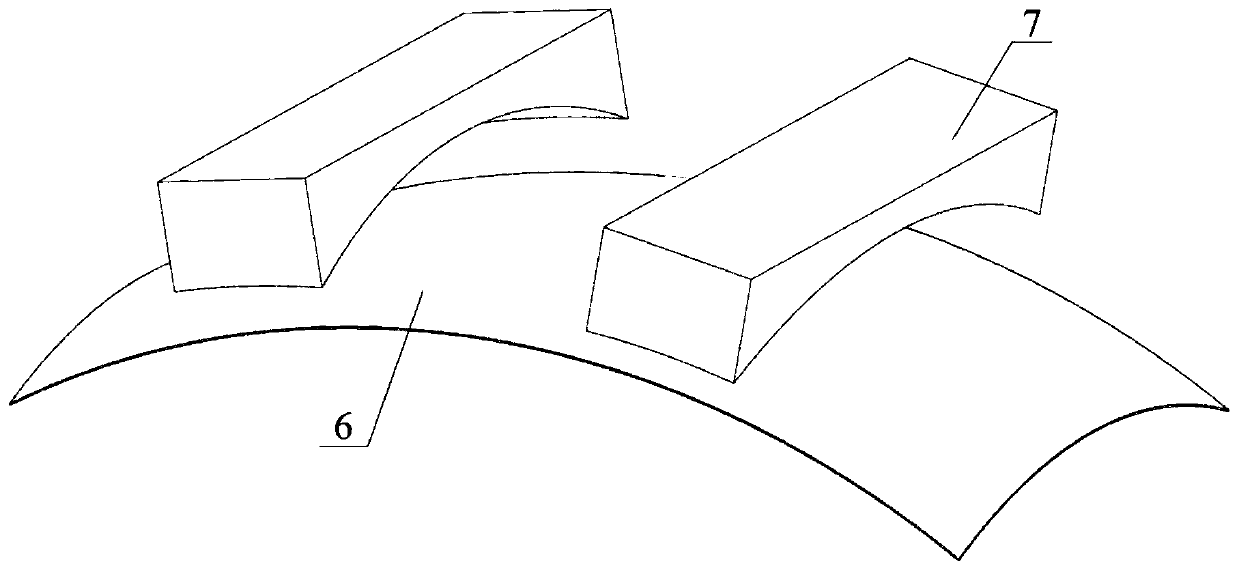

Stretch forming-electromagnetism composite forming device and method for multi-curvature skin piece

ActiveCN111167919ARaise the forming limitIncrease the tensile stressShaping toolsEngineeringElectromagnetic forming

The invention discloses a stretch forming-electromagnetism composite forming device and method for a multi-curvature skin piece. The stretch forming-electromagnetism composite forming device comprisesa bottom plate, a mold and an electromagnetic coil used for forming a plate on the mold, the mold is mounted on the bottom plate, and the electromagnetic coil is arranged above the mold. The stretchforming-electromagnetism composite forming device is characterized in that the stretch forming-electromagnetism composite forming device further comprises a vertical oil cylinder, a tangential oil cylinder, and a chuck used for clamping the edge of the plate, one end of the tangential oil cylinder used for tangentially stretching the plate is hinged to the bottom plate, and the other end of the tangential oil cylinder used for tangentially stretching the plate is hinged to the chuck. A stretch forming and discharging composite process is adopted, stretch forming is conducted to solve a certainspringback problem, then remaining springback is eliminated through electromagnetic force, in this way, the thickness reduction of the plate can meet the design requirement, and meanwhile the requirement for electromagnetic forming energy can also be greatly lowered.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com