Lightweight aggregate concrete used for 3D printing and preparation method and application thereof

A lightweight aggregate concrete, 3D printing technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem of printing structure without mold support, to reduce the possibility of collapse, reduce pressure, reduce plastic deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

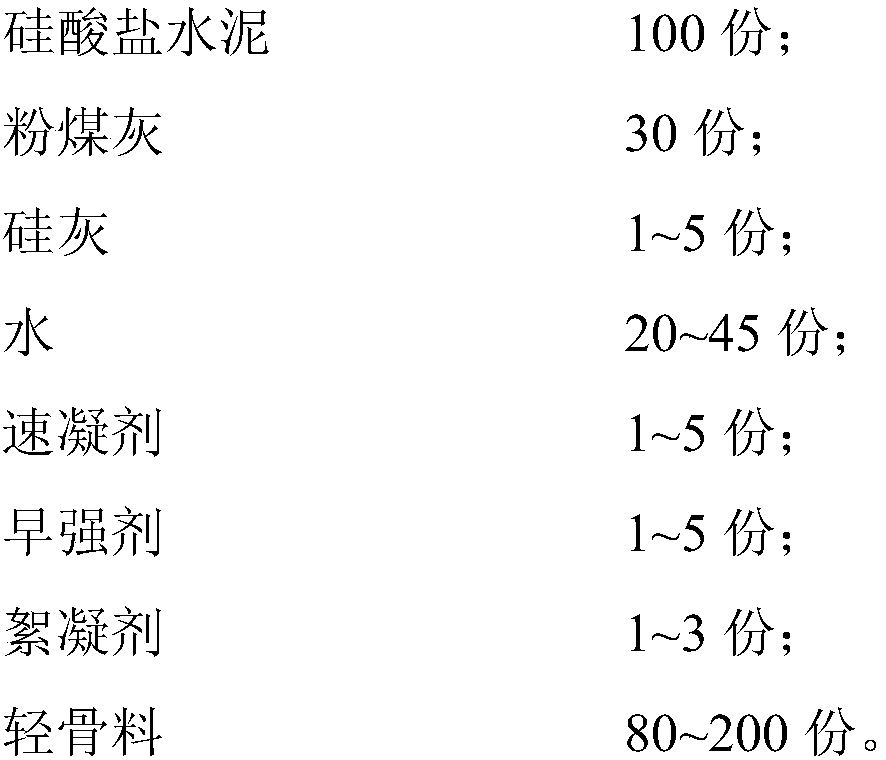

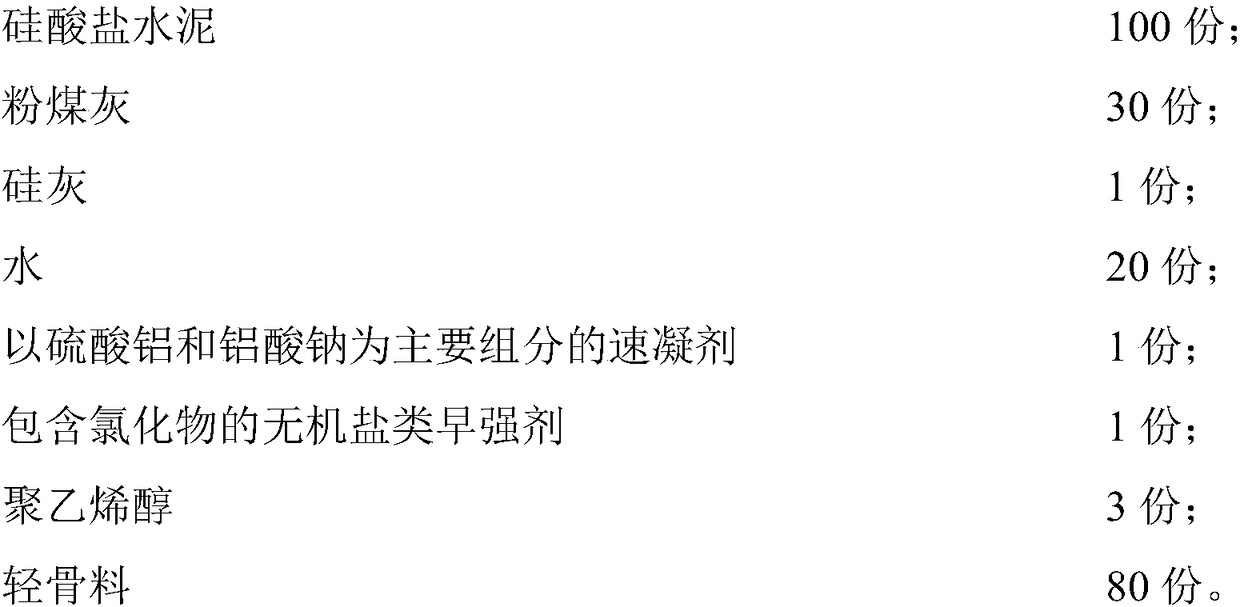

[0025] A lightweight aggregate concrete for 3D printing, comprising the following raw materials in parts by weight: 100 parts of 42.5R ordinary Portland cement, 30 parts of grade I fly ash, 1 part of grade I silica fume, 20 parts of water, quick-setting 2 parts of agent, 2 parts of early strength agent, 1 part of flocculant, 100 parts of lightweight aggregate.

[0026] The raw materials and weight ratio of lightweight aggregate are: 3-5mm fly ash ceramsite: 1-3mm fly ash ceramsite: 0-1mm ceramic particles = 20:80:30.

[0027] The preparation method of the above-mentioned lightweight aggregate concrete for 3D printing comprises the following steps:

[0028] Step 1: Mix ceramic particles of 0-1 mm, fly ash ceramsite with a particle size of 1-3 mm and fly ash ceramsite of 3-5 mm according to the formula, and stir evenly to prepare light aggregate raw materials for use;

[0029] Step 2: Mix 42.5R ordinary Portland cement, fly ash, silica fume, accelerator, early strength agent an...

Embodiment 2

[0033] A lightweight aggregate concrete for 3D printing, comprising the following raw materials in parts by weight: 100 parts of 42.5R ordinary Portland cement, 30 parts of grade I fly ash, 5 parts of grade I silica fume, 25 parts of water, quick-setting 3 parts of agent, 3 parts of early strength agent, 1 part of flocculant, and 120 parts of lightweight aggregate.

[0034] The raw materials of lightweight aggregate and their weight ratio are: 0-1mm ceramic particles: 3-5mm shale ceramsite: 1-3mm fly ash ceramsite = 30:30:70.

[0035] The preparation method of the above-mentioned lightweight aggregate concrete for 3D printing comprises the following steps:

[0036] Step 1: Mix according to the formula amount: 0-1mm ceramic particles, 1-3mm particle size fly ash ceramsite and 3-5mm shale ceramsite, stir evenly, and prepare light aggregate raw materials, set aside;

[0037] Step 2: Mix 42.5R ordinary Portland cement, fly ash, silica fume, accelerator, early strength agent and f...

Embodiment 3

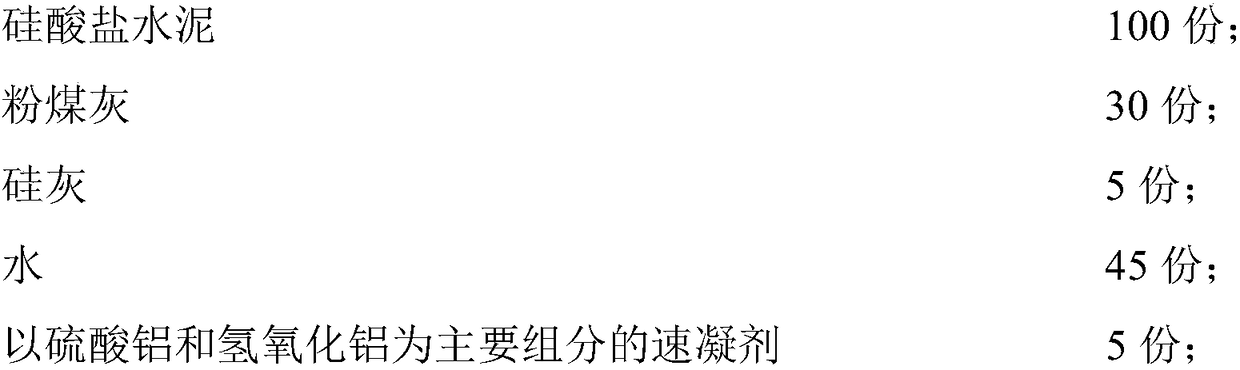

[0046]Adopt the formula similar to embodiment 2, difference is that, the formula of the present embodiment is as follows:

[0047]

[0048] After testing, lightweight aggregate concrete has good tensile and compressive properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com