Patents

Literature

84results about How to "Reduced chance of collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

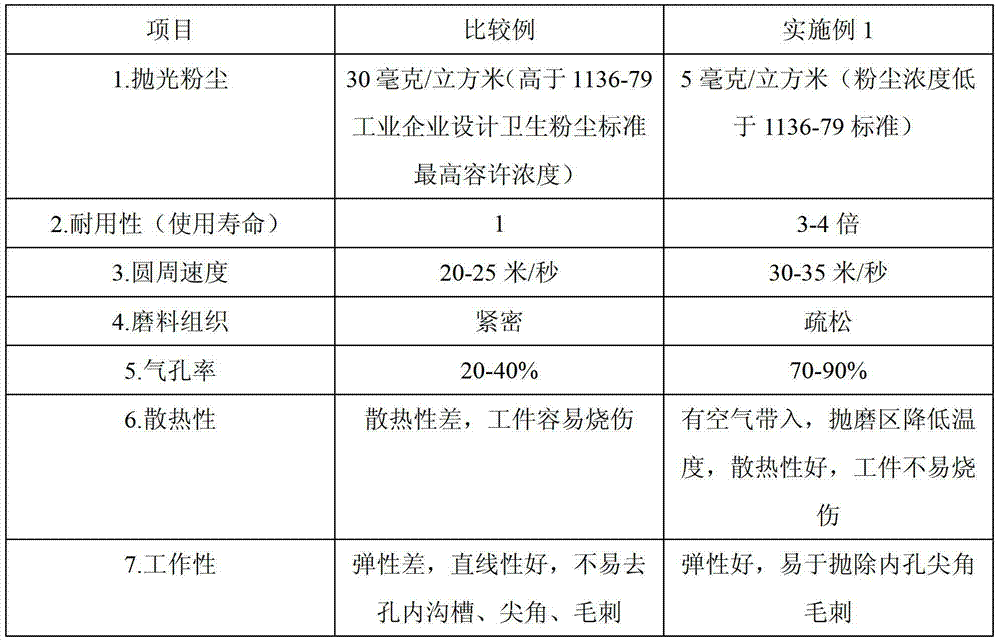

Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

InactiveCN103395011AUniform cellsNo stuffingAbrasion apparatusGrinding devicesWater bathsDistilled water

The invention discloses a polyvinyl alcohol-polyurethane elastic buffing wheel and a preparation method of the polyvinyl alcohol-polyurethane elastic buffing wheel. The preparation method comprises the steps that firstly, polyvinyl alcohol is mixed with distilled water, and the mixture is dissolved for 20-30 minutes under the condition of 50-95 DEG C water bath and at the rotation speed of 400-600r / min to obtain a polyvinyl alcohol aqueous solution; then, the polyvinyl alcohol aqueous solution is heated up to 30-100 DEG C, grinding materials are firstly added into the polyvinyl alcohol aqueous solution, after the mixture of the grinding materials and the polyvinyl alcohol aqueous solution is stirred and mixed evenly at the rotation speed of 400-600r / min, polyurethane pre-polymers, catalysts and air hole generating agents are added, and all the components are stirred and mixed evenly at the rotation speed of 400-600r / min and react for 5-10min; solidification is conducted for 2-4h under the condition of 30-100 DEG C, and then the buffing wheel which is good in elasticity, good in water resistance, good in heat-dissipating performance and high in mechanical strength is obtained. The elastic buffing wheel is even in foam hole, good in abrasion resistance and grinding force, not prone to deforming or curling in humid environment and applicable to long-time grinding work.

Owner:SOUTH CHINA UNIV OF TECH

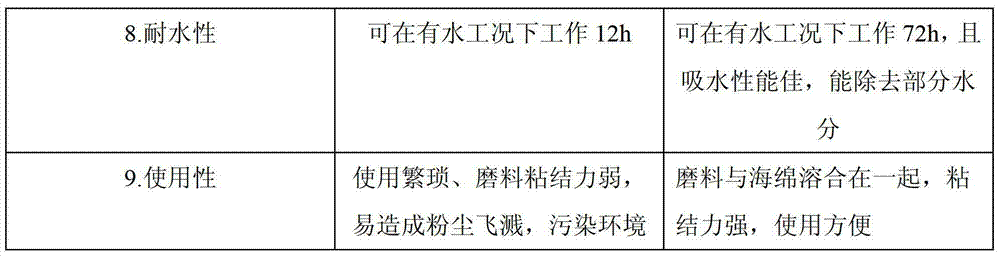

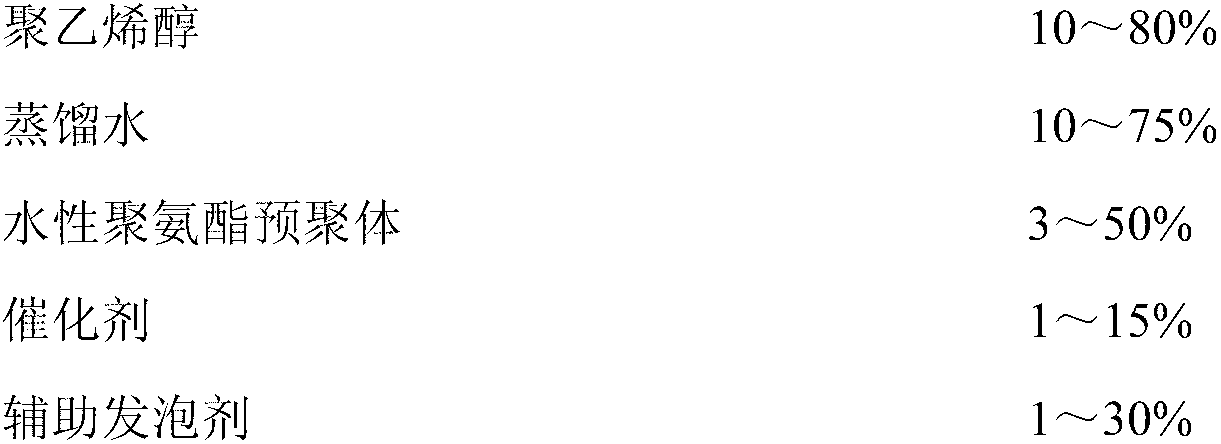

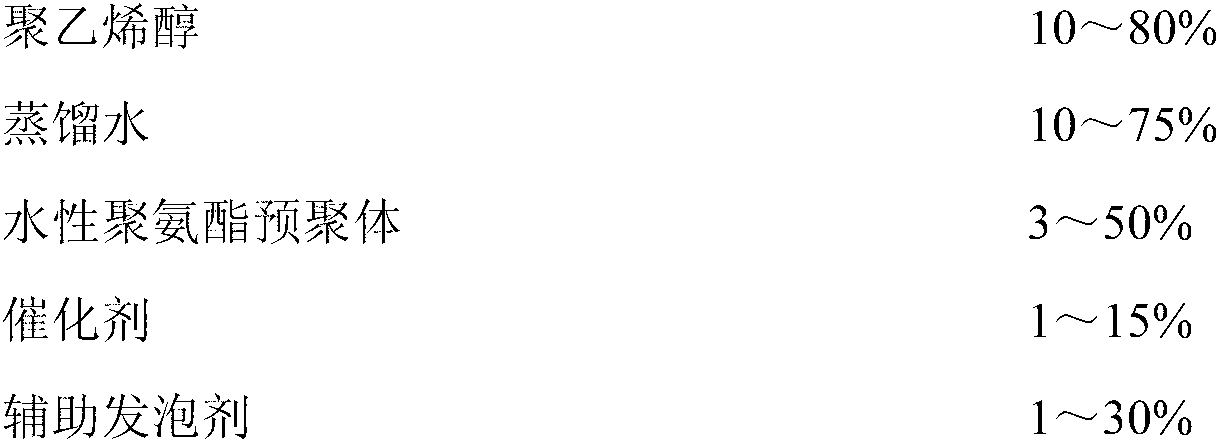

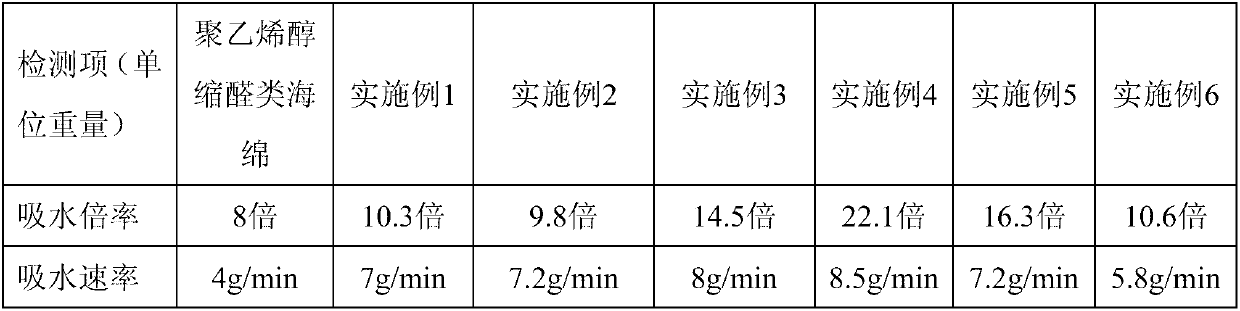

Method for preparing polyvinyl alcohol and polyurethane super absorbent sponge

The invention discloses a method for preparing a polyvinyl alcohol and polyurethane super absorbent sponge. The method includes mixing polyvinyl alcohol with distilled water at first, dissolving the polyvinyl alcohol for 20 to 30 minutes under the condition that the water bath temperature ranges from 50 DEG C to 95 DEG C and rotational speed ranges from 400r / min to 600r / min to obtain polyvinyl alcohol aqueous solution; and then heating the polyvinyl alcohol aqueous solution until the temperature of the polyvinyl alcohol aqueous solution ranges from 30 DEG C to 100 DEG C, adding water-based polyurethane prepolymer, catalysts and auxiliary foaming agents into the polyvinyl alcohol aqueous solution, stirring and uniformly mixing the mixture under the condition of rotational speed ranging from 400r / min to 600r / min, enabling the mixture to react for 5 minutes to 10 minutes, and solidifying the mixture for 2 to 4 hours at the temperature ranging from 30 DEG C to 100 DEG C to obtain the sponge with the water absorbent rate higher than 9.8. The water absorbent rate of the obtained sponge is increased to 10-20 times from the original 6-8 times of an existing polyvinyl acetal sponge, the water absorbing velocity of the sponge is increased to 8g / ming from the original 4g / ming, and the polyvinyl alcohol and polyurethane super absorbent sponge has a broad development prospect in fields of aquatic product processing, food, clinical medicine, water treatment and the like.

Owner:SOUTH CHINA UNIV OF TECH

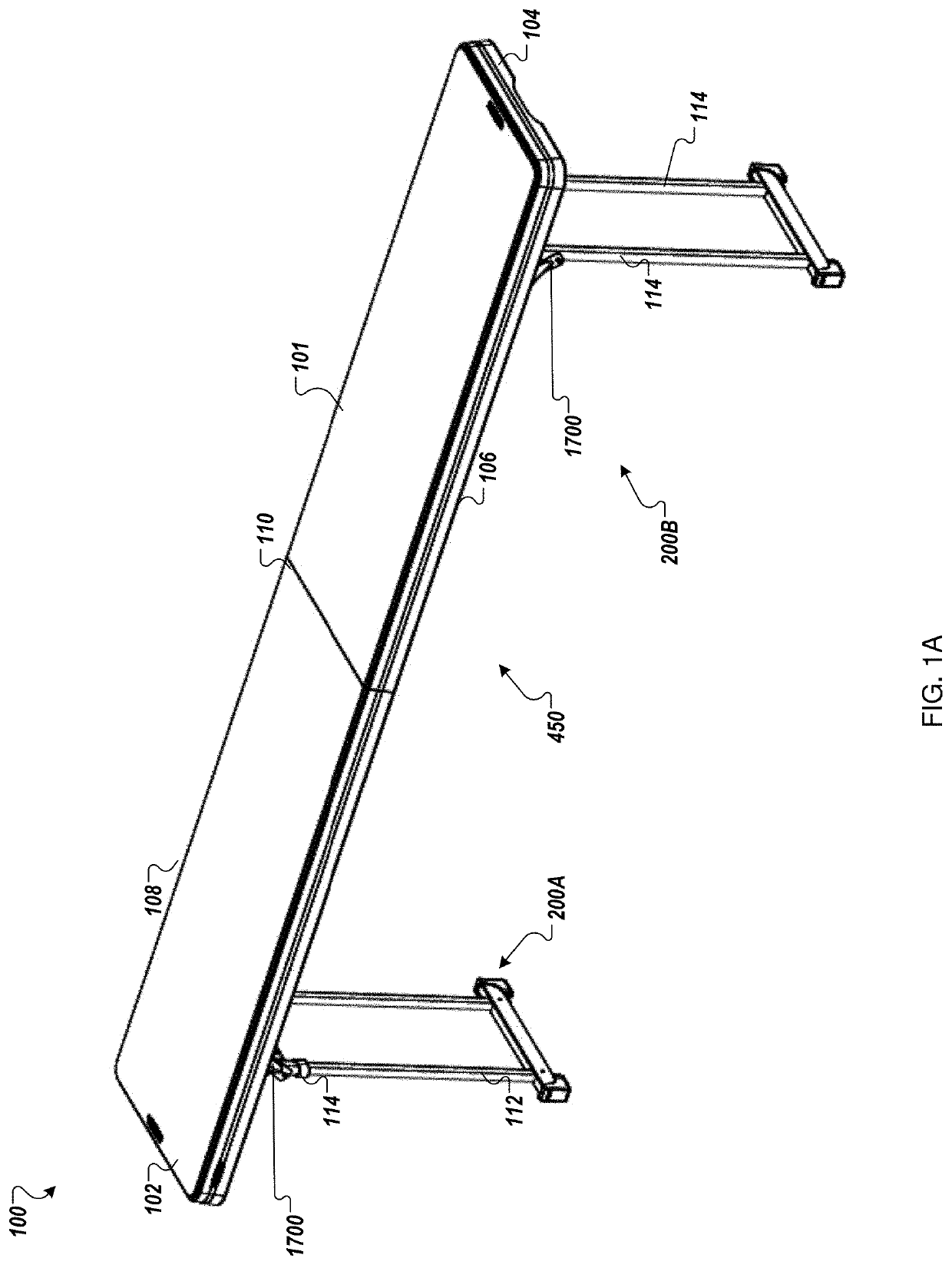

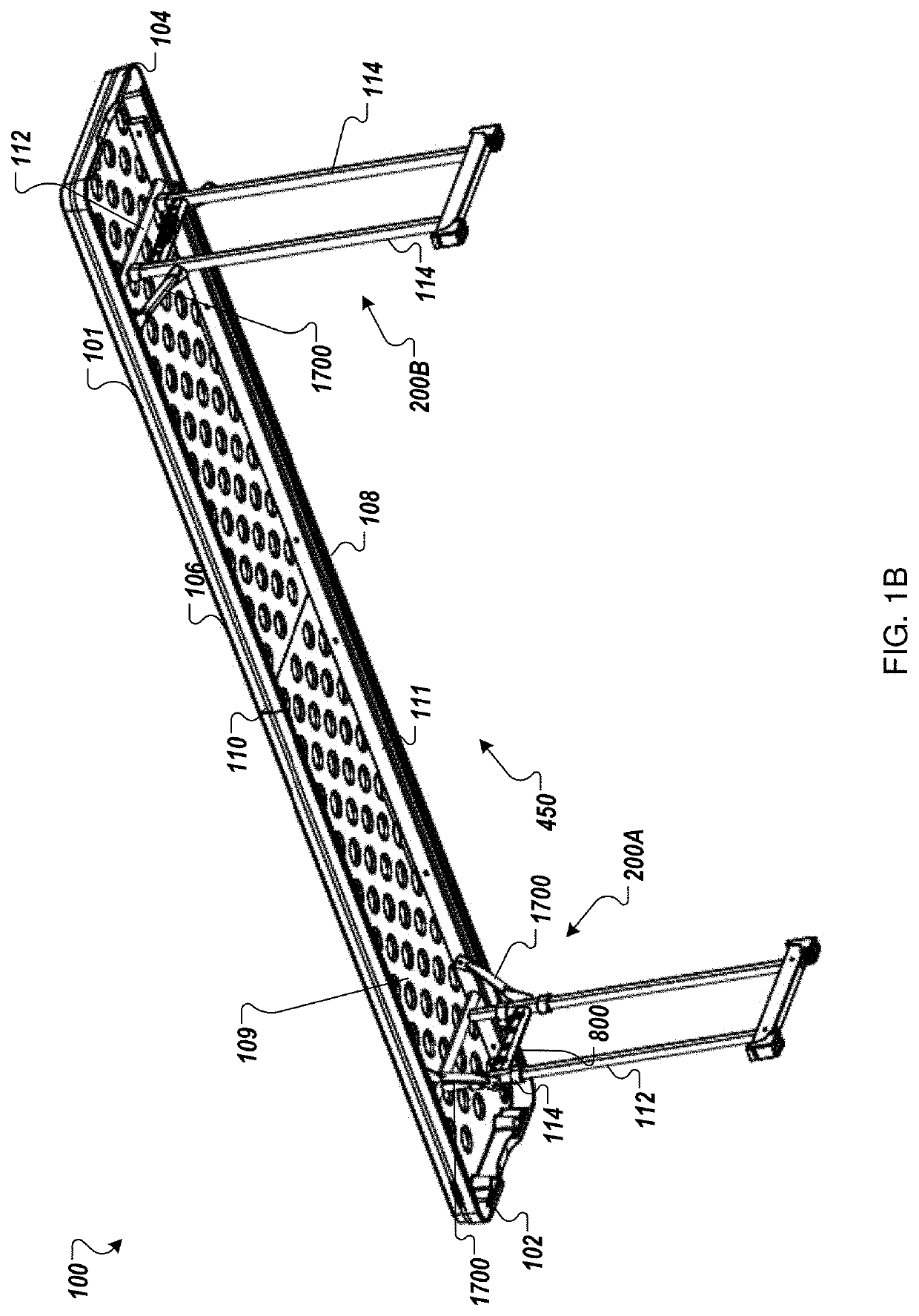

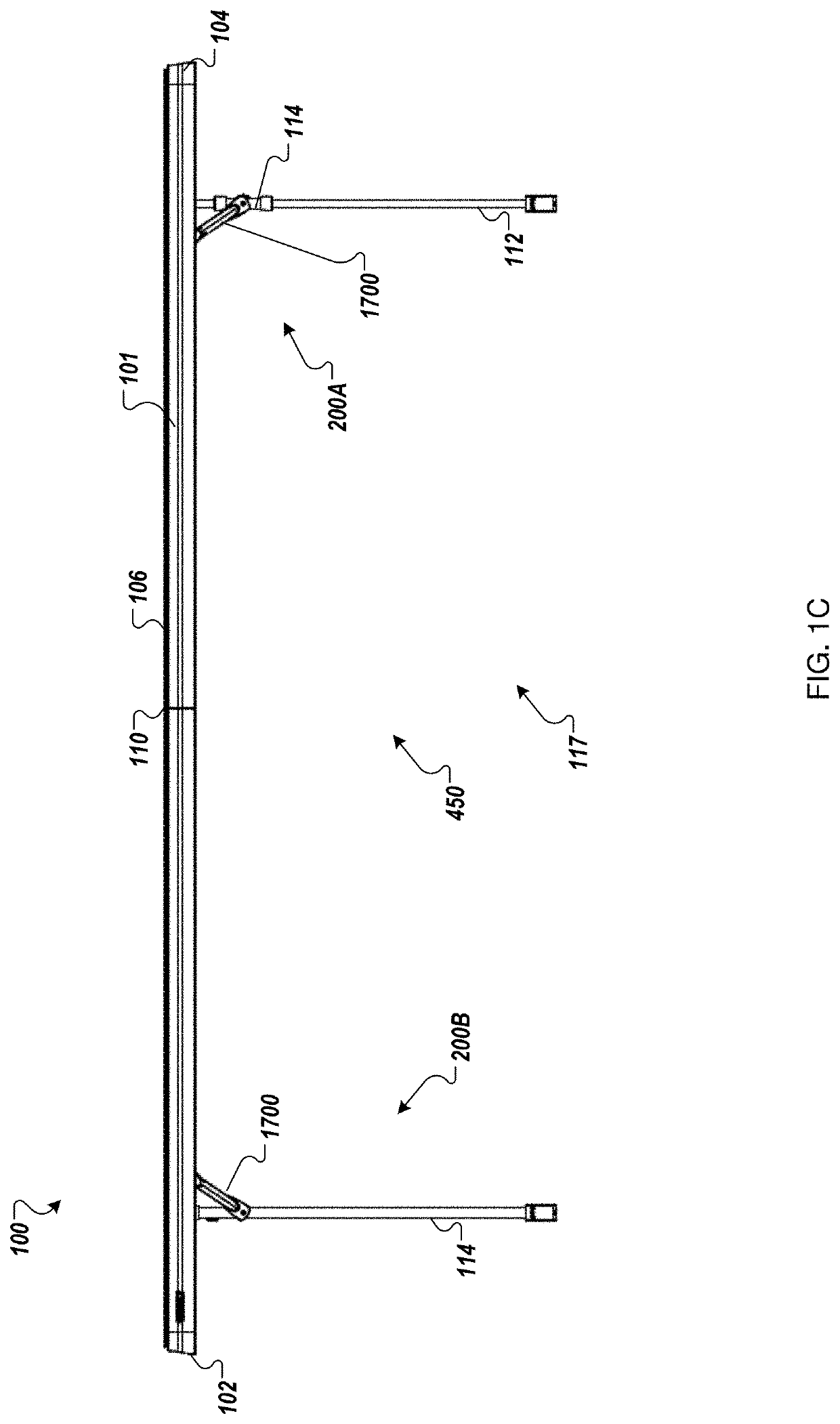

Two-stage lock assembly

PendingUS20210007474A1Prevent crashReduce the possibilityBenchesDismountable chairsEngineeringMechanical engineering

A two-stage lock assembly comprising a multi-element lock tab configured for disposition in a lateral structure of a lock device. The multi-element lock tab may include a body that includes an end on which a first element and a second element are disposed. The first element may extend from the body farther than the second element to enable the first element to be introduced into a receiver prior to the second element. The multi-element lock tab may be configurable in a disengaged configuration in which the first element and the second element are not positioned in a receiver, a first engaged configuration in which the first element is positioned in the receiver and the second element is not, and a second engaged configuration in which the first and the second elements are positioned in the receiver.

Owner:LIFETIME PRODUCTS

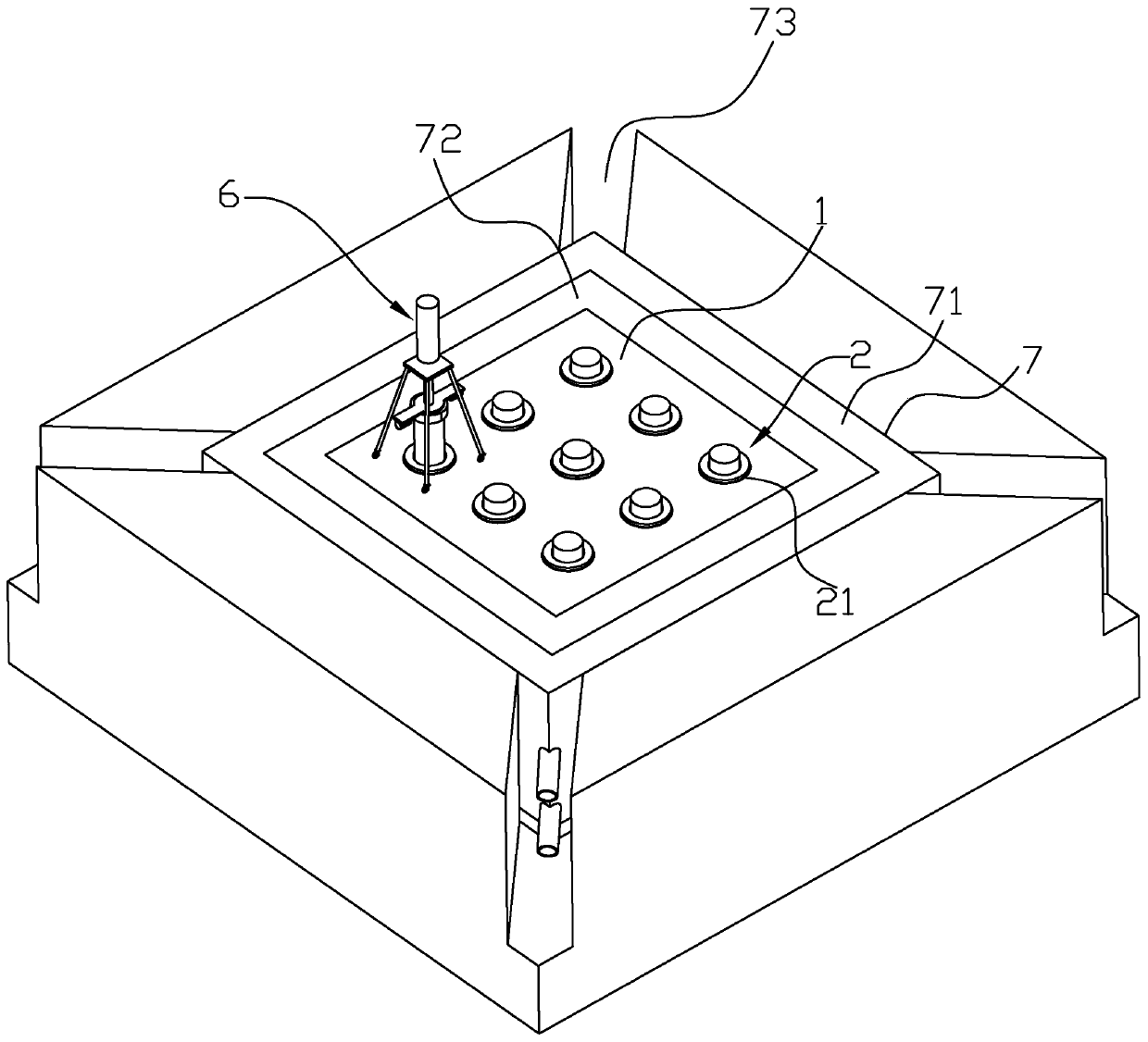

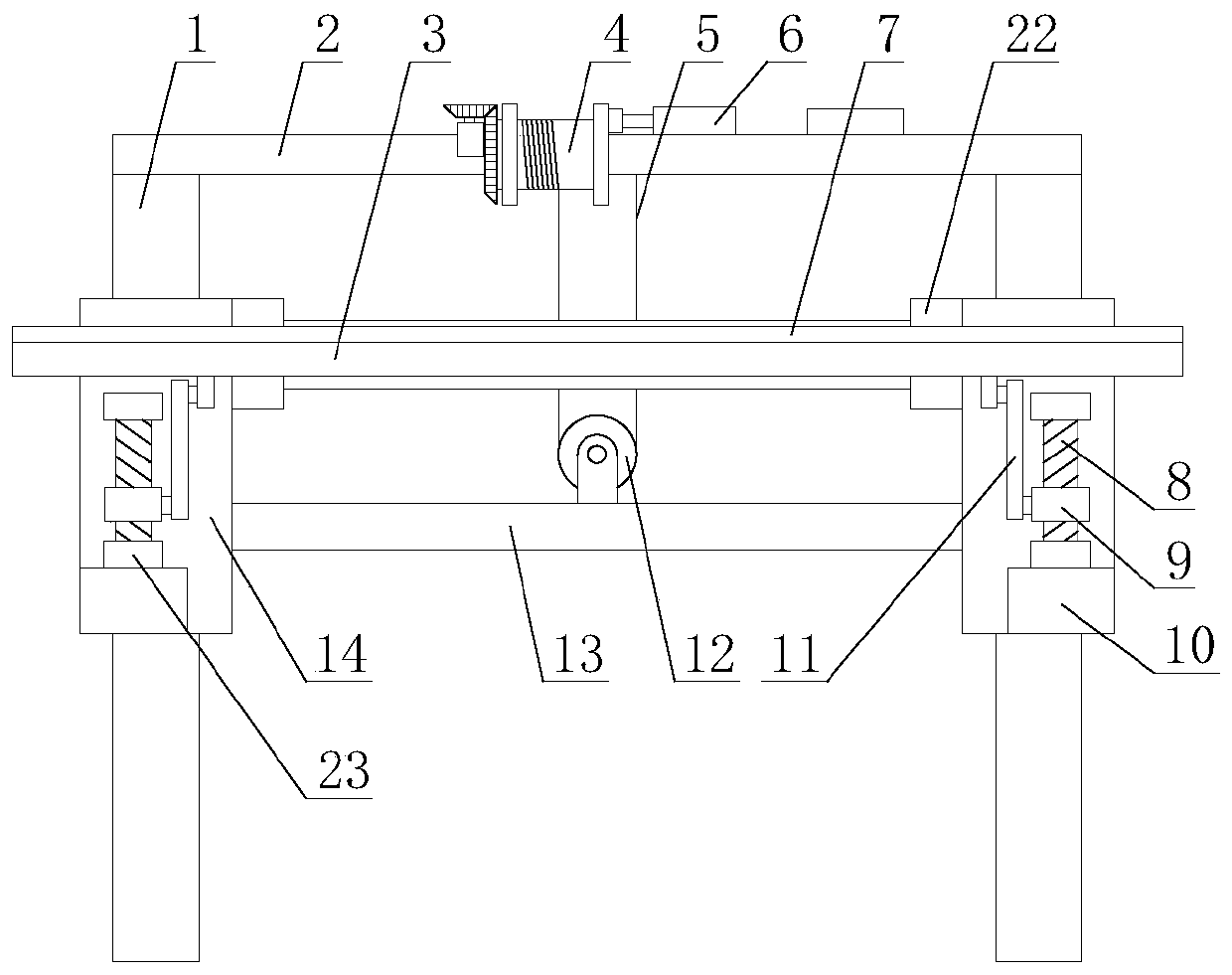

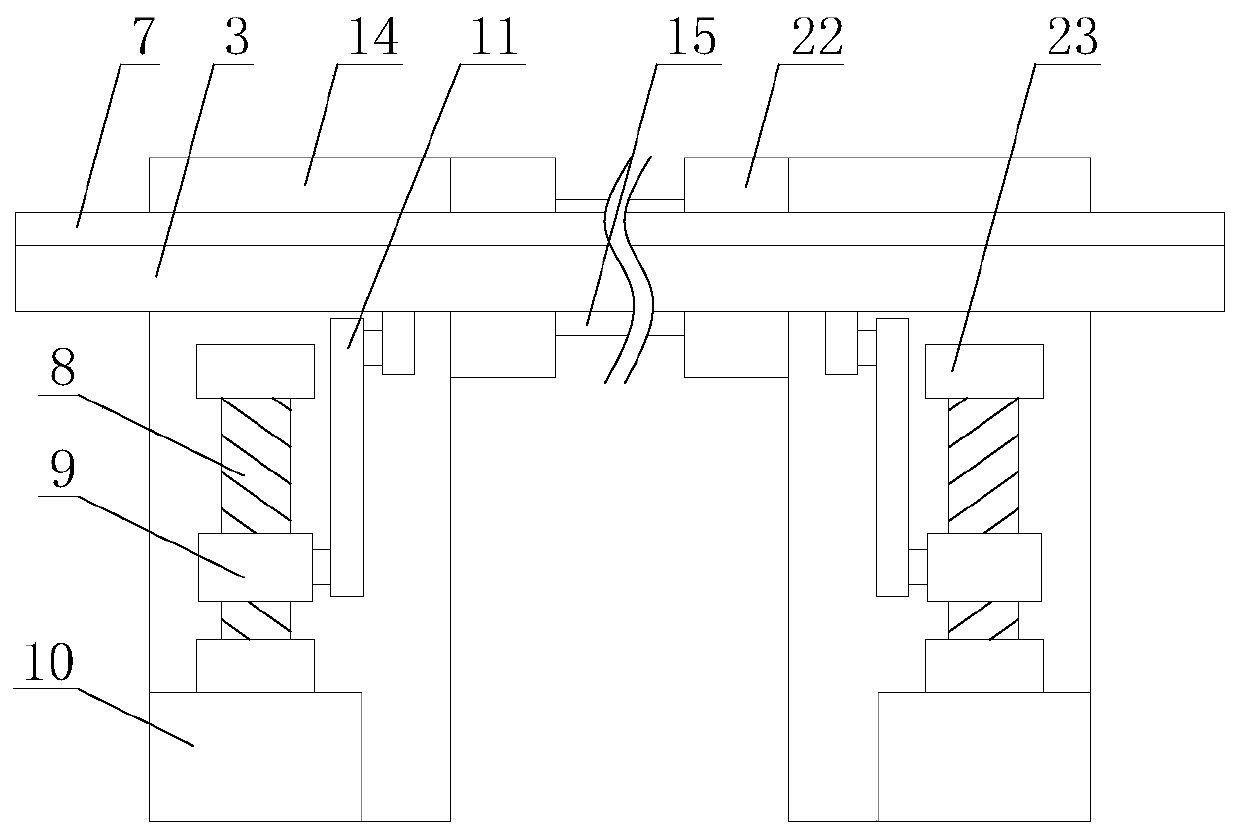

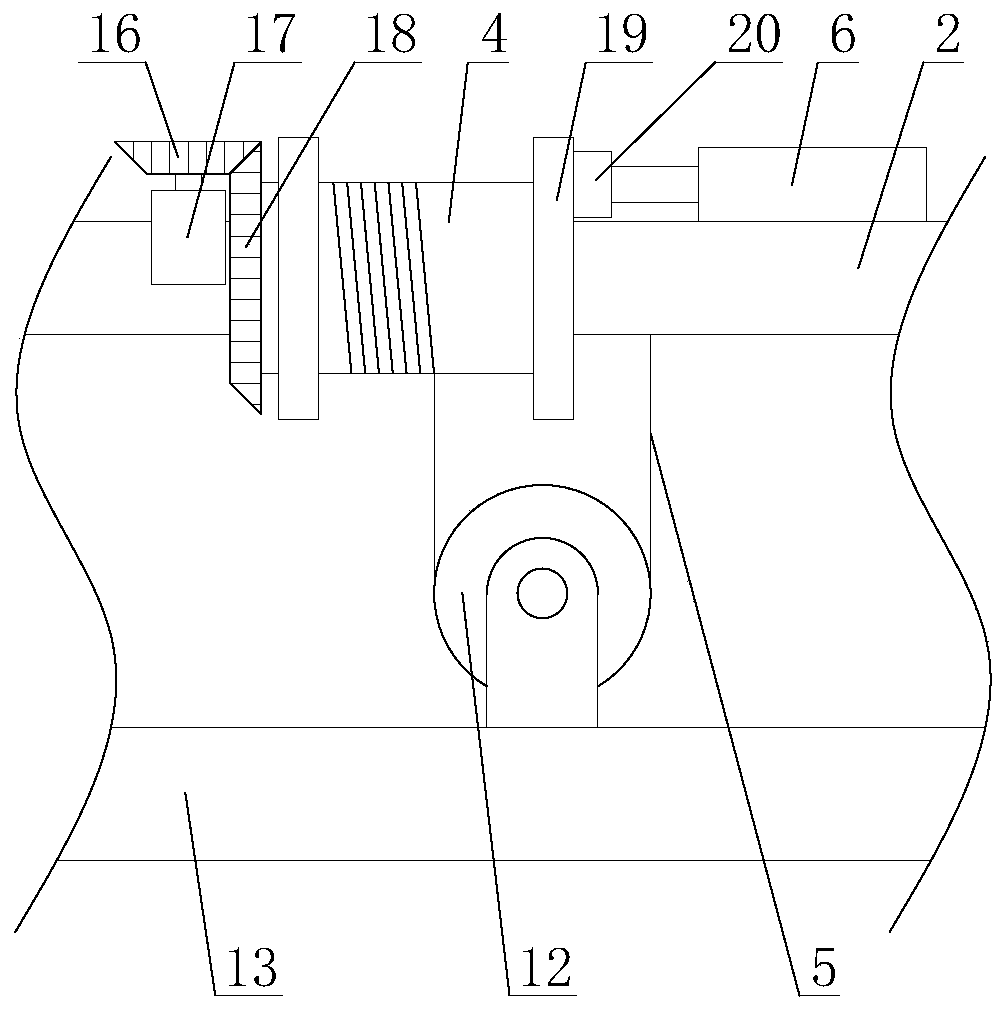

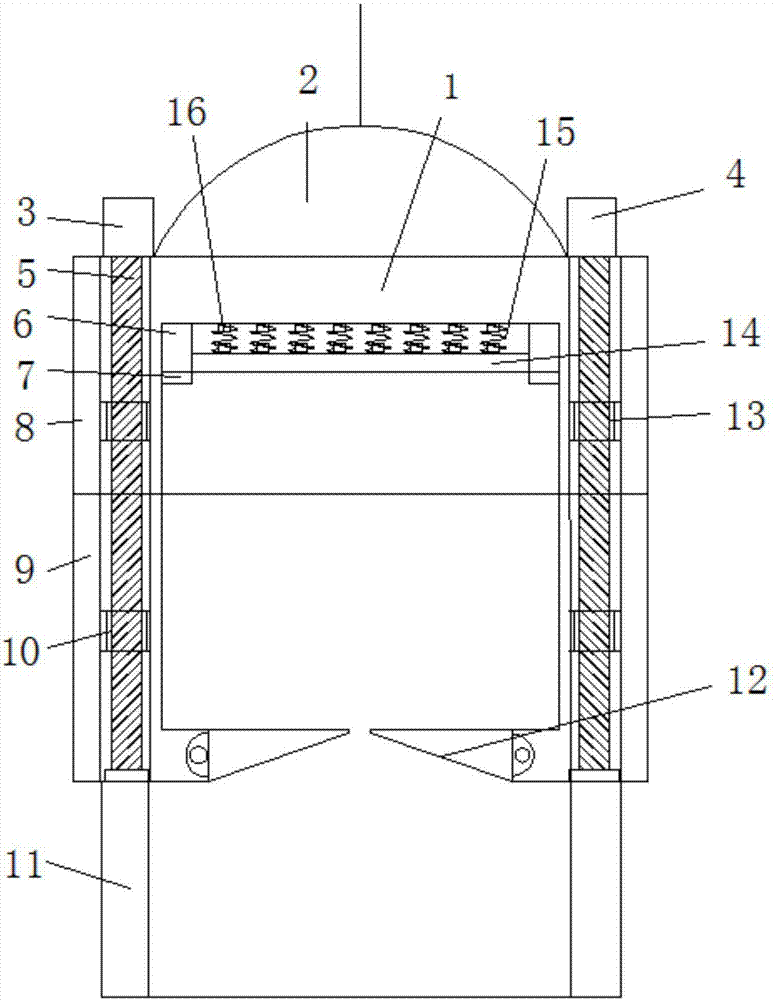

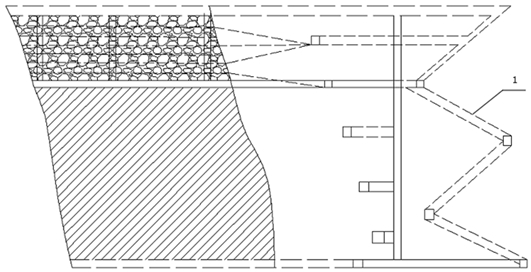

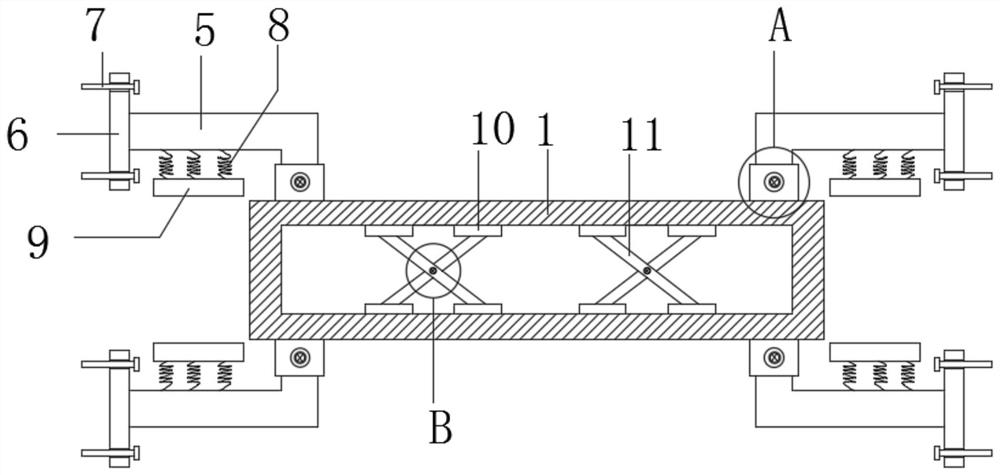

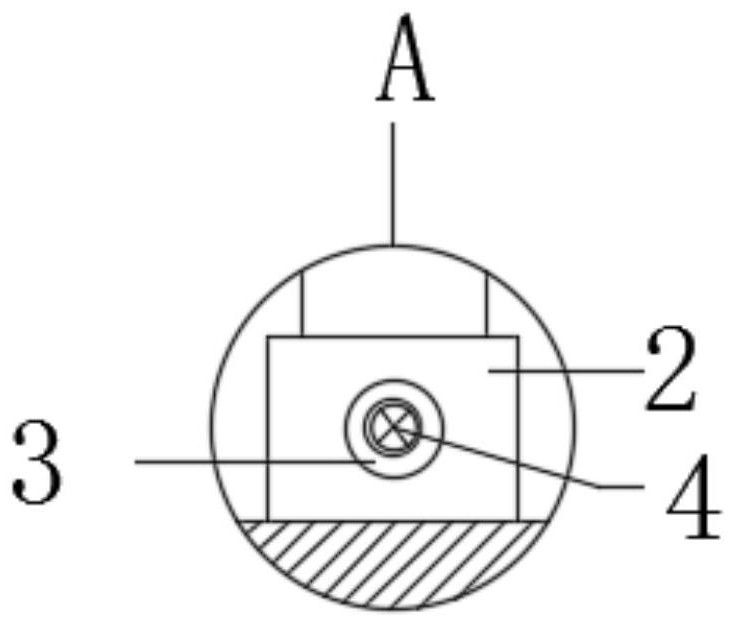

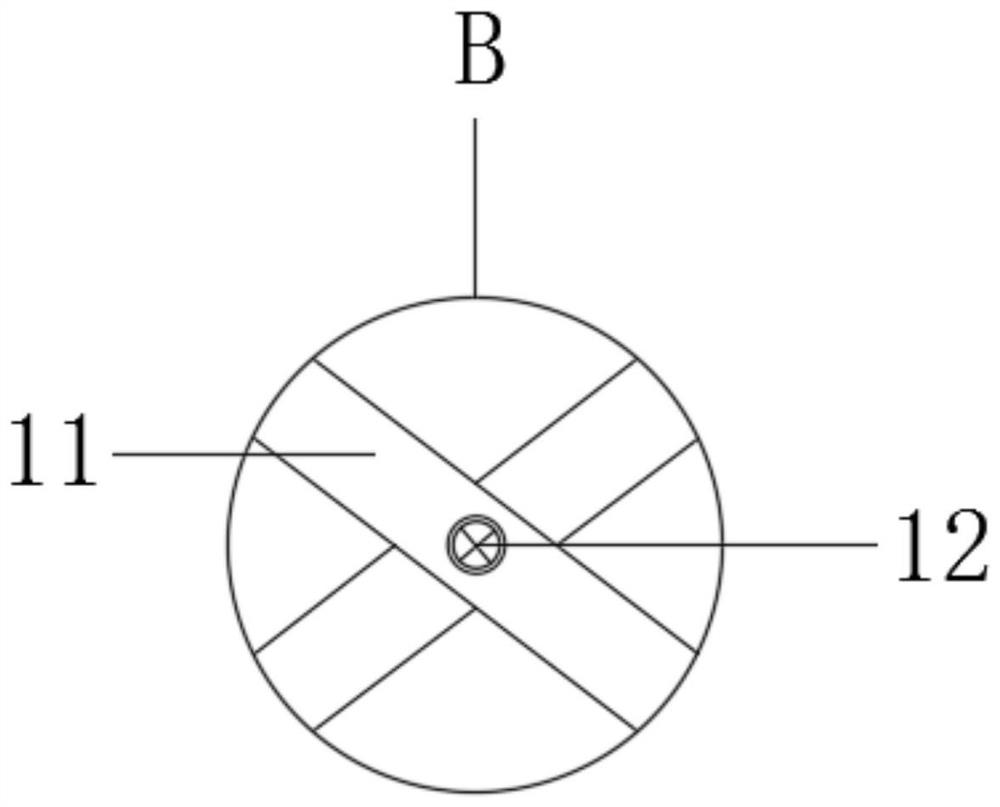

Settlement prevention foundation structure for soft soil foundations and method thereof

ActiveCN110158632AReduce the likelihood of subsidenceBlocking movementSoil preservationEngineeringBuilding construction

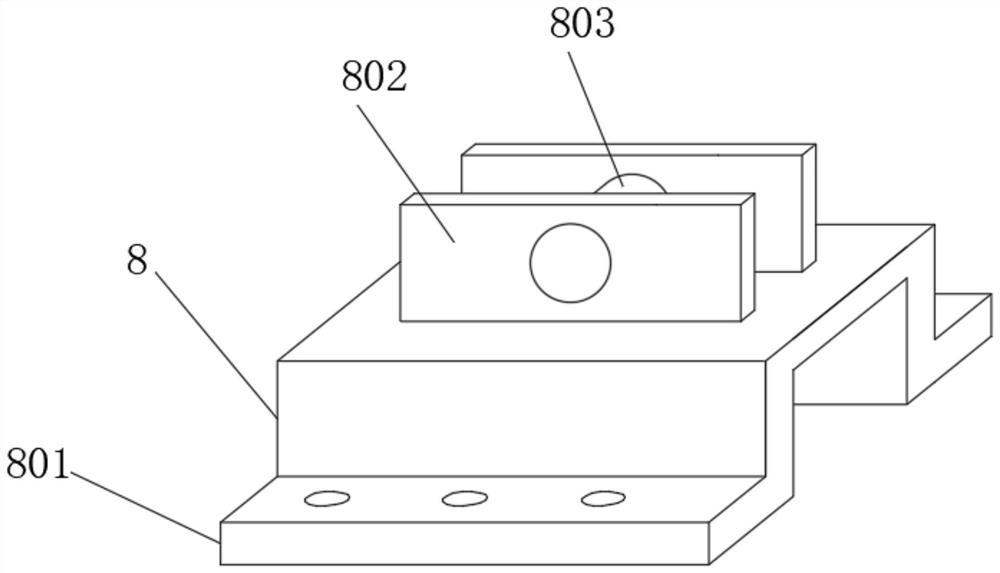

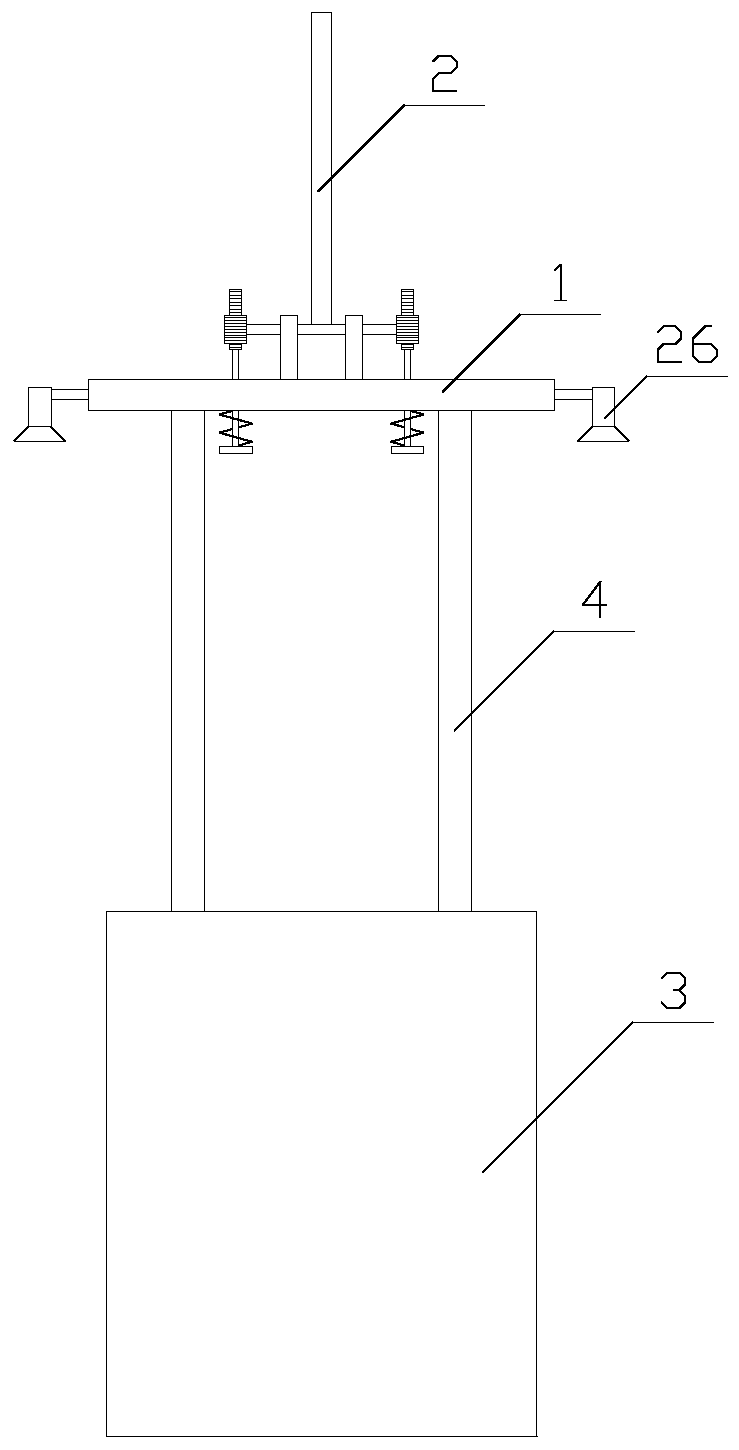

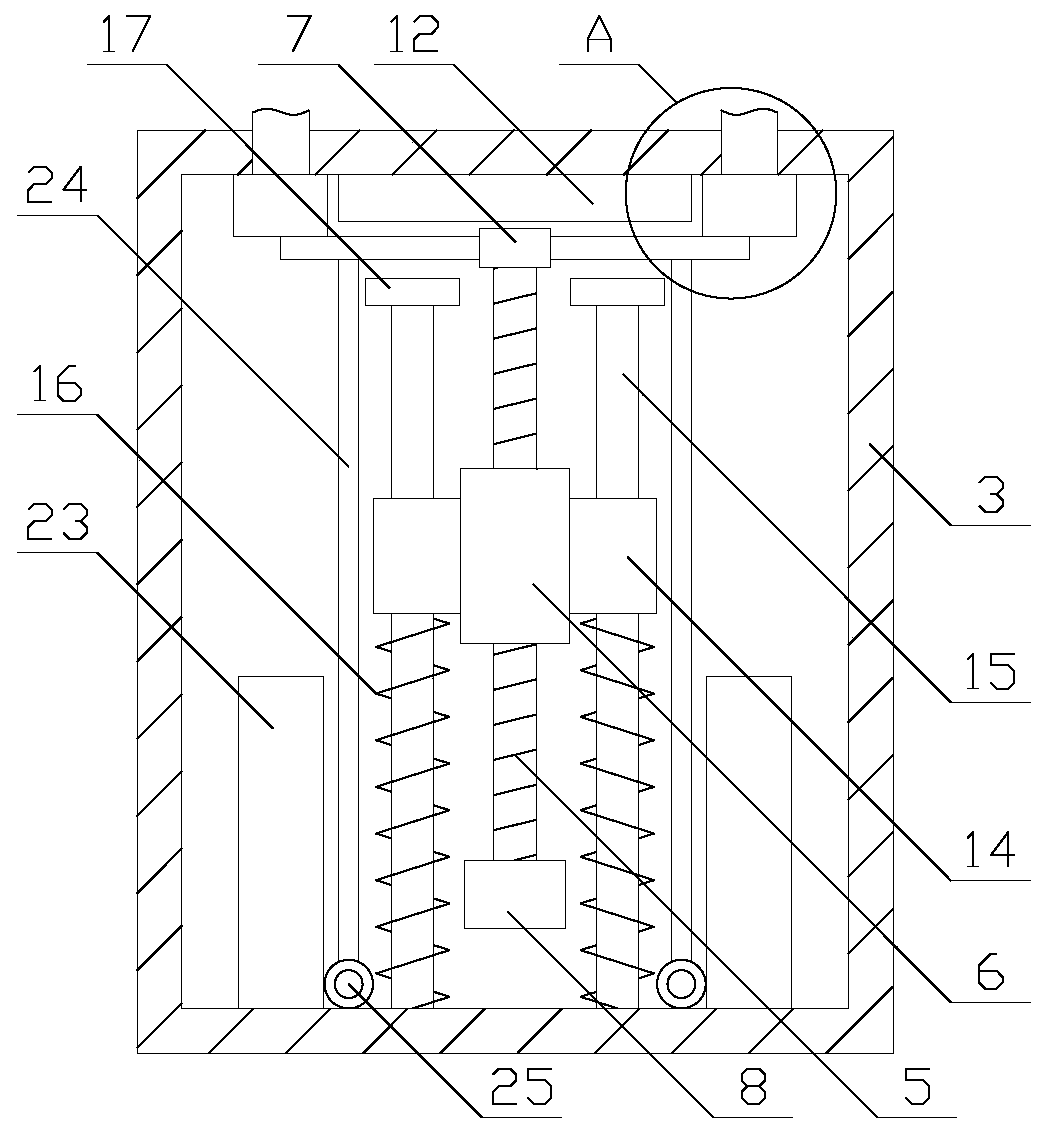

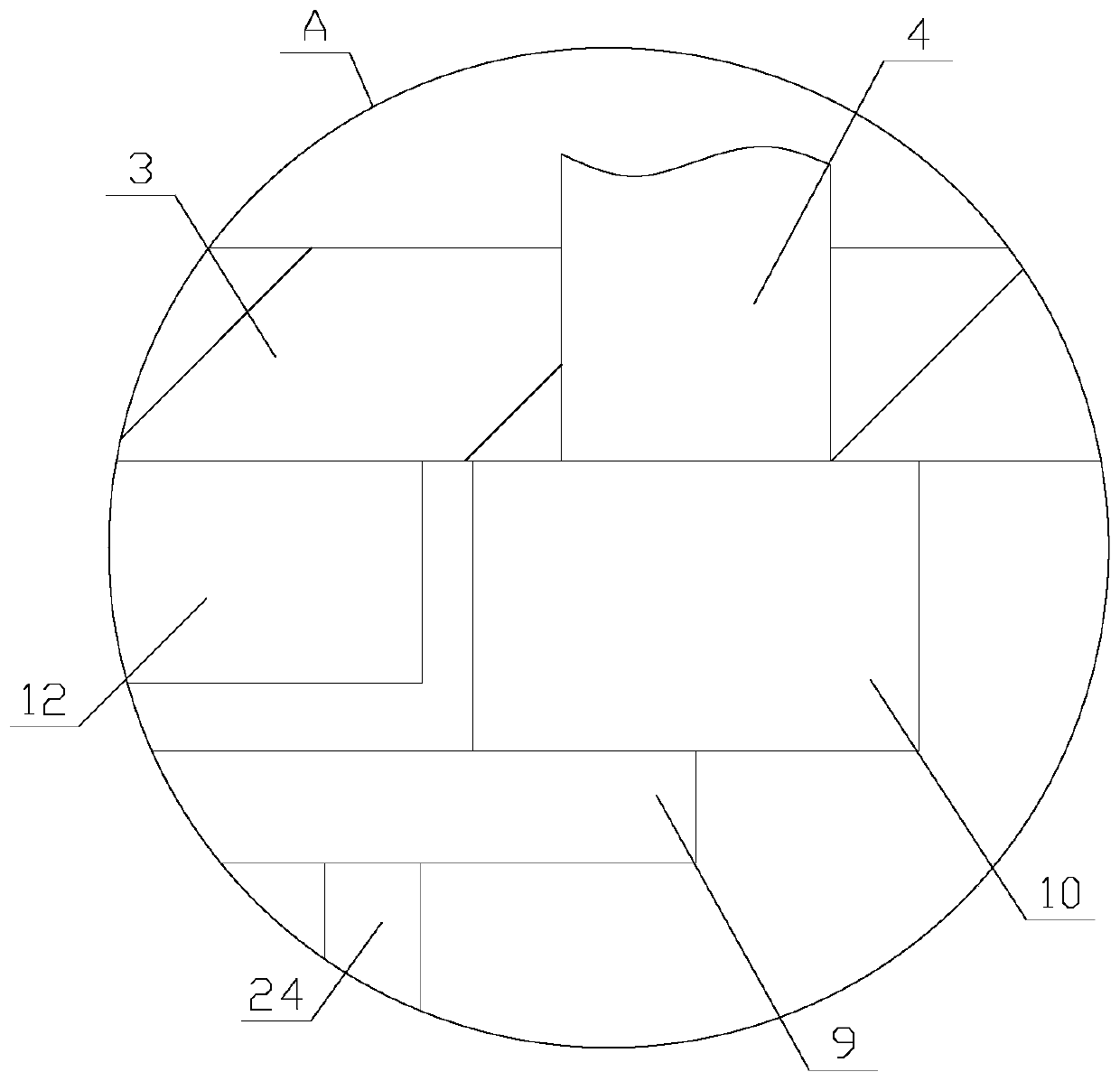

The invention discloses a settlement prevention foundation structure for soft soil foundations and a method thereof and relates to the technical field of building construction. According to main points of the technical scheme, the foundations are included, and multiple sets of settlement prevention devices arranged in the foundations are further included; each set of settlement prevention device comprises an installing hole, a connection barrel arranged in the installing hole, and a plurality of through holes evenly distributed in the peripheral face of the connection barrel in the circumferential direction of the connection barrel, wherein an abutting plate is slidably connected in each through hole in the radial direction of the connection barrel, an elastic assembly used for limiting the abutting plate is installed at the bottom of the connection barrel, a cylindrical push rod used for pushing the abutting plate to move is arranged in the connection barrel, an inwards concave firstcambered face is arranged at the end, close to the push rod, of the abutting plate, an outwards convex second cambered face is arranged at the other end of the abutting plate, the first cambered faceabuts against the peripheral face of the push rod, a circular truncated cone block is arranged at the bottom end of the push rod, and a driving mechanism used for driving the push rod to move is arranged on the foundations. The settlement prevention devices are arranged so that the possibility of settlement of the foundations can be lowered.

Owner:WUHAN ZHONGLI GEOTECHN ENG

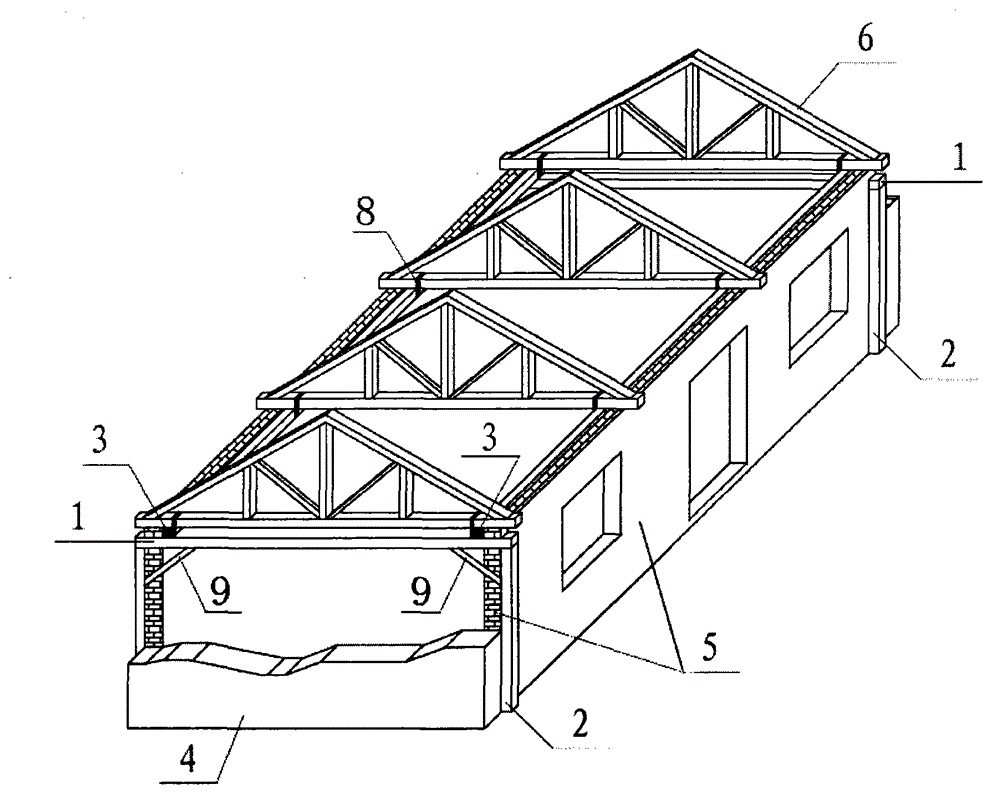

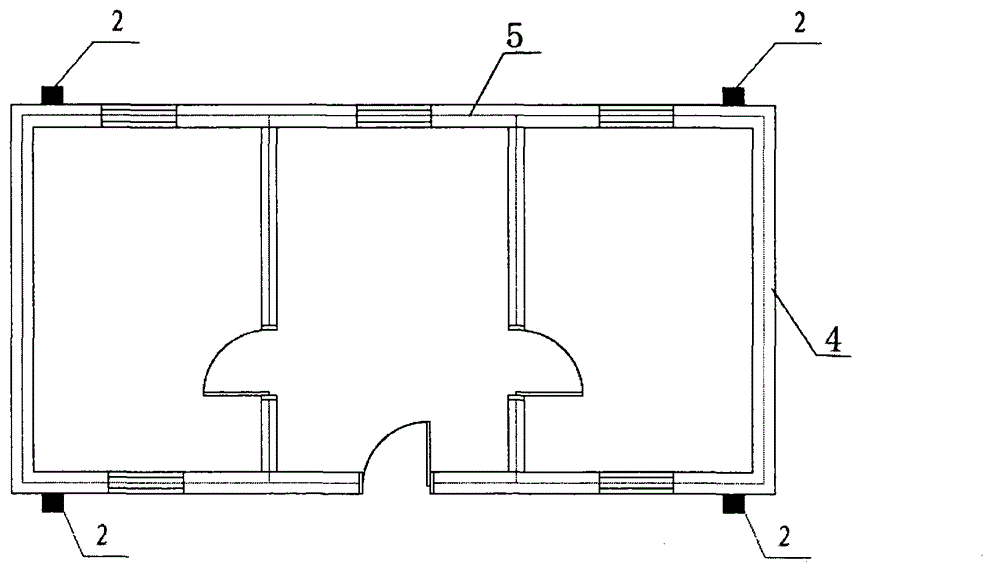

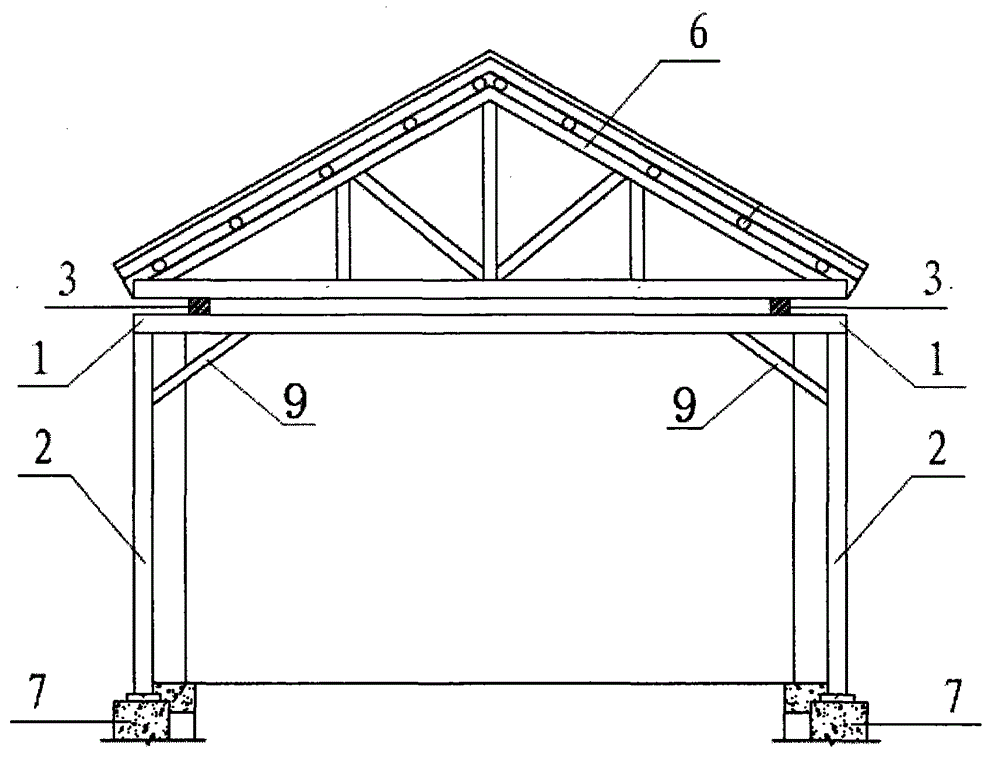

Single-floor masonry residential building steel-frame canopy guard structure and construction method thereof

ActiveCN102943572ASimple structurePower transmission is clearBuilding repairsProtective buildings/sheltersSocial benefitsBrick

The invention relates to a single-floor masonry residential building steel-frame canopy guard structure and a construction method thereof. A single-floor masonry residential building is provided with an original roof truss, the bottom surface of the original roof truss is provided with a reinforced steel frame, the reinforced steel frame consists of at least two external transverse steel beams, two external longitudinal steel beams, four external steel columns and an external foundation, the external longitudinal steel beams are arranged on the inner side of an original longitudinal wall, the external transverse steel beams are arranged on the outer side of an original gable wall, the end part of each external longitudinal steel beam is lapped on and fixedly connected with the external transverse steel beam to collectively form a contour which is identical to the plane shape of the original structure, the external steel columns are closely attached to the original gable wall or the original longitudinal wall, the top end of the external steel column is supported on the end part of the external transverse steel beam, and the bottom end of the external steel column is supported on the external foundation. Due to the adoption of the single-floor masonry residential building steel-frame canopy guard structure, under the situation that the application function of the original structure is not influenced, the anti-seismic performance is improved, good economic benefit and social benefit can be realized, the single-floor masonry residential building steel-frame canopy guard structure can be widely used for reinforcing the masonry residential building structure and particularly for reinforcing a stone house or a brick house which does not have the supporting column.

Owner:河南中装建设集团有限公司

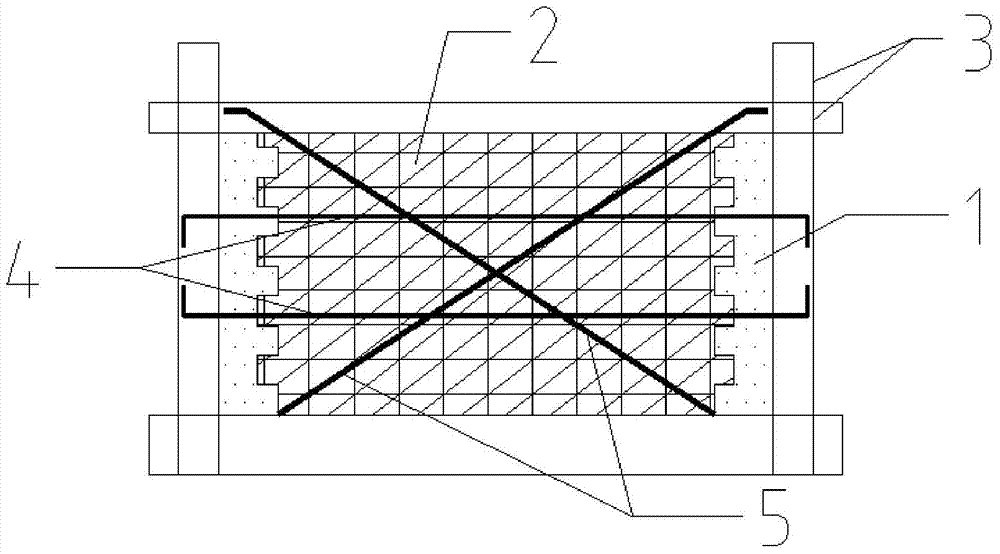

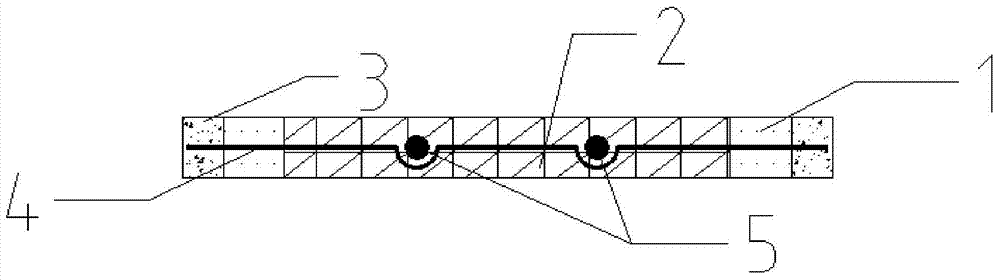

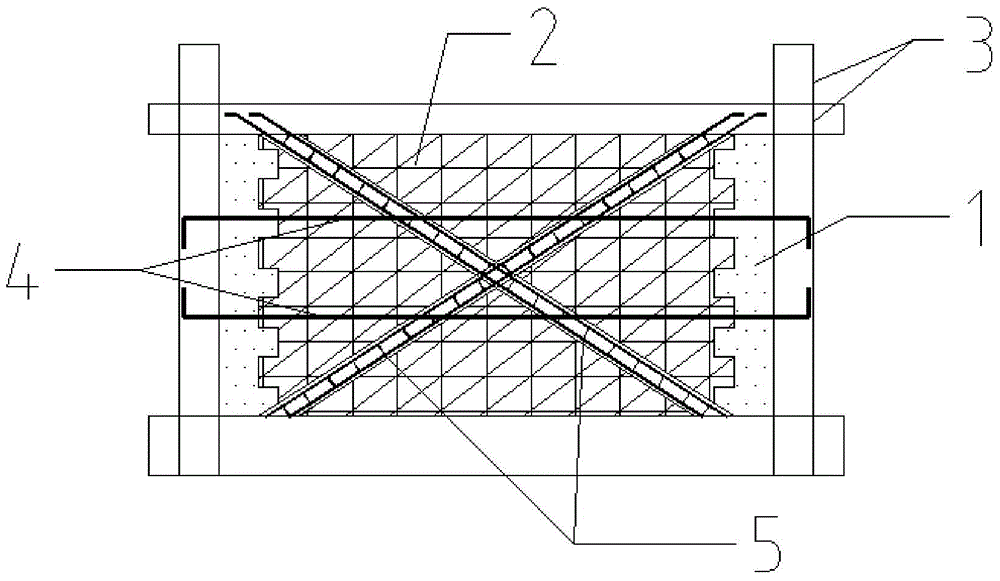

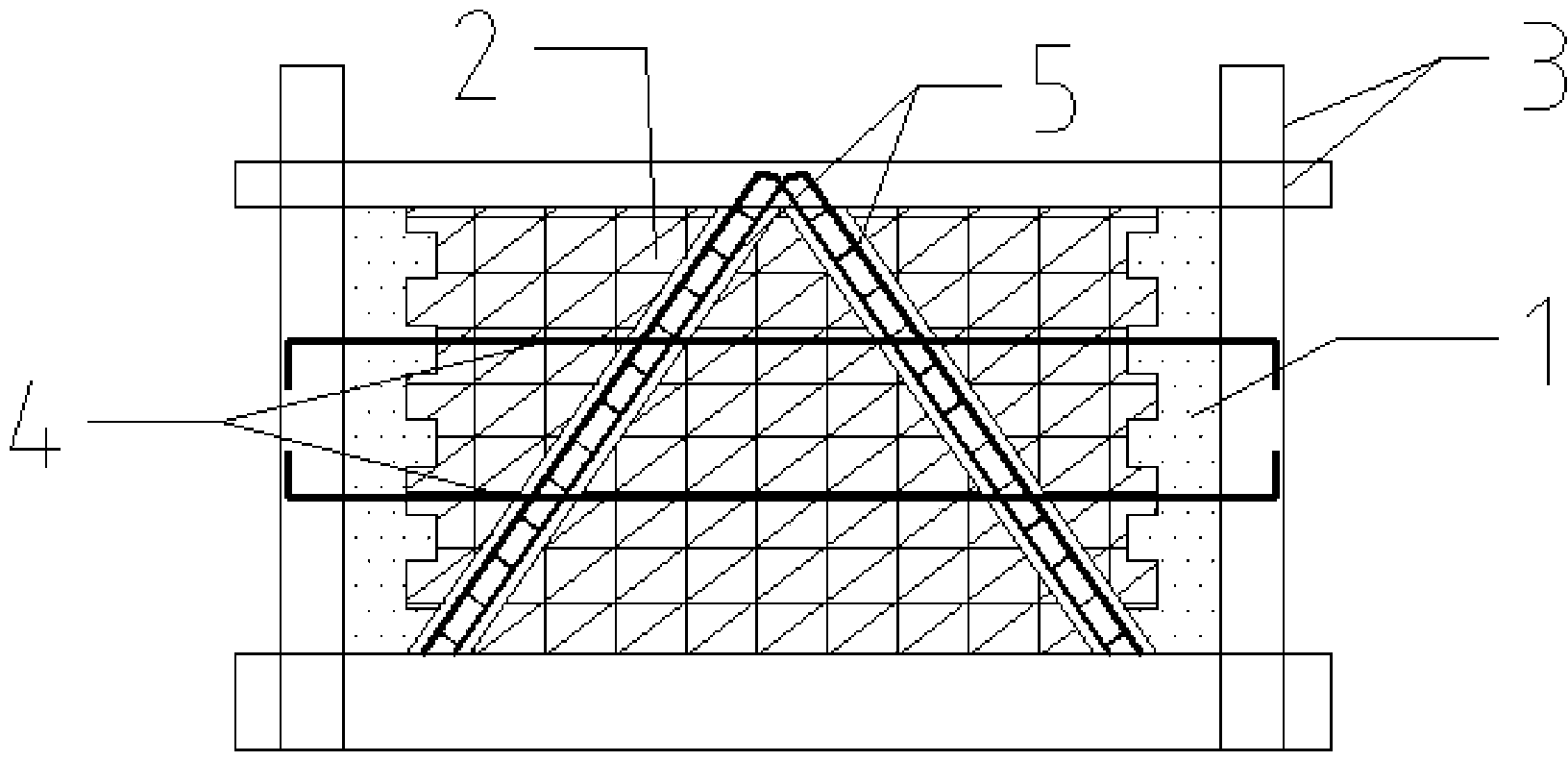

Infilled wall with build-in cross steel bars and manufacturing method of infilled wall

InactiveCN103669651AImprove performanceReduced chance of collapseWallsShock proofingRebarToxic industrial waste

The invention provides an infilled wall with build-in cross steel bars and a manufacturing method of the infilled wall, and belongs to the technical field of earthquake prevention and disaster reduction. The infilled wall is located in a frame structure and composed of energy dissipation strips, concrete blocks, a concrete frame, reserved steel tie bars and the cross steel bars. The concrete frame and the cross steel bars are manufactured according to common frames, and meanwhile the reserved steel tie bars are manufactured. The vertical energy dissipation strips are located on two sides of the frame infilled wall, and the energy dissipation strips not only prevent the frame structure from being damaged by the infilled wall and dissipate earthquake energy but also can make tight contact with frame columns and reduce the number of construction procedures. The cross steel bars enhance the shear-bearing capacity of the wall body, enhance overall performance of the wall body and improve energy-dissipating capacity. The infilled wall with the build-in cross steel bars makes full use of the energy-dissipating capacity of diagonal bracing portions and a masonry structure, light materials can be made of industrial waste, an ecological environmental protection effect is achieved, and the infilled wall is suitable for being used in the concrete frame structure and has wide application prospect.

Owner:BEIJING UNIV OF TECH

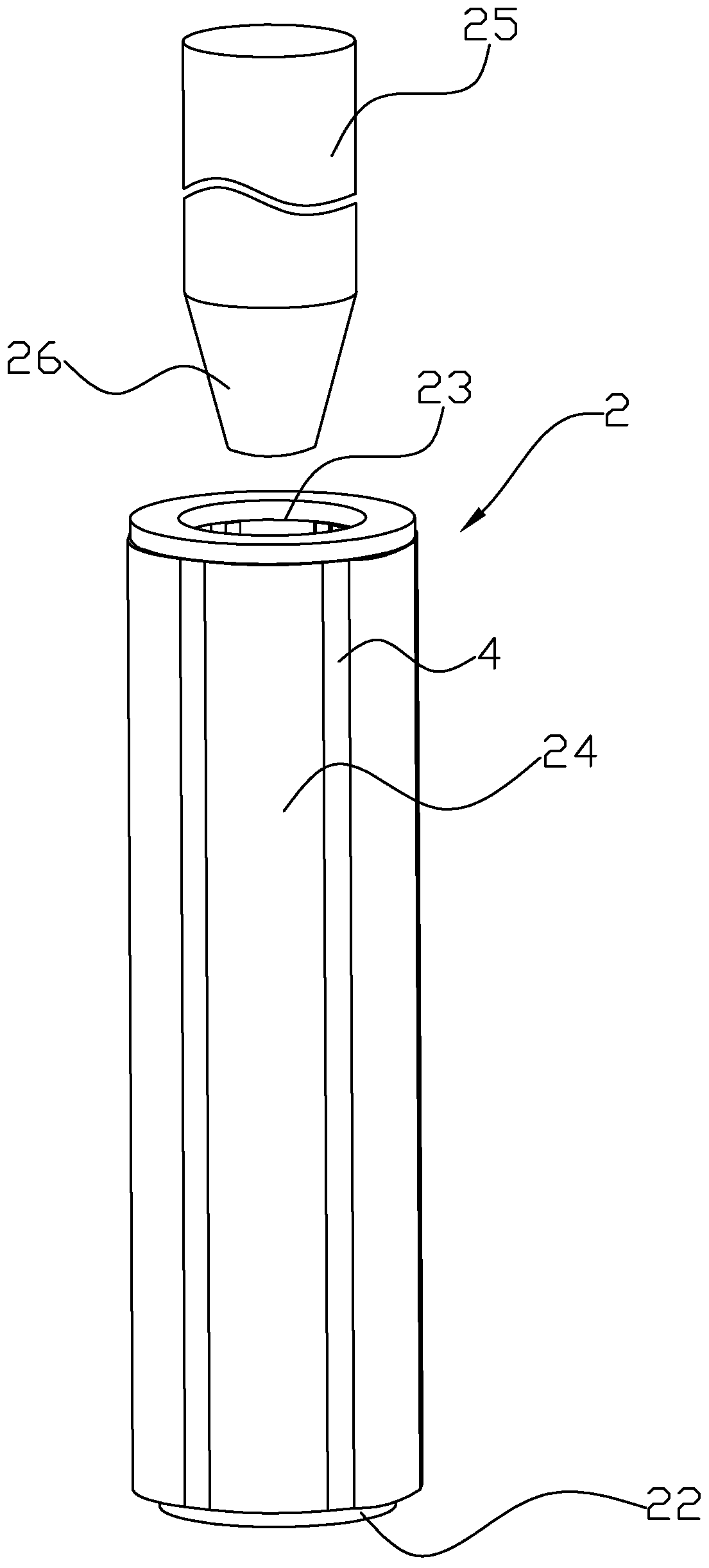

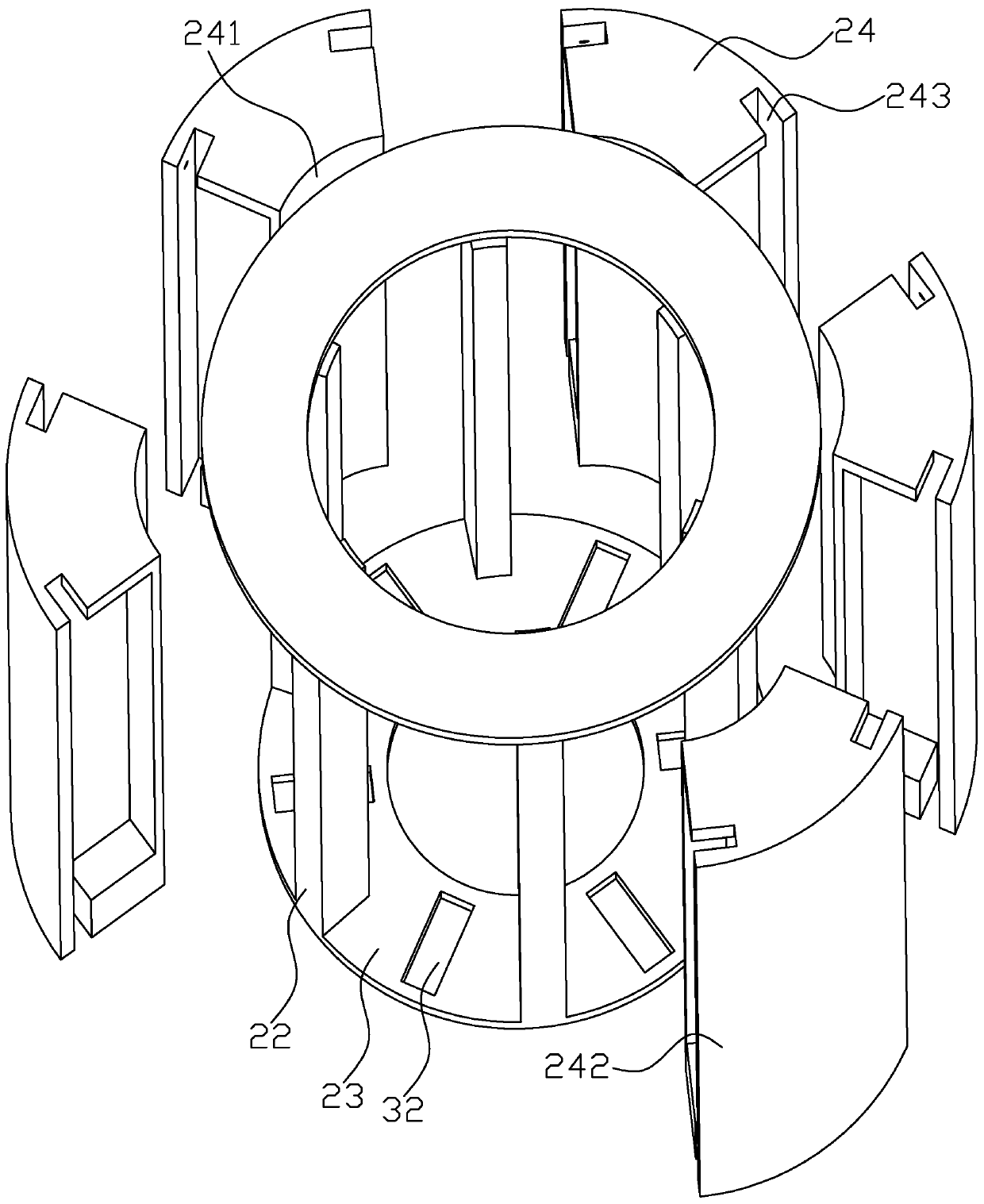

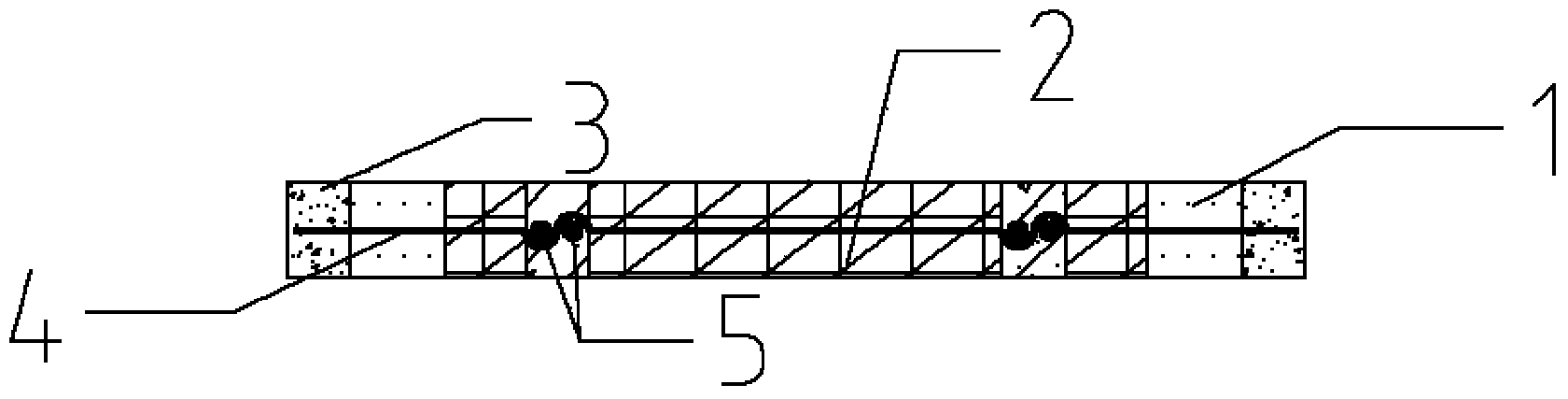

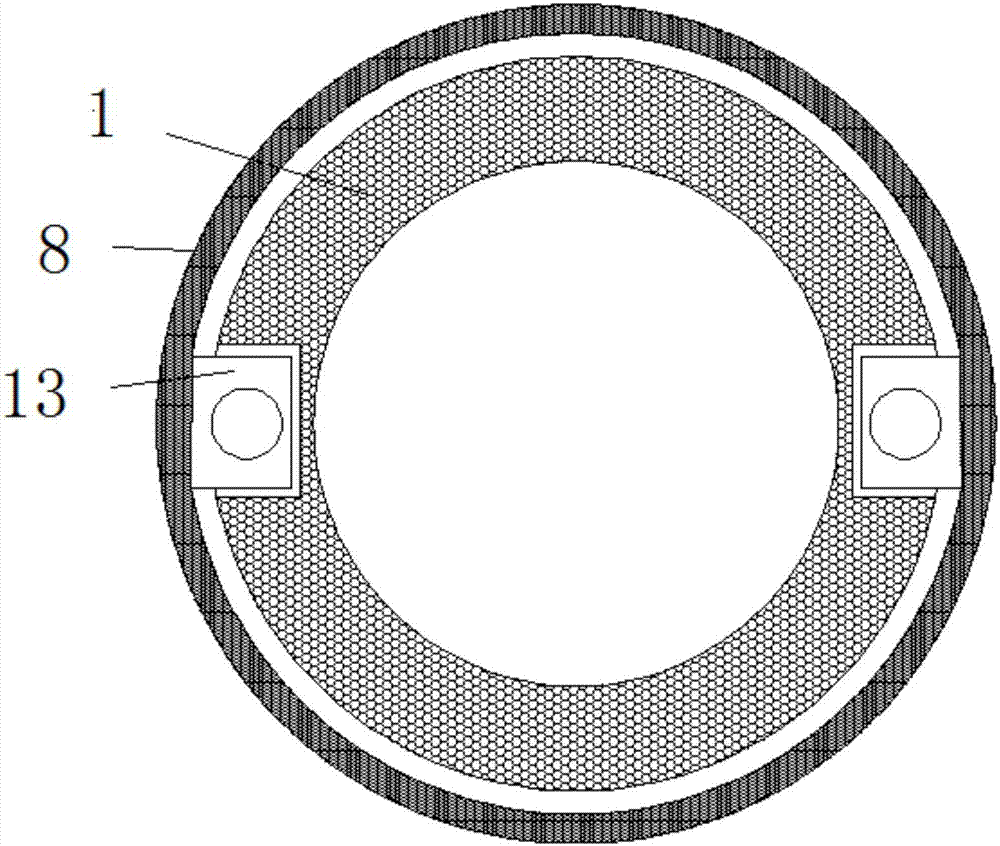

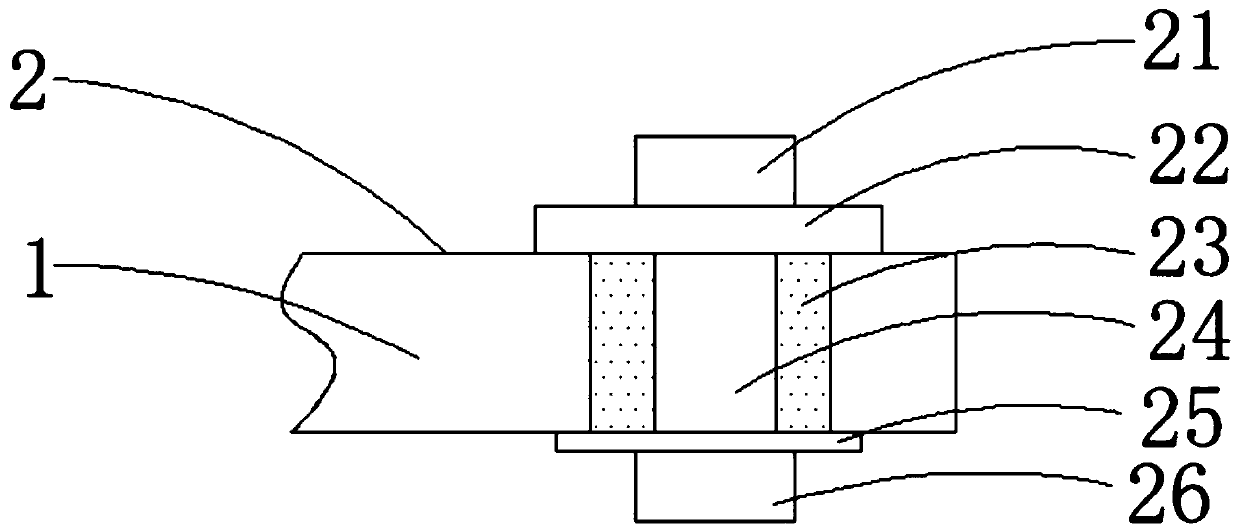

Winding needle, wound battery cell and production process of wound battery cell

ActiveCN110649328AImprove the defect of gap detachmentQuick releaseFinal product manufactureSecondary cellsMechanical engineeringBattery cell

The invention discloses a winding needle which is a columnar needle body made of an insulating rigid material. The winding needle is a columnar needle body made of an insulating rigid material, and the winding needle is wound in a diaphragm and a tab and is packaged into a battery shell along with a battery cell, so that the operation of pulling out a winding needle in the prior art is avoided, and the alignment degree of a wound battery cell is ensured, and the battery cell defect caused by the pulling-out of a silver winding needle in the existing technology is overcome. When the interior ofthe battery cell is short-circuited, the winding needle and a winding body ascend at the same time to press a safety valve on a battery cap, in order to realize rapid pressure relief and overcome thedefect that a center needle is separated from a battery cell due to gap. Heating is fast in the charging and discharging process, and due to winding tension, the pole pieces of the battery cell deform and extrude towards the inner ring of the battery cell, and the diaphragm looses and even collapses. Compared with the center needle, there is no gap between the winding needle and the diaphragm, the winding needle can well support the battery cell, and the looseness or collapse probability of the diaphragm is reduced. The invention further discloses a wound battery cell comprising the winding needle and a production process of the wound battery cell.

Owner:LINKDATA NEW ENERGY CO LTD

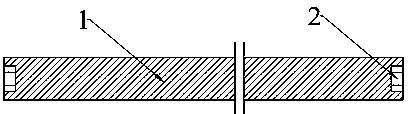

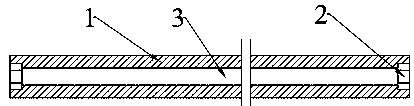

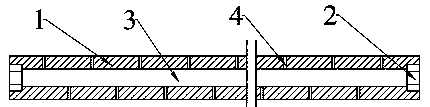

Filler wall with built-in crossed ladder reinforcing steel bars and manufacture method of filler wall

InactiveCN103912072AImprove performanceReduced chance of collapseWallsShock proofingIndustrial wasteSteel bar

The invention relates to a filler wall with built-in crossed ladder reinforcing steel bars and a manufacture method of the filler wall. The filler wall is located in a framework structure and consists of energy dissipation strips, concrete blocks, a concrete framework, reserved rachel tendons, and a ladder reinforcing steel mesh inclined strut. During manufacture, according to the design and normal frameworks, the concrete framework and the inclined strut are manufactured, and simultaneously, the reserved rachel tendons are shaped through manufacture. The energy dissipation strips and the concrete blocks are used for construction, the reserved rachel tendons are completely arranged at the positions of reserved reinforcing steel bars of the concrete framework, by means of the vertical energy dissipation strips, the filler wall is prevented from destroying the framework structure in an earthquake and consuming earthquake energy, the filler wall can be closely contacted with framework columns, and construction processes are saved; by means of the crossed ladder reinforcing steel mesh inclined strut, shear capacity of a wall body is improved, integrality of the wall body is enhanced, and energy-dissipating capacity is improved; according to the filler wall with built-in crossed ladder reinforcing steel bars, energy consumption capacity of an inclined strut portion and a masonry structure are fully utilized, light materials can be manufactured from industrial waste, and a function of eco-environment protection is achieved.

Owner:BEIJING UNIV OF TECH

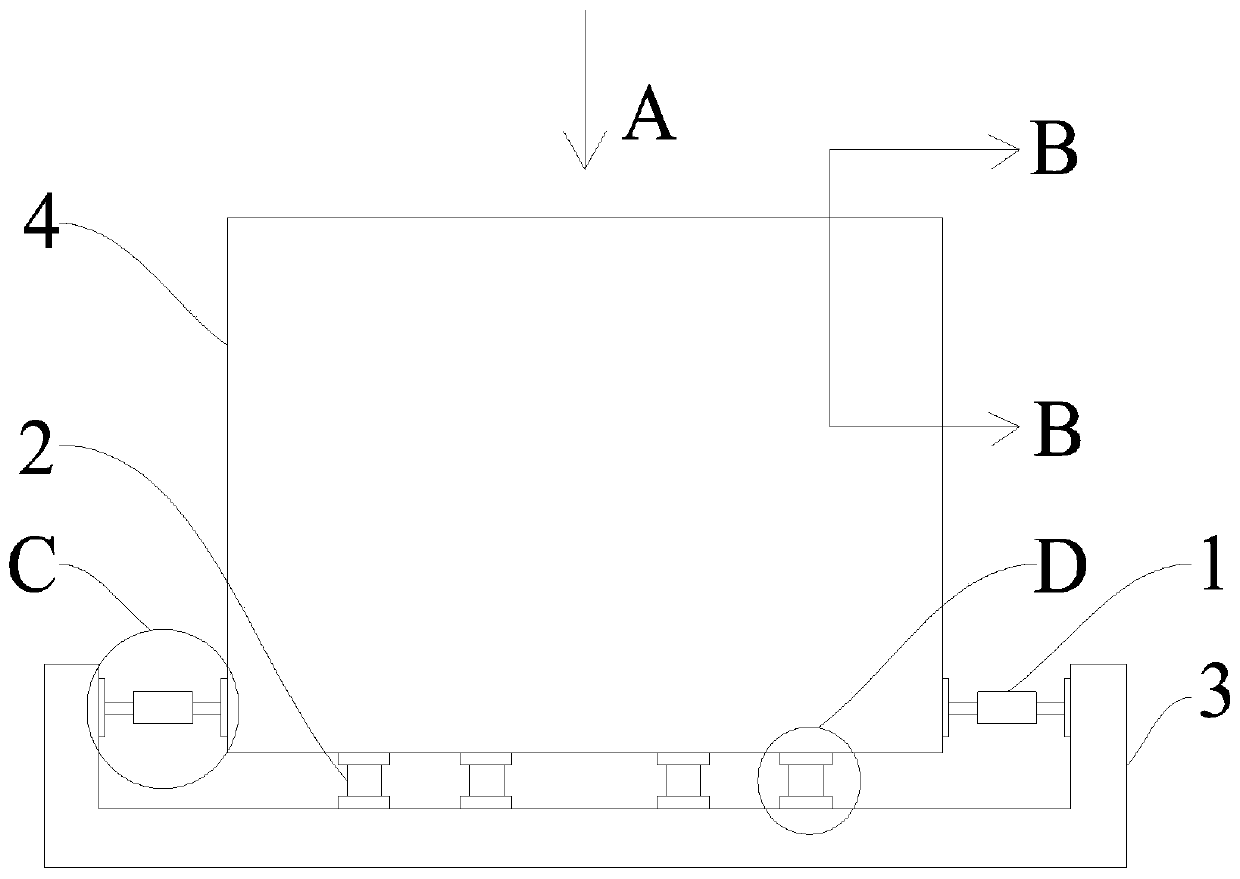

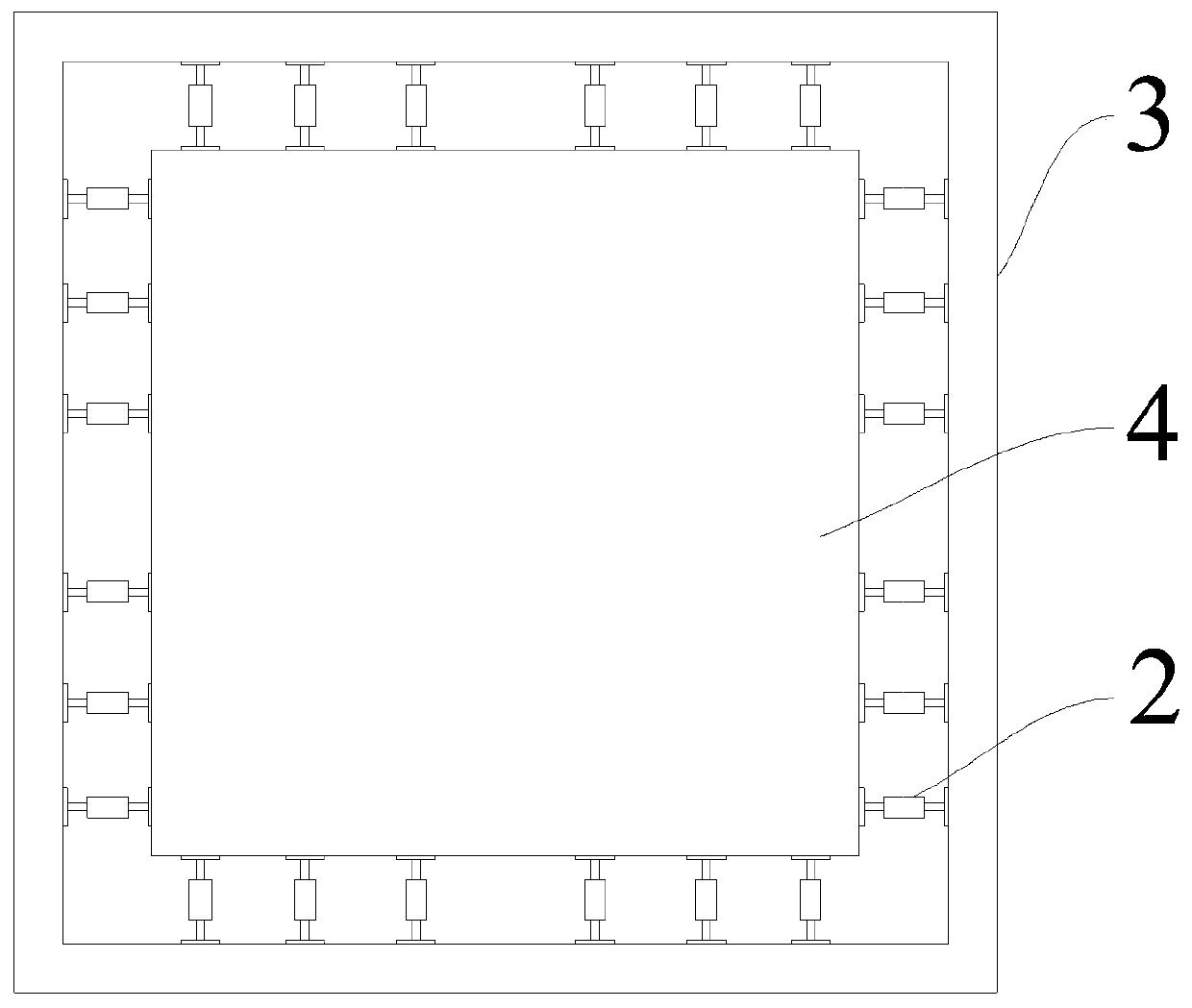

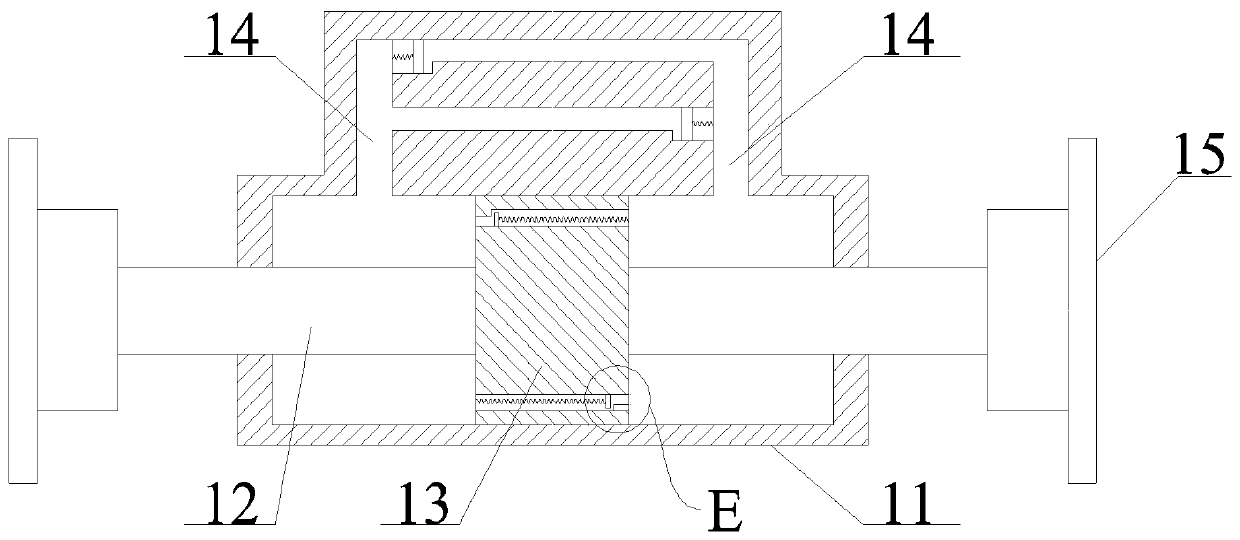

Building earthquake-resistance structure

InactiveCN110565829AWeakening rangeReduced chance of collapseProtective buildings/sheltersShock proofingBreaking strengthEarthquake resistance

The invention relates to the technical field of building earthquake-resistance, and provides a building earthquake-resistance structure. The structure comprises transverse dampers, longitudinal dampers and reinforcing nets; the transverse dampers are uniformly arranged between a building body and a foundation pit in a surrounding mode and used for consuming and absorbing the transverse swing energy of the building body, reducing the transverse swing amplitude of the building body, and reducing the breaking strength of earthquake transverse waves to the building body; the longitudinal dampers are arranged between the bottom of the building body and the foundation pit and used for absorbing the longitudinal vibration energy of the building body, reducing the longitudinal vibration amplitudeof the building body, and reducing the breaking strength of earthquake longitudinal waves to the building body; and the reinforcing nets are coated on the two sides of a wall of the building body andused for increasing the strength of the wall so as to prevent the brittle collapse of the wall. According to the structure, the transverse dampers and the longitudinal dampers are arranged between thebuilding body and the foundation pit, so that the energy of the earthquake transverse waves and the energy of the earthquake longitudinal waves are consumed and absorbed, the transverse vibration amplitude and the longitudinal vibration amplitude of the building body is reduced, the collapse probability of the building body is reduced, and the earthquake-resistance capacity is improved.

Owner:WEIFANG CHANGDA CONSTR GROUP

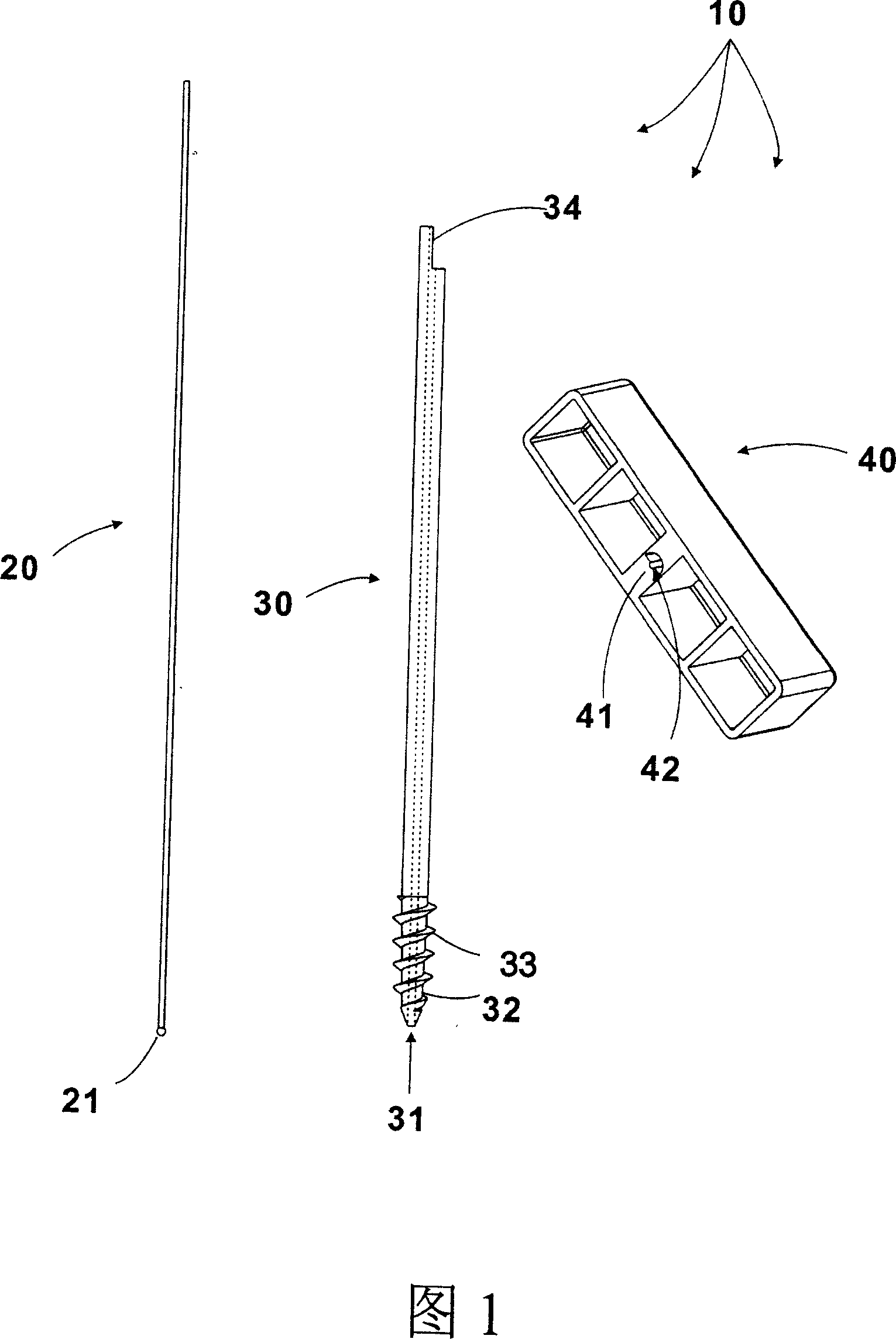

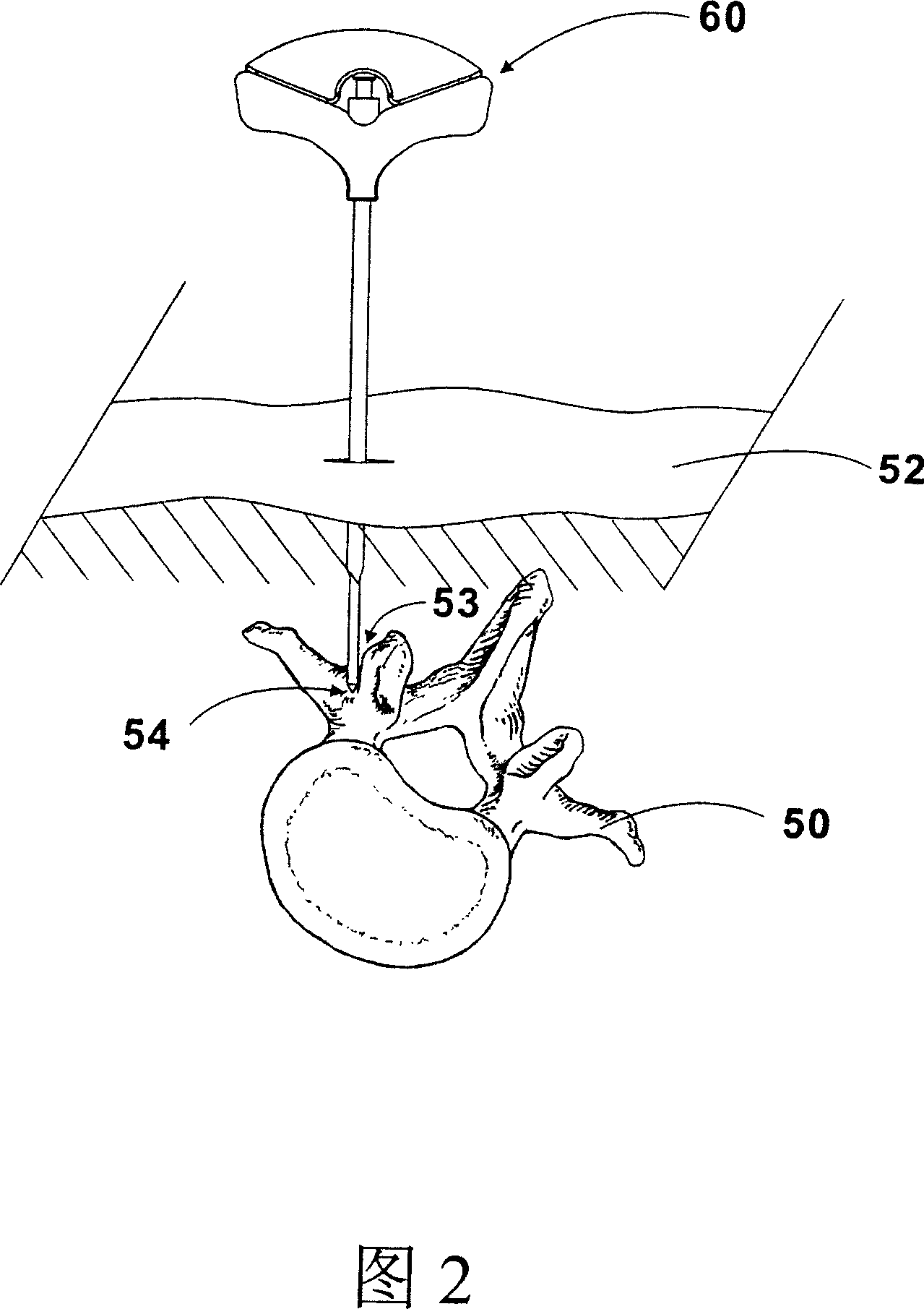

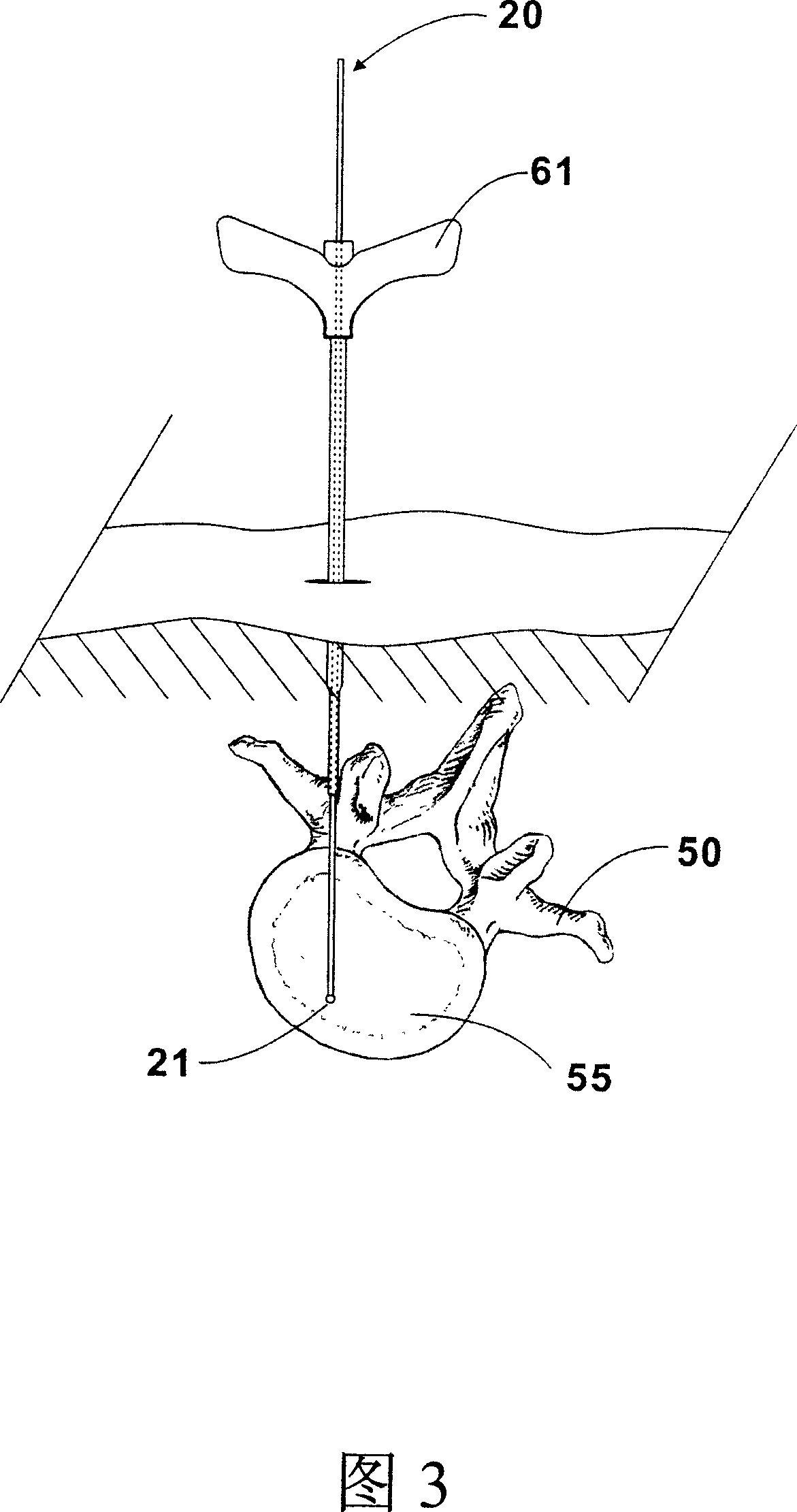

Transdermal guiding bone reaming tool device and method

The present invention relates to a percutaneous guided bone reaming tool device and its method. It mainly includes a blunt point guide pin and a guide screw tube, one end of said guide screw tube is made into a flat cone portion, its external surface is equipped with a helical toothed section. Said blunt point guide pin can be passed through skin and inserted into a bone tissue, said guide screw tube can be covered into said blunt point guide pin, and said flat cone portion and said helical toothed section can be clutched in said bone tissue, so that a working tube whose tube diameter can be covered into said guide screw tube can be punctured into said bone tissue along said guide screw tube.

Owner:王超然

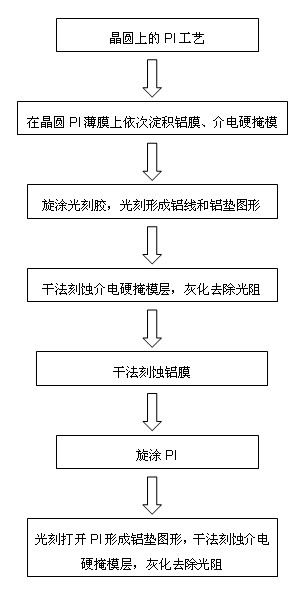

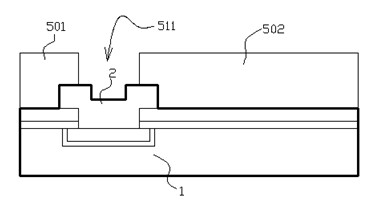

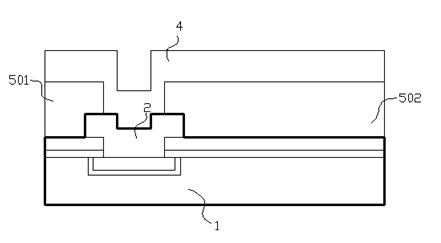

Production process of aluminum pad based on polyimide matrix

ActiveCN102420148AAvoid damageReduces the possibility of collapse of narrow aluminum wiresSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistEtching

The invention provides a production process of an aluminum pad based on a polyimide matrix. The production process comprises the following steps of: depositing a polyimide layer on a semiconductor device and photoetching the polyimide layer to form a trench pattern; sequentially depositing an aluminum film layer and a dielectric hard mask layer on the semiconductor device, spin coating photoresist and photoetching the photoresist to form a trench pattern; carrying out dry-method etching on the dielectric hard mask layer and removing the photoresist by ashing; carrying out dry-method etching on the aluminum film; and spin coating the polyimide layer, photoetching and opening the polyimide layer to form an aluminum pad pattern and then removing the dielectric hard mask layer on the aluminum pad by dry-method etching. In the production of the aluminum pad, the ashing step after the aluminum film is subjected to photoetching is omitted, and thus the damage to the polyimide matrix is avoided and the possibility of causing the collapse of a narrow aluminum line is reduced. The production process is relatively simple and the produced aluminum pad can meet the demand on the layout change of the aluminum pad.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

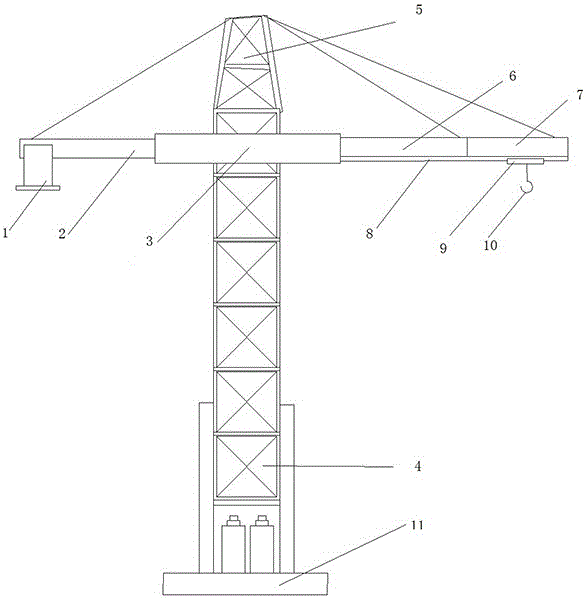

On-load luffing boom lifting apparatus

The invention discloses an on-load luffing boom lifting apparatus. The apparatus includes a pedestal, a crane body is arranged above the pedestal, a crane top is arranged at the top end of the crane body, an operating room is arranged between the crane body and the crane top, a balancing arm and a boom are respectively arranged at two sides of the operating room, the protruding ends of the balancing arm and the boom are respectively connected with the crane top through pull bars, a weight running device is arranged on the balancing arm, the boom comprises a first boom and a second boom which are connected with the crane top through ropes, the second boom is in sliding connection with the first boom, and a rotating device is arranged at a maximum sliding displacement position. The balancing arm and the boom are fixedly connected with the operating room. A mobile dolly with the bottom connected with a lifting hook body is arranged on the second boom. The mobile dolly is connected with a pulley arranged on the boom, and a noise reduction sleeve sleeves the surface of the pulley.

Owner:四川宇盛智创科技有限公司

Filler wall with herringbone ladder rebars inlaid and construction method of filler wall

InactiveCN103883033AImprove performanceReduced chance of collapseWallsShock proofingRebarIndustrial waste

The invention discloses a filler wall with herringbone ladder rebars inlaid and a construction method of the filler wall and belongs to the technical field of earthquake prevention and disaster mitigation. The filler wall is arranged in a frame structure and composed of energy-dissipation strips, concrete blocks, a concrete frame, preset connected rebars and diagonal ladder rebar net braces. During construction, the concrete frame and the diagonal braces are manufactured as designed according to common frames, and the preset connected rebars are manufactured and formed. With the presence of the vertical energy-dissipation strips, the frame structure is protected from damage by the filler wall in the earthquakes, and earthquake energy can be dissipated. Also, the filler wall can tightly contact with frame columns, and construction procedures are saved. Shear-bearing capacity of the filler wall is improved by the diagonal herringbone ladder rebar net braces, the integrality of the filler wall is improved and energy dissipation is increased. The filler wall with the herringbone ladder rebars inlaid sufficiently adopts energy dissipation of the braces and the block structure, is environment friendly due to the fact light materials thereof can be manufactured by industrial waste, and is applicable to concrete frame structures and wide in application prospect.

Owner:BEIJING UNIV OF TECH

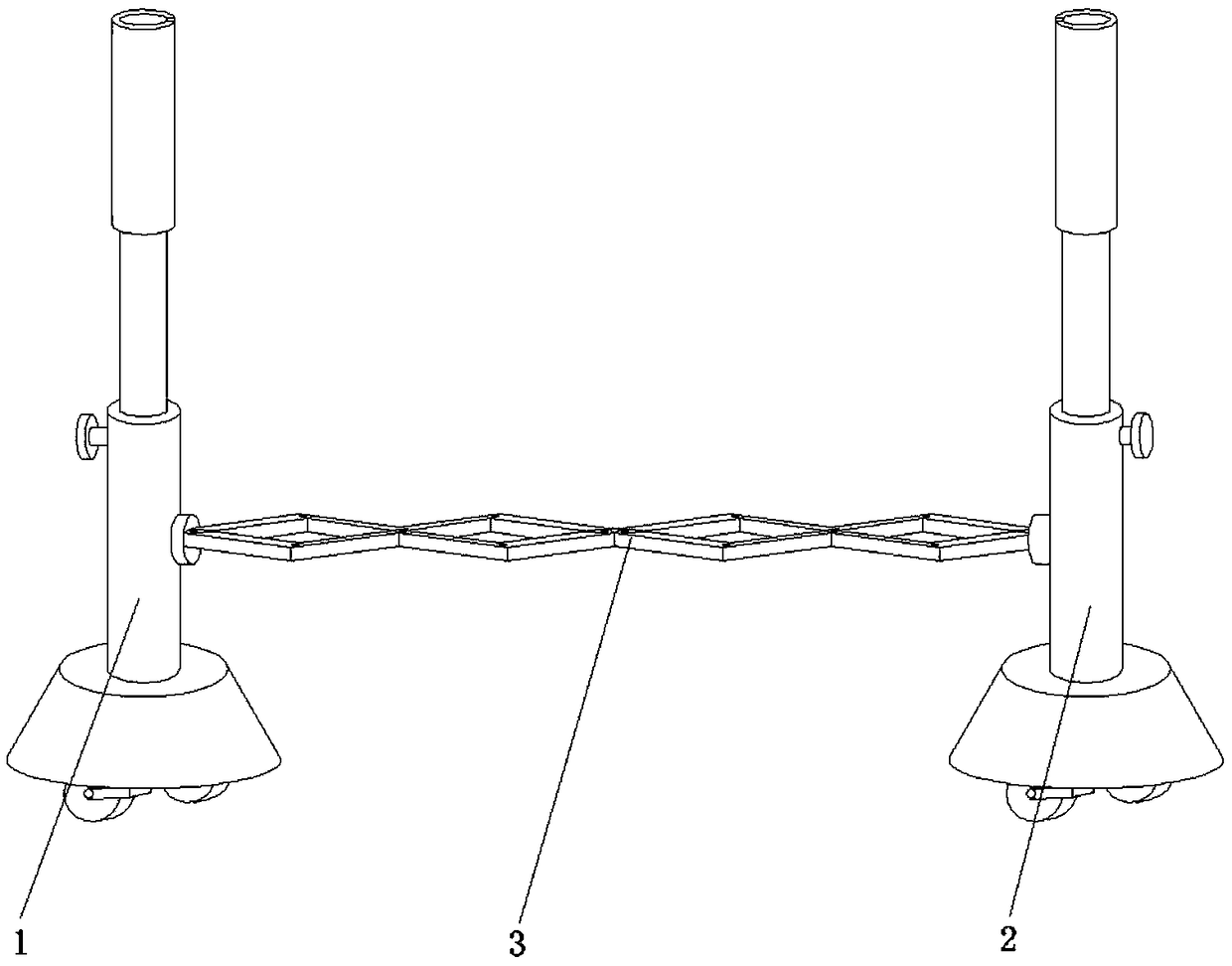

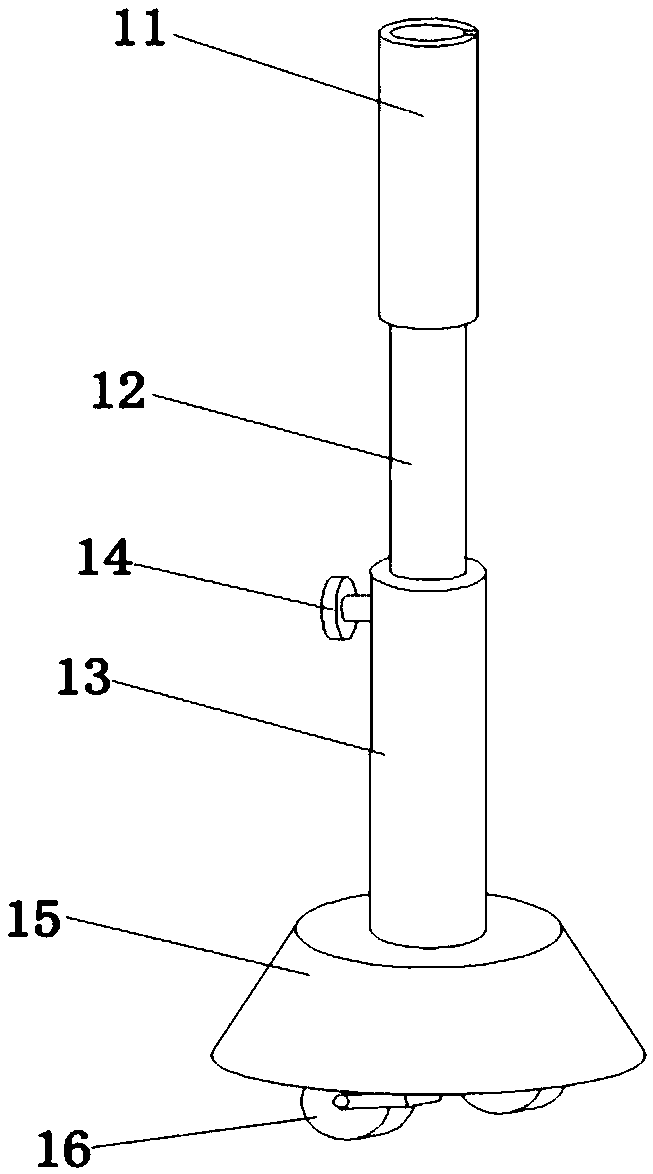

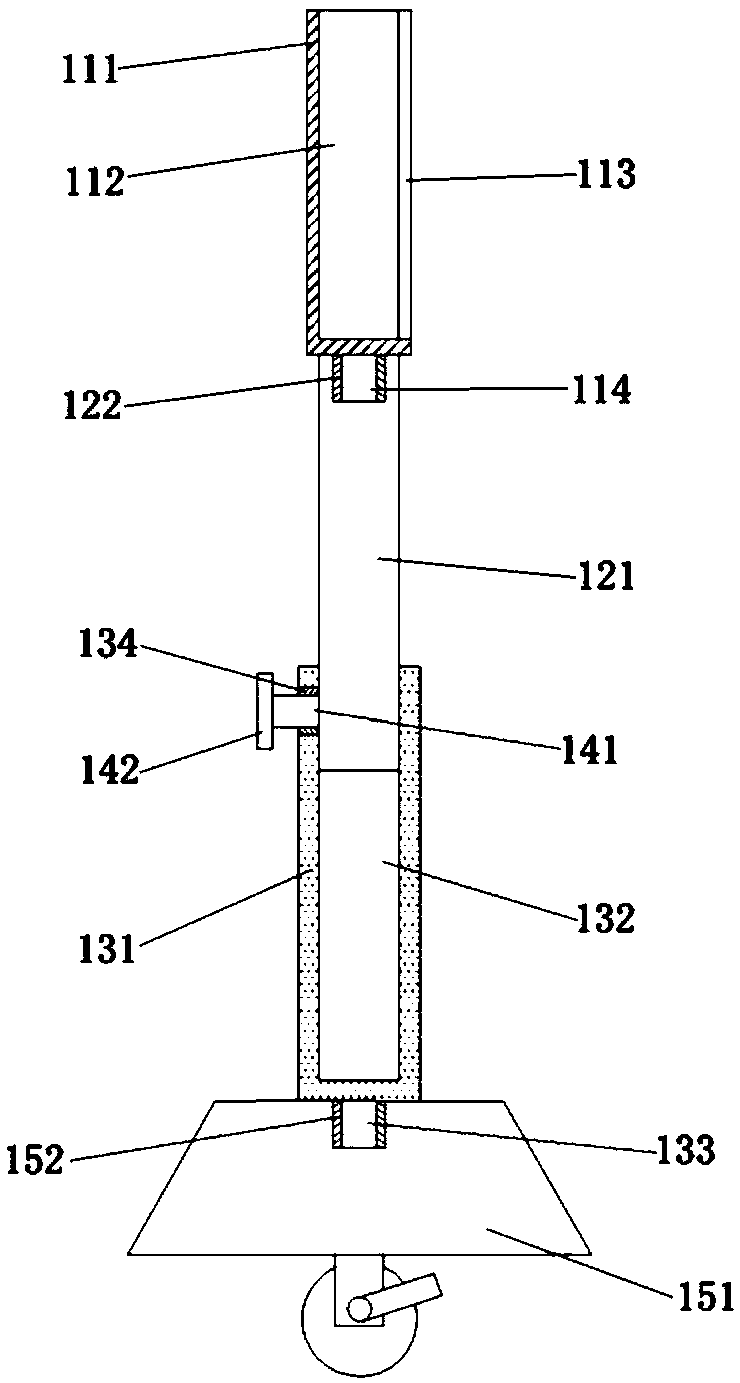

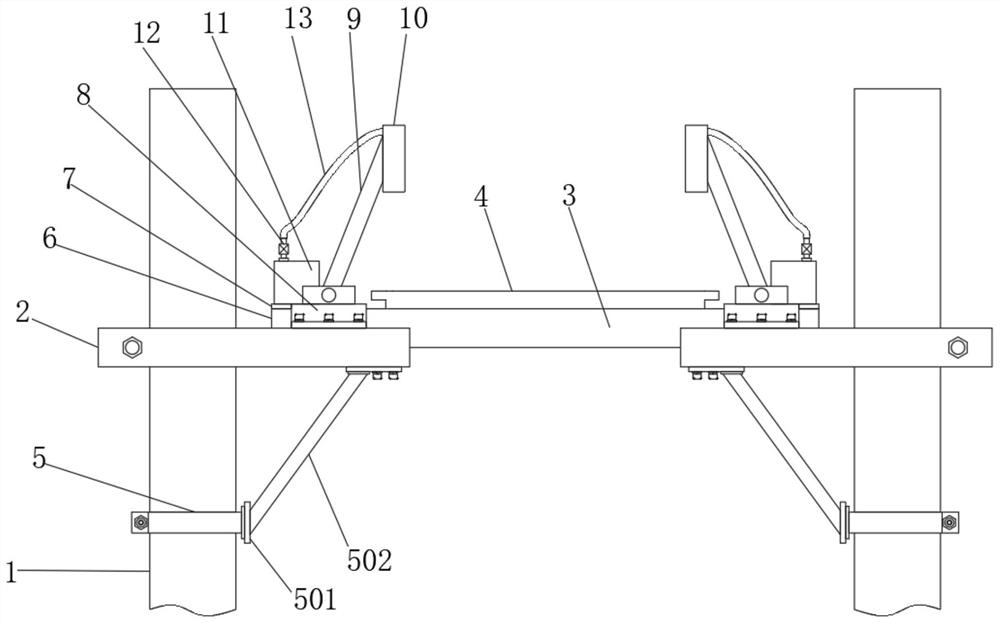

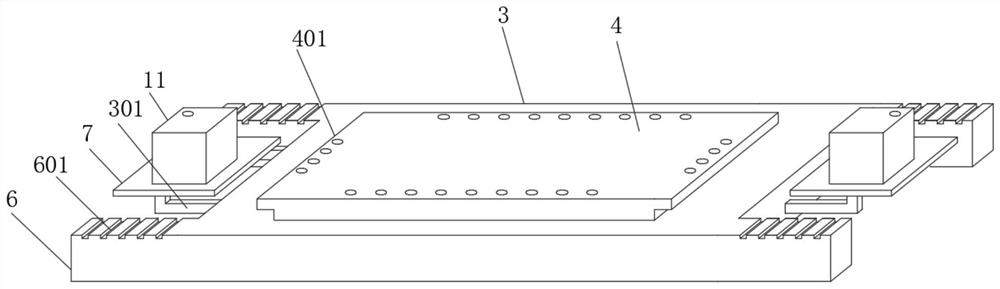

Indoor-outdoor supporting hanger for banners

The invention provides an indoor-outdoor supporting hanger for banners, comprising a body. The body includes a first supporting hanging mechanism, a connection mechanism and a second supporting hanging mechanism; the first supporting hanging mechanism is connected with the second supporting hanging mechanism through the connection mechanism; the first supporting hanging mechanism includes a firsthanging barrel, a first adjusting rod, a first sleeve, a first lock, a first bearing base and first moving wheels. Two end shafts of a banner are placed in the hanging barrels respectively; one supporting hanging mechanism enables the banner to fully spread; the requirement on the use of banners having different lengths can be met. The lengths of extensions of the adjusting rods in the sleeves areadjusted so that the banner reaches a required height and is horizontally hung. The indoor-outdoor supporting hanger for banners is convenient to use, has no need for ladders and other climbing devices, has no potential safety hazards, can be disassembled and assembled, is low transport space consumption, convenient to carry and move and reusable and helps utilize resources maximally.

Owner:湖州振锋贸易有限公司

Solar vehicle shed with snow removal function and good rain-proof performance

InactiveCN110409685AImprove the effect of rain protectionReduced chance of collapseBuilding roofsSnow trapsSnowpackEngineering

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

Manual hole digging pile blasting protection device

ActiveCN107504874AAvoid damageIncrease internal pressureClimate change adaptationBlastingArchitectural engineeringElectric machinery

The invention discloses a manual hole digging pile blasting protection device. The blasting protection device comprises a shell, a first protective layer and a second protective layer; the first protective layer and the second protective layer are located on the outer side of the shell; the second protection layer is located under the first protection layer; sliding grooves are formed in the outer walls of the two sides of the shell separately and are symmetric; two first moving blocks are fixedly arranged on the inner walls of the two sides of the first protective layer separately, and two second moving blocks are fixedly arranged on the inner walls of the two sides of the second protective layer separately; threaded holes are formed in the first moving blocks and the second moving blocks; and a first motor and a second motor are fixedly arranged at the top of the shell. According to the blasting protection device, the protection layers are combined with the shell structure so that the safety protection of constructors can be effectively improved, and the amount of blasting residues in a hole and around the hole can be decreased, meanwhile, a certain protection effect can be achieved on the protective walls, and the construction cost can be effectively lowered.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

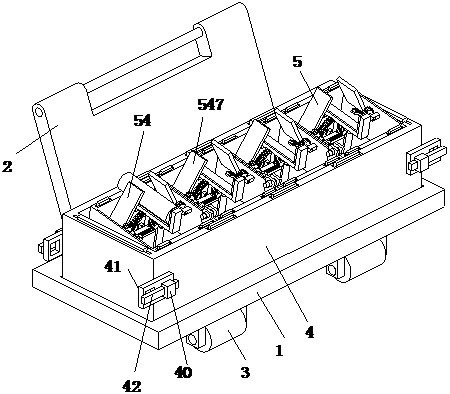

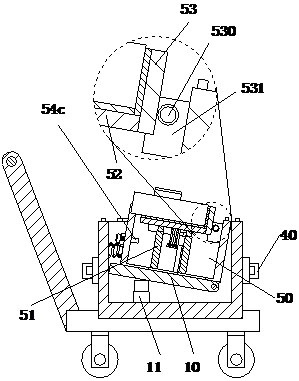

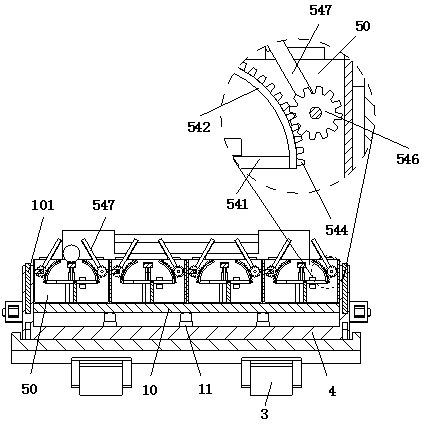

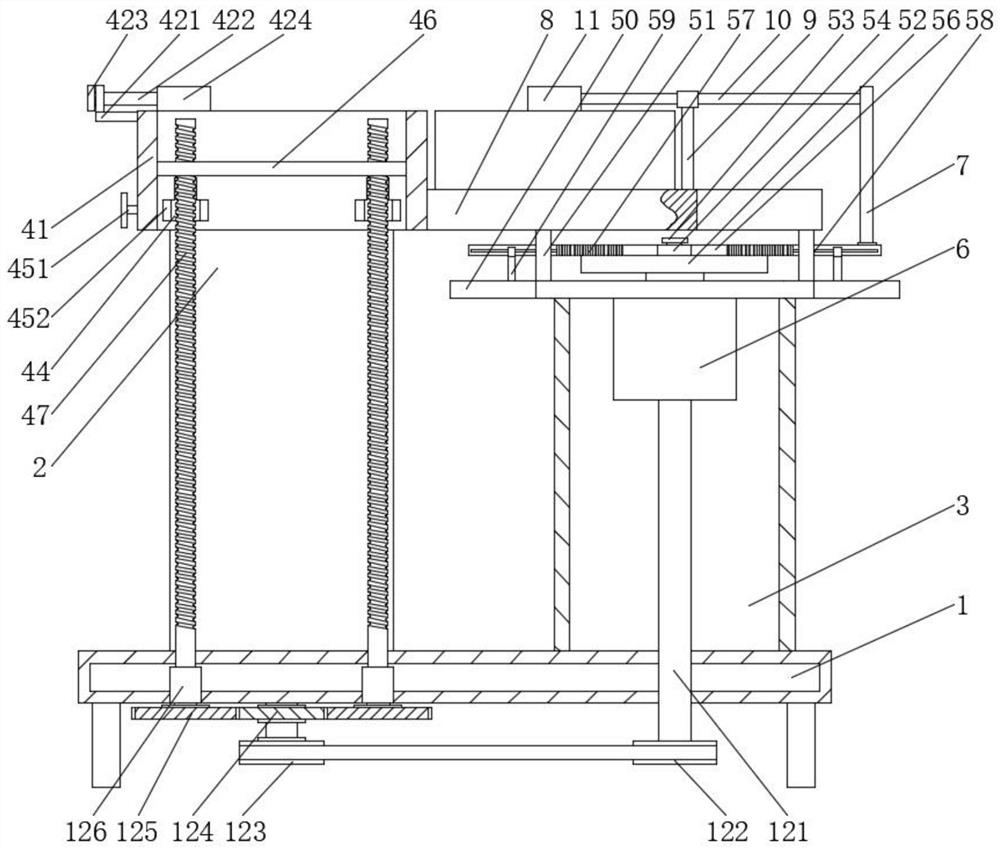

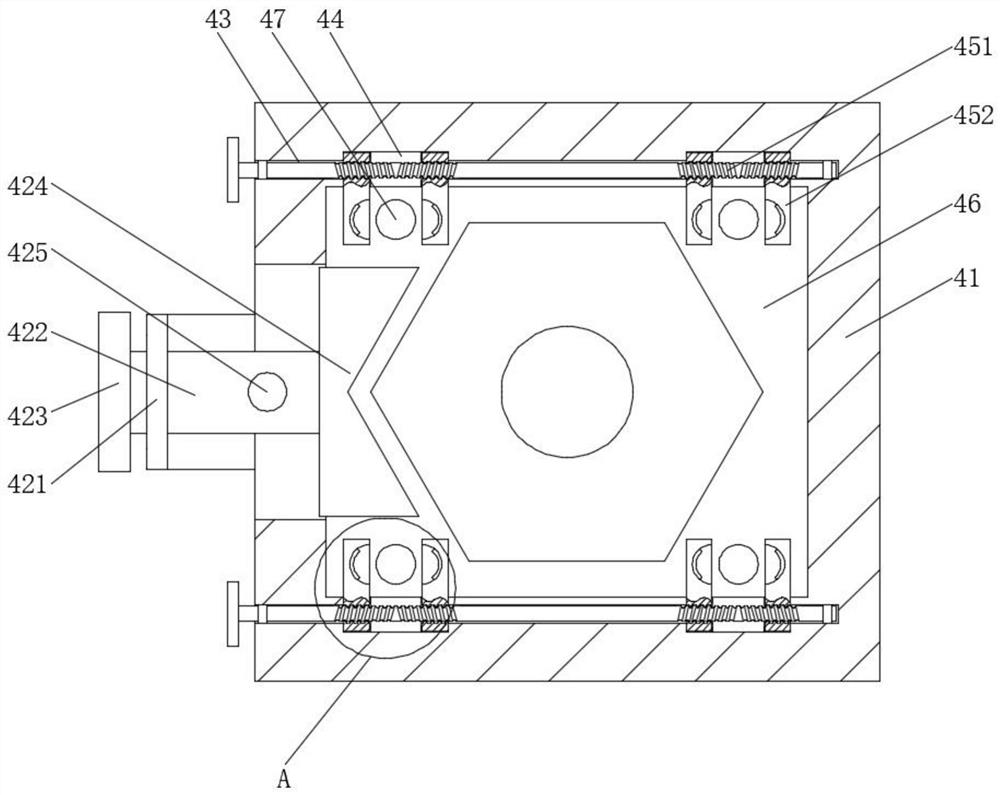

Intelligent conveying and stacking integrated equipment for cylindrical lithium batteries

ActiveCN113306848AImprove stabilityReduce the chance of sheddingRigid containersExternal fittingsStructural engineeringMechanical engineering

The invention relates to the field of lithium battery conveying instruments, in particular to intelligent conveying and stacking integrated equipment for cylindrical lithium batteries. Intelligent conveying and stacking of the cylindrical lithium batteries are carried out by adopting the design concept of multi-form stacking storage, and the whole equipment can achieve the function of multi-form storage operation of the cylindrical lithium batteries. Furthermore, the storage form of the cylindrical lithium batteries can be adjusted according to the size of a site, so that the purpose of utilizing the site to the maximum extent is achieved, and meanwhile, the whole equipment can independently fix the single cylindrical lithium battery to prevent the cylindrical lithium batteries from colliding with one another in the conveying process. Meanwhile, arranged clamping and fixing sets can carry out multi-direction freedom degree limitation on the cylindrical lithium batteries, so that the overall stability of the cylindrical lithium batteries is improved, and the probability that the cylindrical lithium batteries fall off in the conveying period is further reduced.

Owner:山东柏源技术有限公司

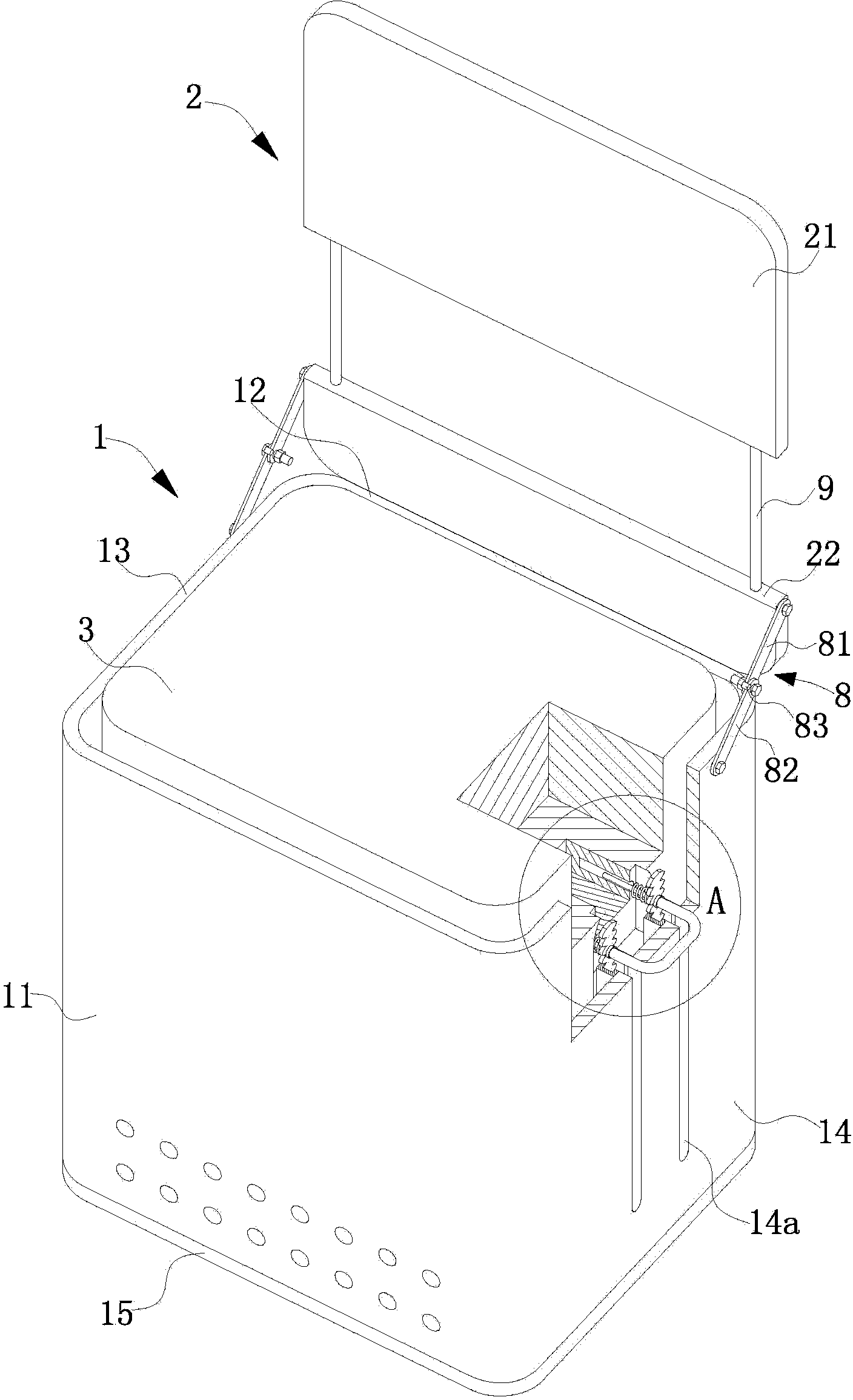

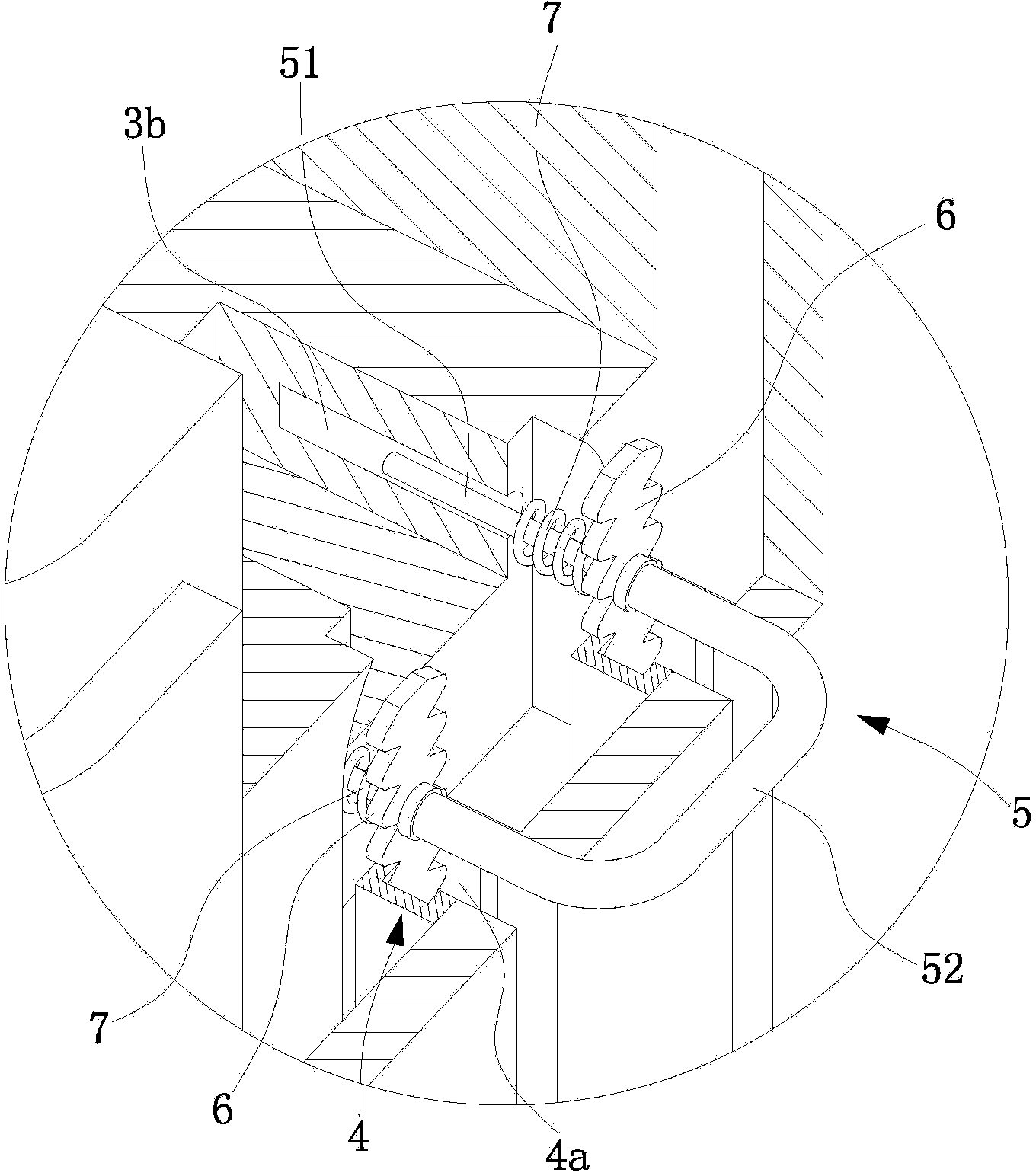

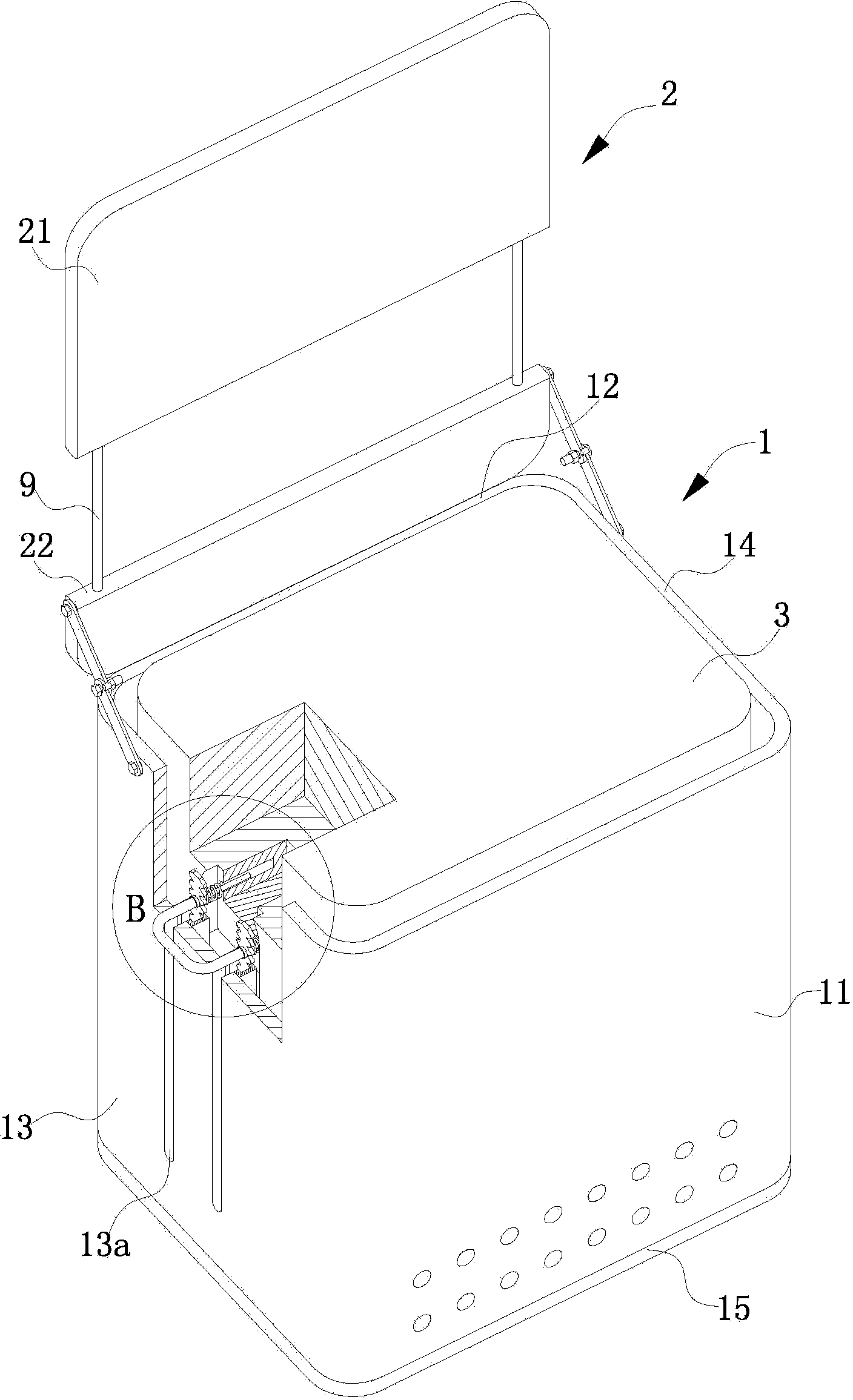

Exhibition box

ActiveCN103895935ASimple structureInnovative designNon-removalbe lids/coversInternal fittingsComputer engineering

Owner:蚌埠市创新科普产品工程研究中心有限公司

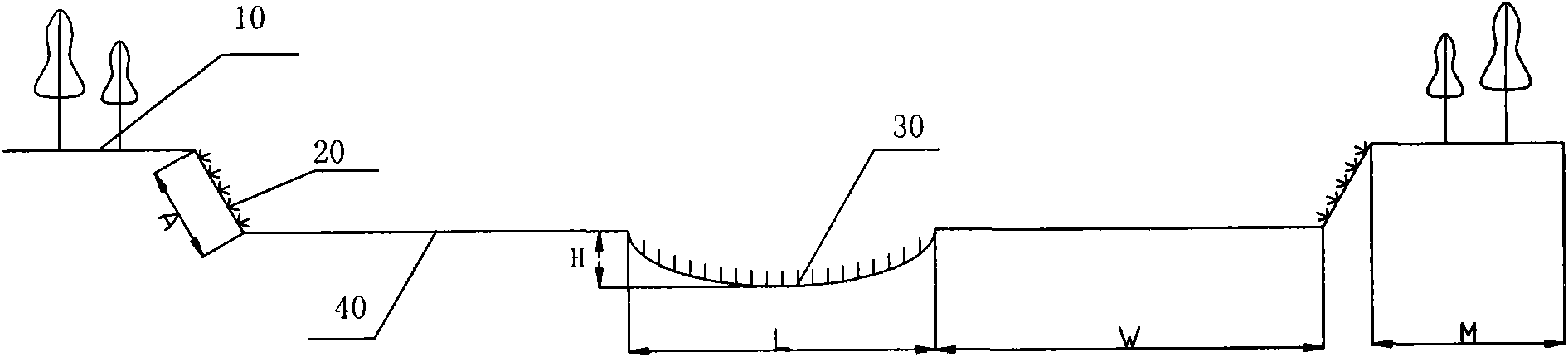

Ecological soil road

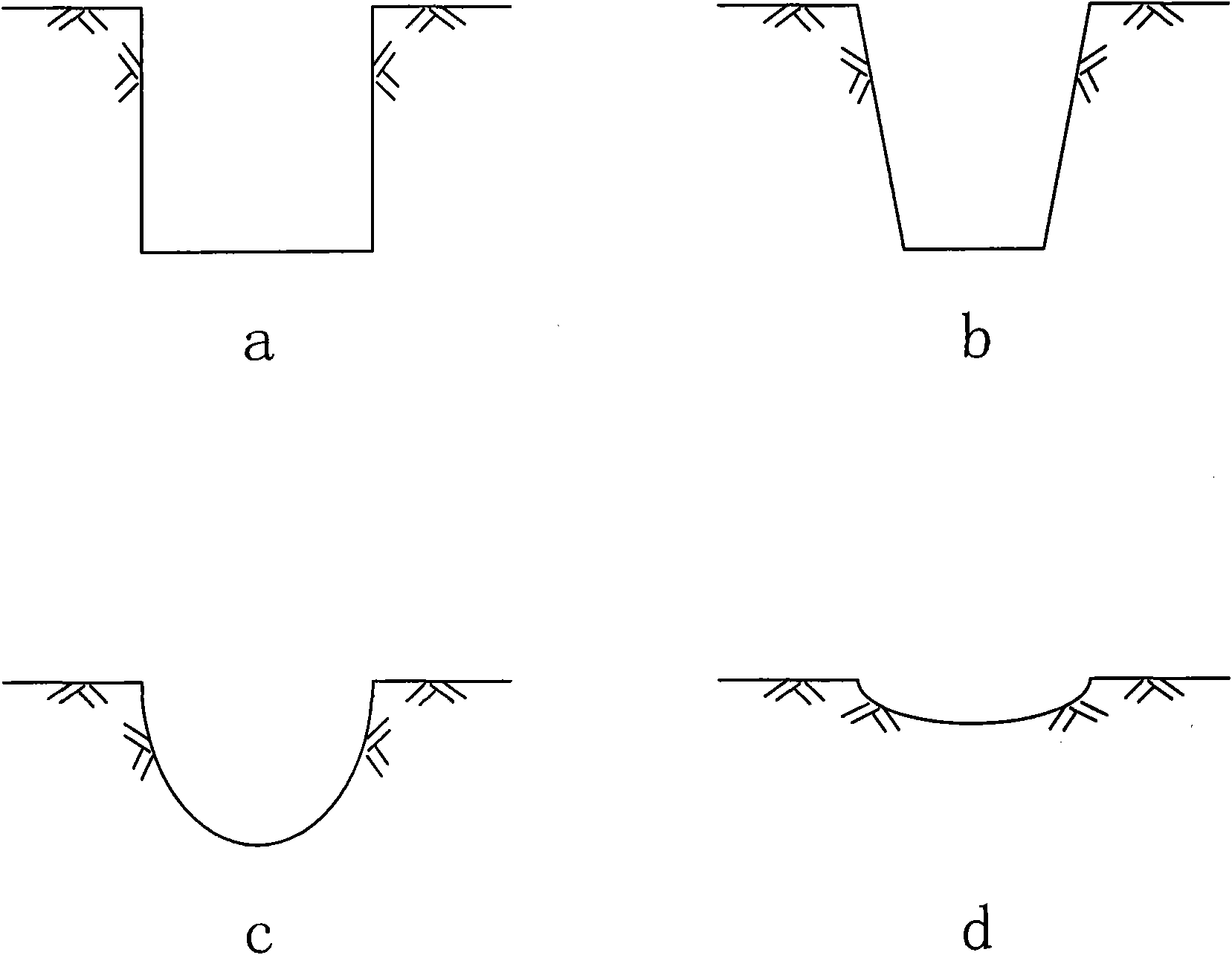

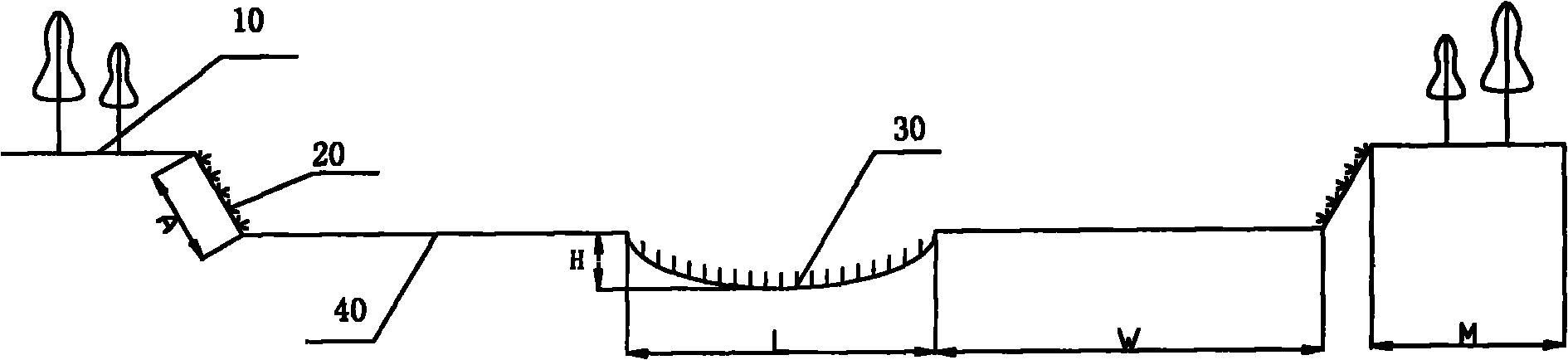

InactiveCN102080350AReduce the chance of collapseSmooth drainagePaving gutters/kerbsClimate change adaptationEngineeringSocial benefits

The invention discloses an ecological soil road which is characterised in that a road drain with a section of an arc shape having a small curvature is positioned in the middle of the road; the bottom width of the drain is 50 to 100 cm and the height thereof is 10 to 20 cm; two sides of the road are slopes on which shrubs are planted; and arbor belts with a width of 50 cm are also planted on the two sides of the road. The invention can substantially reduce drain collapse probabilities, smooth draining and minimize pavement radial flows; simultaneously planted grass in the drain can fix and conserve soil; furtherly lightweight vehicles can move in the drain for a short distance, so that a clear road is ensured. The invention possesses relatively substantial social benefits.

Owner:XIAN UNIV OF SCI & TECH

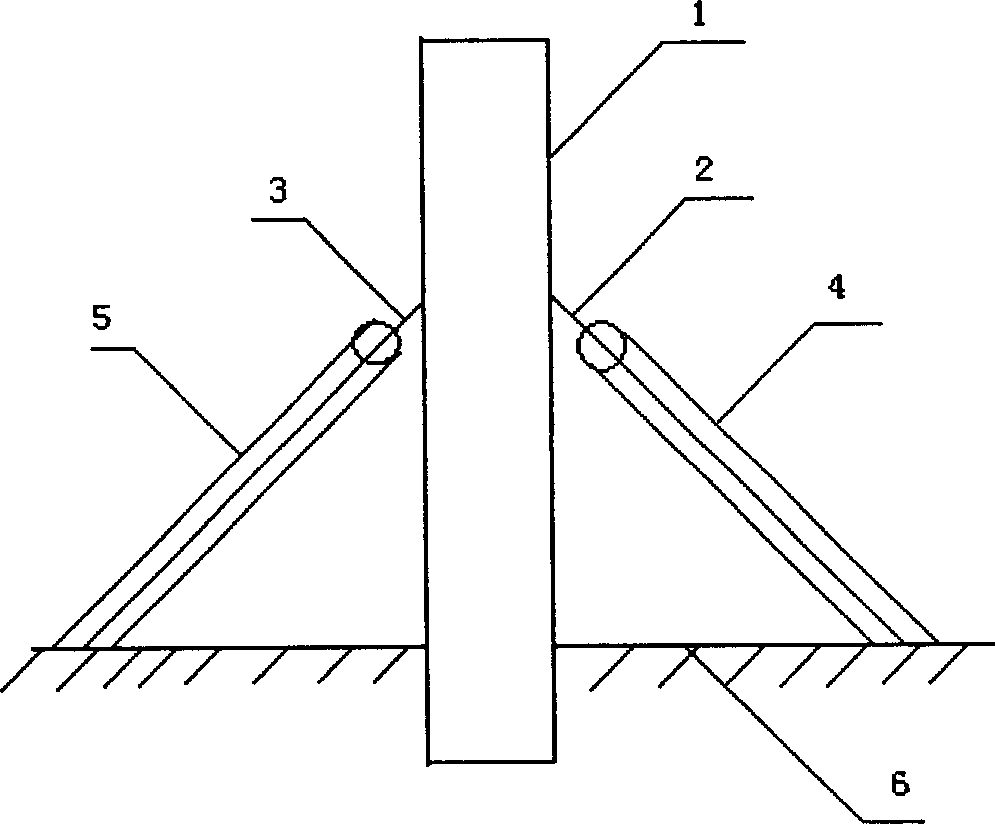

Compound wire drawing

The invention relates to a complex pull wire. The feature is adding a steel pipe on the pull wire and there is clearance between the wire and the pipe to make the wire have the function of compression resistant. The steel pipe is fixed with the groundsill firmware of the pull wire. When the connection component between pull wire, or pull wire and perch, or the connection component between pull wire and groundsill is broken, the side direction moving would be stopped by steel pipe. Thus, the possibility of the perch break down would be reduced.

Owner:GUANGXI UNIV

Novel bridge damping support

Owner:李文静

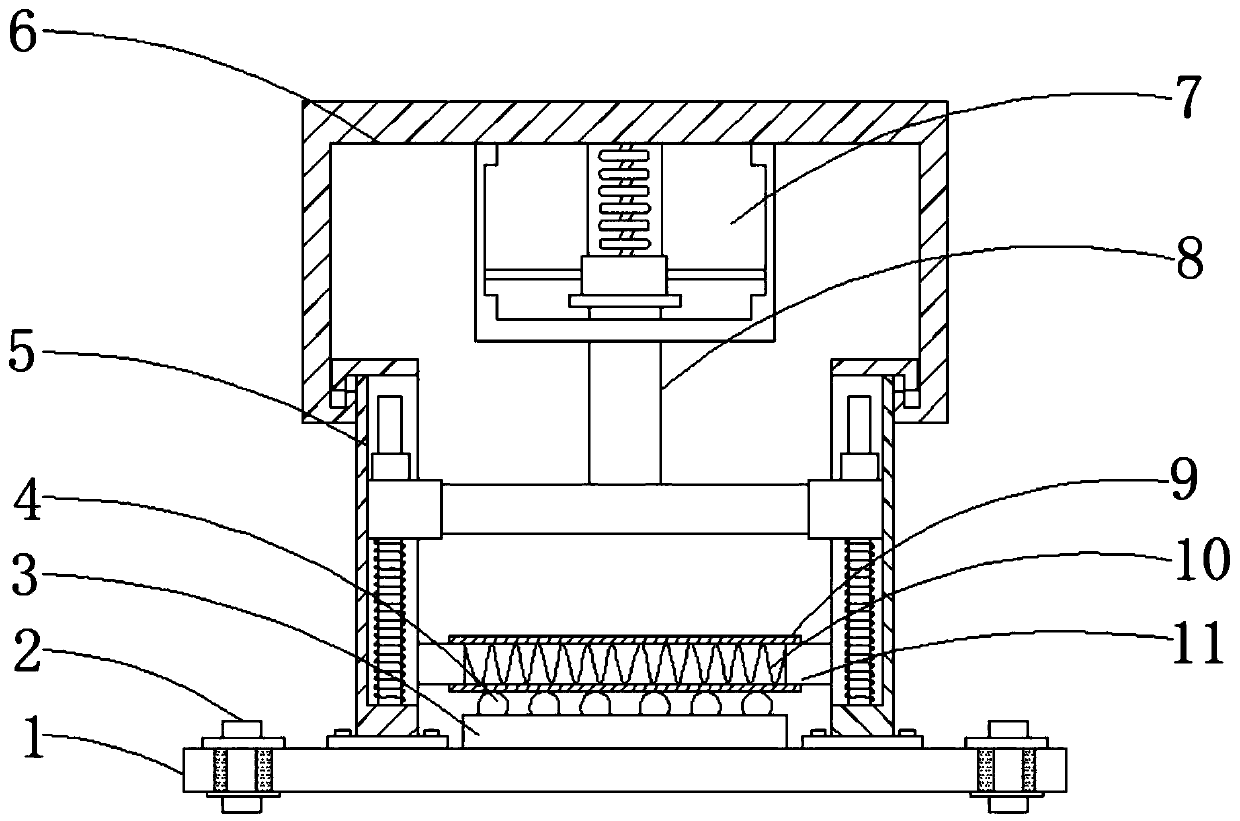

Supporting structure for installing multifunctional transformer

ActiveCN111863390AImprove stabilityStable bearing environmentTransformers/reacts mounting/support/suspensionFire rescueTransformerMechanical engineering

The invention relates to the technical field of transformer supporting structures. The utility model discloses a supporting structure and particularly relates to a multifunctional transformer mountingsupporting structure. The supporting structure comprises two telegraph pole bodies and two fixing plates, wherein the two fixing plates are symmetrically arranged on column bodies of the two telegraph pole bodies, second open grooves are formed in the positions, close to the middle, of the opposite faces of the two fixing plates, and sliding grooves are formed in the two sides, away from the second open grooves, of the opposite faces of the two fixing plates. The supporting structure is advantaged in that the fixing plates, the bearing plate, the mounting plate, the fixing block, the fixing sleeve and other structures are designed, the transformer can be effectively mounted, during installation, the length of the supporting structure can be adjusted according to the distance between the two telegraph pole bodies, the supporting structure can be installed between telegraph pole bodies with different intervals, so applicability of the supporting structure is greatly improved, that the device has good stability after installation is completed can be guaranteed, and stability of the transformer after installation is improved.

Owner:滁州市智宏工程咨询有限责任公司

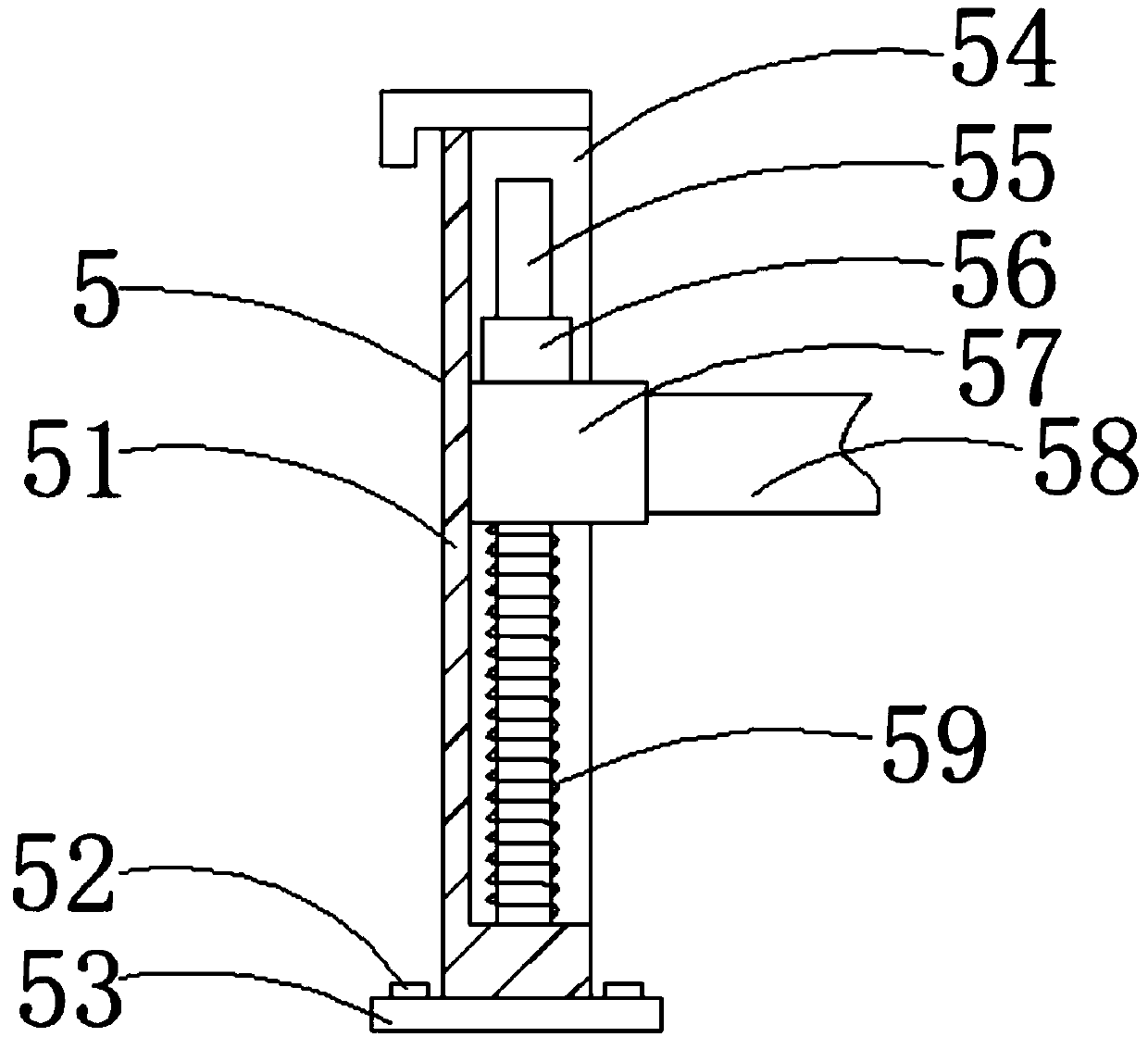

5G communication equipment with good protection effect

ActiveCN111509359AReduce bruisesAvoid damageNon-rotating vibration suppressionAntenna supports/mountingsTelecommunicationsBall screw

The invention relates to 5G communication equipment with a good protection effect, which comprises a supporting plate and an antenna, wherein the supporting plate is horizontally arranged; the shape of the antenna is cylindrical; the antenna is perpendicular to the supporting plate and is arranged above the supporting plate; a supporting mechanism is arranged at the bottom of the supporting plate;a connecting mechanism is arranged at the top of the supporting plate; the bottom end of the antenna is connected with the top of the supporting plate through a connecting mechanism; the supporting mechanism comprises a bottom box, a control assembly, two supporting rods and two mounting holes; and the control assembly comprises a lead screw, a ball screw bearing, a one-way bearing, a first bearing, two stop levers, two fixing blocks and two moving assemblies. According to the 5G communication equipment with the good protection effect, the height of the equipment can be reduced during an earthquake through the supporting structure, so that the probability of injuring surrounding personnel when the equipment collapses can be reduced, and in addition, the probability of damage caused by collision between the antenna and other objects when the equipment collapses is reduced through the connecting mechanism.

Owner:北京航天爱锐科技有限责任公司

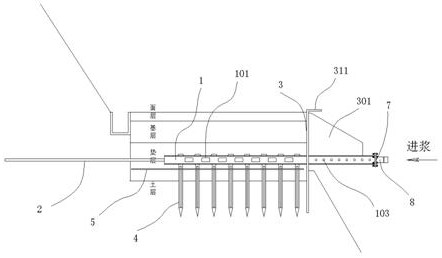

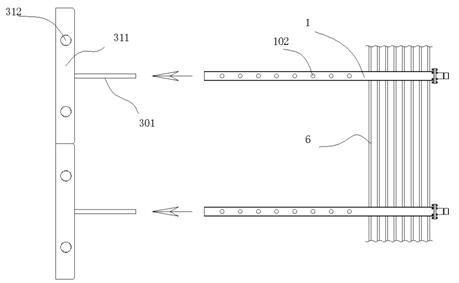

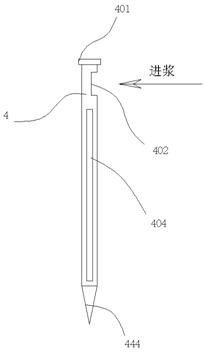

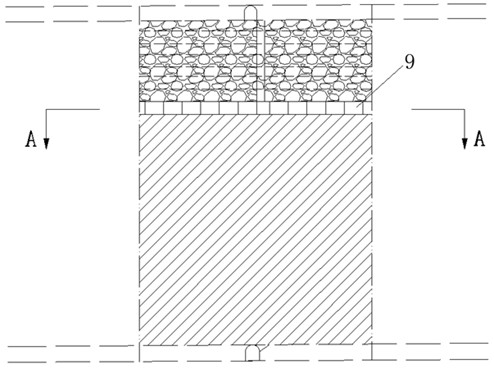

Municipal road reinforcing device and construction method

ActiveCN113174794AAvoid damageShallow depthRoadwaysBulkheads/pilesArchitectural engineeringHollow core

The invention discloses a municipal road reinforcing device and a construction method. The municipal road reinforcing device comprises a plurality of steel rods buried in a cushion layer, the steel rods are of hollow structures, the right ends of the steel rods extend out of the cushion layer, inserting rods are inserted into the left ends of the steel rods, and the inserting rods are knocked into a mountain; the front end face and the rear end face of the steel plate are each provided with a guiding-out groove used for guiding out concrete grout. a wall plate is assembled outside the steel rod, the wall plate is limited outside the cushion layer, and the lower end of the wall plate is inserted into the soil layer; and rib plates are welded in the outer sides of the wall plates. According to the device and method, the mountain road can be reinforced, and the construction cost is low.

Owner:江苏楷正建设有限公司

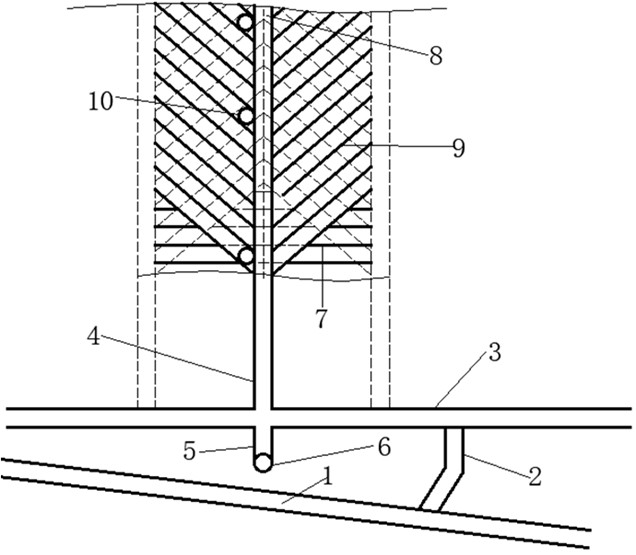

Mechanical mining method of thick and large ore body heading machine

PendingCN112360463AReduced chance of collapsePlay a supporting roleUnderground miningTunnel/mines ventillationDust controlStoping

The invention provides a mechanical mining method of a thick and large ore body heading machine, and relates to the technical field of non-coal mining. The mechanical mining method of the thick and large ore body heading machine comprises the following steps: A, an ore body is divided into a plurality of layers in stages or subsections in the vertical direction, and the height of each layer is a single stoping height; each layered ore body is divided into ore block units on a plane; B, an ore removal roadway is arranged in each ore block unit, and a stoping access is arranged along the ore removal roadway; C, the stoping accesses in the adjacent layered ore block units are crossed in an X shape; D, mechanical ore breaking stoping is conducted in the stoping accesses through a heading machine; E, during stoping of the heading machine, ventilation and dust removal are achieved in a press-in type and draw-out type combined ventilation mode; and F, filling is conducted timely after the stoping of each stoping access is finished. In a vertical space, the stoping accesses in the ore block units can form a three-dimensional net-shaped structure, a space structure beneficial to the stability of a filling body is formed, and the probability of ore body collapse in the mining process is reduced.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

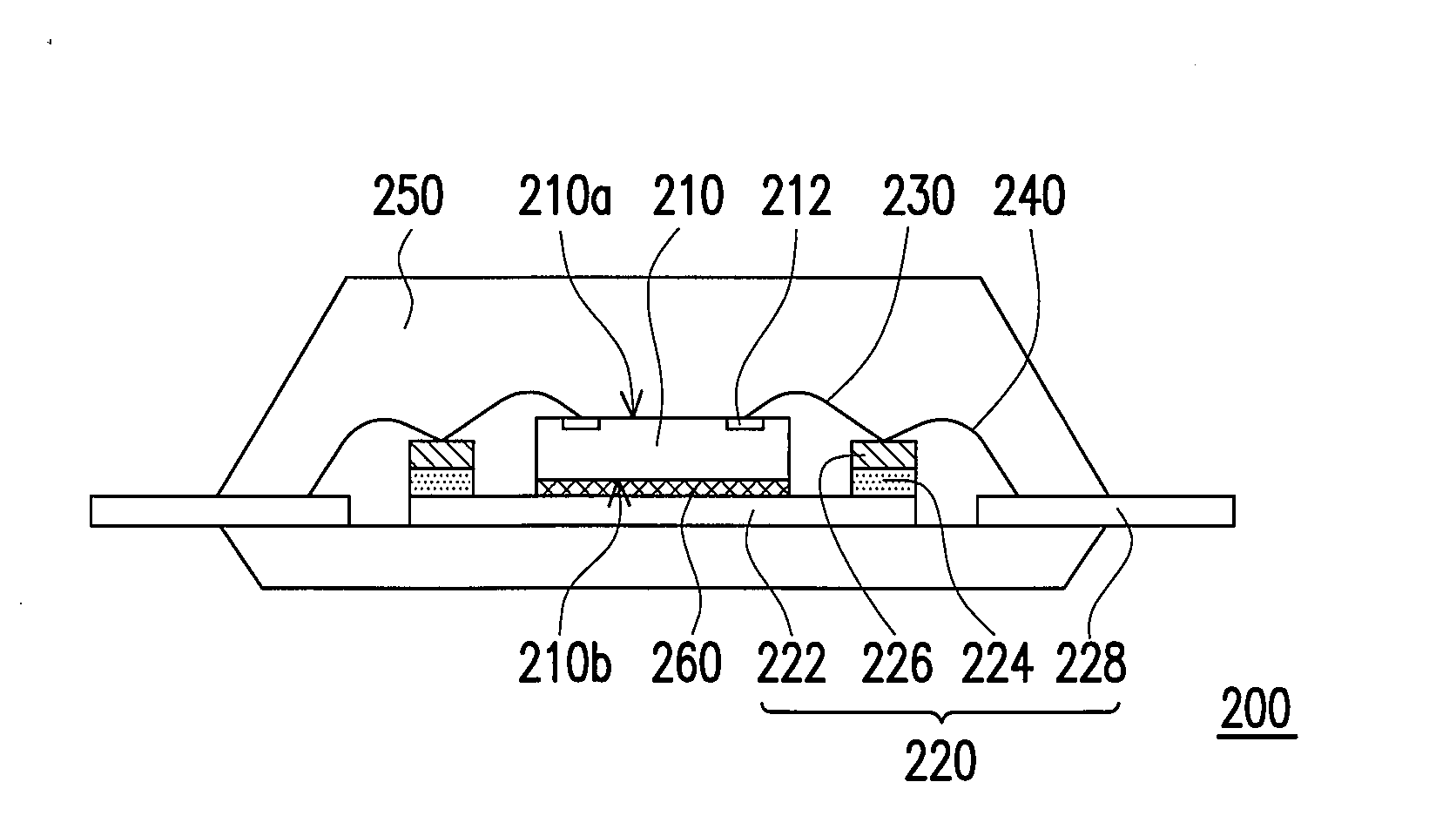

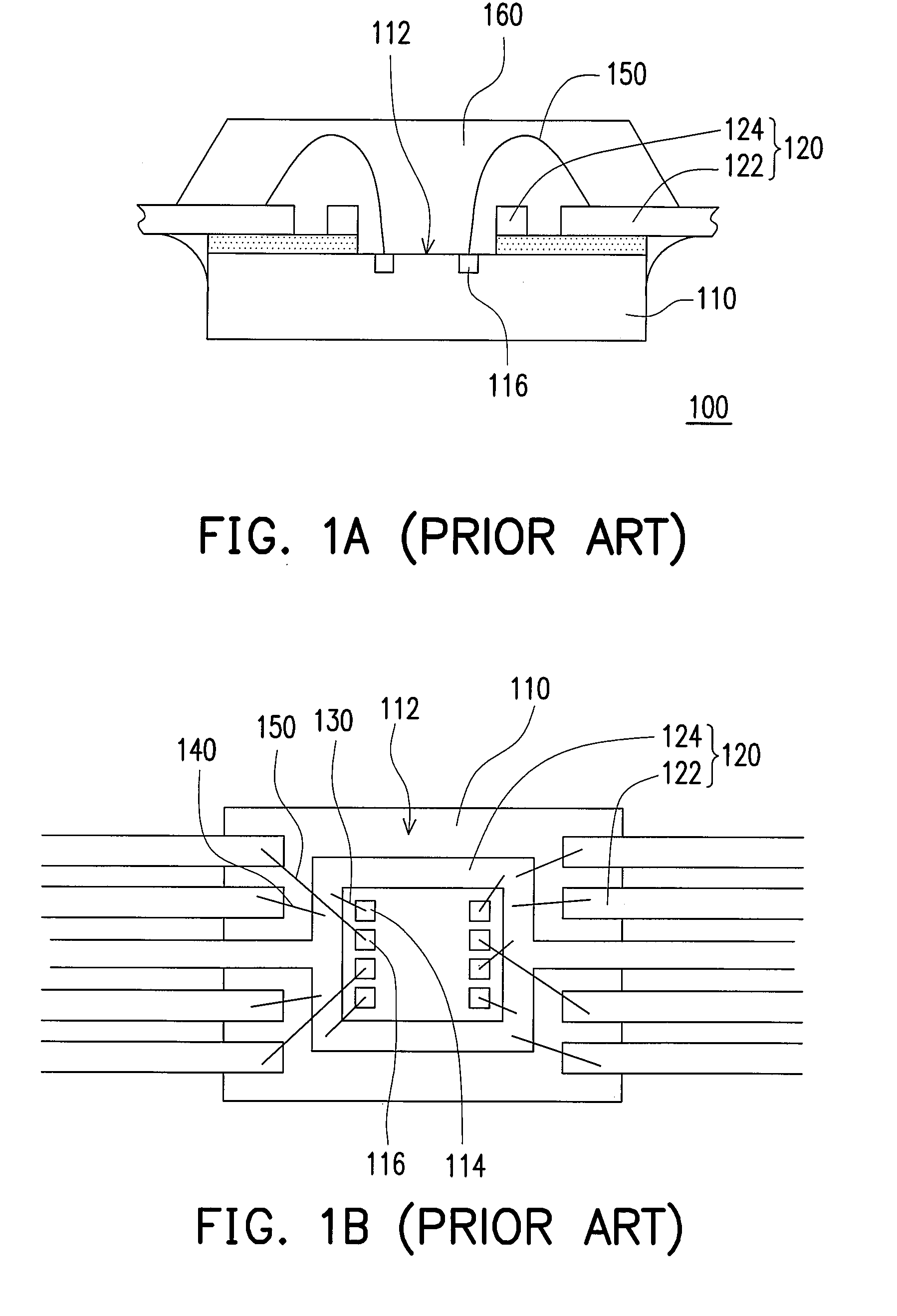

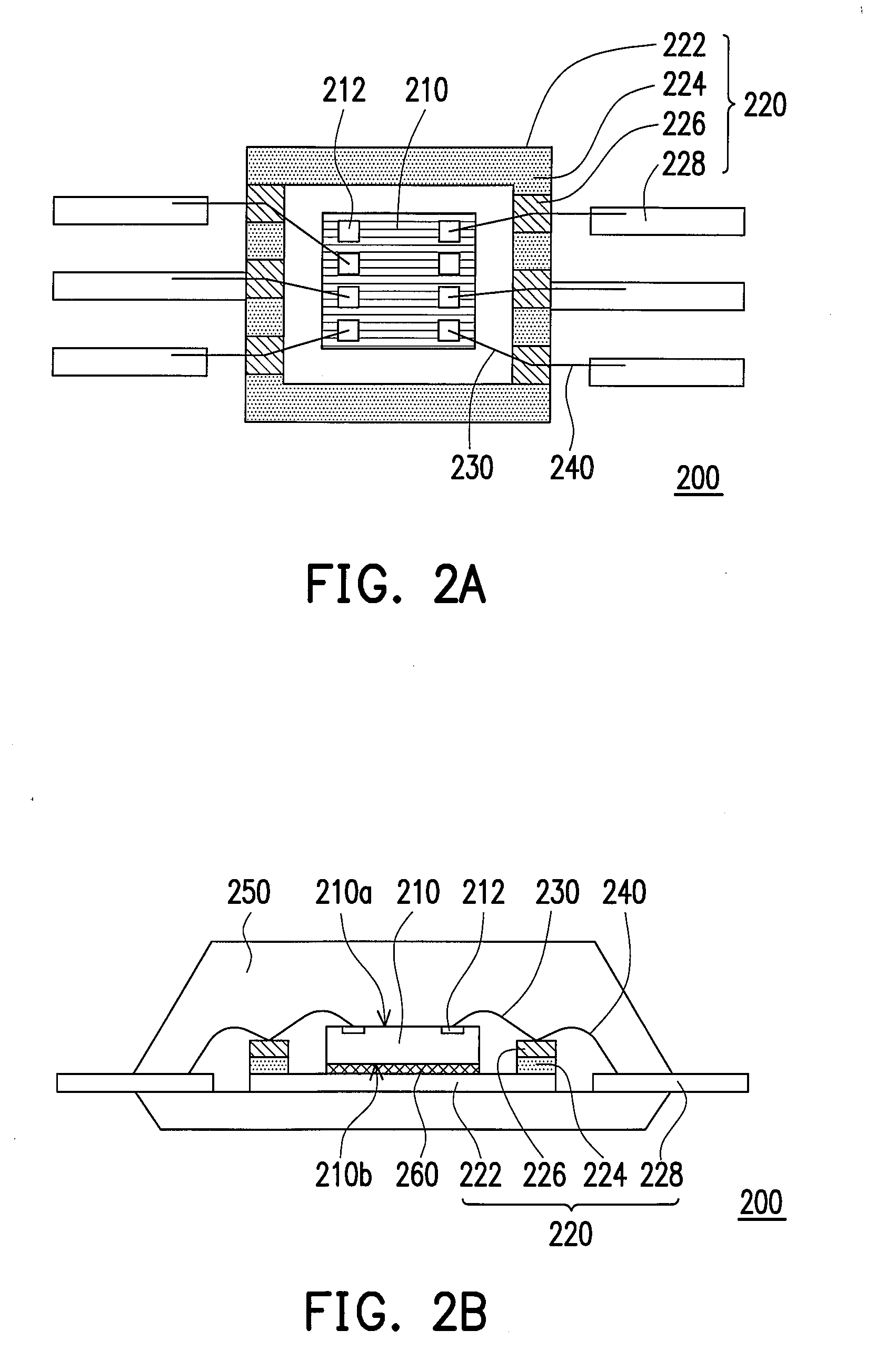

Chip package structure

InactiveUS20080157304A1Reduce volumeLower the volumeSemiconductor/solid-state device detailsSolid-state devicesLead frameYield rate

A chip package structure including a chip, a lead frame, first bonding wires and second bonding wires is provided. The chip has an active surface, a back surface and bonding pads disposed on the active surface. The lead frame includes a die pad, an insulating layer, transfer bonding pads and inner leads. The back surface of the chip is fixed on the die pad. The insulating layer is disposed on the die pad outside the chip. The transfer bonding pads are disposed on the insulating layer. The first bonding wires are respectively connected to the bonding pads and the transfer bonding pads. The second bonding wires are respectively connected to the transfer bonding pads and the inner leads. The chip package structure has smaller volume and a higher yield rate.

Owner:CHIPMOS TECH INC

Novel building structure reinforced beam structure

InactiveCN112878582AAchieving a triple fixation effectReduced chance of collapseGirdersJoistsStructural engineeringMechanical engineering

Owner:无锡市索利得工程技术有限公司

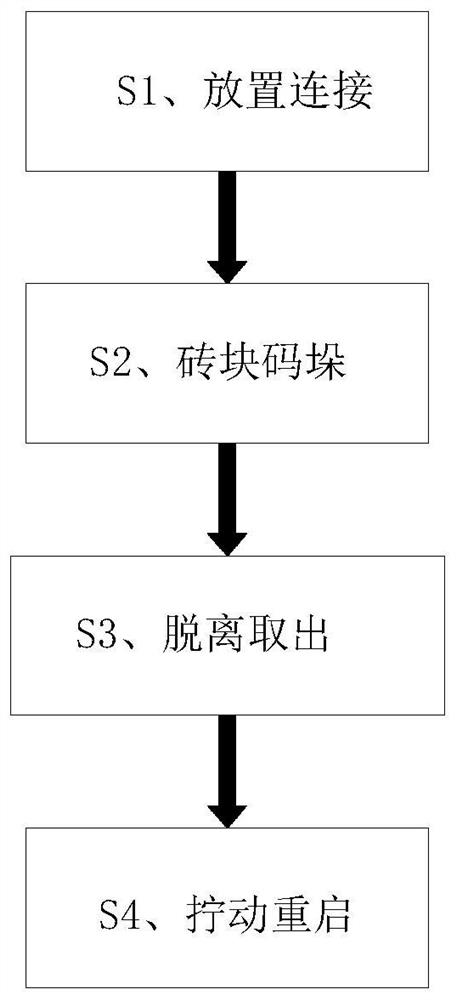

Stacking method for grass planting brick

InactiveCN111846973AReduced chance of collapseEnsure safetyStacking articlesBrickAgricultural engineering

The invention relates to a stacking method for a grass planting brick, and the stacking method is mainly completed by a stacking machine for the grass planting brick. The stacking machine for the grass planting brick comprises a bottom shell, wherein a support plate is fixedly installed on the left side of the upper surface back of the bottom shell, and a support frame is fixedly installed on theright side of the upper surface back of the bottom shell. According to the invention, an alignment device is movably installed on an upper surface of a stacking frame, so a handle is pushed to a rightmost end after a bearing plate is placed on a drive screw rod, and then a limiting pin is placed in a limiting hole to fix the position of a limiting correction block; and then according to a shape, apushing block which is the same as the limiting correction block pushes the brick on a conveyor belt into the stacking frame under a drive effect of a pushing device, so that the brick is translatedto the upper surface of the bearing plate. Due to the limitation of the shape of the limiting correction block and the pushing block and the clamping effect produced by the limiting correction block and the pushing block, a placement angle and a position of each pushed brick are ensured to be exactly the same; and thus the center of gravity is not shift, which not only ensures the safety of workers, but also ensures to not increase the production cost.

Owner:陈 月

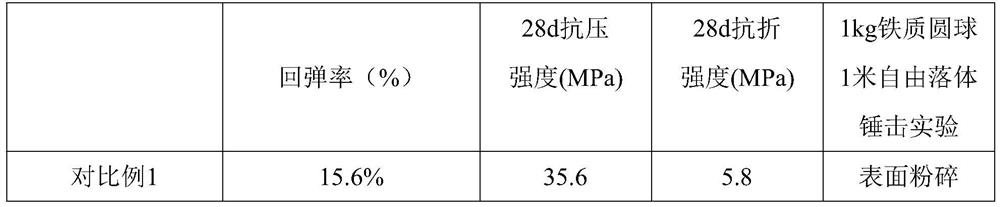

Sprayed concrete for foundation pit slope, and construction method thereof

The invention relates to a construction method of a sprayed concrete for a foundation pit slope. The sprayed concrete mainly comprises a grouting layer, a covering layer and a concrete layer, and the grouting layer comprises 20-50 parts of a water glass solution, 30-50 parts of garbage bottom slag powder, 1-10 parts of MgO, 10-20 parts of magnesium chloride and 50-100 parts of water; the garbage bottom slag powder needs to be immersed in a 0.05-0.2 mol / L hydrochloric acid solution for 1-3 h before being used, the mass ratio of the garbage bottom slag powder to the solution is 1: 10-1: 20, then a water glass solution is dropwise added into the bottom slag powder solution while stirring is conducted, the stirring speed is 10-30 r / min, the mass ratio of the water glass solution to the garbage bottom slag powder is 1: 30-1: 80, and then suction filtration, washing and drying are conducted; the covering layer comprises cotton and linen fibers and a water glass solution; and the concrete layer is prepared from 300-500 parts of cement clinker, 100-200 parts of lithium slag powder, 300-500 parts of ceramsite, 5-20 parts of ferric chloride, 10 -20 parts of microcrystalline cellulose and 120-150 parts of water. The problems that common sprayed concrete is prone to collapse and high in rebound rate are solved.

Owner:江苏镇淮建设集团有限公司

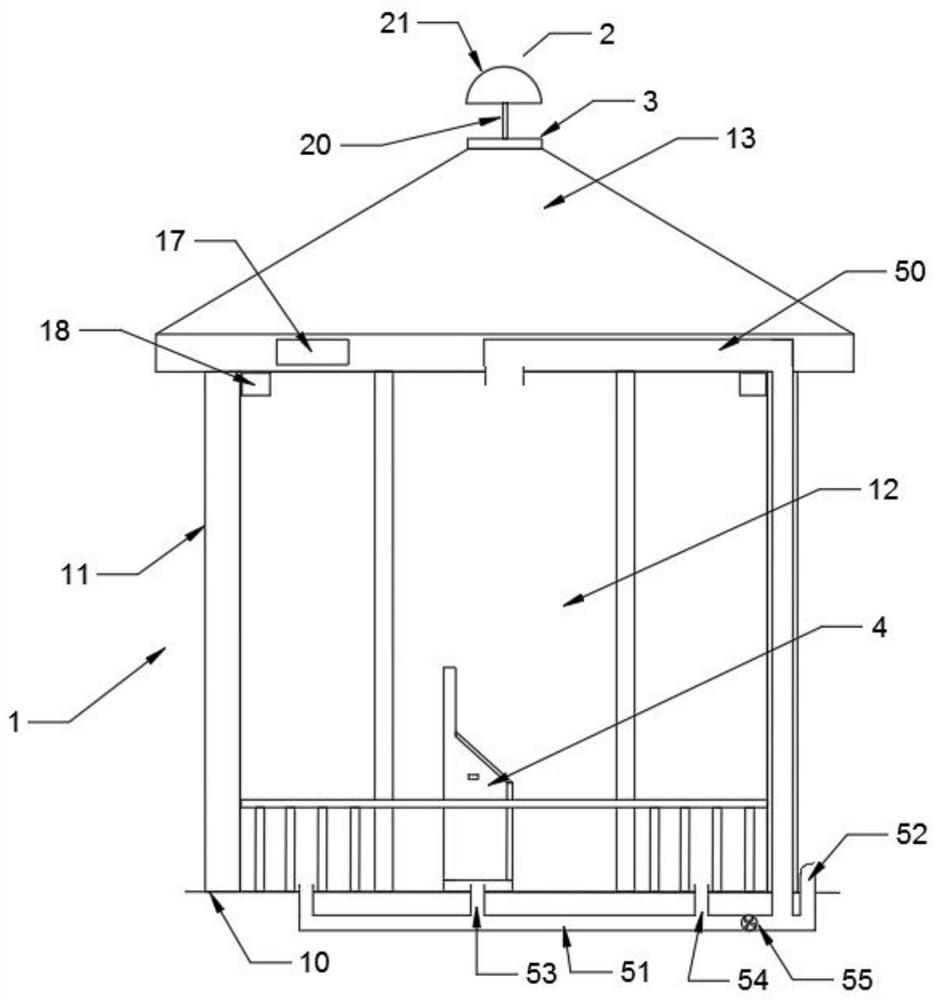

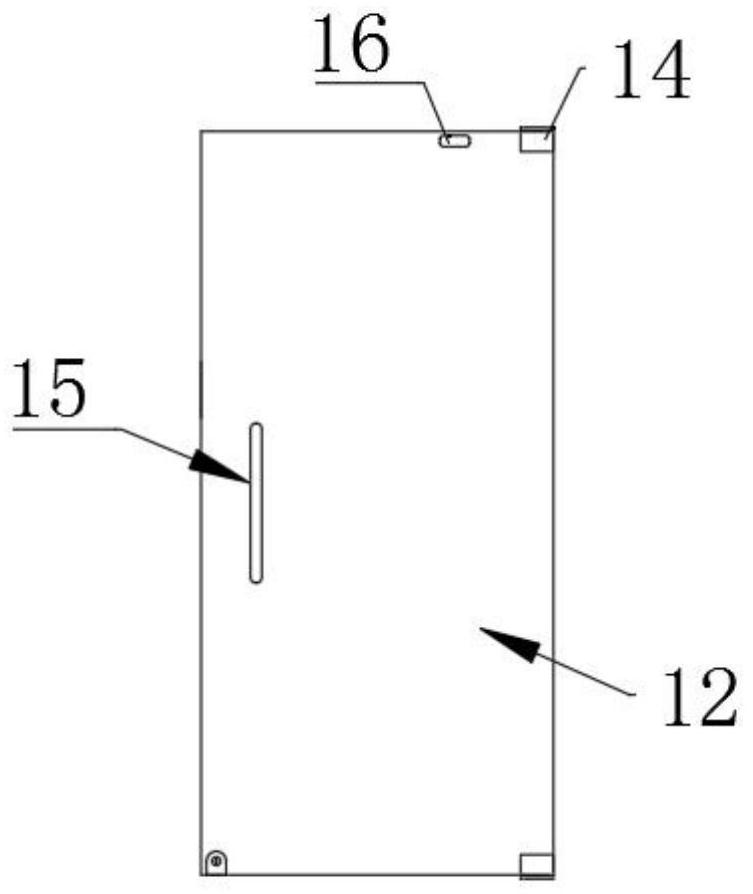

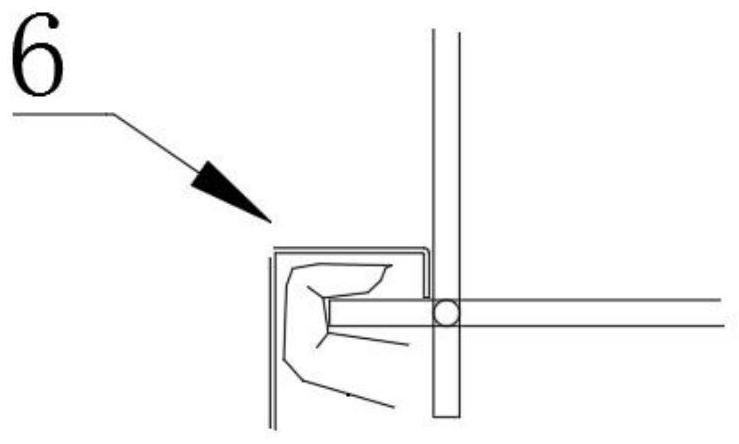

Diverse reading kiosk integral structure

PendingCN112610033AStable structureEasy to installCo-operative working arrangementsCharacter and pattern recognitionMechanical engineeringEngineering

The invention discloses a diverse reading kiosk integral structure. The diverse reading kiosk integral structure comprises a kiosk body, the kiosk body comprises a base, an outer frame, a glass door and a ceiling, wherein the kiosk body is detachably designed, the glass door is arranged on the outer frame, an anti-pinch mechanism is arranged on one side of the glass door, and the top of the ceiling is rectangular; a pushing mechanism is arranged on the top of the ceiling, a power mechanism is arranged on the pushing mechanism, and the power mechanism is connected with one side of the pushing mechanism in a transmission mode. The diverse reading kiosk integral structure is scientific and reasonable in structure and safe and convenient to use, a manufacturing mode of integrated forming in a market is changed, a detachable assembling mode is adopted, the structure is stable, installation is convenient, so that the production cost and the transportation cost can be effectively saved, and the damage probability of glass is reduced, and buckle structure is easy and convenient to install.

Owner:上海懿教信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com