Method for preparing polyvinyl alcohol and polyurethane super absorbent sponge

A technology of polyvinyl alcohol and polyurethane, which is applied in the preparation of polyvinyl alcohol-polyurethane water-absorbing sponge, and in the field of polyvinyl alcohol-polyurethane superabsorbent sponge, which can solve the problem that the water absorption rate cannot meet the requirements of urban life, and the hydrophilicity and water retention are still to be expected. Improvement, sponge cells are not uniform and fine, etc., to reduce the impact of pollution and product toxicity, reduce the probability of large cells or hollow collapse, and the effect of moderate hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

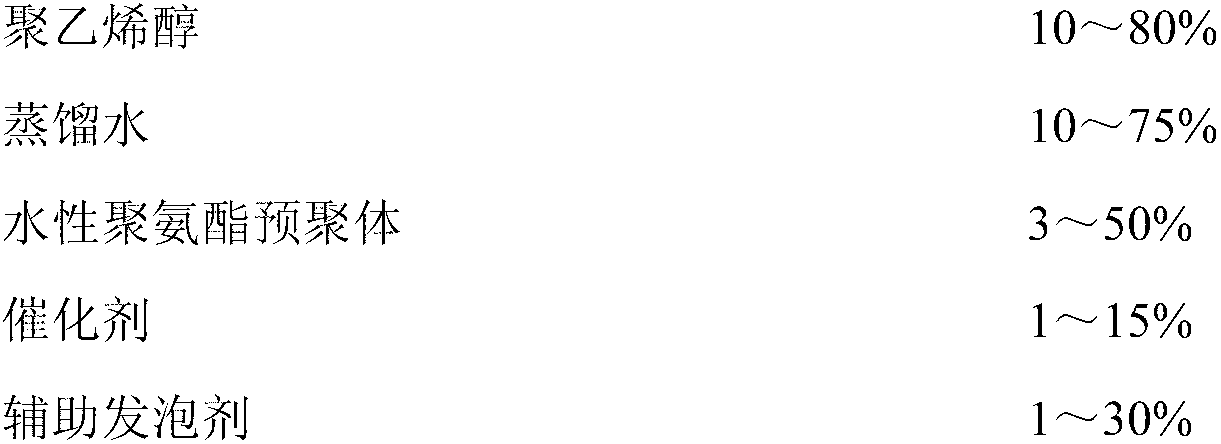

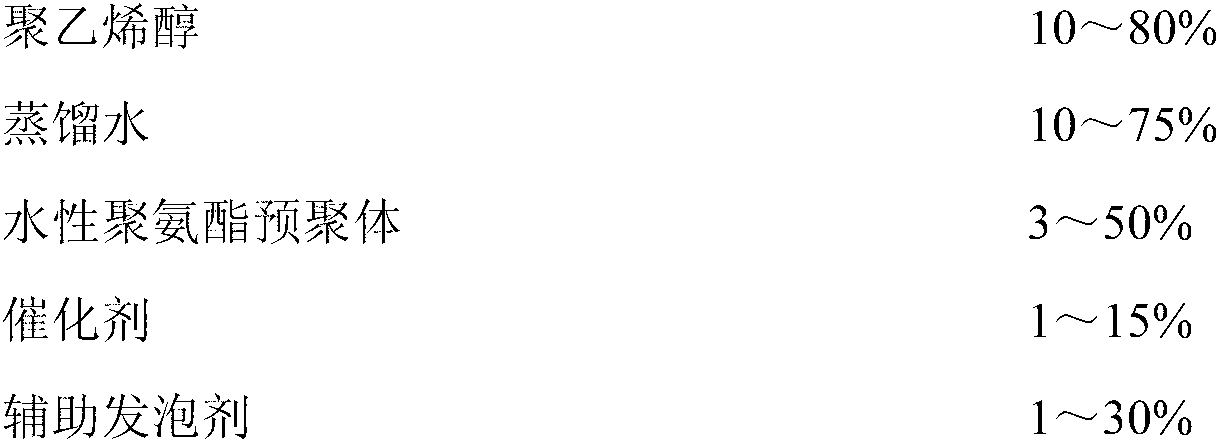

Method used

Image

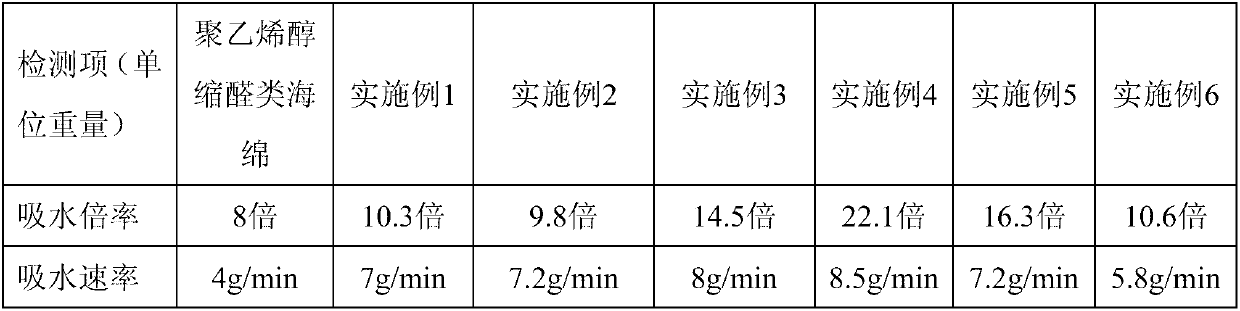

Examples

Embodiment 1

[0029] A preparation method of polyvinyl alcohol-polyurethane superabsorbent sponge, comprising the steps of:

[0030] (1) Add 5g of polyvinyl alcohol of type 1799 and 30g of distilled water into the reactor, and dissolve it for 20min under the condition of a rotating speed of 400r / min in a water bath at 90-95°C to obtain an aqueous solution of polyvinyl alcohol .

[0031] (2) Take the above polyvinyl alcohol aqueous solution, add dropwise 5g of water-based polyurethane prepolymer, the model is Bayhydur305, then add dropwise 0.8g of catalyst stannous octoate, mix evenly in a water bath at 30°C, and stir in a mixer at a speed of 400r / min Under stirring, react for 5 minutes.

[0032] (3) Curing the colloidal solution obtained in step (2) at 60°C for 2 hours, the resulting product is white sponge-like, with uniform cells and micron-level pores; light and elastic, good flexibility; moderate hardness, water absorption Afterwards, it can become soft, and has excellent water absorp...

Embodiment 2

[0035] A preparation method of polyvinyl alcohol-polyurethane superabsorbent sponge, comprising the steps of:

[0036] (1) Add 2g of polyvinyl alcohol of type 1788, 3g of type 1799, and 37.5g of distilled water into the reactor, and dissolve it for 30min under the condition of a speed of 600r / min with a stirrer in a water bath of 50-60°C, An aqueous solution of polyvinyl alcohol is obtained.

[0037] (2) Take the above-mentioned polyvinyl alcohol aqueous solution, add dropwise 5g model is Bayhydur2655, 5g model is the aqueous polyurethane prepolymer of Bayhydur401-7, then add dropwise catalyst stannous octoate 0.4g, triethylenediamine 0.4g, carboxylate Potassium dibutyltin 0.4g, dibutyltin dilaurate 0.4g, add 4g starch, 0.8g pentane, 0.05g glutaraldehyde, 0.8g sodium lauryl sulfate at the same time, mix evenly in 80 ℃ water bath, in the mixer at the speed of Under 600r / min stirring, react for 10min.

[0038] (3) Put the colloidal solution obtained in step (2) into an oven, a...

Embodiment 3

[0041] A preparation method of polyvinyl alcohol-polyurethane superabsorbent sponge, comprising the steps of:

[0042] (1) Add 1g of polyvinyl alcohol of model 1799, 2g of model 1788, 2g of model 124, and 5g of distilled water into the reactor, and dissolve it in a water bath at 90°C with a stirrer at a speed of 500r / min 25min to obtain polyvinyl alcohol aqueous solution.

[0043](2) Get above-mentioned polyvinyl alcohol aqueous solution, add dropwise the aqueous polyurethane prepolymer of 5gBayhydurT0607, 5gBayhydurN3390, 5gBayhydur2547, 5gBayhydur 3100, 5gBayerBayhydrol BL 5140, then add dropwise 0.4g catalyst stannous octoate and 0.4g triethylenediamine, At the same time, add 1g starch, 0.5g calcium carbonate (old powder), 0.5g magnesium silicate (talc powder), 0.5g barite powder, 0.5g pentane, 0.5g hexane, 0.05g glutaraldehyde, 0.05g butanediol Aldehyde, 0.05g phosphoric acid, 0.05g benzenesulfonic acid, 0.1g sodium lauryl sulfate, 0.1g silicone oil, 0.1g stearic acid, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com