On-load luffing boom lifting apparatus

A technology for lifting devices and booms, which is applied to cranes and other directions, can solve the problems that the length of booms cannot be adjusted according to needs, and the length of booms of tower cranes cannot be adjusted according to needs, so as to protect the service life and reduce The possibility of collapse and the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

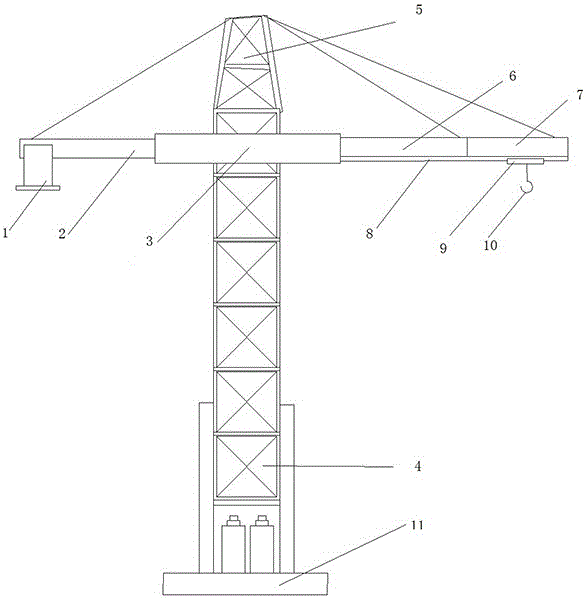

[0021] Such as figure 1 As shown, the present invention is a boom lifting device capable of variable amplitude with load, comprising a base 11, a tower body 4 is arranged above the base 11, and a tower top 5 is arranged at the top of the tower body 4, so that An operation room 3 is arranged between the tower body 4 and the tower top 5, and the balance arm 2 and the lifting arm are respectively arranged on both sides of the operation room 3, and the extension of the balance arm 2 and the lifting arm The ends are respectively connected to the tower top 5 through tie rods. The balance arm 2 is provided with a counterweight traveling device 1. The boom includes the first boom 6 and the second boom 7, both of which are connected to the top of the tower through the tie rods. 5 connection, the second boom 7 is slidingly connected to the first boom 6, and a rotating device is provided at the maximum sliding displacement. The balance arm 2 and the lifting arm are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com