Municipal road reinforcing device and construction method

A technology for reinforcing devices and municipal roads, which is applied to roads, roads, infrastructure projects, etc., can solve the problems of high construction cost, large anchor bolt depth, and difficult construction, and achieves low construction cost, simple construction technology, and reduced collapse. effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

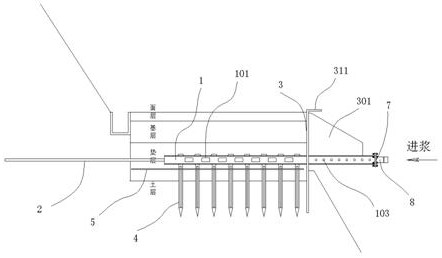

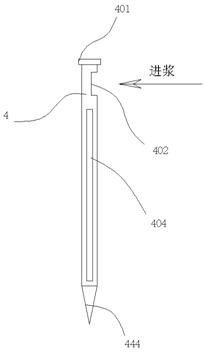

Embodiment 1

[0039]A municipal road reinforcement device, comprising a plurality of steel rods 1 embedded in the cushion layer, the steel rods 1 are hollow structures, the right ends of the steel rods 1 extend to the outside of the cushion layer, and the left ends of the steel rods 1 are inserted into the There is an insertion rod 2, and the insertion rod 2 is driven into the mountain body; the front and rear end faces of the steel plate 1 are provided with export grooves 101 for exporting concrete slurry; the outside of the steel rod 1 is equipped with a wall plate 3 , the wall plate 3 forms a limit on the outside of the cushion, and the lower end of the wall plate 3 is inserted into the soil layer; a rib plate 301 is welded on the outer side of the wall plate 3, and the lower end of the rib plate 301 acts as On the top of the steel plate 1; the top position of the part of the steel rod 1 located in the cushion layer is provided with a socket 102, and an anchor rod 4 is inserted in the soc...

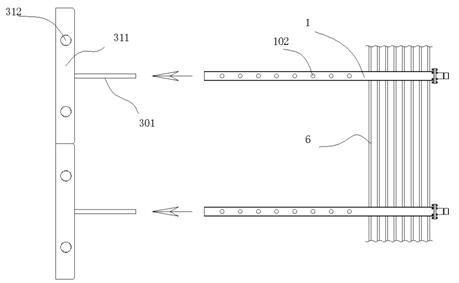

Embodiment 2

[0041] The upper end of the wall plate 3 is bent horizontally to form an assembly part 311, and the top of the assembly part 311 is vertically penetrated with an assembly hole 312 for installing a guardrail; the above-mentioned structure is mainly for installing a side guardrail. In the above-mentioned structure, The fitting part 311 is located on the outside of the road, so the passing width of the road surface can be increased.

Embodiment 3

[0043] A plurality of perforations 103 are provided on the longitudinal end surface of the part of the steel rod 1 extending to the outside of the cushion; the perforation 103 runs through the steel rod 1 in a longitudinal direction, and passes through the The perforation 103 is equipped with a steel cable 6, and the steel cable 6 is grouted after the perforation is completed, and the concrete grout is solidified to cover the steel cable 6, and the steel cable 6 blocks the perforation 103; the above structure Among them, the width of the steel pole 1 extending to the outside of the road surface is greater than 2 meters, and the distance between adjacent steel cables 6 is controlled at 14cm. Through the above structure, after the vehicle collides with the side guardrail and causes the side guardrail to fail, the steel cable 6 can pass through. Undertake the vehicle to prevent the vehicle from falling off the cliff, and a gap is formed between adjacent steel cables 6. The existen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com