Polyvinyl alcohol-polyurethane elastic buffing wheel and preparation method thereof

A polyurethane elasticity and polyvinyl alcohol technology, applied in the field of polishing grinding wheels, can solve the problems of large differences in finished product density and cell structure, difficult to control the ratio of abrasive and binder, difficult to control the degree of acetalization, etc., and achieve uniform cell size. , uniform and beautiful grinding surface, reducing the effect of a lot of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

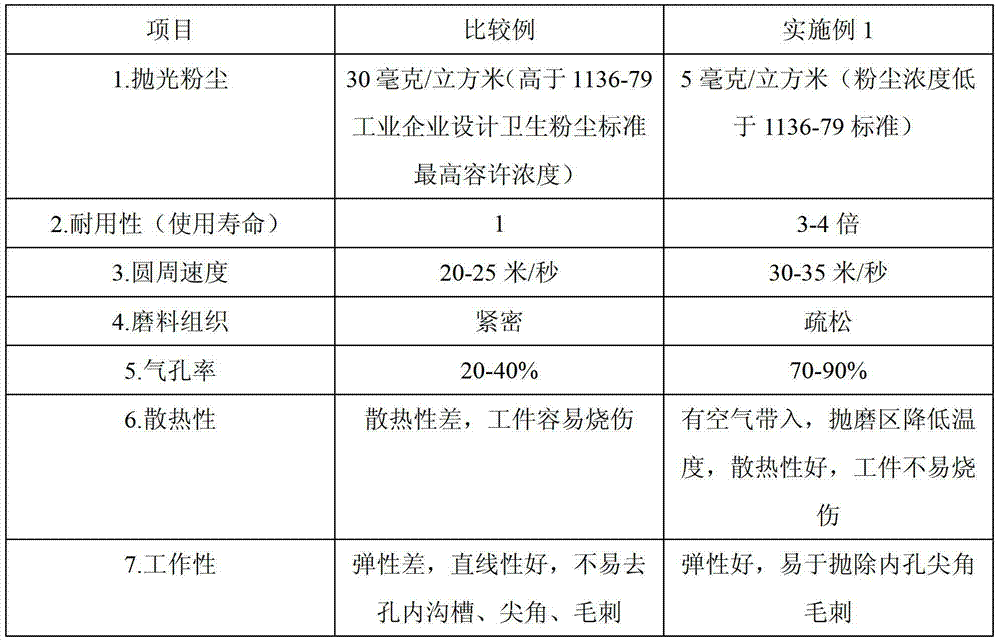

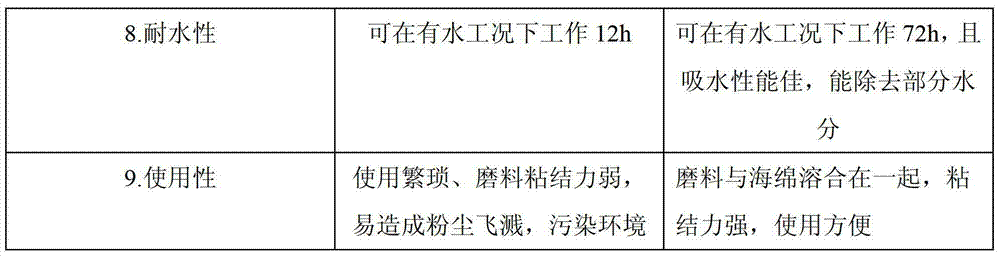

Examples

Embodiment 1

[0031] A kind of preparation method of polyvinyl alcohol-polyurethane elastic polishing emery wheel, comprises the steps:

[0032] (1) Add 5g of polyvinyl alcohol of model 1799 provided by Shanghai Sinopharm Group Chemical Reagent Co., Ltd. and 25g of distilled water into the reactor, and use a stirrer under the condition of 400r / min in a water bath at 95-100°C The solution was dissolved for 20 minutes to obtain an aqueous solution of polyvinyl alcohol.

[0033] (2) Take the above polyvinyl alcohol aqueous solution, add 6g of abrasive silicon carbide with a particle size of 200 mesh, and use a disperser to stir evenly at a speed of 300r / min.

[0034] (3) Add 10g of water-based polyurethane prepolymer dropwise to the suspension obtained in step (2), the model is Bayhydur3100, and then add dropwise 0.8g of the catalyst stannous octoate, mix evenly in a water bath at 30°C, and stir in a mixer at a speed of 400r / min under stirring, react for 5min.

[0035] (4) Curing the colloi...

Embodiment 2

[0044] A kind of preparation method of polyvinyl alcohol-polyurethane elastic polishing emery wheel, comprises the steps:

[0045] (1) Add 2g of polyvinyl alcohol of model 1788 provided by Shanghai Sinopharm Chemical Reagent Co., Ltd., 3g of polyvinyl alcohol of model 1799 provided by Shanghai Sinopharm Chemical Reagent Co., Ltd., and 37.5g of distilled water into the reactor. In a water bath at ~60°C, a stirrer was used to dissolve for 30 minutes under the condition of a rotating speed of 600 r / min to obtain an aqueous solution of polyvinyl alcohol.

[0046] (2) Take the above polyvinyl alcohol aqueous solution, add 3g of silicon carbide, 5g of aluminum oxide and 5g of magnesium oxide with a particle size of 1800 mesh, and use a disperser to stir evenly at a speed of 450r / min.

[0047] (3) Add 5g of Bayhydur2655 and 5g of Bayhydur401-7 water-based polyurethane prepolymer dropwise to the suspension obtained in step (2), then add 0.4g of catalyst stannous octoate and 0.4g of tr...

Embodiment 3

[0052] A kind of preparation method of polyvinyl alcohol-polyurethane elastic polishing emery wheel, comprises the steps:

[0053] (1) The 1g model provided by Shanghai Sinopharm Chemical Reagent Co., Ltd. is 1799, the 2g model provided by Shanghai Sinopharm Chemical Reagent Co., Ltd. is 1788, and the 2g model provided by Shanghai Sinopharm Chemical Reagent Co., Ltd. is BF-17 The polyvinyl alcohol and 5 g of distilled water were added into the reactor, and dissolved in a stirrer at 500 r / min for 25 min in a water bath at 90° C. to obtain an aqueous solution of polyvinyl alcohol.

[0054] (2) Take the above polyvinyl alcohol aqueous solution, add 1g of white corundum, 1g of zirconia corundum, 3g of black corundum, 5g of silicon carbide and 5g of alumina with a particle size of 600 mesh, and use a disperser to stir evenly at a speed of 600r / min .

[0055] (3) Add 5gBayhydurT0607, 5gBayhydurN3390, 5gBayhydur2547, 5gBayhydur3100, 5gBayerBayhydrol BL5140 water-based polyurethane p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com