Natural rubber white odorless spongy cushion for in situ color-protecting shoes and preparation method thereof

A technology of natural rubber and sponge pads, applied in insoles, chemical instruments and methods, applications, etc., can solve problems such as high fatigue, emission, and poor color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

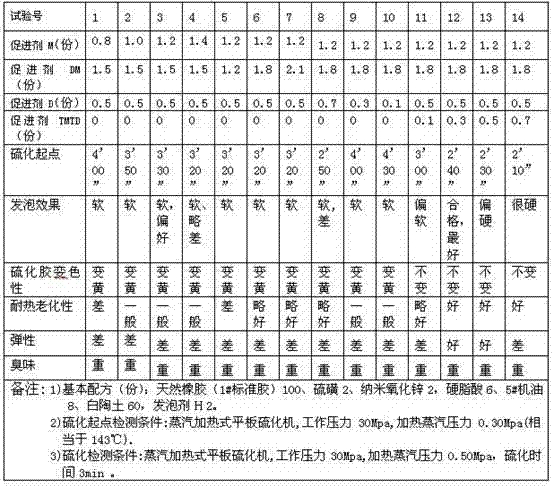

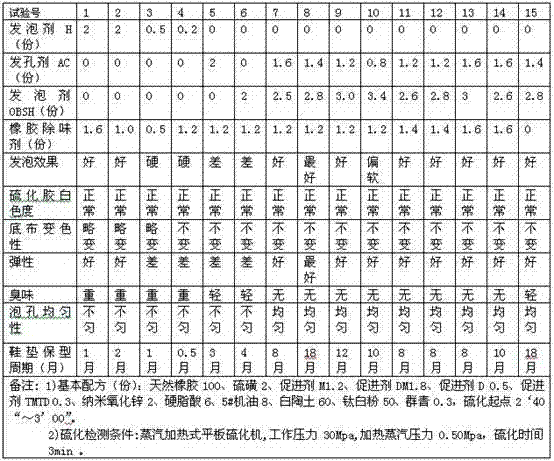

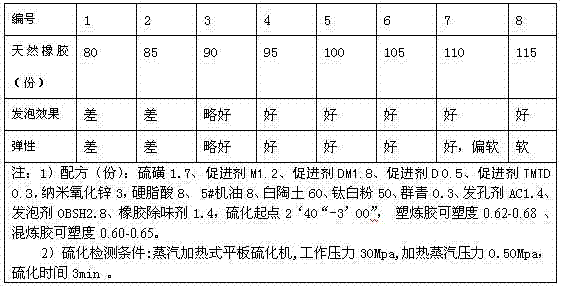

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 of the present invention: in-situ color-retaining type shoe natural rubber white tasteless sponge pad, calculated in parts by weight, it includes 100 parts of natural rubber, 1.7 parts of sulfur, 3.8 accelerators (every 3.8 parts of accelerators are composed of 1.2 parts Accelerator M, 1.8 parts of accelerator DM, 0.5 parts of accelerator D and 0.3 parts of accelerator TMTD), 11 parts of vulcanization activator (each 11 parts of vulcanization activator is composed of 8 parts of stearic acid and 3 parts of nano zinc oxide) , 1.4 parts of pore-forming agent AC, 50 parts of titanium dioxide, 10 parts of 5# engine oil, 60 parts of kaolin, 1.4 parts of rubber deodorant, 2.8 parts of foaming agent OBSH, 0.35 parts of ultramarine blue and 1.5 parts of anti-aging agent SP-C.

[0051] The preparation method of natural rubber white odorless sponge pad for in-situ color-preserving shoes, the natural rubber (selecting 1# standard rubber) was pressed in the internal mixe...

Embodiment 2

[0052] Embodiment 2 of the present invention: in-situ color-retaining type shoe natural rubber white tasteless sponge pad, calculated in parts by weight, it comprises 95 parts of natural rubber, 1.6 parts of sulfur, 3.5 parts of accelerator (every 3.8 parts of accelerator are made up of 1.2 Accelerator M, 1.8 parts of accelerator DM, 0.5 parts of accelerator D and 0.3 parts of accelerator TMTD), 9 parts of vulcanization activator (every 11 parts of vulcanization activator is composed of 8 parts of stearic acid and 3 parts of nano zinc oxide ), 1.2 parts of pore-forming agent AC, 45 parts of titanium dioxide, 8 parts of 5# engine oil, 55 parts of kaolin, 1.2 parts of rubber deodorant, 2.6 parts of foaming agent OBSH, 0.3 parts of ultramarine blue and 1.3 parts of anti-aging agent SP-C .

[0053] The preparation method of natural rubber white odorless sponge pad for in-situ color-preserving shoes, the natural rubber (selecting 1# standard rubber) was pressed in the internal mixe...

Embodiment 3

[0054] Embodiment 3 of the present invention: in-situ color-retaining type shoe natural rubber white tasteless sponge pad, calculated in parts by weight, it comprises 110 parts of natural rubber, 1.8 parts of sulfur, 3.5 parts of accelerator (every 3.8 parts of accelerator are made of 1.2 Accelerator M, 1.8 parts of accelerator DM, 0.5 parts of accelerator D and 0.3 parts of accelerator TMTD), 14 parts of vulcanization activator (every 11 parts of vulcanization activator is composed of 8 parts of stearic acid and 3 parts of nano zinc oxide ), 1.6 parts of pore forming agent AC, 55 parts of titanium dioxide, 12 parts of 5# engine oil, 65 parts of kaolin, 1.6 parts of rubber deodorant, 3 parts of foaming agent OBSH, 0.4 parts of ultramarine blue and 1.7 parts of antioxidant SP-C .

[0055] The preparation method of natural rubber white odorless sponge pad for in-situ color-preserving shoes, the natural rubber (selecting 1# standard rubber) was pressed in the internal mixer for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com