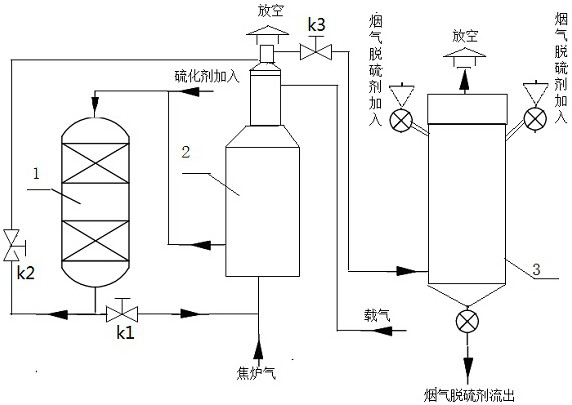

Gas hydrogenation catalyst sulfurization and sulfurization waste gas treatment and emission process

A hydrogenation catalyst and waste gas treatment technology, applied in the field of coal chemical industry, can solve the problem of being reduced before vulcanization, and achieve high utilization efficiency, short vulcanization time, and good vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Sulfurization of 50 m in a coke oven gas to synthetic natural gas plant in Xinjiang 3 Primary hydrogenation. The volume ratio of the catalyst to the external presulfurized catalyst is 8:7, respectively 26.7 m 3 and 23.3 m 3 , the total number of layers in the room is 15 layers, and each layer is filled with 3.3 m 3 . The external presulfided catalyst is prepared by dry method, and the degree of sulfidation is 70%. Vulcanizing agent is CS 2 , prepare 2.02 tons. Replace flue gas desulfurizer 7.31 m 3 , The sulfur capacity of the flue gas desulfurizer is 31%. SO in exhaust flue gas 2 less than 30mg / m 3 , no white smoke is generated. The specific vulcanization process is as follows:

[0042] (1) Use a heating furnace to heat nitrogen to raise the temperature of the catalyst at a heating rate of 20°C / h, and control the temperature of each point of the bed to not exceed 200°C , Control the pressure at 0.1MPa, raise the temperature for 9 hours to 200°C in the upper...

Embodiment 2

[0048] Sulfurization of 18.7 m in a coke oven gas to methanol plant in Shaanxi 3 Prehydrogenation. The volume ratio of the catalyst to the external presulfurized catalyst is 3:2, respectively 11.2 m 3 and 7.5 m 3 , the total number of layers in the room is 5 layers, and each layer is filled with 3.7m 3 . The presulfurized catalyst outside the device is prepared by wet method, and the degree of sulfidation is 40%. The vulcanizing agent is dimethyl disulfide, and 0.94 tons are prepared. Replace flue gas desulfurizer 2.85 m 3 , Flue gas desulfurization agent sulfur capacity 30%. SO in exhaust flue gas 2 less than 30mg / m3 , no white smoke is generated. The specific vulcanization process is as follows:

[0049] (1) Use a heating furnace to heat nitrogen to raise the temperature of the catalyst at a heating rate of 30°C / h, and control the temperature of each point of the bed to not exceed 200°C , The pressure is controlled at 0.2MPa; after 6 hours, the temperature of the u...

Embodiment 3

[0055] Sulfurization of 29 m in a coke oven gas to synthetic natural gas plant in Hebei 3 Primary hydrogenation. The loading volume ratio of the catalyst to the external presulfurized catalyst is 5:4, respectively 16.1 m 3 and 12.9 m 3 , the total number of layers in the room is 9 layers, and each layer is filled with 3.2m 3 . The external presulfided catalyst is prepared by dry method, and the degree of sulfidation is 55%. Vulcanizing agent is CS 2 , prepare 1.31 tons. Replace flue gas desulfurizer 4.74 m 3 , The sulfur capacity of the flue gas desulfurizer is 32%. SO in exhaust flue gas 2 less than 30mg / m 3 , no white smoke is generated. The specific vulcanization process is as follows:

[0056] (1) Use a heating furnace to heat nitrogen to raise the temperature of the catalyst at a heating rate of 25°C / h, and control the temperature of each point of the bed to not exceed 200°C , The pressure is controlled at 0.15MPa; after 7.2 hours, the temperature of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com