Patents

Literature

401results about How to "Improve vulcanization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-hardness high-flexibility double-component condensed type organic silicon potting adhesive composition

InactiveCN101565600AGood waterproof and moisture-proof performanceImprove vulcanization effectNon-macromolecular adhesive additivesOther chemical processesPliabilityChemistry

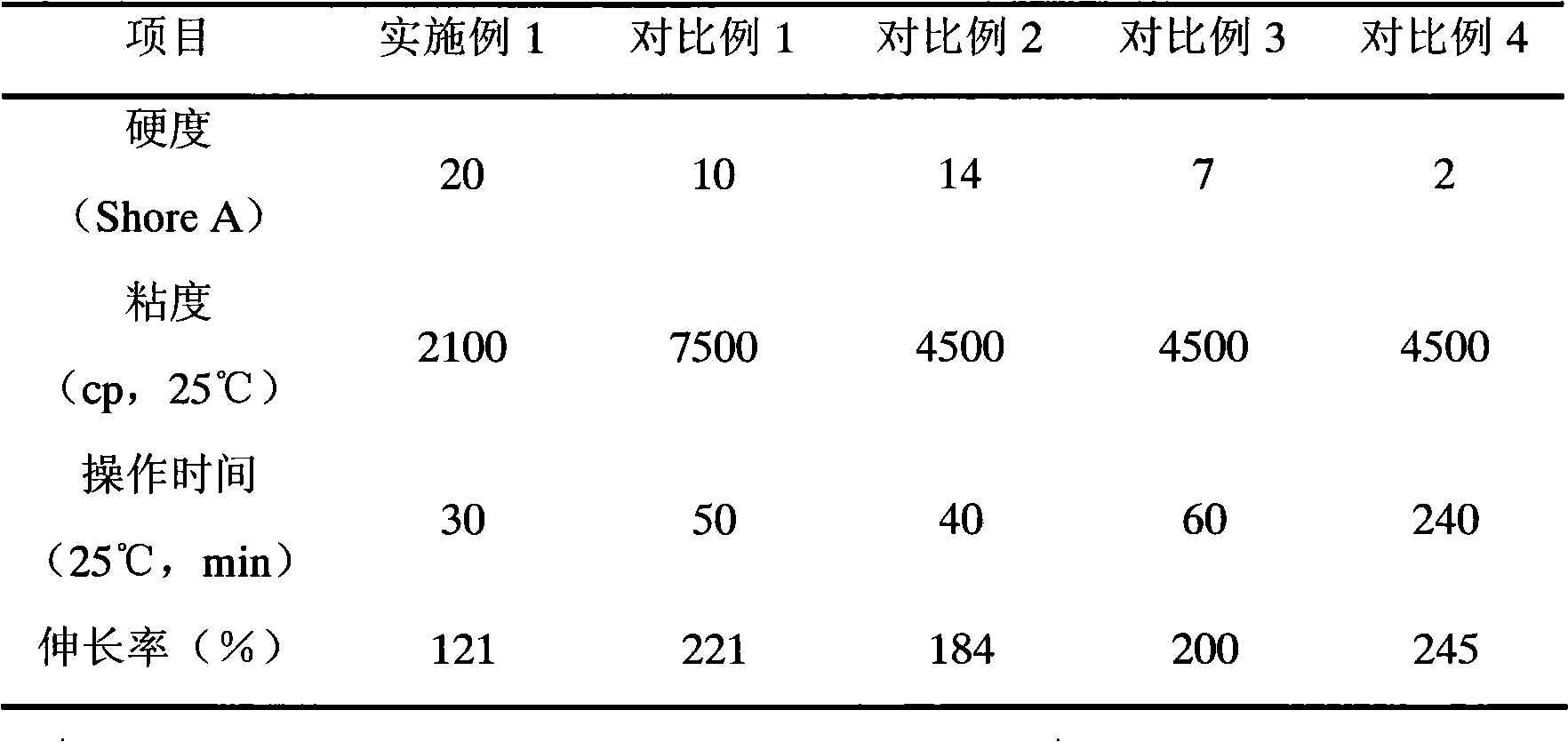

The invention mainly relates to potting adhesive, in particular to a low-hardness and high-flexibility double-component condensed type organic silicon potting adhesive composition suitable for potting a light emitting diode (LED) display screen module. The composition comprises a component A and a component B, wherein the component A comprises a basic polymer, a filling material, a plasticizing agent and a deep curing agent; and the component B comprises a cross-linking agent, a tackifier and a catalyst. The component A and the component B are mixed according to designed proportion to have a cross-linking reaction so as to realize the effects of potting the LED display screen module, preventing adhesive layer cracking during repeatedly bending and folding LED tubes and providing excellent waterproof and dampproof properties.

Owner:GUANGZHOU HUITIAN FINE CHEM

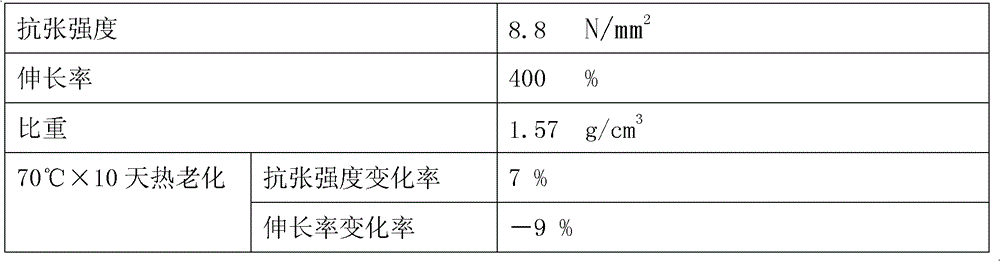

Rubber mixtures

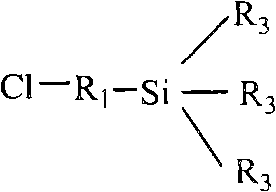

ActiveUS8252863B2Improve vulcanization effectSilicon organic compoundsSpecial tyresPolymer scienceTransesterification

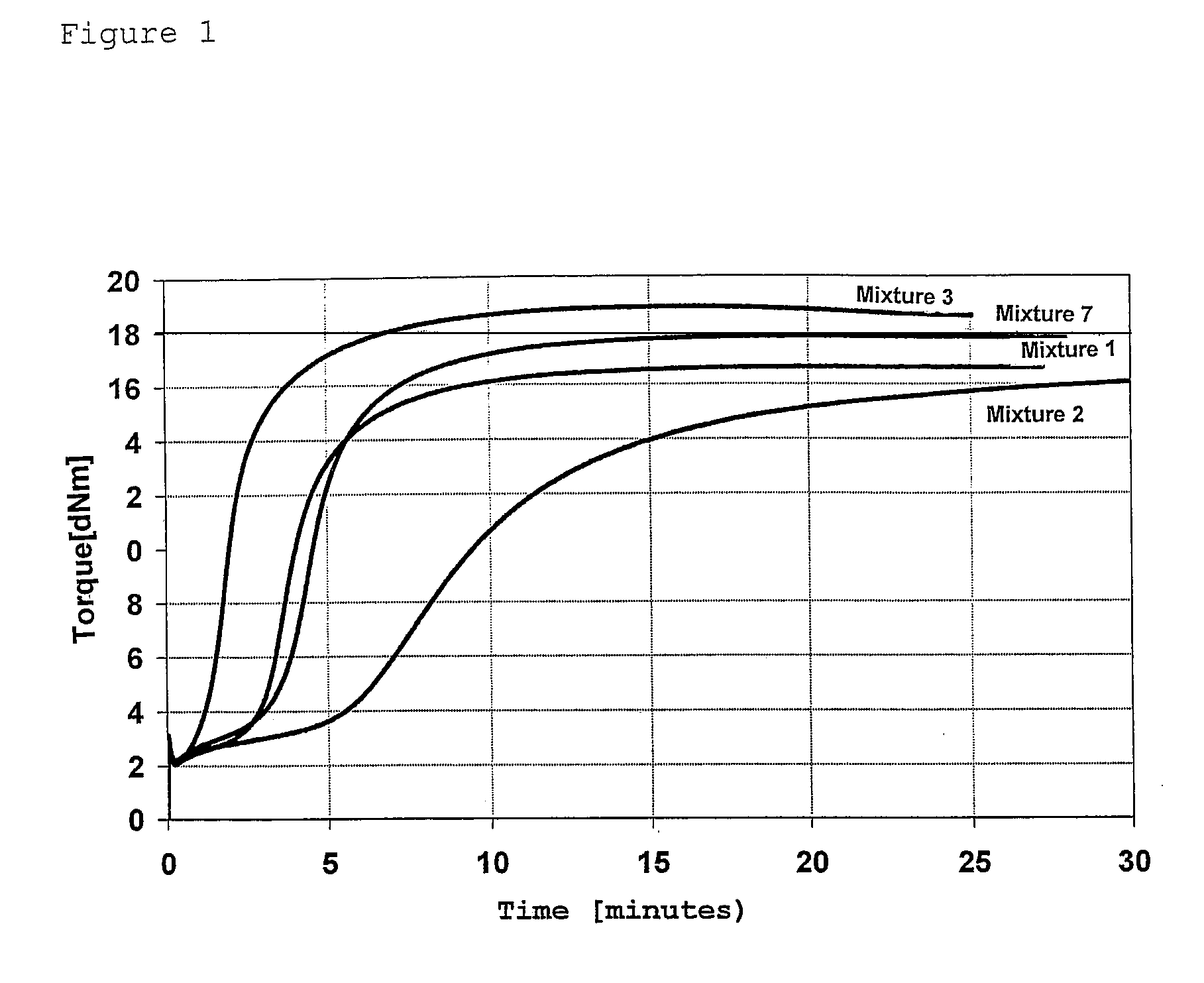

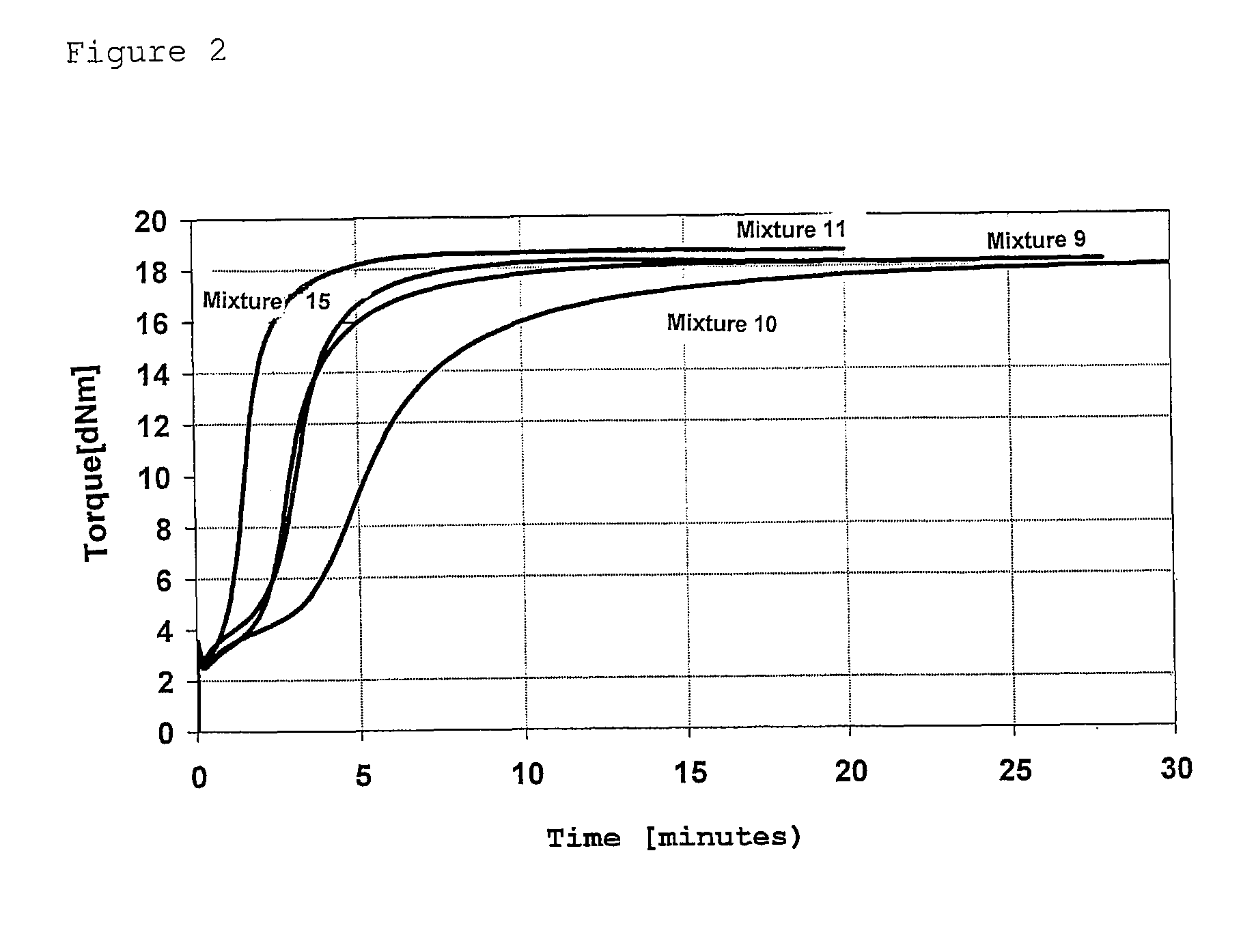

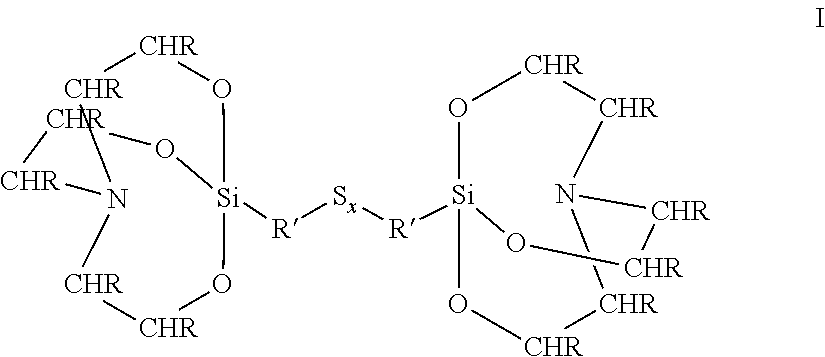

Rubber mixtures, including at least one rubber, a filler, an organosilicon compound of the formula Ione rubber accelerator and one co-accelerator. The rubber mixtures are prepared by mixing at least one rubber, a filler, an organosilicon compound of the formula I, one rubber accelerator and one co-accelerator. The rubber mixtures can be used for production of moldings. Also disclosed is a process for preparation of the organosilicon compound of the formula I via transesterification.

Owner:EVONIK OPERATIONS GMBH

Method for regenerating and pre-vulcanizing hydrogenation catalyst

InactiveCN102310006AEasy to useImprove active recovery effectCatalyst regeneration/reactivationCatalyst activation/preparationVulcanizationActive state

The invention discloses a method for regenerating and pre-vulcanizing a hydrogenation catalyst, which comprises the following steps of: after carrying out charcoal burning on the inactivated hydrogenation catalyst, cooling to a certain temperature; and then directly carrying out suitable pre-vulcanizing treatment and passivating treatment outside a device. In the method disclosed by the invention, the regeneration and vulcanization of the inactivated hydrogenation catalyst are organically combined, so that the generated catalyst is directly subjected to pre-vulcanizing and passivating treatment without being cooled, active metal components can be in a certain active state, and at the time, if the pre-vulcanizing is directly carried out, the vulcanizing effect and the utilization rate of a vulcanizer can be improved. A test shows that in the process, the activity recovery effect of the regenerated catalyst can be improved and the service performance of the regenerated catalyst can be improved. Meanwhile, due to the adoption of the method disclosed by the invention, the energy consumption can be reduced, the production cost is reduced and the production period is shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn process of vulcanized catalyst

ActiveCN101088620AImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationChemistryThiram

The present invention relates preparation process of vulcanized catalyst. During the preparation process, thiram in 0.5-25 wt% of the catalyst, sulfur element in 30-150 % of the theoretic sulfur demand of the catalyst and organic solvent in 0.1-50 wt% of the catalyst are first introduced into the catalyst in oxide state, and the catalyst is then heat treated in dynamic heating apparatus. The catalyst has raised sulfur holding rate, smooth heat release, shortened vulcanizing period and raised production efficiency. The method of the present invention may be used in the treatment of various kinds of hydrogenating catalyst before application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the preparation of a catalyst based on tungsten for use in hydrotreatment or in hydrocracking

ActiveUS20140323779A1Good dispersionHigh activityMolecular sieve catalystOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenation reactionTungsten

The invention concerns a process for the preparation of a catalyst based on tungsten intended for hydrotreatment or hydrocracking processes.The invention concerns a process for the preparation of a catalyst for carrying out hydrogenation reactions in hydrotreatment and hydrocracking processes. Said catalyst is prepared from at least one mononuclear precursor compound based on tungsten (W), in its monomeric or dimeric form, having at least one W═O or W—OR bond or at least one W═S or W—SR bond where [R═CxHy where x≧1 and (x−1)≦y≦(2x+1) or R═Si(OR′)3 or R═Si(R′)3 where R′═Cx′Hy′ where x′≧1 and (x′−1)≦y′≦(2×t+1)], optionally at least one Mo precursor and optionally at least one promoter element from group VIII. Said precursors are deposited onto an oxide support which is suitable for the process in which it is used, said catalyst advantageously being sulphurized before being deployed in said process.

Owner:INST FR DU PETROLE

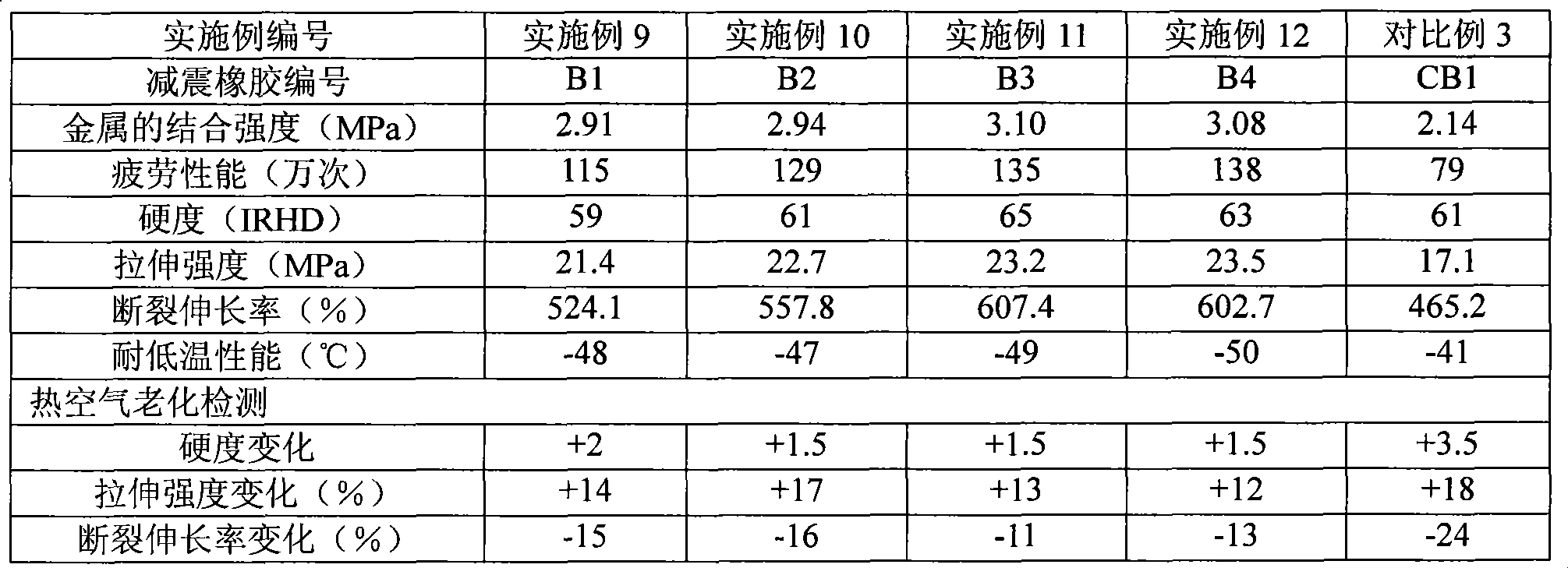

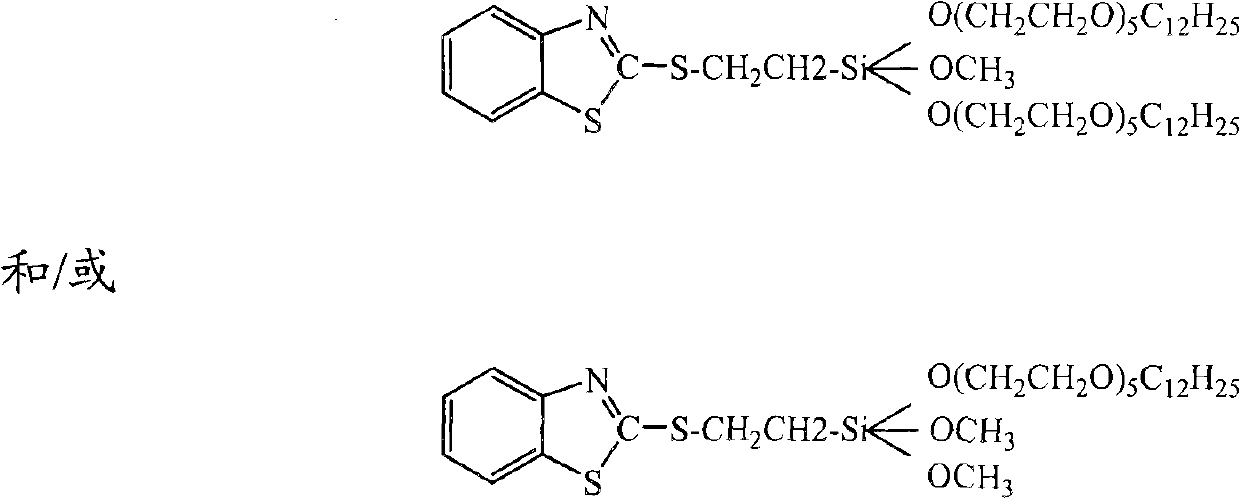

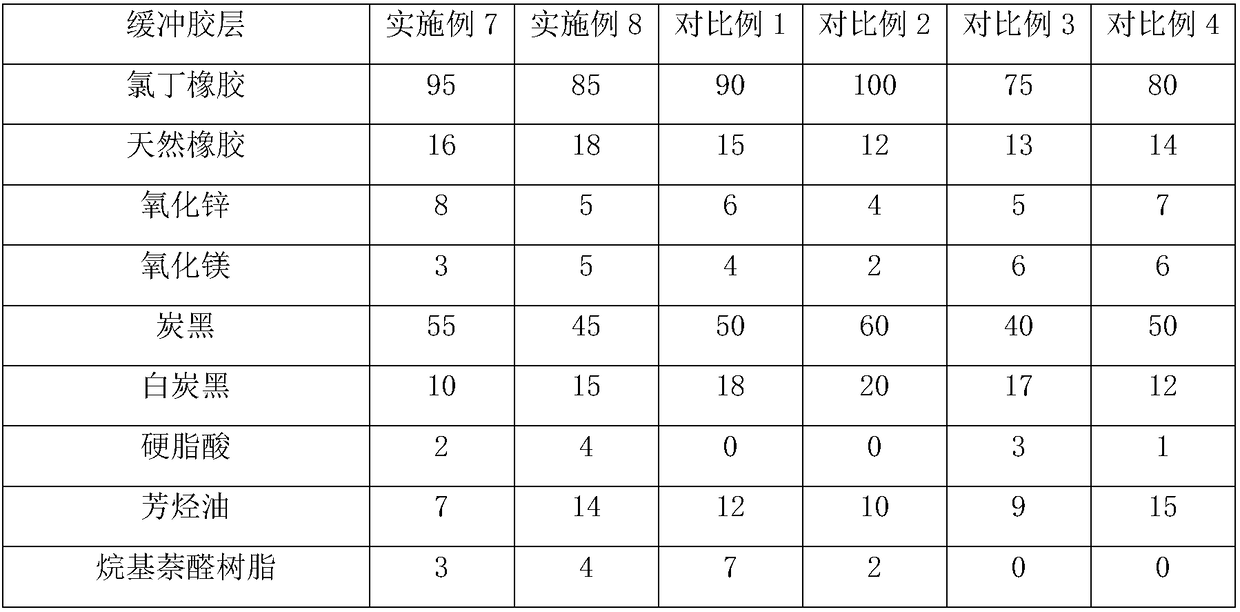

Composition for cushion rubber, preparation method thereof and cushion rubber

The invention provides a composition for damping rubber. The composition comprises rubber, a plasticizer, a vulcanizing agent, an accelerator, an antioxidant, an activating agent, a filler and a softener, wherein the rubber is natural rubber and cis-butadiene rubber; the vulcanizing agent comprises curing resin and sulfur; and the weight ratio of the curing resin to the sulfur is between 1:0.1-10. The invention also provides a method for preparing the composition for damping rubber and the damping rubber obtained through vulcanization of the composition. The composition for damping rubber can remarkably improve fatigue performance and mechanical strength of the damping rubber and can meet the requirement of vehicle damping.

Owner:BYD CO LTD

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

Ceramic fire-resistant and flame-retardant silicone rubber and preparation method thereof

InactiveCN106398231AImprove fire and flame retardant performanceImprove performancePolymer scienceSilanes

The invention relates to the technical field of silicone rubber, and particularly relates to a ceramic fire-resistant and flame-retardant silicone rubber and a preparation method thereof. The ceramic fire-resistant and flame-retardant silicone rubber is composed of a component A and a component B in a weight ratio of 0.8-1.2: 1. The component A comprises the following raw materials in weight part: 60-140 parts of silicone rubber A, 35-45 parts of reinforcing agent, 60-100 parts of filler A, 11.4-17.2 parts of silane auxiliary agent A, 0.15-0.25 part of lubricant A, 0.1-0.3 part of flame retardant, and 0.5-1.5 parts of vulcanizing agent. The component B comprises the following raw materials in weight part: 60-140 parts of silicone rubber B, 230-290 parts of filler B, 3-6 parts of silane auxiliary agent B, and 0.2-0.4 part of lubricant B. According to the technical scheme of the invention, the ceramic fire-resistant and flame-retardant silicone rubber is good in fire-resistant and flame-retardant property, and excellent in comprehensive performance.

Owner:东莞市朗晟材料科技有限公司

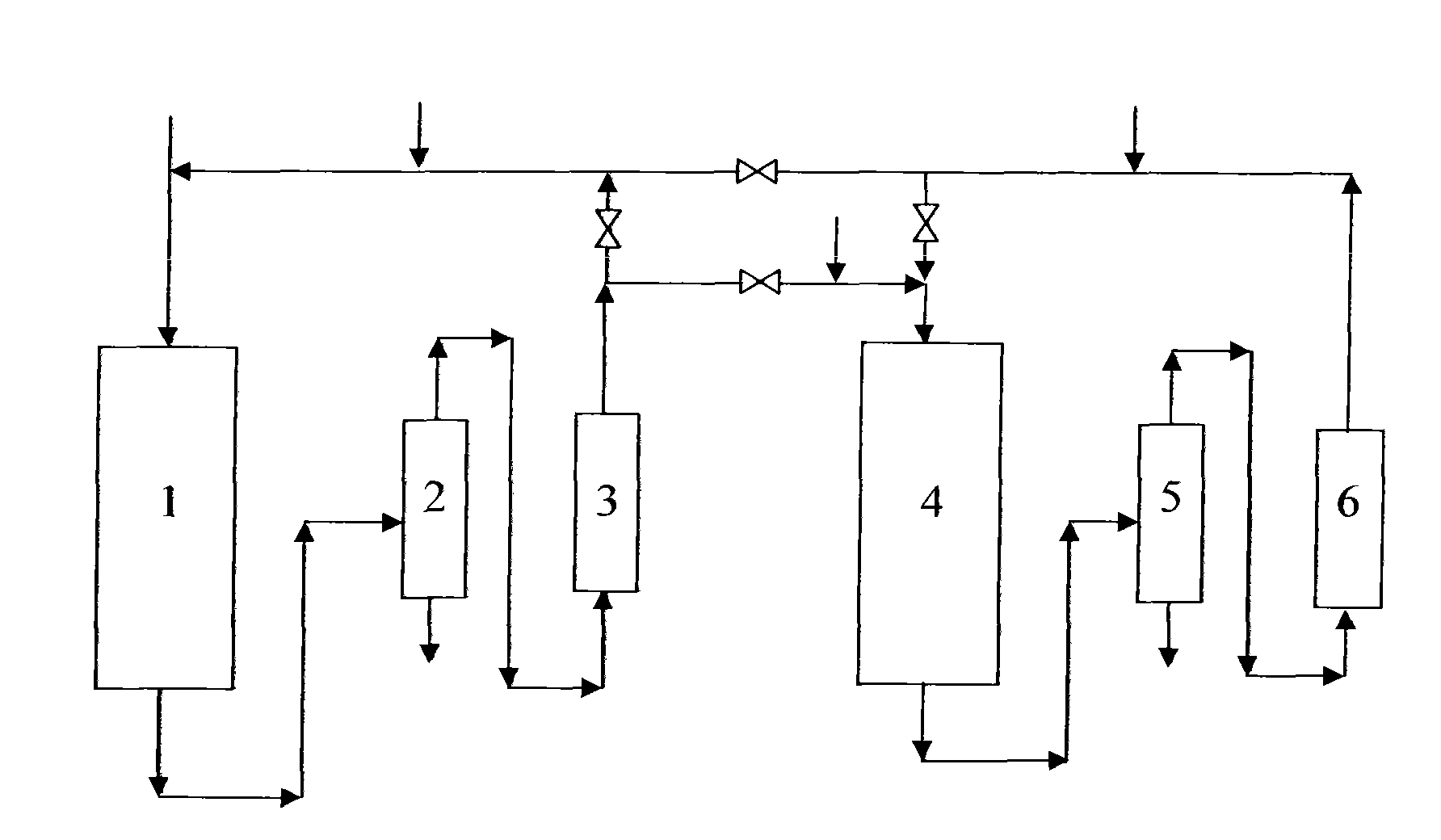

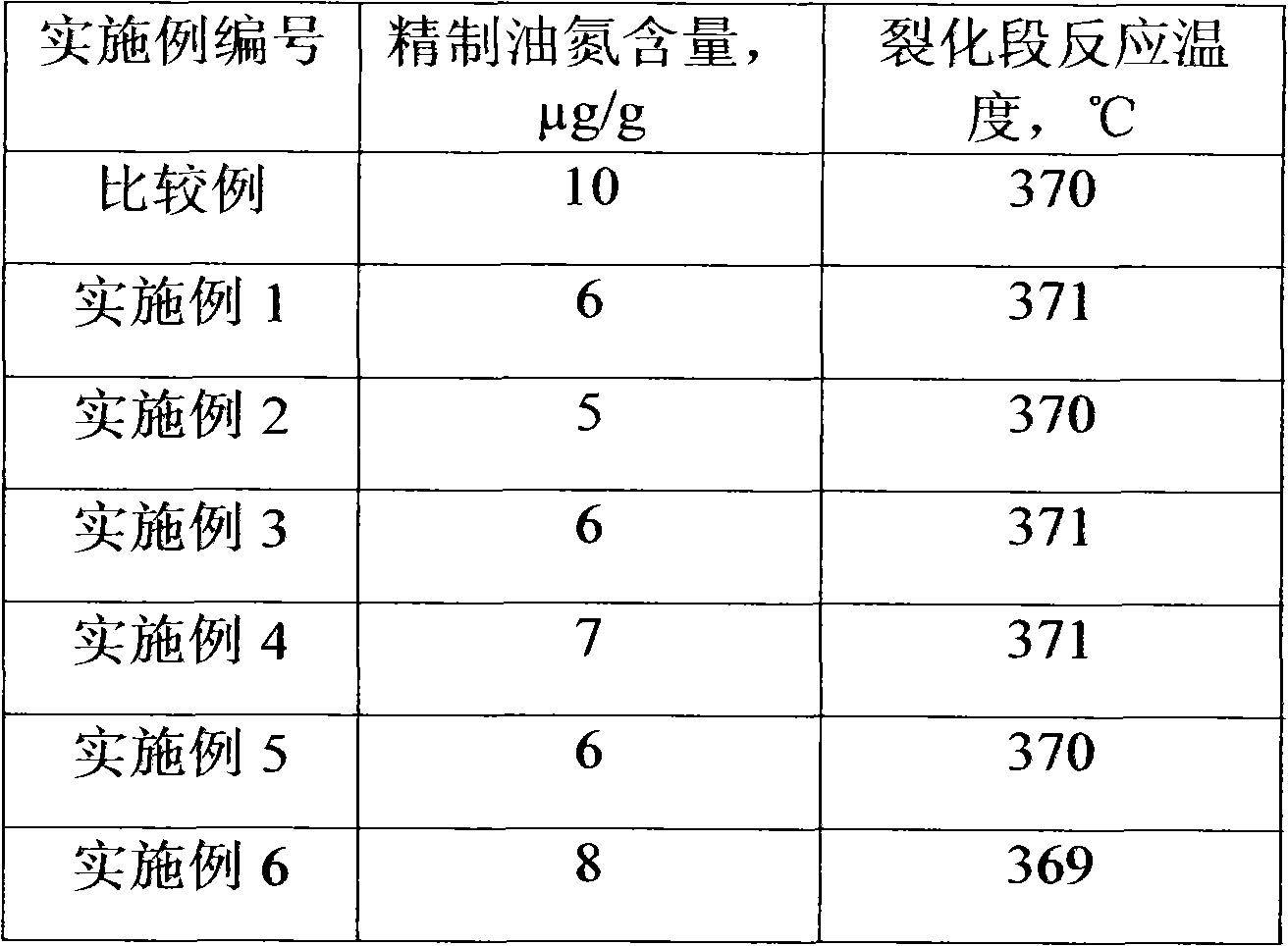

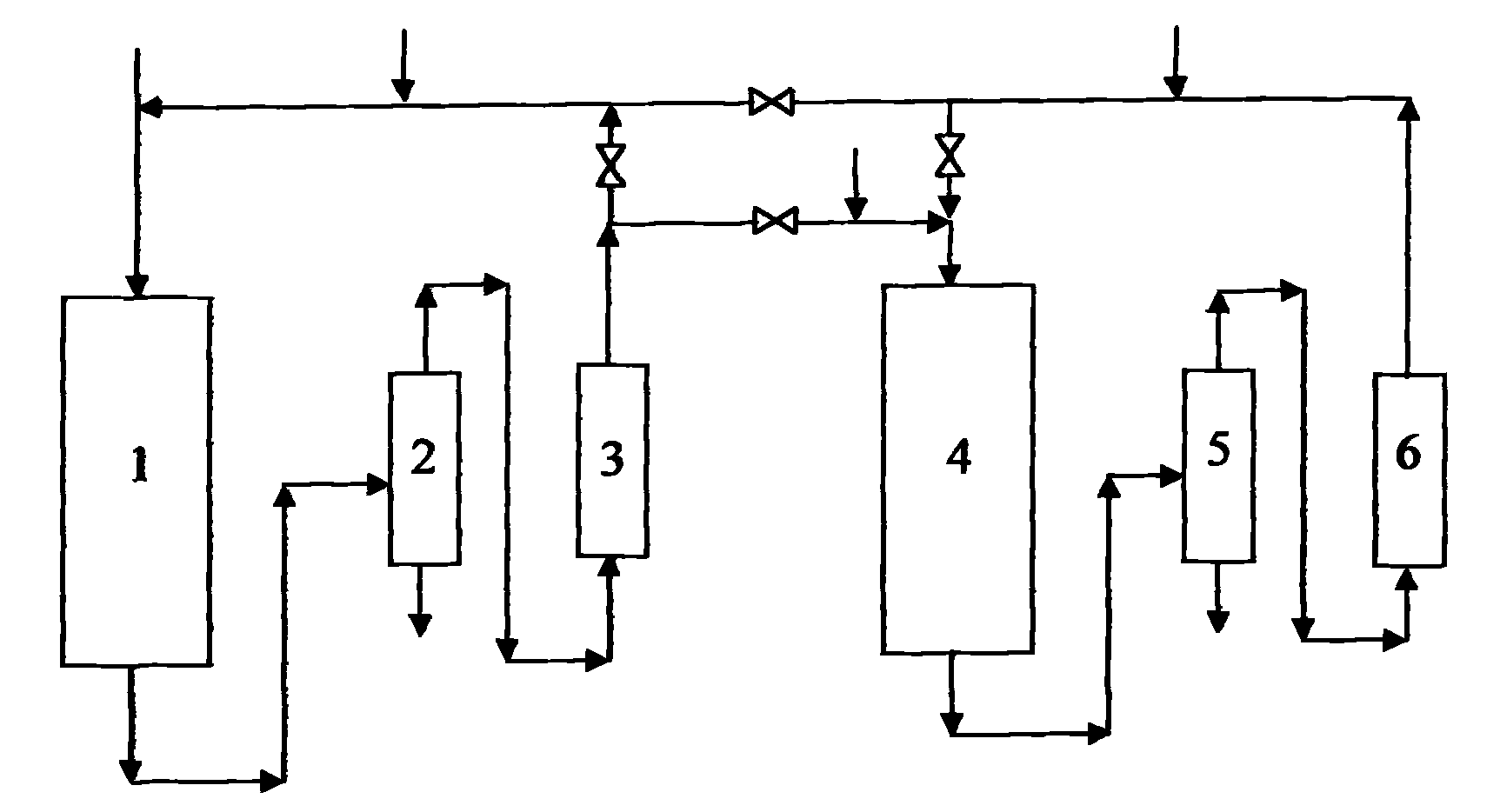

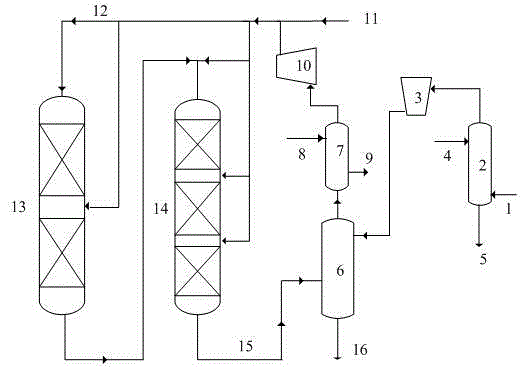

Sulfuration method of catalyst for hydrocracking technology

ActiveCN102465008AImprove vulcanization effectAvoid poisoningCatalyst activation/preparationTreatment with hydrotreatment processesWaxHydrogen

The invention discloses a sulfuration method of a catalyst for hydrocracking technology. The method is as below: (1) a normally running wax oil hydrotreatment apparatus or a residuum hydrotreatment apparatus; (2) hydrocracking technical apparatuses comprise a hydrocracking reactor and a selectable hydrocracking pre-refining reactor; (3) adjusting a desulfurization rate of a recycle hydrogen sulfureted hydrogen removal apparatus in the normally running wax oil hydrotreatment apparatus or the residuum hydrotreatment apparatus; (4) introducing sulfureted hydrogen-containing gas emitted from the recycle hydrogen sulfureted hydrogen removal apparatus in the normally running wax oil hydrotreatment apparatus or the residuum hydrotreatment apparatus to the hydrocracking unit and carrying out sulfuration operation on the hydrocracking unit; (5) carrying out sulfuration according to normal conditions of a dry sulfuration method of a hydrocracking unit until completion. The method of the invention can increase sulfuration efficiency and reduce vulcanizing agent consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

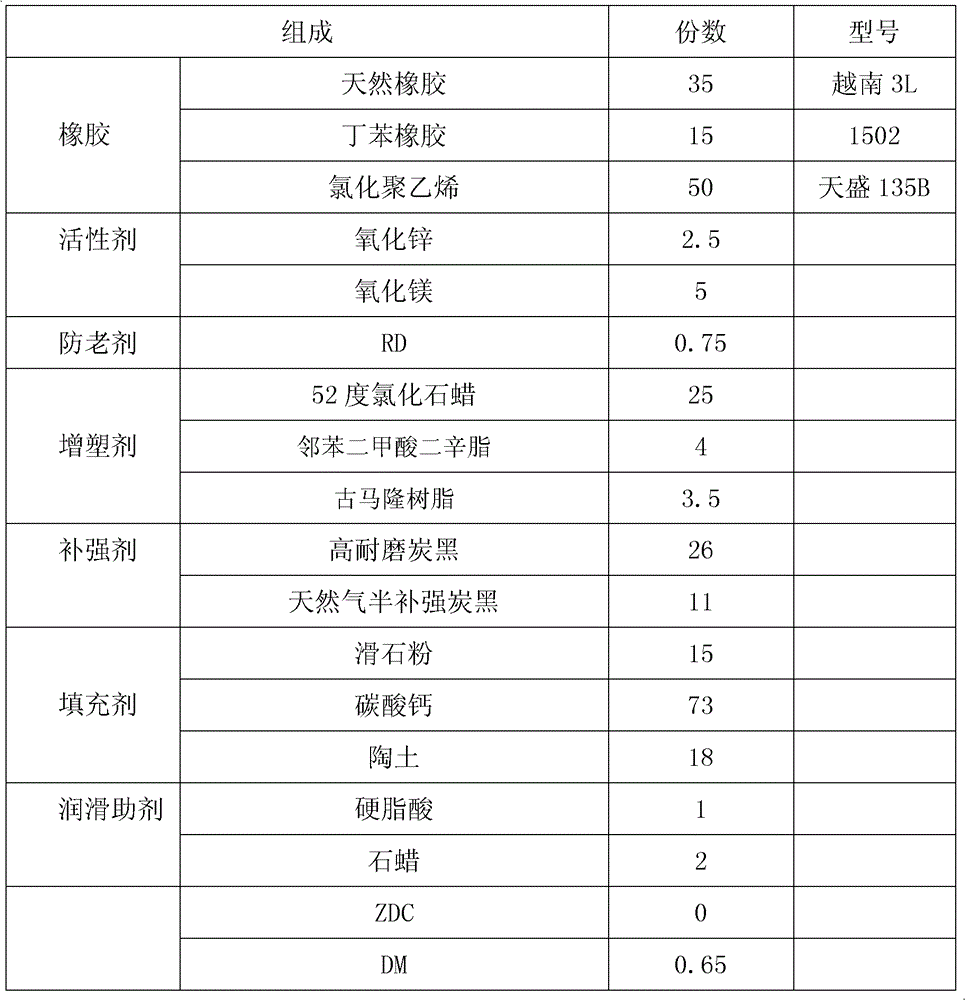

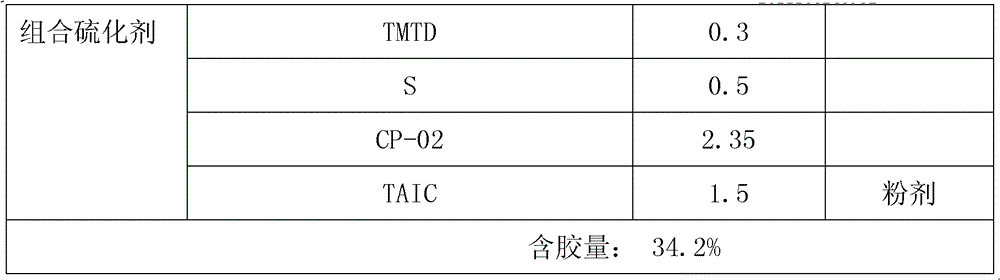

Sheath rubber for rubber sheath flexible cables

InactiveCN103059352ATo achieve the purpose of complementary performanceImprove vulcanization effectRubber insulatorsPlastic/resin/waxes insulatorsPlasticizerEngineering

The invention relates to a sheath rubber for rubber sheath flexible cables, which is prepared from the following components in parts by mass: 30-70 parts of natural rubber, 10-30 parts of styrene-butadiene rubber, 5-10 parts of activating agent, 0.5-2 parts of anti-aging agent, 2-45 parts of plasticizer, 30-60 parts of reinforcing agent, 80-180 parts of filler, 2-8 parts of lubricating assistant and 1.5-6.5 parts of composite vulcanizing agent. The gel content in the sheath rubber is 30-40%, wherein the gel content is (weight of natural rubber+weight of styrene-butadiene rubber+weight of chlorinated polyethylene) / total weight*100%. The invention adopts a natural rubber / styrene-butadiene rubber / chlorinated polyethylene three-element sharing method to improve the properties of the sheath rubber for rubber sheath flexible cables, thereby achieving the goal of property complementation and satisfying the property requirements for SE3 rubber in national standard.

Owner:FAR EAST CABLE +2

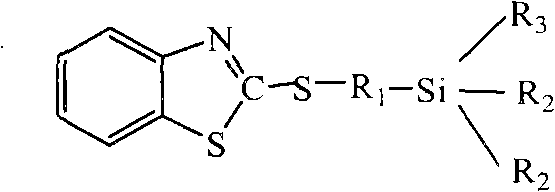

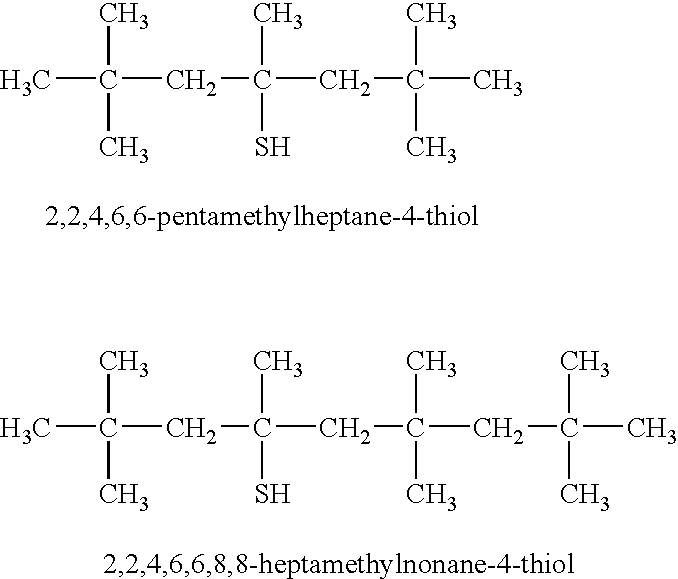

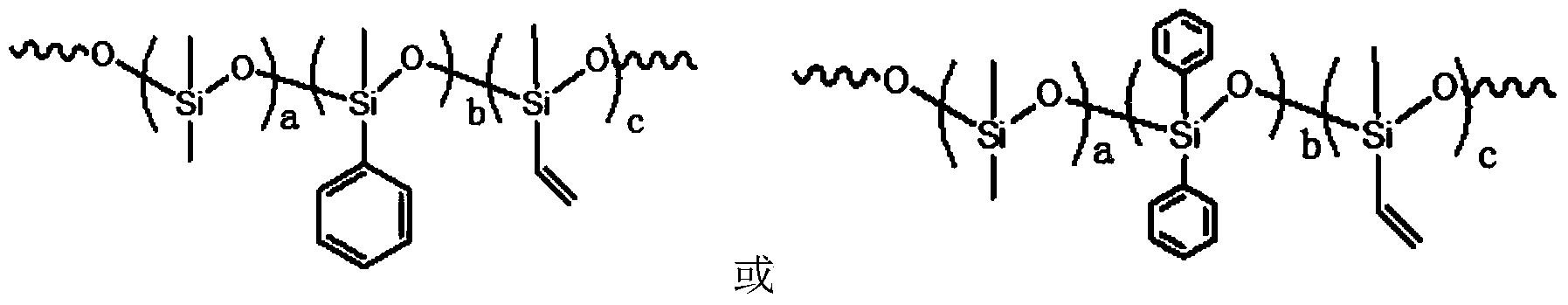

Low-volatility benzothiazolyl mercaptosilanes and preparation method thereof

ActiveCN102344462AImprove bindingImprove mechanical propertiesGroup 4/14 element organic compoundsRubber materialPolymer science

The invention discloses a low-volatility benzothiazolyl mercaptosilane and a preparation method thereof. A molecular structural formula of the low-volatility benzothiazolyl mercaptosilane is shown in the patent specification. The preparation method of the low-volatility benzothiazolyl mercaptosilane comprises the following steps that 1, a polyether and a chloroalkyl silane undergo a reaction at a temperature of 30 to 180 DEG C in the presence of one or more catalysts; and R3-H is separated from the reaction products so that a silane semi-finished product is obtained; and 2, 2-mercaptobenzothiazole is added into an organic solvent; and one or more alkalis and semi-finished silane are added into the 2-mercaptobenzothiazole solution to undergo a reaction with stirring at a temperature of 20 to 120 DEG C in a nitrogen atmosphere for 0.5 to 24 hours; the reaction products are subjected to filtration, washing and reduced pressure distillation to produce a brown-red liquid desired product. The low-volatility benzothiazolyl mercaptosilane can release a small quantity of alcohols, can improve reinforcing effects, mechanical properties and dynamic mechanical properties of vulcanized rubbers, and rolling resistance and wet skid resistance of tread rubber, has long scorch time and fast sulfuration speed, and can improve greatly sulfuration performances of rubber materials.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Treatment method before application of hydrogenation catalyst

ActiveCN1861257AImprove sulfur retentionHigh activityCatalyst activation/preparationRefining to eliminate hetero atomsOrganic solventOxidation state

A process for treating the hydrocatalyst before it is used features that the organic solvent and sulfur-contained substance are introduced to the oxidation-state hydrocatalyst for higher activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

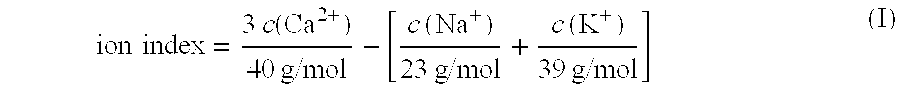

Nitrile rubbers

An improved polymerization and work-up process makes it possible to produce specific nitrile rubbers which have a particular ion index which is responsible for an excellent vulcanization rate and leads to vulcanizates having an advantageous property profile.

Owner:ARLANXEO DEUT GMBH

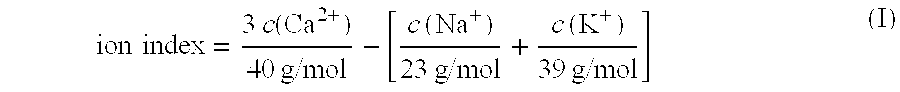

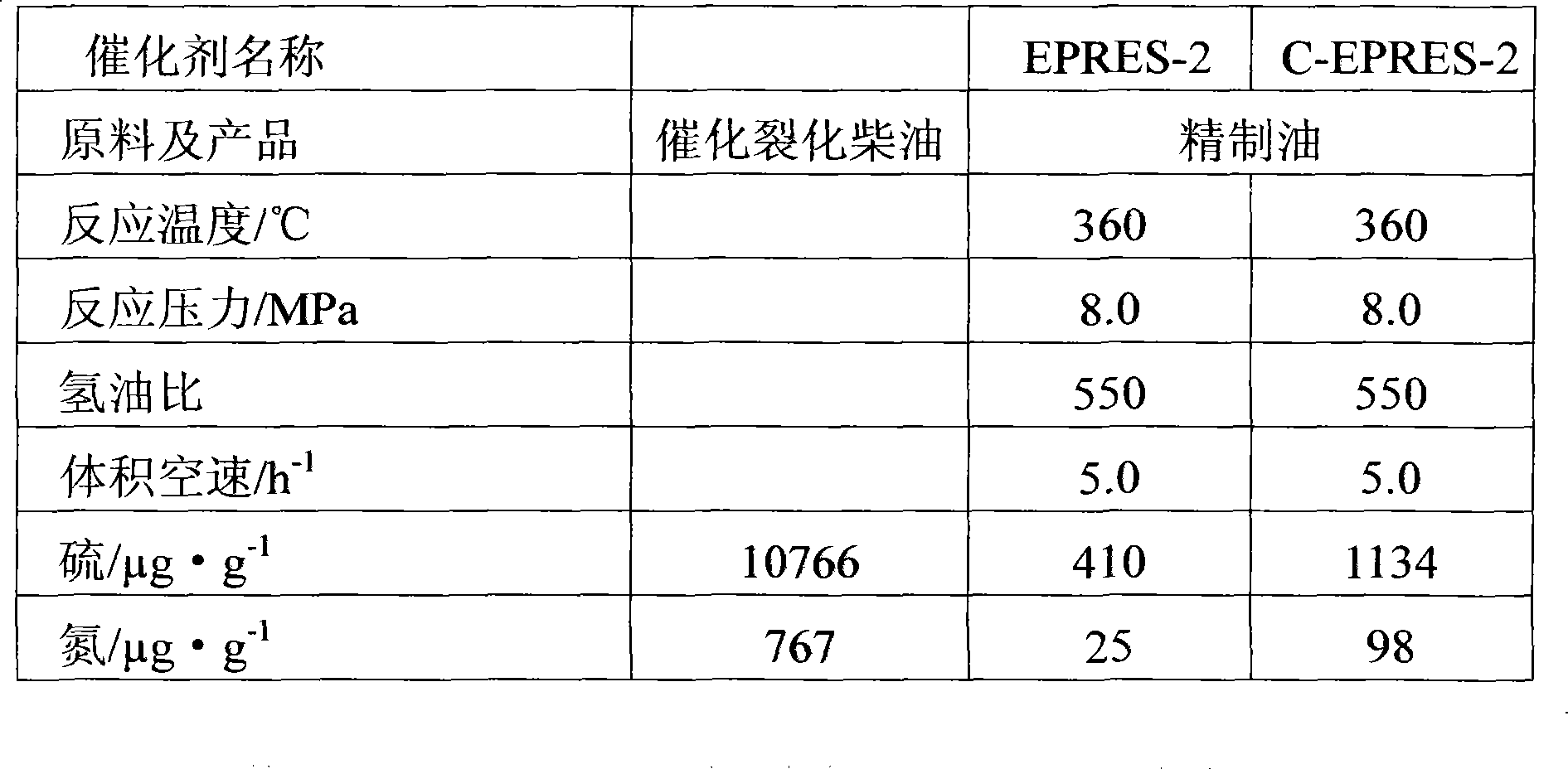

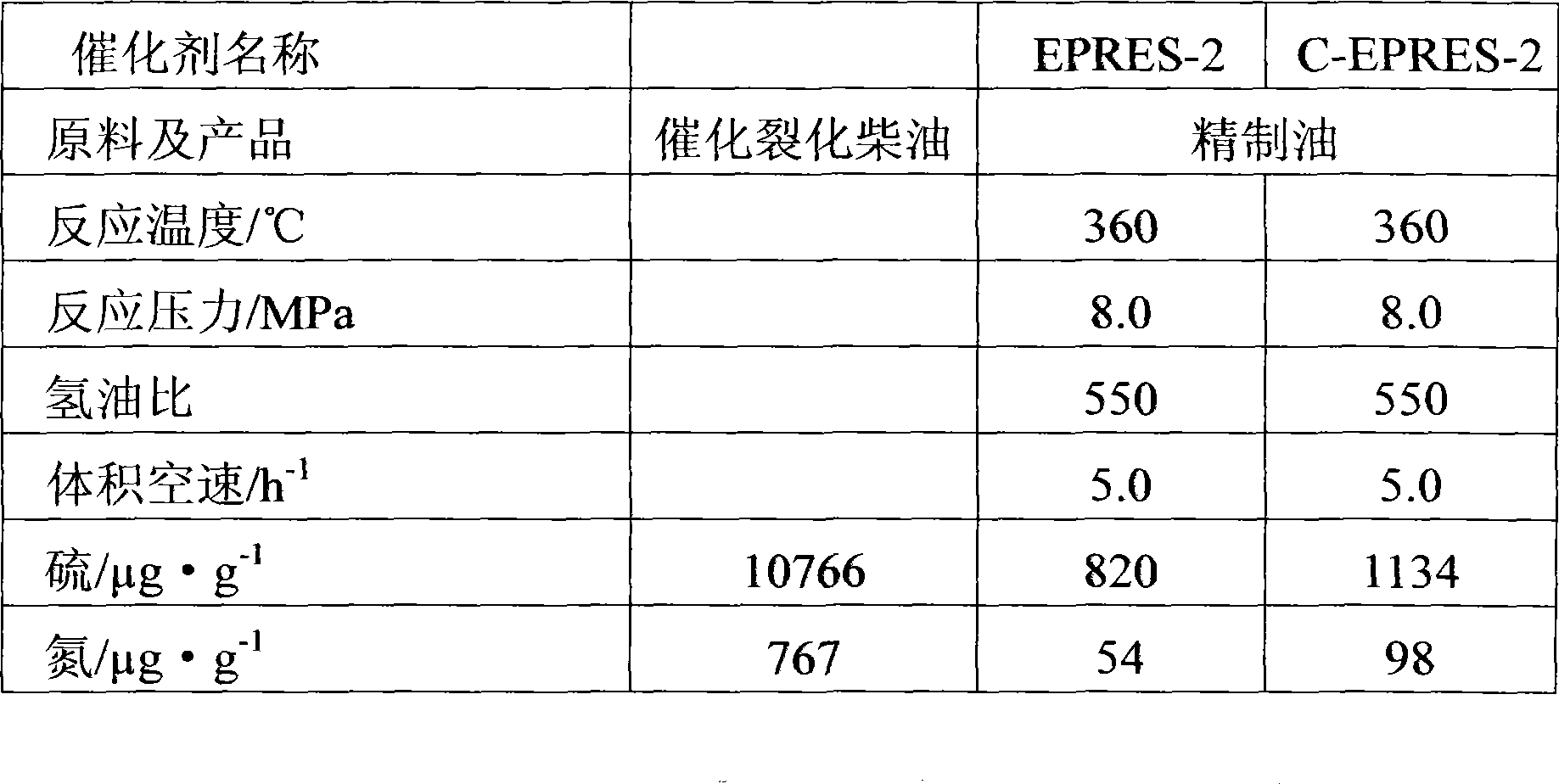

Catalyst for hydro-denitrification of inferior heavy distillate oil and preparation method and application of catalyst

ActiveCN103212432AGood dispersionImprove vulcanization effectMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveVulcanization

The invention provides a catalyst for hydro-denitrification of inferior heavy distillate oil and a preparation method and application of the catalyst. The preparation method comprises the following steps of: performing surface acid treatment on aluminum oxide and an HY molecular sieve separately; mechanically compounding the aluminum oxide subjected to the acid treatment and the HY molecular sieve subjected to the acid treatment into a carrier; dipping steeping liquid containing catalyst active components to load the catalyst active components; and drying to obtain the catalyst for hydro-denitrification of heavy distillate oil. In the carrier, the content of the HY molecular sieve subjected to the acid treatment is 5 to 20 percent, the active components comprise Mo and / or W, and Co and / or Ni, the steeping liquid also comprises a complexing agent, the Mo and / or W oxide content of the catalyst is 10 to 30 percent, and the Co and / or Ni oxide content of the catalyst is 1 to 10 percent. The catalyst has the characteristics of reasonable acidic distribution, a large number of active metal stacking piles and complete metal vulcanization, has a high hydro-denitrification activity to the inferior heavy distillate oil, and has high hydro-desulfurization performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

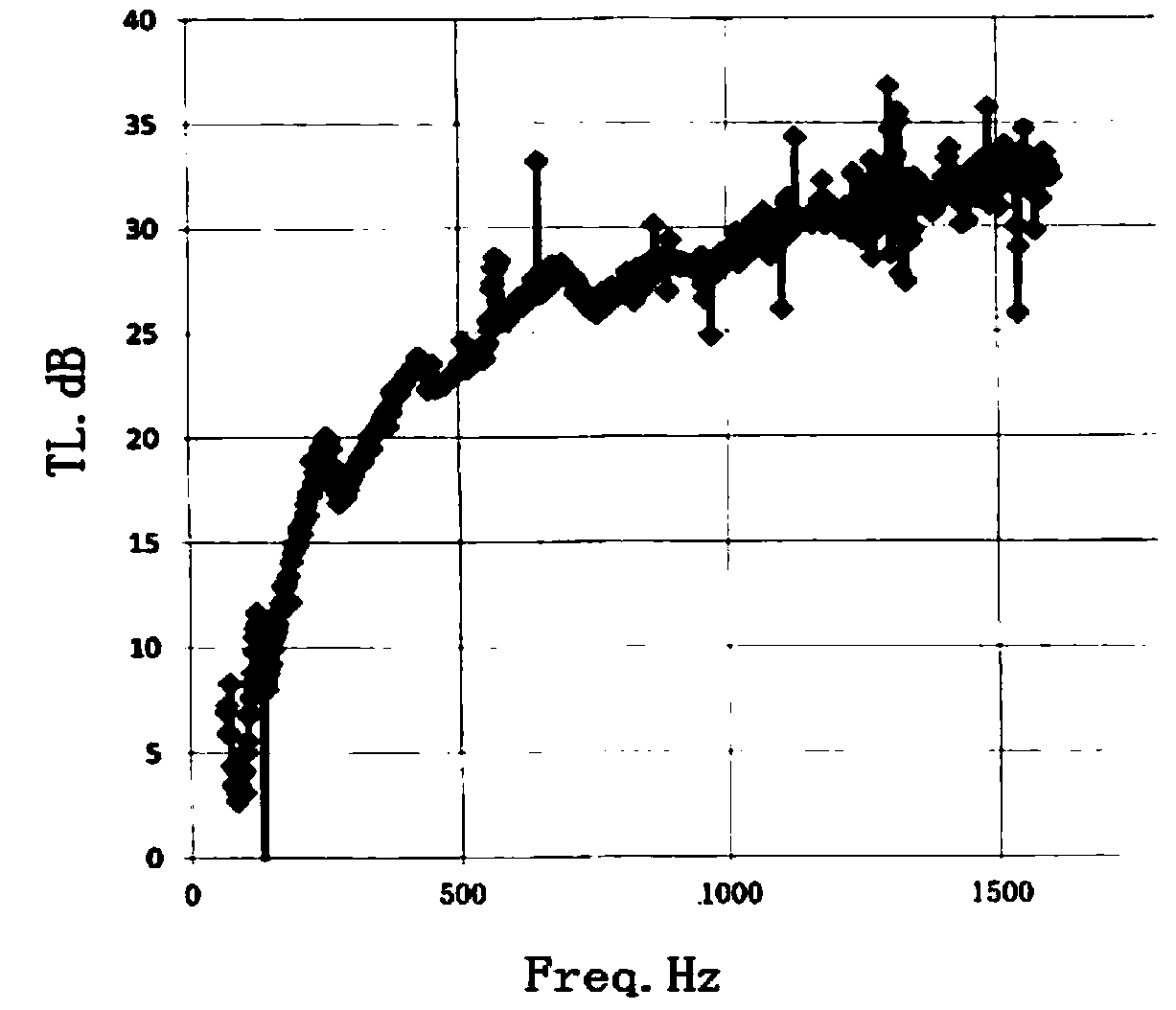

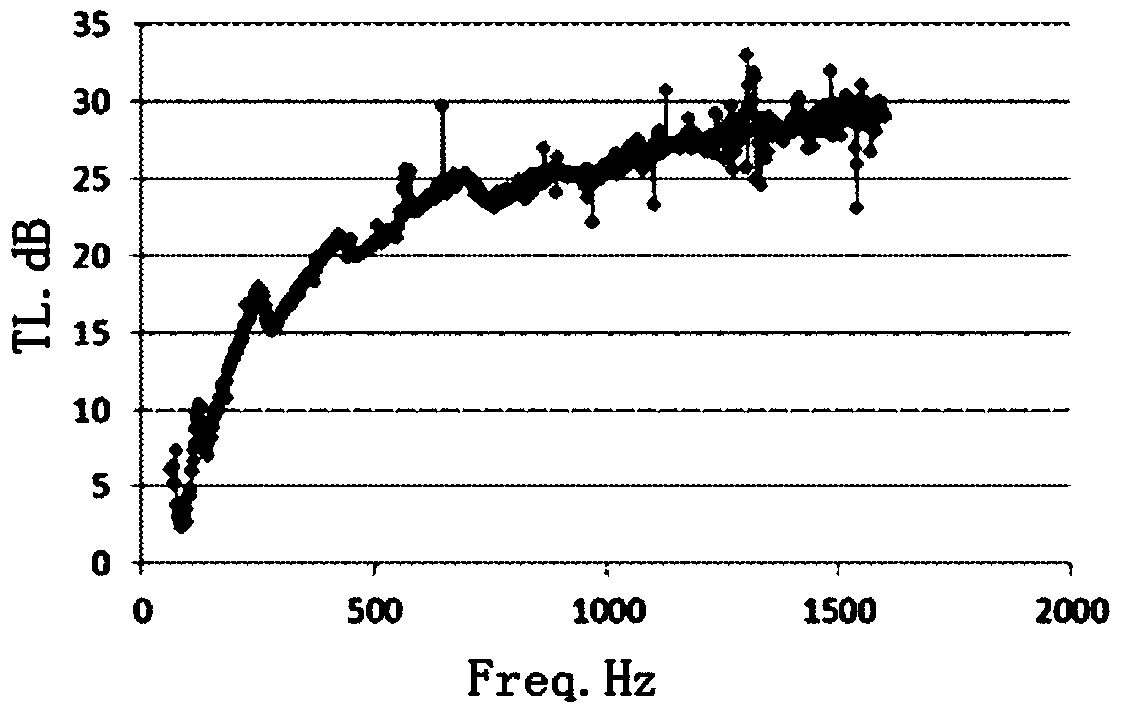

Damping silicon rubber sound insulation material filled with glass microbeads

The invention discloses a damping silicon rubber sound insulation material filled with glass microbeads. The damping silicon rubber sound insulation material is prepared from the following raw materials in parts by weight: 80-120 parts of damping silicon rubber, 5-40 parts of glass microbeads, 0.2-0.8 part of vinyl trimethoxysilane, 0.1-2 parts of tetramethyl thiuram and 0.5-5 parts of peroxide vulcanizing agent, wherein in the damping silicon rubber, the content of vinyl chain elements is 0.2-10% by mole percent, and the content of phenyl chain elements is 10-20% by mole percent; and the peroxide vulcanizing agent is bis (2,4-dichlorobenzoyl) peroxide, the vulcanizing agent, namely 2, 5-dimethyl-2, 5-di (tert-butylperoxy) hexane or dibenzoyl peroxide. The invention further discloses a preparation method of the damping silicon rubber sound insulation material. The glass microbeads are filled in the damping silicon rubber, so that the weight of the damping silicon rubber material is reduced, the sound insulation performance of the material is further improved and the damping silicon rubber sound insulation material is conductive to expanding the application of the silicon rubber sound insulation material.

Owner:STATE GRID CORP OF CHINA +1

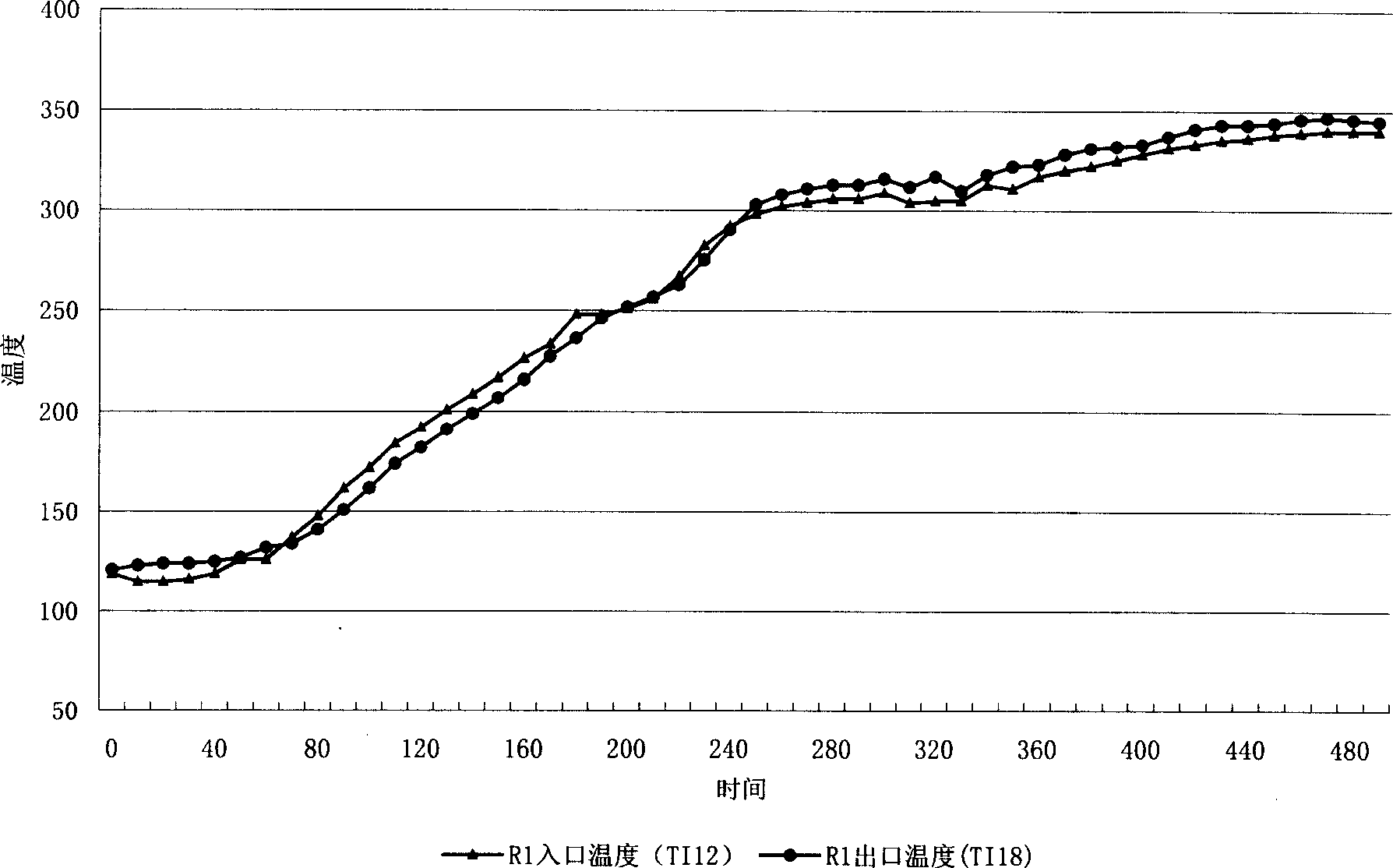

Hydrogenation catalyst processing method

ActiveCN101417245AImprove vulcanization effectImprove hydrogenation reaction performanceMolecular sieve catalystsCatalyst activation/preparationOrganic solventWater vapor

The invention relates to a processing method used for a hydrogenation catalyst, comprising the detailed process as follows: the catalyst carrier is dipped in catalyst active metal component and dried to certain water content; subsequently, organic solvent and elemental sulfur are introduced; and finally, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the water contained in the catalyst adjusts the interaction of the sulfur and the active composition of the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

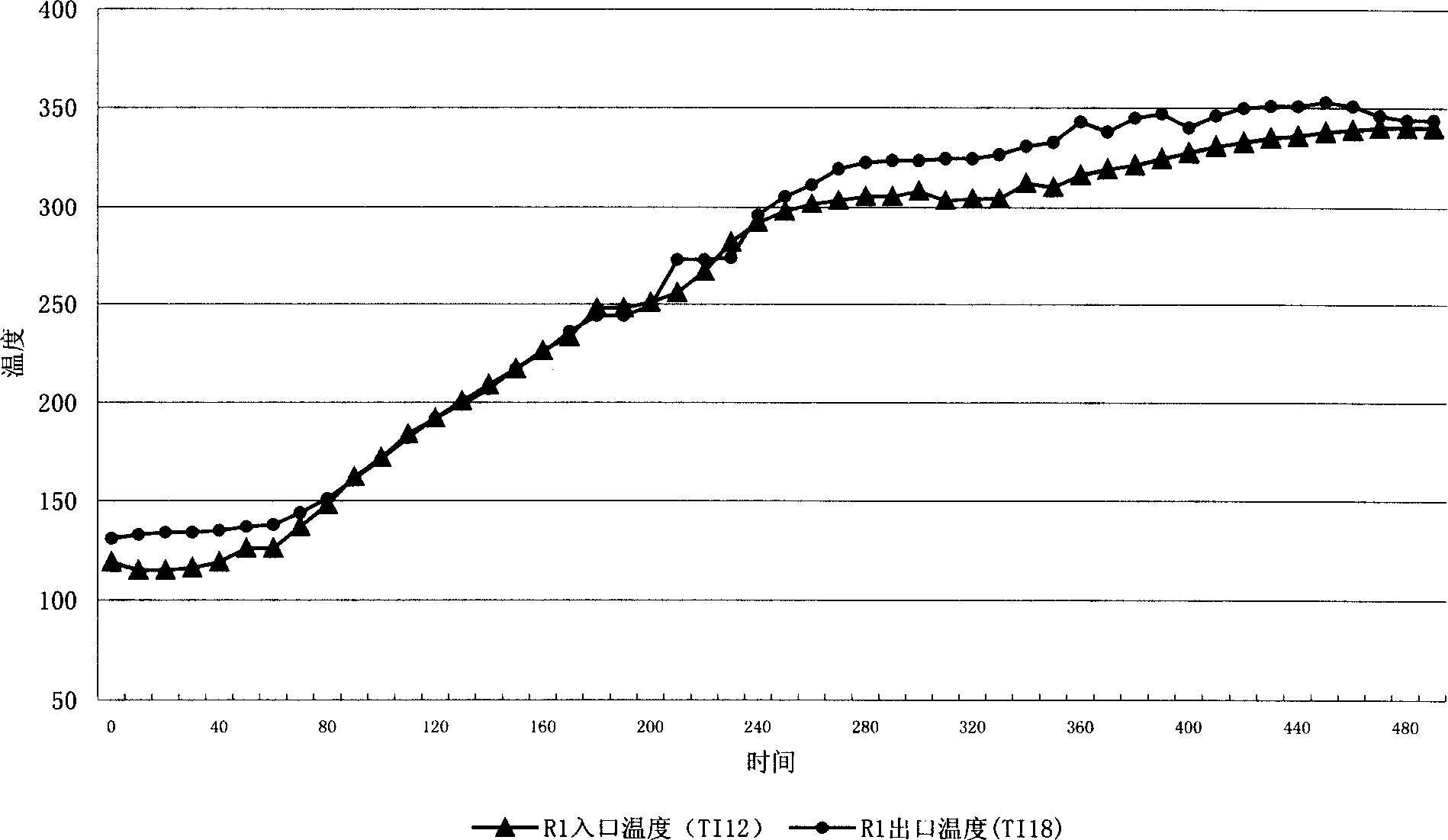

Processing method before using hydrogenation catalyst

ActiveCN101417246AEasy to useIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventWater vapor

The invention relates to a processing method before the application of hydrogenation catalyst, comprising the detailed process as follows: organic solvent, elemental sulfur and water are introduced in oxidated hydrogenation catalyst; subsequently, heating predisposal is carried out under a certain condition. The processing method before the application of the hydrogenation catalyst loads the sulfur-contained substance such as the elemental sulfur to the hydrogenation catalyst; a certain interaction is generated and little heat is discharged; and the water vapor which is generated during the heat disposal process of the added water adjusts the interaction of the sulfur and the catalyst and reduces the heat discharging degree during the heat disposal process. Compared with the prior art, the catalyst obtained by the method has the advantages of high utilization ratio of the sulfur-contained matter, gradual increment of the temperature of the catalyst bed and high activity of the catalyst when the activation is applied. The method can be used for processing before the application of various hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for circularly and rapidly pre-vulcanizing sulfur tolerant shift catalyst and carrying out segmental pre-vulcanizing by utilizing sulfur tolerant shift catalyst

ActiveCN103657741AThe vulcanization method is simpleHeating up fastCatalyst activation/preparationSocial benefitsVulcanization

The invention relates to a segmental pre-vulcanizing method of a sulfur tolerant shift catalyst in a multi-segment conversion process, particularly relates to a method for rapidly pre-vulcanizing cobalt-molybdenum-series sulfur tolerant shift catalysts and belongs to the technical field of pretreatment of the sulfur tolerant shift catalyst. According to the method, aiming at the situations of the temperature raising and the slow vulcanizing speed caused due to insufficient vulcanizing conditions, a segmental vulcanizing method is utilized, namely the rapid pre-vulcanizing of a first-segment furnace is reinforced to raise the temperature of a subsequent second-segment furnace; first-segment vulcanizing conditions are reinforced to guarantee the vulcanization of the catalyst so as to realize the rapid, efficient and complete vulcanization, meanwhile, the temperature of a subsequent second-segment bed is raised by high-temperature vulcanized gas in a rapid vulcanizing process, and the subsequent working segments are similarly processed, so that the vulcanizing and temperature raising time is greatly shortened, and the vulcanizing cost is lowered; by utilizing a circular vulcanizing manner, the emptying quantity is few, the overtemperature is avoided, the vulcanizing process is convenient and safe, the pollution is light, and the method has remarkable economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

Degradable highly-elastic sponge and preparation technology thereof

The invention relates to degradable highly-elastic sponge and a preparation technology thereof. The degradable highly-elastic sponge and the preparation technology thereof have the advantages that thedegradable highly-elastic sponge is made of green, natural and healthy materials according to the environment-friendly preparation technology, harmless to human bodies and capable of avoiding resource waste and environment pollution, and its mechanical properties including rebound resilience and compression set value are in compliance with the international standards; through adoption of recyclable pineapple fibers, resource waste is reduced and physical properties of low-density sponge with natural latex matrixes are improved to comply with the international standards; sodium alcohol ether sulphate and sodium lauryl sulfate which serve as foaming agents substitute for traditional pollutional ones to further avoid pollution; the high-performance low-density sponge with the excellent mechanical properties can be produced at a low preparation cost; the preparation technology is safe, simple and environment friendly.

Owner:德清舒华泡沫座椅有限公司

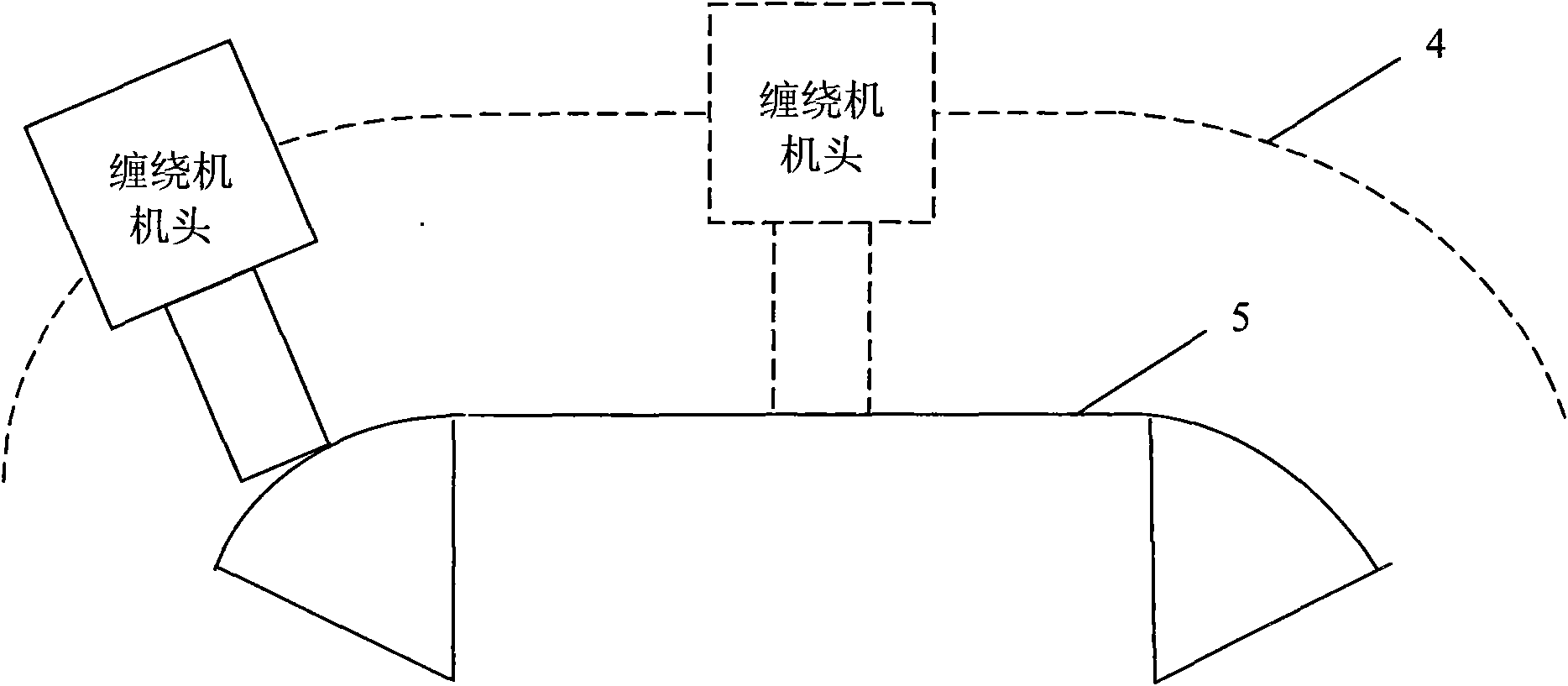

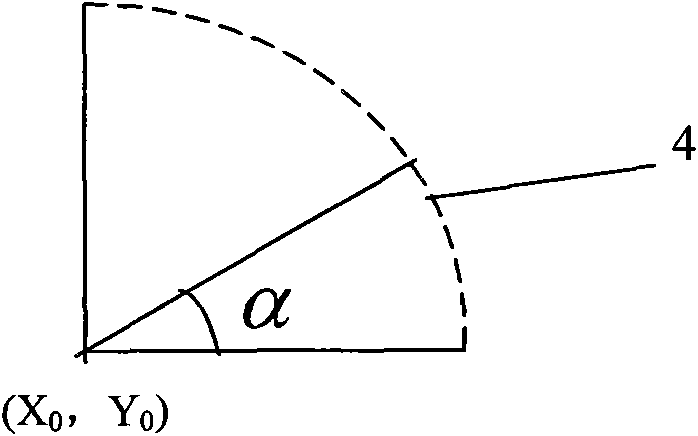

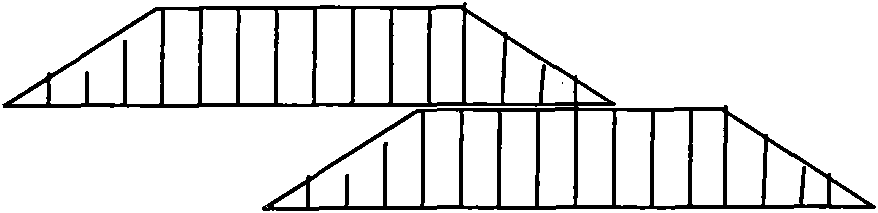

Controlling method for wrapping surface of tire

InactiveCN101625557AGood smoothnessImprove vulcanization effectProgramme control in sequence/logic controllersLine segmentEngineering

The invention provides a controlling method for wrapping the surface of a tire, comprising the following steps: an industrial personal computer (IPC) analog simulates the deformation of rubber pieces in the process of spire piling and the arrangement distribution situation of the each rubber piece in the surface of the tire to obtain spire pitches among each rubber piece; the IPC computes the virtual circle central coordinate and the radius of a wrapper at each loop of the arc of the surface of the tire, and sends a date to a PLC; the IPC respectively computes the arc of the each loop of the arc section of the surface of the tire, the horizontal coordinate of the each loop of the linear section of the surface of the tire and a corresponding theoretical velocity, to form a data table to be sent to the PLC; the PLC computes the real velocity of the wrapper according to the received data table; and the PLC computes to obtain a track coordinate data of the wrapper corresponding at the each loop and finally controls the wrapper to wrap the surface of the tire. The method realizes analog simulation in the process of wrapping the surface of the tire, adjusts the walk track and the walk velocity of the head of the wrapper immediately, and greatly improves the wrapping quality of the surface of the tire.

Owner:柳州市华工百川橡塑科技有限公司

Powder rubber preparation method

InactiveCN104788752AImprove hydrophilicityImprove vulcanization performanceComposite materialActive agent

The invention discloses a powder rubber preparation method, and relates to the technical field of rubber preparation. The powder rubber preparation method comprises three process steps of performing ball milling, stirring and performing spray-drying. According to the method disclosed by the invention, the hydrophilicity of carbon black can be improved through wet ball milling processing; sodium dodecyl benzene sulfonate serving as a surfactant is favorable to the diffusion of the carbon black in natural latex; the carbon black and the natural latex are mixed and are fully stirred, so that a carbon black / natural latex suspension in a stable state is favorably prepared; under similar conditions, compared with mechanically mixed rubber material, the curability of the powder rubber prepared by the spray-drying method is greatly improved, the peak value of the torque of a vulcanization curve is improved by about one time, the scorch time in rubber preparation can be effectively shortened, and the preparation process is simple.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

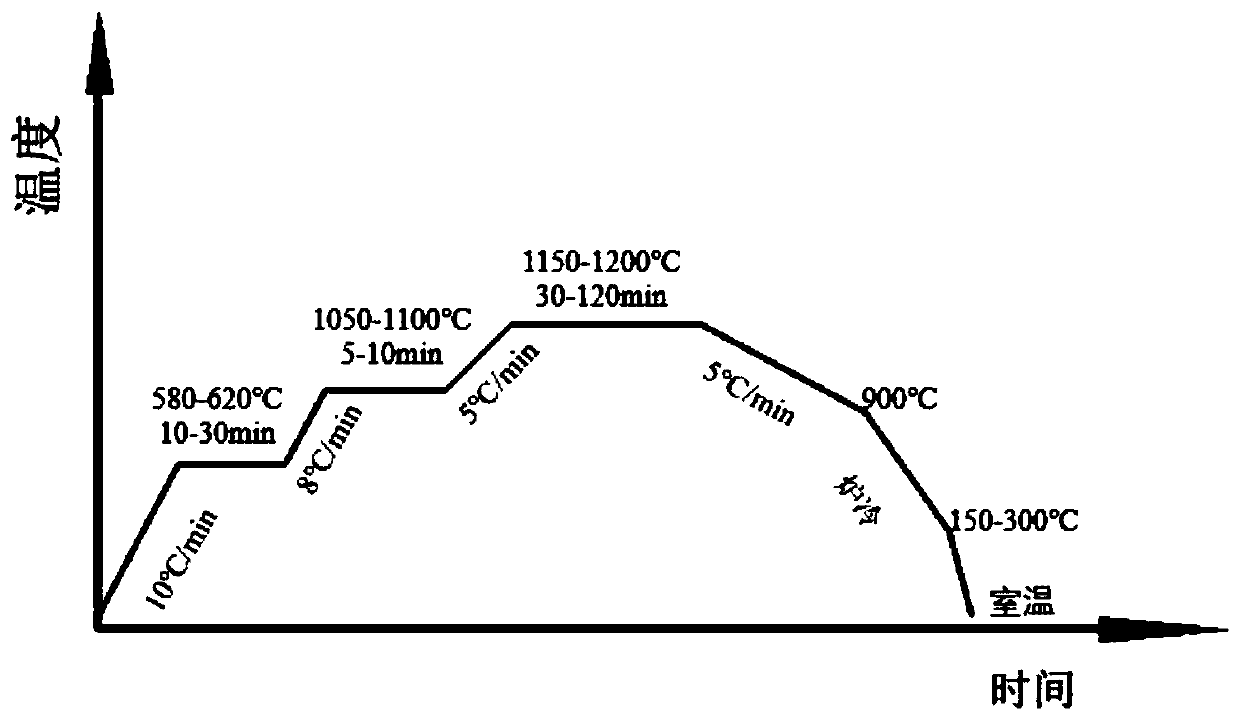

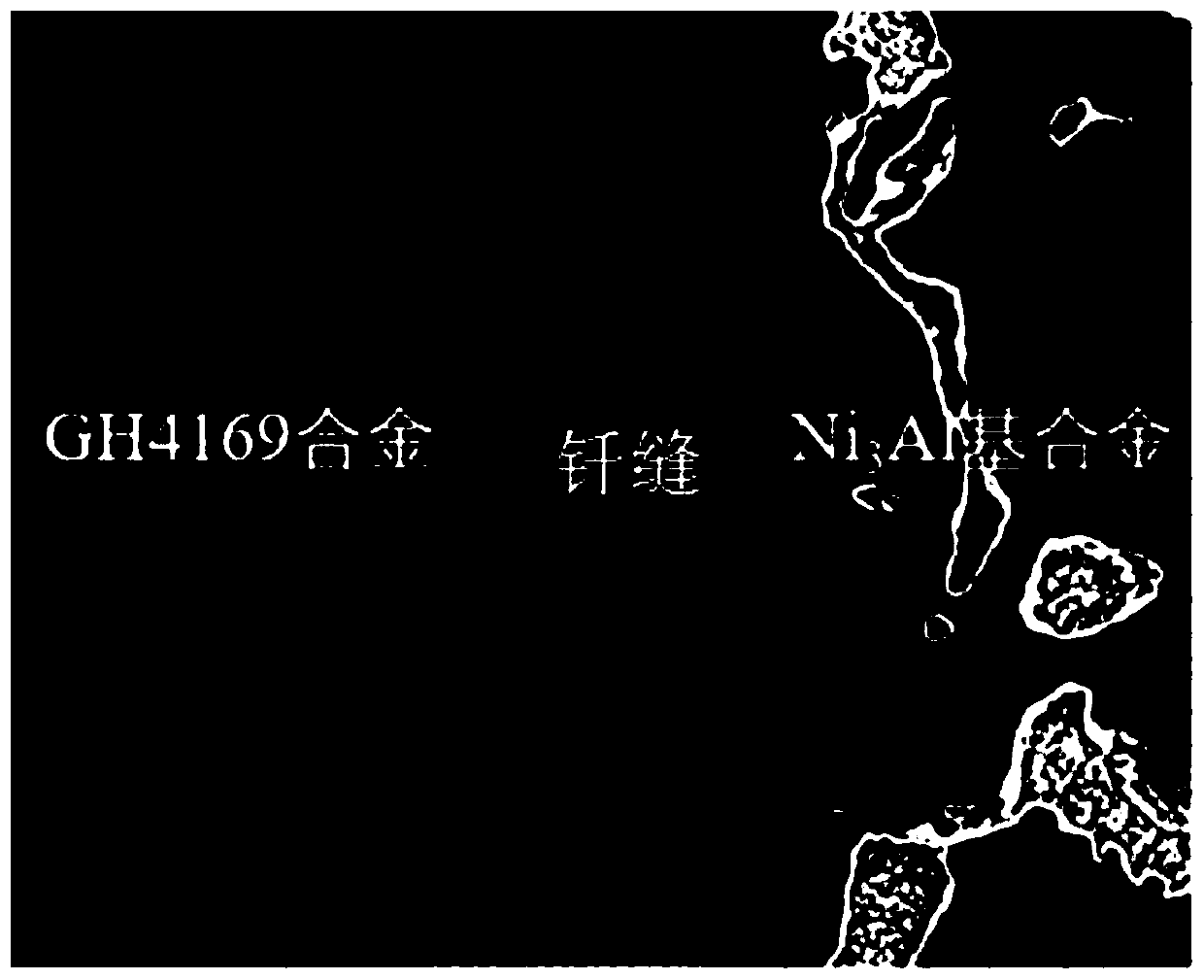

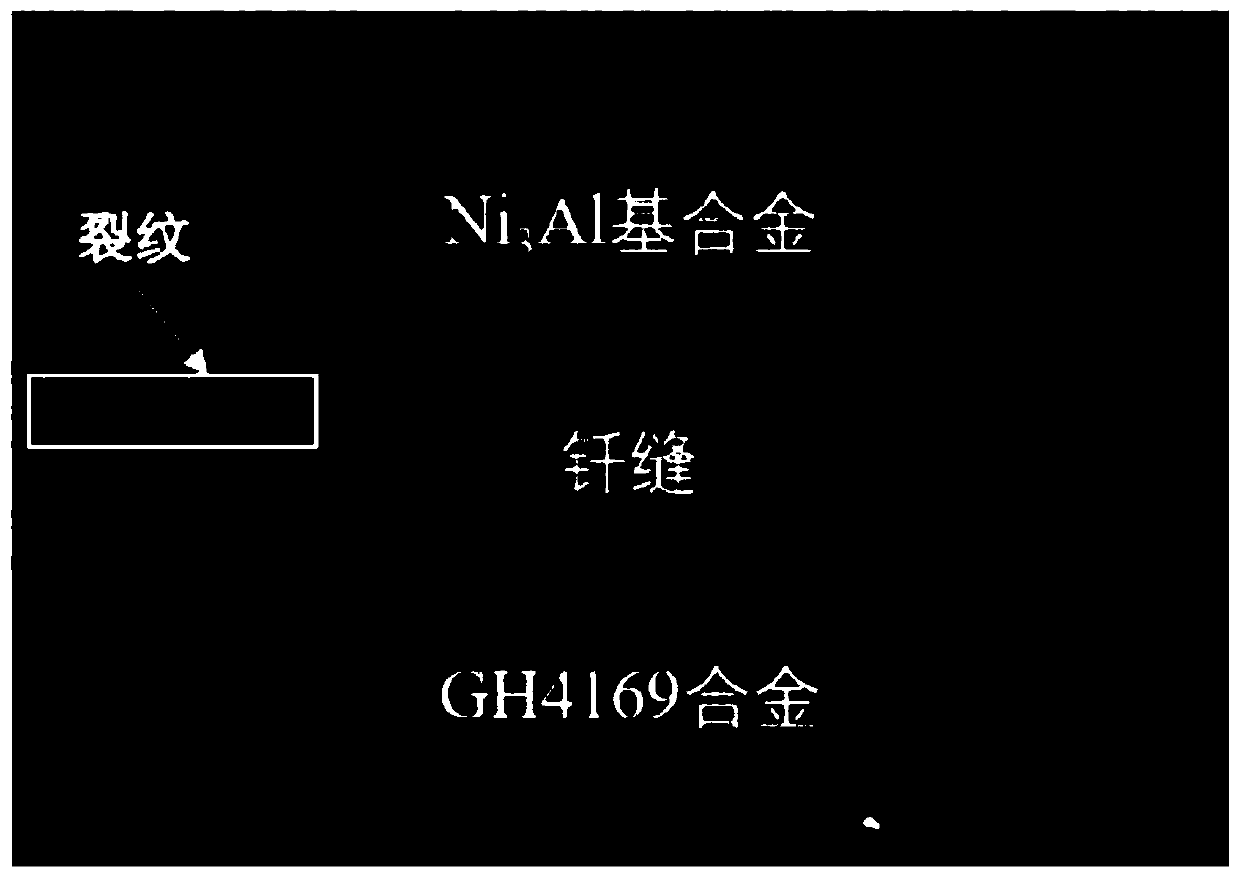

Deformed nickel-based alloy and brazing process of cast Ni3Al-based alloy

ActiveCN110394522AReduce manufacturing costLow equipment requirementsSoldering auxillary devicesTemperature resistanceTube furnace

The invention relates to a deformed nickel-based alloy and a brazing process of a cast Ni3Al-based alloy. The process comprises the following steps of carrying out surface treatment on a to-be-weldedpart of a to-be-welded base material; a nickel-based brazing filler metal, a brazing flux and a gel binding agent are mixed into paste, the paste-shaped brazing filler metal is laid on the surface ofthe to-be-welded base material, the other to-be-welded base material is stacked on the brazing filler metal to obtain the lap-jointed brazing sample; placing the lap-jointed brazing sample in a clampand putting in a tube furnace; after the brazing assembly is placed in a tube furnace, introducing protective gas, then heating to 1150 -1200 DEG c in a segmented manner; performing segmented coolingafter welding, cooling to room temperature; placing the welded sample which is cooled to room temperature in a box furnace under atmospheric conditions for treatment, wherein the heat preservation temperature is 600-650 DEG c, the time is 2-4 hours, and then taking out after cooling to room temperature along with the furnace. According to the process, the oxidation of the Ni-Cr-Al-based cast Ni3Al-based high-temperature alloy can be avoided, the base material is not damaged, the components of the joint are uniform, the high-temperature resistance of the welded joint is improved, and the residual stress is reduced.

Owner:HEBEI UNIV OF TECH

Method for preparing nano magnetic ferrite particle and magnetic damping rubber thereof

InactiveCN101186761AImprove mechanical propertiesImprove magnetic propertiesPigment treatment with macromolecular organic compoundsActivator 1Polymer science

The invention relates to magnetic shock-absorption rubber and nanophase magnetic ferrite particles, specifically a process for preparing the nanophase magnetic ferrite particles and magnetic shock-absorption rubber prepared by using the nanophase magnetic ferrite particles. The invention is used for resolving the problems that the existing magnetic particles can not meet the physically mechanical property and magnetic shock-absorption effect of magnetic shock-absorption rubber and materials of the existing magnetic shock-absorption rubber are not properly selected and matched. 1.4-5.11g FeCl3, 6H2O, 1.75-6g FeSO4, 7H2O and 0.00025 mol polyethylene glycol with molecular weight of 400-10000 are added into 560ml distilled water, and further sodium hydroxide solution is added into the mixture, thereby nanophase magnetic ferrite particles which has certain shape and is coated by polyethylene glycol is achieved. The magnetic shock-absorption rubber is composed of components with percentage by weight of plantation rubber 15-60%, ethylene-propylene-diene monomer 15-60%, nanophase magnetic ferrite particles 5-50%, vulcanized agent 1-10%, vulcanizing activator 1-10%, vulcanization accelerator 1-10%, aging inhibitor 0.1-5% and reinforcing agent 10-40%.

Owner:ZHONGBEI UNIV

Hydrocarbon hydroprocessing technique

ActiveCN101148607AImprove performanceImprove vulcanization effectRefining to eliminate hetero atomsAmount of substanceOrganic solvent

The present invention relates to hydrocarbon hydrotreating process including the steps of loading catalyst into the reactor, activating, reaction, etc. The hydrotreating catalyst contains thiram matter in 0.5-25 wt% of the catalyst, simple substance sulfur in the amount of 30-150 % of the theoretical sulfur demand of the catalyst, and organic solvent in 0.1-50 wt% of the catalyst. The hydrotreating catalyst with the common action of thiram matter, sulfur and organic solvent has high sulfur holding rate in activation, less concentrated heat release, lowered temperature rise in the catalyst bed and high activity. It may be applied in various kinds of hydrocarbon hydrotreating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

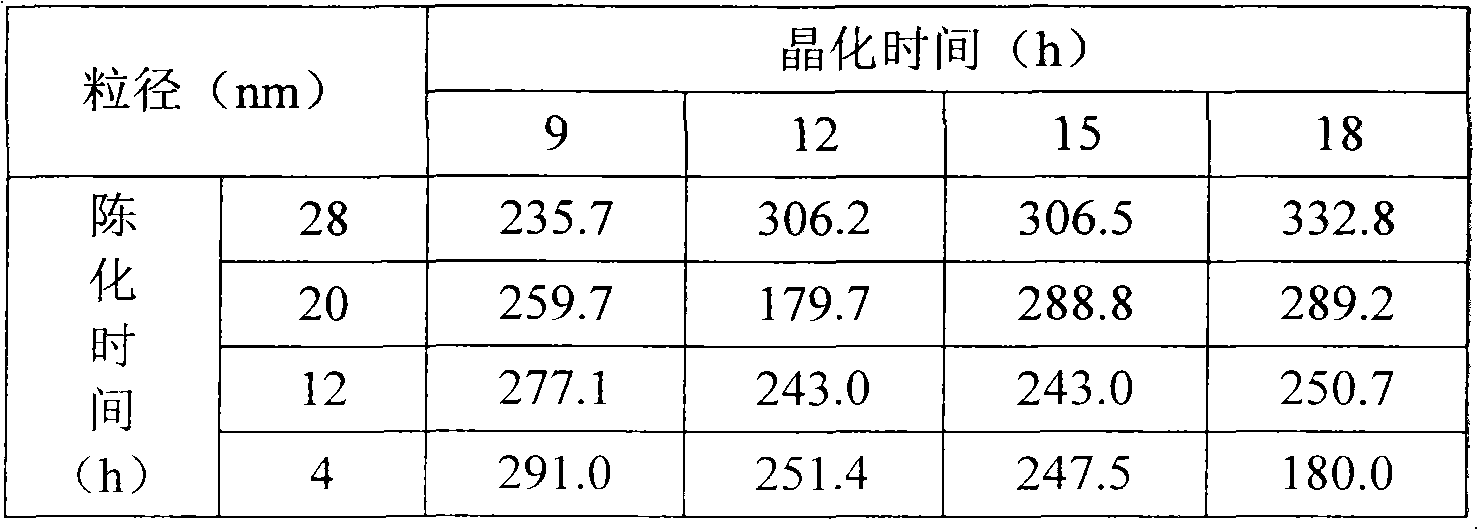

Preparation method of high-medium oil selective hydrocracking catalyst

InactiveCN101844085ASolve reunionSolve filterabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveActive component

The invention relates to a preparation method of a high-medium oil selective hydrocracking catalyst. The invention firstly provides a preparation method of a Y-molecular sieve / Si-Al oxide composite catalytic material, comprising the steps of: synthesizing a Y-molecular sieve by a guide agent method, controlling the synthesis temperature of mother solution to be below 0 DEG C, the ageing time to be 4-8h, the crystallization temperature to be 90-95 DEG C and the crystallization time to be 9-18h, and obtaining slurry formed by the Y-molecular sieve and the rest crystallization liquid; carrying out ammonium exchange treatment on the Y-molecular sieve, and obtaining the mixed solution; and adding an Al source and a Si source into the mixed solution, adjusting the pH value to be 6-10 to form gel, drying the gel, and obtaining the composite catalytic material. The invention also provides the preparation method of the high-medium oil selective hydrocracking catalyst, comprising the following steps of: preparing the Y-molecular sieve / Si-Al oxide composite catalytic material according to the method; taking the composite catalytic material as a carrier for carrying active components; and obtaining the high-medium oil selective hydrocracking catalyst by drying and calcining.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

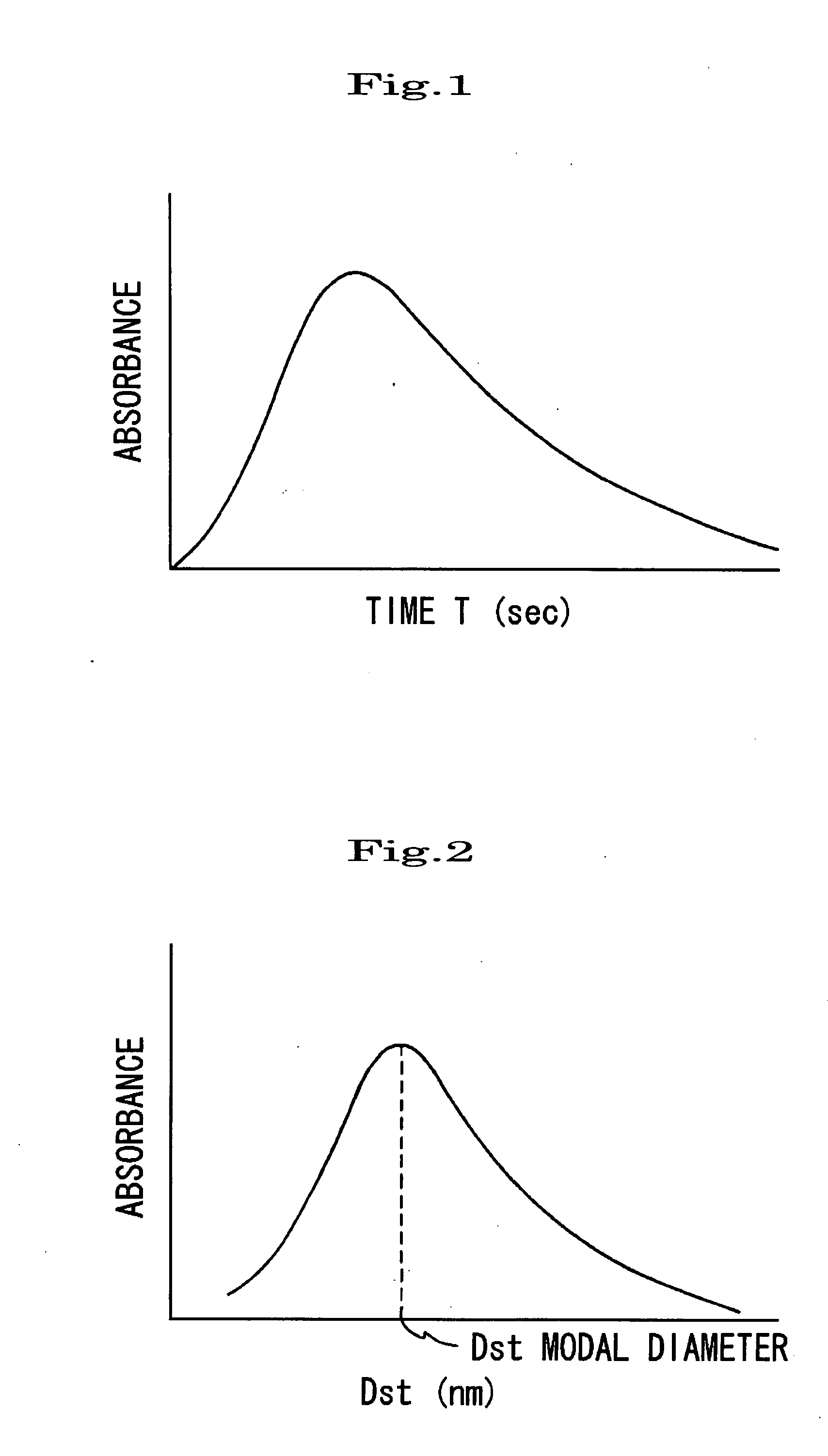

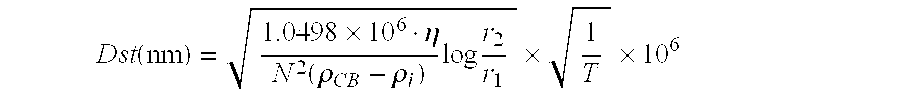

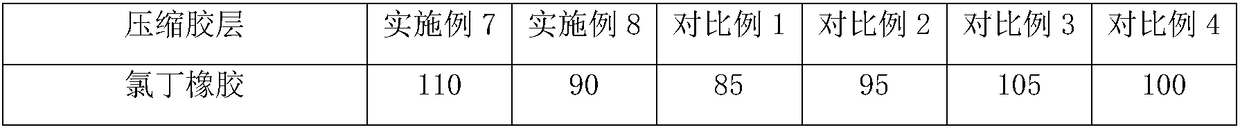

Carbon black for functional rubber component

InactiveUS20080095696A1Well-balanced mannerImprove stabilityPigmenting treatmentAlkali metal halidesPolymer scienceVulcanization

The present invention provides carbon black for a functional rubber component which can provide rubber with an excellent set resistance and a high UHF vulcanization performance by high frequency induction heating. The carbon black has a nitrogen adsorption specific surface area (N2SA) of 15 to 30 m2 / g and a DBP absorption of 100 to 135 cm3 / 100 g, and satisfies the relationship of the following formulas (1) and (2).460−10.5×N2SA≧Dst (1)2900≧H (2)wherein N2SA denotes the nitrogen adsorption specific surface area (m2 / g), Dst denotes the modal diameter (nm) of a Stokes diameter distribution of carbon black aggregates, and H denotes the hydrogen content (μg / g) per 1 g of carbon black.

Owner:TOKAI CARBON CO LTD

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

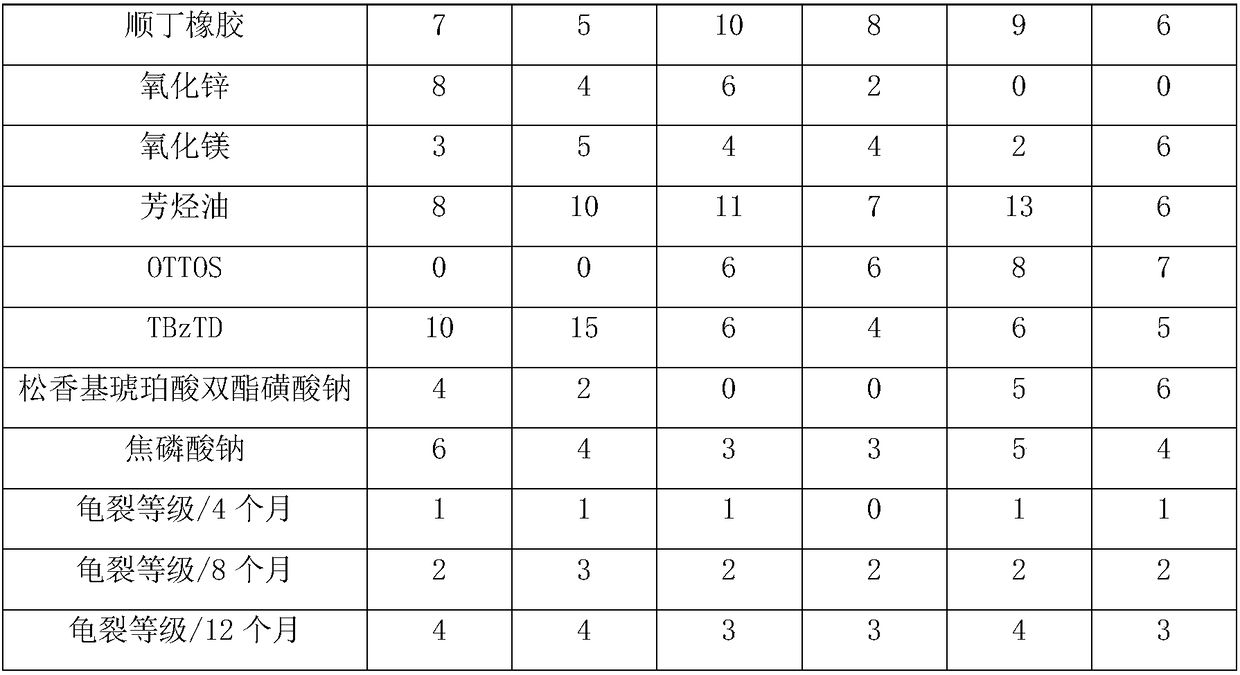

Triangle belt with high tensile strength and high weather resistance and preparation method thereof

The invention discloses a triangle belt with high tensile strength and high weather resistance and a preparation method thereof. The triangle belt comprises a strength layer, a buffer rubber layer, acompressed rubber layer and a coating cloth layer. Raw materials of the compressed rubber layer comprise the following components of chloroprene rubber, cis-polybutadiene rubber, zinc oxide, filler, aromatic oil, a vulcanizing agent and rosin-based sodium sulfosuccinate diester. The rosin-based sodium sulfosuccinate diester has dispersion and emulsification effects and can improve the compatibility and mixing uniformity of the vulcanizing agent, the chloroprene rubber and the cis-polybutadiene rubber , the vulcanizing effect of the vulcanizing agent is improved, and the weather resistance andthe tensile strength of the compressed rubber layer are improved. The zinc oxide has the property of a reinforcing agent and enables the compressed rubber layer to have good tear resistance and elasticity. The zinc oxide has the property of a vulkacit and enhances the vulcanization activity of the compressed rubber layer. The emulsification effect of the rosin-based sodium sulfosuccinate diester can improve the acting force between the zinc oxide, the chloroprene rubber and the cis-polybutadiene rubber and improve the performance enhancement effect of the zinc oxide as the reinforcing agent and the vulkacit on the compressed rubber layer.

Owner:浙江金久胶带股份有限公司

Startup presulfurization method of hydrogenation catalyst

ActiveCN103059913AConvenience and Economic PathwayEmission reductionHydrocarbon oil crackingHydrogen purityHydrogen

The invention discloses a startup presulfurization method of a hydrogenation catalyst. The method consists of: collecting the sulfur-containing effluent gas of a refinery plant, first conducting light hydrocarbon absorption to remove the light hydrocarbon with a high content of C1-C4, and enhancing the hydrogen purity and hydrogen sulfide concentration; then mixing the effluent gas with a circulating gas in a high pressure separator, and passing the gas generated in the high pressure separator through a circulating hydrogen desulfurization tower; and adjusting the operations on the desulfurization tower to control the concentration of hydrogen sulfide in circulating hydrogen, thus finishing sulfurization of the hydrogenation catalyst. The method provided in the invention can, on the one hand, cancel the consumption of a sulfurization agent, and on the other hand can perform optimization treatment on the sulfur-containing effluent gas, so that a more convenient and economical approach can be found for governance of sulfur-containing exhaust gases from refinery plants while startup sulfurization of hydrogenation equipment is completed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com