Deformed nickel-based alloy and brazing process of cast Ni3Al-based alloy

A brazing process and nickel-based alloy technology, which is applied in the manufacture of tools, metal processing equipment, welding equipment, etc., can solve problems such as high cost and complex structure, achieve low equipment requirements, improve high-temperature mechanical properties, and reduce joint brittleness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

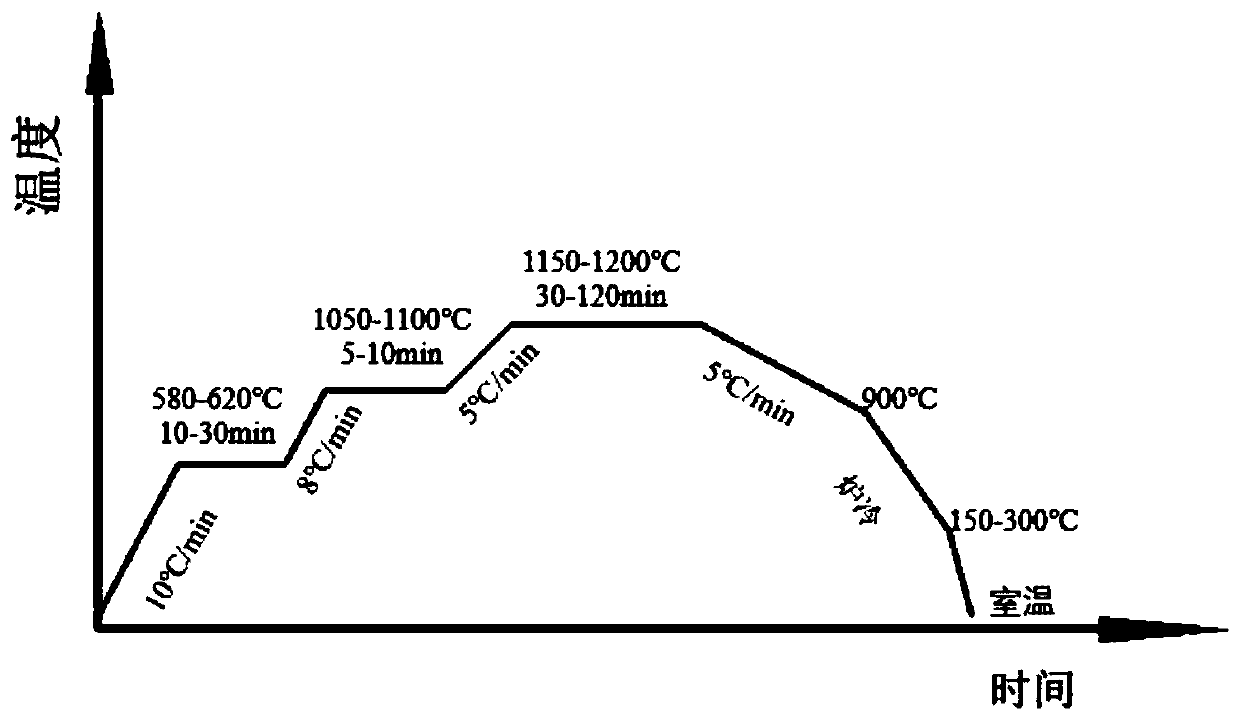

Method used

Image

Examples

Embodiment 2

[0047] The difference between this example and Example 1 is that in step 3, the temperature was raised to 1170°C at a heating rate of 5°C / min and kept for 2 hours. Others are the same as in Example 1.

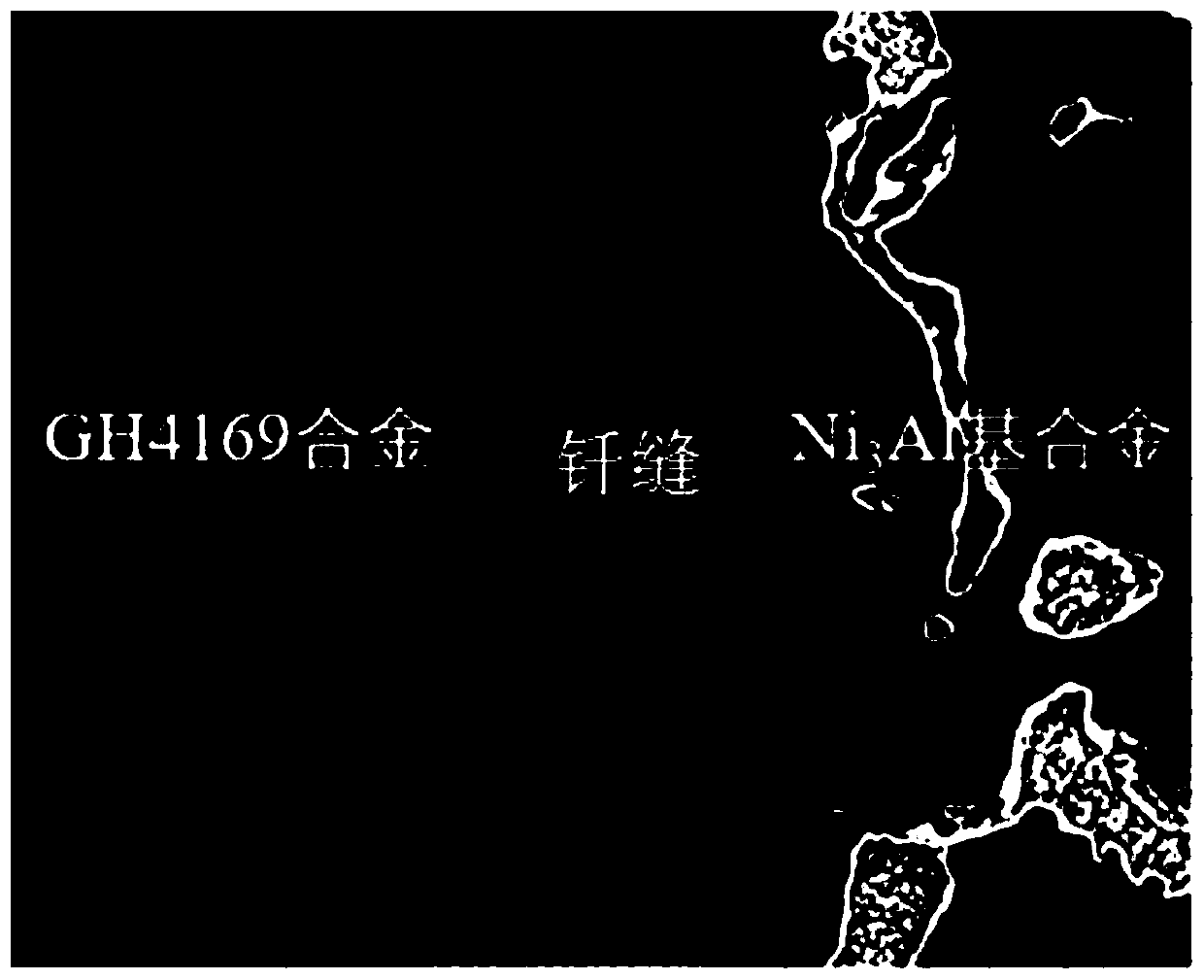

[0048] Obtain deformed nickel-based alloy GH4169 alloy and Ni-Cr-Al cast Ni 3 Al-based superalloy diffusion brazing joints, the highest shear strength is 565MPa. There is no enrichment of elements in a certain area of the welded joint and there are no cracks, pores and other defects in the weld.

Embodiment 3

[0050] The difference between this embodiment and the embodiment 1 is that in the second step, the nickel-based solder and the gel binder are mixed into a paste, that is, no flux is added, and the others are the same as the embodiment 1. The thickness of the intermediate layer alloy (brazing seam) is 50 μm.

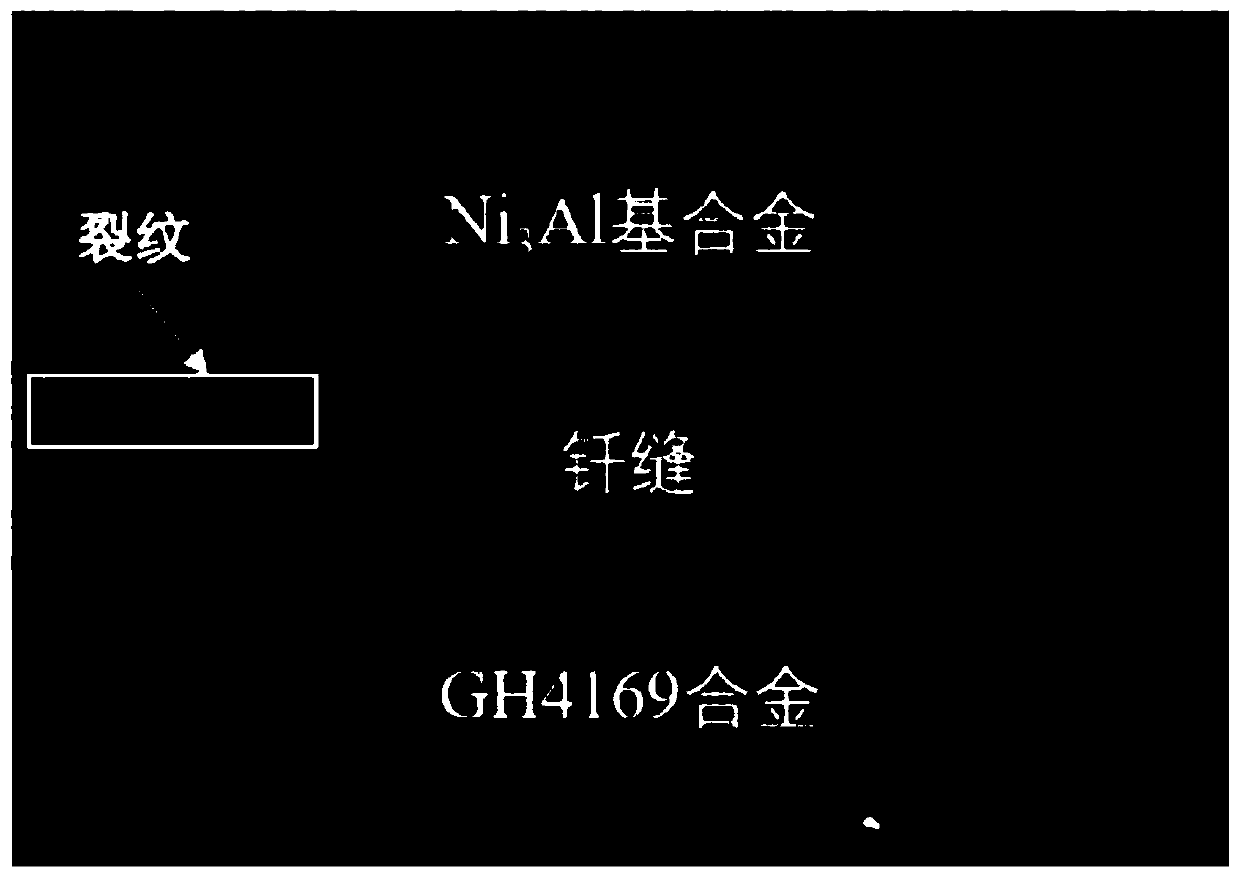

[0051] A brazed joint is obtained, and its microscopic appearance is as follows image 3 As shown, there are obvious welding defects at the welded joints, and the cracks are large and serious.

Embodiment 4

[0053] The difference between this embodiment and Example 1 is that the brazing flux is changed to the brazing flux of 201, its main component: Na 2 B 4 o 7 : 12%, CaF 2 : 10%, the remainder is B 2 o 3 , others are identical with embodiment 1.

[0054] A diffusion brazed joint is obtained, and its microscopic morphology is as follows Figure 4 As shown, the welded joint is greatly improved compared with Example 3, but still has welding defects such as pores and cracks, and the shear strength is only 226MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com