Triangle belt with high tensile strength and high weather resistance and preparation method thereof

A high tensile strength, V-belt technology, applied in the field of transmission belts, can solve problems such as poor blending performance, weak component force, poor performance improvement of V-belts, etc., to improve mixing uniformity, improve vulcanization effect, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

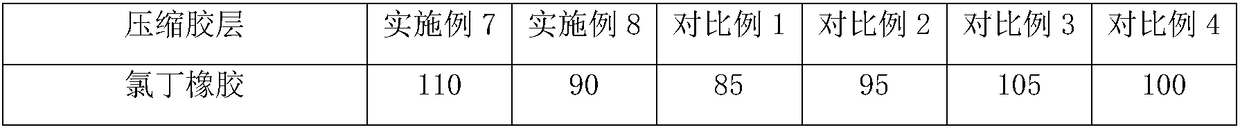

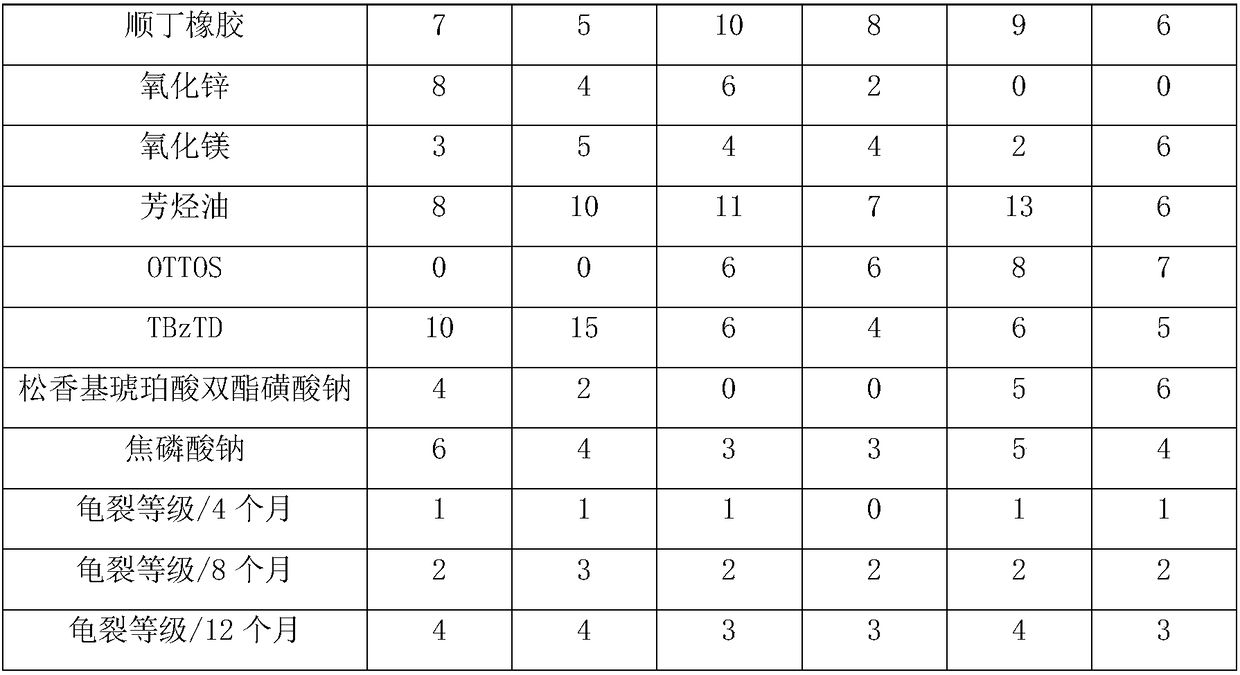

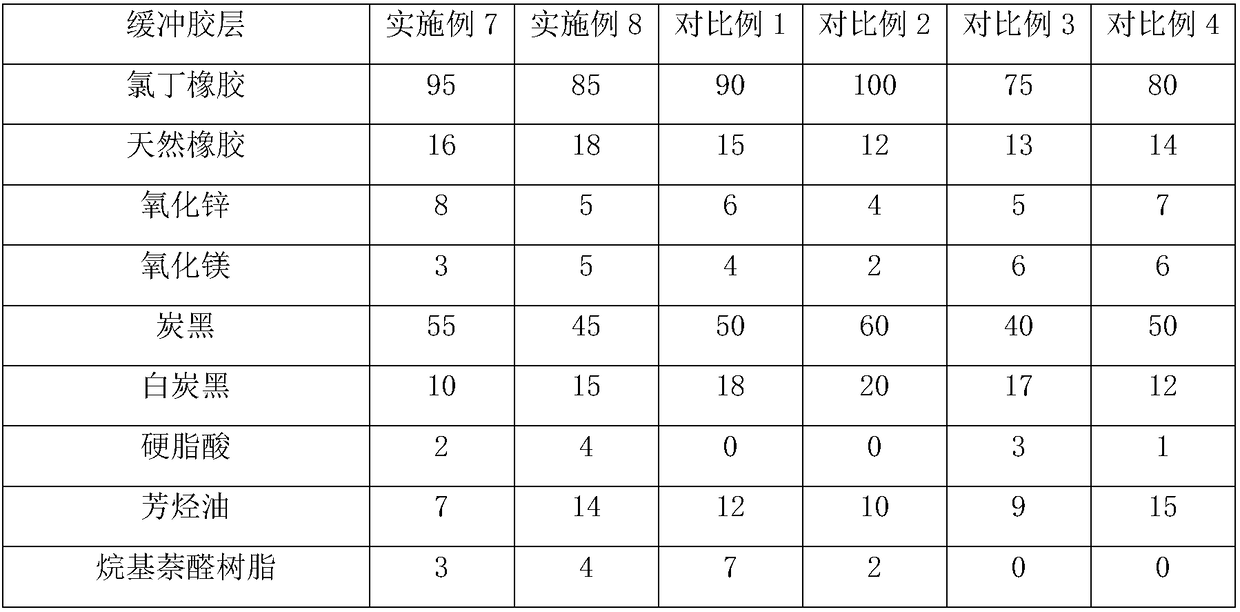

[0037] Embodiment 1: A triangular belt with high tensile strength and high weather resistance, including a strong layer, the outer side of the strong layer is wrapped with a buffer rubber layer, and the lower end surface of the buffer rubber layer is fixedly connected with a compression rubber layer, and the buffer rubber layer and the compressed rubber layer The outside of the rubber layer is wrapped with a wrapping cloth layer. The components and parts by weight in the compressed rubber layer raw materials are shown in Table 2, and the components and parts by weight in the buffer rubber layer raw materials are shown in Table 3.

[0038] The preparation method of the triangular belt with high tensile strength and high weather resistance comprises the following steps:

[0039] Step 1, adding chloroprene rubber and butadiene rubber into the plastic mixer for mastication to obtain compressed rubber matrix, put the compressed rubber matrix into the rubber mixer and add zinc oxide,...

Embodiment 2

[0044] Embodiment 2, a triangular belt with high tensile strength and high weather resistance, differs from Embodiment 1 in that the components and parts by weight in the compressed rubber layer raw material are as shown in Table 2, and the buffer rubber layer raw material Each component and parts by weight are shown in Table 3.

Embodiment 3

[0045] Embodiment 3: A triangular belt with high tensile strength and high weather resistance, including a strong layer, the outer side of the strong layer is wrapped with a buffer rubber layer, and the lower end surface of the buffer rubber layer is fixedly connected with a compression rubber layer, and the buffer rubber layer and the compressed rubber layer The outside of the rubber layer is wrapped with a wrapping cloth layer. The components and parts by weight in the compressed rubber layer raw materials are shown in Table 2, and the components and parts by weight in the buffer rubber layer raw materials are shown in Table 3.

[0046] The preparation method of the triangular belt with high tensile strength and high weather resistance comprises the following steps:

[0047] Step 1, adding chloroprene rubber and butadiene rubber into the plastic mixer for mastication to obtain compressed rubber matrix, putting the compressed rubber matrix into the rubber mixer and adding zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com