Patents

Literature

153results about How to "Improve the uniformity of the reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

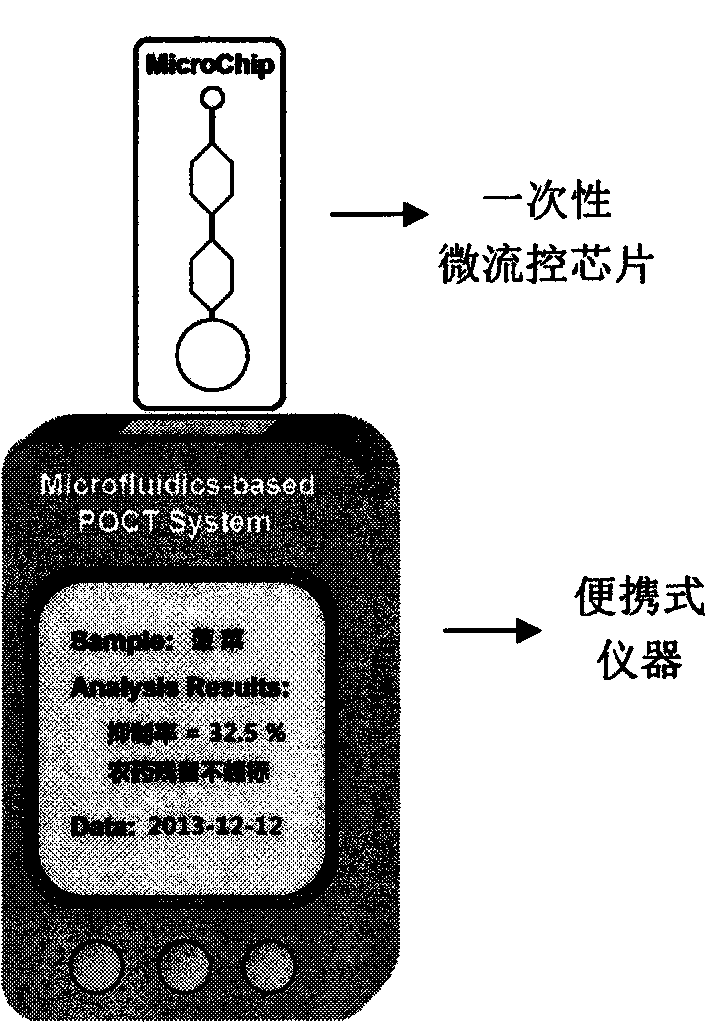

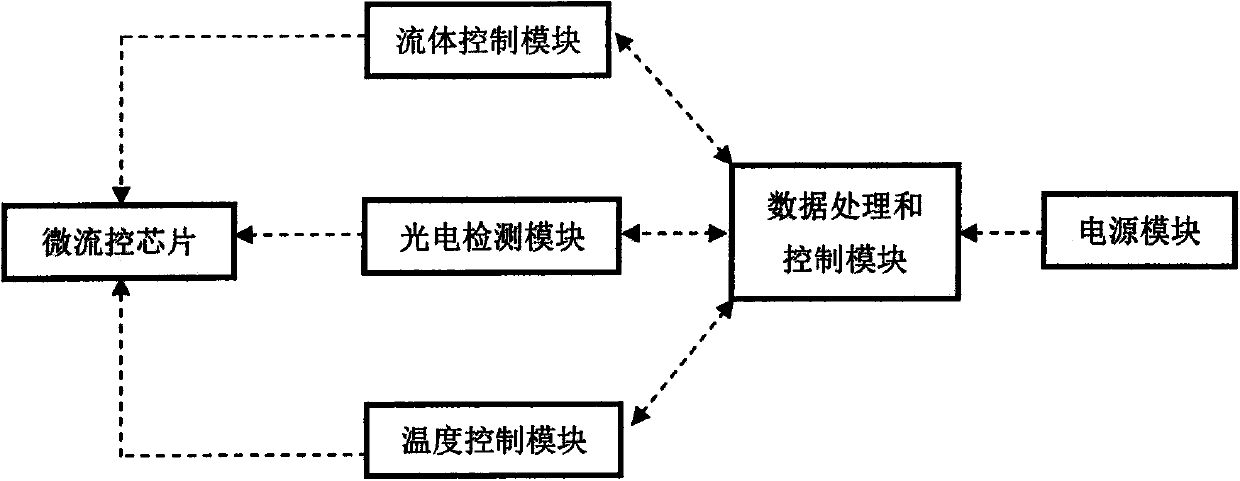

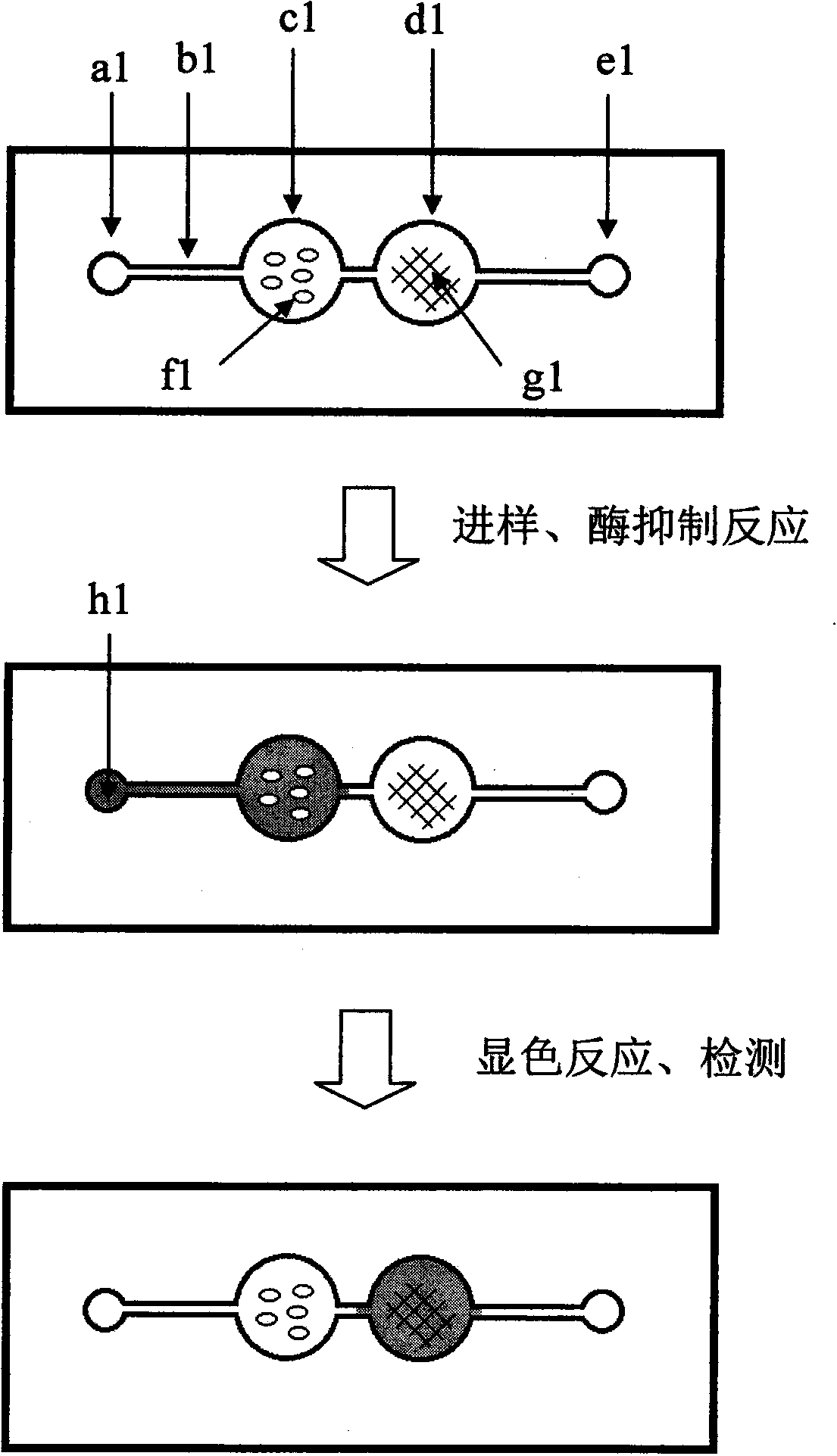

Micro-fluidic chip system and method for pesticide residue field detection

InactiveCN103808948AImprove detection portability and automationQuick checkMaterial analysisMicrofluidic chipMicro fluidic

The invention provides a micro-fluidic chip system and a micro-fluidic chip method for pesticide residue detection, wherein the micro-fluidic chip system is composed of a disposable micro-fluidic chip and a portable instrument, the micro-fluidic chip is composed of a fluid inlet / outlet, a micro channel, a reaction pool and a detection pool; a sample solution inflows from the fluid inlet and flows through the reaction pool and the detection pool along the micro channel to finish the enzyme inhibition reaction and chromomeric reaction of a solution phase, and finally the continuous detection of absorbancy is realized in a chromomeric reaction pool or the detection pool by using the portable instrument so as to obtain the pesticide residue analysis result. The micro-fluidic chip system and method for pesticide residue detection provided by the invention are especially suitable for the field, fast, automatic and accurate detection of the pesticide residue in samples such as fruit, vegetable, soil, water quality and the like.

Owner:HANGZHOU TINKER BIOTECHNOLOGY CO LTD

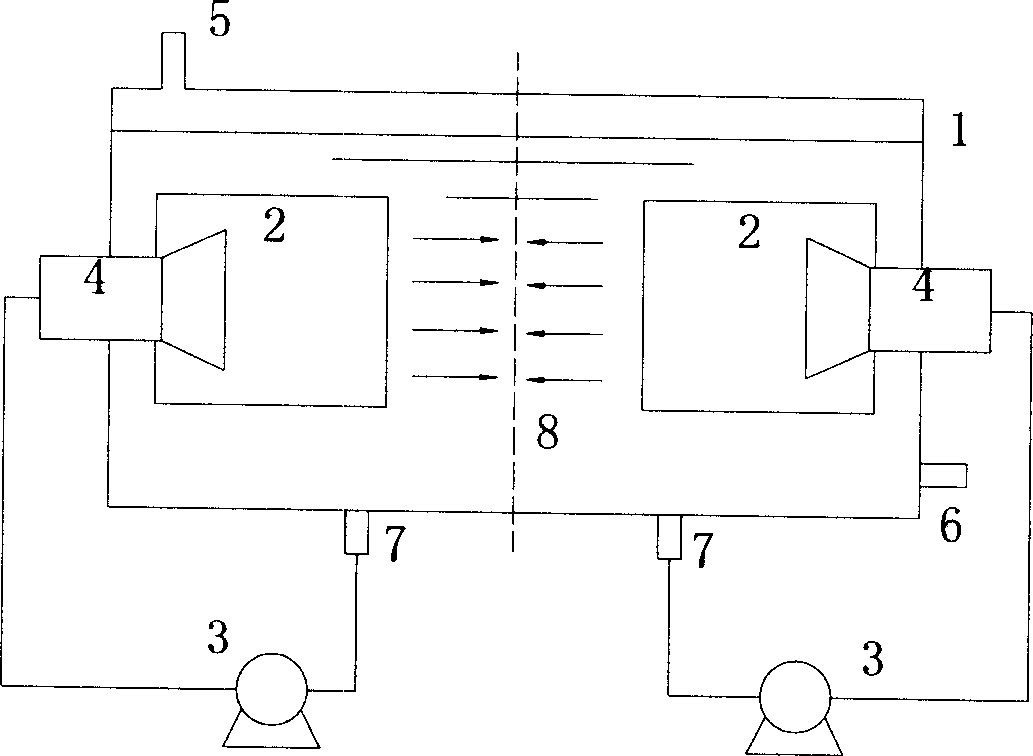

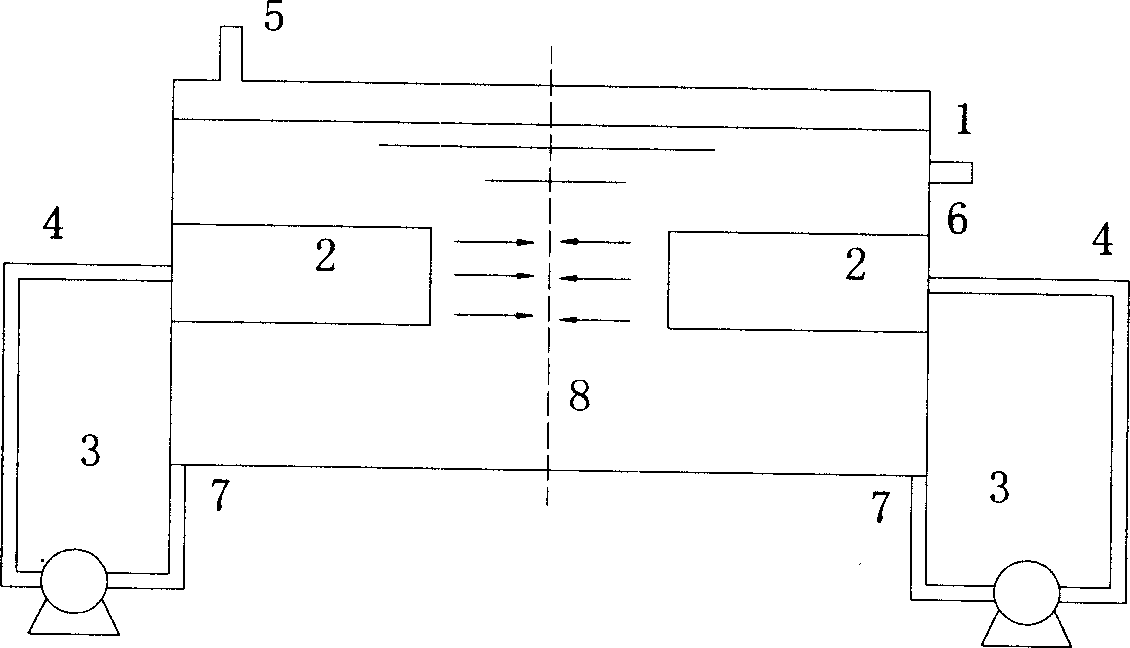

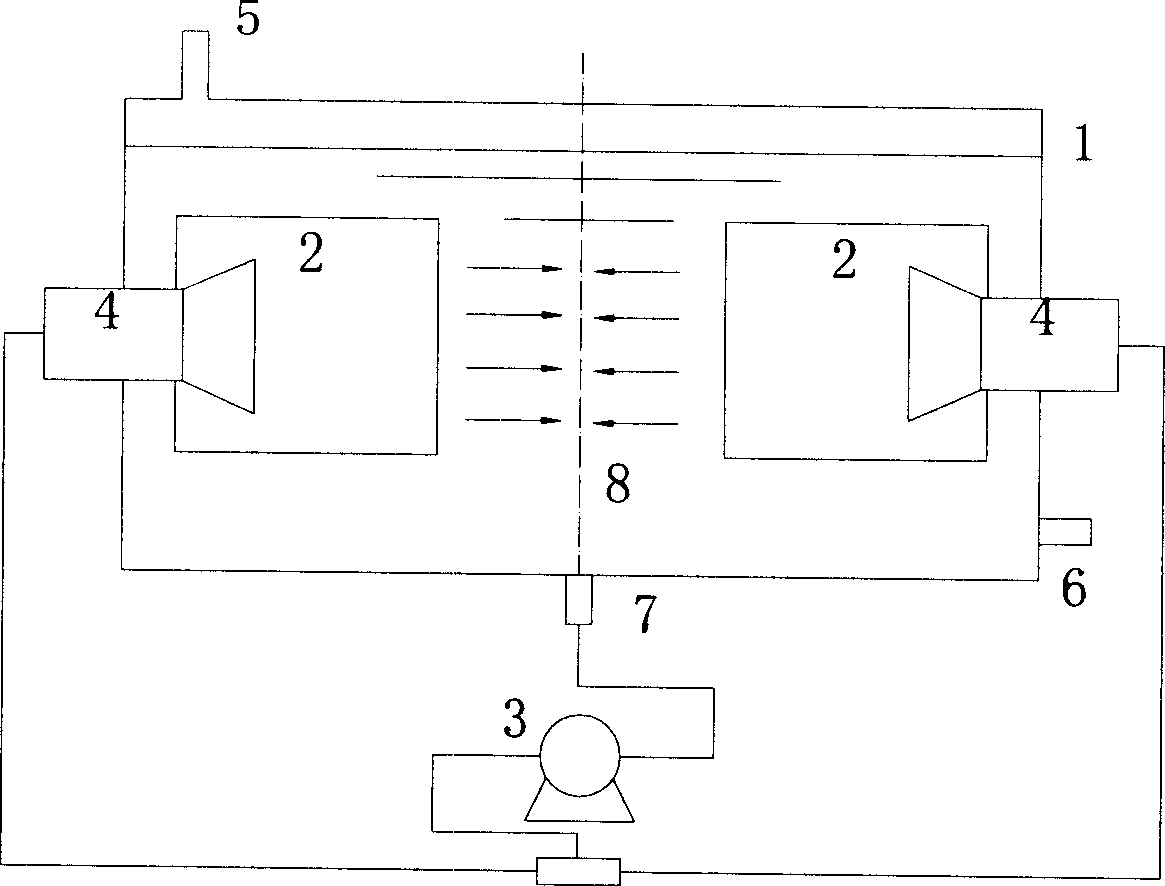

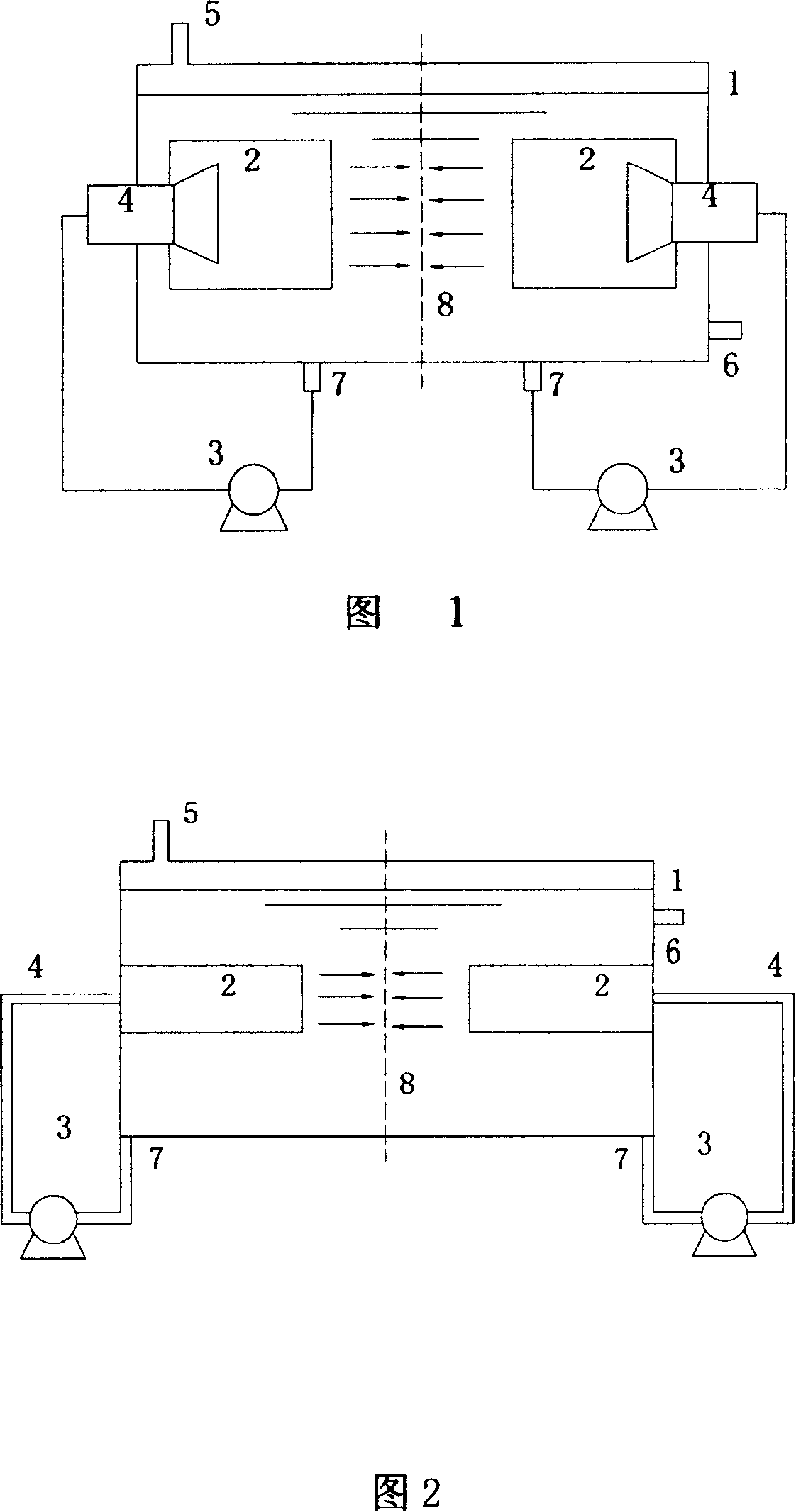

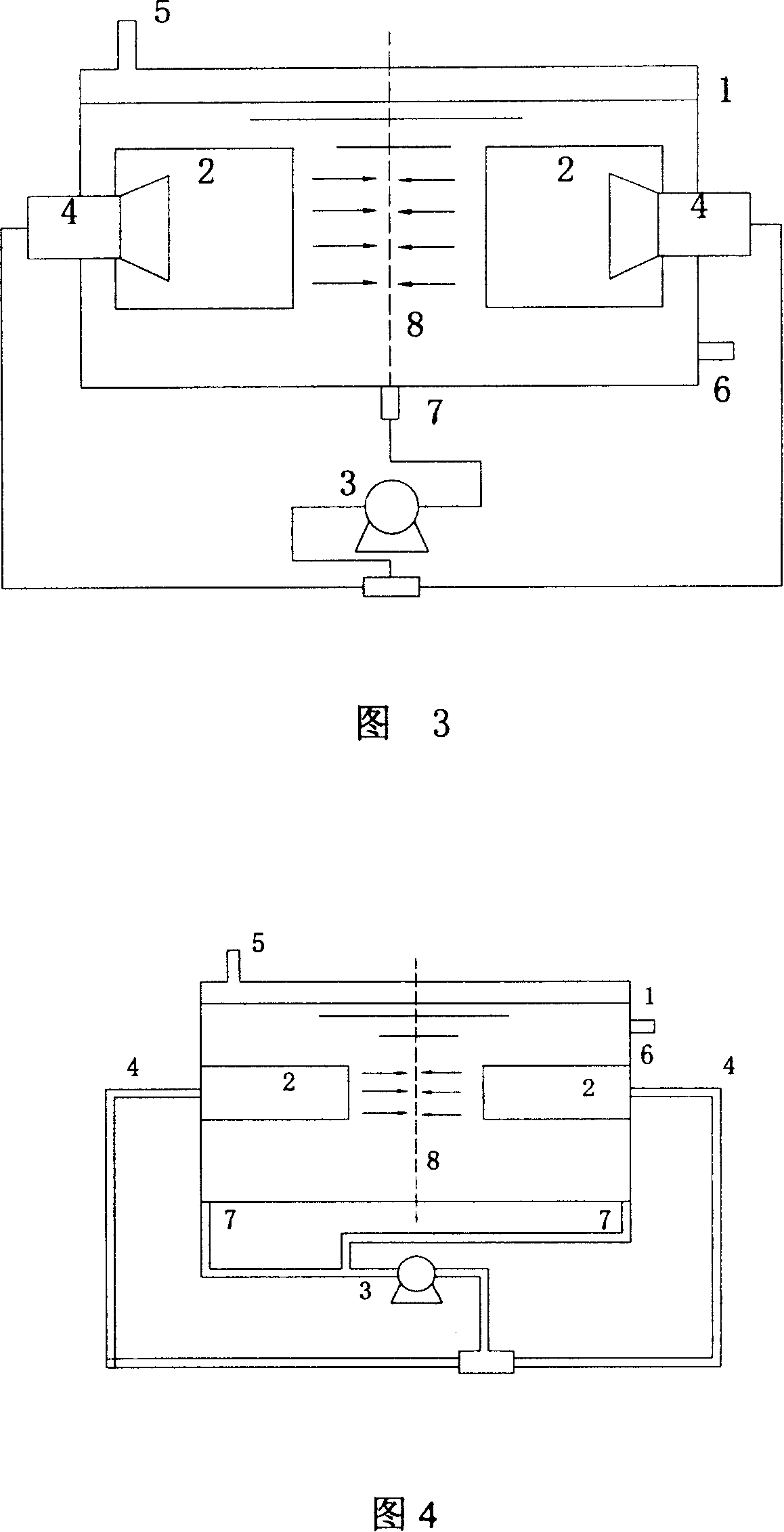

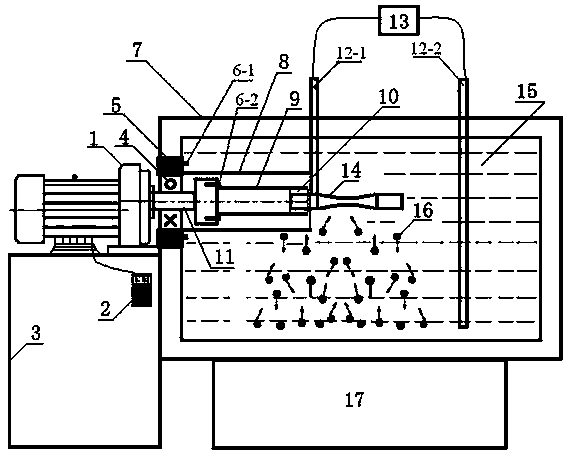

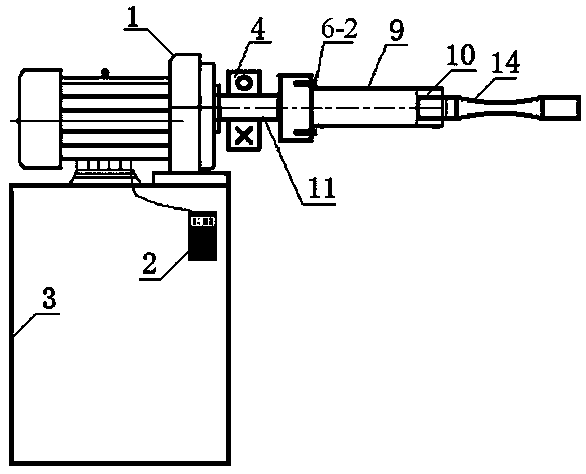

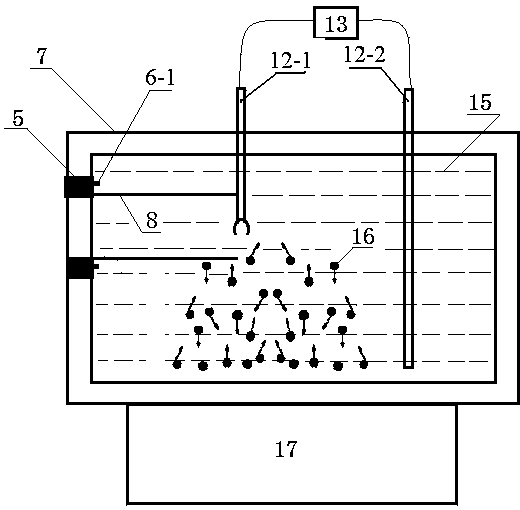

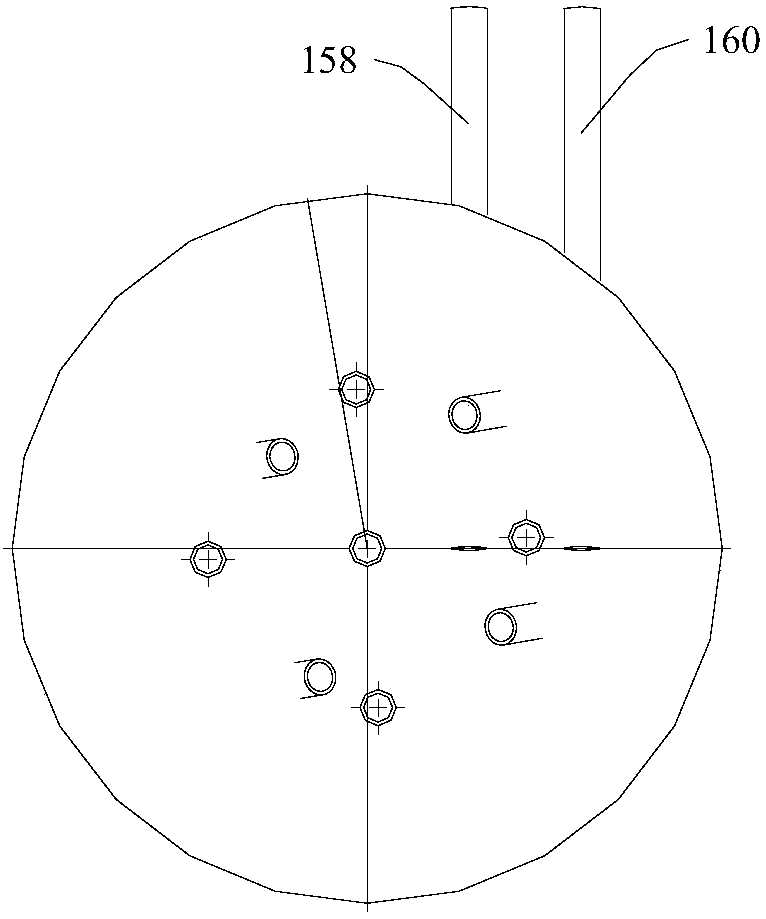

Impact flow reactor for liquid-phase reaction

ActiveCN1814344AImprove mixing uniformityImprove the uniformity of the reactionLiquid-liquid reaction processesFailure ratePropeller

This invention relates to an impact flow reactor used for liquid phase reaction. The reactor is cylindrical form, pipe or quadratic structure, two draft tubes are fixed between reactors, and one or two pumps are set out of the reactor, the exit of the pump is corresponding set at feed side of the tube. The reactant impact with each other after conveyed by materials pump and high speed flow by draft tubes, so the mixing of the reactant is availably improved. The reactor in this invention maintains the advantage of high efficiency mixing and homogeneous reaction of the existing reactor, and some disadvantages of existing reactor is avoided. Its structure plan is facilitated and cost is reduced because of the replacement of pump cycling outside of the reactor of the screw propeller type structure, and engineering problem of shake, radial sealing failure brought by the screw propeller type structure is reduced. It is easy for maintenance, and its failure rate is low, so it is propitious to reaction process of industry scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

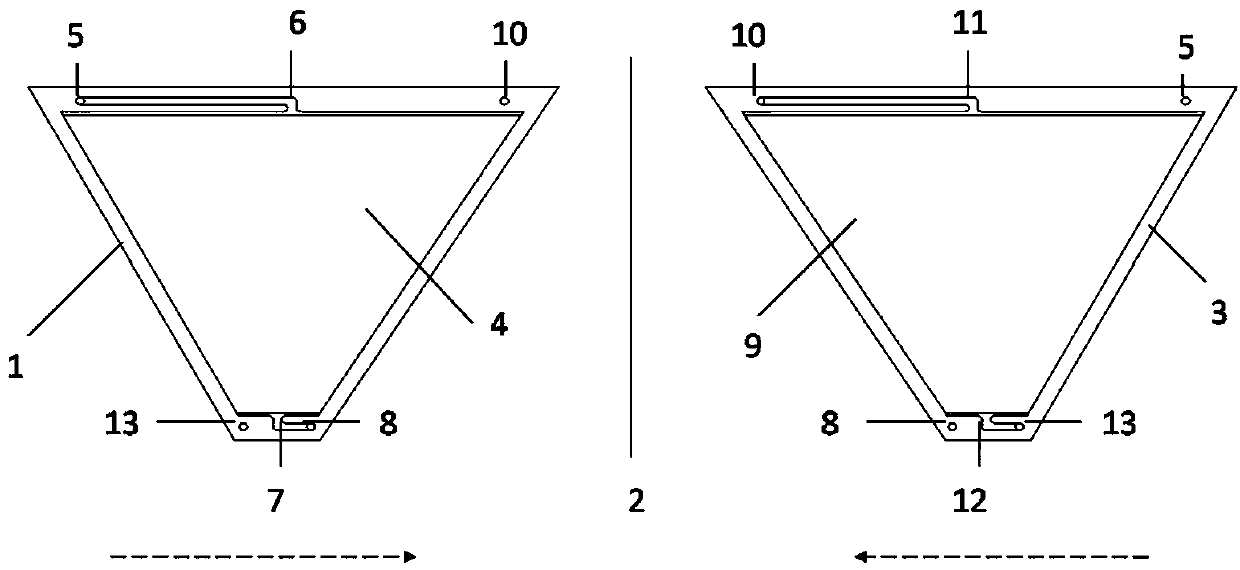

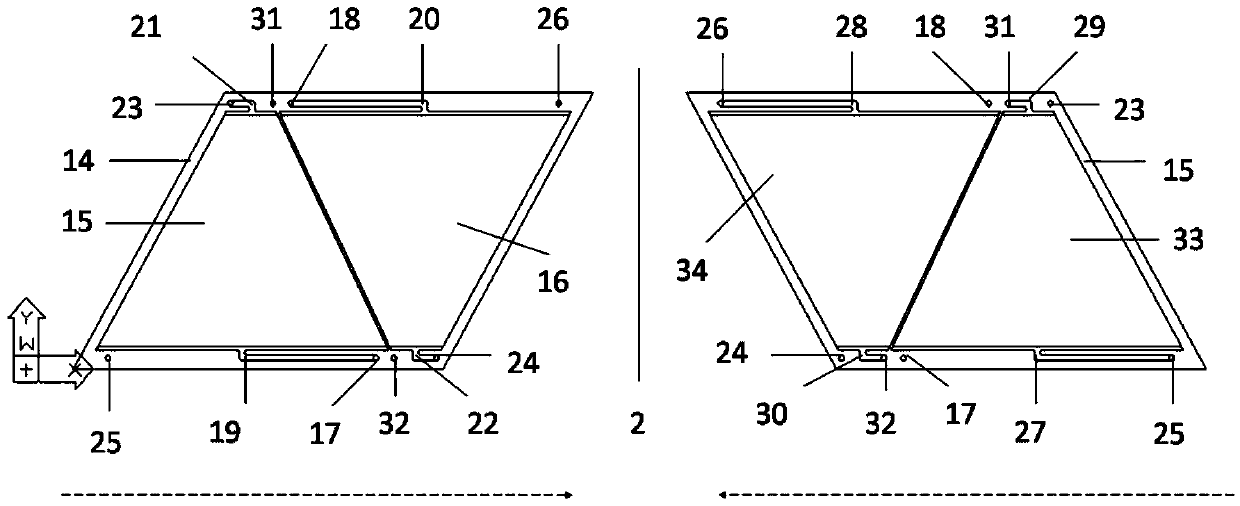

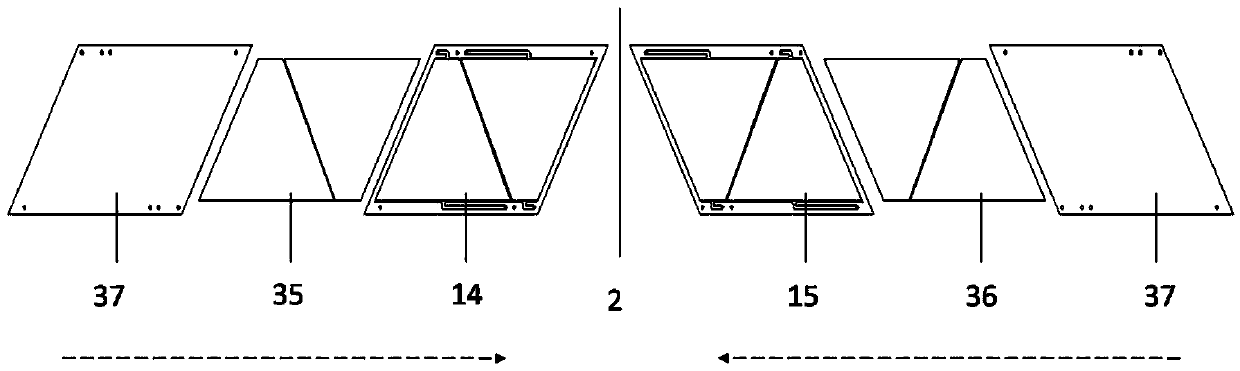

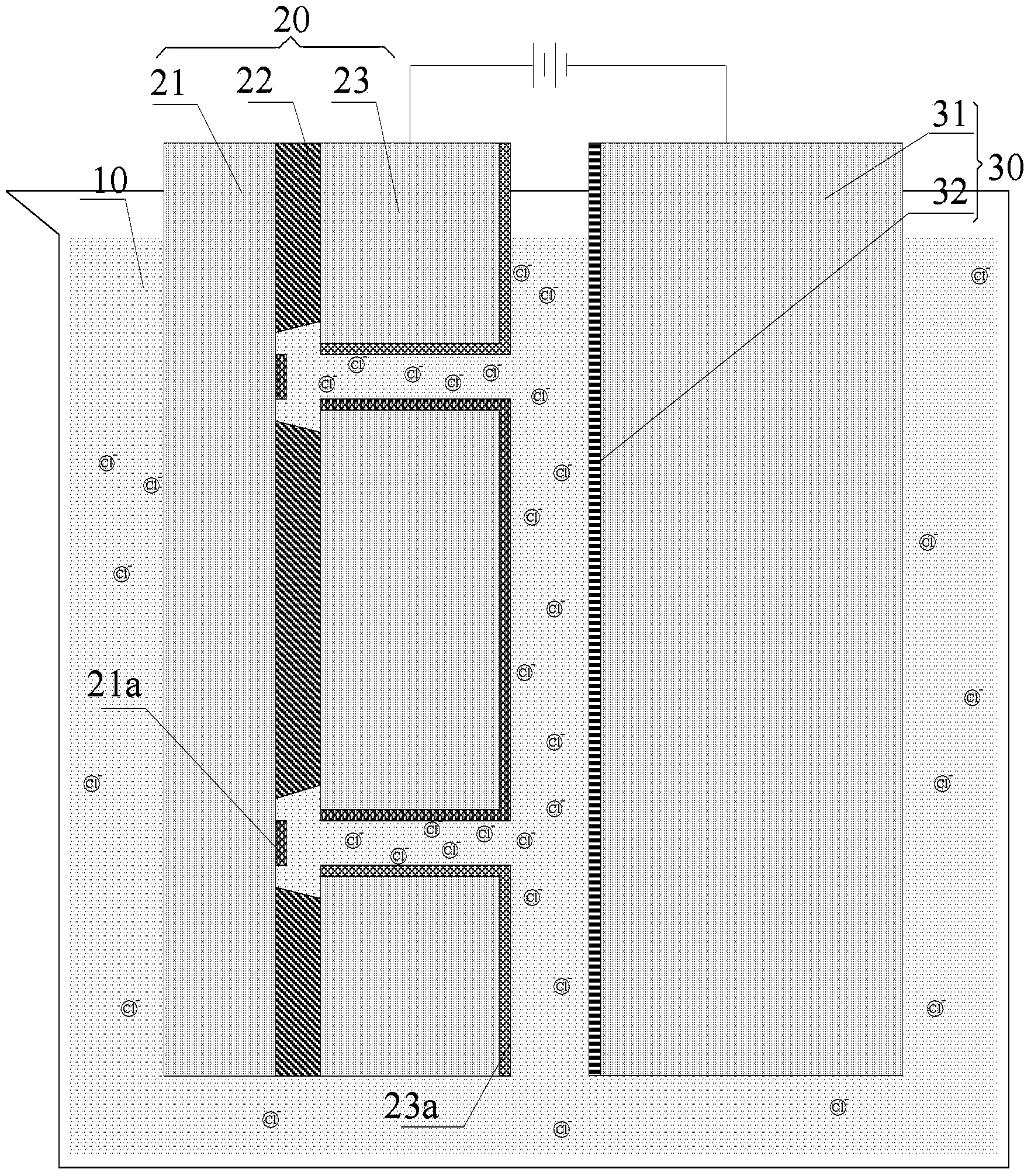

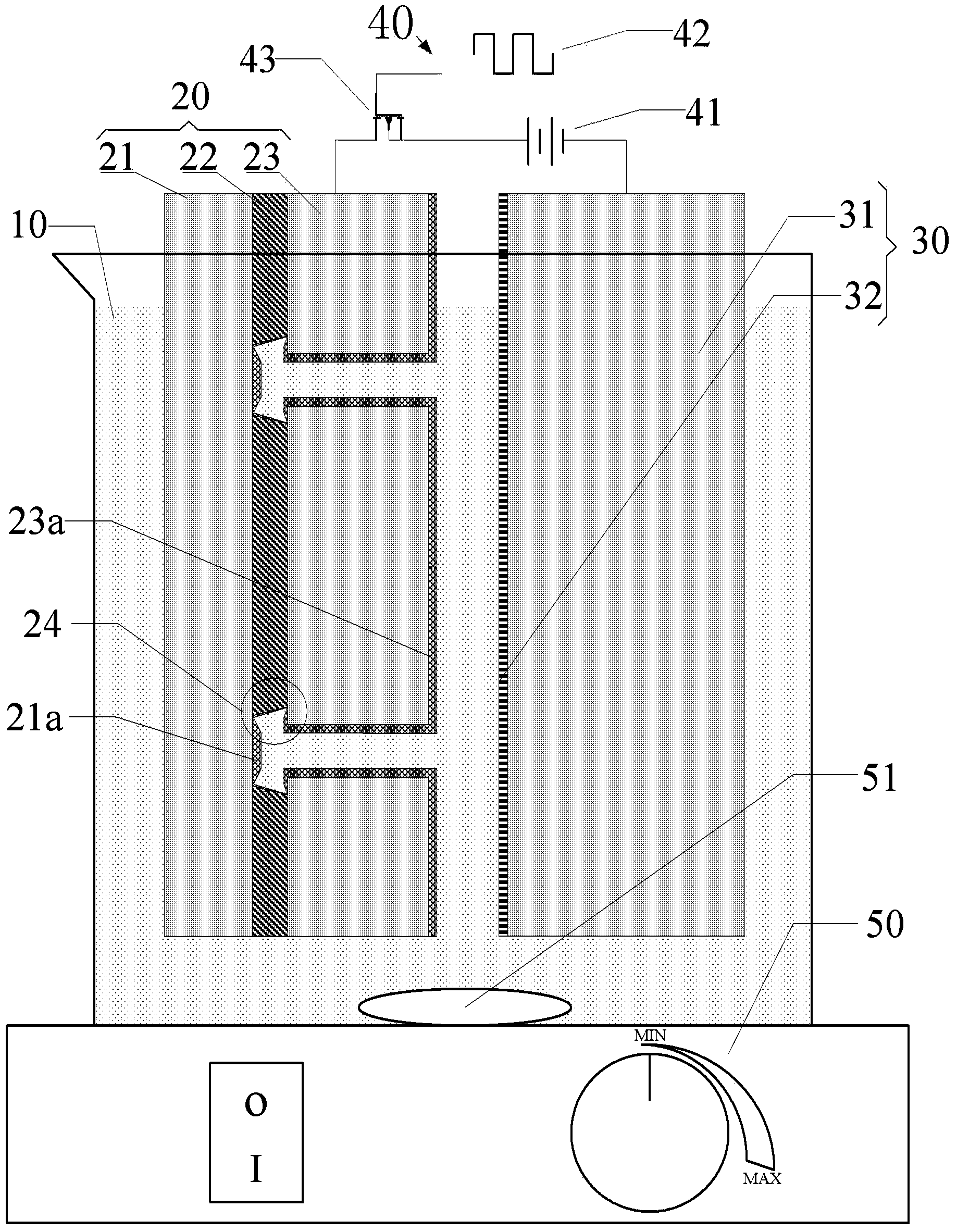

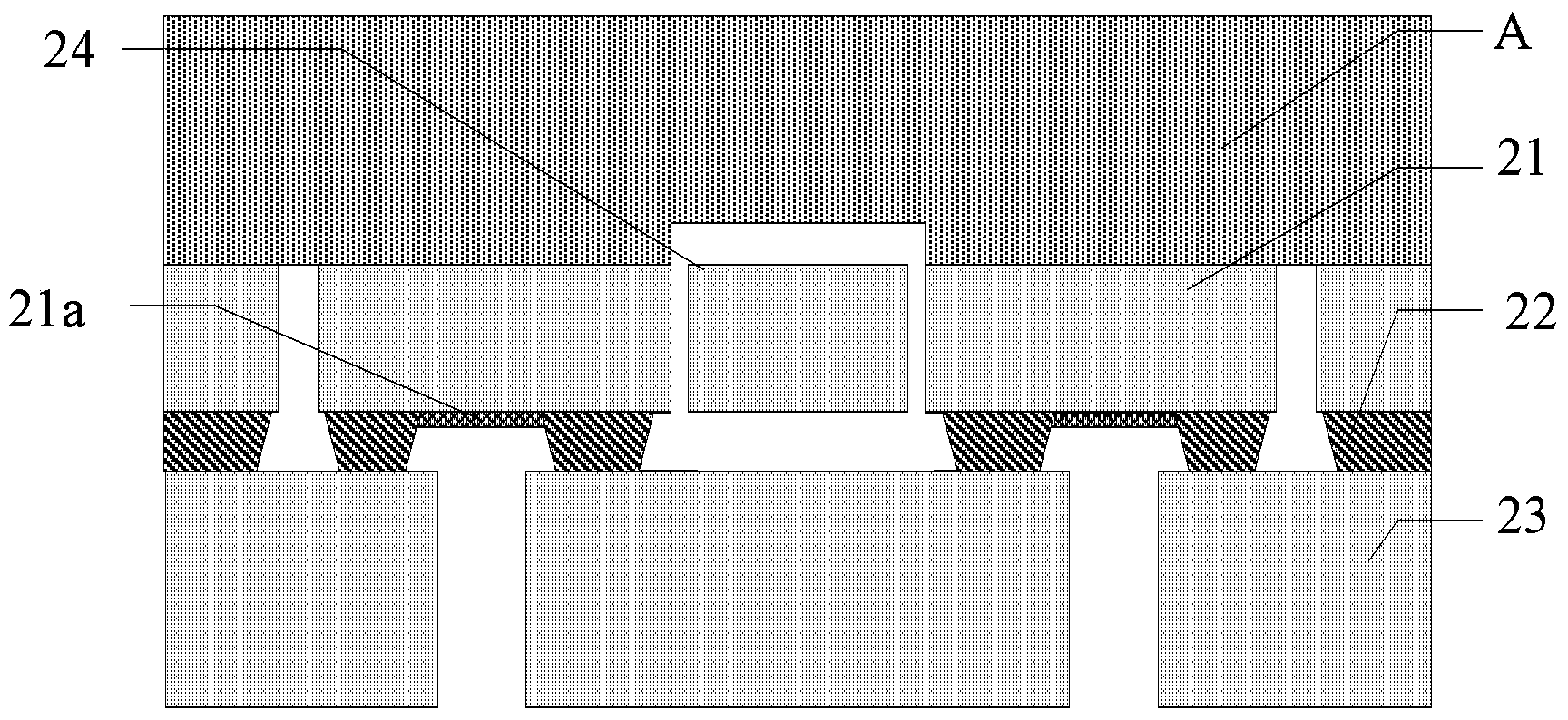

Mono-trapezoid flow battery, poly-trapezoid flow battery and electric pile thereof

ActiveCN105514459AExtend charge and discharge timeIncrease profitFuel cells groupingCell electrodesTotal efficiencyConcentration polarization

The invention provides a mono-trapezoid flow battery, a poly-trapezoid flow battery and an electric pile thereof. Both a cathode porous electrode and an anode porous electrode in the mono-trapezoid flow battery are trapezoidal plate electrodes and are respectively arranged inside a cathode electrolyte flow frame and an anode electrolyte flow frame. On the cathode electrolyte flow frame and the anode electrolyte flow frame, two electrolyte inlet flow paths are arranged nearby the lower bottom edges respectively of the cathode porous electrode and the anode porous electrode, and two electrolyte outlet flow paths are arranged nearby the upper bottom edges respectively of the cathode porous electrode and the anode porous electrode. The electrolyte flows into the cathode porous electrode through the lower bottom edges of the cathode porous electrode and the anode porous electrode and then flows out from the upper bottom edges of the cathode porous electrode and the anode porous electrode. The trapezoid flow battery is reduced in concentration polarization at certain degree and further is reduced in voltage loss, and meanwhile, is improved in utilization efficiency of the electrolyte and is increased in total efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

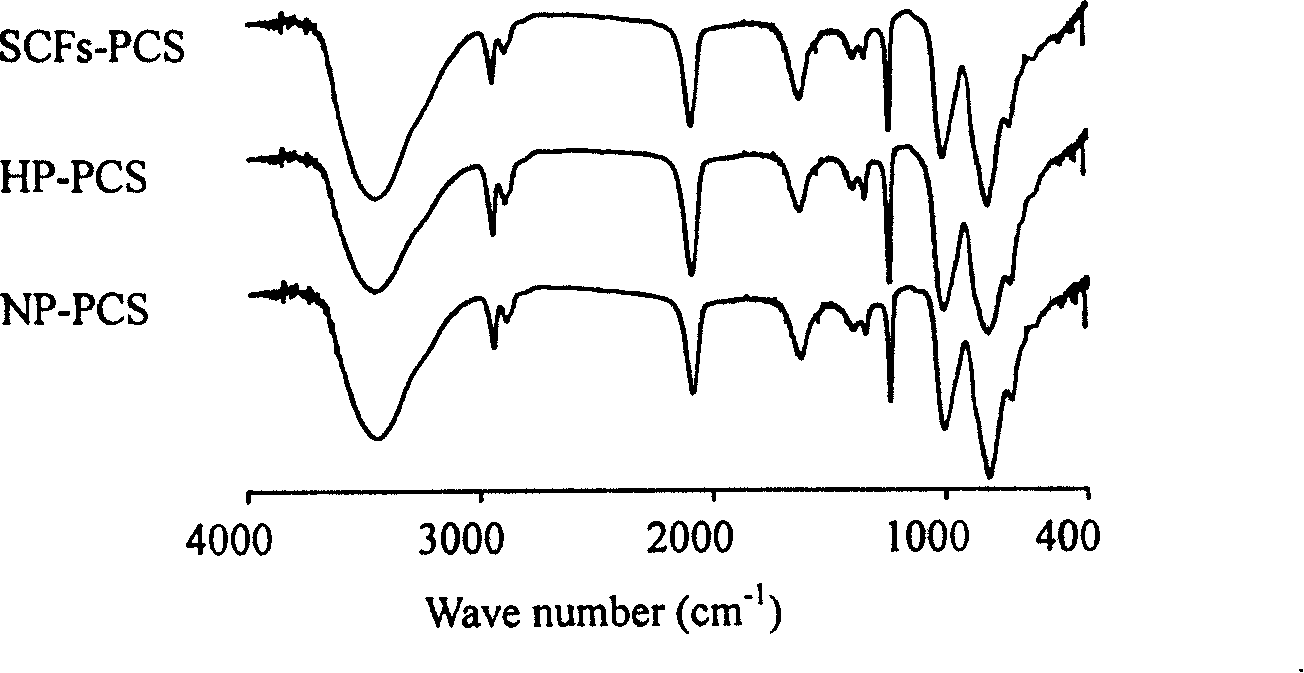

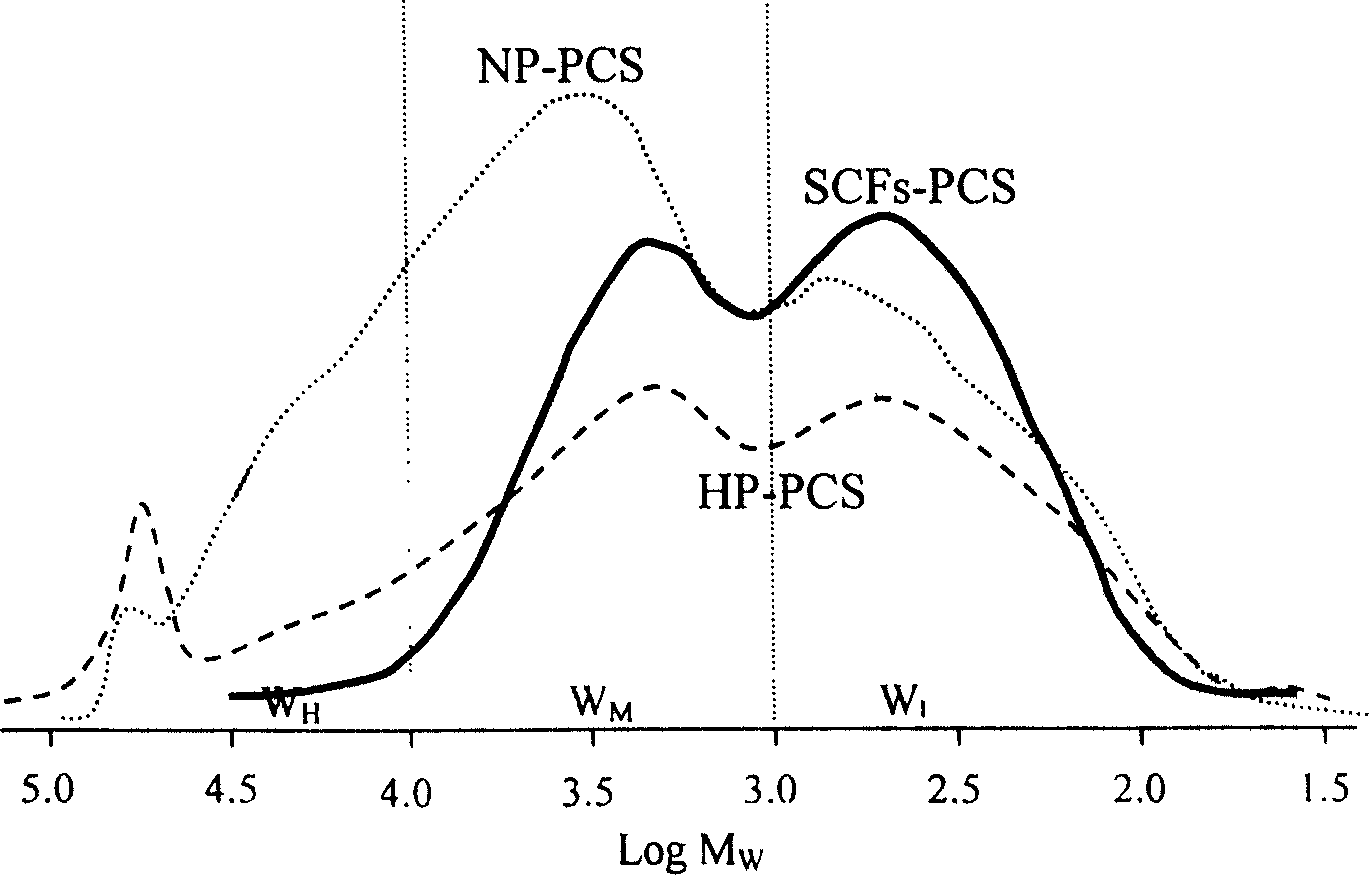

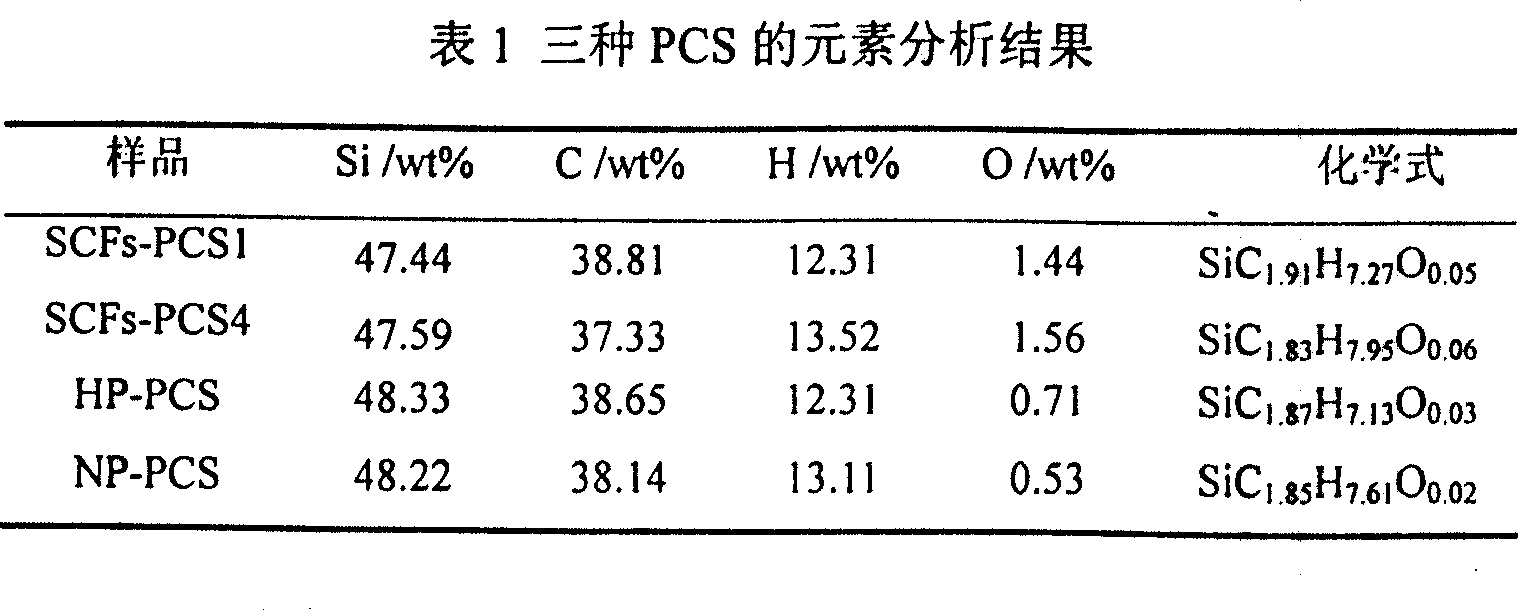

Method for synthesizing supercritical fluid of ceramic precursor polycarbosilane

InactiveCN101240070AImprove heat transfer performanceImprove uniformityBulk chemical productionHigh pressureSuperalloy

The invention discloses a organic silicon compound containing silicon-silicon bond, silicon-carbon bond, silicon-halogen bond and ceramics precursor poly carbon silicon alky synthesized under high pressure and with medium in supercritical fluid status which uses mixture of the aforementioned compound as raw material, uses solvent soluble of poly carbon silicon alky as supercritical fluid medium. Ceramics precursor poly carbon silicon alky with different molecular weight and different softening point can be obtained by controlling reaction condition of synthesis. The inventive method effectively improves uniformity of heat transfer and reaction, with short reaction time, high synthesis efficiency, high synthesis yield. The produced poly carbon silicon has a high molecular weight, high content of bonds of silicon and hydrogen and uniform distribution of molecular weight. The inventive method can be widely used in preparation of SiC fibre, SiC composite, heat resistant alloy with high strength, ceramic binder, SiC membrane, nano-wire, nano-pipe and nano-powder and so on.

Owner:NAT UNIV OF DEFENSE TECH

Impact flow reactor for liquid-phase reaction

ActiveCN100364656CImprove mixing uniformityImprove the uniformity of the reactionLiquid-liquid reaction processesFailure ratePropeller

This invention relates to an impact flow reactor used for liquid phase reaction. The reactor is cylindrical form, pipe or quadratic structure, two draft tubes are fixed between reactors, and one or two pumps are set out of the reactor, the exit of the pump is corresponding set at feed side of the tube. The reactant impact with each other after conveyed by materials pump and high speed flow by draft tubes, so the mixing of the reactant is availably improved. The reactor in this invention maintains the advantage of high efficiency mixing and homogeneous reaction of the existing reactor, and some disadvantages of existing reactor is avoided. Its structure plan is facilitated and cost is reduced because of the replacement of pump cycling outside of the reactor of the screw propeller type structure, and engineering problem of shake, radial sealing failure brought by the screw propeller type structure is reduced. It is easy for maintenance, and its failure rate is low, so it is propitious to reaction process of industry scale.

Owner:CHINA PETROLEUM & CHEM CORP +1

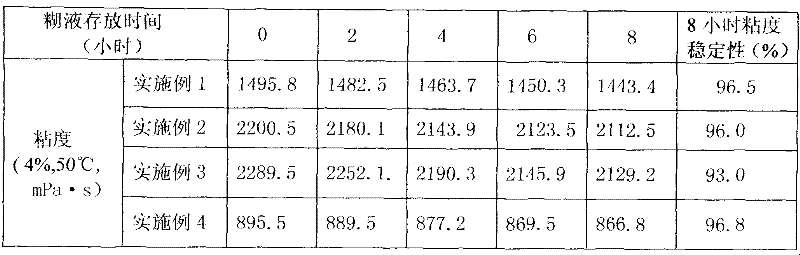

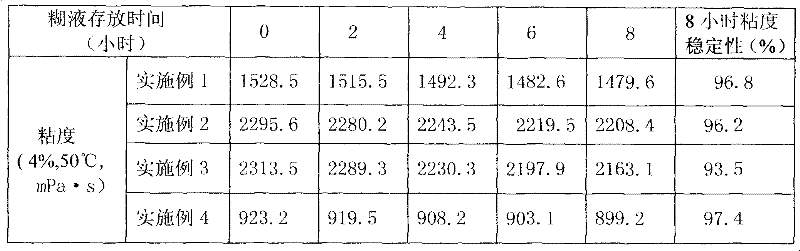

Preparation method for cassava starch modified by combining three kinds of modification processes

ActiveCN104031295AImprove reaction efficiencyImprove the uniformity of the reactionFibre treatmentPaper coatingWater contentChemistry

A disclosed preparation method for cassava starch modified by combining three kinds of modification processes is characterized by comprising: taking starch as a raw material, employing a wet-process crosslinking-oxidation-esterification chemical modification technological route, specifically, performing a crosslinking reaction and an oxidation reaction on an active starch slurry at the same time, then adding a pretreated composite esterification reagent to perform esterification reaction, and adjusting the pH value of the starch slurry to 5.0-6.5, so as to finish combined modification of cassava starch, filtering to obtain wet starch with the water content of 35% or less, then adding polyethylene glycol, mixing uniformly, and performing drying, cooling, crushing and sieving, so as to obtain the cassava starch modified by combining three kinds of modification processes. Only one time of post-processing process comprising washing, centrifugation, drying and the like is performed, the technological process is continuous and automatic, energy and reaction time are saved; and the product is low in gelatinization temperature, good in formability, improved in permeability, caking property, film forming ability and anti-ageing property, and is suitable for being used as a coating adhesive and a surface sizing agent in papermaking industry, a sizing agent in weaving industry, an industrial binder and the like.

Owner:广西农垦明阳生化有限公司

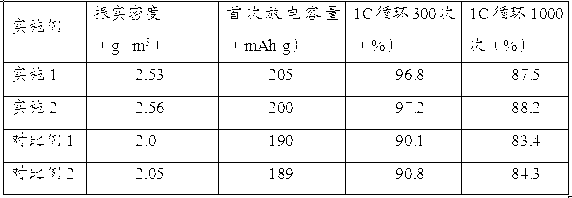

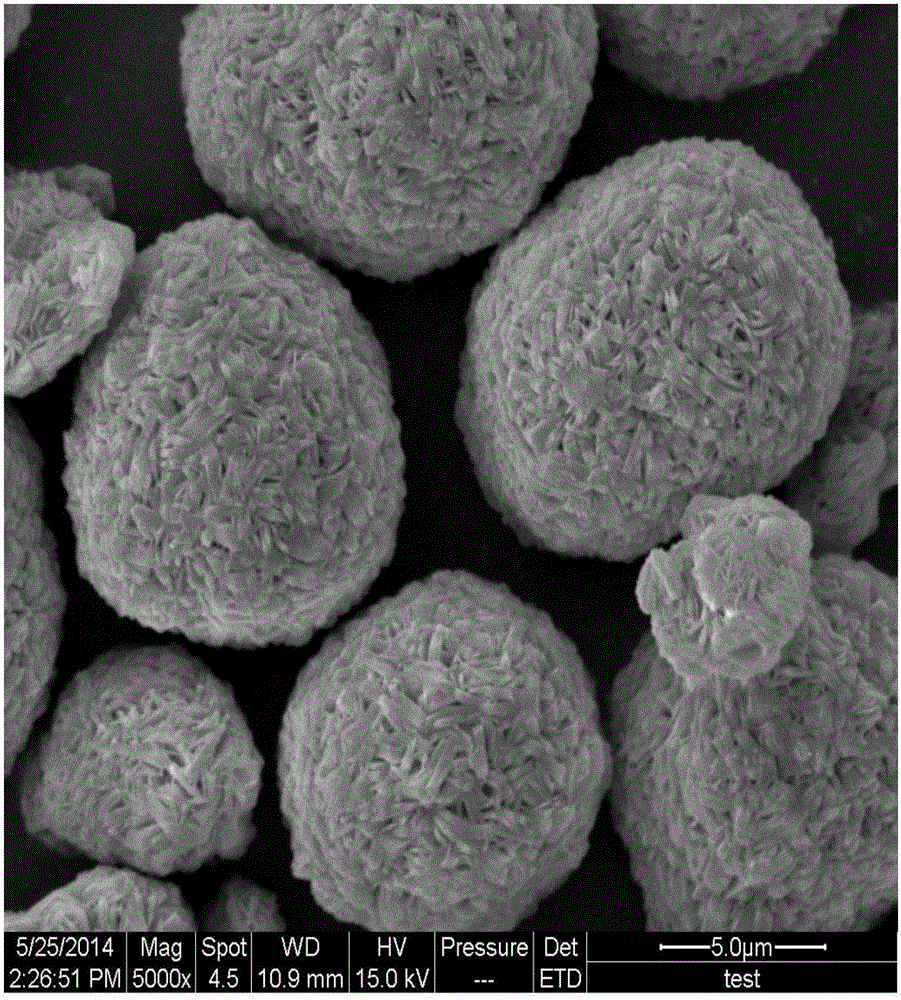

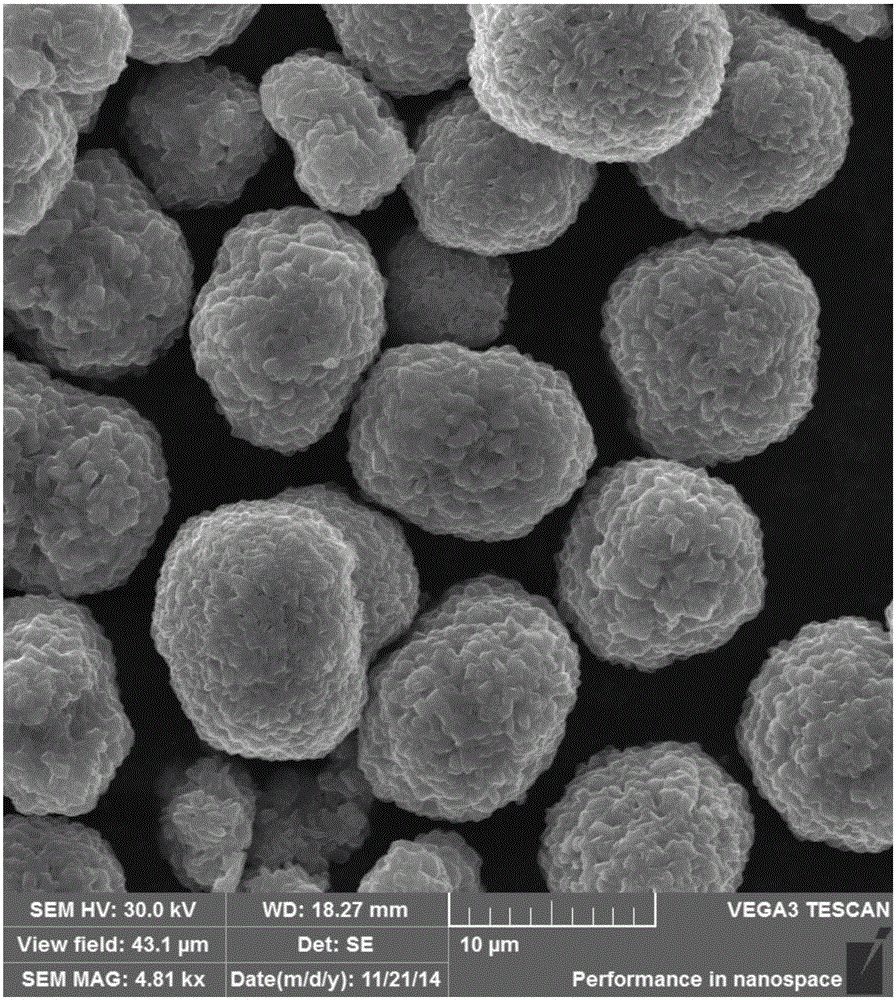

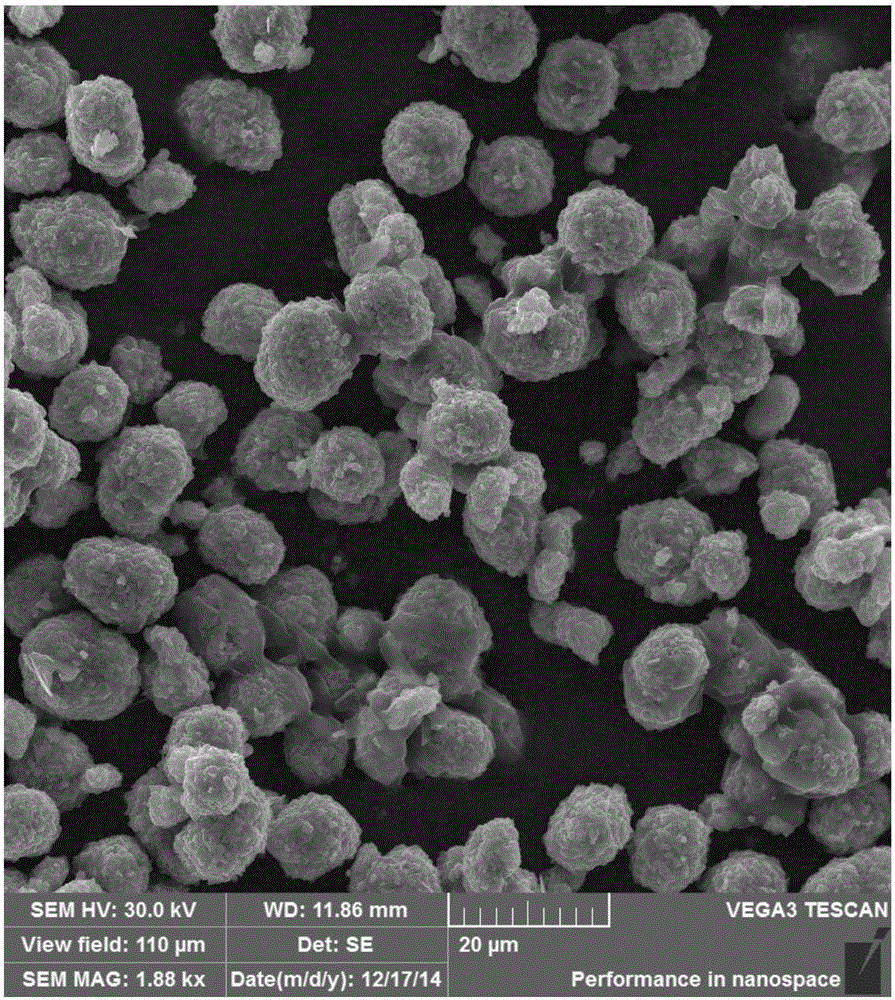

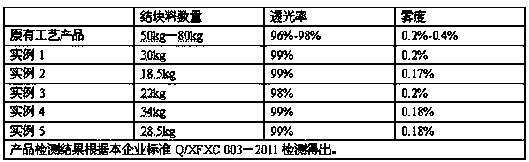

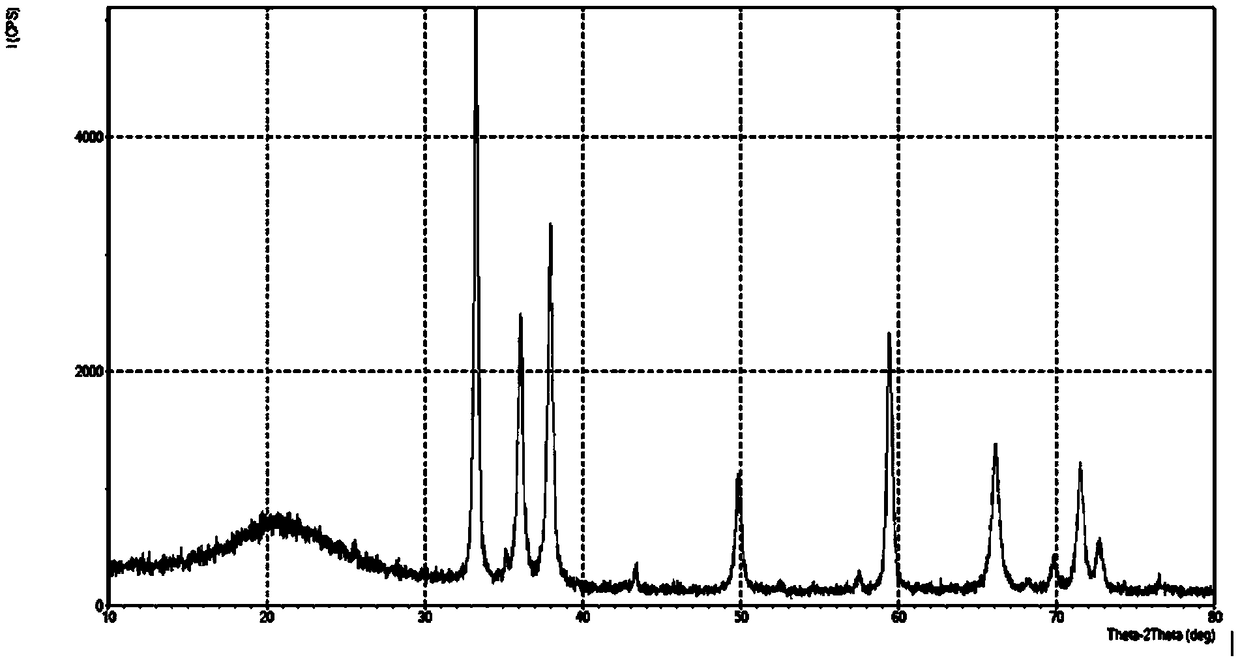

Ternary cathode material of lithium ion battery and preparation method thereof

The invention discloses a ternary cathode material of a high-performance lithium ion battery and a preparation method thereof. The ternary cathode material is characterized by having an alpha-NaFeO2 laminar structure and comprising chemical components of Li[1+z]Ni[x]Co[y]Mn[1-x-y]O[2], wherein z is not smaller than 0 and not more than 0.2, x is not smaller than 0.5 and not more than 0.8, and y is not smaller than 0.1 and not more than 0.2. The invention has the advantages and effects that: oxides of nickel, cobalt and manganese are used as raw materials, so that the influences of other anions are reduced; the raw materials are cracked into smaller particle sizes by using a pneumatic cracker, so that the reaction activity of the materials is enhanced; and solid-phase ball milling fusion is directly adopted, so that the reaction activity and the uniformity of the materials are increased, and no wastewater and waste gas are generated in the whole process, and environment friendliness is achieved. According to the invention, a special postprocessing manner is adopted to remove residual lithium on the surfaces of the materials, so that the cyclic property, the high-temperature property and the safety property of the materials are greatly increased. The preparation method disclosed by the invention has the advantages of simple process, easily controlled production process, easiness for realizing large-scale production, short production cycle and low cost. The ternary cathode material prepared in the invention has the characteristics of high specific capacity, large tap density, good cycle property, favorable high-temperature performance and good safety.

Owner:HENAN THINKER ENERGY MATERIALS

Multi-element cathode material for lithium ion battery and preparation method for multi-element cathode material

InactiveCN102709548AReduce the impactHigh reactivityCell electrodesPhysical chemistryLithium-ion battery

The invention discloses a multi-element cathode material for a lithium ion battery and a preparation method for the multi-element cathode material. The multi-element cathode material for the lithium ion battery has an alpha-NaFeO2 layered structure, and comprises the chemical components of Li1+zNixCoyM1-x-yO2, wherein z is more than or equal to 0, and is less than or equal to 0.2; x is more than or equal to 0.85, and is less than or equal to 0.98; y is more than or equal to 0.04, and is less than or equal to 0.1; and M comprises but not limited to Al, Mg and Zn. The multi-element cathode material for the lithium ion battery has the advantages of ultra-high specific capacity, high cycle performance, high thermal stability, high safety and the like.

Owner:广州鸿森材料有限公司

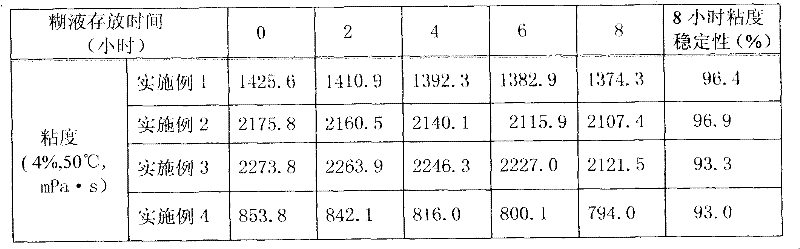

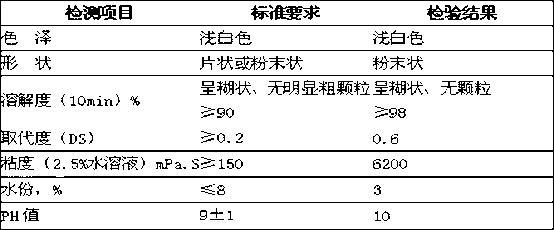

Preparation method of high viscosity cationic starch

The invention relates to a preparation method of high viscosity cationic starch, which comprises the technological steps of: 1) using the mixture of an alkaline catalyst and an inhibitor to adjust the pH of starch slurry to be 10swung dash12; 2) heating and adding the mixture of an alkaline activating agent and a cationic etherifying agent, and stopping heating until the temperature reaches 40 DEG C; 3) using the mixture of the alkaline catalyst and the inhibitor to adjust the pH of the starch slurry to be 11swung dash12, keeping heating until the temperature of the starch slurry reaches 49swung dash50 DEG C, and etherifying for 1swung dash5h; 4) adding an alkaline cross-linking agent, and reacting for 1swung dash6h; and 5) dehydrating the starch slurry, obtaining green starch, adding an acidulant, mixing uniformly, acidizing the starch for 0.5swung dash2h at 50swung dash100 DEG C, and after cooling, smashing and screening, obtaining a product. The product has high paste viscosity, high acid and alkaline-resistant stabilities, and can be applied in the fields of paper making, mineral separation, oil fields, adhesives, waste water treatment and the like.

Owner:广西农垦明阳生化有限公司

Production method of carboxymethyl cellulose acetate butyrate

ActiveCN105418770AImprove the uniformity of the reactionThorough responseCoatingsChemistryN-Butyrate

The invention discloses a production method of carboxymethyl cellulose acetate butyrate and aims to provide a continuous production process of carboxymethyl cellulose acetate butyrate that overcomes the existing difficulty that carboxymethyl cellulose acetate prepared by a traditional kneader method is inapplicable to the preparation of carboxymethyl cellulose acetate butyrate. The production method includes sodium carboxymethyl cellulose preparation, acidification, activation, esterification and purification. The production method has a short production period, the temperature is low, unit energy consumption is low, loss of raw materials is low, an operating process is simple, and manufacturing cost is greatly reduced; waterborne overlay coatings prepared based on the carboxymethyl cellulose acetate butyrate meet the requirement on environmental protection, are less harmful to the environment and human body and have excellent performance, and in the face of the requirement of automobile and aviation industries expanding day by day on waterborne overlay coatings, the carboxymethyl cellulose acetate butyrate has a promising application prospect and can also be made into different types of products according to different requirements, meeting requirements of a wider range.

Owner:CHONGQING LIHONG FINE CHEM +1

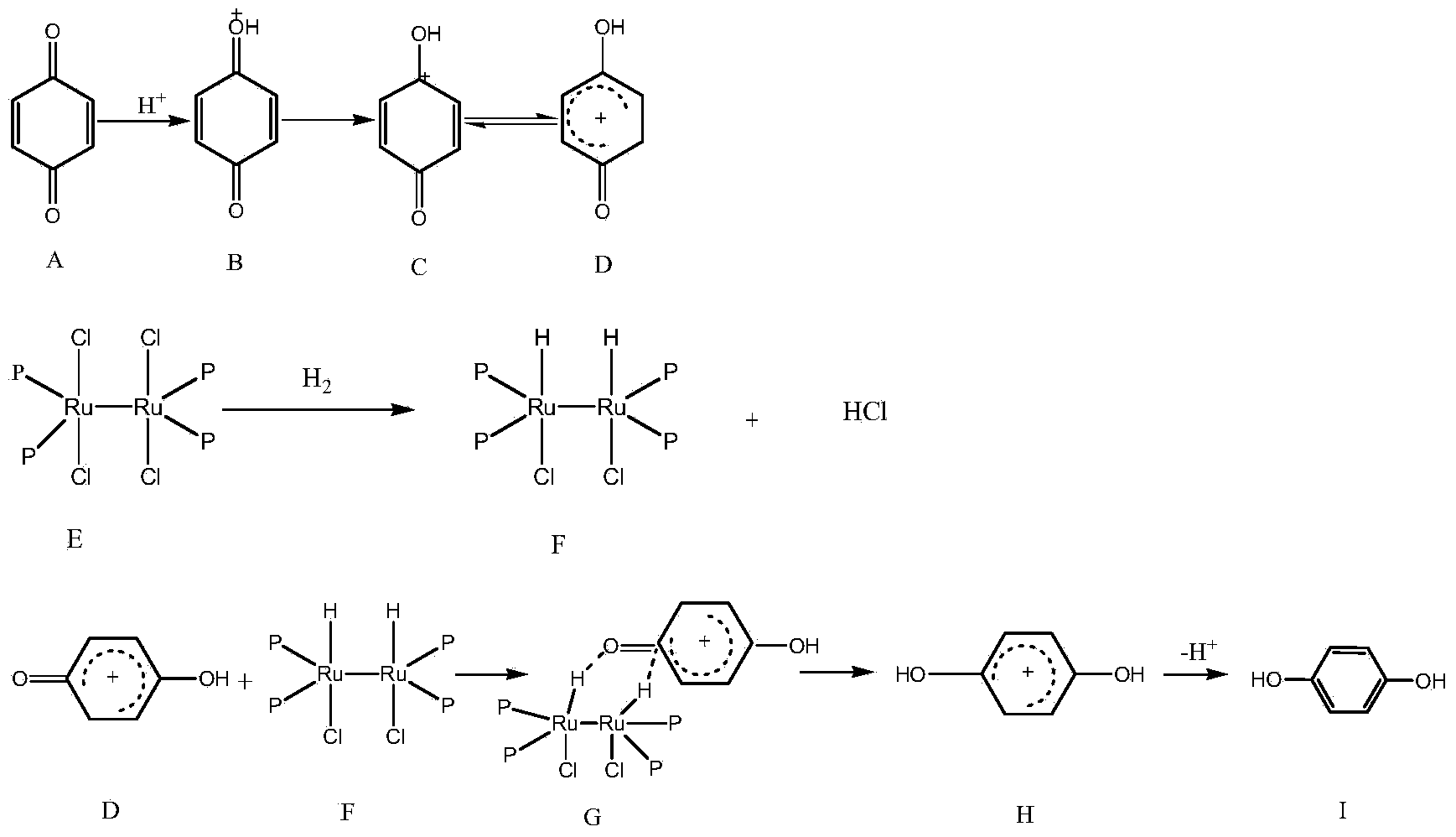

Method for preparing hydroquinone

ActiveCN104030890AReduce dosageReduce manufacturing costOrganic chemistryOrganic compound preparationTPPTSRuthenium

The invention relates to a method for preparing hydroquinone. According to the method, a water-soluble ruthenium complex (RuCl<2>(TPPTS)<2>)<2> is used as a catalyst, in a medium with a pH value of 0-4, the hydroquinone is prepared by reducing p-benzoquinone through catalytic hydrogenation, and reaction time is controlled to range from 10 minutes to 100 minutes; after the reaction is finished, the yield of the hydroquinone is larger than 85%, and the catalyst can be reused. The method greatly lowers the amount of the recoverable catalyst and remarkably reduces the cost; the catalytic efficiency and the reaction uniformity are improved by the adoption of the homogeneous catalyst, the reaction is sped up on the acidic condition, and the preparing time is shortened; the catalyst and the product are convenient to separate, the catalyst is capable of being reused, economical and environmentally friendly, and operation is easy and convenient to carry out.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

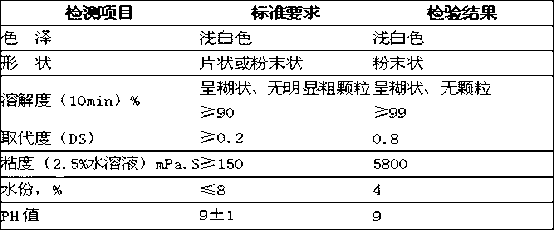

Cooked gelatine powder and preparation method thereof

ActiveCN103131350AImprove the uniformity of the reactionWill not degradeNon-macromolecular adhesive additivesStarch derivtive adhesivesPtru catalystMaterials science

The invention relates to cooked gelatine powder and a preparation method thereof. The cooked gelatine powder comprises the following components in parts by weight: 70-85 parts of starch, 2-5 parts of a modifier, 3-8 parts of a catalyst, 5-15 parts of an etherifying agent, 2-3 parts of a thickening agent and 0.5-1 part of a nucleater. The method comprises the following steps: carrying out refining and activating treatment in advance and an instantaneous high-temperature and high-pressure etherification reaction on starch; and carrying out powerful shearing in short time under conditions of a dry method to achieve the purpose that etherification reaction is quick and the starch is not degraded to obtain the cooked gelatine powder. The obtained cooked gelatine powder is uniform in reaction, high in reaction efficiency and substitution degree, fluffy, good in instant dissolving in cold water, low in preparation cost, small in investment of production equipment and capable of absorbing water quickly without generating an inclosure and achieving efficient preparation.

Owner:山东国九堂制药集团股份有限公司

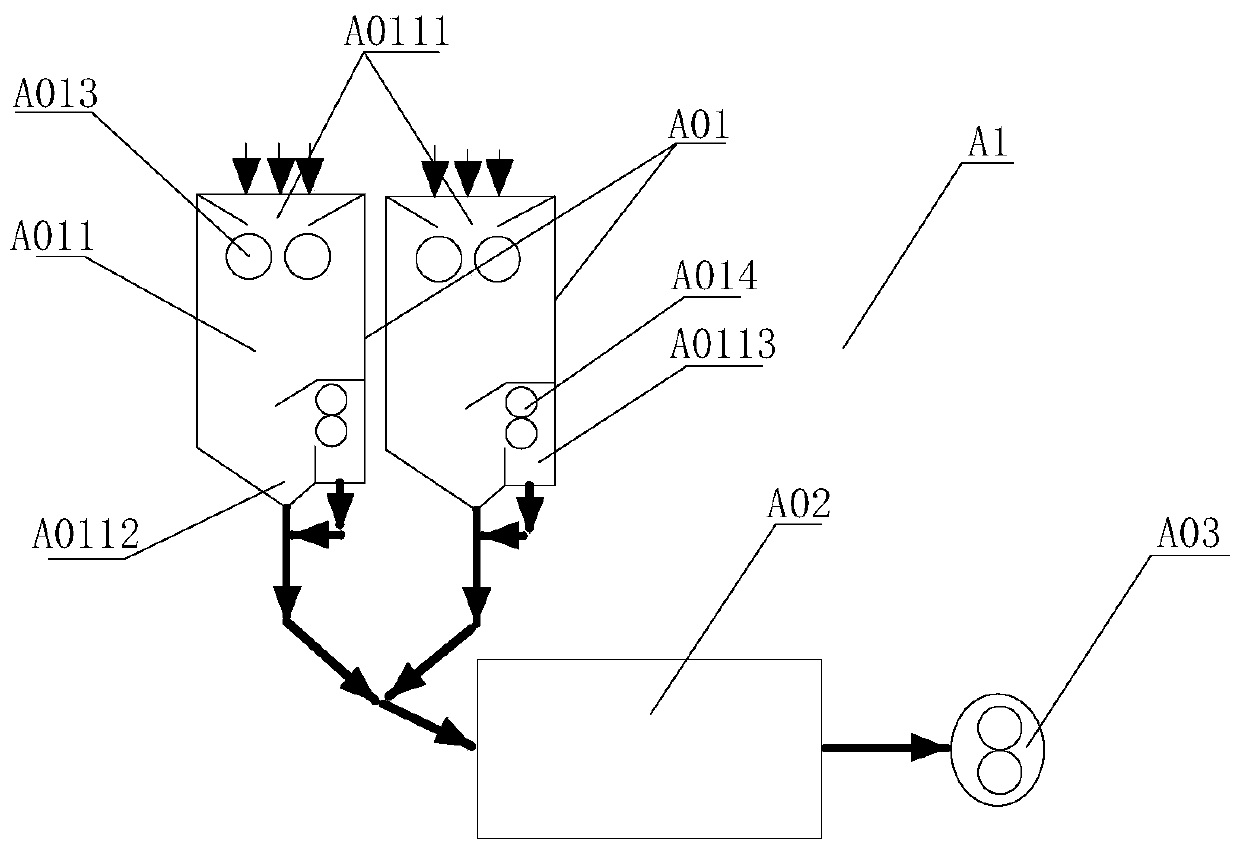

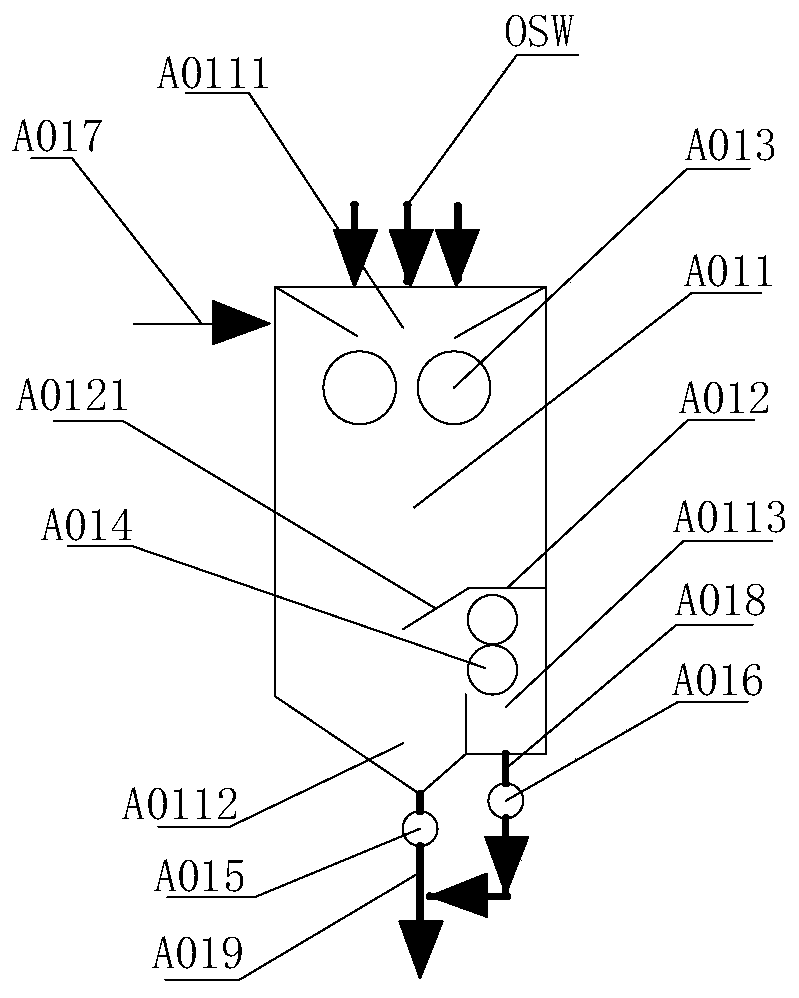

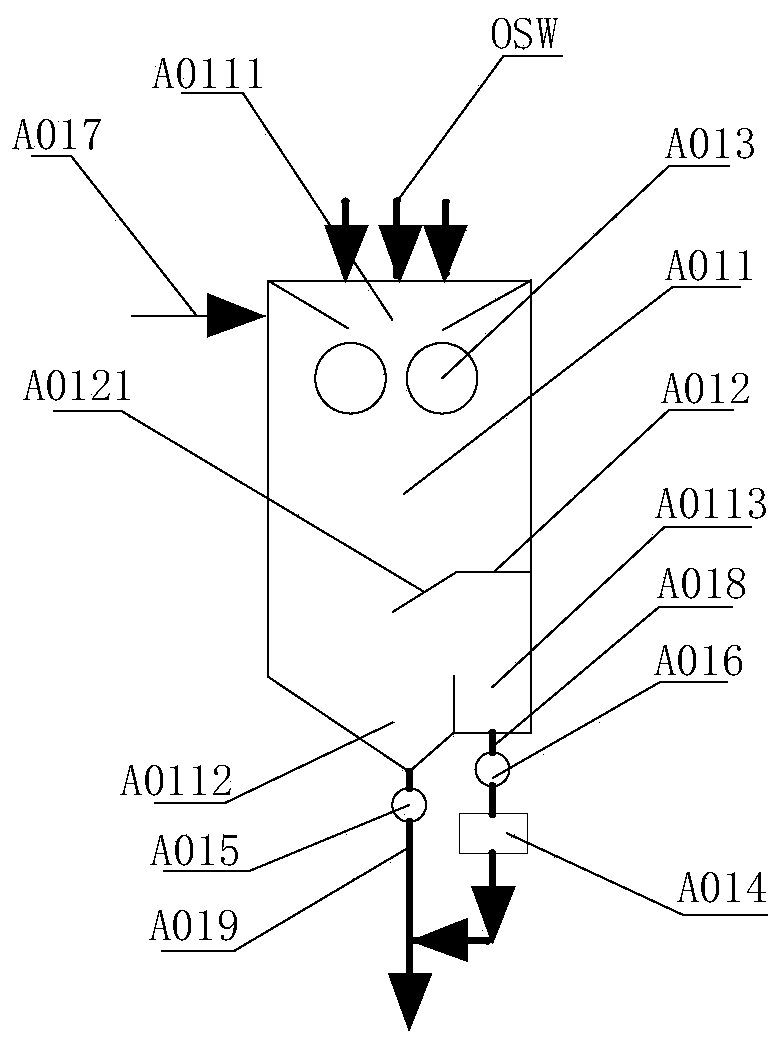

Organic solid waste pretreatment system and process and corresponding organic solid waste continuous hydrothermal treatment system and process

ActiveCN111346897ASave heating energyReduce energy costsWaste processingSolid waste disposalProcess engineeringEnvironmental engineering

The invention discloses an organic solid waste pretreatment system and process and a corresponding organic solid waste continuous hydrothermal treatment system and process. The organic solid waste pretreatment system comprises a weight sorting-smashing device and a ball milling device; the water weight sorting-smashing device comprises a sorting cavity and a second-stage smashing unit, separationof light materials and heavy materials can be achieved through the sorting cavity, smashing the light materials by the second-stage smashing unit is carried out to prepare primary mud, the ball milling device receives the primary mud and carries out ball milling to prepare mud containing impurities, the heavy materials separated by the sorting cavity can enter the ball milling device to be used asabrasive materials. The organic solid waste pretreatment system is simple and reasonable in structure, facilitates separation of light and heavy materials and utilization of heavy material waste, refines, homogenizes and fluidizes organic solid waste, can achieve organic solid waste synergism, high efficiency and continuous hydrothermal treatment, effectively prevents continuous hydrothermal technology blockage and the like, fully recovers heat energy in the technological process, and improves the utilization rate of organic solid waste, resource utilization of products can be realized, and obvious environment-friendly and economic benefits are obtained.

Owner:TSINGHUA UNIV

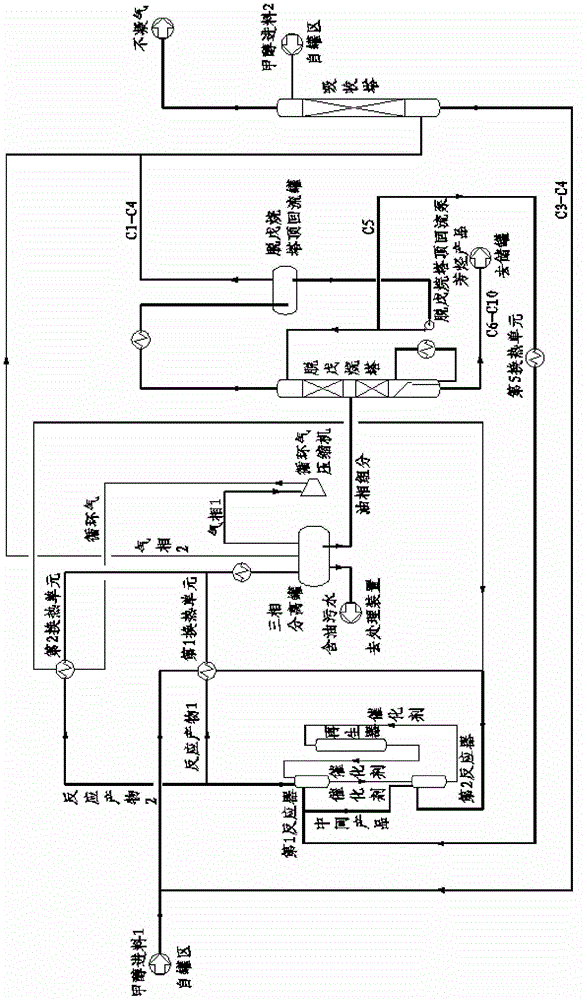

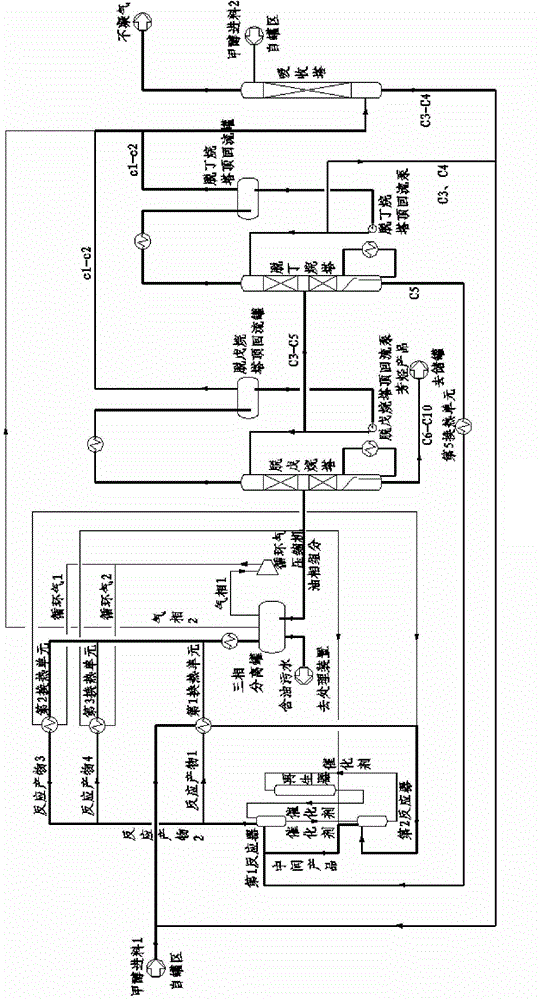

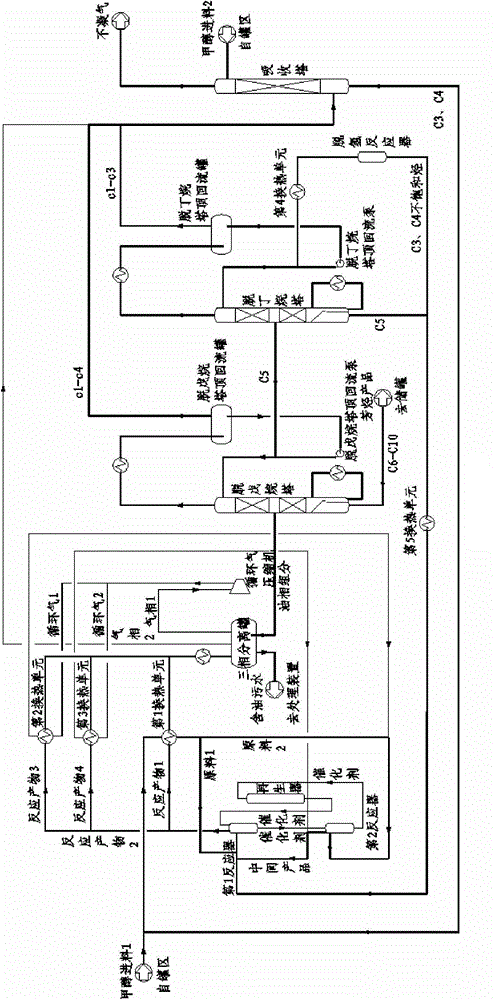

Moving bed methanol-to-hydrocarbon method

ActiveCN104818042AGuaranteed conversion rateImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAromatic hydrocarbonMoving bed

The invention relates to a moving bed methanol-to-hydrocarbon method. The method comprises the steps of hydrocarbon synthesis, separation and post-treatment, at least two serially connected reactors are adopted in the hydrocarbon synthesis step, a reaction raw material and a catalyst sequentially flow through the reactors in a countercurrent direction, low carbon olefin-containing circulation gas generated in the separation step returns to different feeding positions in the hydrogen synthesis step as quenching gas or raw material supplement gas in the hydrocarbon synthesis step, and a raw material methanol is used to wash and absorb C1-C4 light components generated in the separation step, returns, is fed and is converted in order to convert methanol into mixed aromatic hydrocarbon-containing stable light hydrocarbon with high added values. The method allows step complete utilization of the activity of the catalyst to be carried out, so the method improves the fine control of the reaction process, realizes effective material utilization and heat integration between processing processes, improves the product yield, reduces energy consumption and reduces environmental pollution.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

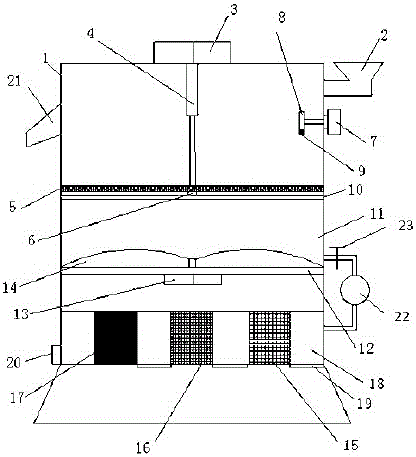

Coating wastewater treatment equipment

InactiveCN106830443AImprove reaction speedImprove the uniformity of the reactionTreatment involving filtrationMultistage water/sewage treatmentImpellerChemical reaction

The invention discloses a paint wastewater treatment equipment, which comprises a machine casing, a water inlet, a first motor, a telescopic rod, a filter plate, a second motor, a cleaning device, a slag outlet, a chemical reaction pool, a wave wheel agitator, and an activated carbon layer , microfiltration membrane layer, ultrafiltration membrane layer, the first motor is fixed at the middle position of the upper part of the casing, the first motor is connected to the telescopic rod, the lower end of the telescopic rod is connected to the filter plate, the lower end of the filter plate is provided with a support plate, the filter plate and the support A weight sensor is arranged between the plates, the second motor is arranged on the upper right side of the casing, the second motor passes through the casing to connect to the cleaning device, and the lower end of the cleaning device is provided with an infrared induction device, the wastewater treatment equipment of the present invention can Timely removal of the filtered filter residue can realize continuous wastewater treatment without dismantling the filter assembly, and at the same time avoid the influence of excessive accumulation of waste residue on the filtration effect.

Owner:李威汉

Method for reducing surface tension of molten-state lithium source so as to improve high-temperature solid phase sintering process of cathode material of lithium ion battery

ActiveCN105789621AReduce surface tensionReduce mixingCell electrodesSecondary cellsMolten stateElectrical battery

The invention discloses a method for reducing surface tension of a molten-state lithium source so as to improve a high-temperature solid phase sintering process of a cathode material of a lithium ion battery, relating to a method for improving the high-temperature solid phase sintering process of the cathode material of the lithium ion battery and belonging to the technical field of a lithium ion battery material and a fabrication process thereof. The invention aims to solve the problems of unbalanced reaction and inadequate reaction caused by non-uniform molten-state lithium source distribution and incomplete immersion during the high-temperature solid phase sintering process of the cathode material of the lithium ion battery so that the problems such as rate performance, cycle stability and thermal stability of the material during the charge-discharge cycle process are improved. The improvement process is achieved according to the following steps of 1, pre-processing the lithium source; 2, mixing the lithium source and a precursor material; 3, fully immersing the lithium source and the precursor material; and 4, carrying out high-temperature sintering. The material fabricated according to the method is used for the cathode material of the lithium ion battery.

Owner:HARBIN INST OF TECH

Composite catalytic system and production method of PVB resin adopting composite catalytic system

The invention relates to a composite catalytic system and a production method of PVB resin adopting the composite catalytic system and belongs to the technical field of high polymer chemistry. The composite catalytic system is characterized in that the composite catalytic system is compounded with and prepared from an emulsifying agent and a phase-transfer catalyst; the mass ratio of the emulsifying agent to the phase-transfer catalyst is 1-30 to 1-70; preferably, the mass ratio of the emulsifying agent to the phase-transfer catalyst is 1-8 to 1-30. The composite catalytic system provided by the invention can promote the dispersion of butyraldehyde, effectively reduce the viscosity of a reactant produced by condensation reaction of PVA and the butyraldehyde, facilitate the precipitation of PVB, improve the reaction efficiency of PVB and the reaction uniformity, and reduce caking of materials during the production of PVB resin. According to the production method of PVB resin adopting the composite catalytic system, related to the invention, the dispersion of the butyraldehyde is better, the viscosity of the reactant during the condensation reaction is lower, the reaction is more uniform, caking of materials is effectively reduced, and the product quality is improved.

Owner:HANGZHOU XINFU TECH CO LTD

Box-type multi-purpose furnace for metal heat treatment

ActiveCN108103434AFacilitated DiffusionGuaranteed uniformitySolid state diffusion coatingCarbon depositNitrogen gas

The invention discloses a box-type multi-purpose furnace for metal heat treatment. The box-type multi-purpose furnace comprises an atmosphere control system; a liquid carbon source is premixed with nitrogen according to a certain ratio after being atomized, so that the uniformity of carbon source atmosphere is ensured; the integration of a gas inlet pipe and a fan enables mixed gas flow to be moreevenly distributed in a heating chamber, so that the phenomenon that carbon deposits in the furnace due to the excessively concentrated distribution of the fluid carbon source can be prevented or reduced, and the maintenance cost is lowered; a bearing cooling system is used for fully cooling a bearing, so that not only is the service life of the bearing prolonged, but the temperature rise of a gas inlet pipe passing through the bearing is also reduced to a certain extent, and the carbon deposition in the pipe is reduced; furthermore, once entering the heating chamber, the carbon source rapidly diffuses in the heating chamber under the action of the fan, so that the reaction efficiency and the uniformity are improved, a carburized layer is more evenly distributed, and the quality of the product is ensured.

Owner:重庆臻展热处理有限公司

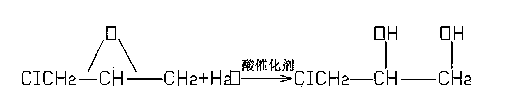

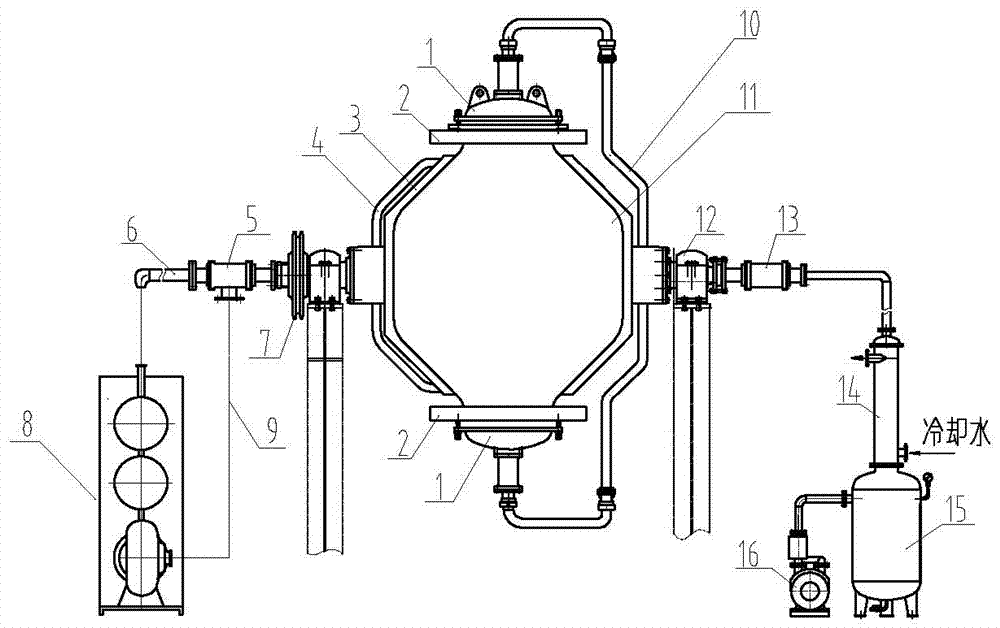

Chloropropanediol purifying apparatus and production method thereof

ActiveCN103360213AIncrease contact areaAdequate responseHydroxy compound separation/purificationPreparation by hydrolysisDistillationHydrolysate

The invention discloses a chloropropanediol purifying apparatus and a production method thereof. The apparatus comprises a hydrolysis kettle, a hydrolysate header tank, ion exchange columns, a distillation still and a condenser which are connected through a pipeline, the output pipeline of the condenser is connected with a front fraction pot and a finished product pot, and the front fraction pot and the finished product pot are respectively connected with a vacuum set. The production method comprises the following steps: respectively pumping softened water, sulfuric acid and an aqueous solution of p-toluenesulfonic acid into the hydrolysis kettle according to a ratio, stirring, heating, adding chloropropylene oxide to the hydrolysis kettle for a reaction, and continuously heating for a new reaction after reaction ending; putting the obtained hydrolysate in the ion exchange columns for ion exchange; adding the obtained ion exchange liquid to the distillation kettle, starting stirring, carrying out steam heating, and starting a hydraulic jet vacuum pump; stopping the hydraulic jet vacuum pump when there is no liquid drop between the condenser and a reception pot, and sequentially starting roots vacuum sets; and conveying the obtained material to the front fraction pot, and switching the front fraction pot to the finished product pot.

Owner:WEIFANG WORLD CHEM

Dynamic high-temperature acid washing device of high-purity quartz sand

The invention relates to a dynamic high-temperature acid washing device of high-purity quartz sand. The dynamic high-temperature acid washing device comprises a reaction kettle, wherein the reaction kettle is of a biconical shape and a hot oil jacket covers an outer wall of the reaction kettle; the hot oil jacket is connected with a heating system through a heat-conducting oil pipe; end covers capable of being opened and closed are arranged at upper end lower ends of the reaction kettle respectively; the end covers are communicated with a vacuum system through a vacuum pipe and the inner part of the reaction kettle is vacuumized; rotary shafts are arranged at two sides of the reaction kettle and are connected with two groups of rotary supporting units respectively, so that the reaction kettle can rotate up and down; the vacuum pipe is provided with a plurality of quick connectors so that the vacuum pipe is convenient to detach and other pipelines are connected. The dynamic high-temperature acid washing device provided by the invention has a reasonable design and a simple structure; chemical reaction can be carried out on the quartz sand at relatively high temperature and under a movement state; acid washing, water washing, dehydration and drying are integrated and are finished in one step, so that a chemical reaction speed and the reaction uniformity are improved and secondary pollution is avoided, and furthermore, favorable conditions are created for improving the quality of products.

Owner:JIANGSU PACIFIC QUARTZ

Magnesium alloy composite surface protective treatment equipment and magnesium alloy composite surface protective treatment method

ActiveCN104109894AImprove corrosion resistanceReduce fatigue damageEdge grinding machinesAnodisationResidual pressureAnodic oxidation

The invention discloses magnesium alloy composite surface protective treatment equipment. The magnesium alloy composite surface protective treatment equipment comprises an anodic oxidation device, wherein the anodic oxidation device comprises an electrolytic cell; an electrolyte is filled in the electrolytic cell; a positive electrode and a negative electrode are arranged in the electrolytic cell; the positive electrode and the negative electrode are connected by virtue of a power supply; the magnesium alloy composite surface protective treatment equipment disclosed by the invention further comprises a magnesium alloy sample rotary device and a surface mechanical grinding device. A vibration generator of the magnesium alloy composite surface protective treatment equipment disclosed by the invention can be used for carrying out surface mechanical grinding on a magnesium alloy sample by vibrating spherical pills on an electrolytic cell lower plate, and circular rod-shaped sample rotary device can drive the magnesium alloy sample to rotate at a uniform speed, so that the surface of the magnesium alloy sample is subjected to uniform mechanical grinding treatment; residual pressure stress is introduced on the surface of the magnesium alloy sample oxidized by an anode to resist residual tensile stress generated by anode oxidization on the surface of the magnesium alloy sample, so that damages on fatigue performances of the magnesium alloy by anode oxidization are lowered while corrosion resistance of the magnesium alloy sample is improved, and therefore, an operation method is simple and practicable.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

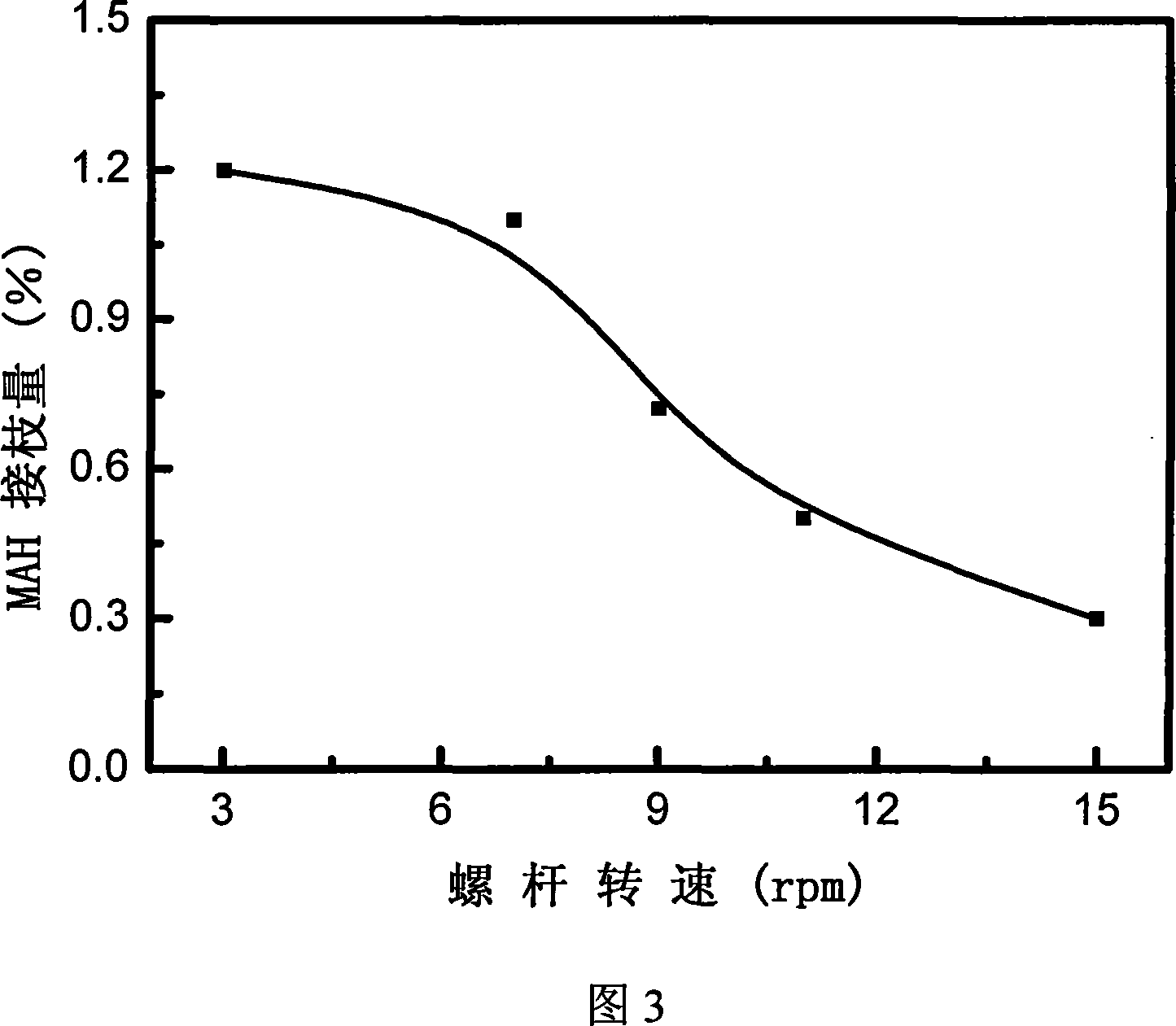

Melt polymer body photochemical reaction device

The invention relates to a fuse polymer optical chemical reaction device, comprising the single worm extruder and ultraviolet illuminating device, solid transportation part of the single worm extruder being common hopper, transportation and measuring parts of the extruder being transparent quartz glass, ultraviolet device installed outside the transparent hopper with the ultraviolet going through the hopper to reach the fused polymer and triggering its optical chemical reaction, through the drive of the worm to push the renewing of the fuse surface and introduce the optical reaction into the inside of the polymer fuse. It can undergo fuse branching, polymer cross jointing, polymer degradation and so on.

Owner:SOUTH CHINA UNIV OF TECH

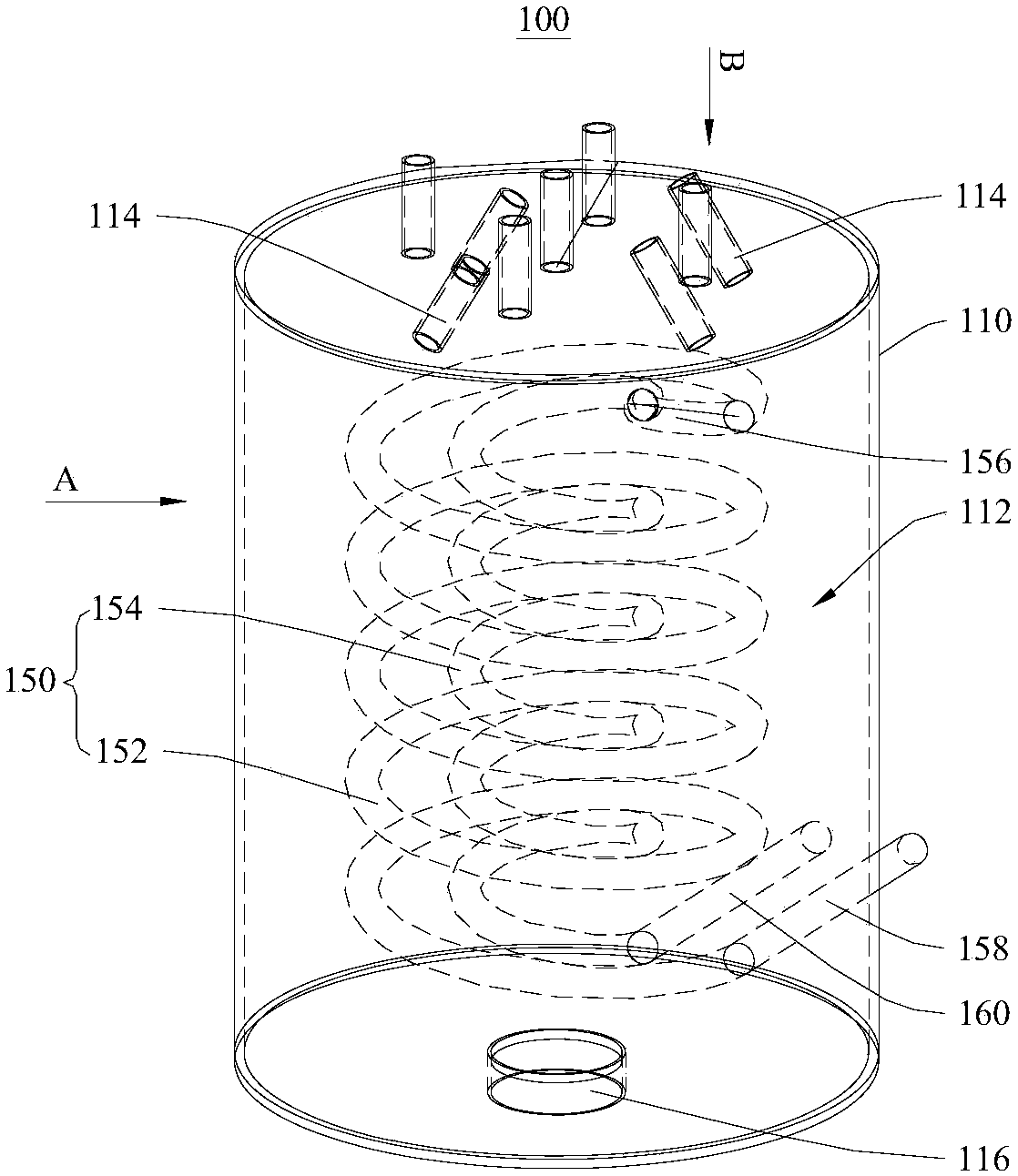

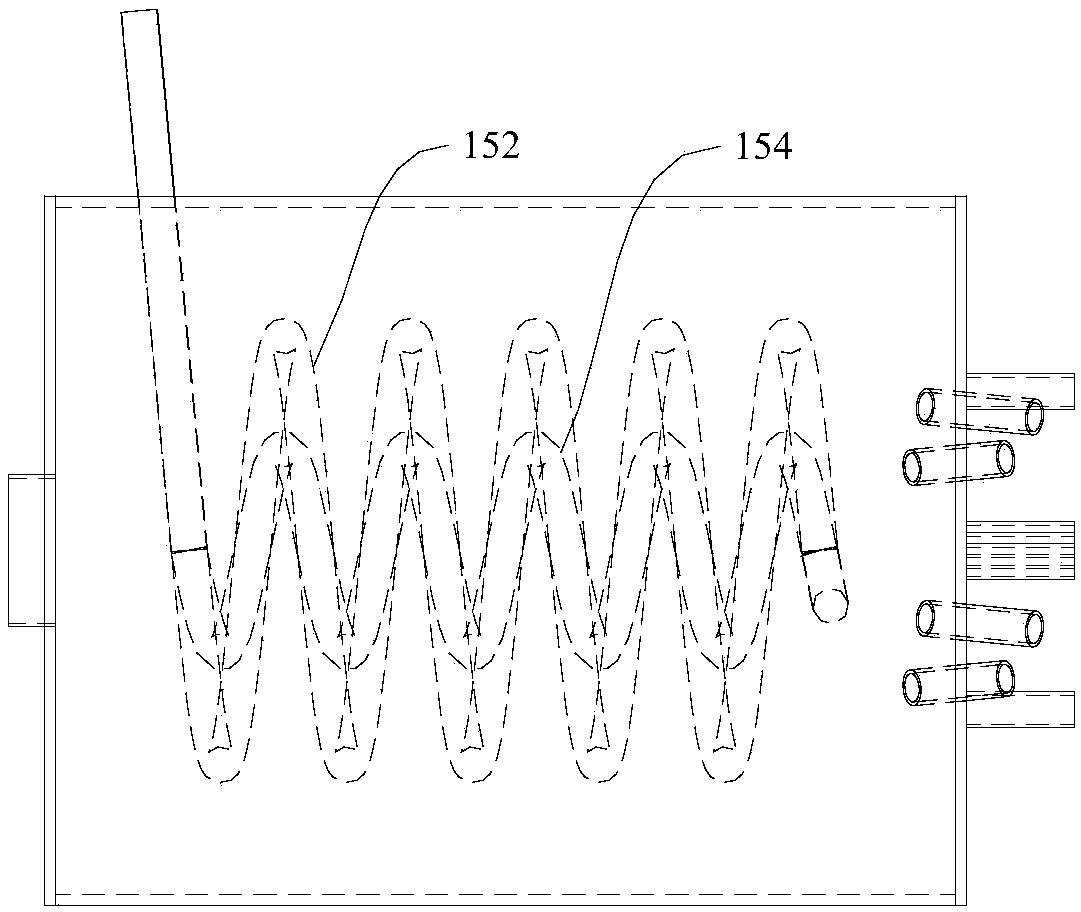

Micro-reactor and chemical industry production system

PendingCN108014730AEasy feedingEasy dischargeChemical/physical/physico-chemical microreactorsMicroreactorChemical industry

The invention provides a micro-reactor and a chemical industry production system, and relates to the field of chemical reaction equipment. The micro-reactor comprises a barrel body, and also comprisesa reaction pipe, wherein the barrel body defines an accommodating hollow cavity; a feeding pipe is mounted on the barrel body and is mutually communicated with the accommodating hollow cavity; the reaction pipe is arranged in the accommodating hollow cavity in a spiral form; two ends of the reaction pipe penetrate both through the barrel body and extend to the outer side of the barrel body. By spiral coiling, coiling length of the reaction pipe in the same space is increased, so that the heat exchange area of a heat exchange medium and a reaction material can be increased by the reaction pipeunder a limited space condition, and the heat exchange efficiency is improved; meanwhile, by the spiral coiling, a mass transfer effect of fluid in the reaction pipe can be further improved, the masstransfer effect and a heat transfer effect are improved at the same time, so that the reaction uniformity of the reaction material is higher, and the reaction yield is higher. The invention also provides the chemical industry production system including the micro-reactor. According to the chemical industry production system disclosed by the invention, by utilizing high-efficient heat exchange ability of the micro-reactor, the aim of improving the production efficiency and the production ability can be fully fulfilled.

Owner:SHANDONG HIMILE CHEM TECH

Preparation method of metal bonding pad in through hole of SOI sheet

ActiveCN104326441ASimple processLow costDecorative surface effectsChemical vapor deposition coatingSoi substrateElectrochemical corrosion

The invention provides a preparation method of a bonding pad in a through hole in MEMS (Micro-electromechanical System) wafer-level vacuum package. According to the preparation method, a special structure of the through hole in an SOI substrate is utilized, and the bonding pad in the through hole is prepared by adopting an electrochemical corrosion method, so that the problem of electrical short circuit of back metal in a base layer of the SOI sheet is effectively solved, and the preparation method has the advantages of being low in cost, suitable for volume production and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Production method of metal chromium

The invention discloses a production method of metal chromium. The production method includes the following steps that 1, chromium sesquioxide and aluminum powder are evenly mixed, and a mixed material is obtained; 2, an electrode is inserted into a smelting furnace, and then part of the mixed material is put in the smelting furnace; 3, the electrode is subjected to ohmic heating, the temperaturein the smelting furnace rapidly rises, and an aluminothermic reduction reaction is carried out; 4, after the interior of the smelting furnace reaches designated smelting temperature, the rest of the mixed material is put in the smelting furnace, the aluminothermic reduction reaction is carried out, the reaction is constant for a certain time, and it is guaranteed that the reaction is complete; 5,the electrode is powered off, heating stops, and the electrode is pulled out of the smelting furnace; and 6, the smelting furnace is cooled, subjected to slag removal, finished and broken, and the metal chromium product is obtained. Electric heating replaces a heating agent autothermal reaction, reaction conditions can be stabilized according to the aluminothermic reaction condition, the reactionuniformity is good, the consumption of an aluminum reducing agent is reduced by 20%, and the chromium yield is increased by 5% or above.

Owner:四川明宏恒正科技有限公司

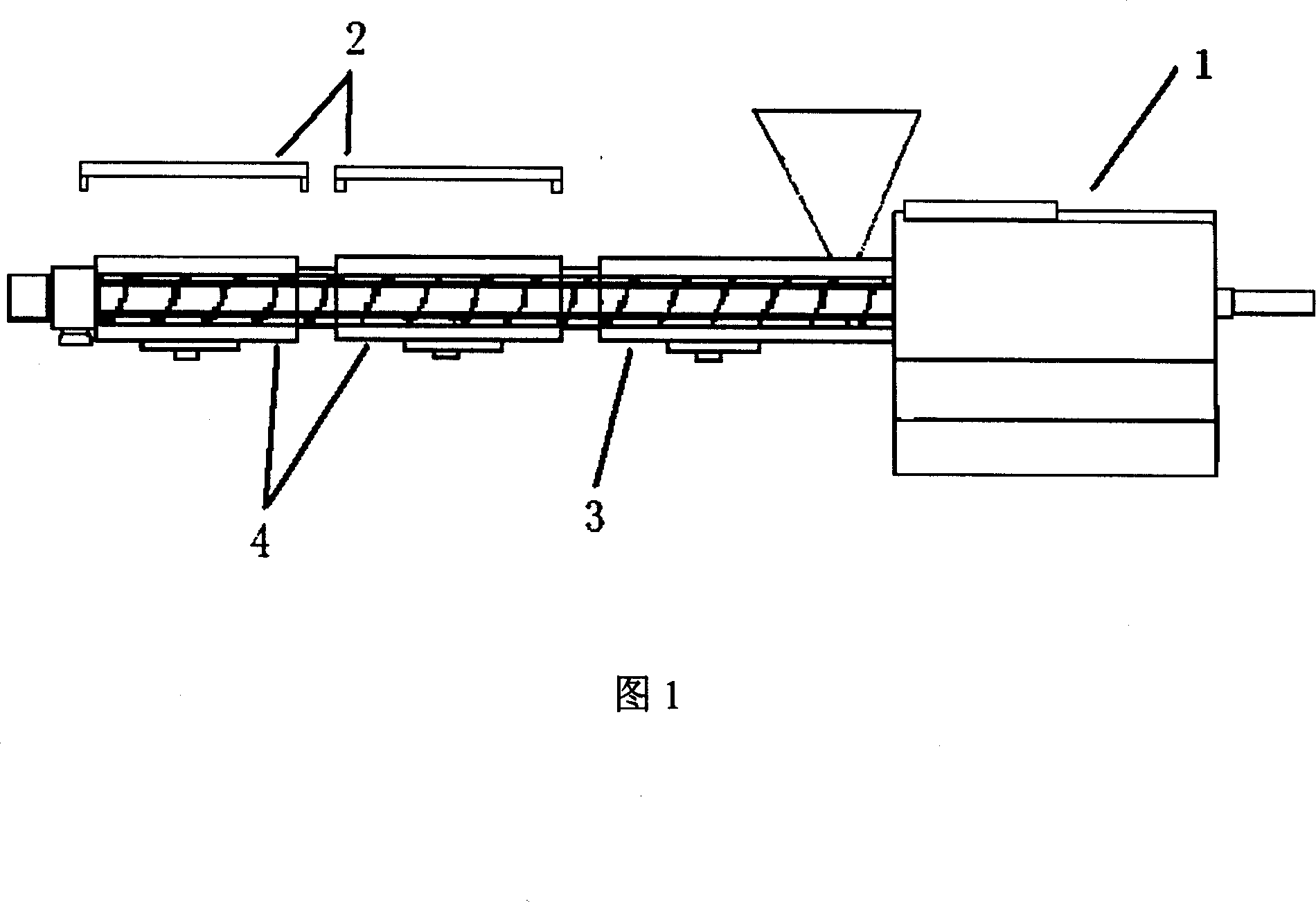

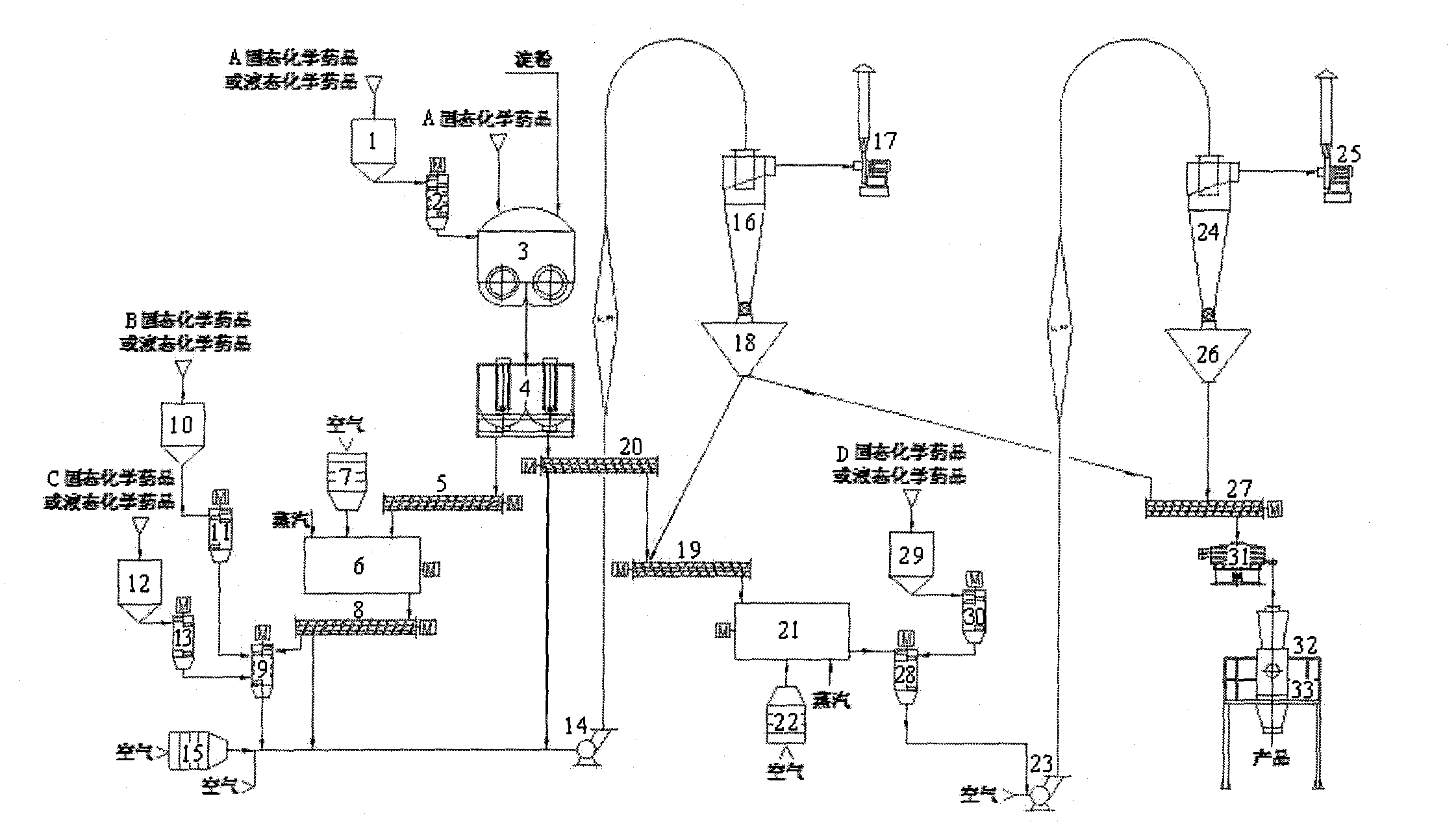

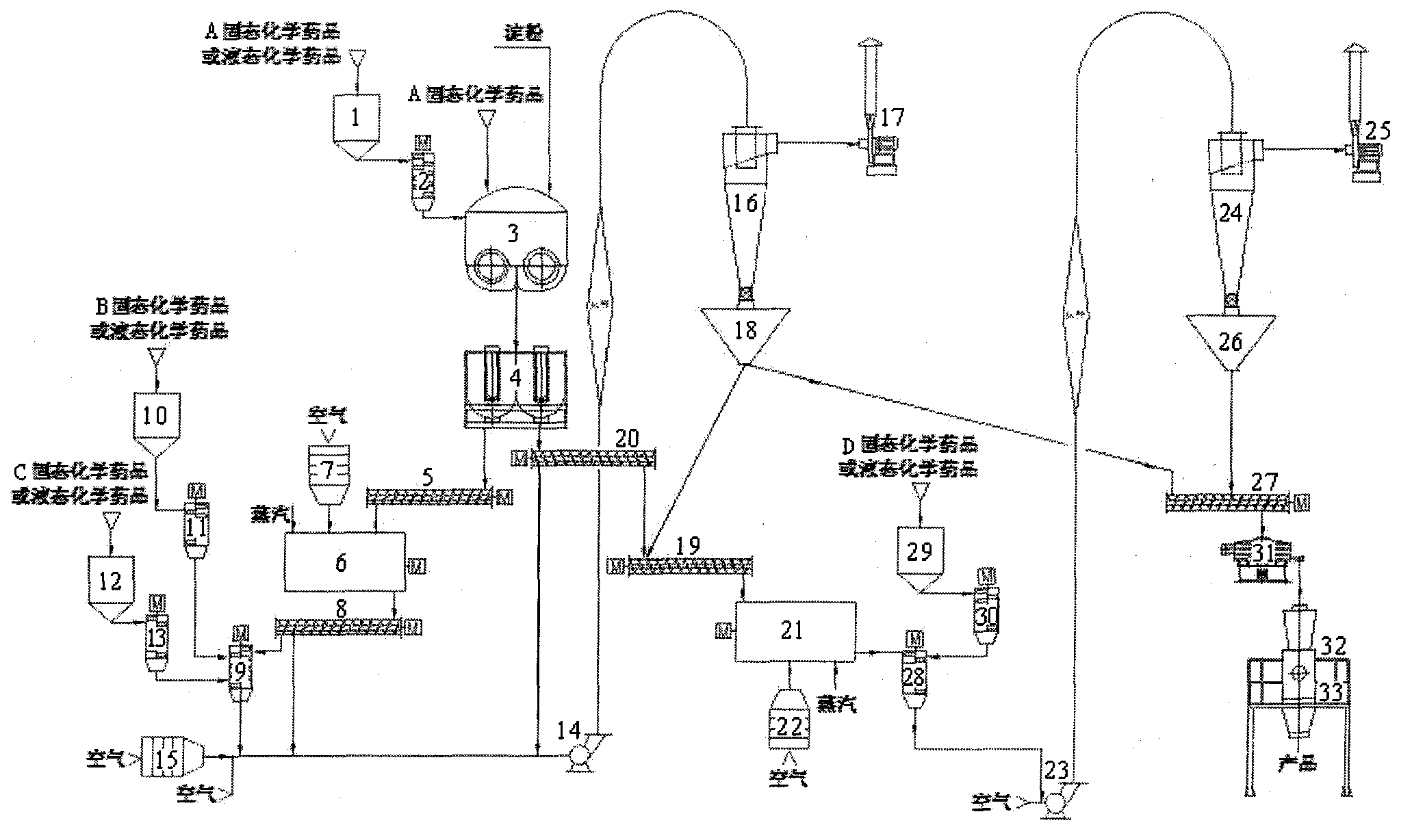

Dry-method double-modified starch continuous production device

InactiveCN102276740AEasy to replaceRealize large-scale continuous productionEcological environmentPhosphate

The invention discloses a dry-method double-modified starch continuous production device which is characterized by comprising a liquor tank, an atomization device, a mixer, a powder storage tank, a speed regulating and metering powder feeder, a reactor, a heater, a screw conveyer, a continuous mixer, a lifter, a classifier, an induced draught fan, a powder collection tank, a vibrating screen, a weighing scale and a packaging machine. Continuous feeding, discharging and reacting are realized; the reaction uniformity is high; starch reaction time is controlled by regulating powder feeding speedof the speed regulating and metering powder feeder; reaction temperature is controlled by regulating flow rates of hot air and steam; and the device meets the requirements of large-scale continuous production of dry-method double-modified or single-modified starch, such as cationized-phosphoric esterified starch, acidified-cationized starch, acidified-phosphoric esterified starch, dextrin, cationic starch, phosphate starch and the like. The production device has the advantages of less investment, high reaction conversion rate, high product yield, low production cost, high adjustability of production capacity, stable product quality and obvious ecological environment friendliness and economic benefits.

Owner:广西农垦明阳生化有限公司

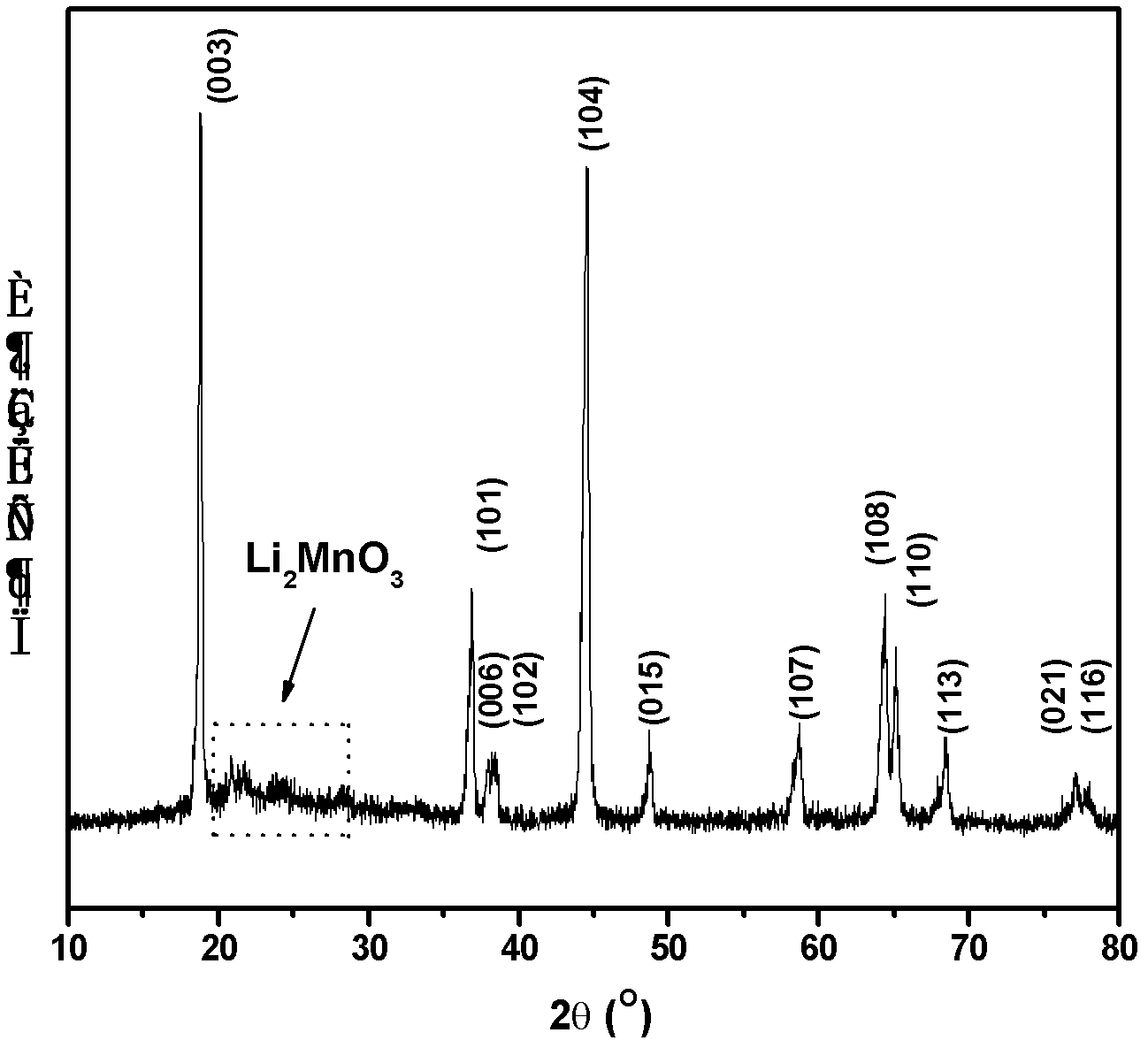

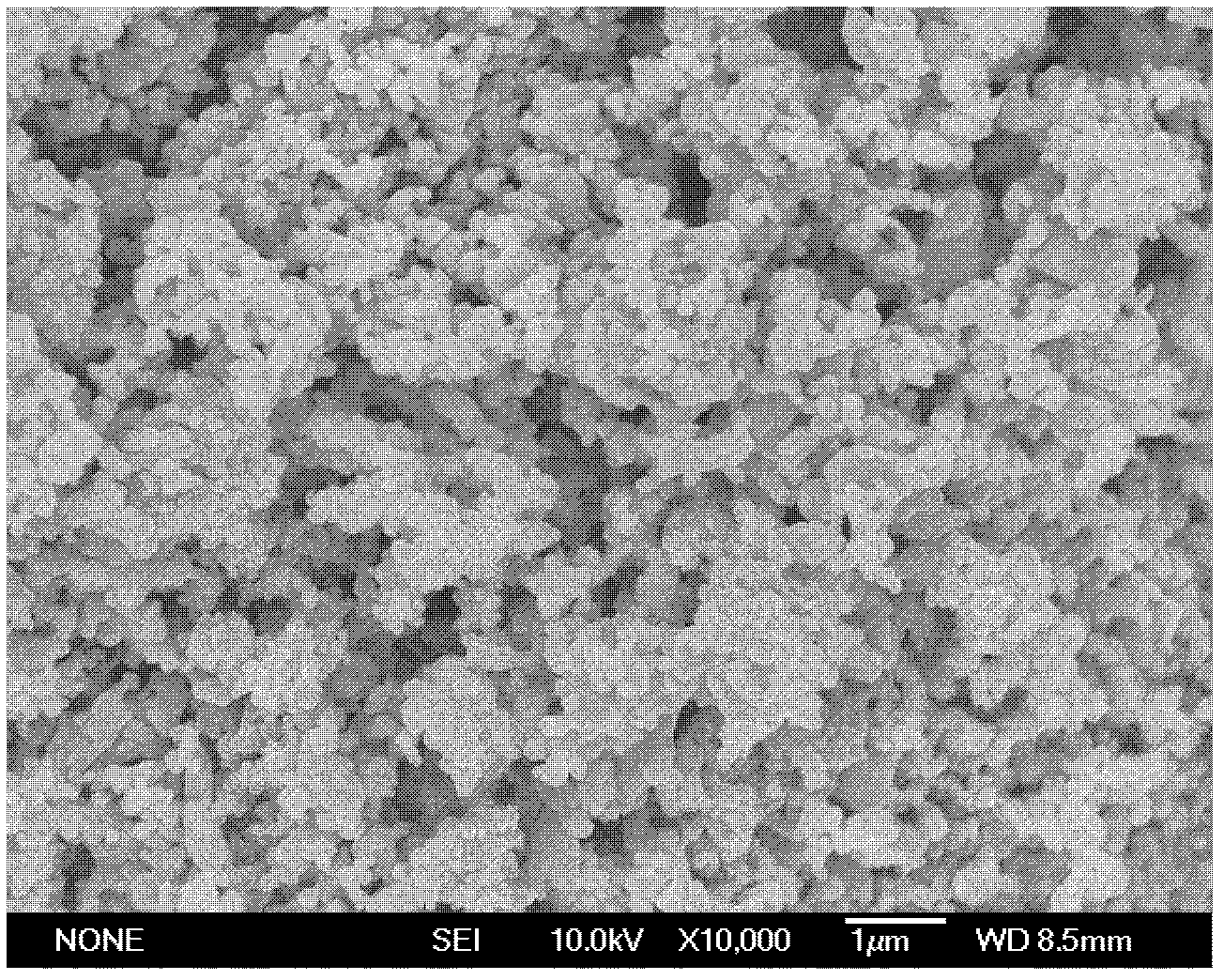

High capacity solid solution composite positive electrode material preparation method

InactiveCN103022466AWide variety of sourcesGood reproducibilityCell electrodesSolid reactionRoom temperature

The present invention relates to a high capacity solid solution composite positive electrode material preparation method, wherein a metal salt and a hydroxide are subjected to a solid phase reaction at a room temperature to obtain a nano-scale precursor, and then the metal salt in the precursor is adopted as a flux in the subsequent heat treatment process, such that the precursor is subjected to complete contact mixing and diffusion in the flux so as to achieve a rapid reaction purpose, and the solid solution composite positive electrode material xLi2MnO3.(1-x)LiMn0.5Ni0.5O2 is finally prepared, wherein x is 0.1-1.0. According to the present invention, lithium ion battery production products produced by using the solid solution composite positive electrode materials have stable electrochemistry performance, stable cycle performance and good reproducibility; and the preparation method has advantages of easy operation, practical process, good safety, low cost, high product material purity, excellent electrochemical performance and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

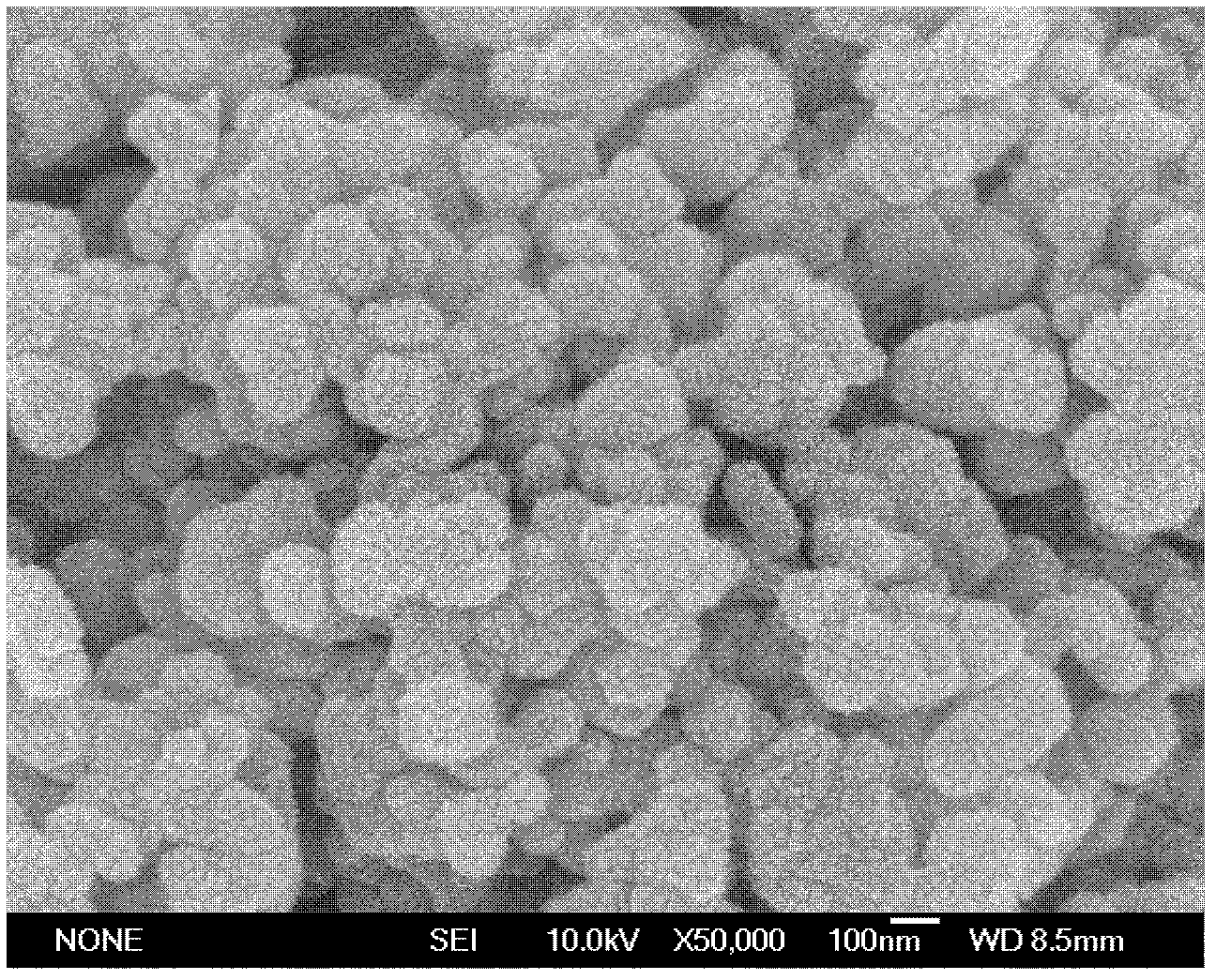

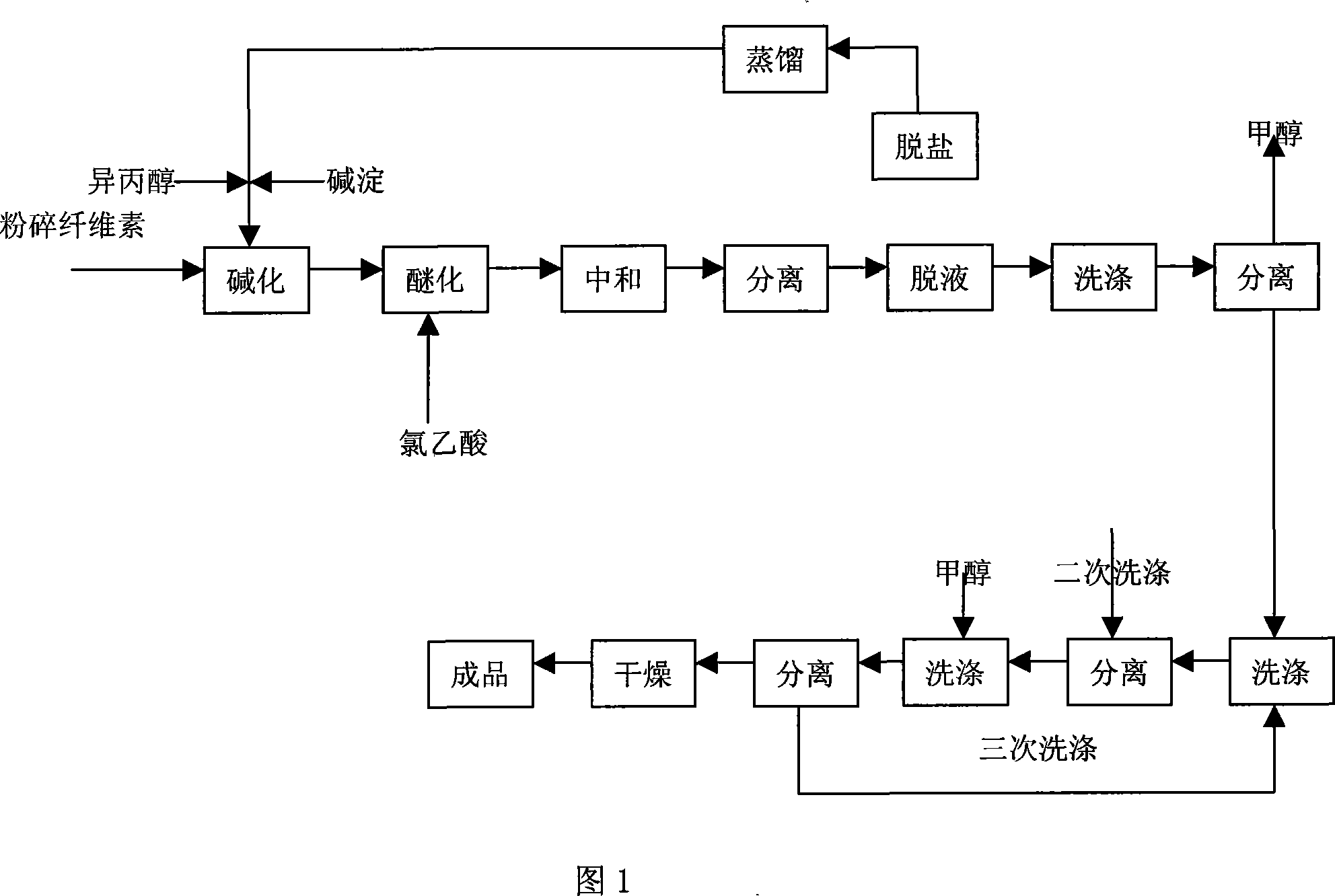

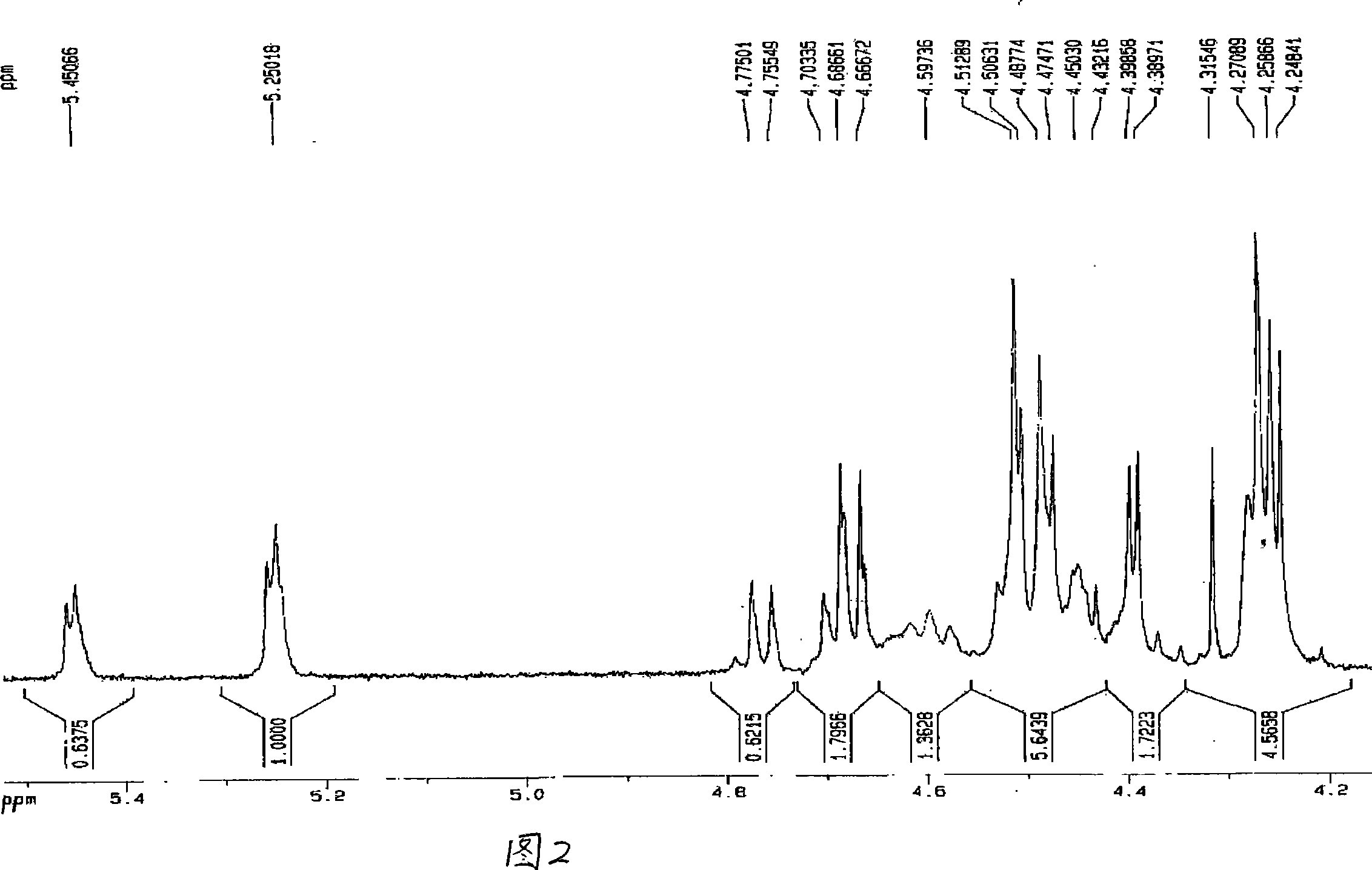

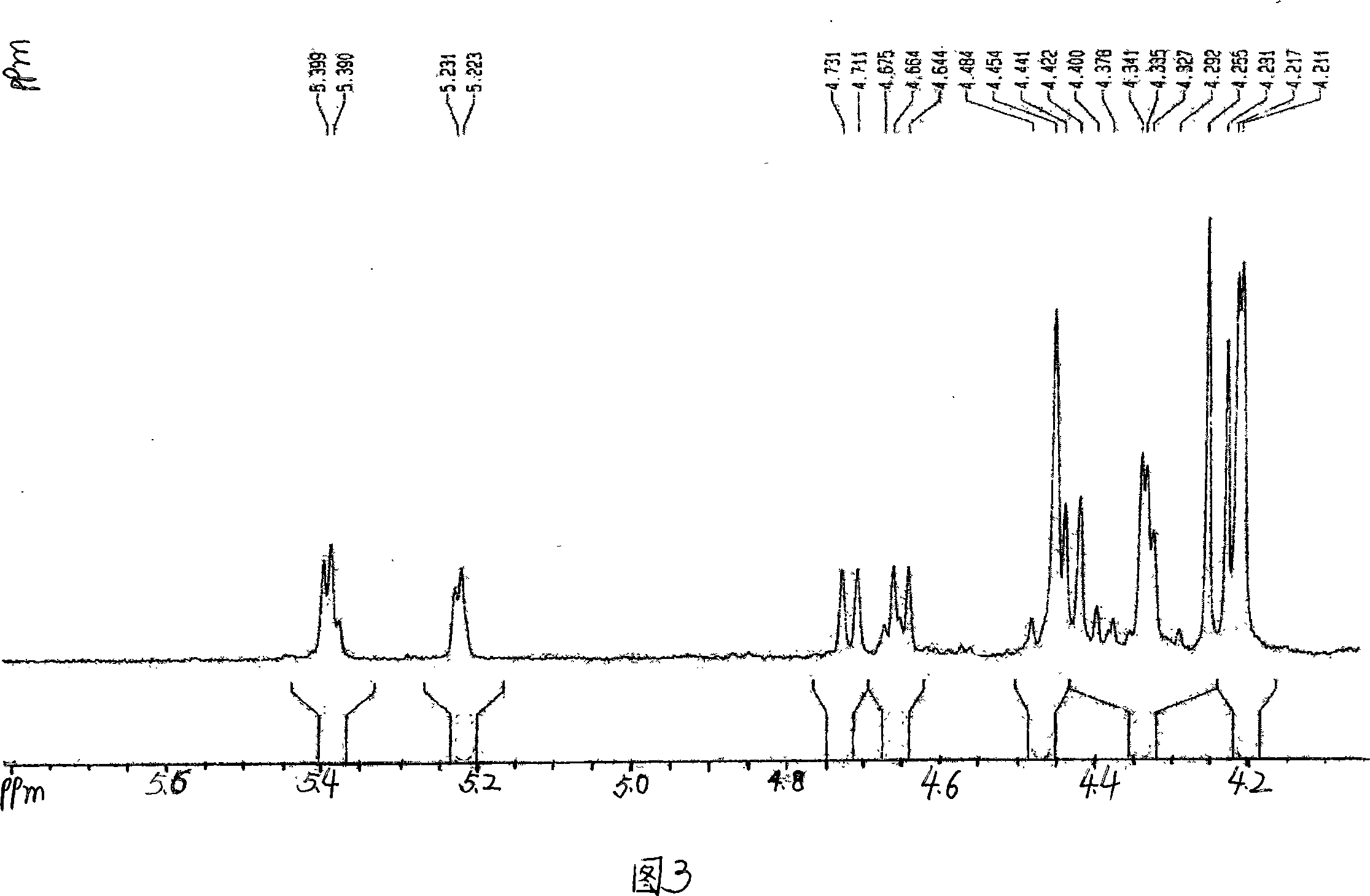

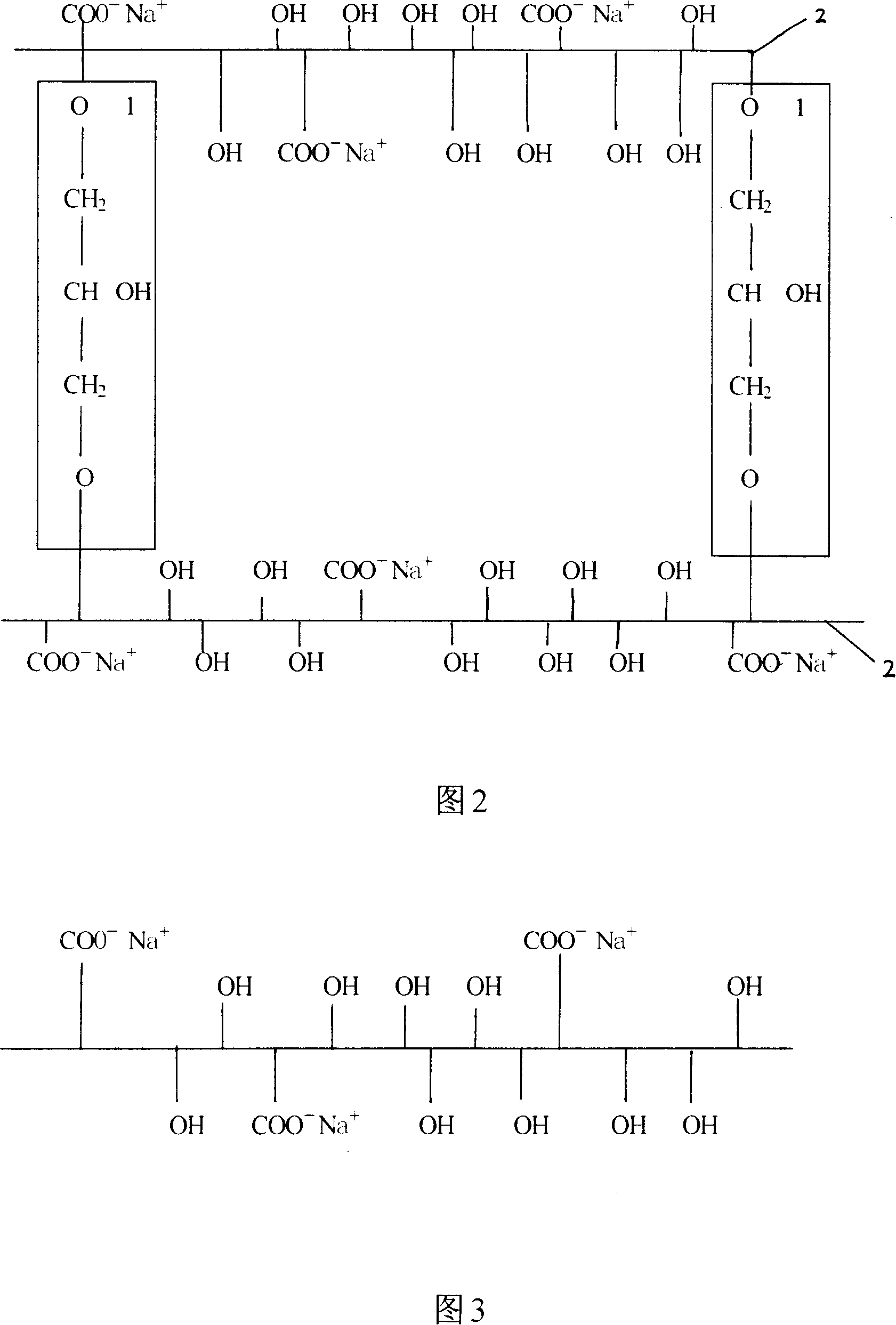

Polyanion cellulose and preparation method and uses thereof

The present invention discloses polyanionic cellulose with a special quality, the multi-step slurry process for preparing the polyanionic cellulose and the ternary complex solvent required. The complex solvent is composed of (A) from 71 percent to 87 percent by weight of isopropyl alcohol, (B) from 10 percent to 20 percent by weight of alcohol and from 71 percent to 87 percent by weight of the soft water. The multi-step slurry process for preparing the polyanionic cellulose has a more excellent technical effect on material economizing, time saving and the properties of product than the traditional one-step slurry process for preparing the polyanionic cellulose. Compared with the properties the product produced by the traditional method, the acid resistance is raised by more than 20 percent, and the viscosity is greatly improved. The polyanionic cellulose is widely used in the fields like petroleum, paint, detergent, building materials, textile industry, paper marking, medicines, foodstuff, etc.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

Method for preparing high thermal conductivity aluminum nitride powder based on graphene

The invention discloses a method for preparing high thermal conductivity aluminum nitride powder based on graphene. The method comprises the following steps of enabling aluminum oxide and the grapheneto be prepared into mixed powder in a mole ratio of (1 to 5)-(5 to 1); enabling the mixed powder to be subjected to nitridation reaction in the atmosphere of nitrogen gas or ammonia gas at the high temperature of 1,200-2,000 DEG C, and maintaining the nitridation reaction for 1-8 hours; introducing reducing gas in the process of nitridation reaction cooling so as to carry out deoxygenization, andcooling to obtain the high thermal conductivity aluminum nitride powder; enabling the powder, which is obtained after the nitridation reaction, to be subjected to low-temperature calcination decarbonization at 500-800 DEG C in the atmosphere of air, maintaining decarbonization time for 0.5-4 hours, and cooling to obtain the high thermal conductivity aluminum nitride powder. The graphene is adopted as a carbon source and has extremely high reactivity and reaction uniformity. In the process of nitridation reaction cooling, the reducing gas is introduced to perform deoxygenization operation, andthe material heat-conducting property is further improved. The method disclosed in the invention has the advantages of low reaction temperature, simple process, low energy consumption, high product performance and the like.

Owner:WUXI HUICHENG GRAPHITE ALKENE TECH APPL CO LTD

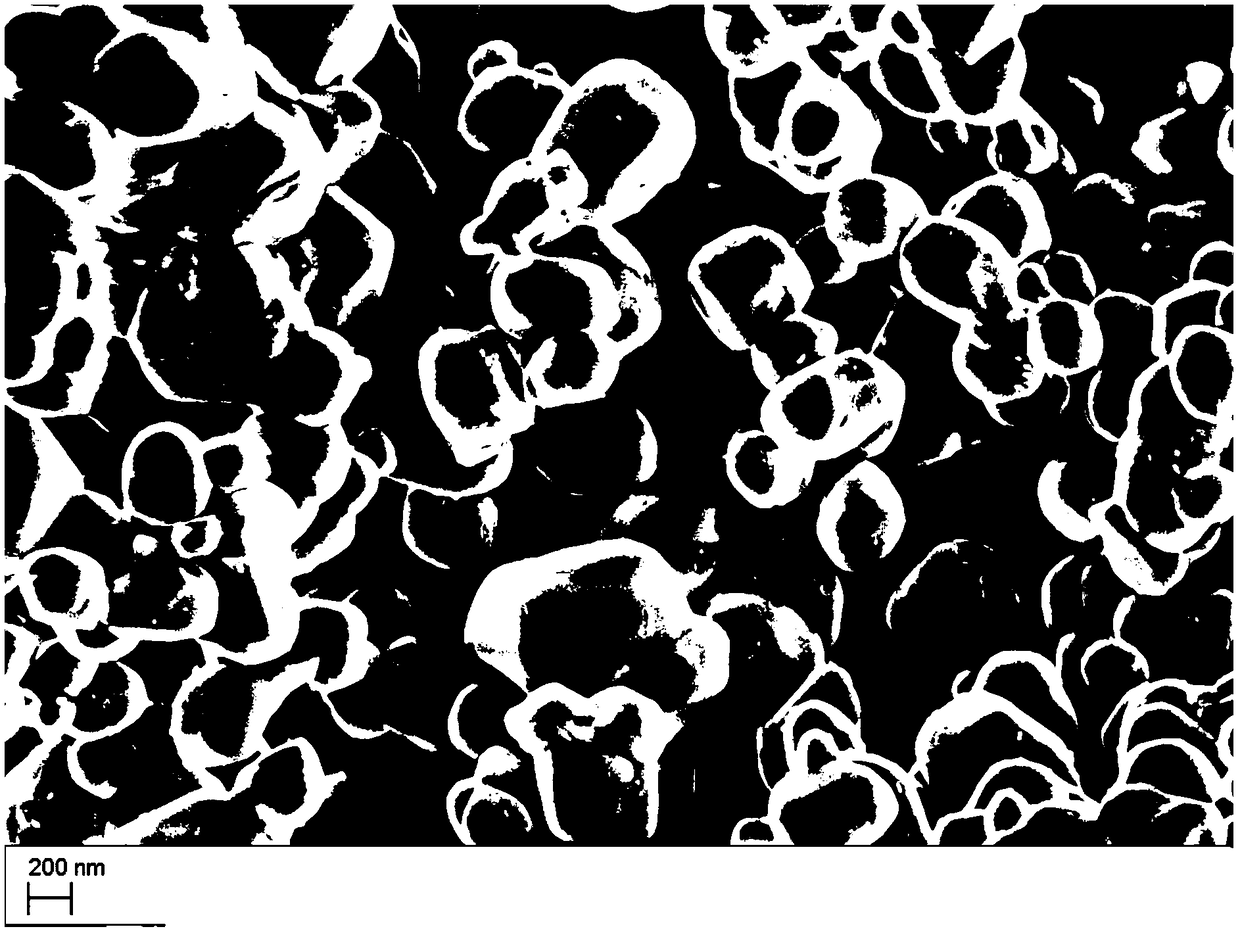

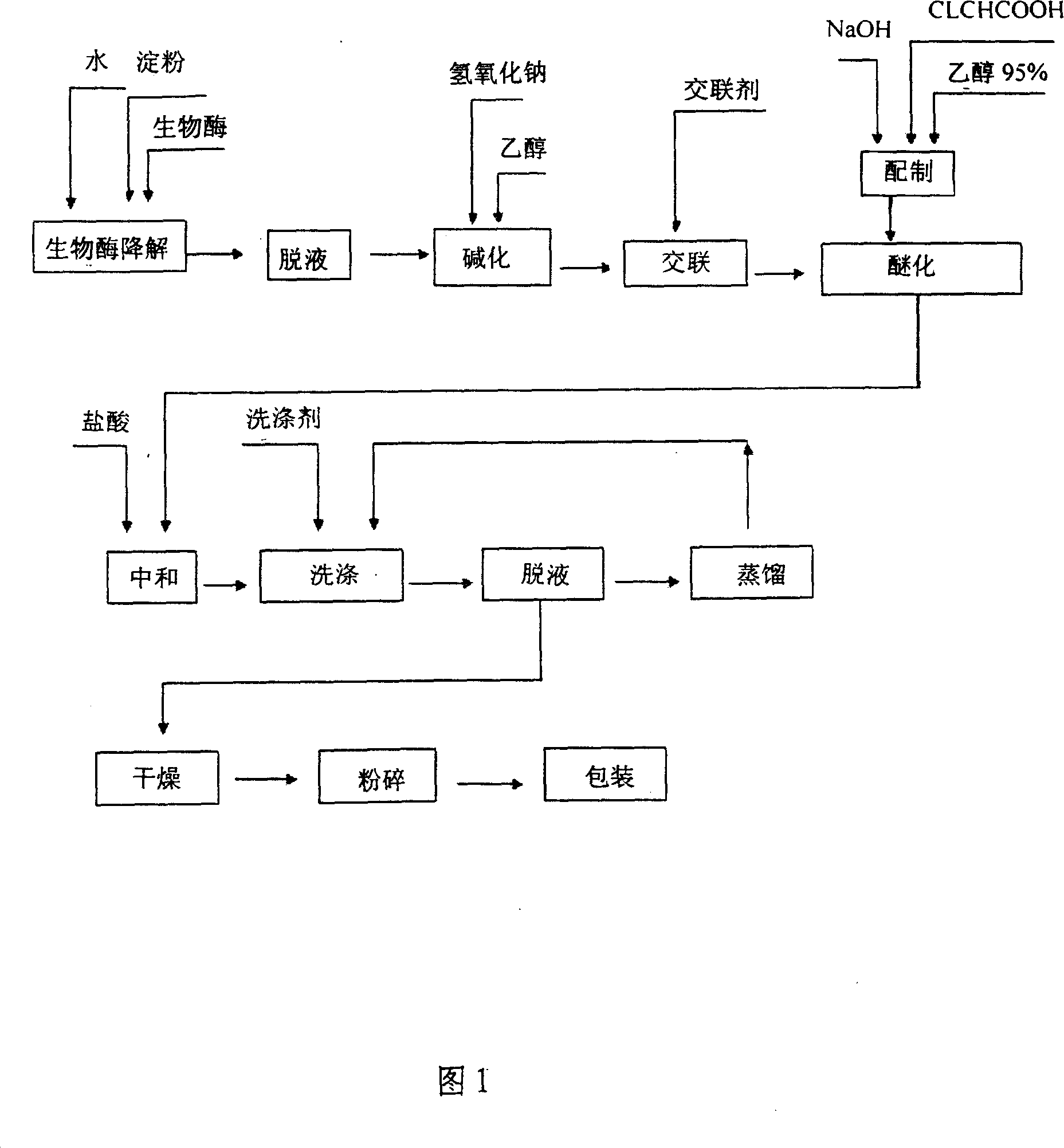

Preparation of medicinal disintegrating agent with biological enzymatic isolation method

InactiveCN101108251AImprove the uniformity of the reactionHigh reactivityPharmaceutical non-active ingredientsControlled releaseActive enzyme

The invention discloses a medical additives added into a medicine, in particular to a method to produce medicinal disintegration by biological enzymic method. The main technique is that: taking corn starch as the main material and ethanol as the dispersing agent. Making use of the selectivity of the biological enzyme Alpha-amylase to make the starch interrupt the chain structure under the effect of the biological active enzyme. By means of a plurality of compound degeneration ways such as alkalization, crosslinking and etherification, the starch is made into a new network structure and strong suction group. The invention has the advantages of the excellent efficacy, high absorbent, quick disintegration and controllable release, and can be widely used as releasing medicinal disintegration in tablets, capsules, controlled-release agent and granules.

Owner:SIPING DONGYI INNOVATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com