Composite catalytic system and production method of PVB resin adopting composite catalytic system

A catalytic system and production method technology, applied in the field of polymer chemistry, can solve the problems of not reducing the viscosity of PVB materials, not substantially promoting the reaction, etc., to achieve the effect of improving the uniformity of the reaction, promoting the precipitation and reducing the viscosity of the reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

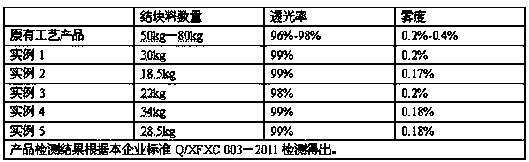

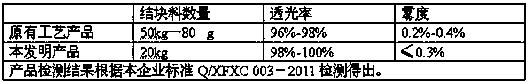

Examples

example 1

[0019] Preparation of composite catalytic system: Dissolve 0.2kg of sodium dodecylbenzenesulfonate and 1.8kg of tetrabutylammonium bromide in 8kg of distilled water and stir evenly to make the mass ratio of emulsifier to phase transfer catalyst 1: The composite catalytic system solution of 9 is standby;

[0020] Dissolve PVA and add to the composite catalytic system: Dissolve 5kg of PVA in 50kg of distilled water, add 0.75kg of hydrochloric acid with a mass concentration of 30%, adjust the pH to ≤2, then add 2kg of the pre-prepared composite catalytic system solution, stir evenly, and cool down to 10°C. At this time, the mass ratio of PVA, inorganic acid and composite catalytic system is 100:4.5:8;

[0021] Condensation reaction with butyraldehyde: under stirring, slowly add 1.95kg of butyraldehyde to the above reactant within 30 minutes, keep it for 30 minutes and then add 1kg of butyraldehyde, keep it for 30 minutes after adding butyraldehyde, and then keep it at a constant ...

example 2

[0025] Dissolve 0.15 kg of dioctyl sulfosuccinate sodium salt and 0.85 kg of tetrabutylammonium chloride in 9 kg of distilled water, and stir evenly to make an aqueous solution of a composite catalytic system with a mass ratio of emulsifier to phase transfer catalyst of 3:17. All the other steps are the same as Example 1.

example 3

[0027] Add 15kg of hydrochloric acid with a mass concentration of 30% to 1 ton of PVA aqueous solution with a mass concentration of 9%, then add 1.5kg of sodium lauryl sulfate and 10kg of dodecyltrimethylammonium chloride, stir well and then cool down to 15°C . That is, the emulsifier and phase transfer catalyst are directly added to the reaction solution in proportion, without making them into a solution in advance;

[0028] Under the condition of stirring, slowly add 50kg of butyraldehyde to the above reaction solution twice within 90 minutes, keep warm for 60 minutes after the addition of butyraldehyde, raise the temperature to 55°C within 2 hours, and keep at this temperature for 1 hour;

[0029] After the heat preservation is completed, add lye to adjust the pH value of the reaction system to 5 and keep it for 30 minutes;

[0030] Wash the reaction product 6 times with distilled water, add lye to adjust the pH value of the reaction system to 8.5, wash the reaction produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com