Magnesium alloy composite surface protective treatment equipment and magnesium alloy composite surface protective treatment method

A composite surface and processing equipment technology, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as fatigue strength reduction, improve corrosion resistance, reduce concentration gradient, and operate methods simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

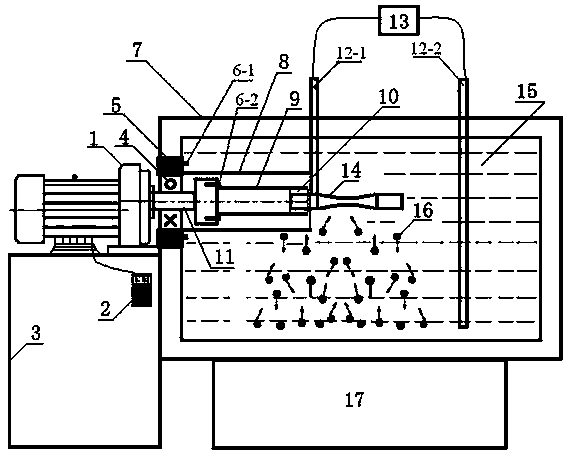

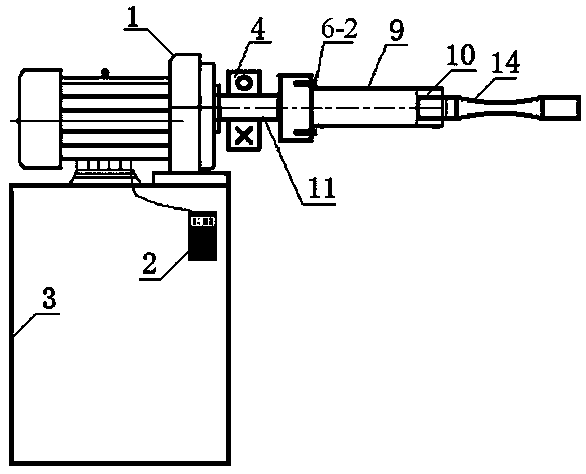

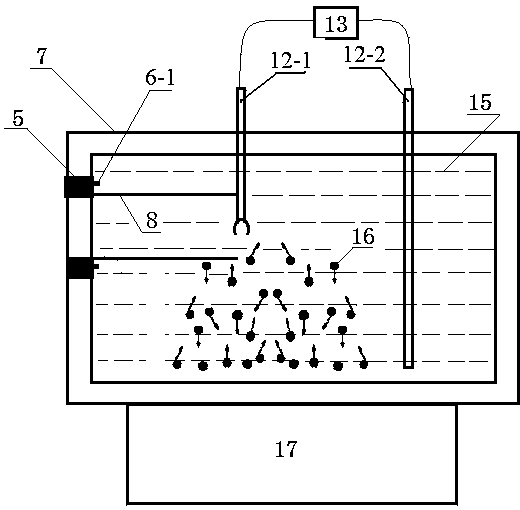

[0030] like figure 1 , 2 Shown in and 3, the magnesium alloy composite surface protection treatment equipment of the present embodiment comprises an anodizing device, a magnesium alloy sample rotating device and a surface mechanical grinding device, the anodizing device comprises an electrolytic cell 7, and the electrolytic cell 7 is filled with an electrolyte 15 , positive electrode 12-1 and negative electrode 12-2 are provided in the electrolytic cell 7, and positive electrode 12-1 and negative electrode 12-2 are connected by power supply 13, and the surface mechanical grinding device is made up of vibration generator 1 and some projectiles 16 , the vibration generator 17 is fixedly arranged under the electrolytic cell 7, and several projectiles 16 are placed on the lower plate of the electrolytic cell 7. The vibration frequency range of the vibration generator 17 is 10-1000 Hz, and several projectiles 16 are spherical ceramic shots and are enough to ensure impact The unifo...

Embodiment 2

[0039] The magnesium alloy composite surface protective treatment equipment and method in this embodiment are the same as in Example 1. In this example, the extruded magnesium alloy AZ31 fatigue sample is protected and treated, and the method is as follows:

[0040] First, the fatigue sample of the extruded magnesium alloy AZ31 is alkali-washed in an alkaline solution of the following composition:

[0041] sodium hydroxide 50g / L sodium phosphate 15g / L lubricant 30ml / L water margin

[0042] After water washing, pickling is carried out in the following acidic solution:

[0043] Phosphoric acid (85%) 350ml / L Sulfuric acid (98%) 15ml / L water margin

[0044] After water washing, anodic oxidation and surface mechanical grinding are carried out in the electrolyte solution of the following composition:

[0045] Phosphoric acid (H 3 PO 4 ) 50g / L Hydrofluoric acid (HF) 35g / L Boric acid (H 3 ...

Embodiment 3

[0048] The magnesium alloy composite surface protective treatment equipment and method in this embodiment are the same as in Example 1. In this example, the extruded magnesium alloy AZ31 fatigue sample is protected and treated, and the method is as follows:

[0049] The extruded state magnesium alloy AZ31 fatigue sample is carried out alkali washing and pickling with the solution of embodiment 2, and then anodic oxidation and surface mechanical grinding are carried out in the following electrolyte;

[0050] Potassium phosphate (K 3 PO 4 ) 60g / L Potassium borate (K 3 BO 3 ) 30g / L Potassium fluoride (KF, 30%) 30g / L water margin

[0051] use NH 4 OH (25%) to adjust the pH value to 7.5, using a current density of 1.3A / dm 2 The direct current: the final voltage is 300V; the solution temperature is 16 °C; the rotation speed of the sample rotating device is 30 revolutions / second, the diameter of the ceramic pellet is 1 mm, the vibration fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com