Patents

Literature

108results about How to "Decrease the concentration gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microfluidic systems, devices and methods for reducing noise generated by mechanical instabilities

InactiveUS20090139576A1Reducing concentration gradient noiseDecrease the concentration gradientFlow mixersLaboratory glasswaresConcentration gradientEngineering

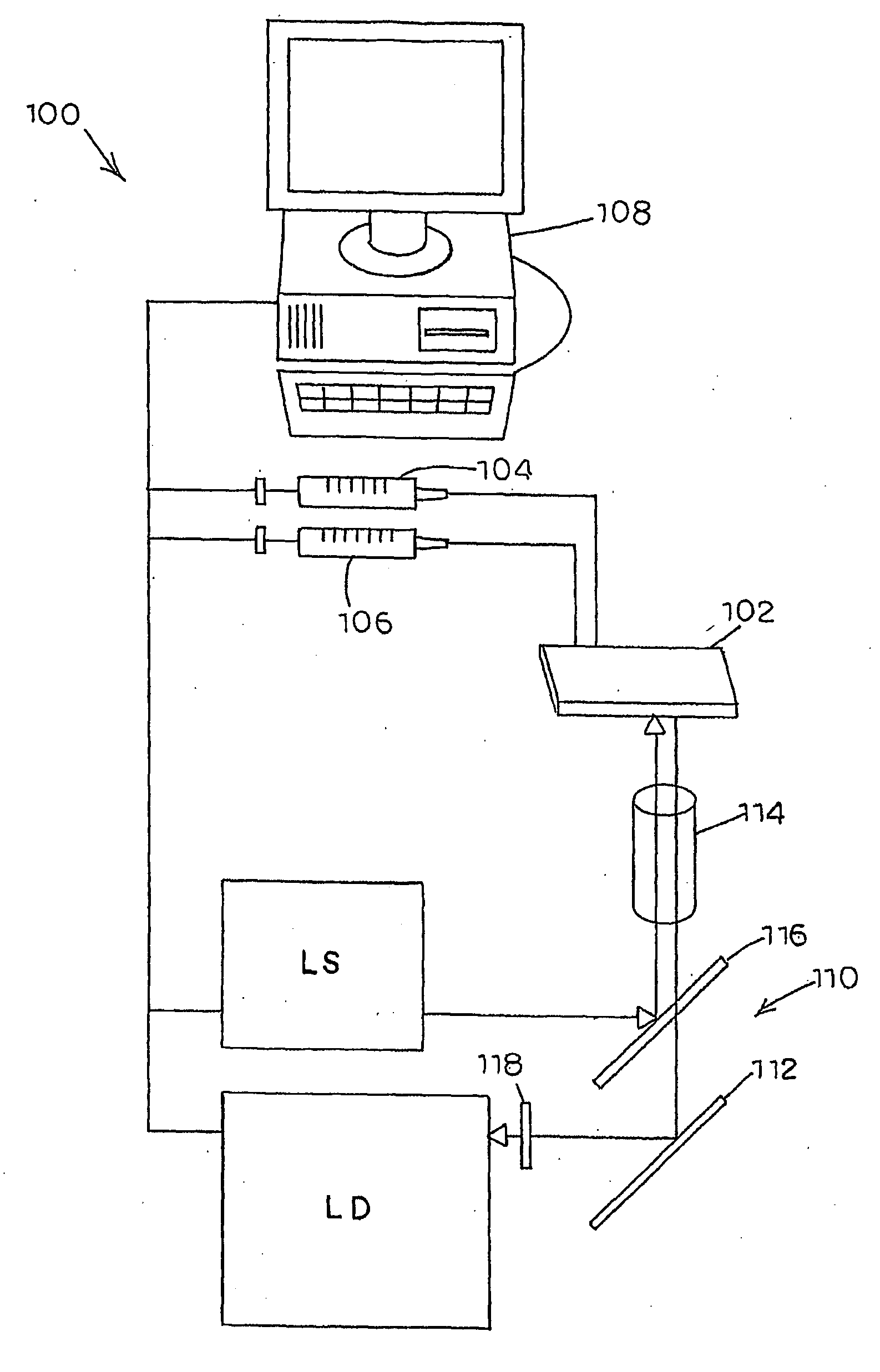

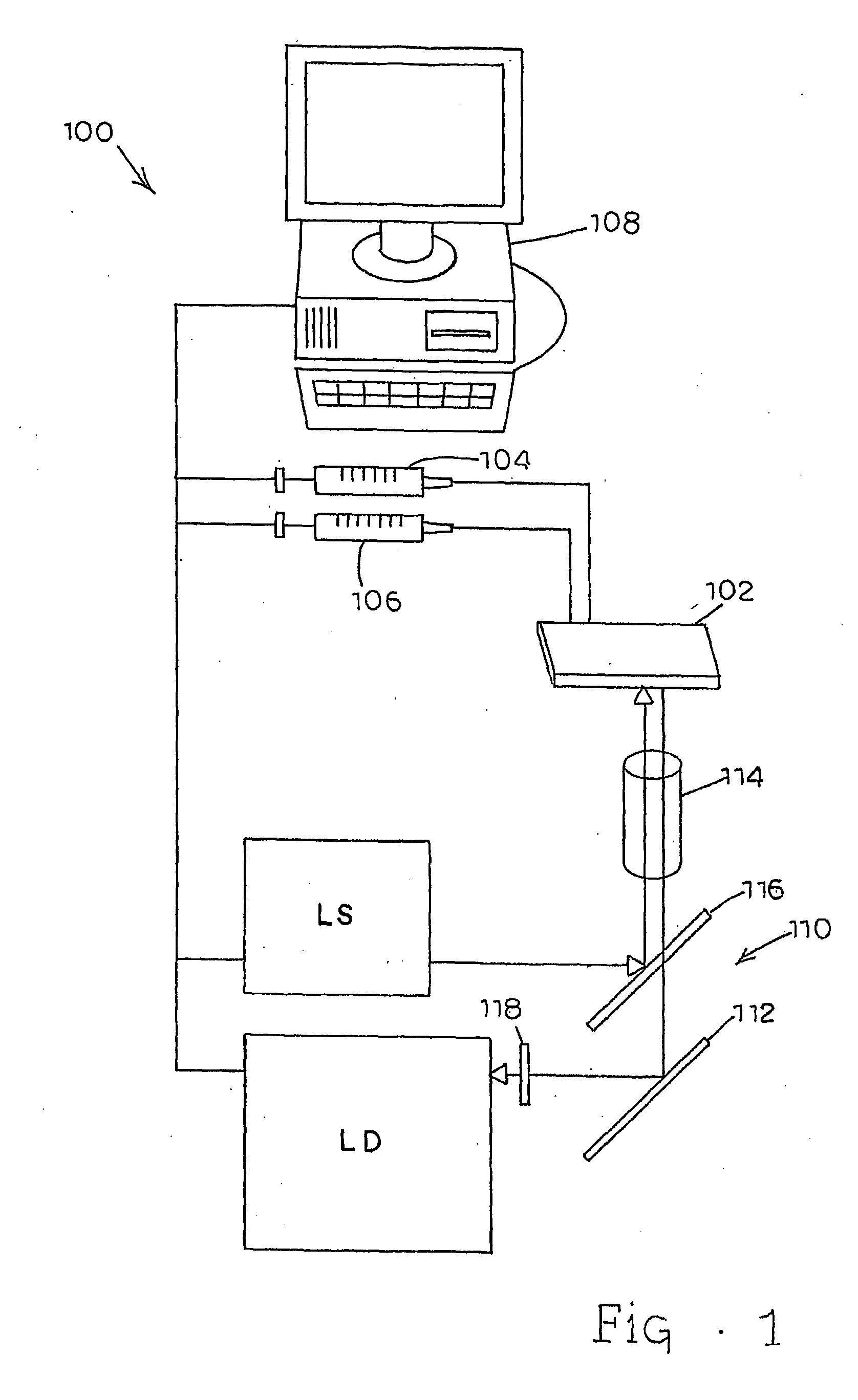

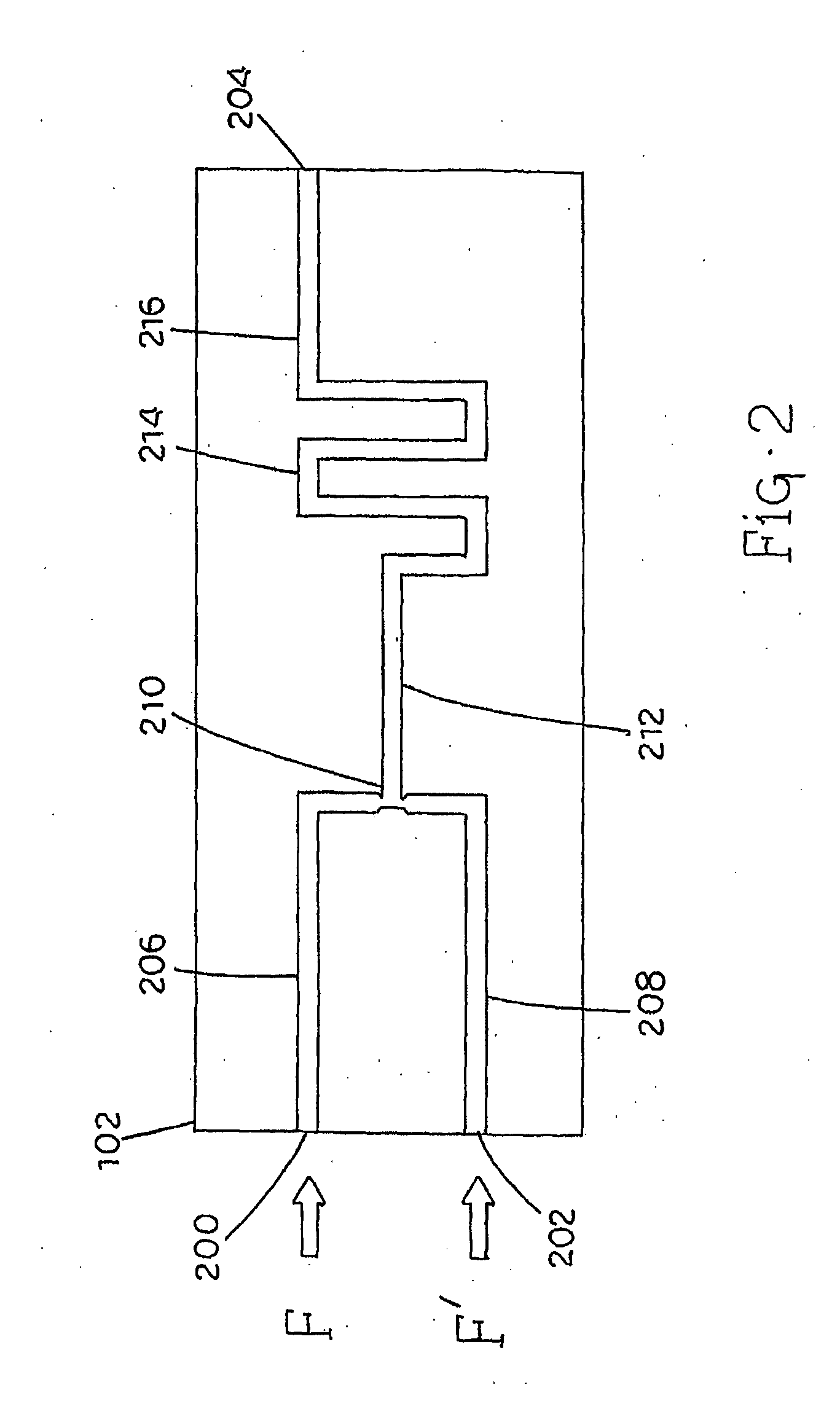

Microfluidic Systems, Devices and Methods for Reducing Noise Generated by Mechanical Instabilities. According to one embodiment, a microfluidic device is provided for reducing noise in a fluid mix. The microfluidic device can include microscale channels for passage of fluids to a mixing junction. The mixing channel can be adapted to combine the fluids into a common fluid flow. The microfluidic device can also include a connector channel including first and second ends. The first end of the connector channel can be connected to the mixing junction. The microfluidic device can also include an expansion channel having connection to the second end of the connector channel. The expansion channel can be adapted for passage of the fluid mix through the expansion channel to reduce concentration gradient noise of the fluid mix by dispersion of the fluid mix as the fluid mix passes through the expansion channel.

Owner:SCIEX

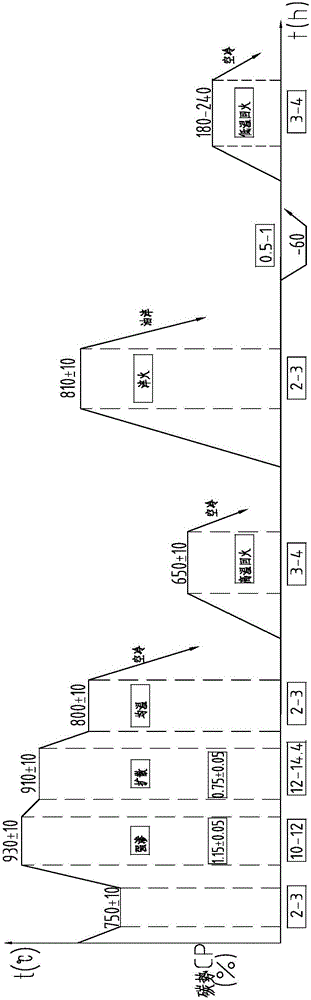

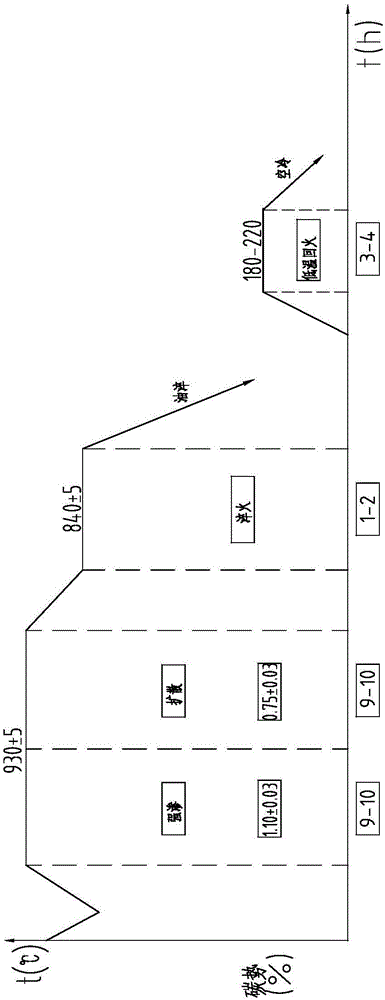

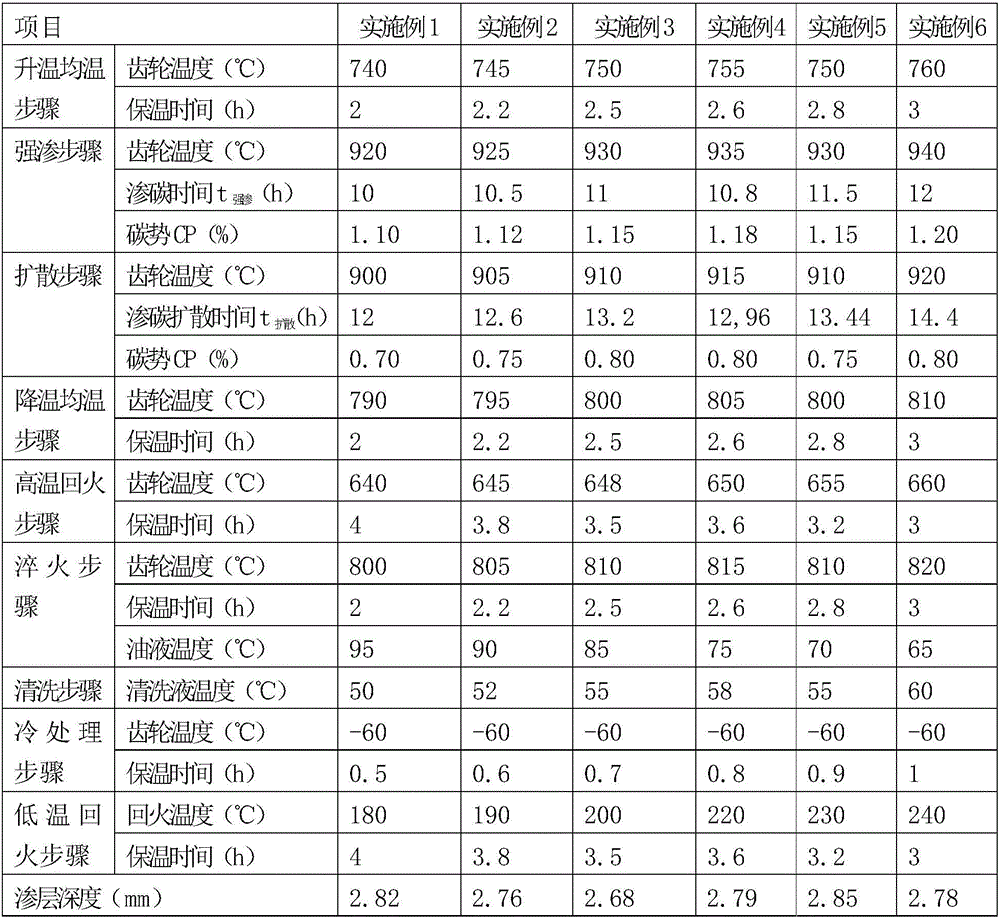

Carburizing and quenching method of low-speed heavy-duty gear

ActiveCN106756753AReduce carbon contentReduce carburizing potentialSolid state diffusion coatingFurnace typesCold treatmentLow speed

The invention relates to a carburizing and quenching method of a low-speed heavy-duty gear. The carburizing and quenching method comprises the steps of (1) temperature increase and temperature uniformization; (2) strong carburizing; (3) diffusion; (4) temperature decrease; (5) high-temperature tempering; (6) quenching; (7) cold treatment; and (8) low temperature tempering. According to the carburizing and quenching method of the low-speed heavy-duty gear, harmful carbide of a gear carburized layer can be effectively removed, dispersively distributed fine granular carbide can be obtained, the content of retained austenite on the surface is greatly decreased, a metallographic structure of the gear surface is improved, the surface hardness and abrasion resistance of the gear are improved, and the heat treatment property of a product is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

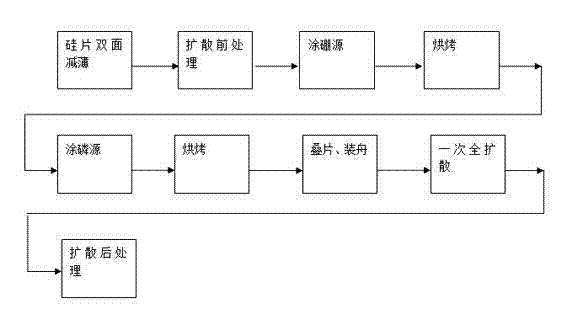

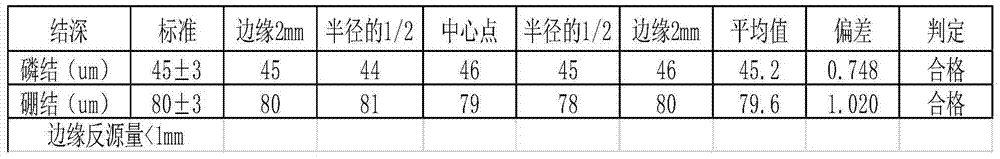

Phosphorus and boron liquid source one-shot perfect diffusion process

ActiveCN104766790ASmall amount of feedbackImprove effective area utilizationSemiconductor/solid-state device manufacturingConcentration gradientProcessing cost

The invention discloses a phosphorus and boron liquid source one-shot perfect diffusion process. The process is mainly implemented through the following steps that one surface of each silicon wafer with two thinned sides is rotated to be coated with a liquid boron source, baked and then rotated again to be coated with a liquid phosphorus source, lamination is conducted after baking, the silicon wafers are stacked on a silicon boat pairwise to be subjected to one-shot perfect diffusion in the mode that each phosphorus source surface is opposite to the corresponding phosphorus source surface and each boron source surface is opposite to the corresponding boron source surface. Diffused junction depth is even, and reverse breakdown voltage of a product can be stable and good in uniformity; the diffusion concentration gradient is reduced, PN junction field intensity can be effectively improved, discharging-resistant capacity of the product is improved, and the reverse surge capacity of the product can be effectively improved; meanwhile, the source return quantity of the edge of the silicon wafer is small, the number of intra defects is small, and product reliability is high. Processing cost is low, the process is simple, and production is easy.

Owner:SUZHOU QILAN POWER ELECTRONICS

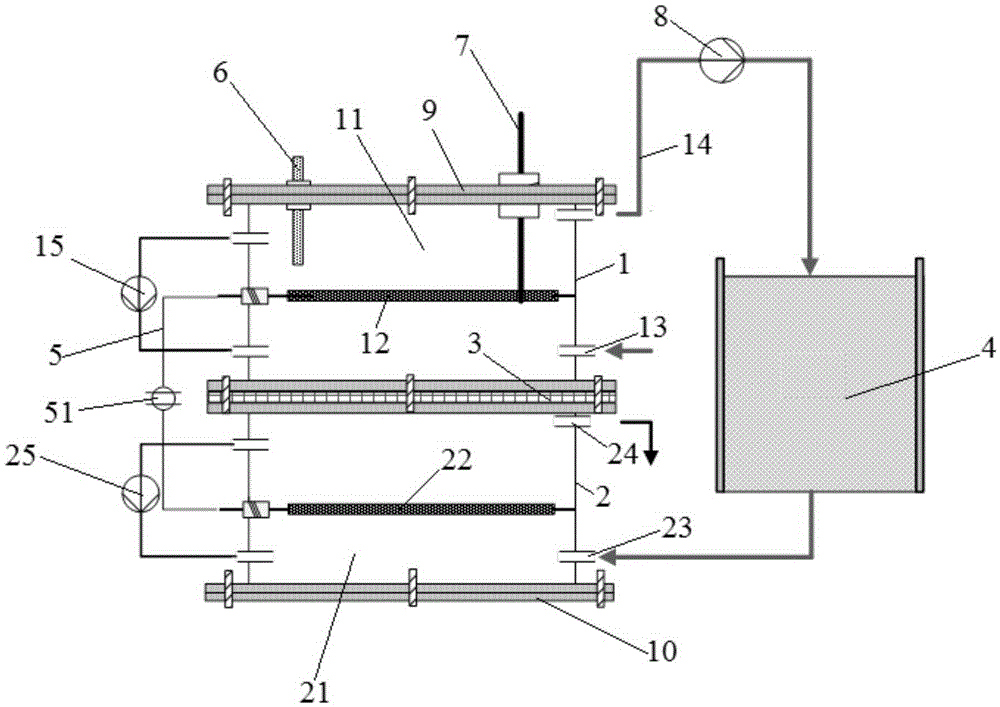

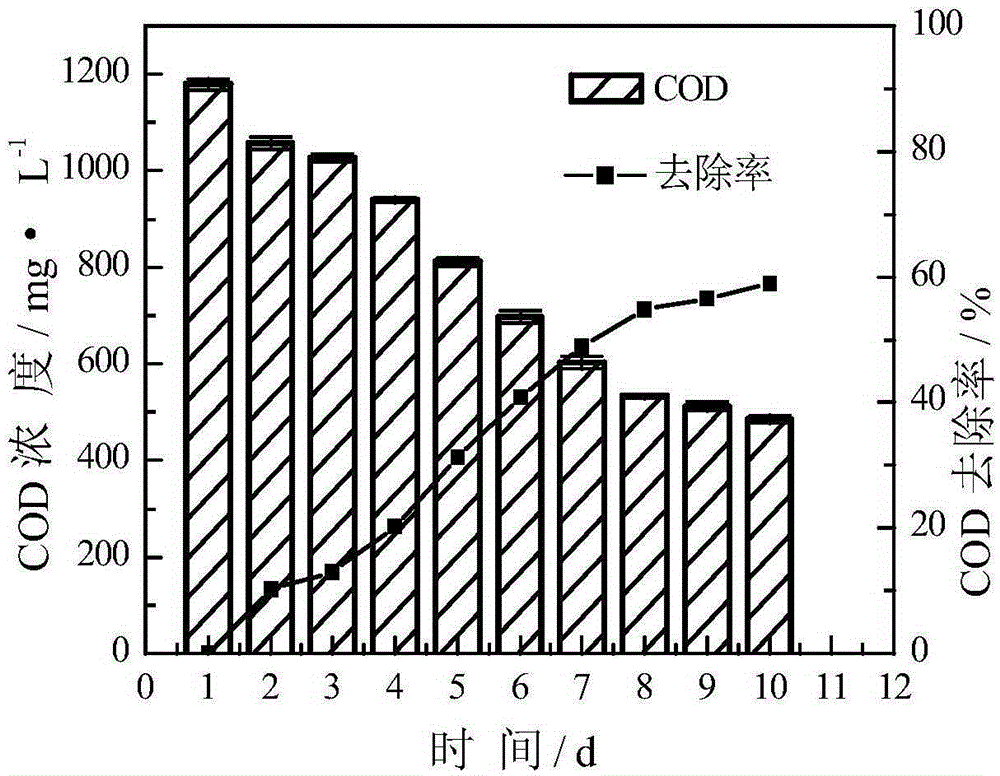

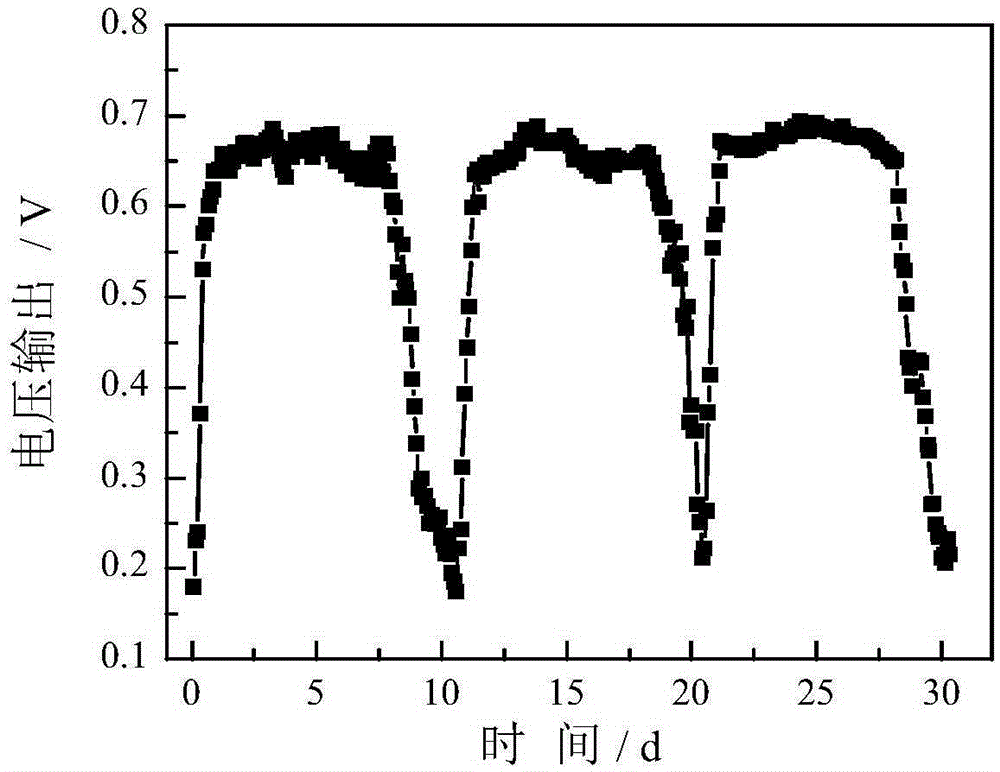

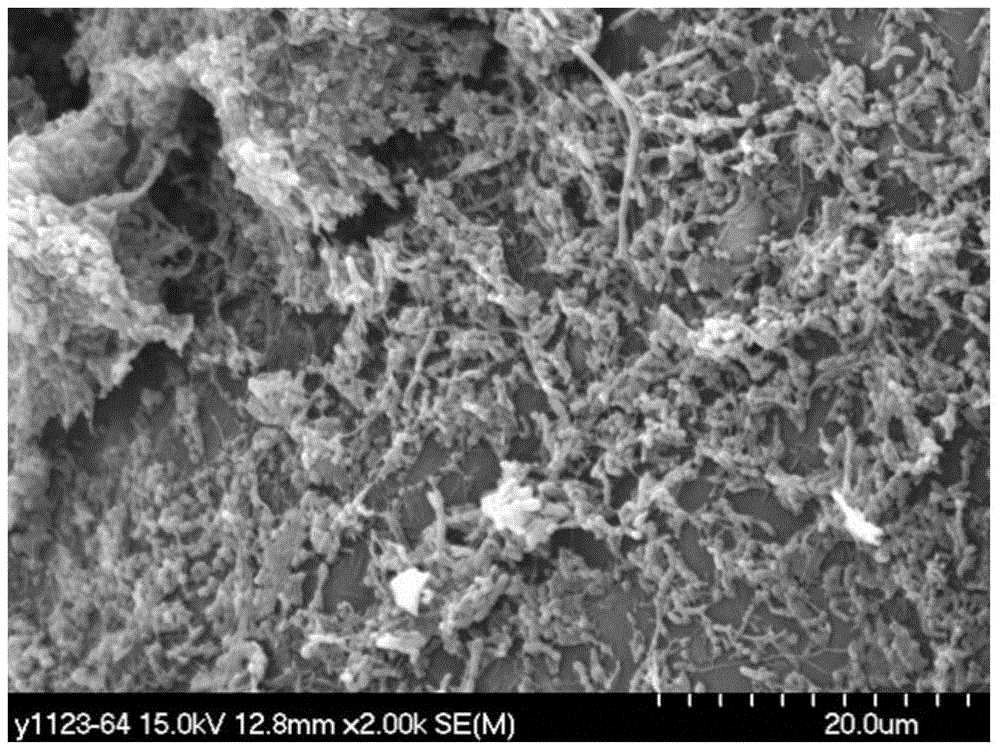

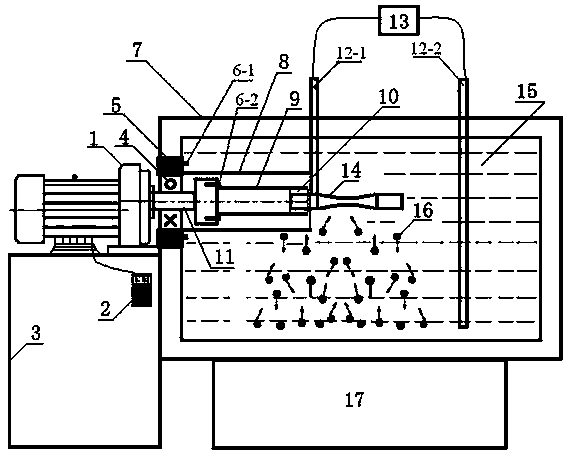

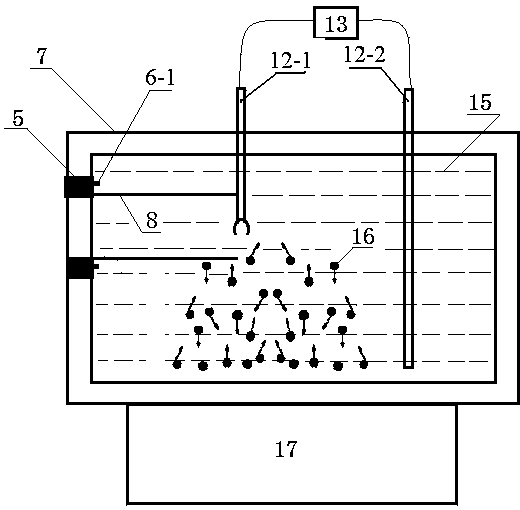

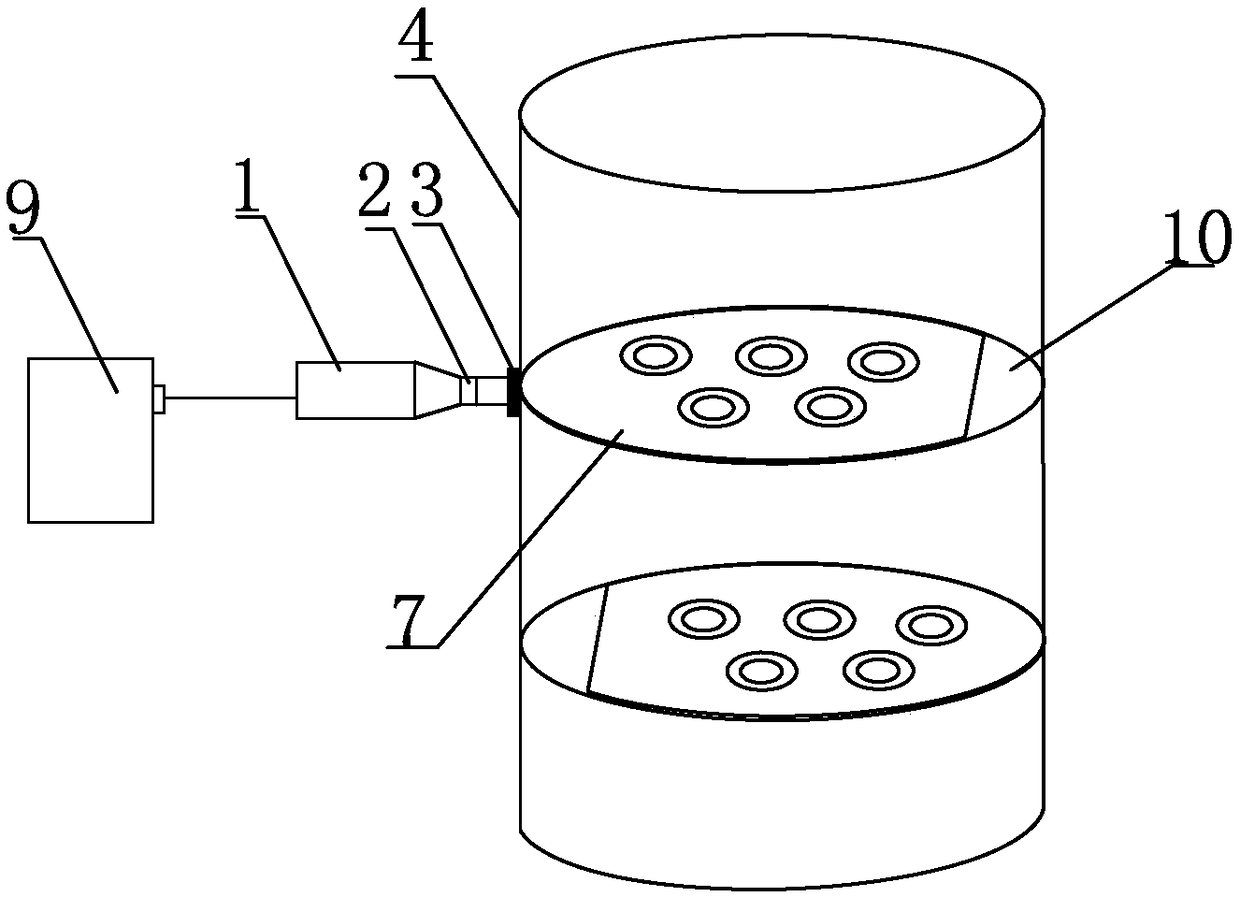

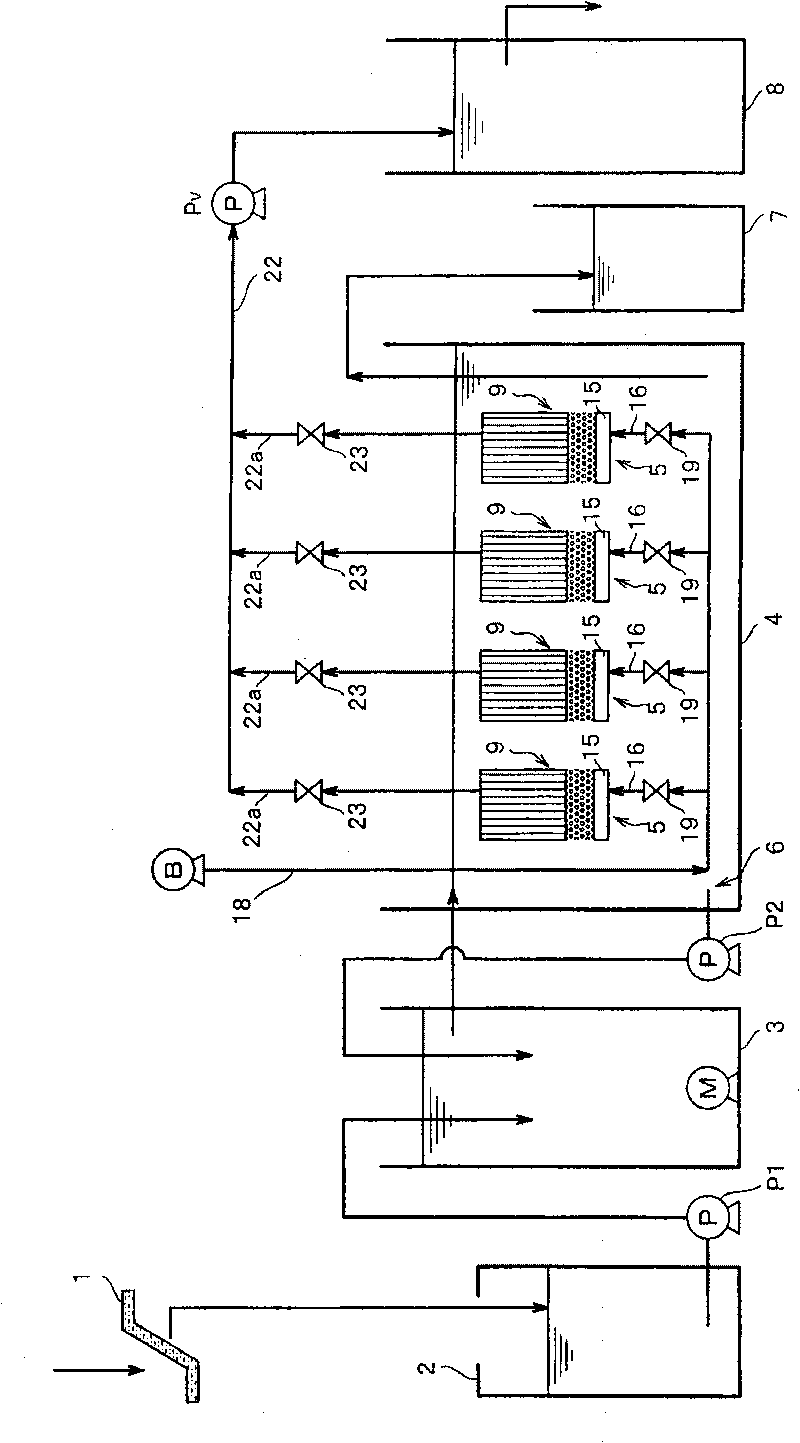

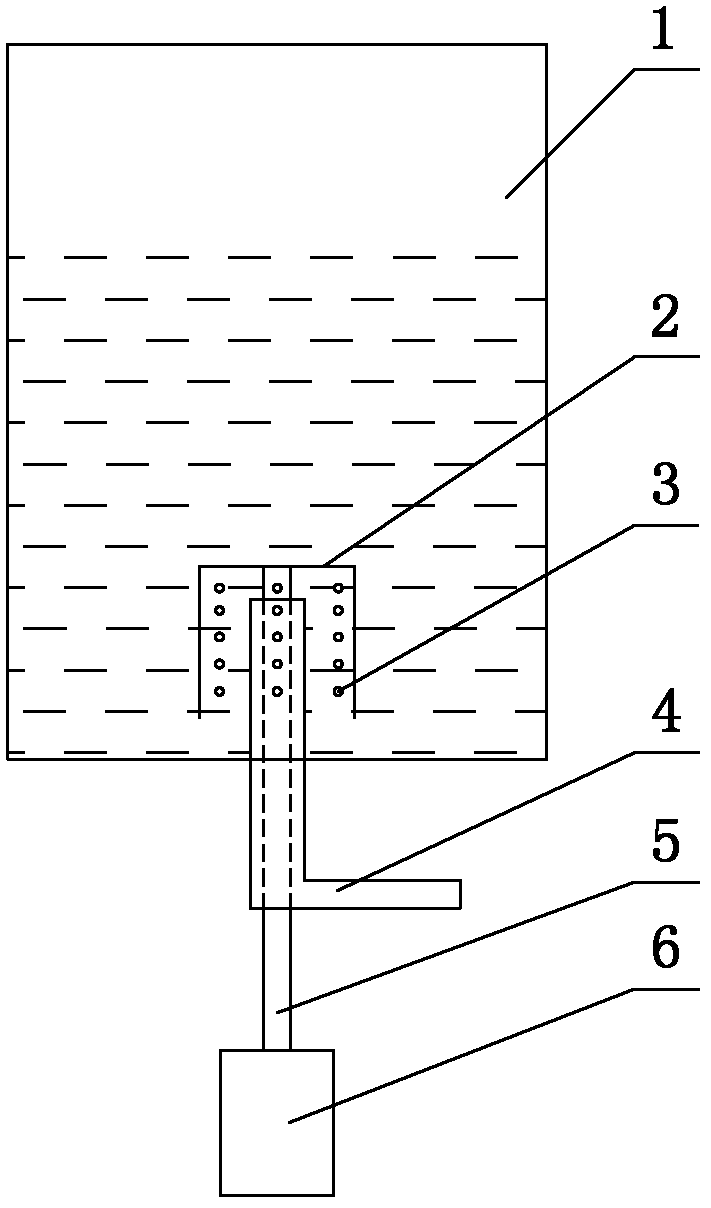

Overlapped microbial fuel cell in-situ test system and application thereof

ActiveCN105390716AEasy to insertReduce difficultyTreatment by combined electrochemical biological processesWater contaminantsResistive circuitsNitration

The invention relates to an overlapped microbial fuel cell in-situ test system and an application thereof. The overlapped microbial fuel cell in-situ test system comprises a positive electrode chamber formed by at least one positive electrode reaction module in a series-wound overlapping manner, a negative electrode chamber formed by at least one negative electrode reaction module in a series-wound overlapping manner, a proton exchange membrane arranged between the positive electrode chamber and the negative electrode chamber, and a circumscribed nitration reactor communicated with the positive electrode chamber and the negative electrode chamber separately; the positive electrode chamber and the negative electrode chamber are arranged oppositely in the mode of an upper one and a lower one that can be exchanged mutually; and a circumscribed adjustable resistive circuit is further arranged between the positive electrode chamber and the negative electrode chamber. The system is used for in-situ test on the characteristic parameters of the electrode biological membrane under the same electrochemical state. Compared with the prior art, the overlapped microbial fuel cell in-situ test system is simple and compact in structure; the functions of decarbonization, nitration and denitrification are arranged in independent units; the pollutant removal efficiency is improved; the system can be changed easily according to the pollutant concentrations and actual water amount; and the overall system is high in sealing property, high in stability, stable in running, and wide in the development and application prospects.

Owner:TONGJI UNIV

Method for rapidly and stably starting wastewater nitrite type mixotrophic desulfurization and denitrification system

InactiveCN104609548AIncrease success rateImprove maneuverabilityWater contaminantsTreatment with anaerobic digestion processesNitriteSulfur

The invention discloses a method for rapidly and stably starting a wastewater nitrite type mixotrophic desulfurization and denitrification system. The method comprises the following steps: controlling ecological factors in stages by virtue of a three-step method, respectively creating an anaerobic environment favorable for improving the activities of sulfur-autotrophic nitrate microbes, mixotrophic nitrate microbes and mixotrophic nitrite microbes, and promoting rapid formation of different functional floras, so that the complexity of the micro flora is reduced. According to the start method disclosed by the invention, stable operation of the desulfurization and denitrification process under high load conditions is promoted, the starting time is reduced, the stability of the system is enhanced, and after the system is started, the removal rate of sulfides and nitrite can rapidly reach 100 percent, the removal rate of the organic matters can be over 90 percent, the yield of elemental sulfur is high and is always over 80 percent, subsequent high-efficiency recovery of the elemental sulfur is promoted, and the wastes are recycled.

Owner:DALIAN MARITIME UNIVERSITY

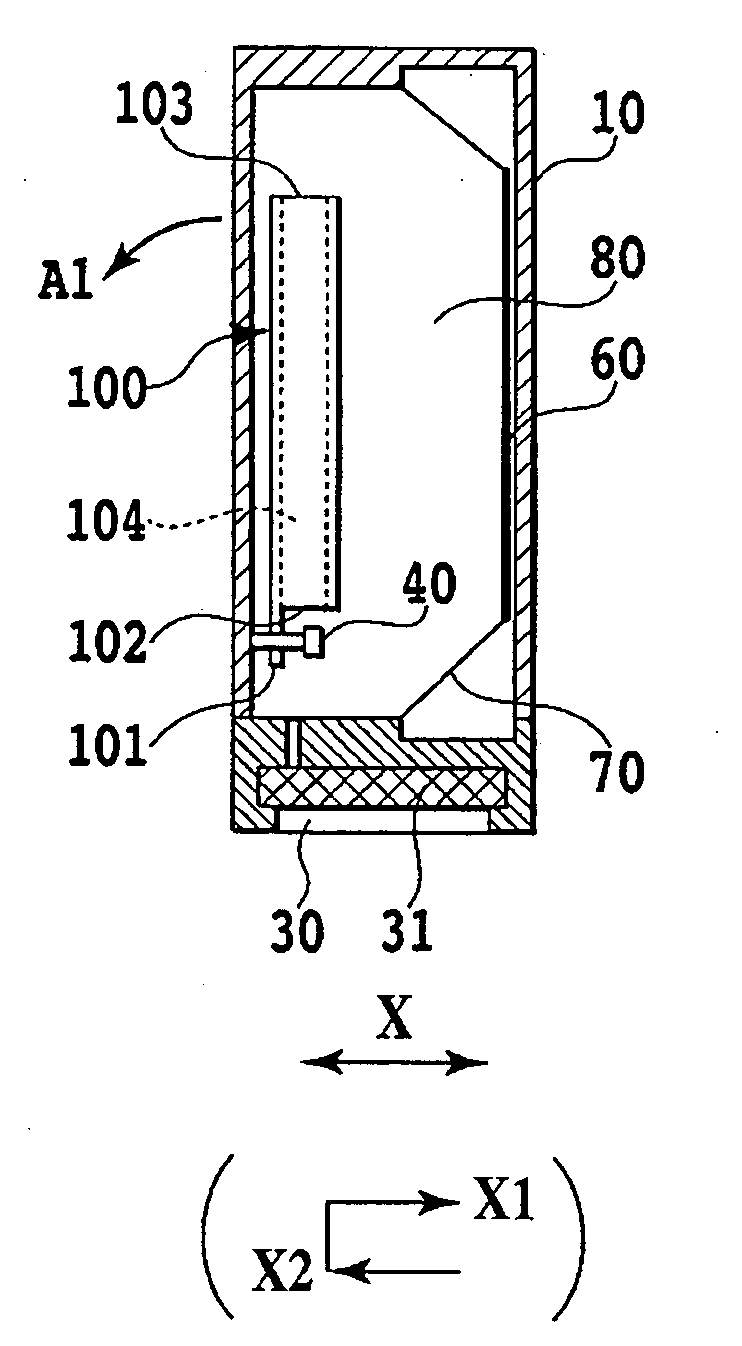

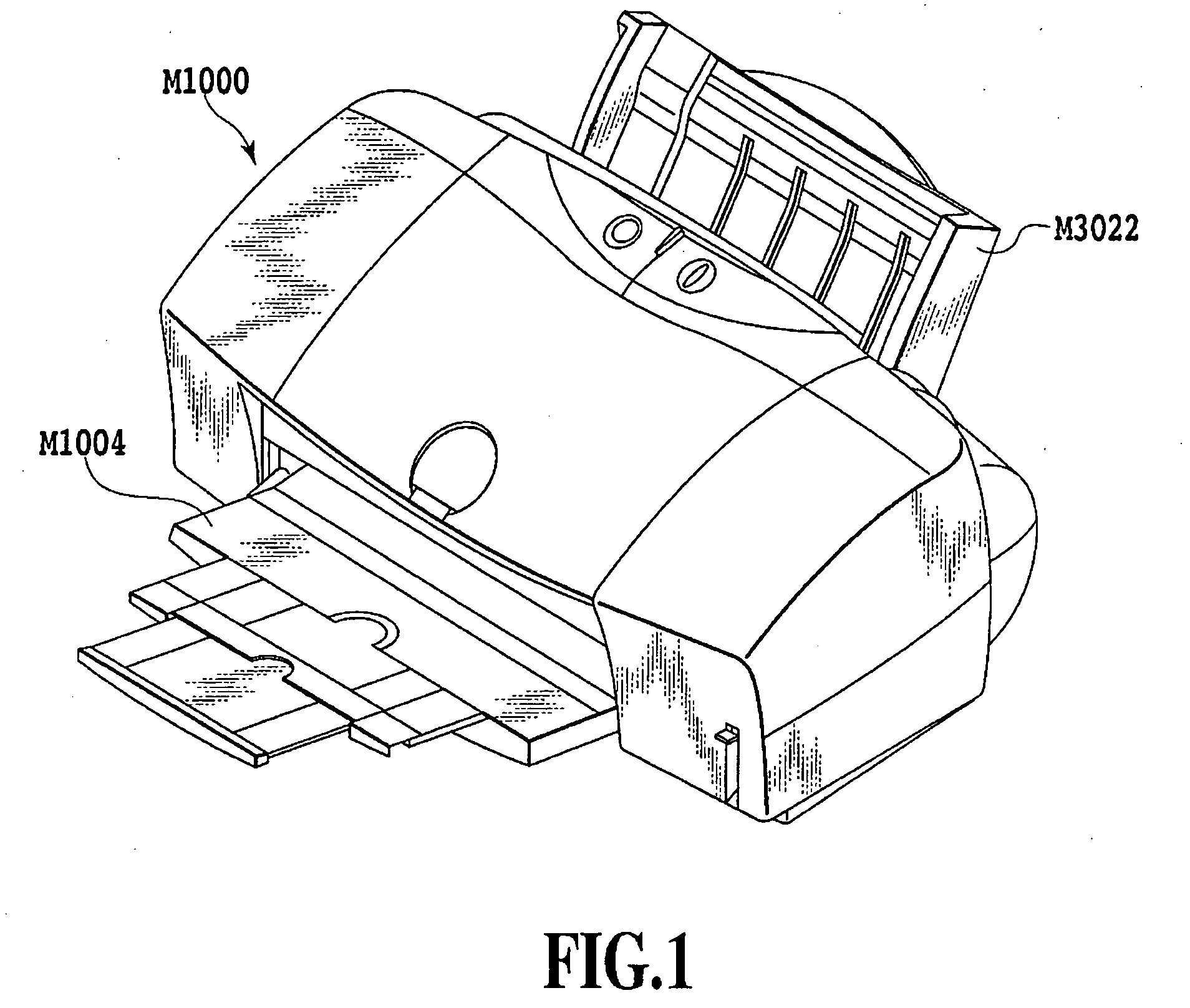

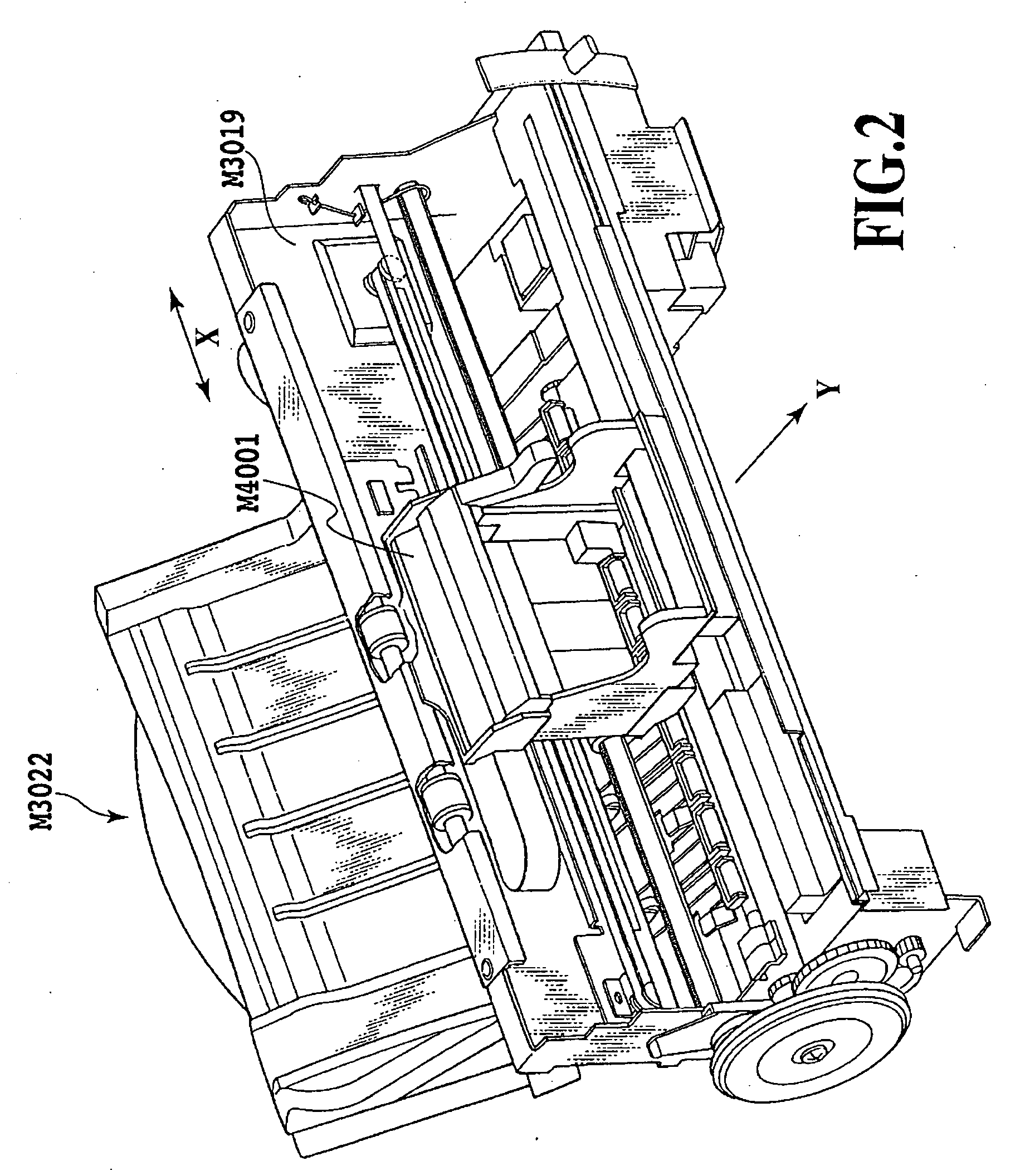

Liquid container, head cartridge, ink jet printing apparatus, and stirring method for liquid container

InactiveUS20070263048A1Easily and reliably raisedEffective stirringShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical engineering

A swing member that is provided in an ink containing chamber is swung according to movement of a carriage of a printing apparatus. Accordingly, an ink flow occurs in a hollow portion of the swing member from one of openings to the other opening, such that ink in an ink tank is stirred.

Owner:CANON KK

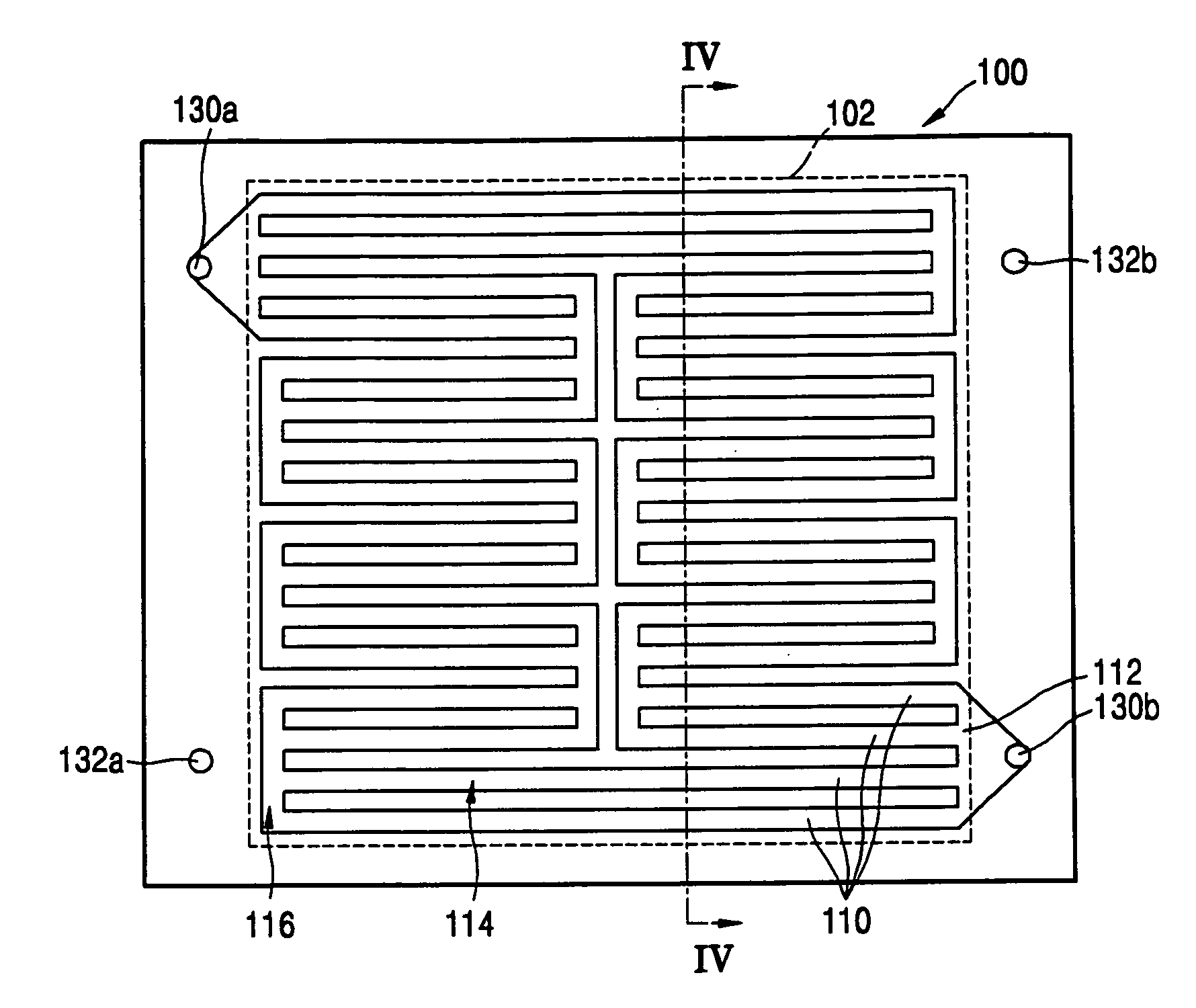

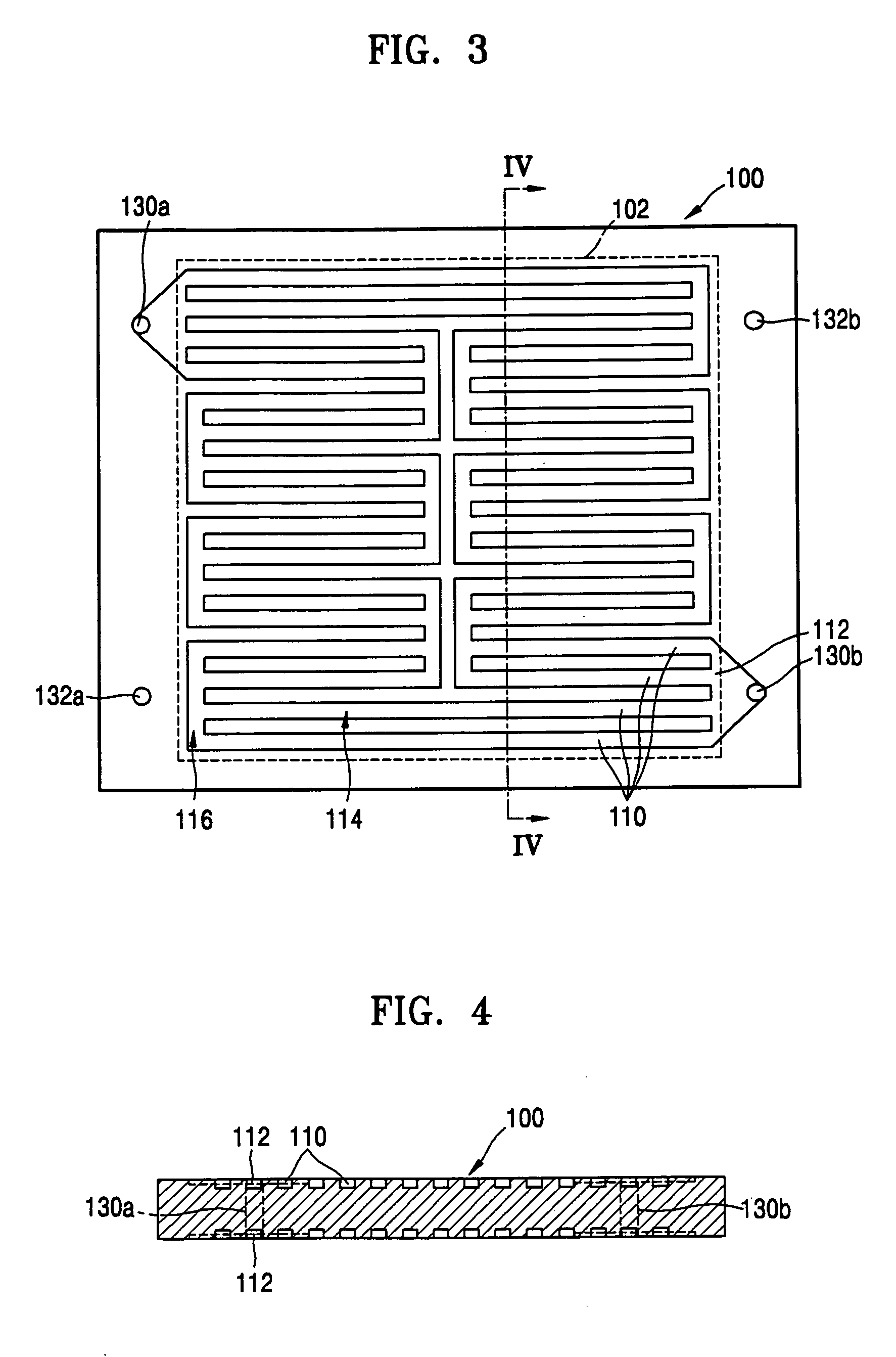

Bipolar plate and direct liquid feed fuel cell stack

InactiveUS20060115705A1Decrease the concentration gradientReduce pressure lossFuel cells groupingElectrode carriers/collectorsFuel cellsElectrical and Electronics engineering

A bipolar plate and a direct liquid feed fuel cell stack are provided. The bipolar plate includes a manifold that is coupled with the fuel / oxidant path holes and a plurality of flow channels that are coupled with the manifold. The flow channels are divided into a plurality of groups, where the flow channel of each group forms a serpentine flow path and a length of each flow channel is substantially the same.

Owner:SAMSUNG SDI CO LTD

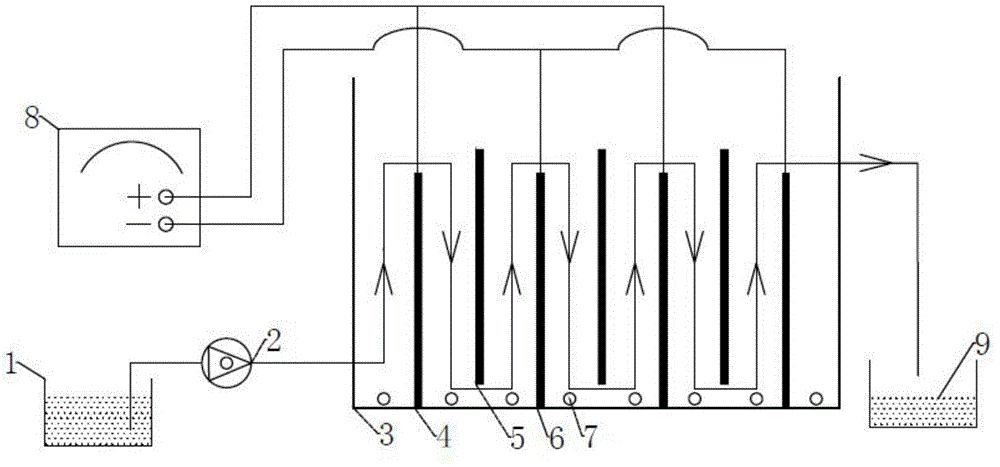

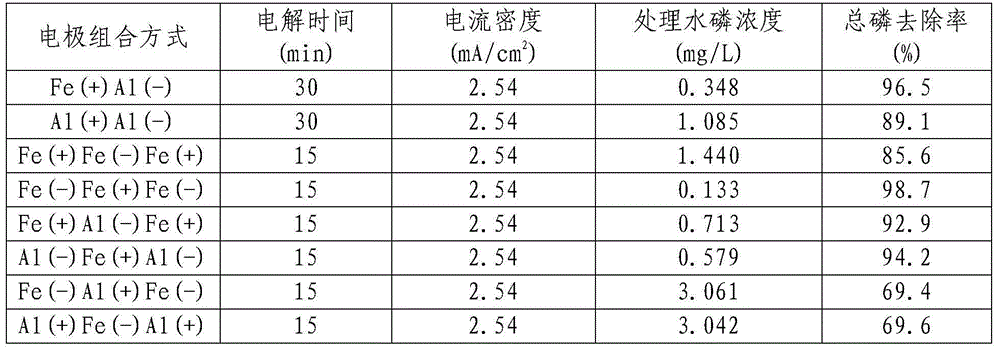

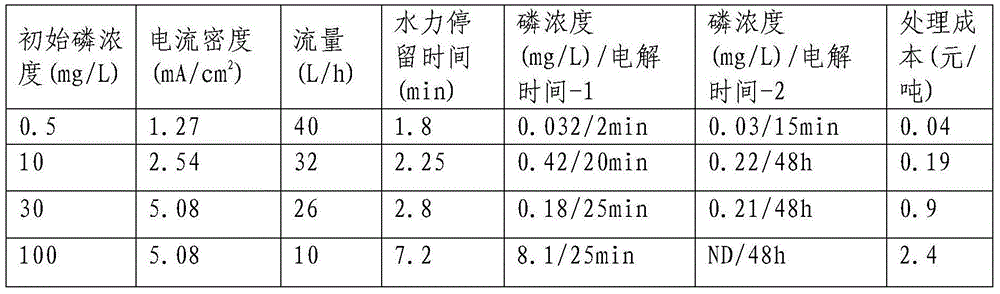

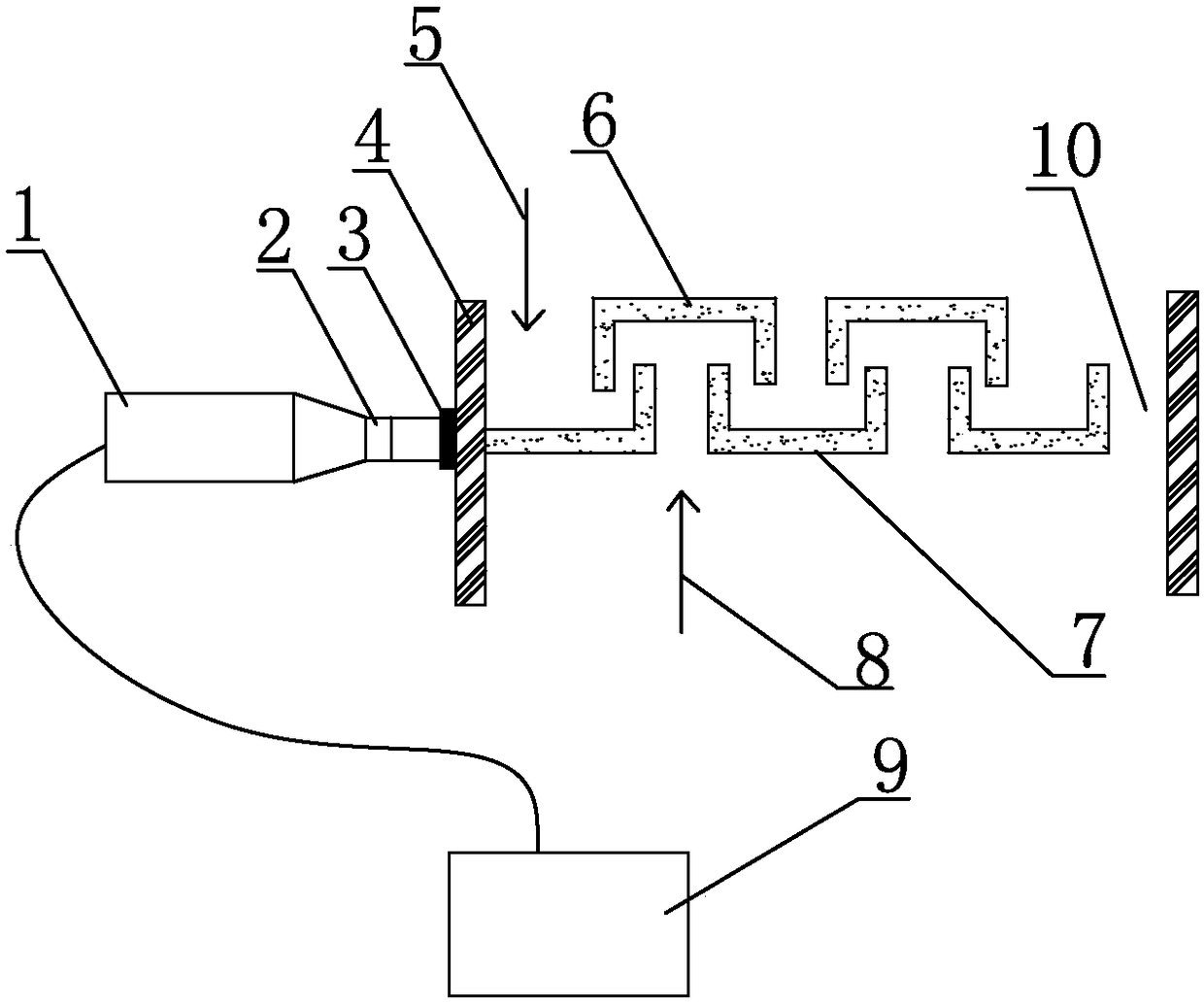

Method and device for treating phosphorus wastewater by adopting multi-electrode baffling electric flocculation process

ActiveCN104787859AReduce processing costsSimple processWater/sewage treatmentPeristaltic pumpElectrochemistry

The invention belongs to the technical field of sewage treatment in environmental engineering, and particularly relates to a method and a device for treating phosphorus wastewater by adopting a multi-electrode baffling electric flocculation process. The PH value of wastewater is regulated with alkaline liquor to 7.0-8.0; the regulated wastewater is pumped into an electric flocculation tank through a peristaltic pump, is subjected to electrolytic flocculation treatment through the baffling of a multi-electrode under the condition of aeration, and then is discharged through an overflow launder, the discharged water is collected and left to stand for 30 minutes, a liquid supernatant is discharged, a floc is recycled; a power supply of the electric flocculation tank is a direct current power supply, the current density is 1.27-5.08mA / cm<2>, and the electrolysis time is 2 minutes to 48 hours. The technical characteristics are as follows: the wastewater baffles along the multi-electrode, then the short stream of the wastewater is avoided, the chance of enabling a pollutant in the wastewater to be in contact with a high-concentration flocculating agent in an electrolysis plate is increased, the flocculent precipitation is promoted, so that the pollutant treatment effect is improved. The multi-electrode baffling electric flocculation process is suitable for treating inorganic phosphorus wastewater at medium and low concentrations, needed equipment is simple, easy in operation and low in cost, and runs stably, so that the process is an electrochemistry phosphorous removal process having a high potential.

Owner:中国中化股份有限公司 +2

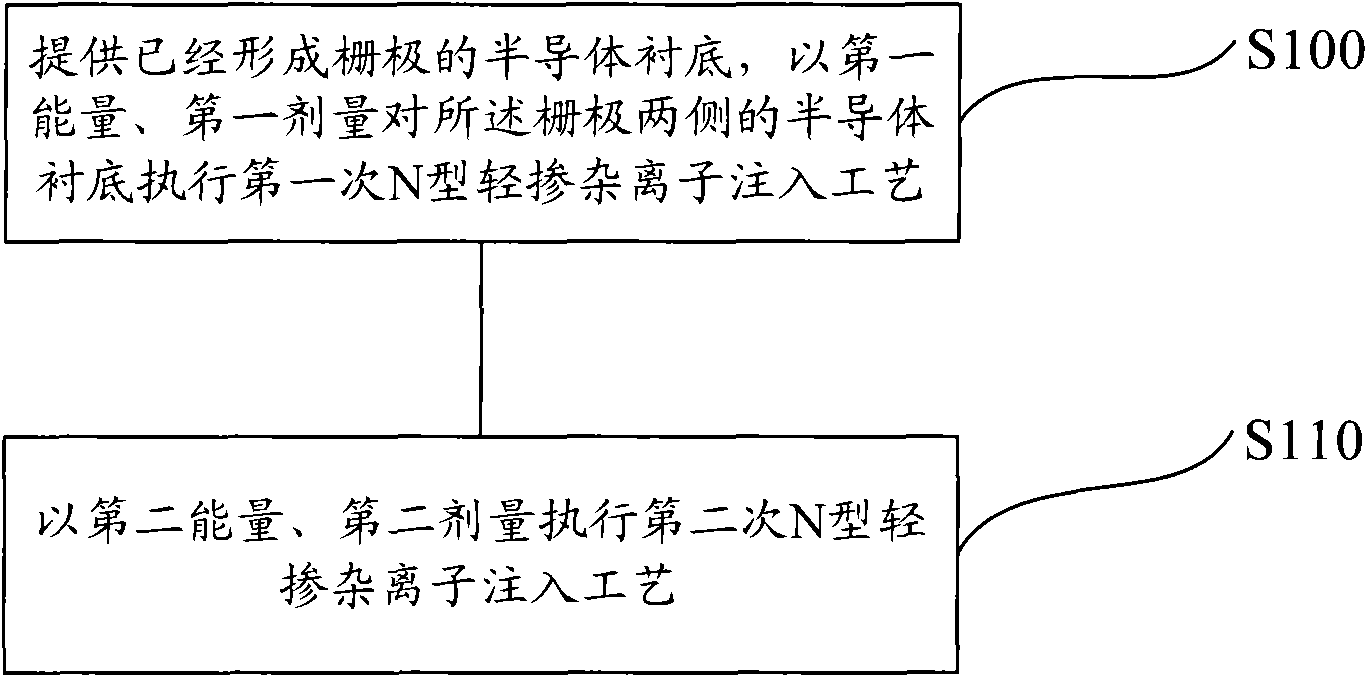

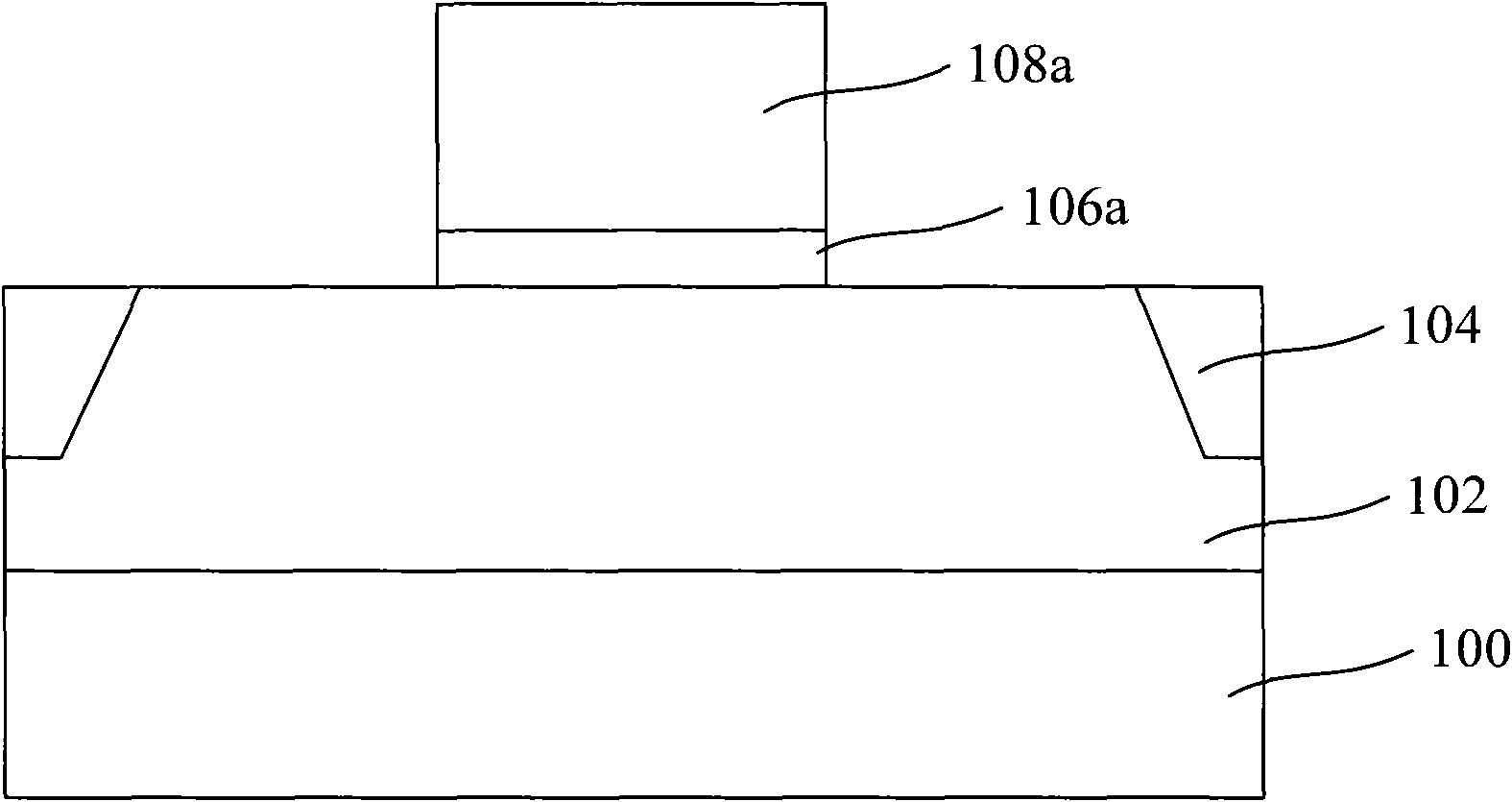

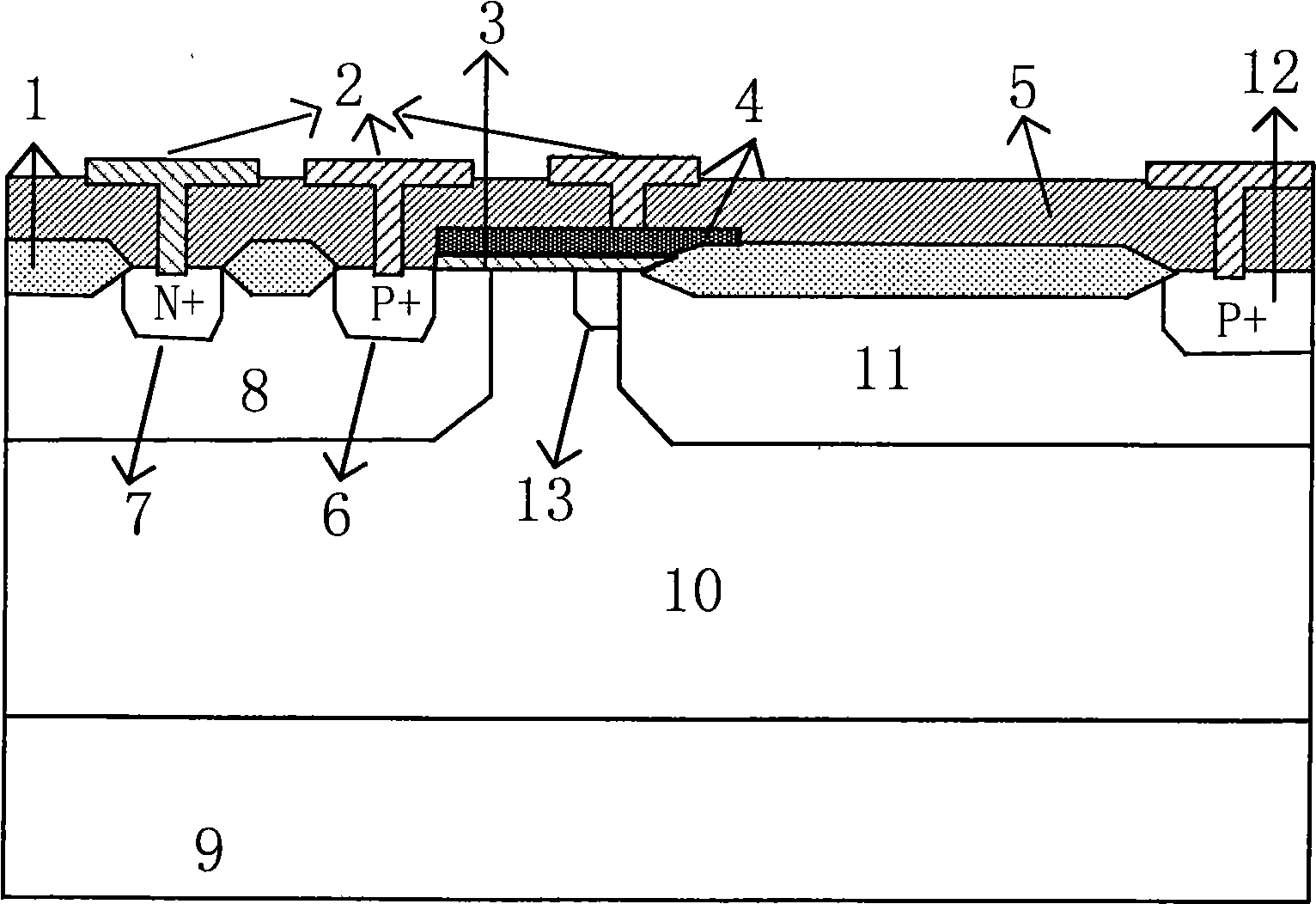

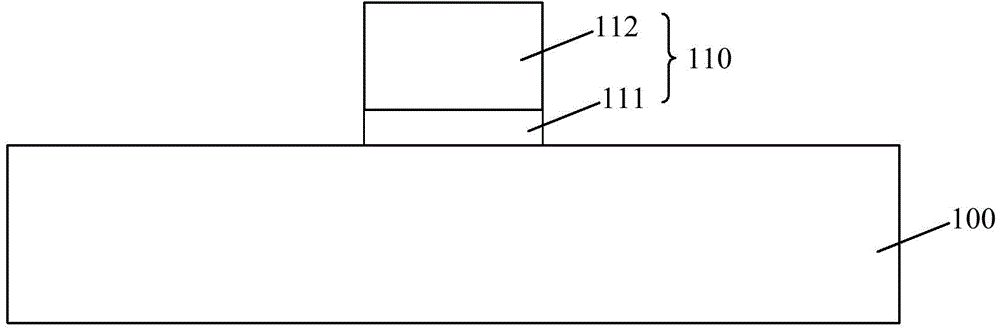

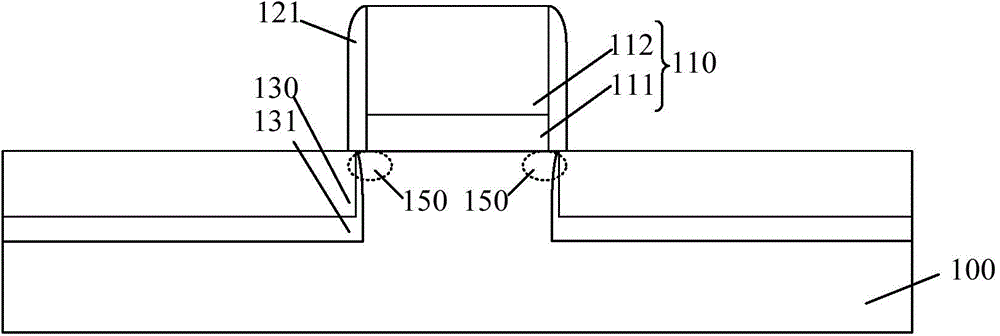

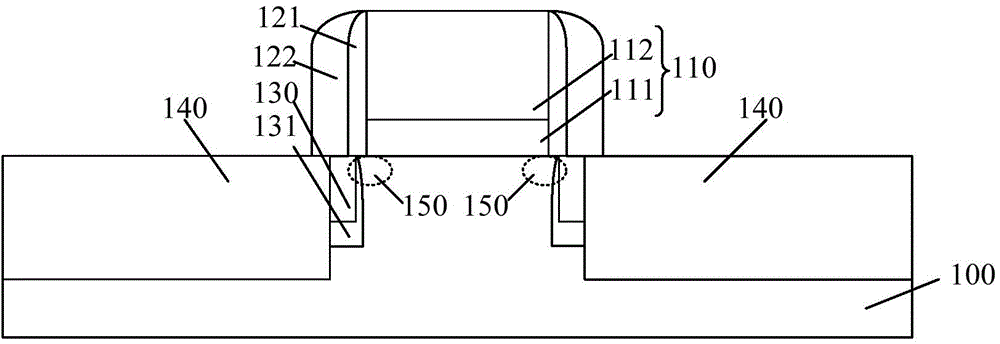

Method for reducing gate induced drain leakage current in N-channel metal oxide semiconductor (NMOS) devices

ActiveCN101593681AReduce sizeDecrease the concentration gradientSemiconductor/solid-state device manufacturingDrain currentImpurity

The invention relates to a method for reducing gate induced drain leakage in NMOS devices. The lightly doped drain injection technology of the NMOS devices includes the following steps: a primary N type lightly doped ion implantation is carried out in primary energy and primary dosage; a secondary N type lightly doped ion implantation is carried out in secondary energy and secondary dosage; wherein, the foreign ion injected in the primary lightly doped ion implantation and the foreign ion injected in the secondary lightly doped ion implantation are elements in the same group, and the diffusion coefficient of the foreign ion injected in the secondary ion implantation is larger than or equal to that of the foreign ion injected in the primary ion implantation; and the energy value of the secondary energy is larger than that of the primary energy and the dosage value of the secondary dosage is smaller than that of the primary dosage. The invention can improve gate induced drain leakage current effect of the NMOS devices without inducing leakage current of PN junction between NLDD doped region and pocket doped region.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

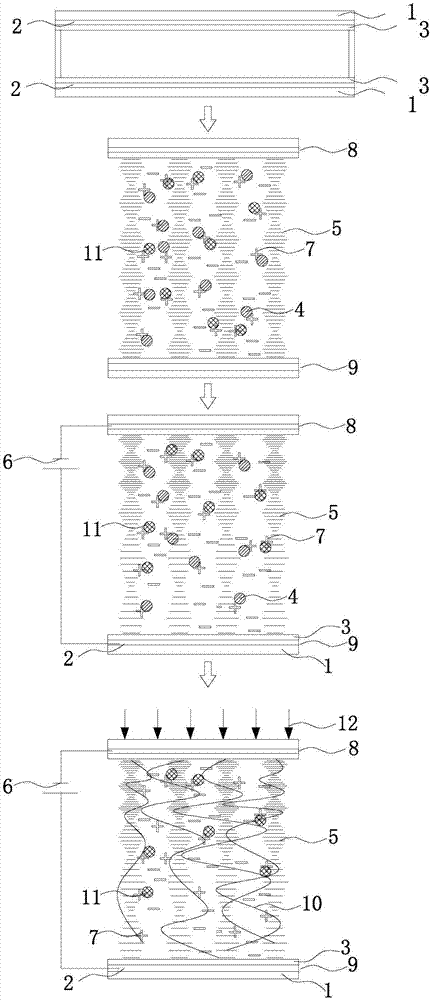

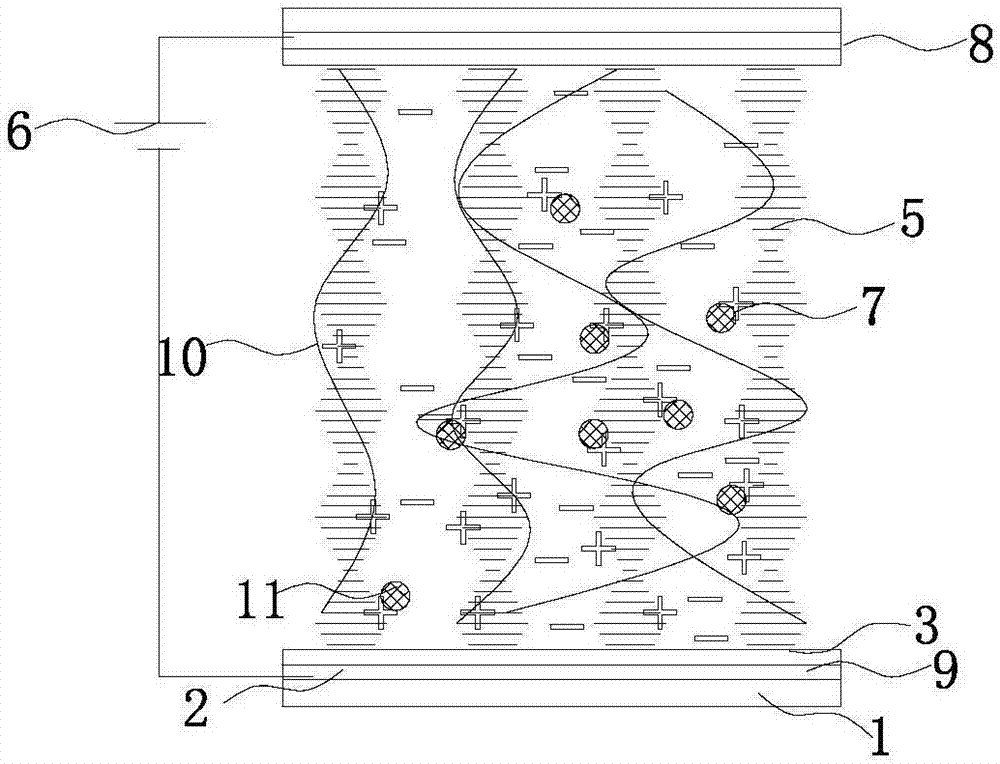

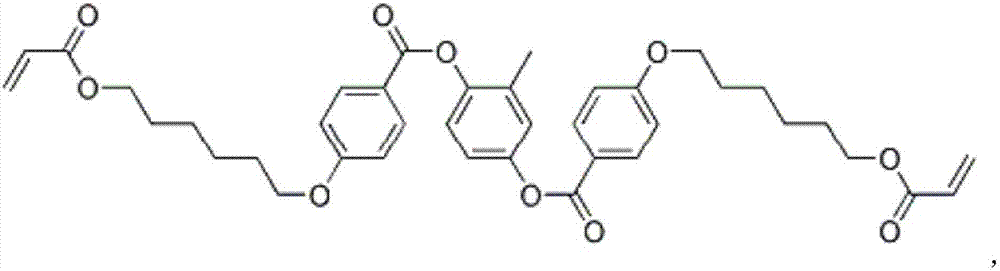

Manufacturing method of infrared reflecting device

InactiveCN106997133AReduce concentration differenceDecrease the concentration gradientLiquid crystal compositionsLight protection screensDopantPolymer network

The invention discloses a manufacturing method of an infrared reflecting device. The manufacturing method of the infrared reflecting device comprises the following steps: making a first conductive light transmitting substrate and a second conductive light transmitting substrate at first, and enabling the two conductive light transmitting substrate to opposite to each other; manufacturing parallel orientation layers on the opposite surfaces of the two conductive light transmitting substrates; manufacturing a liquid crystal box by using the two conductive light transmitting substrates; mixing negative liquid crystal, a chiral dopant, liquid crystal monomers and a photoinitiator to obtain a liquid crystal mixture; injecting the liquid crystal mixture in the liquid crystal box; connecting the first conductive light transmitting substrate with a negative pole of a power supply assembly, connecting the second conductive light transmitting substrate with a positive pole of the power supply assembly, capturing impurity positive ions by using the liquid crystal monomers and / or the chiral dopant so that the liquid crystal monomers and / or the chiral dopant have positive charge, and enabling the liquid crystal monomers and / or the chiral dopant to continue moving towards the negative pole direction; and carrying out ultraviolet irradiation to polymerize the liquid crystal monomers so as to form a polymer network, and enabling the densities of the polymer network to be distributed in a gradient manner in the direction perpendicular to the conductive light transmitting substrate to obtain the infrared reflecting device with wide reflection bandwidth. By change of the direction of an electric field, infrared reflection waveband can be adjusted.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

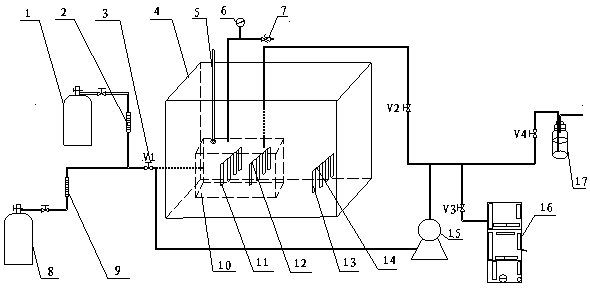

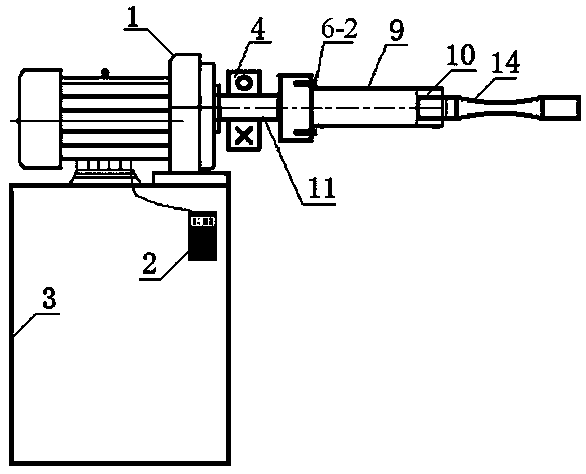

Filter material corrosion simulation experiment device and experiment method

InactiveCN104089869ADecrease the concentration gradientSimple production processWeather/light/corrosion resistanceGas cylinderEngineering

The invention discloses a filter material corrosion simulation experiment device and an experiment method. The experiment device comprises a gas flow control device, a thermostatic chamber, an ageing test chamber, a fan, a flue gas analyzer and an exhaust absorbing device. The gas flow control device comprises a gas bottle, a valve and a flow gauge. The temperature of the thermostatic chamber is adjustable. The ageing test chamber is inside the thermostatic chamber. Stainless steel bars are arranged in the thermostatic chamber and the ageing test chamber. A filter material is suspended vertically and in parallel at the stainless steel bars in the thermostatic chamber and the ageing test chamber. The top of the ageing test chamber is provided with a thermometer and a pressure gauge. The fan is connected to a position between the gas inlet pipe and the gas outlet pipe of the ageing test chamber. The gas outlet pipe is provided with the online flue gas analyzer. The exhaust absorbing device is at the tail end of the pipe. The experiment method can compare corrosion results of the filter material in an acid gas and in air at the same time, and can fully stimulate corrosion situations to the filter material at different temperatures with different concentrations by different gases. The method is simple in operation and reliable in result.

Owner:SOUTH CHINA UNIV OF TECH

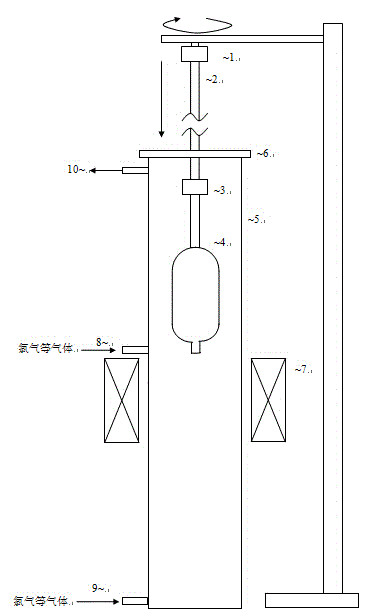

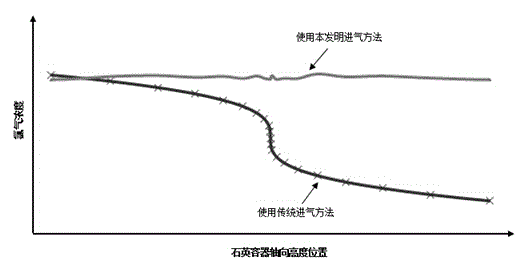

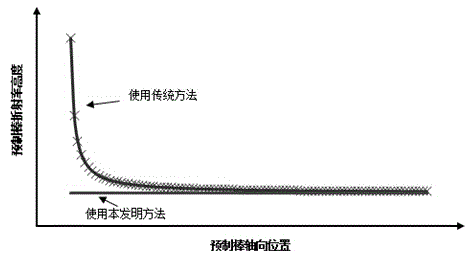

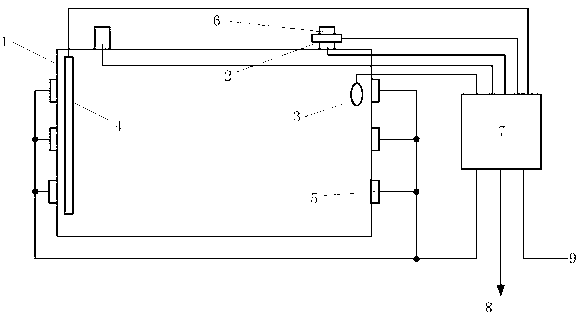

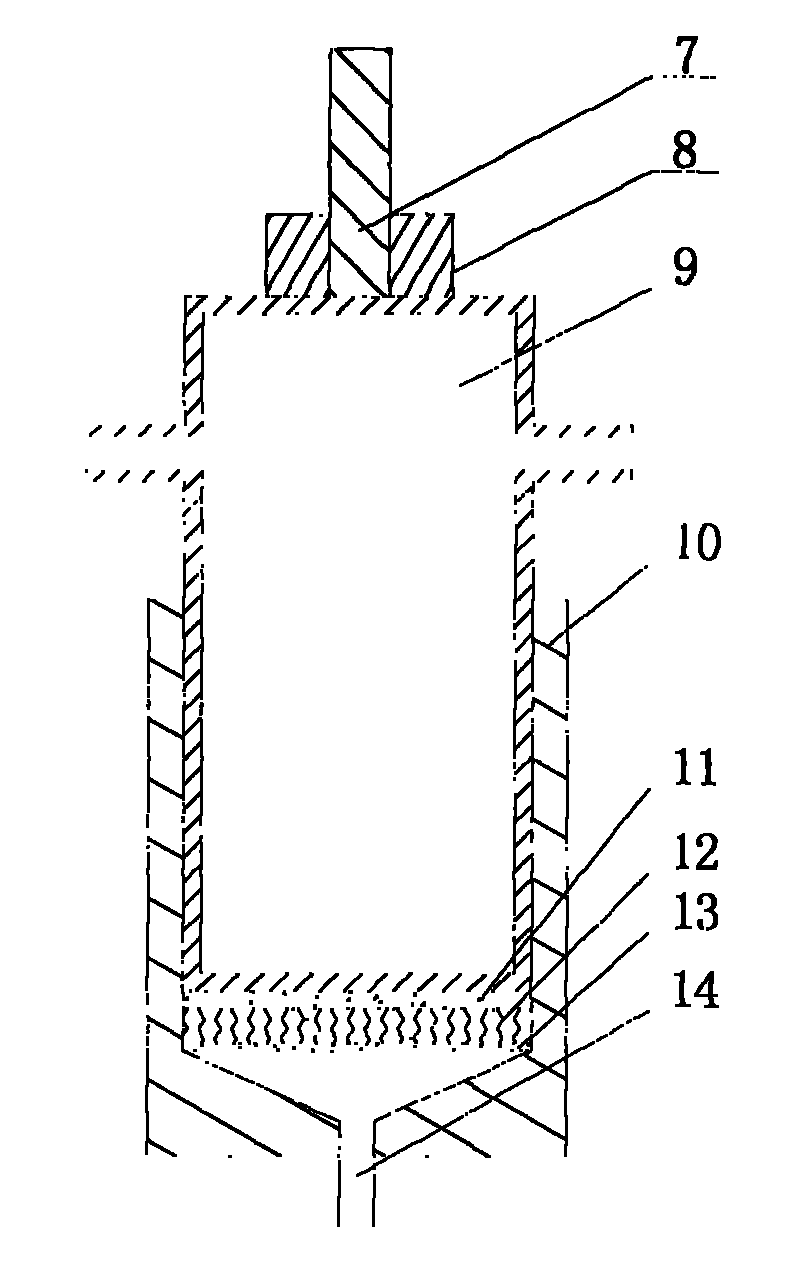

Dehydrating device and dehydrating method for optical fiber powdery loose rod body

ActiveCN104529148AEvenly distributedEvenly distributed and kept constantGlass making apparatusUltrasound attenuationRefractive index

The invention relates to a dehydrating device and a dehydrating method for an optical fiber powdery loose rod body manufactured by a tube-outside method. The device comprises a sintered cylinder, wherein a lower air inlet is formed at the bottom of the sintered cylinder, an air outlet is formed on the upper part of the sintered cylinder, a heating furnace is arranged at the periphery of the sintered cylinder, a rotary chuck is arranged in the sintered cylinder and is connected with a rotary shaft which extends into the cylinder from the top, the upper end of the rotary shaft extends out of the sintered cylinder and is connected with a rotary driving device, and the rotary driving device is connected with a lifting mechanism. The device is characterized in that an upper air inlet is formed in the middle part of the sintered cylinder and the upper and lower air inlets are communicated with a mixed gas source. According to the device and method provided by the invention, the uniformity of refractive index distribution of a prefabricated rod in the axial direction can be effectively improved, the problem that attenuation of the corresponding optical fiber near 1383nm is relatively high on the upper part of the prefabricated rod is effectively solved, and the utilization efficiency of the quartz optical fiber prefabricated rod is improved. The device provided by the invention is simple in structure and convenient to use.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Ultrasonic storage battery

InactiveCN103311593ADecrease the concentration gradientSpeed up chemical reactionsSecondary cells servicing/maintenanceChemical reactionUltrasonic sensor

The invention relates to an ultrasonic storage battery which is characterized in that an electrolyte specific gravity sensor and a liquid level sensor are installed inside a conventional lead-acid storage battery, a current sensor is installed on a storage battery connecting pile, the side surface of the storage battery is provided with an ultrasonic transducer, the electrolyte specific gravity sensor, the liquid level sensor, the current sensor and the ultrasonic transducer are connected with a controller through a conducting wire, and the controller is connected with the exterior of the storage battery through a data bus so as to transmit the data of the storage battery. According to the ultrasonic storage battery, when the drive current is outputted through the ultrasonic transducer, the ultrasonic wave is applied to the inside of the storage battery, the concentration gradient of the electrolyte nearby a polar plate can be efficiently reduced through the ultrasonic effect, the chemical reaction of a solid-liquid interface nearby the polar plate can be accelerated, and large lead sulfate crystals formed in the chemical reaction process can be prevented and even eliminated, so that the large-current charging and discharging can be carried out for a long time, and the cycling life is greatly prolonged compared with the conventional storage battery.

Owner:胡大林

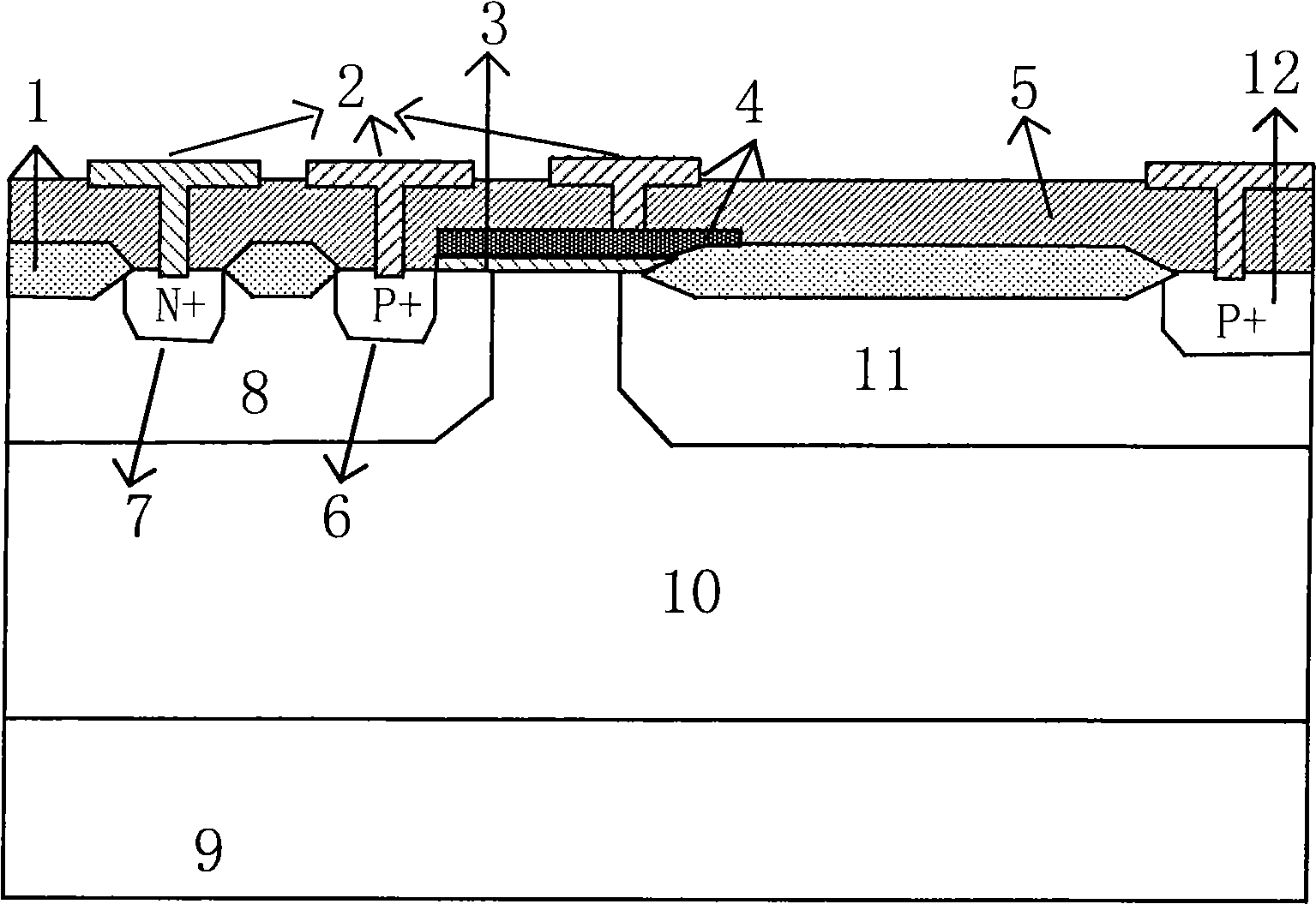

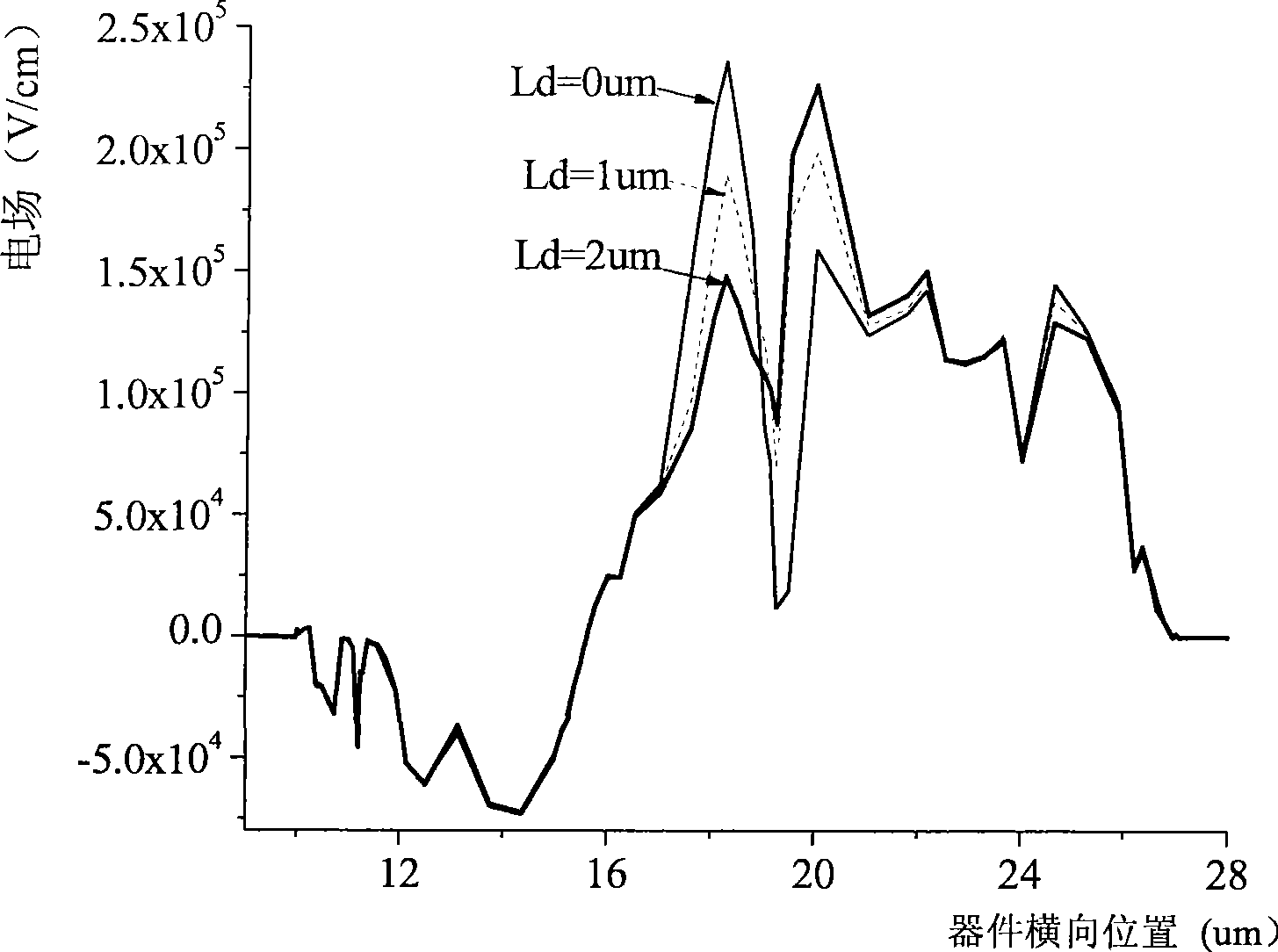

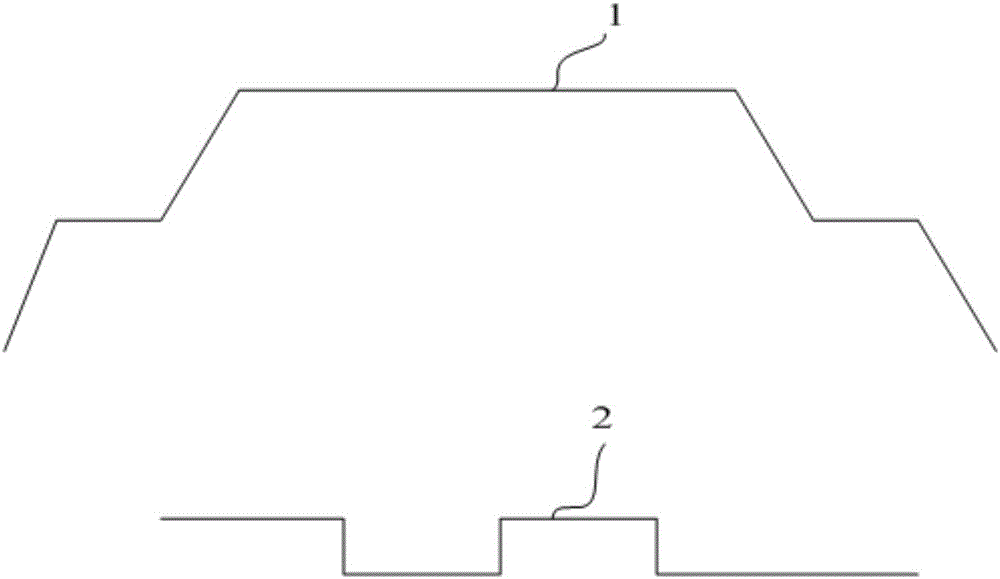

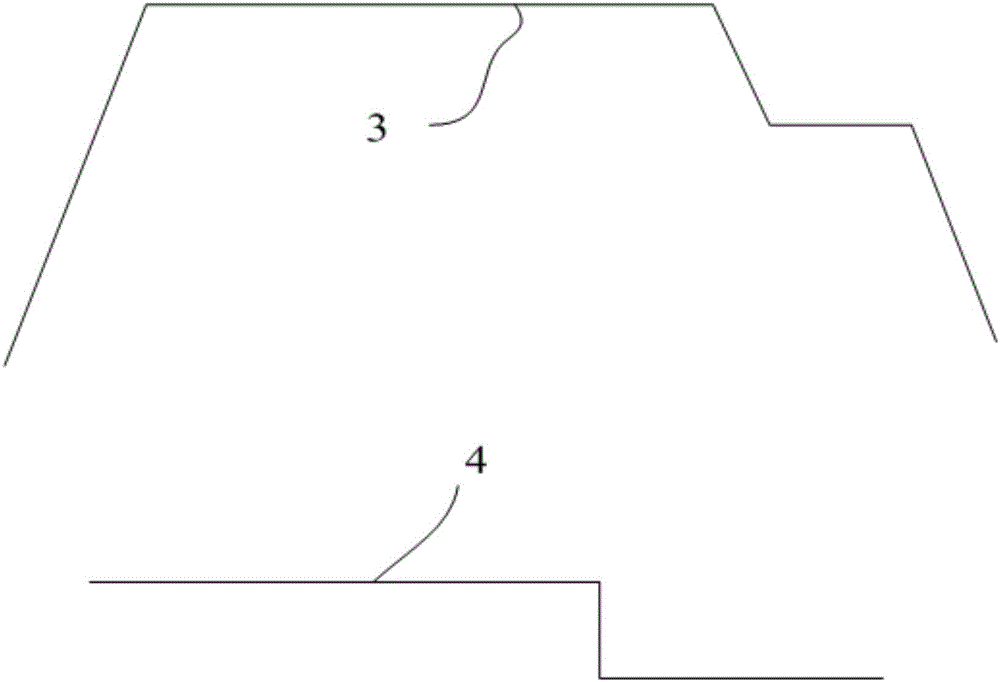

P type transversal bilateral diffusion metal oxide semiconductor tube capable of reducing hot carrier effect

InactiveCN101510560AReduce chargeReduce damageSemiconductor devicesHot carrier effectOxide semiconductor

The invention discloses a P-type lateral double-diffused metal-oxide transistor which is capable of reducing hot-carrier effect and comprises a P-type semiconductor substrate; an N-type well region is arranged on the P-type semiconductor substrate; a P-type well region and a P-type doped semiconductor area are arranged on the N-type well region; a P-type source area and an N-type contact area are arranged on the P-type well region; a P-type drain area is arranged on the P-type doped semiconductor area; and a field oxide layer, a metal layer, a gate oxide layer, a polysilicon grid and an oxide layer are arranged on the upper surface of the device. The P-type lateral double-diffused metal-oxide transistor is characterized in that: a lightly-doped shallow P-type area is arranged in the N-type well region and positioned between the P-type well region and the P-type doped semiconductor area and covers a corner which is formed by the gate oxide layer and the P-type doped semiconductor area.

Owner:SOUTHEAST UNIV

Method for extracting essential oil from fresh tissues of plants

InactiveCN102212424AExtract suitable forLittle effect on chemical structureEssential-oils/perfumesWaxWater baths

The invention discloses a method for extracting essential oil from fresh tissues of plants, which comprises the following steps of: 1, adding a certain proportion of distilled water into the fresh tissues of the plants and then carrying out breaking and homogenate; 2, placing the product in the step 1 in a container, and adding an extracting agent, i.e., 30 to 60 DEG C petroleum ether, wherein the volume ratio of the petroleum ether to homogenate tissues is 1: (3-5); 3, placing an amplitude transformer of an ultrasonic wave generator in a long container for ultrasonic extraction; 4, separating a mixed liquor obtained in the step 3 by using a centrifugal machine with the speed of 3000 to 6000 turn / m, and taking a supernatant liquid; 5, decompressing the extracting liquid in the step 4 in a constant temperature water bath so as to remove an organic solvent, and obtaining oil; and 6, dewaxing the oil to obtain the essential oil. According to the method disclosed by the invention, the collection and extraction of oil components in the fresh tissues of the plants can be realized in one step; and few natural aroma of the prepared essential oil product is lost.

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE

Composite stepped carburizing and quenching technology of gear shaft

InactiveCN106835004AEliminate processing stressReduce the temperature difference between inside and outsideSolid state diffusion coatingFurnace typesTemperature differenceConcentration gradient

The invention belongs to the technical field of heat treatment, in particular to a composite stepped carburizing and quenching technology of a gear shaft. The composite stepped carburizing and quenching technology of the gear shaft includes the steps of entering furnace and heating, preserving heat, reheating, preserving heat of the stepped carburizing and quenching, reducing temperature and preserving heat, outing furnace and quenching, and the like. By adoption the composite stepped carburizing and quenching technology of the gear shaft, a constant temperature is firstly applied at a temperature below the critical point of the transformation before the workpiece is carburized, the temperature of the workpiece tends to be uniform inside and outside the temperature, thus, the internal and external temperature difference, the heating speed, and the thermal stress are reduced; and in carburizing stage, the stepped carburizing is adopted, that is, increase of cyclation and decrease of carbon concentration gradient, thus, the diffusion rate of carbon atoms is increased, the holding time of workpieces at high temperature is reduced, the deformation of heat treatment is reduced, and the requirements of metallurgical structure and mechanical properties are met.

Owner:ZHANGQIU HAILI MACHINERY MFG CO LTD

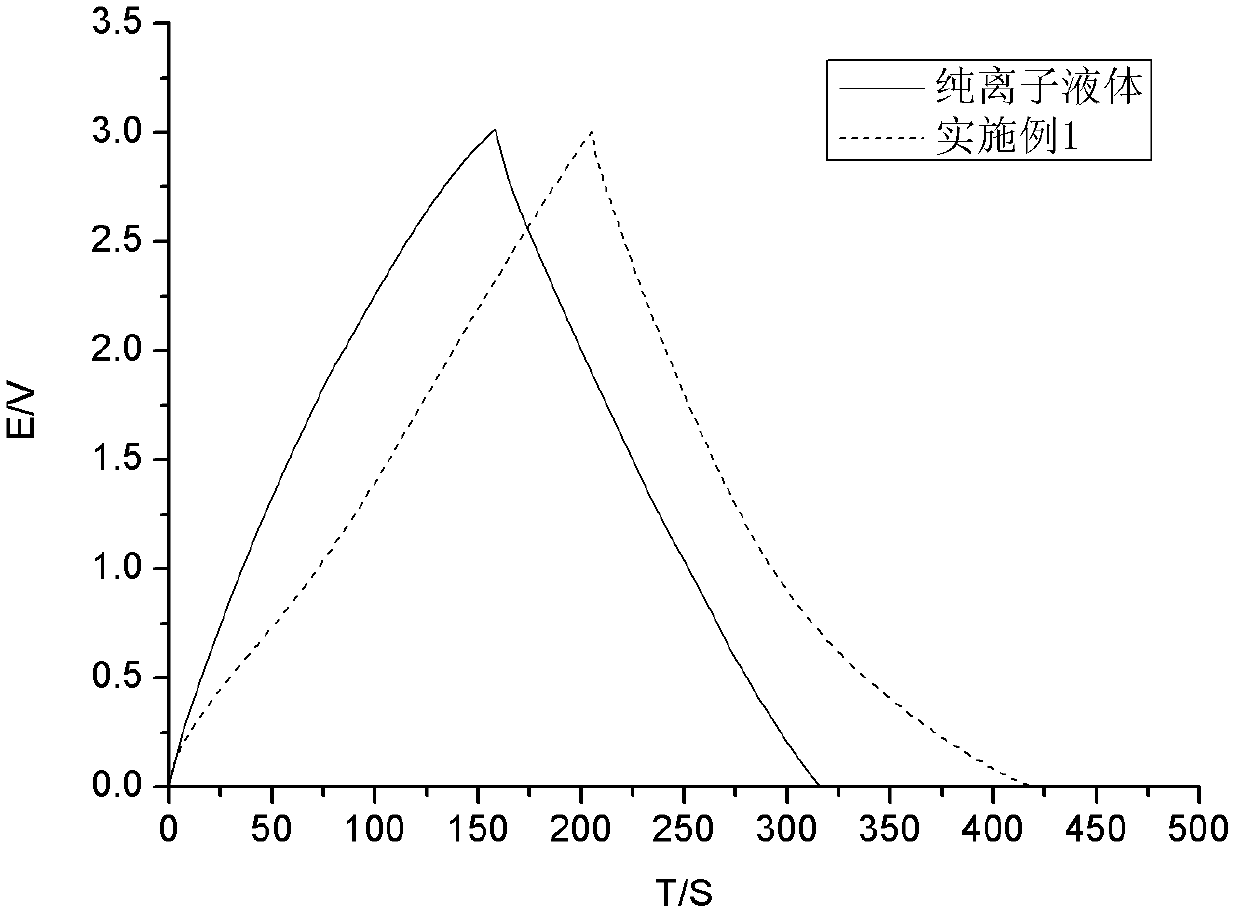

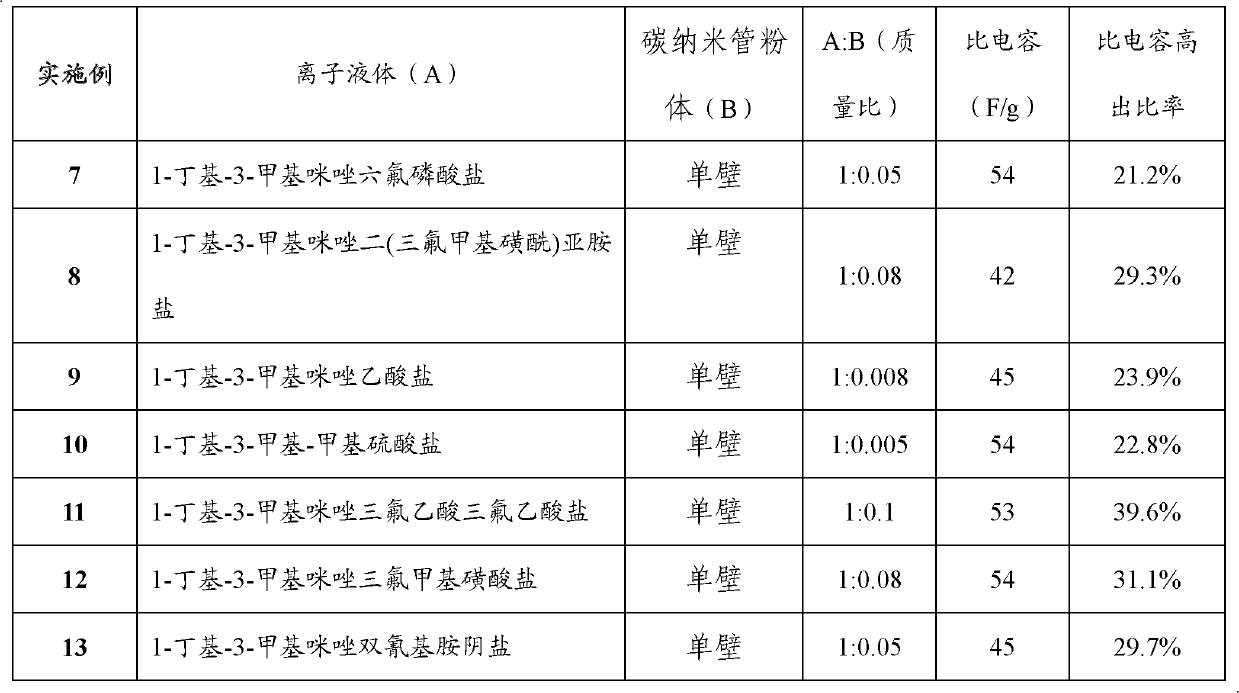

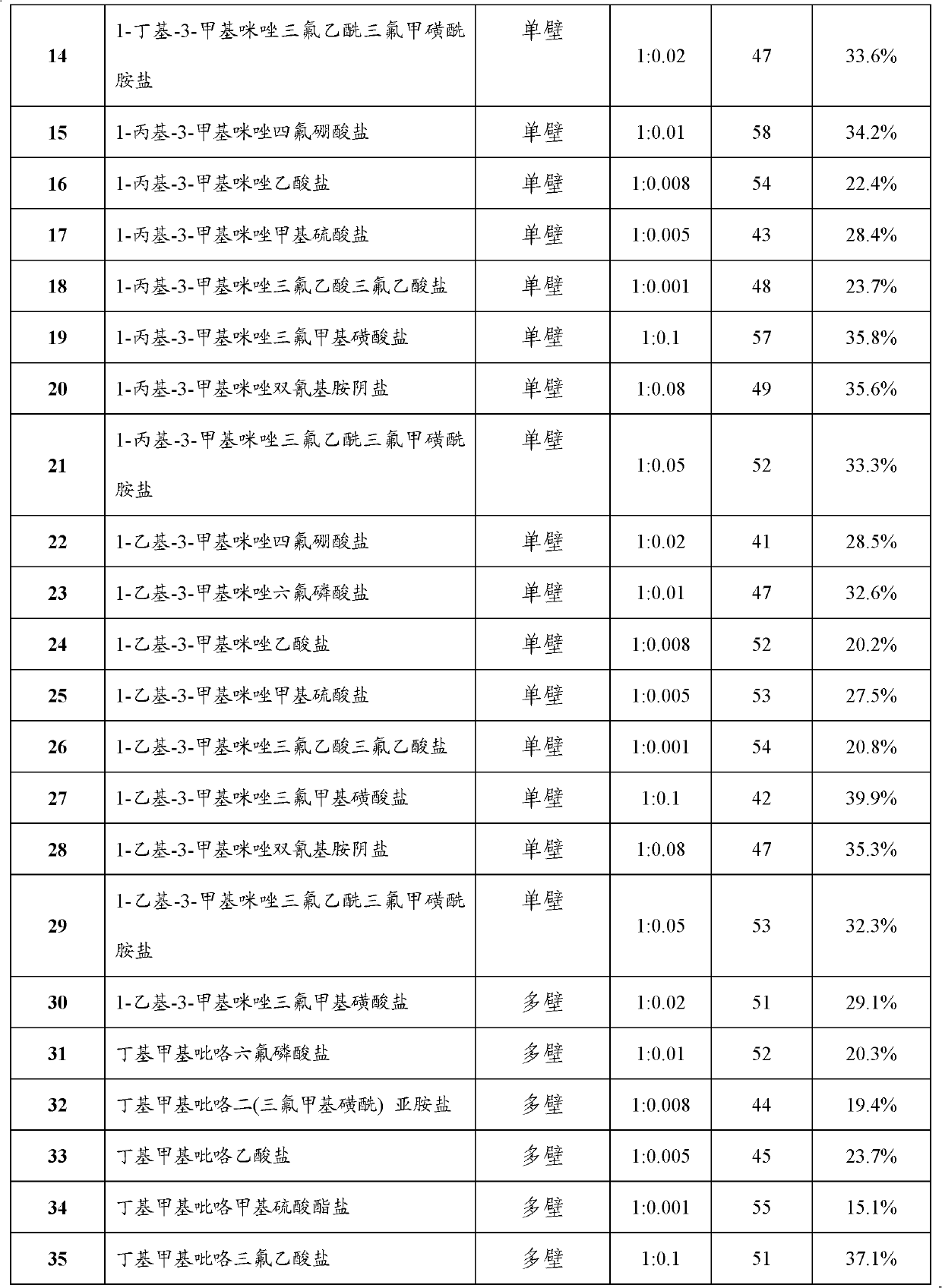

Double electric layer capacitor electrolytic solution

InactiveCN103377836AReduce equivalent internal resistanceWill not increase the risk factor of flammability and explosionHybrid capacitor electrolytesInternal resistanceCarbon nanotube

The invention belongs to the field of electrolytic solutions, and discloses a double electric layer capacitor electrolytic solution which is characterized by comprising ionic liquid and carbon nano tube powder with the mass ratio of 1:0.001-0.1. The ionic liquid is formed by any one negative ion of imidazolium cation or a pyrrole positive ion and fluoboric acid positive ion, a fluorophosphoric acid negative ion, a diimine (fluoroform sulfonyl) negative ion, an acetic acid negative ion, a methyl organosulfate positive ion, a trifluoroacetic acid negative ion, a trifluoromethane sulfonic acid negative ion, a dicyandiamide negative ion and a trifluoroacetyl trifluoromethanesulfonamide negative ion. The double electric layer capacitor electrolytic solution is formed by the ionic liquid and the carbon nano tube powder in a mixed mode, the negative ions of the ionic liquid can be adsorbed by carbon nano tubes, the carbon nano tubes can promote efficient dissociation of the ionic liquid, the transference number of the ionic liquid is increased, and thus equivalent internal resistance of a double electric layer capacitor is greatly reduced; the carbon nano tubes do not volatilize, so flammable and combustible danger coefficients cannot be increased.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Magnesium alloy composite surface protective treatment equipment and magnesium alloy composite surface protective treatment method

ActiveCN104109894AImprove corrosion resistanceReduce fatigue damageEdge grinding machinesAnodisationResidual pressureAnodic oxidation

The invention discloses magnesium alloy composite surface protective treatment equipment. The magnesium alloy composite surface protective treatment equipment comprises an anodic oxidation device, wherein the anodic oxidation device comprises an electrolytic cell; an electrolyte is filled in the electrolytic cell; a positive electrode and a negative electrode are arranged in the electrolytic cell; the positive electrode and the negative electrode are connected by virtue of a power supply; the magnesium alloy composite surface protective treatment equipment disclosed by the invention further comprises a magnesium alloy sample rotary device and a surface mechanical grinding device. A vibration generator of the magnesium alloy composite surface protective treatment equipment disclosed by the invention can be used for carrying out surface mechanical grinding on a magnesium alloy sample by vibrating spherical pills on an electrolytic cell lower plate, and circular rod-shaped sample rotary device can drive the magnesium alloy sample to rotate at a uniform speed, so that the surface of the magnesium alloy sample is subjected to uniform mechanical grinding treatment; residual pressure stress is introduced on the surface of the magnesium alloy sample oxidized by an anode to resist residual tensile stress generated by anode oxidization on the surface of the magnesium alloy sample, so that damages on fatigue performances of the magnesium alloy by anode oxidization are lowered while corrosion resistance of the magnesium alloy sample is improved, and therefore, an operation method is simple and practicable.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

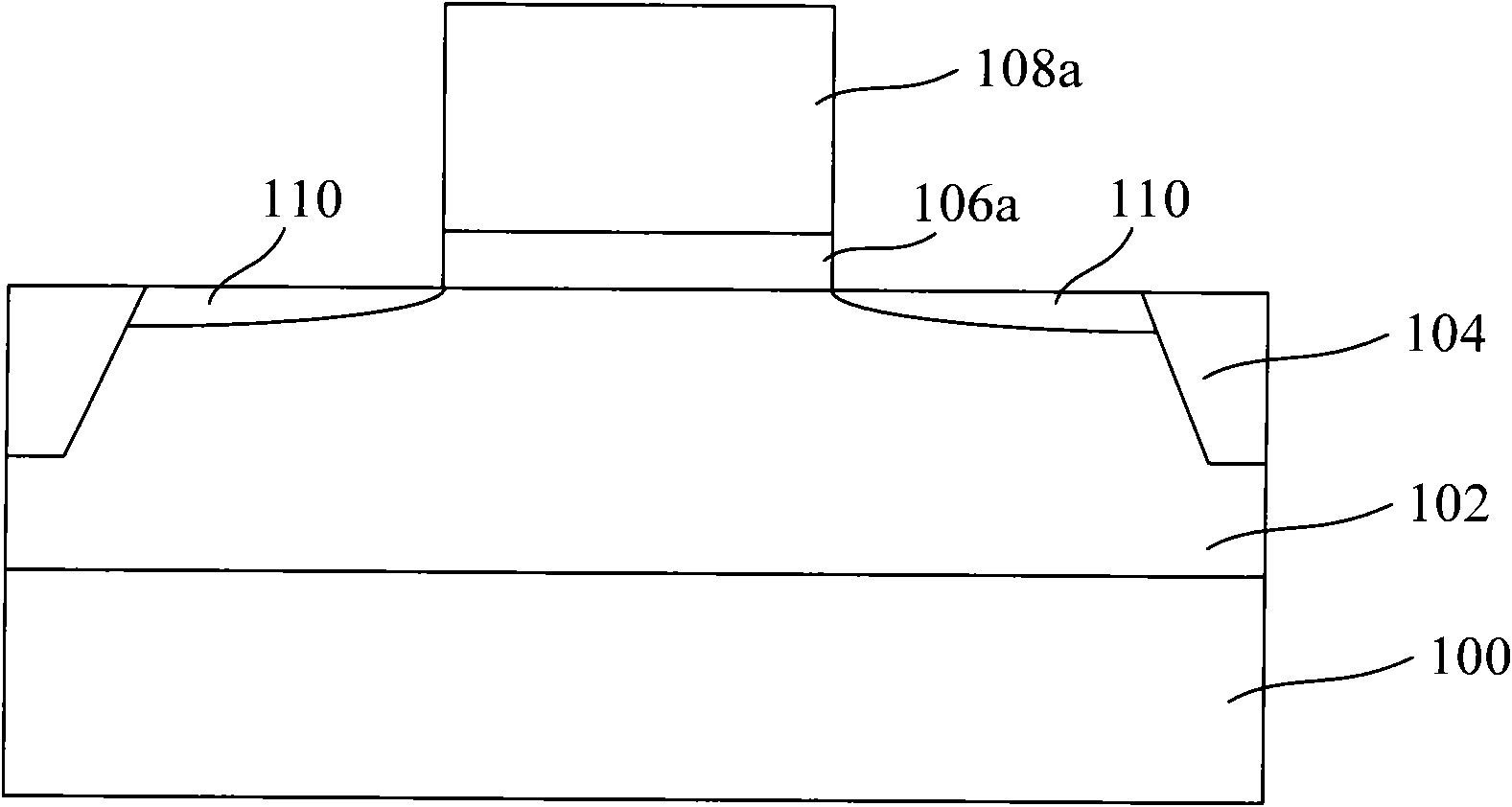

MOS transistor forming method

ActiveCN106158657AIncrease the areaImprove performanceSemiconductor/solid-state device manufacturingEngineeringSemiconductor

An MOS transistor forming method includes providing a semiconductor substrate whose surface is provided with a grid structure; performing first aureole injection on the semiconductor substrate on two sides of the grid structure by taking the grid structure as a mask; forming a shift side wall on the surface on two sides of the grid structure after first aureole injection; performing light-doped drain injection on the semiconductor substrate on the two sides of the grid structure by taking the grid structure with the shift side wall as the mask; and forming a source drain zone in the semiconductor substrate on the two sides of the grid structure. The MOS transistor forming method can improve performance and reliability of transistors.

Owner:SEMICON MFG INT (SHANGHAI) CORP

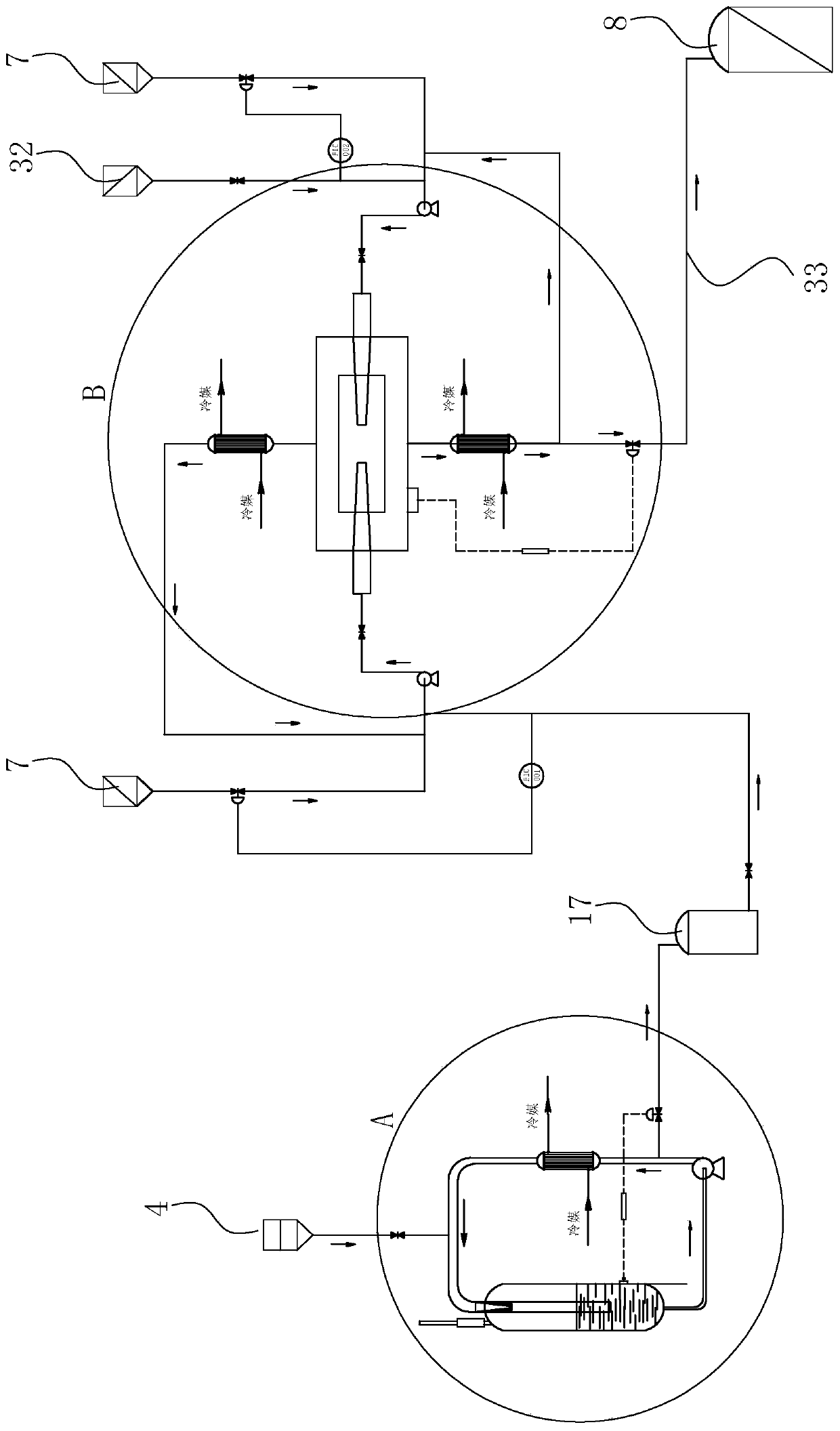

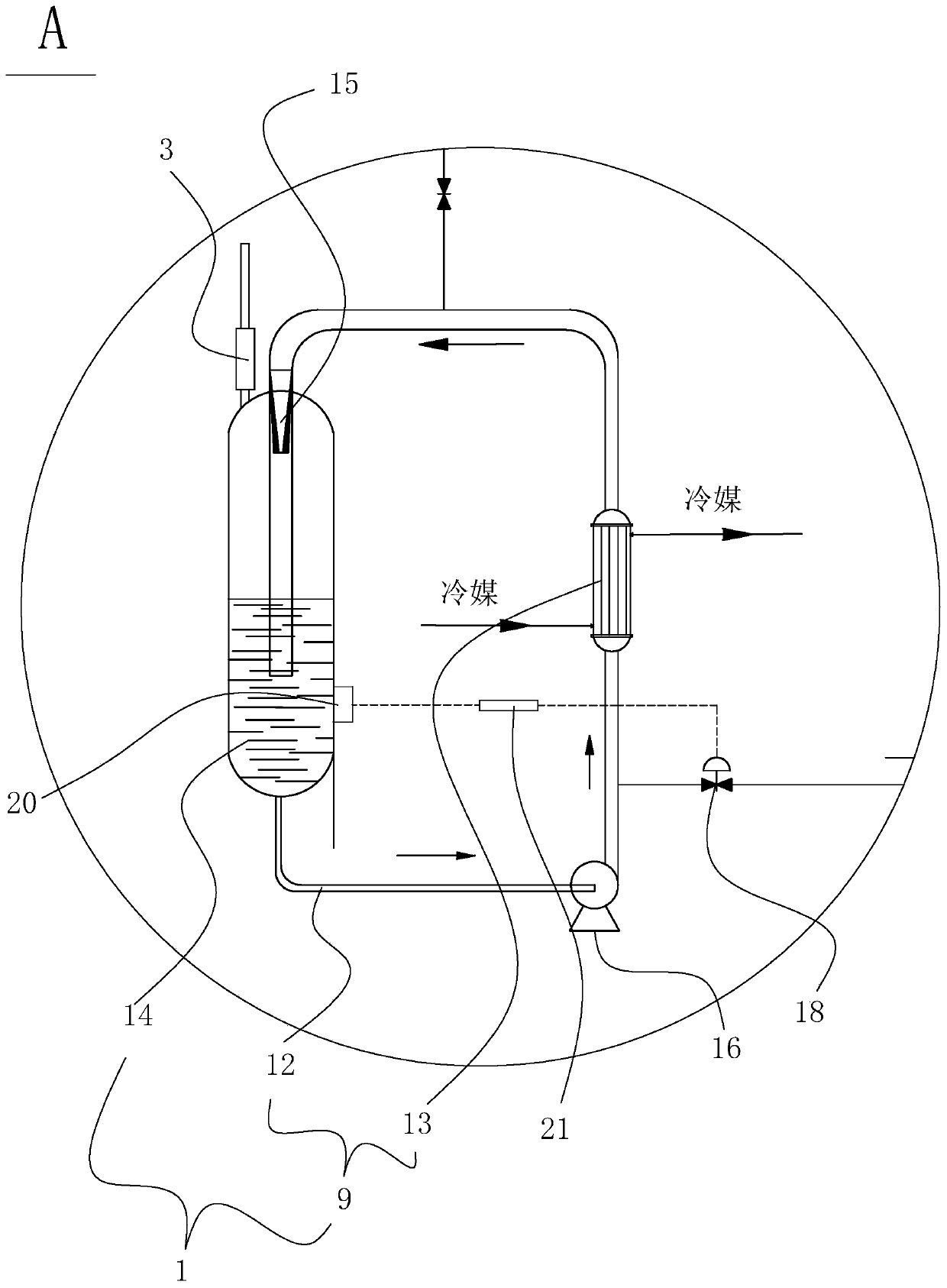

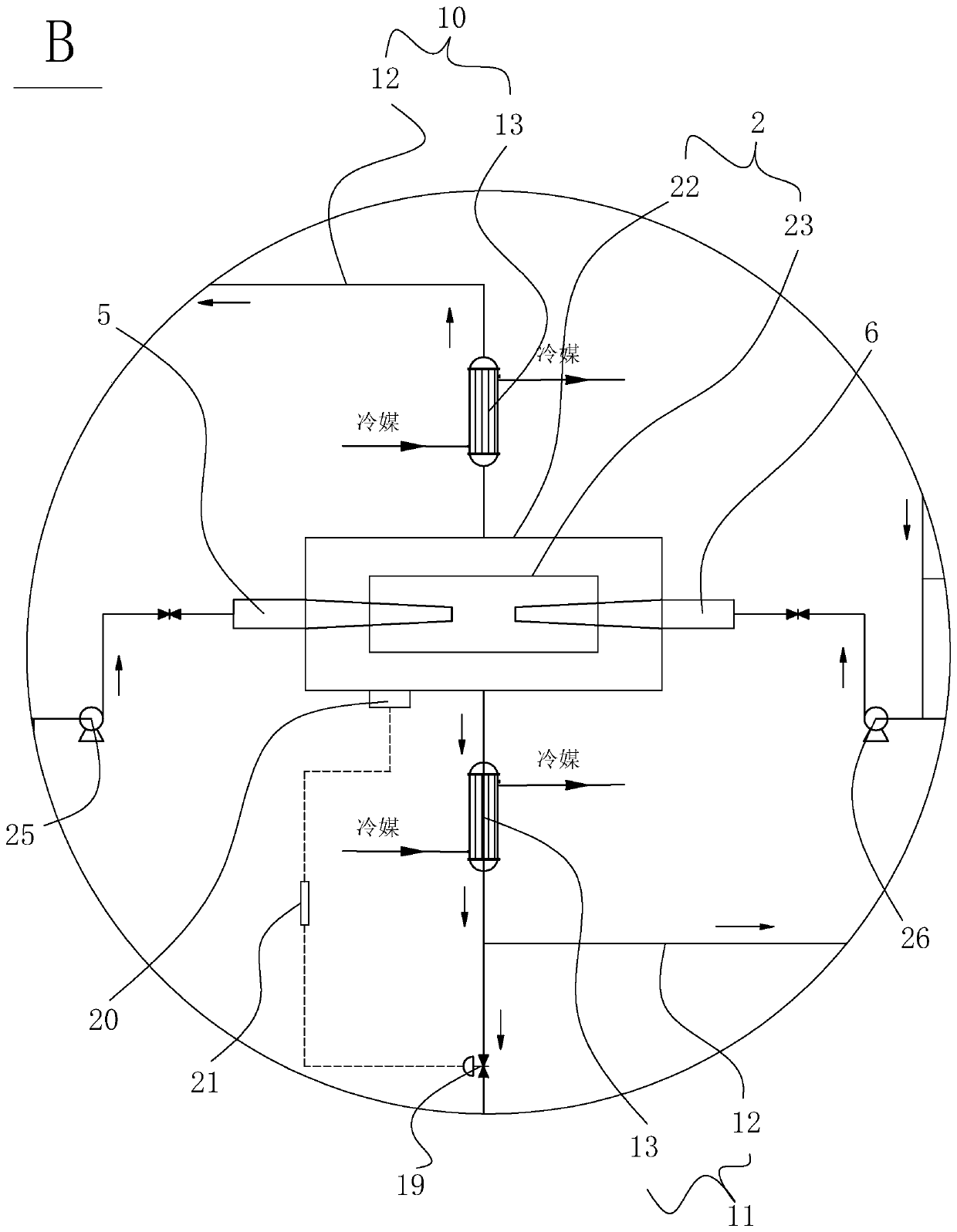

Automatic continuous liquid azo dye production process and synthesis system

PendingCN110845860ARealize automatic continuous productionImprove mass transfer effectMonoazo dyesCoupling reactionDiazo

The invention discloses an automatic continuous liquid azo dye production process and a synthesis system, and belongs to the field of azo dye synthesis. The automatic continuous liquid azo dye production process comprises the following steps: adding a diazonium component, starting a first circulating temperature control device, adding a nitrite, circulating materials by using the first circulatingtemperature control device, and controlling the temperature; continuously adding the diazonium component and the nitrite; opening a diazonium discharge valve, and enabling a diazonium reaction liquidto flow out; starting a first feeding pump and a second feeding pump, and meanwhile starting a second circulation temperature control device and a third circulation temperature control device; continuously spraying a mixed solution of the diazonium reaction solution and a dispersing agent out from a first spray head, continuously spraying a mixed solution of a coupling component and a dispersingagent out from a second spray head, wherein the first spray head and the second spray head are designed for opposite spraying; adopting the second circulating temperature control device and the thirdcirculating temperature control device for circulating materials in a coupling reaction device and controlling the coupling reaction temperature; and opening a coupling discharging valve to obtain a liquid dye. The automatic continuous liquid azo dye production process and the synthesis method can be used for continuously producing azo dyes.

Owner:ZHEJIANG UNIV OF TECH

Film pressure thermal dehydration method and equipment for high-moisture sludge

InactiveCN102108001ADecrease the concentration gradientMoisture migration path is shortSludge treatment by de-watering/drying/thickeningSludge dewateringMoisture

The invention discloses a film pressure thermal dehydration method and equipment for high-moisture sludge, and belongs to the technical field of sludge dehydration. The method is characterized by comprising the following steps of: spreading the sludge subjected to conventional mechanical dehydration into a film of 1 to 10mm, regulating hot extrusion temperature and pressure for partition wall hot extrusion dehydration, separating out moisture in a liquid form, and further applying the sludge after the moisture is separated out. The invention has the advantages that: the energy consumption is low, and the energy utilization rate is high; in the dehydration process, seamless compression is adopted, and a wall-sticking phenomenon of conventional equipment is avoided, so that the whole dehydration process is smooth and feasible; and the process flow is simple and high in feasibility, other substances are not introduced, and the further treatment and recycle of the sludge are not influenced.

Owner:DALIAN UNIV OF TECH

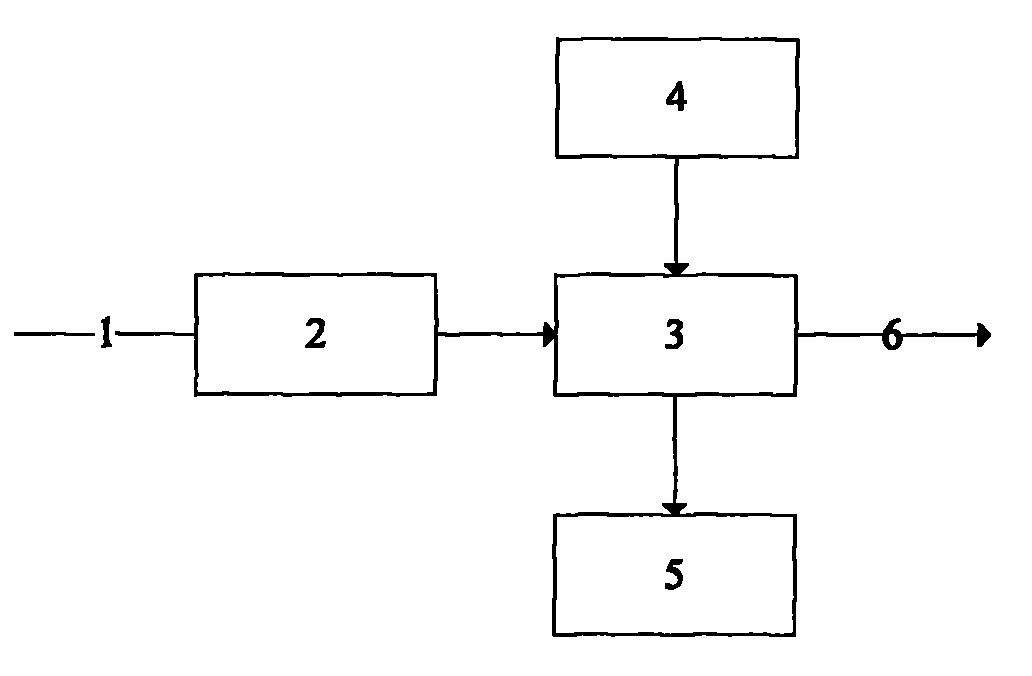

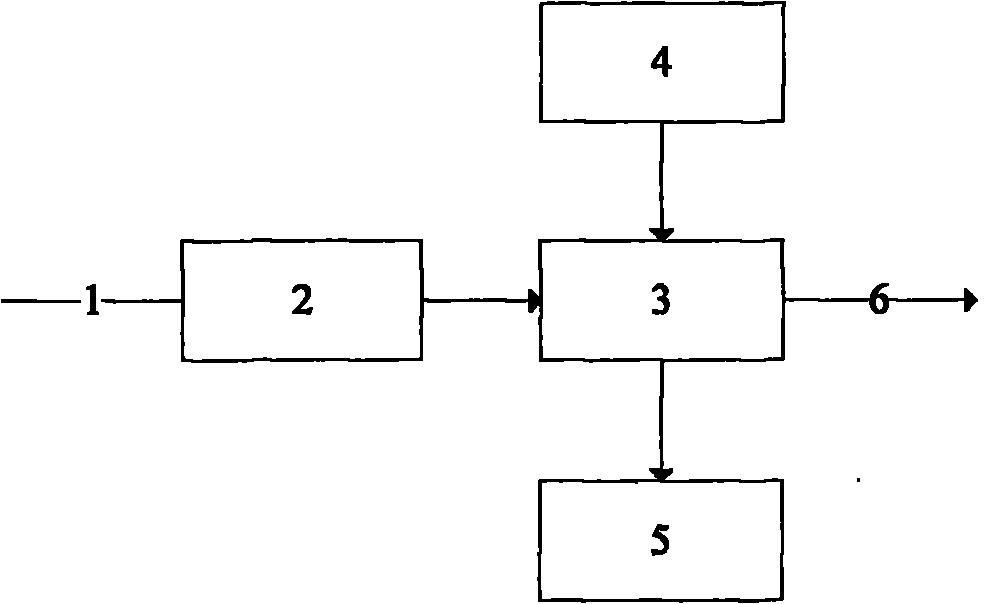

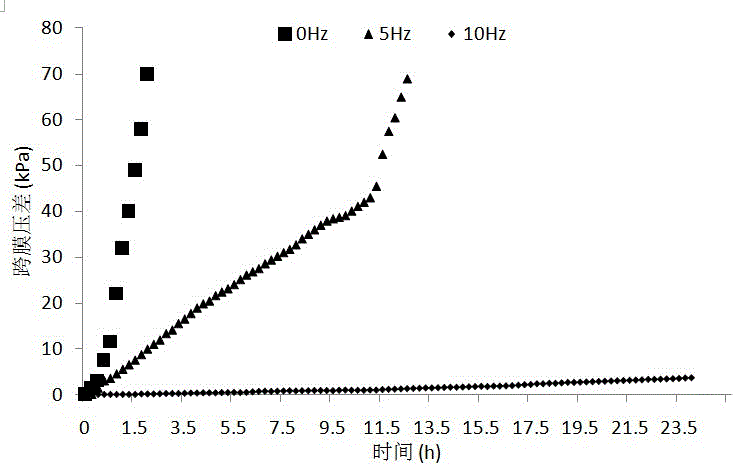

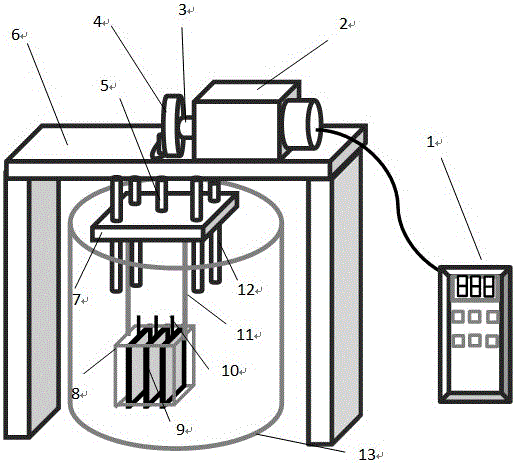

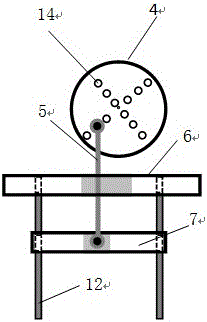

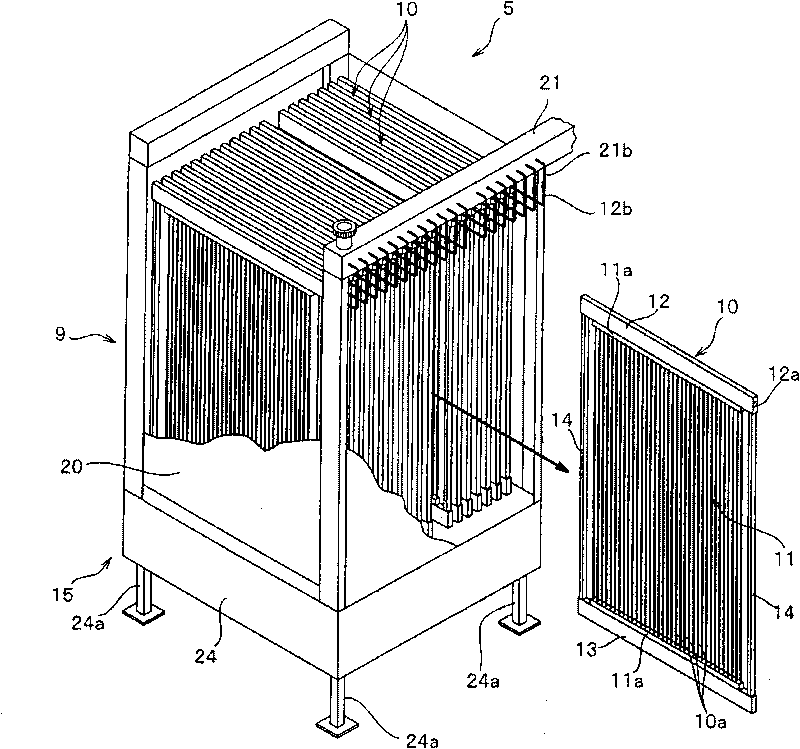

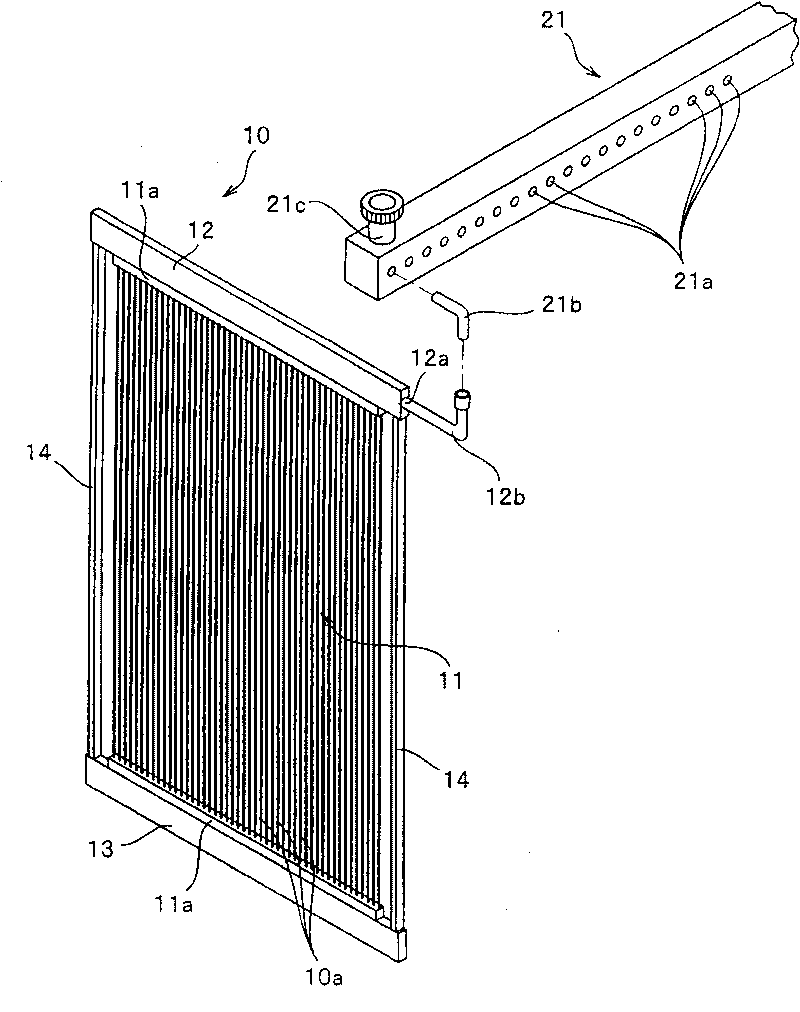

Axial vibrating flat sheet membrane device capable of improving membrane flux and effectively controlling membrane pollution

ActiveCN105709602AReduce cleaning frequencyImprove filtration efficiencyMembranesSemi-permeable membranesVibration amplitudeMembrane technology

The invention relates to an axial vibrating flat sheet membrane device capable of improving membrane flux and effectively controlling membrane pollution. When the membrane technology is used for microalgae recycle or water treatment, membrane pollution is an inevitable problem all the time. Membrane pollution will reduce membrane flux and reduce the filtering efficiency, besides, cleaning of a membrane will consume more manpower and materials, the membrane is damaged, and the service life of the membrane is shortened. The axial vibrating flat membrane device quickly vibrates up and down to generate shear force on the surface of the membrane, deposition of pollutants on the surface of the membrane can be effective prevented, accordingly membrane pollution can be slowed down, and the membrane flux can be improved. According to the device, the vibration amplitude can be adjusted by punching in a rotary plate in turn, the rotary plate and a motor rotary shaft are connected, the rotary plate rotates along with the motor rotary shaft, and the vibration amplitude can be increased from 1 mm to 40 mm. A motor is connected with a frequency regulator, and the vibration frequency of a vibrating film can be adjusted by the frequency regulator. When the vibration amplitude is set to be 1-40 mm, the frequency of a vibrating device can be adjusted to be 0-60 Hz. According to the device, only a membrane assembly is driven to vibrate up and down, an aqueous solution in a reactor does not need to be driven, and accordingly energy consumption for vibration can be reduced.

Owner:TONGJI UNIV

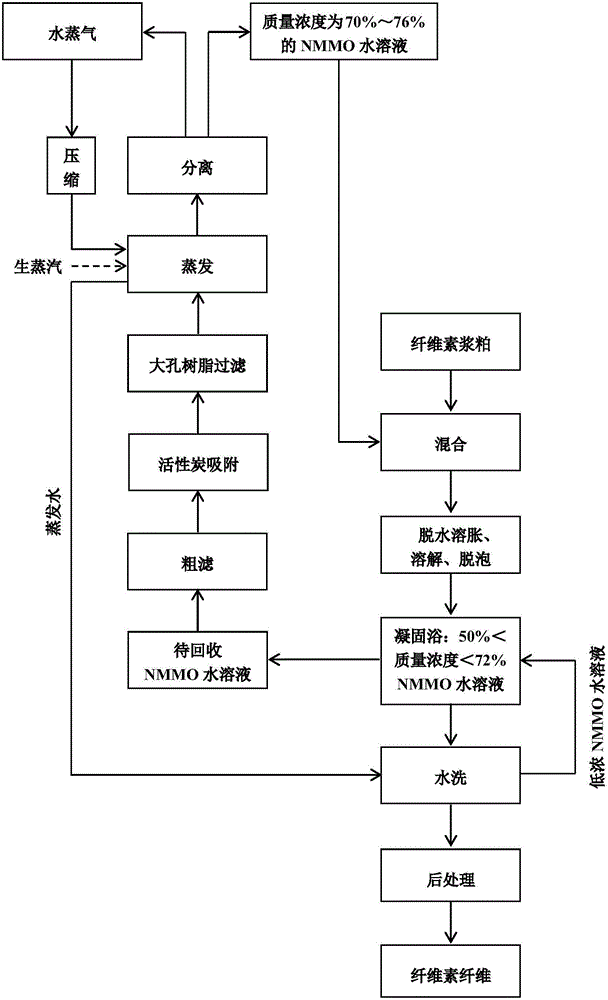

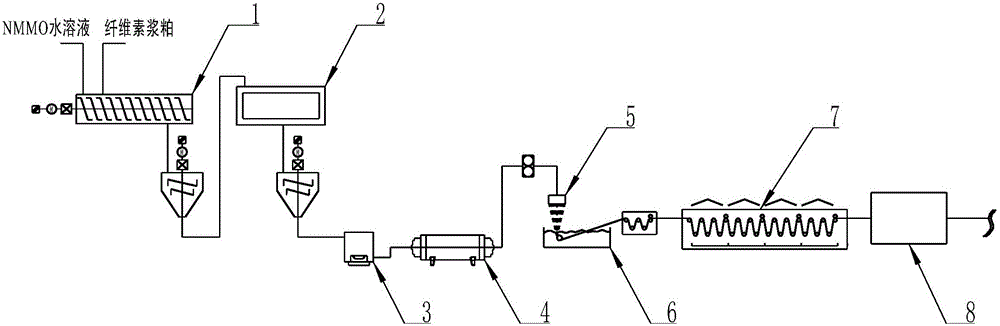

Preparation method of cellulosic fibers

ActiveCN106222771ASimple preparation processEliminate security risksArtificial filament recoveryArtificial filament washing/dryingCellulose fiberDissolution

The invention discloses a preparation method of cellulosic fibers. The preparation method includes the following steps that 1, cellulose pulp is mixed with an NMMO water solution with the mass concentration of 60%-85%, preferably 70%-76% to obtain a uniform mixture; 2, the obtained uniform mixture is subjected to dehydration swelling and dissolution defoaming to obtain a cellulose spinning solution; 3, the obtained cellulose spinning solution is filtered and subjected to heat exchange and then enters a spinning machine, after the cellulose spinning solution is extruded through a spinning assembly and air-cooled, the cellulose spinning solution enters a solidification system and is solidified in an NMMO solidification bath with the mass concentration larger than 50% and smaller than 72%, and nascent fibers are obtained; 4, the obtained nascent fibers are washed to obtain cellosilk bundles, and then the cellulosic fibers are obtained through subsequent section treatment. Equipment investment can be greatly reduced, the process is simplified, energy consumption and industrialization cost are reduced, safety production is promoted, the homogeneity and mechanical performance of the fibers are improved, and therefore the preparation method is more suitable for efficient low-consumption industrial production.

Owner:CHINESE TEXTILE ACAD

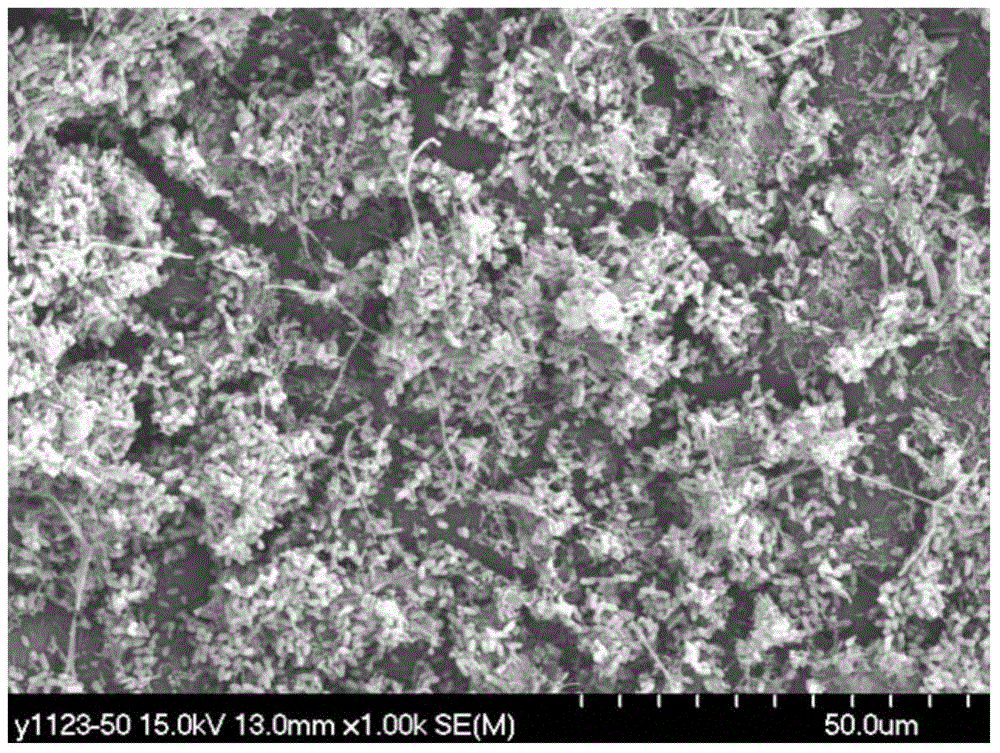

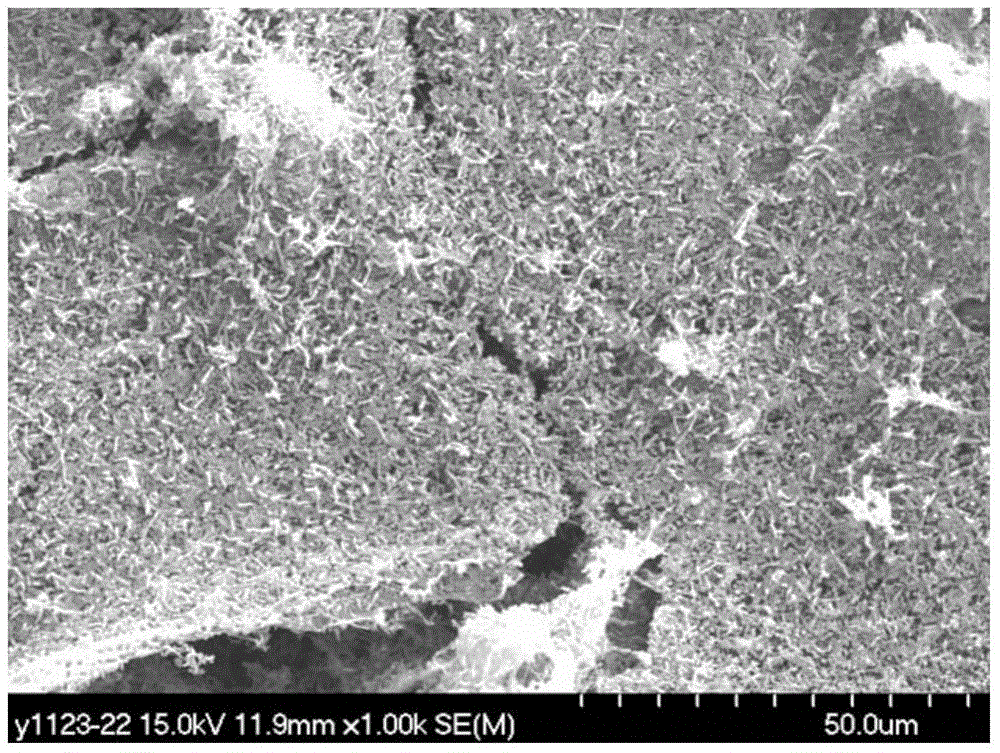

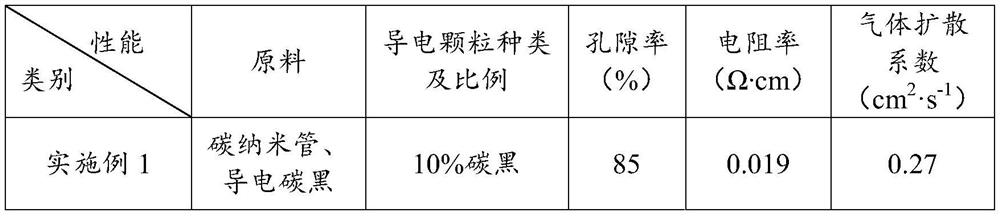

Preparation method of carbon paper for gas diffusion layer of high-carbon-content fuel cell

ActiveCN111900417ASuppress or eliminate the effectHigh carbon contentFinal product manufactureCell electrodesFiberCarbon fibers

The invention discloses a preparation method of carbon paper for a gas diffusion layer of a high-carbon-content fuel cell. The method comprises the following steps: immersing carbon fiber paper into first conductive ink, carrying out ultrasonic treatment, carrying out negative pressure impregnation, and drying to compound solute in the first conductive ink with the carbon fiber paper to obtain a carbon paper precursor A; carbonizing the carbon paper precursor A to obtain a carbon paper precursor B; the carbon paper precursor B and the second conductive ink being subjected to dipping-curing-carbonization treatment to obtain a carbon paper precursor C, and the carbon paper precursor C and the third conductive ink being repeatedly subjected to dipping-curing-carbonization treatment once to obtain a carbon paper precursor D; and graphitizing the carbon paper precursor D to obtain the carbon paper. The prepared carbon paper has the mechanical strength and gas diffusion performance of a gasdiffusion layer, is high in porosity, and has the characteristics of stable chemical performance, low resistivity and high conductivity.

Owner:QILU UNIV OF TECH

Method for controlling residual aluminum in electroslag remelting steel

The invention relates to the electroslag remelting technology, in particular to a method for controlling residual aluminum in electroslag remelting steel, and aims to overcome the disadvantages of the prior electroslag remelting technology, such as poor stability of remelting slag system, poor efficiency in controlling aluminum increase in metal melting pond in remelting process, high difficulty in controlling residual aluminum in electroslag remelting steel, and poor quality of electroslag remelting steel. The control method is realized by the electroslag remelting process in the existing electroslag furnace, wherein the remelting slag consists of, by weight, CaO 28% to 40%, Al2O3 10% to 15%, MnO 0.2% to 0.5%, CaF2 15% to 25%, and the balance of Al2(SiO3)3. In the remelting process, the content of FeO in the remelting slag is controlled to be not larger than 0.5% by deoxidization. The method provided by the invention is effective in controlling aluminum increase in the metal melting pond, and easy in controlling residual aluminum in the electroslag remelting steel, and has the advantages of high stability of the remelting slag system and high quality of electroslag remelting steel.

Owner:ZHEJIANG ELECTROSLAG NUCLEAR MATERIAL

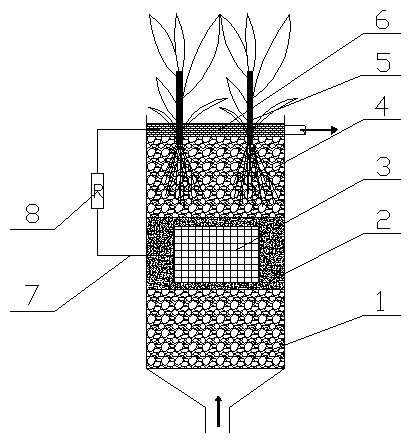

Synchronous electricity generation and sewage purification device utilizing steel slag as positive electrode

ActiveCN105541046AEfficient use ofLow costTreatment by combined electrochemical biological processesWater/sewage treatmentConstructed wetlandElectrical battery

The invention discloses a synchronous electricity generation and sewage purification device utilizing steel slag as a positive electrode. The steel slag utilized as positive electrode filler for a battery is embedded into a vertical flow artificial wetland system, so that a novel structure method with a microbial fuel cell and a constructed wetland which are coupled is formed. A bottom non-conductive filler layer, a steel slag positive electrode layer, a current collector inserted into the steel slag positive electrode layer, a top non-conductive filler layer, wetland plants planted in the non-conductive filler layers and a top negative electrode layer are laid on the system from bottom to top, wherein the negative electrode layer and the positive electrode layer are respectively connected with a resistor box through wires so as to form a closed loop. The steel slag electrode is embedded into a positive electrode of the microbial fuel cell and meanwhile coupled with the vertical current constructed wetland, so that dual effects of synchronous electricity generation and sewage purification are realized, the positive electrode teleportation efficiency is improved, the internal resistance of the battery is reduced, the electricity generation performance is improved, and meanwhile the water acidification problem is solved.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Ultrasonic bubble column rectification device and method

InactiveCN108499148AApplicable separation operationImprove efficiencyEnergy based chemical/physical/physico-chemical processesFractional distillationBubble columnPetrochemical

The invention specifically relates to an ultrasonic bubble column rectification device and a method, belonging to the field of rectification-rectification technology in the petrochemical industry. Theultrasonic bubble column rectification device comprises a bubble column and an ultrasonic generator, wherein the bubble column is internally provided with a plurality of trays and bubble caps; the outer wall of the bubble column is provided with a distributor at a position corresponding to one of the trays; the distributor is connected with the ultrasonic generator via an ultrasonic transducer; and the included angle of the ultrasonic transducer and the distributor is 45 to 135 degrees. According to the invention, ultrasonic waves are effectively and uniformly transmitted to the trays in virtue of a proper angle; and a gas-liquid interface is greatly increased in virtue of the microjet effect of ultrasonic waves, so the heat transfer and mass transfer of gas-liquid-phase materials on thetrays are reinforced, and the plate efficiency is improved. The invention also provides the method using the device.

Owner:CHINA PETROLEUM & CHEM CORP

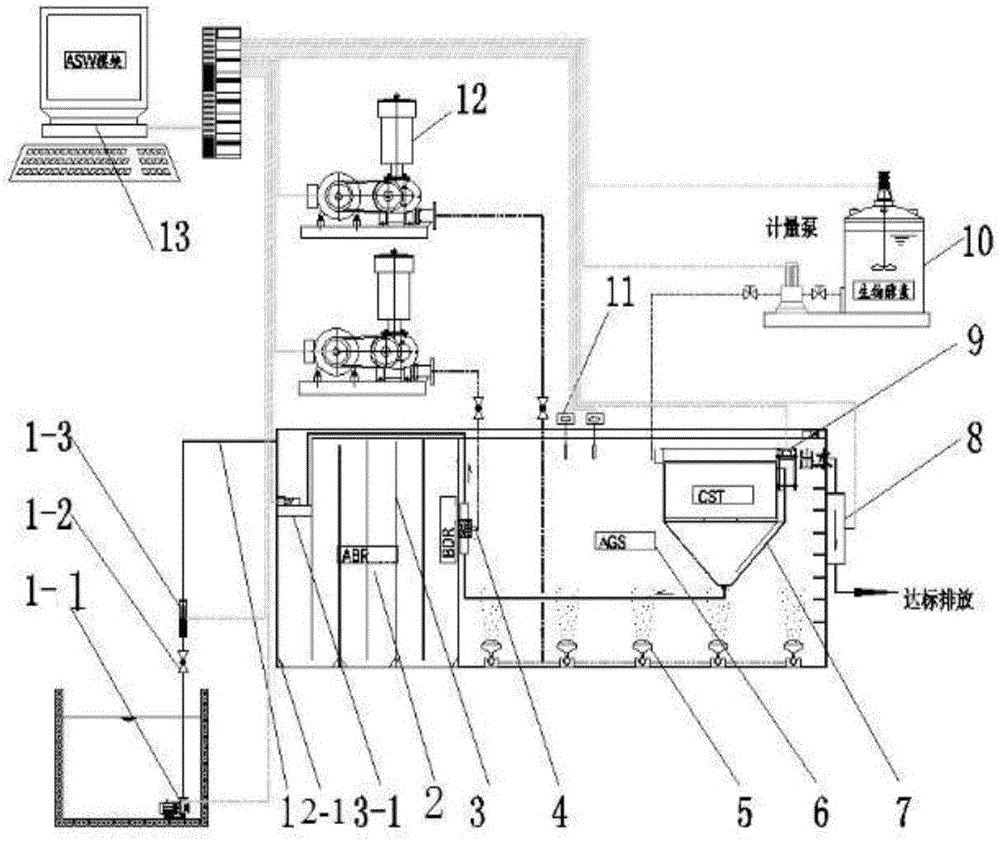

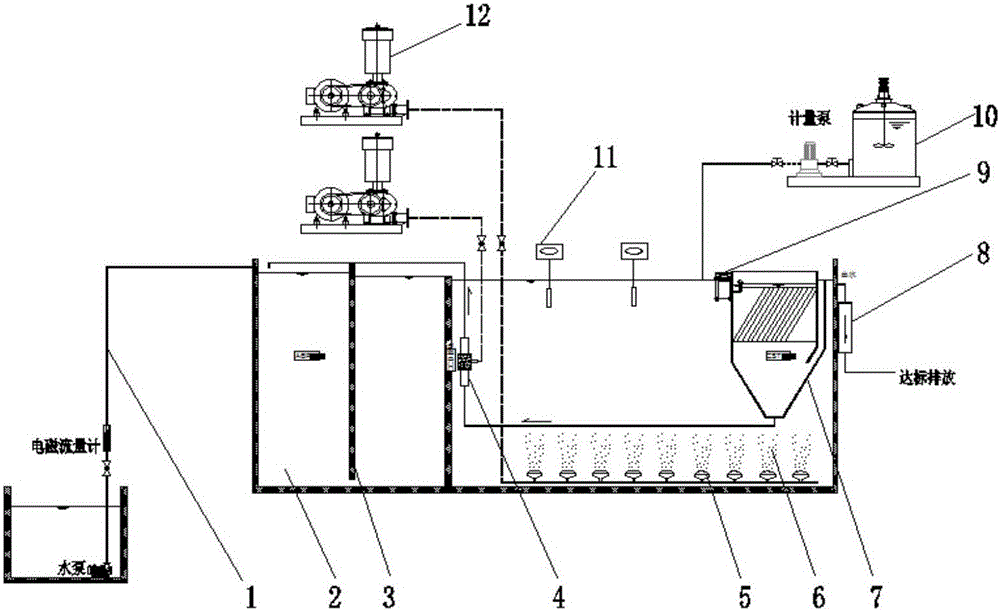

Distributed and structured town sewage pelletization treatment process and pelletization reactor

InactiveCN106007178APurify waterMaintain ultra-high bioconcentrationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsWater qualityPotassium

The invention discloses a distributed and structured town sewage treatment pelletization reactor which comprises a reactor body, a BDR gas stripping backflow device, a titanium alloy aerator, an ultraviolet disinfection device, an ultrasonic solid-liquid separation device, an ORP oxidoreduction potentiostat, a biological enzyme adding device, an oilless silent air compressor and the like. The reactor body forms an anaerobic granular sludge-aerobic granular sludge-biological enzyme ternary coupling recycling water purification pelletization treatment process. The pelletization reactor is a biological compositing tank, and after anaerobic-aerobic-biological enzyme ternary coupling composting, discharged sludge contains rich enzymes, nitrogen, phosphorus, potassium and other nutrients and can be directly used as high-quality green organic fertilizer. Large-proportion BDR gas stripping backflow is adopted, the very small organic matter concentration gradient in the pelletization reactor is guaranteed, the unevenness of inflow water is eliminated, the problems about town sewage quality and water yield load impacts are solved, and the investment cost per ton of water is greatly reduced. The invention further discloses the distributed and structured town sewage pelletization treatment process.

Owner:阿斯旺(北京)环保科技有限公司

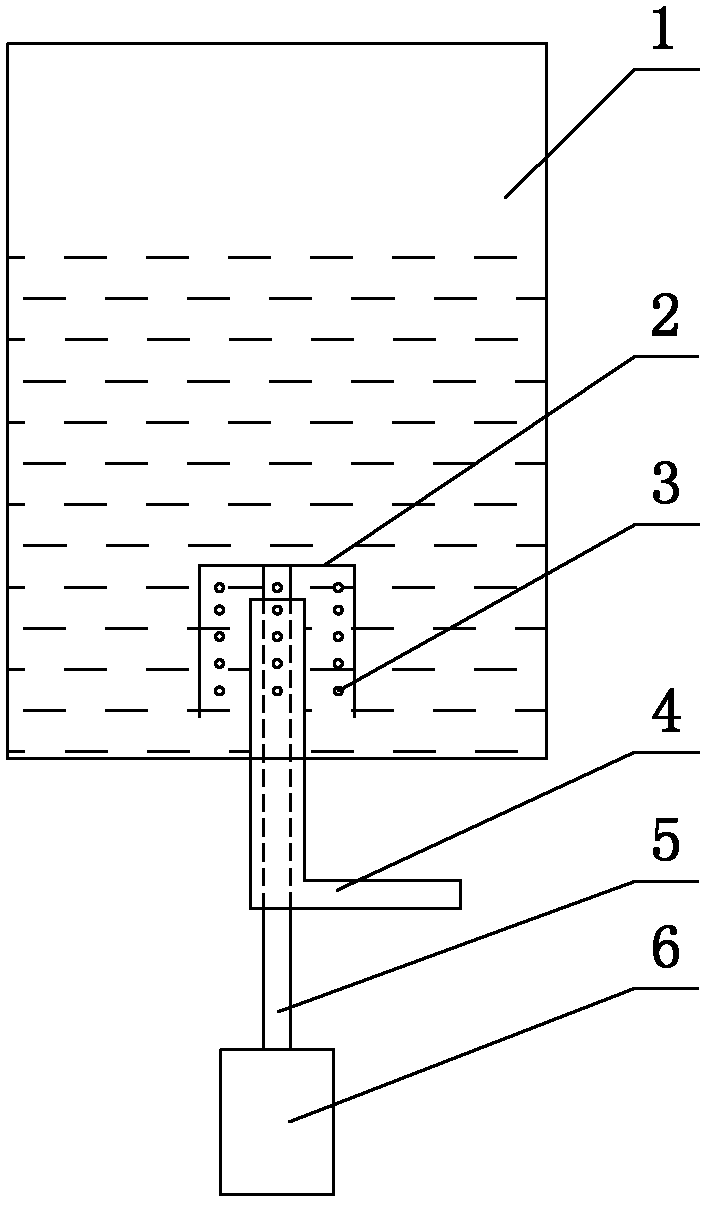

Method of water disposal

InactiveCN101765564AIncrease concentrationReduce volumeMembranesTreatment using aerobic processesSludgeMembrane surface

A biological method of water disposal that avoids disadvantages caused by an increase of the number of membrane filter units attributed to an increase of the volume of sludge disposed of, maintaining a given rate of sludge disposed of. Four or more membrane filter units (5) are immersed and laid at given intervals in series in aeration tank (4). The amount of suctioned filtrate water of each membrane filter unit (5) and / or the amount of air emitted toward each membrane filter unit (5) is sequentially increased from the raw water inflow side to the sludge discharge side. Accordingly, in response to the amount of solid matter adhering to the membrane surface of membrane filter units (5) on the sludge recovery side, the solid matter can be unfailingly detached from the membrane surface. Simultaneously, the sludge concentration at edge portions of the recovery side exhibiting the highest sludge concentration would be increased, thereby facilitating the discarding operation of recovered sludge and further realizing reduction of drying energy at discarding. Moreover, the discharge of filtrate water can be efficiently carried out.

Owner:MITSUBISHI RAYON CO LTD

Efficient gas-liquid reactor

InactiveCN102580632AAdequate responseImprove responseChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesGas liquid reactionProcess engineering

The invention relates to an efficient gas-liquid reactor, which comprises a reactor body and a gas inlet pipe, wherein an agitation motor is arranged below the reactor body, a motor shaft of the agitation motor extends into the reactor body, a cover-shaped turntable which is positioned in the reactor body is installed at the upper end of the motor shaft, a group of air holes are produced in the cover body of the cover-shaped turntable, the gas inlet pipe is coaxially sleeved on the motor shaft, and the gas outlet of the gas inlet pipe is positioned in the cover-shaped turntable. The efficient gas-liquid reactor provided by the invention has a reasonable design and a simple structure, is easy to produce and has high practicability, the reactor is added with the cover-shaped turntable which has an agitation function, a plurality of air holes are arranged in the cover-shaped turntable and can produce a large quantity of small bubbles during the rotation process, so the gas-liquid contact surface area for unit gas quantity is greatly increased, the gas-liquid reaction speed is accelerated, and the reaction efficiency is improved.

Owner:TIANJIN UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com