Distributed and structured town sewage pelletization treatment process and pelletization reactor

A sewage treatment and reactor technology, applied in the field of village sewage treatment and environmental protection, can solve the problems of large volume, secondary pollution, high moisture content of excess activated sludge, and achieve the effect of low sludge output and small organic matter concentration gradient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described in conjunction with the following examples.

[0037] The first purpose of the present invention is to provide a distributed, structured pelletizing reactor for sewage treatment in villages and towns, which is realized by the following technical solutions:

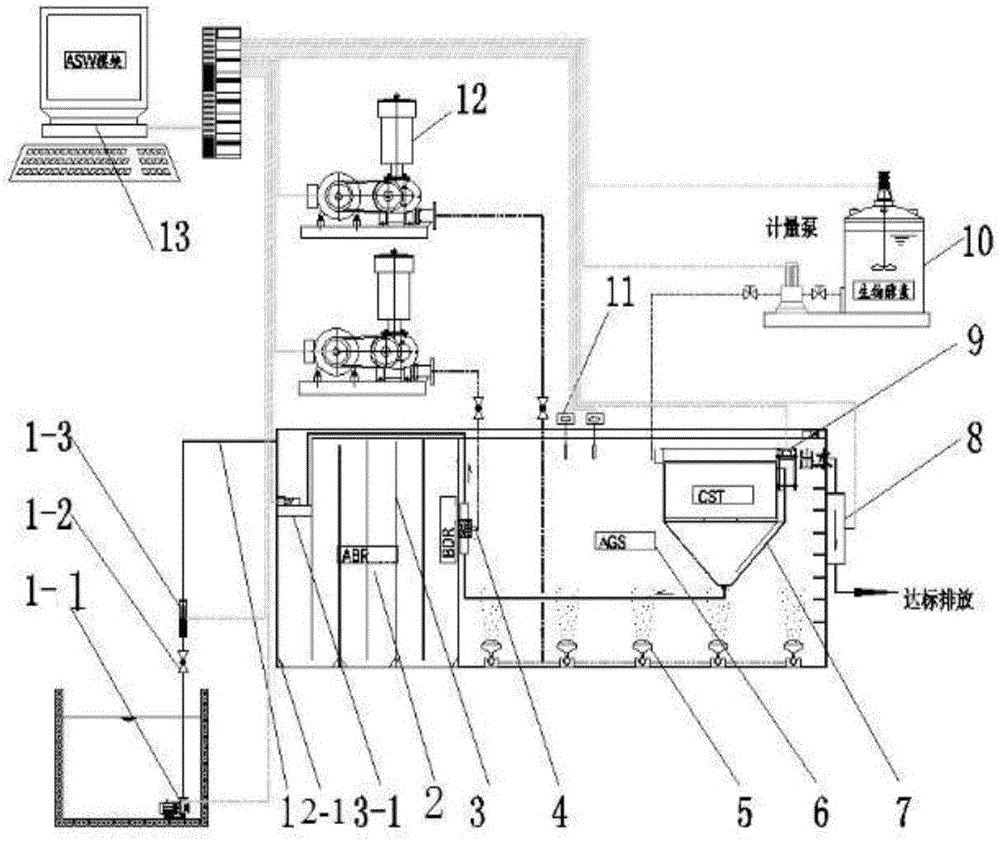

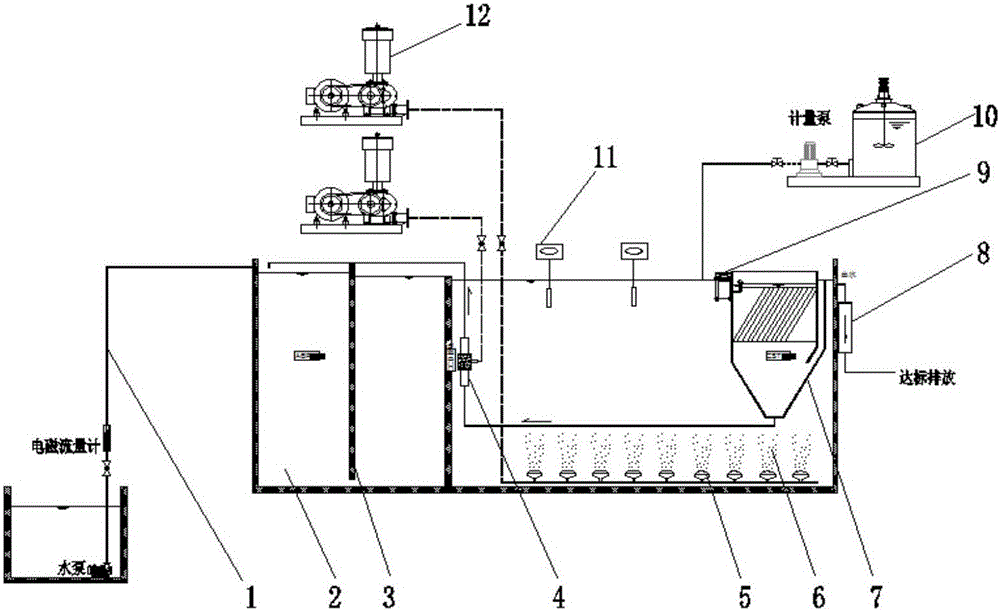

[0038] like figure 1 The distributed and structured village and town sewage treatment pelletization reactor shown includes the main body of the reactor and supporting equipment. The main body of the reactor includes ABR anaerobic pellet reaction zone 2, BDR air stripping reflux device 4, AGS aerobic pellet reaction zone 6, CST adsorption and precipitation module 7 placed inside AGS aerobic pellet reaction zone 6 and A biological enzyme dosing device 10 for adding biological enzymes to the AGS aerobic pellet reaction zone 6 , and the biological enzyme dosing device 10 is arranged on the top of the AGS aerobic pellet reaction zone 6 . The supporting equipment includes water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com