Filter material corrosion simulation experiment device and experiment method

A technology for simulating experimental devices and filter materials. It is used in measurement devices, weather resistance/light resistance/corrosion resistance, and analysis materials to achieve the effects of improving production processes, sufficient contact, and increasing circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be described in detail in conjunction with the following drawings and examples, but the implementation and protection of the present invention are not limited thereto.

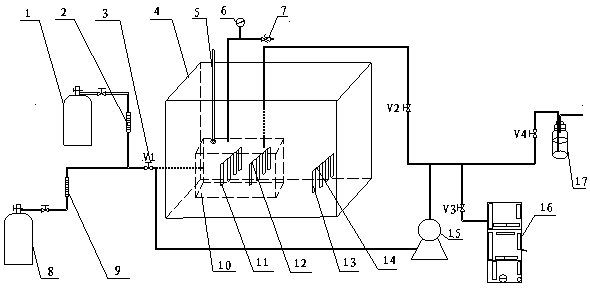

[0021] like figure 1 As shown, the filter material corrosion simulation experiment device includes a gas flow control device, a constant temperature box 4, an aging test chamber 10, a blower fan 15, a flue gas analyzer 16 and an absorption bottle 17; the gas flow control device includes a first gas cylinder 1, The first flowmeter 2, the valve 3, the second gas cylinder 8 and the second flowmeter 9; the side and top of the incubator 4 have holes for the gas inlet and outlet pipes of the aging test chamber 10 to pass through; the interior of the incubator 4 is arranged horizontally A first stainless steel bar 14 is provided, and this stainless steel bar 14 is positioned at the outside of aging test box 10, and the first filter material 13 is suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com